Effects of Light Conversion Film on the Growth of Leafy Vegetables in Facilities under Haze Weather

Abstract

:1. Introduction

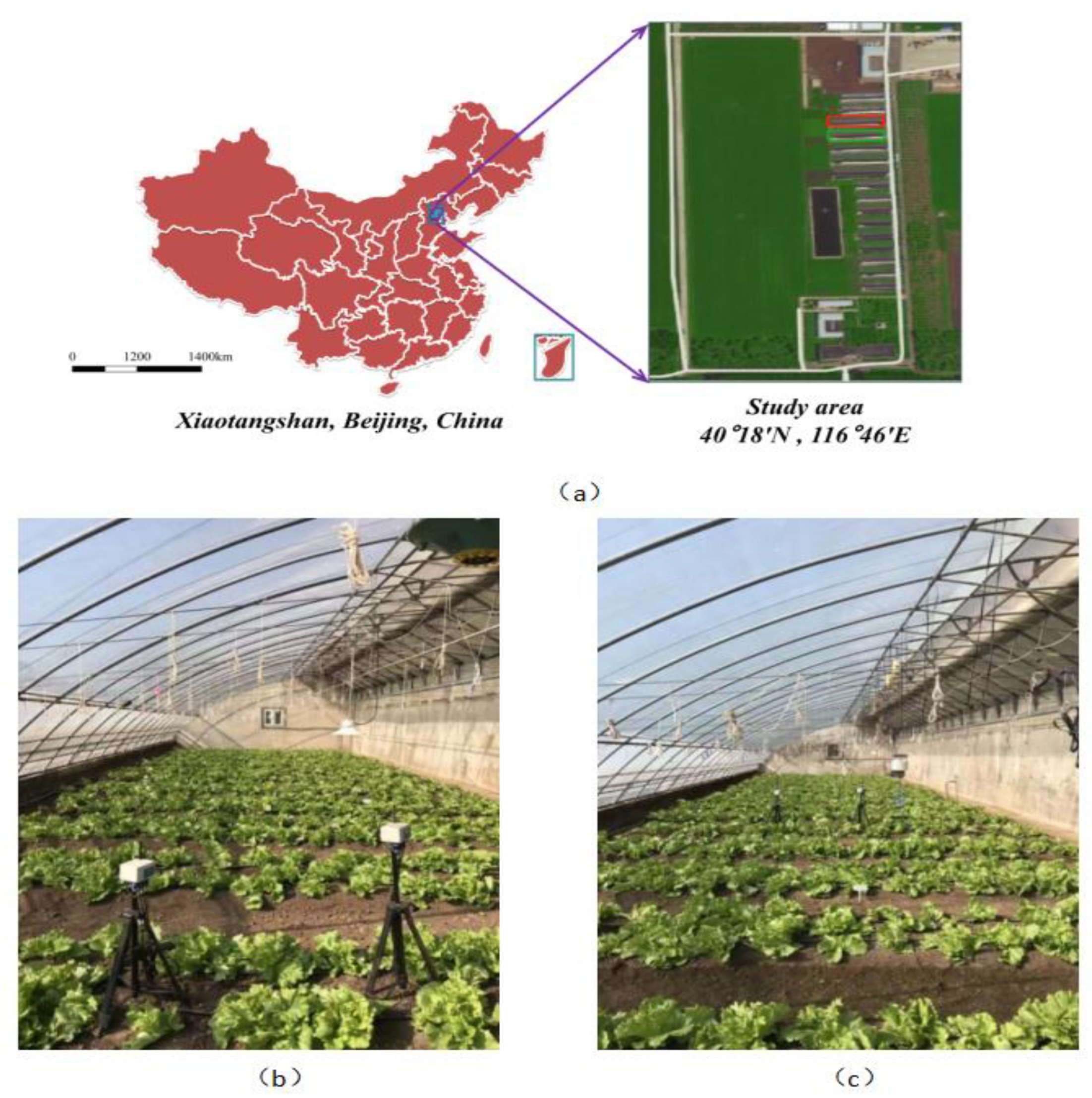

2. Materials and Methods

2.1. Experimental Design

2.2. Measurement Indexes

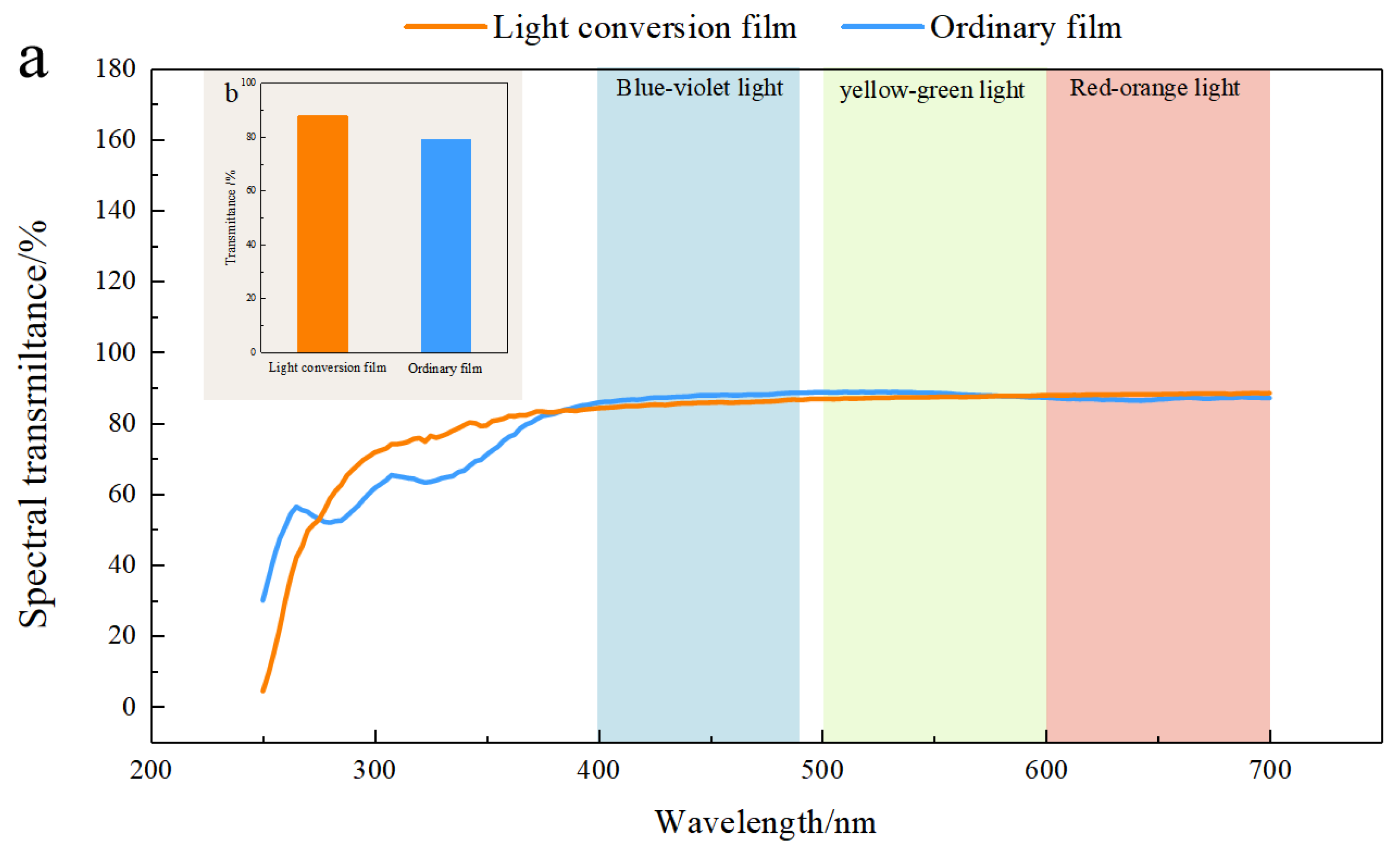

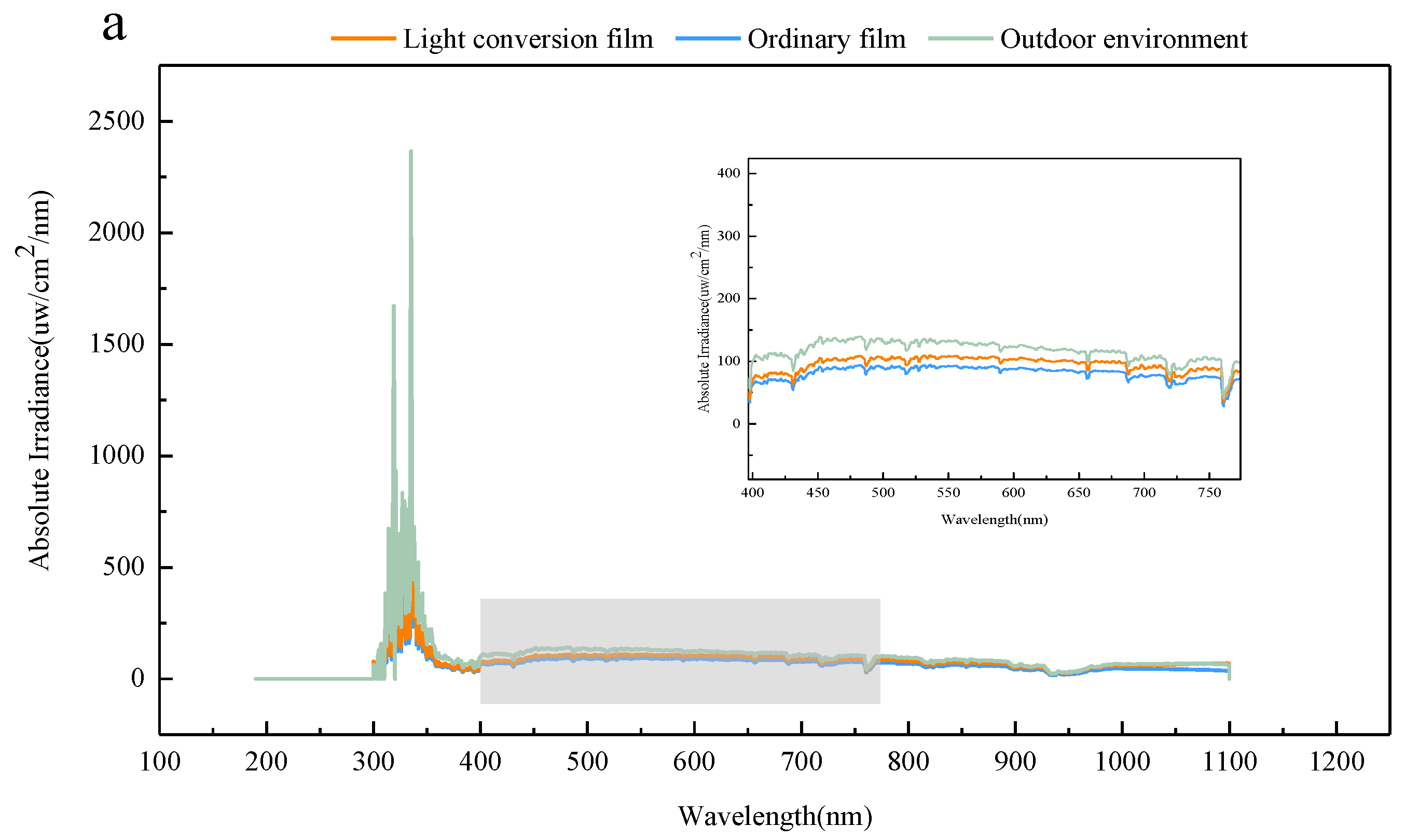

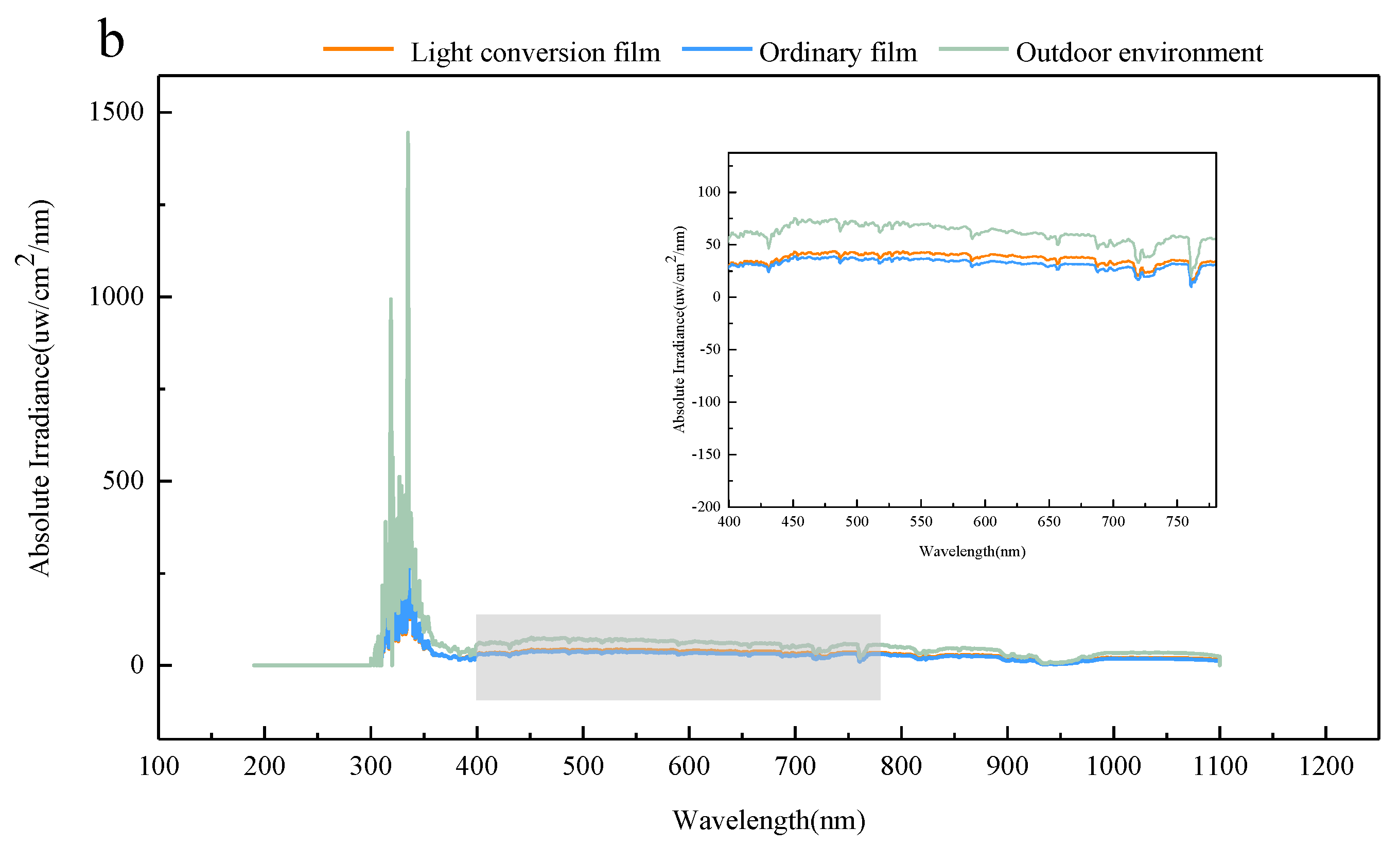

2.2.1. Determination of Properties of Light Conversion Film

2.2.2. Greenhouse Environment Monitoring

2.2.3. Determination of Soil Parameters

2.2.4. Crop Index Determination

2.3. Data Analysis

3. Results

3.1. Performance Test of Light Conversion Film

3.2. Effect of Light Conversion Films on the Greenhouse Environment

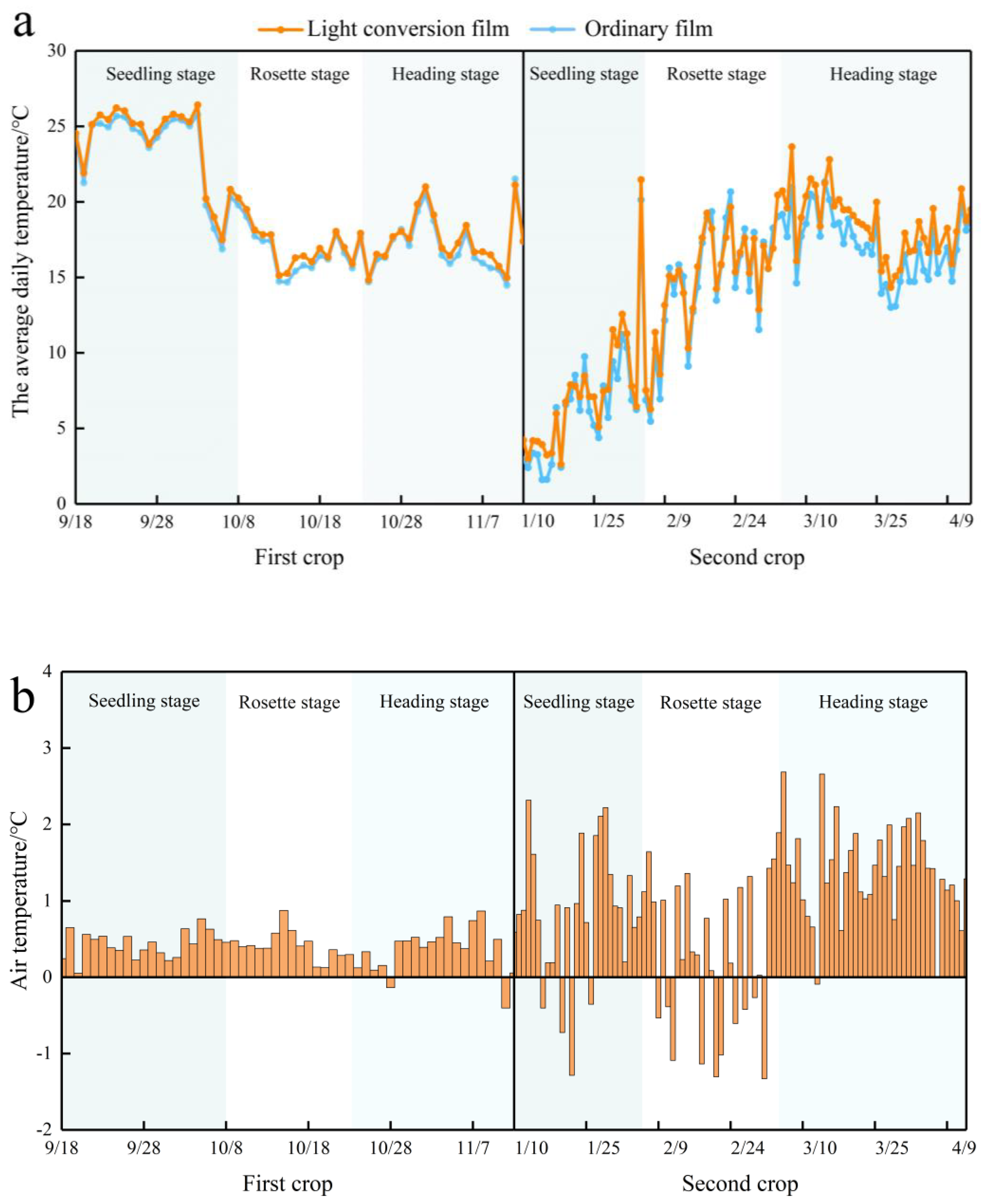

3.2.1. Air Temperature

