Development of an Optimal Algorithm for Detecting Damaged and Diseased Potato Tubers Moving along a Conveyor Belt Using Computer Vision Systems

Abstract

:1. Introduction

- Computer vision systems working with piece objects will not be able to realize the throughput required for a vegetable store;

- It is necessary to develop a sorting mechanism that will allow removing damaged objects from a moving conveyor belt at the recommended speeds of its movement (Table 1), following their current coordinates established by the computer vision system.

- Tubers moving on the conveyor are captured by the camera several times, and each time they are perceived by the system as different. So, re-capturing the image slows down the system significantly.

- While moving on a conveyor, tubers may overlap each other and thereby hinder precise shape recognition.

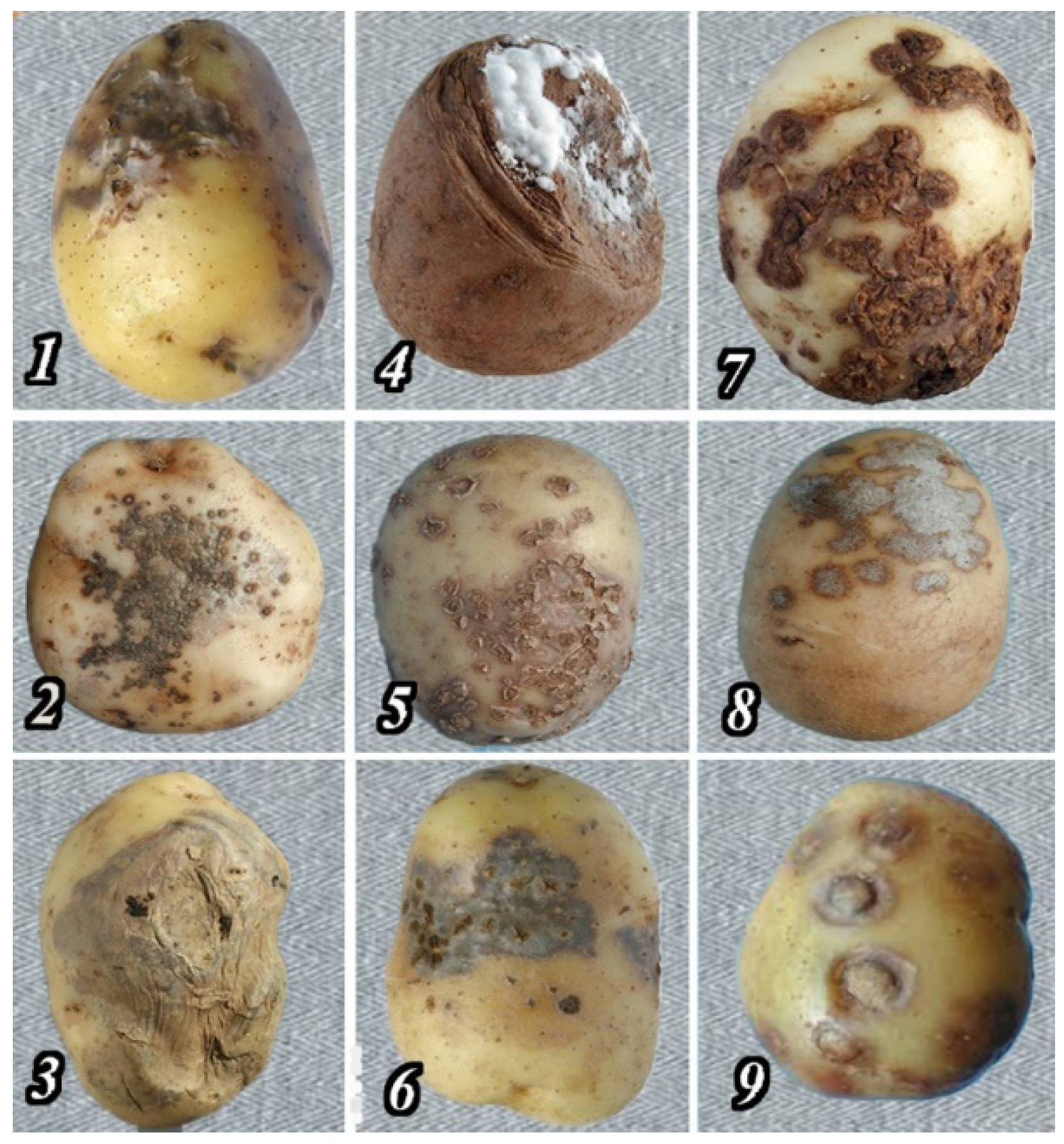

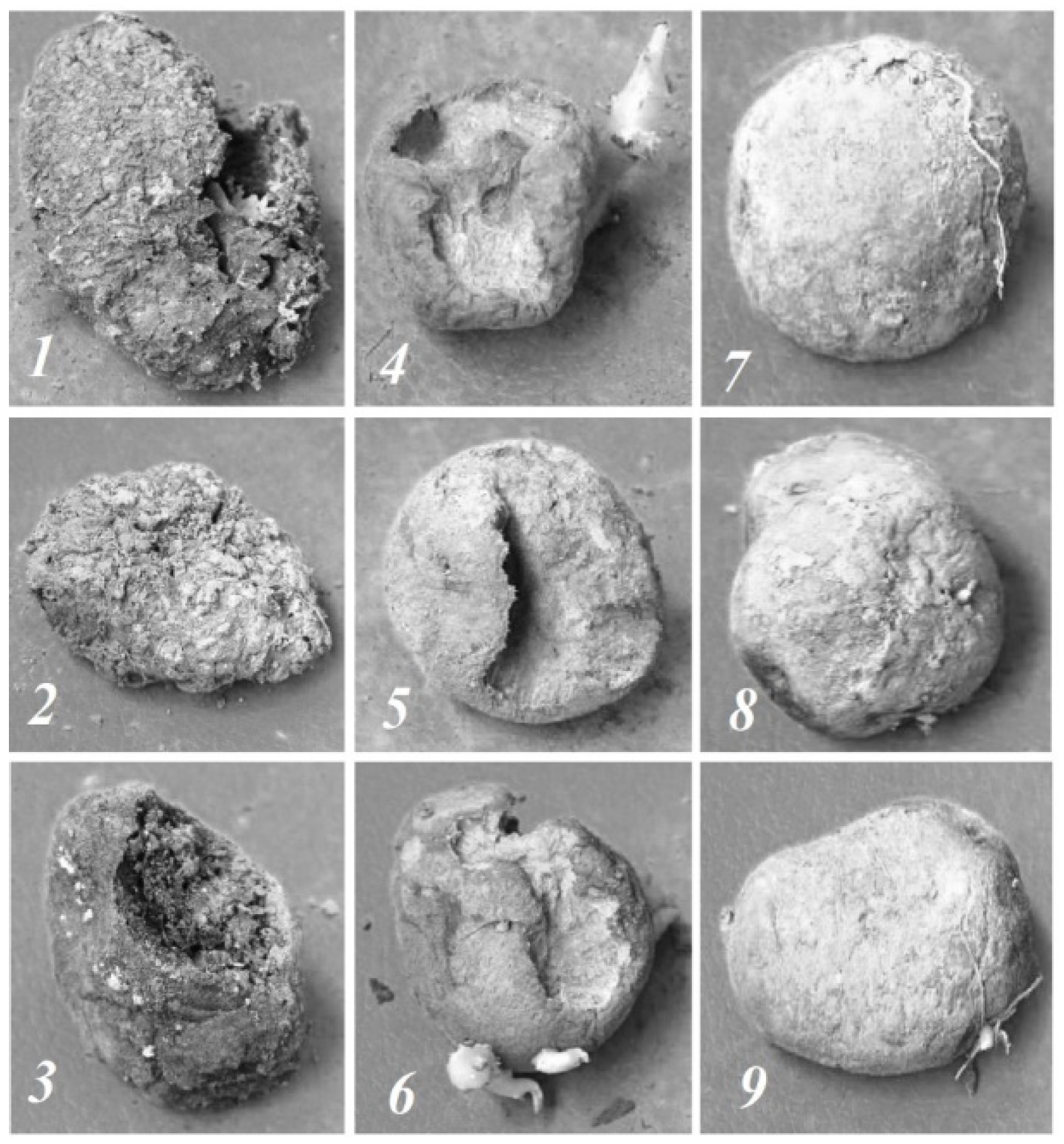

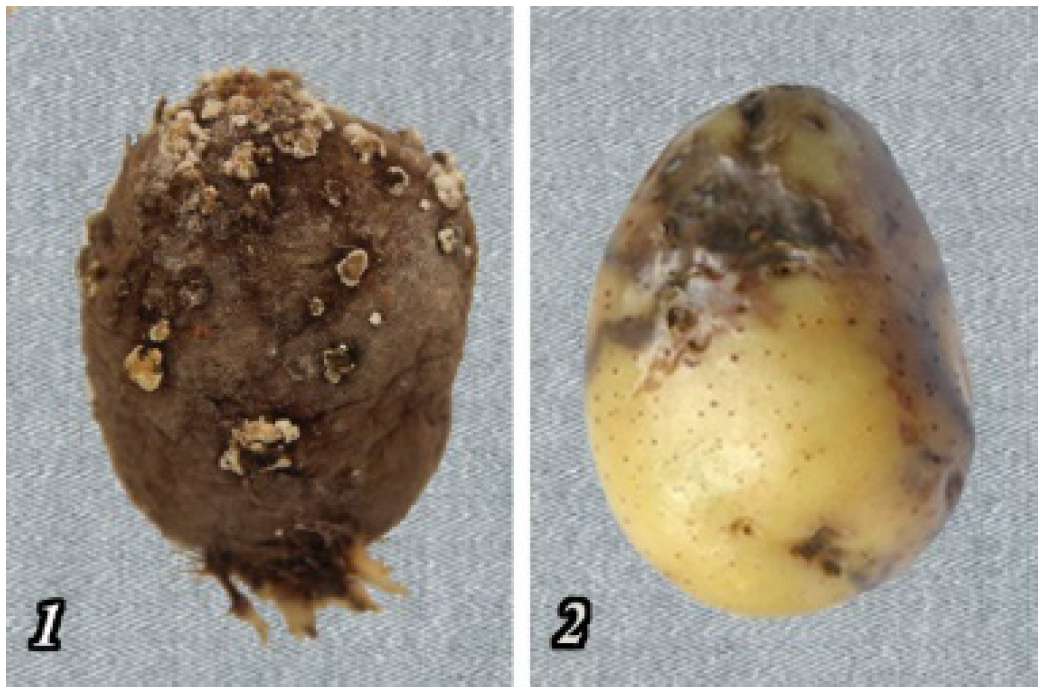

- The problem of direct identification of tubers affected by disease or rodents.

- The background subtraction method is applicable in conveyor conditions;

- Getting rid of shadows is carried out by selecting the position of light sources;

- Elimination of partial overlapping of objects is carried out by metering the supply of these objects to the conveyor and increasing the conveyor speed.

- It is enough to use video cameras operating in the visible part of the spectrum to identify diseased tubers;

- Some laboratory methods are available to detect subsurface damage, but these methods are not suitable for vegetable stores.

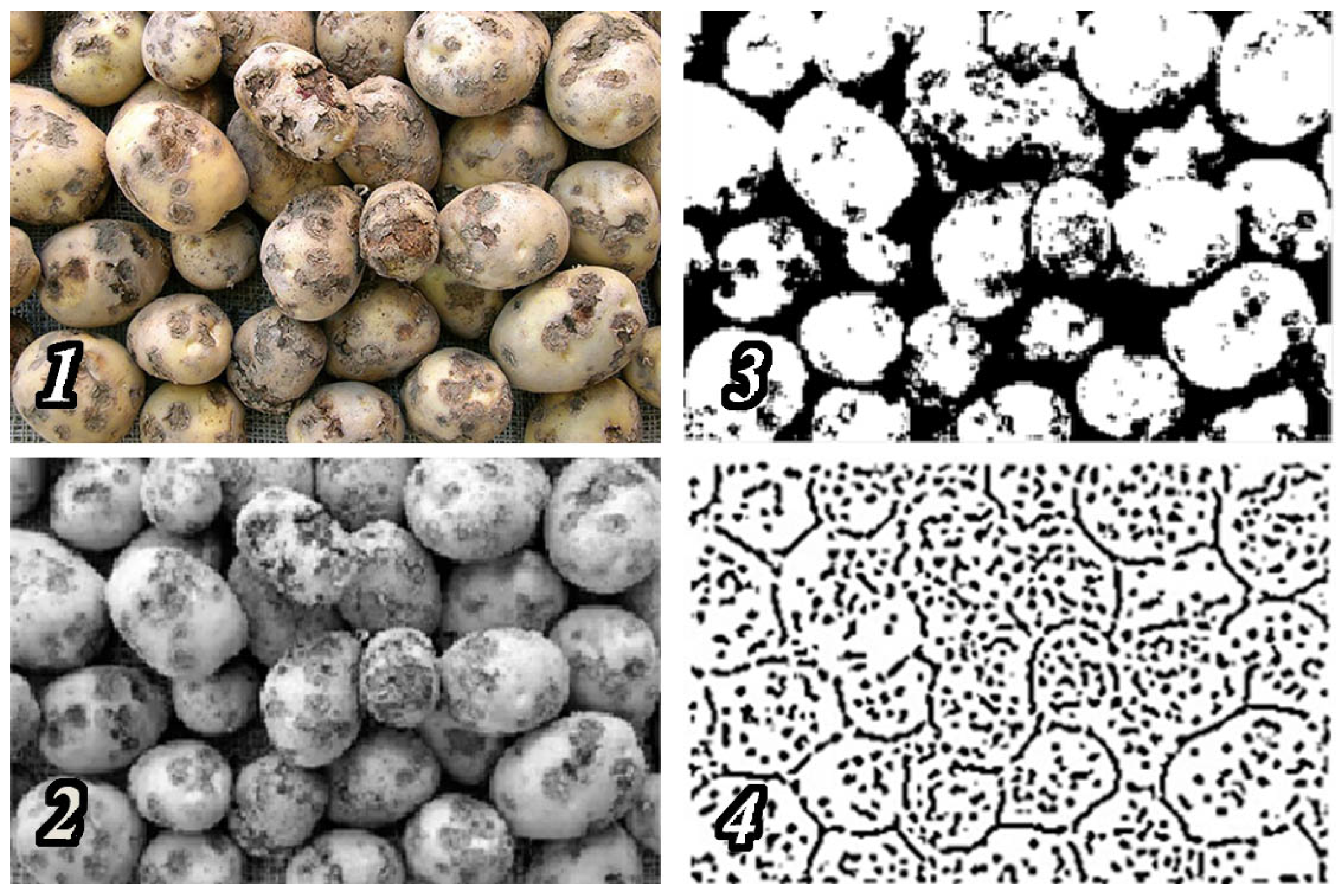

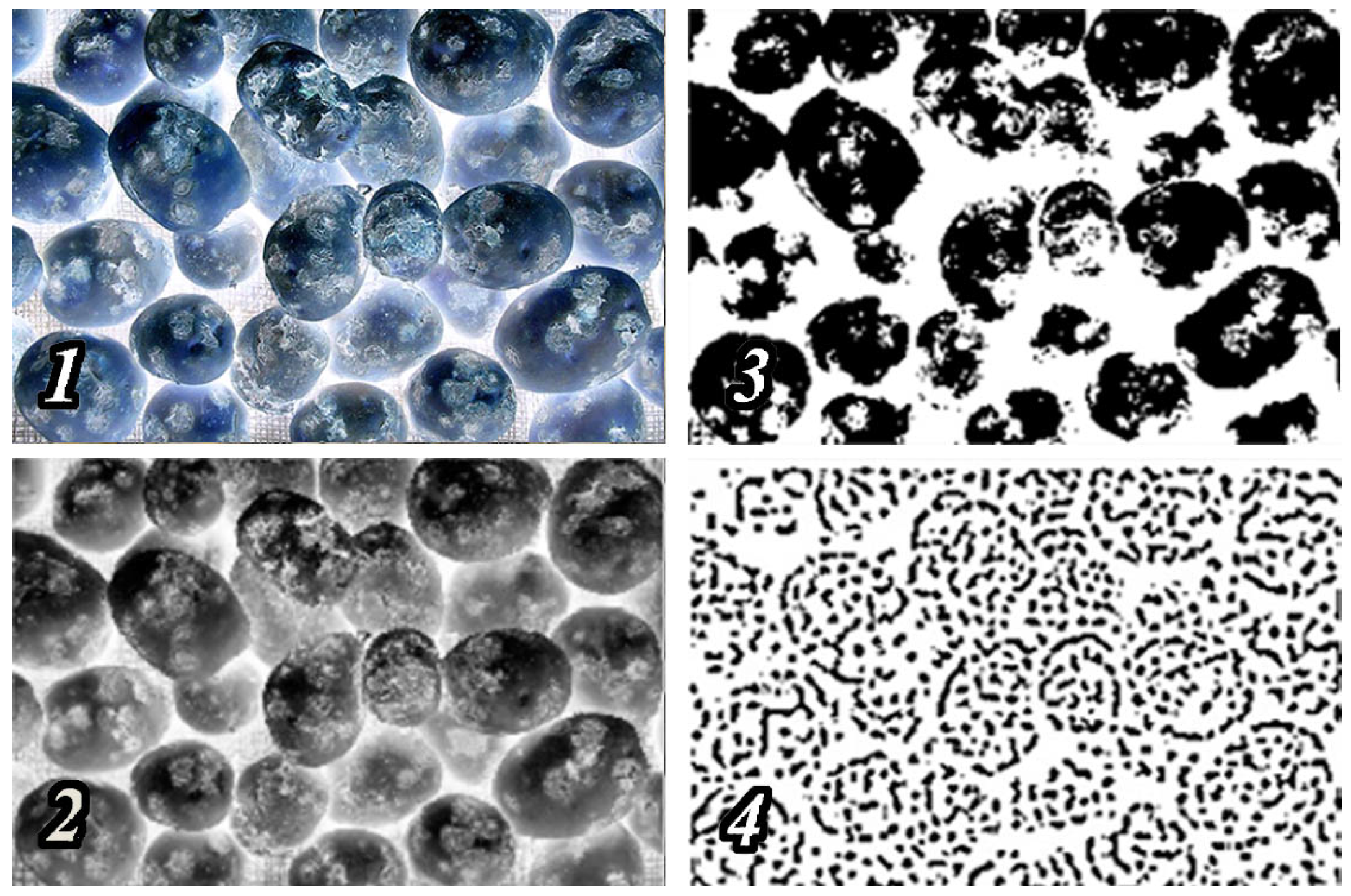

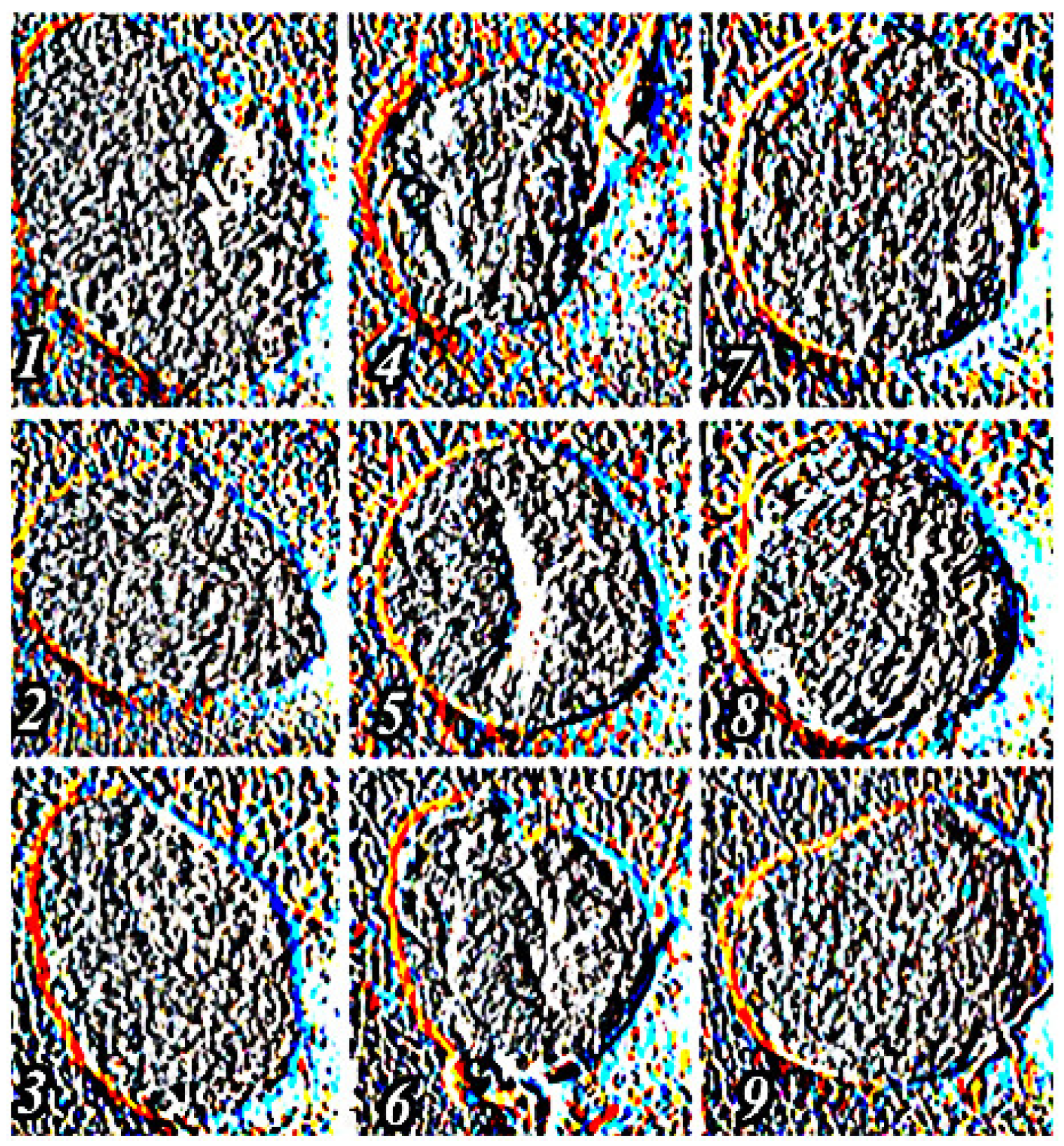

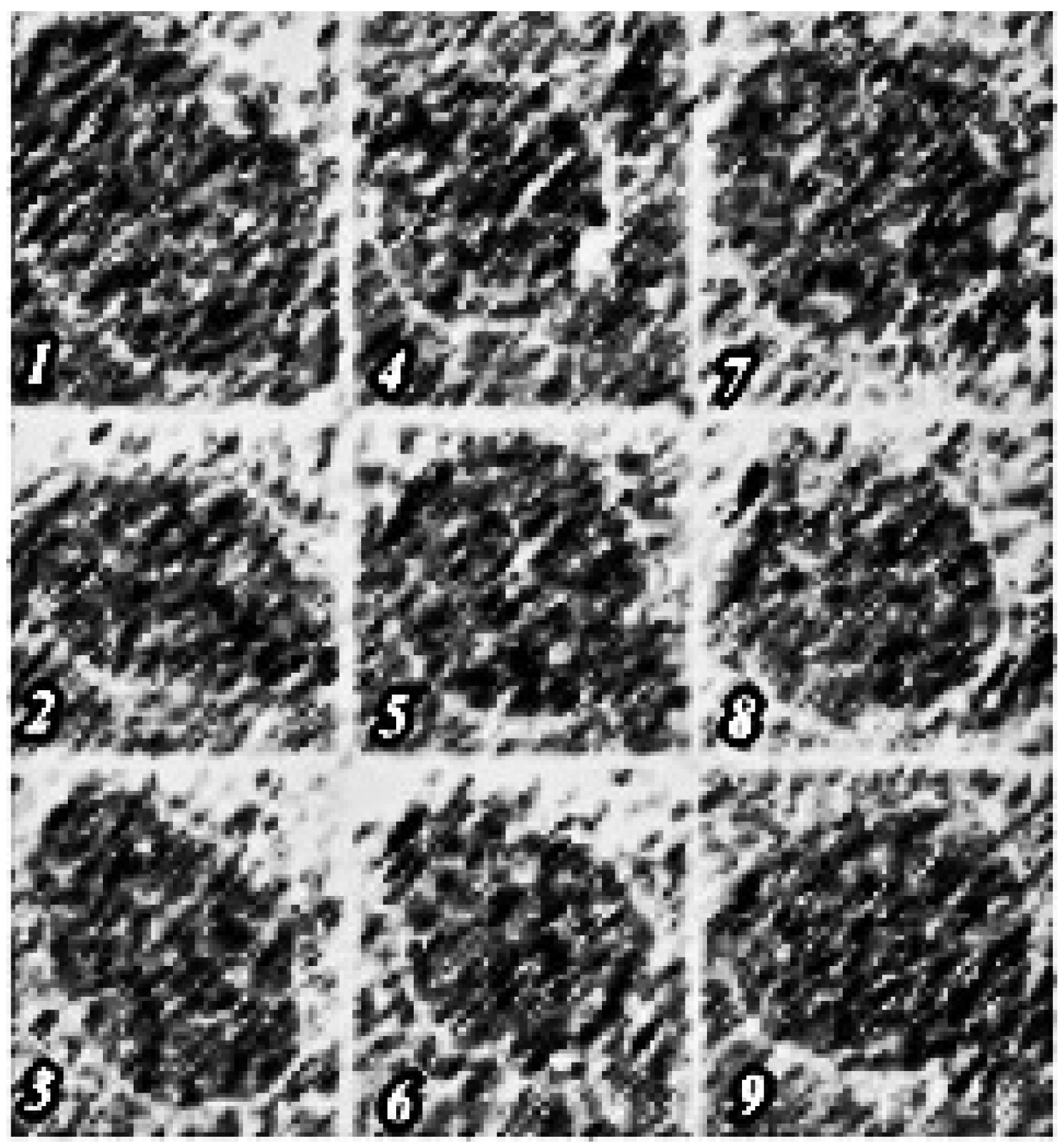

2. Materials and Methods

- ease of implementation;

- adaptation to various kinds of images by choosing the optimal threshold;

- fast lead time.

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arthurs, S.; Dara, S.K. Dara Microbial biopesticides for invertebrate pests and their markets in the United States. J. Invertebr. Pathol. 2019, 165, 13–21. [Google Scholar] [CrossRef] [PubMed]

- Keswani, C.; Dilnashin, H.; Birla, H.; Pratap, S. Singh Regulatory barriers to Agricultural Research commercialization: A case study of biopesticides in India. Rhizosphere 2019, 11, 100155. [Google Scholar] [CrossRef]

- Argüeso, D.; Picon, A.; Irusta, U.; Medela, A.; San-Emeterio, M.G.; Bereciartua, A.; Alvarez-Gila, A. Few-Shot Learning approach for plant disease classification using images taken in the field. Comput. Electron. Agric. 2020, 175, 105542. [Google Scholar] [CrossRef]