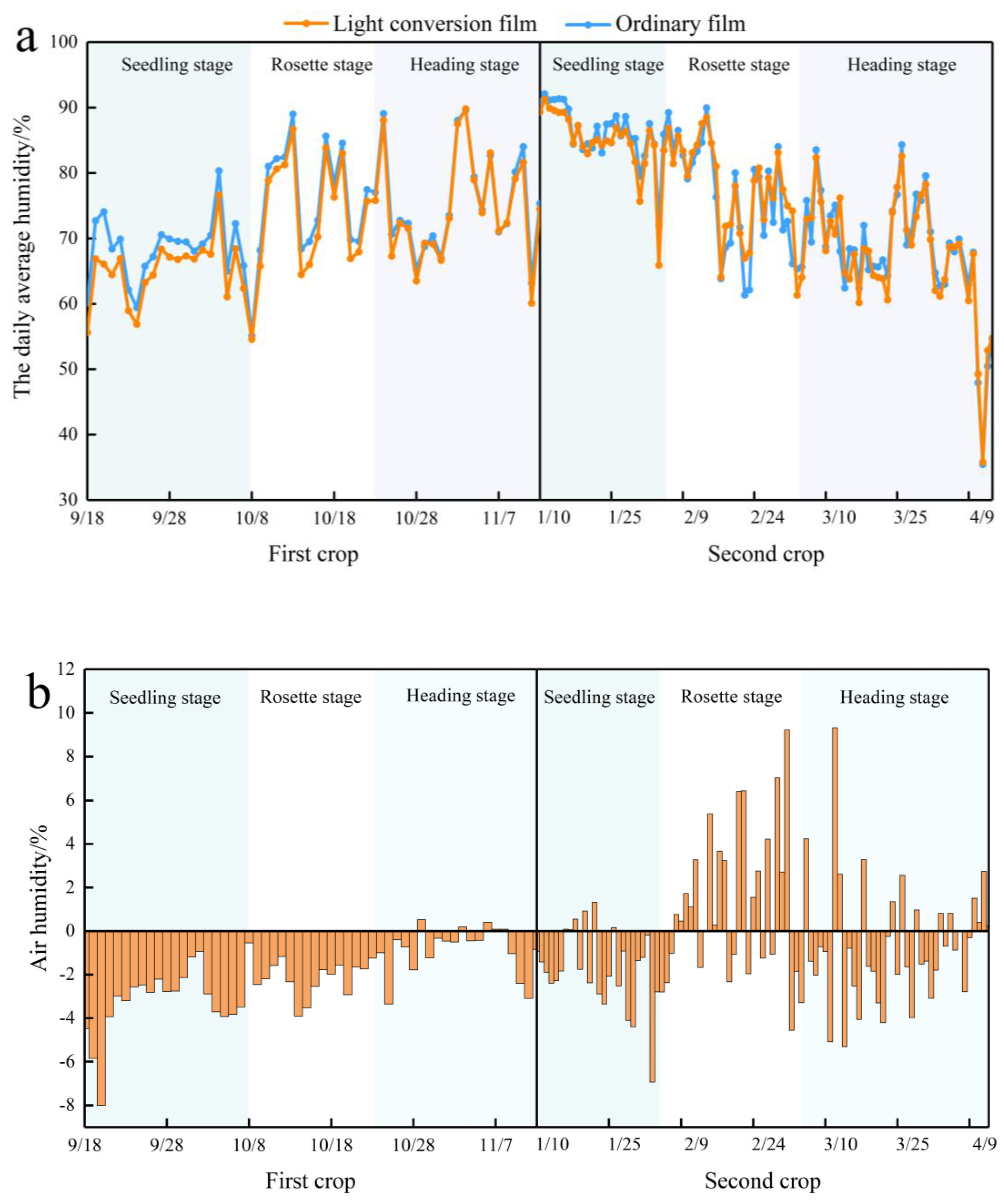

3.2.2. Greenhouse Air Humidity

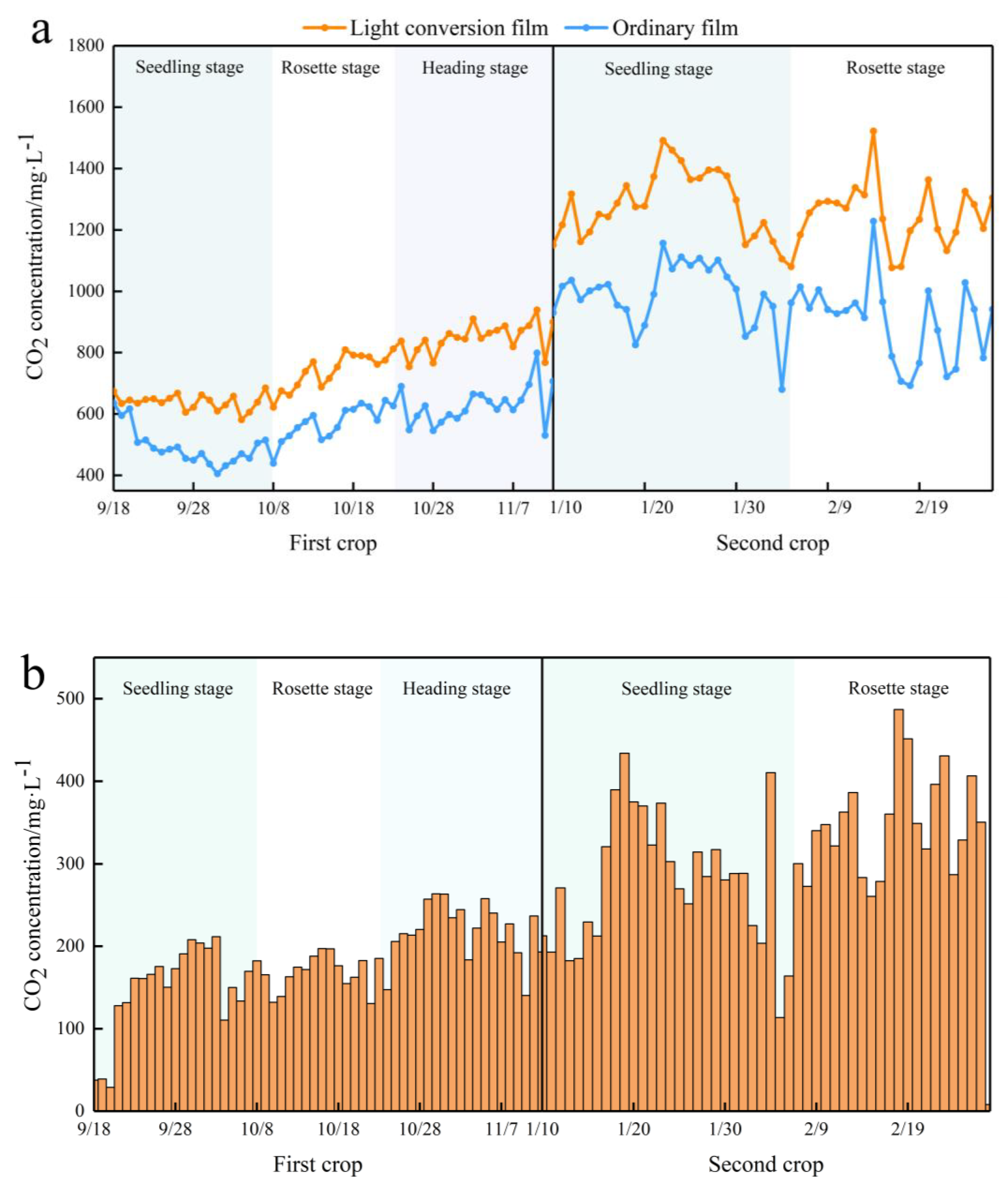

3.2.3. Greenhouse CO2 Concentration

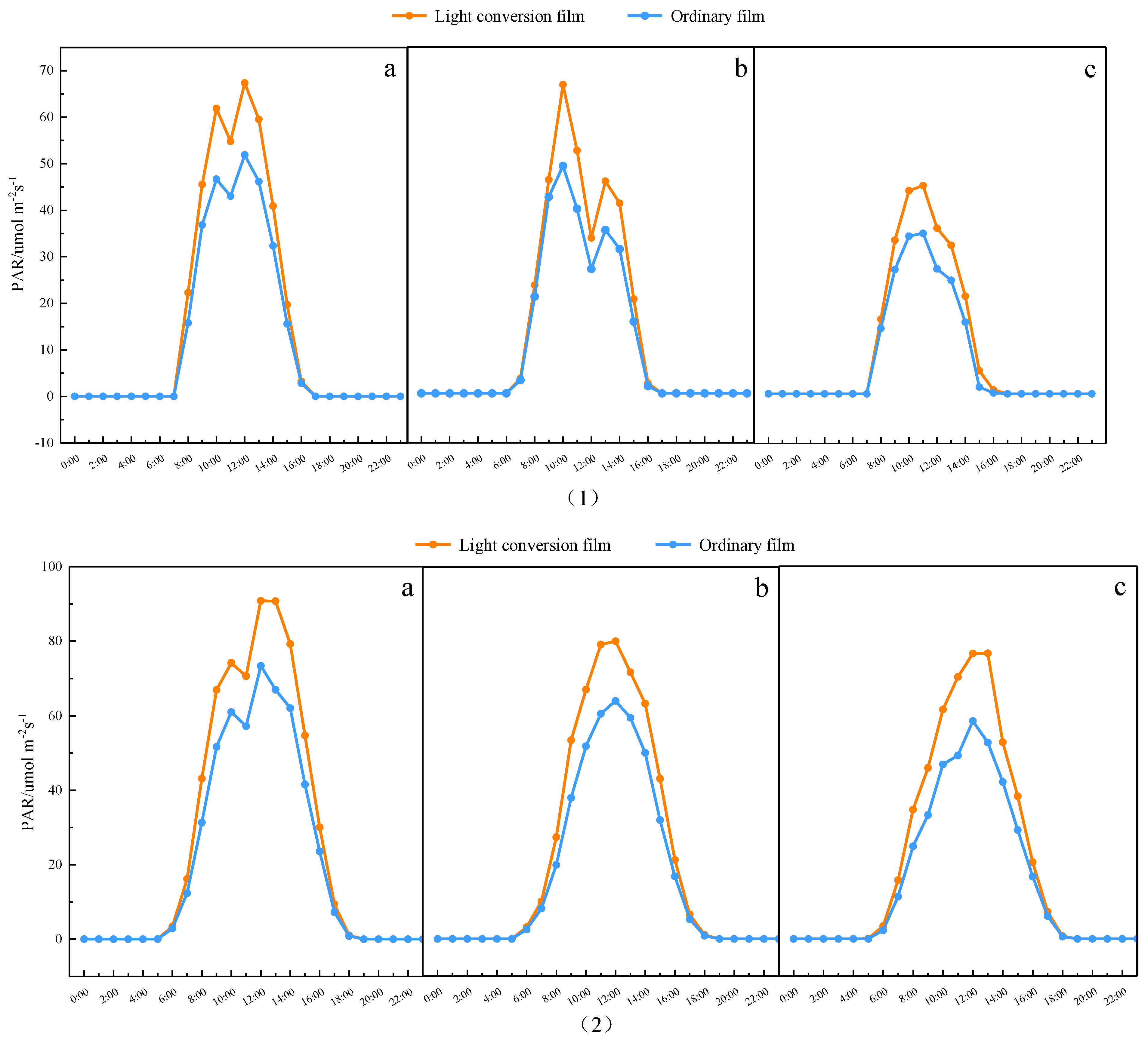

3.2.4. Photosynthetically Active Radiation

3.3. Effect of Light Conversion Films on the Greenhouse Soil Environment

3.4. Analysis of the Synergistic Influence of Light Conversion Films on Greenhouse Environmental Parameters

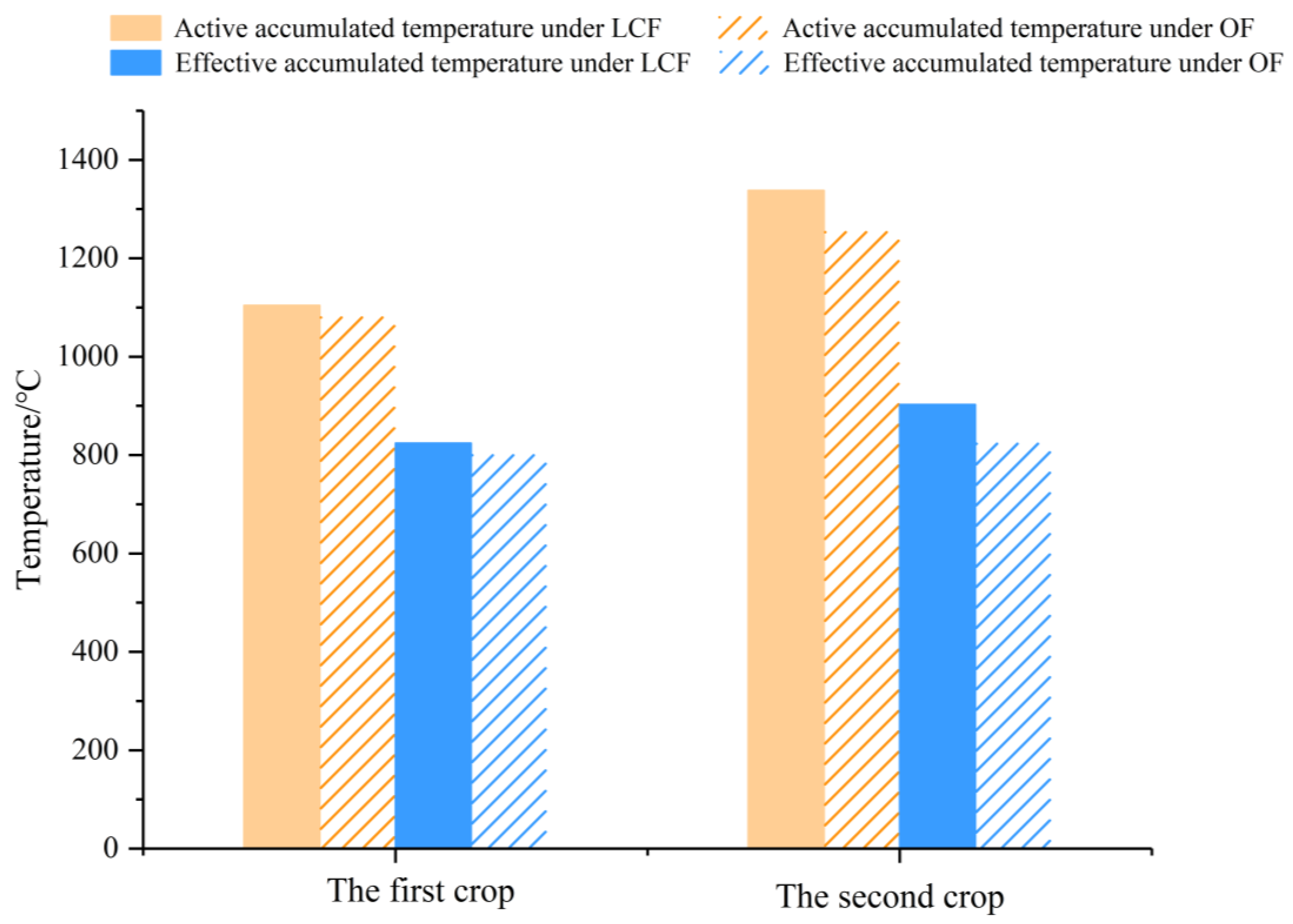

3.5. Effect of LCF on Crop Growth

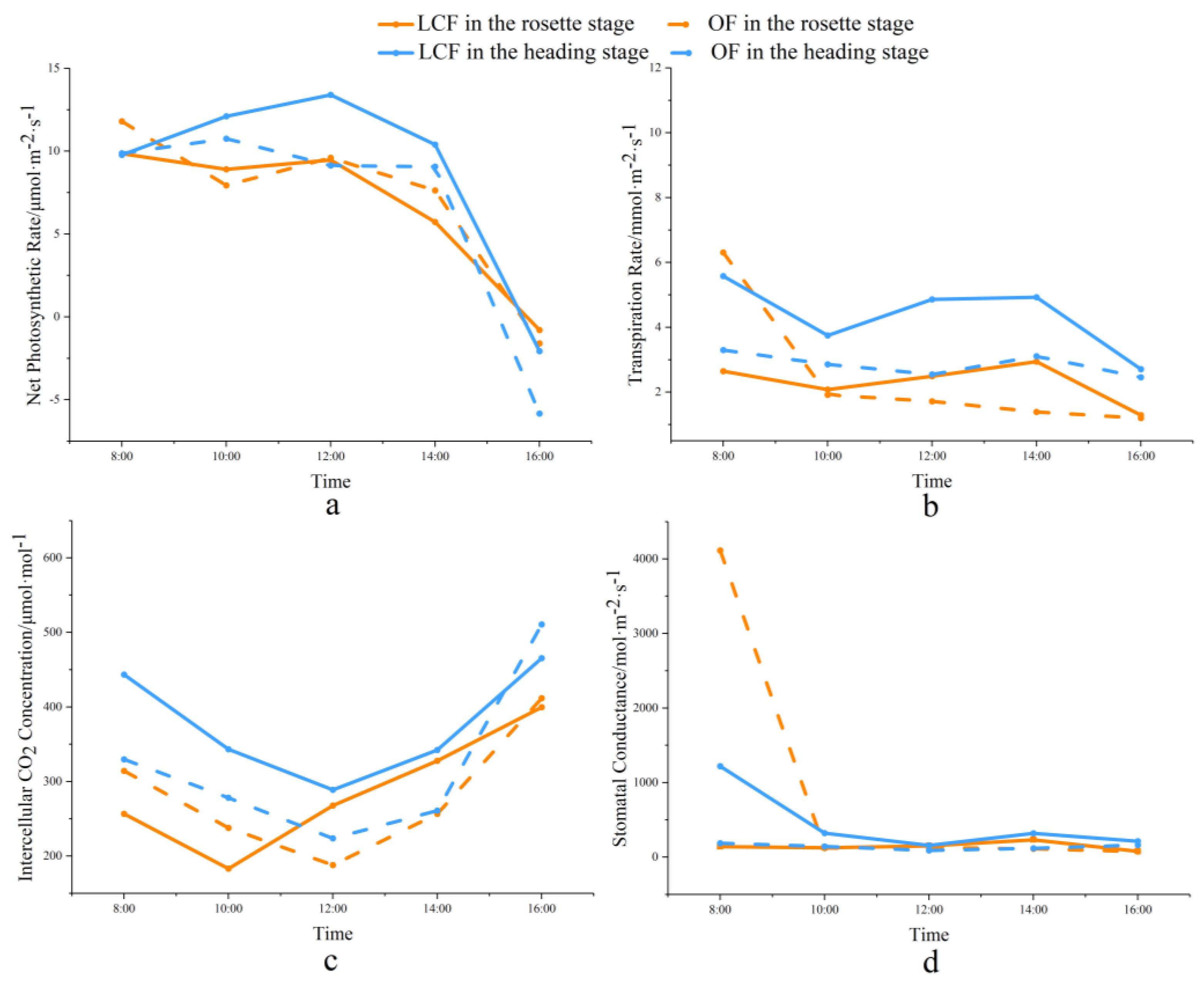

3.5.1. Photosynthetic Characteristics of Plant Leaves

3.5.2. Effect of LCF on Crop Yield and Quality

4. Discussion

4.1. Effect of LCF on the Soil-Plant-Atmosphere Continuum of Greenhouse

4.2. Correlation between Microclimate Environment of Light Conversion Film Greenhouse