- Gao, J.; Westergaard, J.C.; Sundmark, E.H.R.; Bagge, M.; Liljeroth, E.; Alexandersson, E. Automatic late blight lesion recognition and severity quantification based on field imagery of diverse potato genotypes by deep learning. Knowl. Based Syst. 2021, 214, 106723. [Google Scholar] [CrossRef]

- Hajjar, G.; Quellec, S.; Pépin, J.; Challois, S.; Joly, G.; Deleu, C.; Leport, L.; Musse, M. MRI investigation of internal defects in potato tubers with particular attention to rust spots induced by water stress. Postharvest Biol. Technol. 2021, 180, 111600. [Google Scholar] [CrossRef]

- Payman, M.; Navid, R.; Mohsen, A. Computer vision-based potato defect detection using neural networks and support vector machines. Int. J. Robot. Autom. 2013, 28, 1–9. [Google Scholar]

- Wang, C.; Li, X.; Wu, Z.; Zhou, Z.; Feng, Y. Machine vision detecting potato mechanical damage based on a manifold learning algorithm. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2014, 30, 245–252. [Google Scholar]

- Przybyl, K.; Boniecki, P.; Koszela, K.; Gierz, L.; Lukomski, M. Computer vision and artificial neural network techniques for classification of damage in potatoes during the storage process. Czech J. Food Sci. 2019, 37, 135–140. [Google Scholar] [CrossRef]

- Bautista, J.F.; Oceña, C.D.; Cabreros, M.J.; Alagao, S.P.L. Automated Sorter and Grading of Tomatoes using Image Analysis and Deep Learning Techniques. In Proceedings of the 2020 IEEE 12th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Manila, Philippines, 3–7 December 2020; pp. 1–6. [Google Scholar]

- Jijesh, J.J.; Shankar, S.; Ranjitha; Revathi, D.C.; Shivaranjini, M.; Sirisha, R. Development of Machine Learning based Fruit Detection and Grading system. In Proceedings of the 2020 International Conference on Recent Trends on Electronics, Information, Communication & Technology (RTEICT), Bangalore, India, 12–13 November 2020; pp. 403–407. [Google Scholar]

- De la Cruz, J.E.C.; Ramirez, O.J.V. Convolutional neural networks for the Hass avocado classification using LabVIEW in an agro-industrial plant. In Proceedings of the 2020 IEEE XXVII International Conference on Electronics, Electrical Engineering and Computing (INTERCON), Lima, Peru, 3–5 September 2020; pp. 1–4. [Google Scholar]

- Örnek, M.; Hacıseferoğulları, H. Design of Real Time Image Processing Machine for Carrot Classification. Yüzüncü Yıl Üniversitesi Tarım Bilimleri Derg. 2020, 30, 355–366. [Google Scholar] [CrossRef]

- Bazame, H.C.; Molin, J.P.; Althoff, D.; Martello, M. Detection, classification, and mapping of coffee fruits during harvest with computer vision. Comput. Electron. Agric. 2021, 183, 106066. [Google Scholar] [CrossRef]

- Istiadi, A.; Sulistiyanti, S.R.; Fitriawan, H. Model Design of Tomato Sorting Machine Based on Artificial Neural Network Method Using Node MCU Version 1.0. J. Phys. 2019, 1376, 012026. [Google Scholar] [CrossRef]

- Putra, K.T.; Hariadi, T.K.; Riyadi, S.; Chamim, A.N.N. Feature Extraction for Quality Modeling of Malang Oranges on an Automatic Fruit Sorting System. In Proceedings of the 2018 2nd International Conference on Imaging, Signal Processing and Communication (ICISPC), Kuala Lumpur, Malaysia, 20–22 July 2018; pp. 74–78. [Google Scholar]

- Behera, S.K.; Jena, L.; Rath, A.K.; Sethy, P.K. Disease Classification and Grading of Orange Using Machine Learning and Fuzzy Logic. In Proceedings of the 2018 International Conference on Communication and Signal Processing (ICCSP), Chennai, India, 3–5 April 2018; pp. 0678–0682. [Google Scholar]

- Abbas, H.M.T.; Shakoor, U.; Khan, M.J.; Ahmed, M.; Khurshid, K. Automated Sorting and Grading of Agricultural Products based on Image Processing. In Proceedings of the 2019 8th International Conference on Information and Communication Technologies (ICICT), Karachi, Pakistan, 16–17 November 2019; pp. 78–81. [Google Scholar]

- Manual Design Conveyor Transport Belt Conveyors (to SNIP 2.05.07-85), All-Union Design and Research Institute Industrial Transport (Promtransniiproekt) Gosstroya USSR, Moscow Stroyizdat 1988. Available online: https://xn--c1ahwb.xn--p1ai/uploadedFiles/files/Metodika_rascheta_lentochnykh_konveyerov_k_SNiP__2.05.07-85.pdf (accessed on 1 September 2021).

- Khalil, I. Al-Mughrabi Biological Control of Fusarium Dry Rot and Other Potato Tuber Diseases Using Pseudomonas fluorescens and Enterobacter Cloacae. Biol. Control 2010, 53, 280–284. Available online: https://www.researchgate.net/publication/240445223_Biological_control_of_Fusarium_dry_rot_and_other_potato_tuber_diseases_using_Pseudomonas_fluorescens_and_Enterobacter_cloacae (accessed on 2 July 2021).

- Aqel, S.; Hmimid, A.; Sabri, M.A.; Aarab, A. Road traffic: Vehicle detection and classification. In Proceedings of the Intelligent Systems and Computer Vision (ISCV), Fez, Morocco, 17–19 April 2017; pp. 1–5. [Google Scholar]

- Liu, F.; Zeng, Z.; Li, Z. A fast background update mechanism for vehicle detection in urban roads. In Proceedings of the 2017 9th Computer Science and Electronic Engineering (CEEC), Colchester, UK, 27–29 September 2017; pp. 60–64. [Google Scholar]

- Soin, A.; Chahande, M. Moving vehicle detection using deep neural network. In Proceedings of the 2017 International Conference on Emerging Trends in Computing and Communication Technologies (ICETCCT), Dehradun, India, 17–18 November 2017; pp. 1–5. [Google Scholar]

- Wei, Y.; Tian, Q.; Guo, J.; Huang, W.; Cao, J. Multi-vehicle detection algorithm through combining Harr and HOG features. Math. Comput. Simul. 2019, 155, 130–145. [Google Scholar] [CrossRef]

- Raj, R.; Rajiv, P.; Kumar, P.; Khari, M.; Verdú, E.; Crespo, R.G.; Manogaran, G. Feature based video stabilization based on boosted HAAR Cascade and representative point matching algorithm. Image Vis. Comput. 2020, 101, 103957. [Google Scholar] [CrossRef]

- Marino, S.; Beauseroy, P.; Smolarz, A. Weakly-supervised learning approach for potato defects segmentation. Eng. Appl. Artif. Intell. 2019, 85, 337–346. [Google Scholar] [CrossRef]

- Afonso, M.; Blok, P.M.; Polder, G.; van der Wolf, J.M.; Kamp, J. Sydney, Australia.: Blackleg Detection in Potato Plants using Convolutional Neural Networks. IFAC-Pap. 2019, 52, 6–11. [Google Scholar]

- Wu, A.; Zhu, J.; Ren, T. Detection of apple defect using laser-induced light backscattering imaging and convolutional neural network. Comput. Electr. Eng. 2020, 81, 106454. [Google Scholar] [CrossRef]

- Kuznetsova, A.; Maleva, T.; Soloviev, V. Using YOLOv3 Algorithm with Pre- and Post-Processing for Apple Detection in Fruit-Harvesting Robot(Article). Agronomy 2020, 10, 1016. Available online: https://www.mdpi.com/2073-4395/10/7/1016 (accessed on 2 July 2021). [CrossRef]

- Korchagin, S.; Serdechny, D.; Kim, R.; Terin, D.; Bey, M. The use of machine learning methods in the diagnosis of diseases of crops. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2020; Volume 176, p. 04011. [Google Scholar]

- Marino, S.; Beauseroy, P.; Smolarz, A. Unsupervised adversarial deep domain adaptation method for potato defects classification. Comput. Electron. Agric. 2020, 174, 105501. [Google Scholar] [CrossRef]