4.3. Effect of LCF on the Greenhouse Environment under Different Weather Conditions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gorjian, S.; Calise, F.; Kant, K.; Ahamed, M.S.; Copertaro, B.; Najafi, G.; Zhang, X.X.; Aghaei, M.; Shamshiri, R.R. A review on opportunities for implementation of solar energy technologies in agricultural greenhouses. J. Clean. Prod. 2020, 285, 124807. [Google Scholar] [CrossRef]

- McNulty, J. Solar Greenhouses Generate Electricity and Grow Crops at the Same Time. UC Santa Cruz Study Reveals. 3 November 2017. Available online: https://phys.org/news/2017-11-solargreenhouses-electricity-crops.html (accessed on 5 July 2019).

- Zhang, S.H.; Guo, Y.; Zhao, H.J.; Wang, Y.; Chow, D.; Fang, Y. Methodologies of control strategies for improving energy efficiency in agricultural greenhouses. J. Clean. Prod. 2020, 274, 122695. [Google Scholar] [CrossRef]

- Mobtaker, H.G.; Keyhani, A.; Mohammadi, A.; Rafiee, S.; Akram, A. Sensitivity analysis of energy inputs for barley production in Hamedan Province of Iran. Agriculture, Ecosystems and Environment. Agric. Ecosyst. Environ. 2010, 137, 367–372. [Google Scholar] [CrossRef]

- Abhayapala, R.; Costa, J.D.; Malaviarachchi, W.; Kumara Aruna Suriyagoda, L.; Fonseka, R. Exploitation of differential temperature-sensitivities of crops for improved resilience of tropical smallholder cropping systems to climate change: A case study with temperature responses of tomato and chilli. Agric. Ecosyst. Environ. 2018, 261, 103–114. [Google Scholar] [CrossRef]

- Ma, J.J.; Kong, F.T.; Zhou, X.Y. Research Progress of Influence of Haze-fog on Agricultural Production and Agricultural Product Circulation. J. Agric. Sci. Technol. 2017, 19, 1–7. [Google Scholar] [CrossRef]

- Zhou, J. Influence of haze weather on agricultural production in Beijing. Sci. Technol. 2015, 25, 62. [Google Scholar] [CrossRef]

- Thomsen, I.K.; Lægdsmand, M.; Olesen, J.E. Crop growth and nitrogen turnover under increased temperatures and low autumn and winter light intensity. Agric. Ecosyst. Environ. 2010, 139, 187–194. [Google Scholar] [CrossRef]

- Wu, X.Y.; Cao, H.X.; Hao, S.X.; Wang, H.B. Effect of planting row spacing and irrigation amount on tomato growth and yield in solar greenhouse in Northwest China. Trans. Chin. Soc. Agric. Eng. 2018, 34, 81–89. [Google Scholar] [CrossRef]