- Puno, J.C.V.; Billones, R.K.D.; Bandala, A.A.; Dadios, E.P.; Calilune, E.J.; Joaquin, A.C. Quality Assessment of Mangoes using Convolutional Neural Network. In Proceedings of the 2019 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE Conference on Robotics, Automation and Mechatronics (RAM), Bangkok, Thailand, 18–20 November 2019; pp. 491–495. [Google Scholar]

- Yin, H.; Gong, Y.; Qiu, G. Fast and efficient implementation of image filtering using a side window convolutional neural network. Signal Process. 2020, 176, 107717. [Google Scholar] [CrossRef]

- Shen, X.; Chen, Y.; Tao, X.; Jia, J. Convolutional neural pyramid for image processing. arXiv 2017, arXiv:1704.02071v1. [Google Scholar]

- Spagnoloa, F.; Perrib, S.; Corsonello, P. Design of a real-time face detection architecture for heterogeneous systems-on-chips. Integration 2020, 74, 1–10. [Google Scholar] [CrossRef]

- Feng, X.; Jiang, Y.; Yang, X.; Du, M.; Li, X. Computer vision algorithms and hardware implementations: A survey. Integration 2019, 69, 309–320. [Google Scholar] [CrossRef]

- Irgens, P.; Bader, C.; Lé, T.; Saxena, D.; Ababei, C. An efficient and cost effective FPGA based implementation of the Viola-Jones face detection algorithm. HardwareX 2017, 1, 68–75. [Google Scholar] [CrossRef]

- Chandana, P.; Ghantasala, G.P.; Jeny JR, V.; Sekaran, K.; Deepika, N.; Nam, Y.; Kadry, S. An effective identification of crop diseases using faster region based convolutional neural network and expert systems. Int. J. Electr. Comput. Eng. 2020, 10, 6531–6540. [Google Scholar] [CrossRef]

- Abouzahir, S.; Sadik, M.; Sabir, E. Bag-of-visual-words-augmented Histogram of Oriented Gradients for efficient weed detection. Biosyst. Eng. 2021, 202, 179–194. [Google Scholar] [CrossRef]

- Aslan, M.F.; Durdu, A.; Sabanci, K.; Mutluer, M.A. CNN and HOG based comparison study for complete occlusion handling in human tracking. Measurement 2020, 158, 107704. [Google Scholar] [CrossRef]

- Soleimanipour, A.; Chegini, G.R. A vision-based hybrid approach for identification of Anthurium flower cultivars. Comput. Electron. Agric. 2020, 174, 05460. [Google Scholar] [CrossRef]

- Tseng, D.-C.; Wei, R.-Y.; Lu, C.-T.; Wang, L.-L. Image restoration using hybrid features improvement on morphological component analysis. J. Electron. Sci. Technol. 2019, 17, 100014. [Google Scholar] [CrossRef]

- Sharifrazi, D.; Alizadehsani, R.; Roshanzamir, M.; Joloudari, J.H.; Shoeibi, A.; Jafari, M.; Hussain, S.; Sani, Z.A.; Hasanzadeh, F.; Khozeimeh, F.; et al. Fusion of convolution neural network, support vector machine and Sobel filter for accurate detection of COVID-19 patients using X-ray images. Biomed. Signal Process. Control 2021, 68, 102622. [Google Scholar] [CrossRef] [PubMed]

- Ravivarma, G.; Gavaskar, K.; Malathi, D.; Asha, K.G.; Ashok, B.; Aarthi, S. Implementation of Sobel operator based image edge detection on FPGA. Mater. Today: Proc. 2021, 45, 2401–2407. [Google Scholar]

- Yogeshwari, M.; Thailambal, G. Automatic feature extraction and detection of plant leaf disease using GLCM features and convolutional neural networks. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Khairnar, S.; Thepade, S.D.; Gite, S. Effect of image binarization thresholds on breast cancer identification in mammography images using OTSU, Niblack, Burnsen, Thepade’s SBTC. Intell. Syst. Appl. 2021, 10–11, 200046. [Google Scholar]

- Saxena, L.P. Niblack’s binarization method and its modifications to real-time applications: A review. Artif. Intell. Rev. 2019, 51, 673–705. [Google Scholar] [CrossRef]

- Imani, E.; Javidi, M.; Pourreza, H.-R. Improvement of retinal blood vessel detection using morphological component analysis. Comput. Methods Programs Biomed. 2015, 118, 263–279. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; KenjiIwana, B.; Uchida, S. Complex image processing with less data—Document image binarization by integrating multiple pre-trained U-Net modules. Pattern Recognit. 2021, 109, 107577. [Google Scholar] [CrossRef]

- Pratikakis, I.; Zagori, K.; Kaddas, P.; Gatos, B. ICFHR 2018 competition on handwritten document image binarization (H-DIBCO 2018). In Proceedings of the 2018 International Conference on Frontiers in Handwriting Recognition, Niagara Falls, NY, USA, 5–8 August 2018; pp. 489–493. [Google Scholar]

- Ahmad, U.; Adji, M.A.P. Accuracy in estimating visual quality parameters of mango fruits as moving object using image processing. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 542, p. 012008. [Google Scholar]

- Balabanov, P.V.; Divin, A.G.; Belyaev, P.S.; Trapeznikov, E.V.; Egorov, A.S.; Zaharov, Y.A.; Yudaev, V.A.; Don-Uni, N.P. Technical vision system for quality control of objects of the ball-shaped form when sorting on the conveyor. J. Phys. 2020, 1546, 012001. [Google Scholar]

- López-Maestresalas, A.; Keresztes, J.C.; Goodarzi, M.; Arazuri, S.; Jarén, C.; Saeys, W. Non-destructive detection of blackspot in potatoes by Vis-NIR and SWIR hyperspectral imaging. Food Control 2016, 70, 229–241. [Google Scholar] [CrossRef] [Green Version]

- Divin, A.; Egorov, A.; Balabanov, P.; Pozhidaev, Y.; Lyubimova, D. Robotic complex for agricultural products sorting. Int. Multidiscip. Sci. GeoConference SGEM 2018, 18, 557–564. [Google Scholar]