- Qiu, R.; Song, J.; Du, T.; Kang, S.; Tong, L.; Chen, R.; Wu, L. Response of evapotranspiration and yield to planting density of solar greenhouse grown tomato in northwest China. Agric. Water Manag. 2013, 130, 44–51. [Google Scholar] [CrossRef]

- Xie, J.; Liu, H.C.; Song, S.W.; Sun, G.W.; Chen, R.Y. Research Progresses in Application of Artificial Supplement Light Source in Greenhouse Vegetable Production. China Veg. 2012, 1, 1–7. [Google Scholar]

- Dyśko, J. Effects of LED and HPS lighting on the growth, seedling morphology and yield of greenhouse tomatoes and cucumbers. Hortic. Sci. 2021, 48, 22–29. [Google Scholar] [CrossRef]

- Bliznikas, Z.; Zukauskas, A.; Samuolienė, G.; Viršilė, A.; Brazaitytė, A.; Jankauskienė, J.; Duchovskis, P.; Novičkovas, A. Effect of supplementary pre-harvest LED lighting on the antioxidant and nutritional properties of green vegetables. In Proceedings of the XXVIII International Horticultural Congress on Science and Horticulture for People (IHC2010): International Symposium on 939, Lisbon, Portugal, 22 August 2010; pp. 85–91. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Q.; Wei, H.B.; Dai, J.; He, W.Q. Effects of Light Conversion Film on Growth and Quality of Strawberry. China Veg. 2019, 9, 62–68. [Google Scholar]

- Ye, Y.C.; Bai, F.C.; Yu, K. Developing Trends of Technique for Agricultural Film in China. China Plast. Ind. 2002, 6, 1–3. [Google Scholar] [CrossRef]

- Jyothi, R.K.; Thenepalli, T.; Ahn, J.W.; Parhi, P.K.; Chung, K.W.; Lee, J. Review of rare earth elements recovery from secondary resources for clean energy technologies: Grand opportunities to create wealth from waste. J. Clean. Prod. 2020, 267, 122048. [Google Scholar] [CrossRef]

- Ji, J.Z.; Liu, H.C.; Liu, X.T.; Song, S.W.; Sun, G.W. Effect of Light Conversion Film on the quality of sweet pepper. In Proceedings of the Abstracts of 2013 Academic Annual Meeting of Facility Horticulture Branch of China Horticultural Society Seminar on High Quality and Safe Production Technology of Vegetables and On-Site Observation Meeting, Guangzhou, China, 21–24 November 2013. [Google Scholar]

- Li, Q.; Zhang, B.G.; Liang, P.X.; Feng, W.M.; Li, X.N.; Liang, B. Effects of light-conversion film on leaf vegetables yield. Guangdong Agric. Sci. 2015, 42, 30–34. [Google Scholar] [CrossRef]

- Wu, W.B.; Zhang, Z.B.; Dong, R.Y.; Xie, G.N.; Zhou, J.X.; Wu, K.J.; Zhang, H.N.; Cai, Q.P.; Lei, B.F. Characterization and properties of a Sr2Si5N8:Eu2+-based light-conversion agricultural film. J. Rare Earths 2020, 38, 539–545. [Google Scholar] [CrossRef]

- Wu, H.Y. Solar radiation and crops. Agric. Jilin 1997, 9, 14–15. [Google Scholar]

- Hu, Z.S.; Li, L.H.; Shao, C.B.; Cai, Q. Light Conversion Film and Its Investigation Status. Mater. Rep. 2008, 22, 290–293. [Google Scholar] [CrossRef]

- Trouwborst, G.; Hogewoning, S.W.; Kooten, O.V.; Harbinson, J.; Leperen, W.V. Plasticity of photosynthesis after the ‘red light syndrome’ in cucumber. Environ. Exp. Bot. 2016, 121, 75–82. [Google Scholar] [CrossRef]

- Kou, E.F.; Deng, P.S.; Song, S.W.; Sun, G.W.; Liu, H.C.; Chen, R.Y. Research Progress on Spectrum Conversion Film Application in Facility Production. North. Hortic. 2018, 1, 155–159. [Google Scholar] [CrossRef]

- Zhang, W.Z.; Han, Y.D.; Du, H.J.; Huang, R.D.; Chen, W.F. Relationship between Canopy Temperature and Soil Wate Content, Yield Components at Flowering Stage in Rice. Chin. J. Rice Sci. 2007, 1, 67–70. [Google Scholar] [CrossRef]

- Yuan, X.K. Research Progress in Effects of High Humidity Environment on Physiological Metabolism and Growing Development of Facility Cultivation Crops. Guizhou Agric. Sci. 2017, 45, 147–149. [Google Scholar] [CrossRef]

- Zhao, T.H.; Huang, G.H. Research Progress on the effects of elevated atmospheric carbon dioxide concentration on plants. Crops 2003, 3, 3–6. [Google Scholar] [CrossRef]

- Qin, L.J.; Tian, Y. The Research on Light Conversion Ability of High Light Energy Agriculture Film. China Plast. 2002, 3, 55–61. [Google Scholar] [CrossRef]

- Verdaguer, D.; Jansen, M.A.K.; Llorens, L.; Morales, L.O.; Neugart, S. UV-A radiation effects on higher plants: Exploring the known unknown. Plant Sci. 2017, 255, 72–81. [Google Scholar] [CrossRef]

| First Crop | Second Crop | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Date | Weather Conditions | Air Temperature under LCF (°C) | Air Temperature under OF (°C) | Variable (°C) | Date | Weather Conditions | Air Temperature under LCF (°C) | Air Temperature under OF (°C) | Variable (°C) |

| 18 September 2019 | Sunny | 24.54 | 24.29 | +0.25↑ | 10 January 2020 | Sunny | 4.24 | 2.95 | +1.29↑ |

| 05 October 2019 | Sunny | 19.00 | 18.24 | +0.76↑ | 03 February 2020 | Sunny | 6.46 | 6.26 | +0.20↑ |

| 08 October 2019 | Sunny | 20.26 | 19.80 | +0.46↑ | 16 February 2020 | Sunny | 15.73 | 14.36 | +1.37↑ |

| 14 October 2019 | Sunny | 15.27 | 14.69 | +0.58↑ | 13 March 2020 | Sunny | 18.40 | 17.74 | +0.66↑ |

| 07 November 2019 | Sunny | 16.70 | 15.96 | +0.74↑ | 02 April 2020 | Sunny | 16.81 | 14.73 | +2.08↑ |

| 11 October 2019 | Cloudy | 17.83 | 17.42 | +0.41↑ | 24 February 2020 | Cloudy | 15.37 | 14.34 | +1.03↑ |

| 16 October 2019 | Cloudy | 16.43 | 15.81 | +0.62↑ | 25 February 2020 | Cloudy | 16.66 | 16.47 | +0.19↑ |

| 18 October 2019 | Cloudy | 16.93 | 16.46 | +0.47↑ | 09 March 2020 | Cloudy | 18.97 | 17.73 | +1.24↑ |

| 01 November 2019 | Cloudy | 19.15 | 18.76 | +0.39↑ | 24 March 2020 | Cloudy | 17.57 | 16.54 | +1.03↑ |

| 10 November 2019 | Cloudy | 14.99 | 14.49 | +0.50↑ | 07 April 2020 | Cloudy | 16.70 | 15.28 | +1.42↑ |

| 21 September 2019 | Haze | 25.76 | 25.20 | +0.56↑ | 18 January 2020 | Haze | 2.63 | 2.44 | +0.19↑ |

| 26 September 2019 | Haze | 25.14 | 24.61 | +0.53↑ | 11 February 2020 | Haze | 14.91 | 13.89 | +1.02↑ |

| 19 October 2019 | Haze | 16.35 | 16.21 | +0.14↑ | 06 March 2020 | Haze | 19.59 | 17.70 | +1.89↑ |

| 23 October 2019 | Haze | 17.93 | 17.63 | +0.30↑ | 25 March 2020 | Haze | 19.99 | 18.71 | +1.28↑ |

| 09 November 2019 | Haze | 15.75 | 15.53 | +0.22↑ | 14 April 2020 | Haze | 19.50 | 18.94 | +0.56↑ |

| First Crop | Second Crop | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Date | Weather Conditions | Air Humidity under LCF (%) | Air Humidity under OF (%) | Variable (%) | Date | Weather Conditions | Air Humidity under LCF (%) | Air Humidity under OF (%) | Variable (%) |

| 18 September 2019 | Sunny | 55.66 | 60.15 | −4.49↓ | 10 January 2020 | Sunny | 92.81 | 94.59 | −1.78↓ |

| 05 October 2019 | Sunny | 61.10 | 65.02 | −3.92↓ | 03 February 2020 | Sunny | 87.03 | 87.22 | −0.19↓ |

| 08 October 2019 | Sunny | 54.60 | 55.14 | −0.54↓ | 16 February 2020 | Sunny | 83.33 | 77.95 | +5.38↑ |

| 14 October 2019 | Sunny | 64.49 | 68.39 | −3.90↓ | 13 March 2020 | Sunny | 77.80 | 68.47 | +9.33↑ |

| 07 November 2019 | Sunny | 71.11 | 71.02 | +0.09↑ | 02 April 2020 | Sunny | 61.63 | 64.72 | −3.09↓ |

| 11 October 2019 | Cloudy | 80.64 | 82.21 | −1.57↓ | 24 February 2020 | Cloudy | 80.85 | 82.80 | −1.95↓ |

| 16 October 2019 | Cloudy | 70.24 | 72.78 | −2.54↓ | 25 February 2020 | Cloudy | 83.03 | 81.47 | +1.56↑ |

| 18 October 2019 | Cloudy | 76.32 | 78.30 | −1.98↓ | 09 March 2020 | Cloudy | 77.11 | 79.13 | −2.02↓ |

| 01 November 2019 | Cloudy | 73.08 | 73.54 | −0.46↓ | 24 March 2020 | Cloudy | 75.28 | 75.53 | −0.25↓ |

| 10 November 2019 | Cloudy | 81.64 | 84.05 | −2.41↓ | 07 April 2020 | Cloudy | 69.73 | 70.61 | −0.88↓ |

| 21 September 2019 | Haze | 64.48 | 68.40 | −3.92↓ | 18 January 2020 | Haze | 90.46 | 90.39 | +0.07↑ |

| 26 September 2019 | Haze | 64.42 | 67.23 | −2.81↓ | 11 February 2020 | Haze | 85.69 | 83.96 | +1.73↑ |

| 19 October 2019 | Haze | 83.01 | 84.56 | −1.55↓ | 06 March 2020 | Haze | 74.06 | 77.35 | −3.29↓ |

| 23 October 2019 | Haze | 75.80 | 77.05 | −1.25↓ | 25 March 2020 | Haze | 79.72 | 78.37 | +1.35↑ |

| 09 November 2019 | Haze | 79.13 | 80.16 | −1.03↓ | 14 April 2020 | Haze | 53.33 | 53.09 | +0.24↑ |

| First Crop | Second Crop | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Date | Weather Conditions | CO2 Concentration under LCF (mg·L−1) | CO2 Concentration under OF (mg·L−1) | Variable (mg·L−1) | Date | Weather Conditions | CO2 Concentration under LCF (mg·L−1) | CO2 Concentration under OF (mg·L−1) | Variable (mg·L−1) |

| 18 September 2019 | Sunny | 673.92 | 636.17 | +37.75↑ | 10 January 2020 | Sunny | 1173.63 | 960.79 | +212.84↑ |

| 05 October 2019 | Sunny | 606.46 | 456.46 | +150.00↑ | 20 January 2020 | Sunny | 1295.92 | 921.05 | +374.87↑ |

| 08 October 2019 | Sunny | 622.58 | 440.17 | +182.41↑ | 03 February 2020 | Sunny | 1184.79 | 981.00 | +203.79↑ |

| 14 October 2019 | Sunny | 688.75 | 516.88 | +171.87↑ | 17 February 2020 | Sunny | 1105.50 | 744.94 | +360.56↑ |

| 07 November 2019 | Sunny | 819.42 | 614.17 | +205.25↑ | 22 February 2020 | Sunny | 1155.67 | 759.36 | +396.31↑ |

| 11 October 2019 | Cloudy | 695.29 | 556.17 | +139.12↑ | 11 January 2020 | Cloudy | 1236.88 | 1043.89 | +192.99↑ |

| 16 October 2019 | Cloudy | 754.21 | 556.92 | +197.29↑ | 17 January 2020 | Cloudy | 1305.38 | 984.46 | +320.92↑ |

| 18 October 2019 | Cloudy | 792.52 | 616.09 | +176.43↑ | 24 February 2020 | Cloudy | 1438.92 | 1136.06 | +302.86↑ |

| 01 November 2019 | Cloudy | 845.21 | 610.38 | +234.83↑ | 25 February 2020 | Cloudy | 1300.96 | 971.77 | +329.19↑ |

| 10 November 2019 | Cloudy | 939.75 | 799.33 | +140.42↑ | 27 February 2020 | Cloudy | 1321.96 | 971.20 | +350.76↑ |

| 21 September 2019 | Haze | 635.92 | 507.88 | +128.04↑ | 18 January 2020 | Haze | 1360.33 | 970.67 | +389.66↑ |

| 26 September 2019 | Haze | 668.46 | 492.92 | +175.54↑ | 26 January 2020 | Haze | 1383.79 | 1132.10 | +251.69↑ |

| 19 October 2019 | Haze | 790.42 | 635.67 | +154.75↑ | 27 January 2020 | Haze | 1409.29 | 1094.71 | +314.58↑ |

| 23 October 2019 | Haze | 812.52 | 627.22 | +185.30↑ | 28 January 2020 | Haze | 1411.00 | 1126.17 | +284.83↑ |

| 09 November 2019 | Haze | 888.73 | 696.55 | +192.18↑ | 13 February 2020 | Haze | 1331.17 | 944.83 | +386.34↑ |

| First Crop | Second Crop | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Date | Weather Conditions | PAR under LCF (µmol m−2s−1) | PAR under OF (µmol m−2s−1) | Variable (µmol m−2s−1) | Date | Weather Conditions | PAR under LCF (µmol m−2s−1) | PAR under OF (µmol m−2s−1) | Variable (µmol m−2s−1) |

| 04 November 2019 | Sunny | 266.16 | 206.50 | +59.66↑ | 05 April 2020 | Sunny | 406.85 | 320.06 | +86.79↑ |

| 07 November 2019 | Sunny | 316.46 | 262.44 | +54.02↑ | 11 April 2020 | Sunny | 447.26 | 349.09 | +98.17↑ |

| 11 November 2019 | Sunny | 311.16 | 251.90 | +59.26↑ | 06 April 2020 | Sunny | 399.25 | 307.36 | +91.89↑ |

| 01 November 2019 | Cloudy | 222.48 | 180.23 | +42.25↑ | 08 April 2020 | Cloudy | 274.35 | 210.86 | +63.49↑ |

| 10 November 2019 | Cloudy | 229.73 | 186.68 | +43.05↑ | 10 April 2020 | Cloudy | 376.96 | 292.74 | +84.22↑ |

| 12 November 2019 | Cloudy | 189.02 | 153.91 | +35.11↑ | 04 April 2020 | Haze | 430.14 | 342.37 | +87.77↑ |

| 09 November 2019 | Haze | 155.53 | 118.23 | +37.30↑ | 07 April 2020 | Haze | 362.66 | 281.74 | +80.92↑ |

| 14 April 2020 | Haze | 358.37 | 265.50 | +92.87↑ | |||||

| First crop | Second crop | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Date | Weather Conditions | Soil Temperature under LCF (°C) | Soil Temperature under OF (°C) | Variable (°C) | Date | Weather Conditions | Soil Temperature under LCF (°C) | Soil Temperature under OF (°C) | Variable (°C) |

| 18 September 2019 | Sunny | 26.34 | 24.00 | +2.34↑ | 03 February 2020 | Sunny | 9.01 | 8.56 | +0.45↑ |

| 05 October 2019 | Sunny | 22.86 | 22.25 | +0.61↑ | 04 February 2020 | Sunny | 18.16 | 16.99 | +1.17↑ |

| 08 October 2019 | Sunny | 22.62 | 22.17 | +0.45↑ | 16 February 2020 | Sunny | 17.04 | 15.87 | +1.17↑ |

| 14 October 2019 | Sunny | 18.04 | 18.01 | +0.03↑ | 13 March 2020 | Sunny | 22.80 | 22.11 | +0.69↑ |

| 07 November 2019 | Sunny | 18.44 | 17.50 | +0.94↑ | 02 April 2020 | Sunny | 19.35 | 18.29 | +1.06↑ |

| 11 October 2019 | Cloudy | 20.35 | 19.55 | +0.80↑ | 24 February 2020 | Cloudy | 18.73 | 17.92 | +0.81↑ |

| 16 October 2019 | Cloudy | 18.97 | 18.48 | +0.49↑ | 25 February 2020 | Cloudy | 18.41 | 18.08 | +0.33↑ |

| 18 October 2019 | Cloudy | 19.39 | 19.14 | +0.25↑ | 09 March 2020 | Cloudy | 20.53 | 19.19 | +1.34↑ |

| 01 November 2019 | Cloudy | 19.29 | 19.22 | +0.07↑ | 24 March 2020 | Cloudy | 20.41 | 19.02 | +1.39↑ |

| 10 November 2019 | Cloudy | 18.82 | 17.56 | +1.26↑ | 07 April 2020 | Cloudy | 19.10 | 18.29 | +0.81↑ |

| 21 September 2019 | Haze | 26.31 | 25.38 | +0.93↑ | 26 January 2020 | Haze | 7.50 | 7.25 | +0.25↑ |

| 26 September 2019 | Haze | 26.20 | 25.27 | +0.93↑ | 11 February 2020 | Haze | 15.85 | 14.58 | +1.27↑ |

| 28 September 2019 | Haze | 26.09 | 25.44 | +0.65↑ | 06 March 2020 | Haze | 21.79 | 21.35 | +0.44↑ |

| 30 September 2019 | Haze | 26.74 | 25.72 | +1.02↑ | 25 March 2020 | Haze | 21.38 | 20.33 | +1.05↑ |

| 09 November 2019 | Haze | 18.25 | 17.31 | +0.94↑ | 14 April 2020 | Haze | 20.27 | 19.37 | +0.90↑ |

| Growth Period | Project | LCF | OF | Variable | p | Sig. |

|---|---|---|---|---|---|---|

| Rosette stage | Net photosynthesis /µmolm−2s−1 | 33.15 | 35.37 | −2.22 | 0.561 | NS |

| Transpiration rate /mmolm−2s−1 | 11.45 | 12.54 | −1.09 | 0.696 | NS | |

| Intercellular CO2 concentration /µmolm−2 | 1436.33 | 1409.83 | +26.5 | 0.326 | NS | |

| Stomatal conductance/molm−2s−1 | 740.83 | 4558.67 | −3817.84 | 0.173 | NS | |

| Heading stage | Net photosynthesis /µmolm−2s−1 | 43.6 | 32.98 | +10.62 | 0.370 | NS |

| Transpiration rate /mmolm−2s−1 | 21.83 | 14.28 | +7.55 | 0.567 | NS | |

| Intercellular CO2 concentration /µmolm−2 | 1884.33 | 1604.83 | +279.5 | 0.005 | ** | |

| Stomatal conductance/molm−2s−1 | 2346.00 | 715.17 | +1630.83 | 0.048 | * |

| Processing | Output (kg·(667 m2)−1) | Total Soluble Sugar (%) | Soluble Protein (%) | Reduction-Type Vitamin C (mg·kg−1) | ||||

|---|---|---|---|---|---|---|---|---|

| First Crop | Second Crop | First Crop | Second Crop | First Crop | Second Crop | First Crop | Second Crop | |

| LCF | 2782.28 | 1285.56 | 2.85 | 2.37 | 0.24 | 0.14 | 183.75 | 502.67 |

| OF | 2553.36 | 921.36 | 2.19 | 2.17 | 0.18 | 0.16 | 151.75 | 495.67 |

| Amplitude variation (%) | +8.97 | +39.53 | +30.14 | +9.22 | +33.33 | −12.50 | +21.09 | +1.41 |

| p | 0.030 | 0.001 | 0.001 | 0.003 | 0.005 | 0.047 | 0.001 | 0.367 |

| Sig. | * | ** | ** | ** | ** | * | ** | NS |

| Repeat | LCF | OF |

|---|---|---|

| Repeat 1 | 22.7 °C | 18.8 °C |

| Repeat 2 | 19.2 °C | 15.4 °C |

| Repeat 3 | 21.2 °C | 22.0 °C |

| p | 0.347 | |

| Sig. | NS | |

| HPS | LED | LCF | |

|---|---|---|---|

| Characteristic | Large energy consumption, large calorific value and many hidden dangers in operation. It is suitable for 10−year planning | Small size, high light efficiency, low power consumption, adapt to various harsh environments, and high one-time cost investment | Good tensile property, good light transmittance, dustproof, anti fog drop, anti-aging and light conversion function |

| Energy consumption (w) | 1055 | 580 | 0 |

| Illumination output (μmol/J) | 2100 | 1170 | -- |

| Efficiency (mol/kWh) | 7.17 | 7.26 | -- |

| Unit price of equipment ($) | $320 | $1200 | $0.1719−0.2813/m2 |

| PPFD (μmol/m2/s) | 250 | 250 | 250 |

| Area covered by each light source (m2) | 8.4 | 4.68 | 260 |

| Total area (m2) | 260 | 260 | 260 |

| Equipment demand | 31 | 56 | 260 m2 |

| Total price of equipment ($) | $9920 | $67,200 | $44.694−73.138 |

| Power consumption ($/kwh) | $0.08 | $0.08 | 0 |

| Service duration (hour) | 3000 | 3000 | 3000 |

| Energy consumption cost ($/year) | $7849.2 | $7795.2 | 0 |

| Total cost ($) | $17,769.2 | $74,995.2 | $44.694−73.138 |

| Air Temperature (°C) | Air Humidity (%) | CO2 Concentration (mg·L−1) | PAR (µmolm−2S−1) | Soil Temperature (°C) | |||

|---|---|---|---|---|---|---|---|

| First crop | Air temperature (°C) | P | 1 | −0.32 | 0.293 | 0.474 * | 0.488 * |

| R2 | 1 | 0.1024 | 0.086 | 0.225 | 0.201 | ||

| Air humidity (%) | P | -- | 1 | 0.546 * | −0.687 ** | −0.213 | |

| R2 | -- | 1 | 0.298 | 0.472 | 0.045 | ||

| CO2 concentration (mg·L−1) | P | -- | -- | 1 | −0.153 | 0.272 | |

| R2 | -- | -- | 1 | 0.023 | 0.074 | ||

| PAR (µmolm−2S−1) | P | -- | -- | -- | 1 | 0.258 | |

| R2 | -- | -- | -- | 1 | 0.067 | ||

| Soil temperature (°C) | P | -- | -- | -- | -- | 1 | |

| R2 | -- | -- | -- | -- | 1 | ||

| Second crop | Air temperature (°C) | P | 1 | −0.707 * | −0.291 | 0.409 | 0.768 ** |

| R2 | 1 | 0.500 | 0.085 | 0.167 | 0.590 | ||

| Air humidity (%) | P | -- | 1 | 0.818 ** | −0.542 | −0.177 | |

| R2 | -- | 1 | 0.669 | 0.294 | 0.031 | ||

| CO2 concentration (mg·L−1) | P | -- | -- | 1 | −0.190 | 0.220 | |

| R2 | -- | -- | 1 | 0.036 | 0.048 | ||

| PAR (µmolm−2S−1) | P | -- | -- | -- | 1 | 0.258 | |

| R2 | -- | -- | -- | 1 | 0.067 | ||

| Soil temperature (°C) | P | -- | -- | -- | -- | 1 | |

| R2 | -- | -- | -- | -- | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhangzhong, L.; Zhang, X.; Wei, X.; Zhang, S.; Wang, L.; Zheng, W. Effects of Light Conversion Film on the Growth of Leafy Vegetables in Facilities under Haze Weather. Agronomy 2022, 12, 2391. https://doi.org/10.3390/agronomy12102391

Li J, Zhangzhong L, Zhang X, Wei X, Zhang S, Wang L, Zheng W. Effects of Light Conversion Film on the Growth of Leafy Vegetables in Facilities under Haze Weather. Agronomy. 2022; 12(10):2391. https://doi.org/10.3390/agronomy12102391

Chicago/Turabian StyleLi, Jingjing, Lili Zhangzhong, Xin Zhang, Xiaoming Wei, Shirui Zhang, Lichun Wang, and Wengang Zheng. 2022. "Effects of Light Conversion Film on the Growth of Leafy Vegetables in Facilities under Haze Weather" Agronomy 12, no. 10: 2391. https://doi.org/10.3390/agronomy12102391

APA StyleLi, J., Zhangzhong, L., Zhang, X., Wei, X., Zhang, S., Wang, L., & Zheng, W. (2022). Effects of Light Conversion Film on the Growth of Leafy Vegetables in Facilities under Haze Weather. Agronomy, 12(10), 2391. https://doi.org/10.3390/agronomy12102391