- Ibrahim, A.; Grassi, M.; Lovati, F.; Parisi, B.; Spinelli, L.; Torricelli, A.; Rizzolo, A.; Vanoli, M. Non-destructive detection of potato tubers internal defects: Critical insight on the use of time-resolved spectroscopy. Adv. Hortic. Sci. 2020, 34, 43–51. [Google Scholar]

- Lu, Y.; Lu, R. Detection of Surface and Subsurface Defects of Apples Using Tructured Illumination Reflectance Imaging with Machine Learning Algorithms. Trans. ASABE 2018, 61, 1831–1842. [Google Scholar] [CrossRef]

- Balabanov, P.V.; Divin, A.G.; Savencov, A.P.; Shishkina, G.V. Algorithms for Detecting Potato Defects Using Images in the Infrared Range of Spectrum. In Proceedings of the 2018 IEEE International Conference "Quality Management, Transport and Information Security, Information Technologies" (IT&QM&IS), St. Petersburg, Russia, 24–28 September 2018; pp. 417–419. [Google Scholar]

- Balabanov, P.V.; Divin, A.G.; Egorov, A.S.; Yudaev, V.A. Mechatronic system for fruit and vegetables sorting. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 734, pp. 18–21. [Google Scholar]

- Ekanayake, J. Bug Severity Prediction using Keywords in Imbalanced Learning Environment. Int. J. Inf. Technol. Comput. Sci. (IJITCS) 2021, 13, 53–60. [Google Scholar]

- Alyushin, M.V.; Alyushin, V.M.; Kolobashkina, L.V. Optimization of the Data Representation Integrated Form in the Viola-Jones Algorithm for a Person’s Face Search. Procedia Comput. Sci. 2018, 123, 18–23. [Google Scholar] [CrossRef]

- Andriyanov, N.; Dementev, V.; Tashlinskiy, A.; Vasiliev, K. The Study of Improving the Accuracy of Convolutional Neural Networks in Face Recognition Tasks. In Pattern Recognition; ICPR International Workshops and Challenges; Lecture Notes in Computer Science; ICPR: New Delhi, India, 2021; Volume 12665, pp. 5–14. [Google Scholar]

- Andriyanov, N. First Step towards Creating a Software Package for Detecting the Dangerous States during Driver Eye Monitoring. In Pattern Recognition; ICPR International Workshops and Challenges; Lecture Notes in Computer Science; ICPR: New Delhi, India, 2021; Volume 12665, pp. 314–322. [Google Scholar]

- Cao, L.; Li, H.; Zhang, Y.; Zhang, L.; Xu, L. Hierarchical method for cataract grading based on retinal images using improved Haar wavelet. Inf. Fusion 2020, 53, 196–208. [Google Scholar] [CrossRef]

- Zhang, M.; He, Z.; Zhang, H.; Tan, T.; Sun, Z. Toward practical remote iris recognition: A boosting based framework. Neurocomputing 2019, 330, 238–252. [Google Scholar] [CrossRef]

- Kalantar, A.; Edan, Y.; Gur, A.; Klapp, I. A deep learning system for single and overall weight estimation of melons using unmanned aerial vehicle images. Comput. Electron. Agriculture. 2020, 178, 105748. [Google Scholar] [CrossRef]

- Kuznetsova, A.; Maleva, T.; Soloviev, V. Detecting Apples in Orchards Using YOLOv3. In Computational Science and Its Applications; Lecture Notes in Computer Science; ICCSA: Cagliari, Italy, 2020; Volume 12249, pp. 923–934. [Google Scholar]

- Kuznetsova, A.; Maleva, T.; Soloviev, V. YOLOv5 versus YOLOv3 for apple detection. Studies in Systems. Decis. Control 2021, 338, 349–358. [Google Scholar]

| Belt Speed v, m/s, with Belt Width B, mm | ||||||||

|---|---|---|---|---|---|---|---|---|

| B | 300–500 | 650 | 800 | 1000 | 1200 | 1400 | 1600 | 2000 |

| v | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1 |

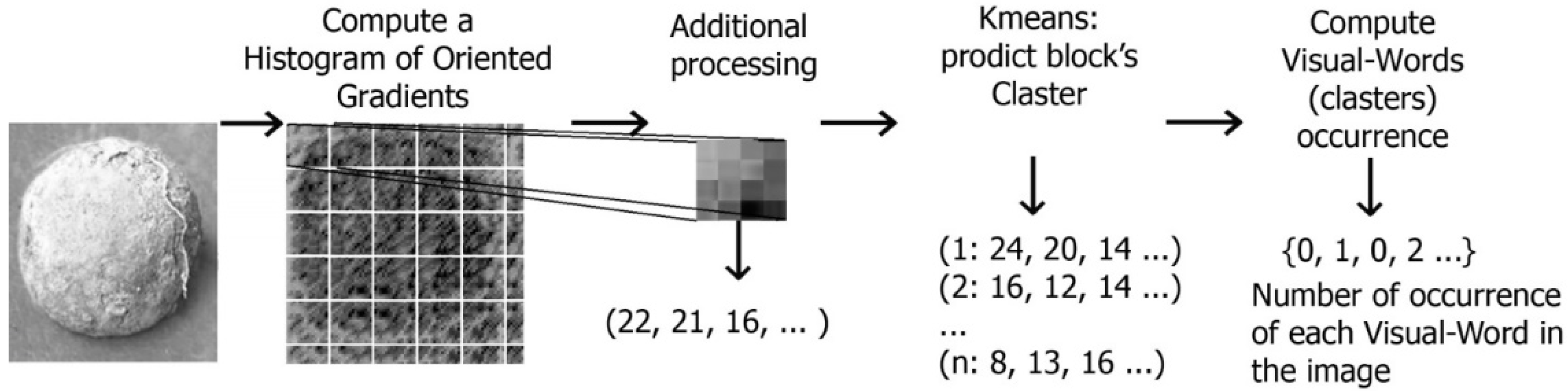

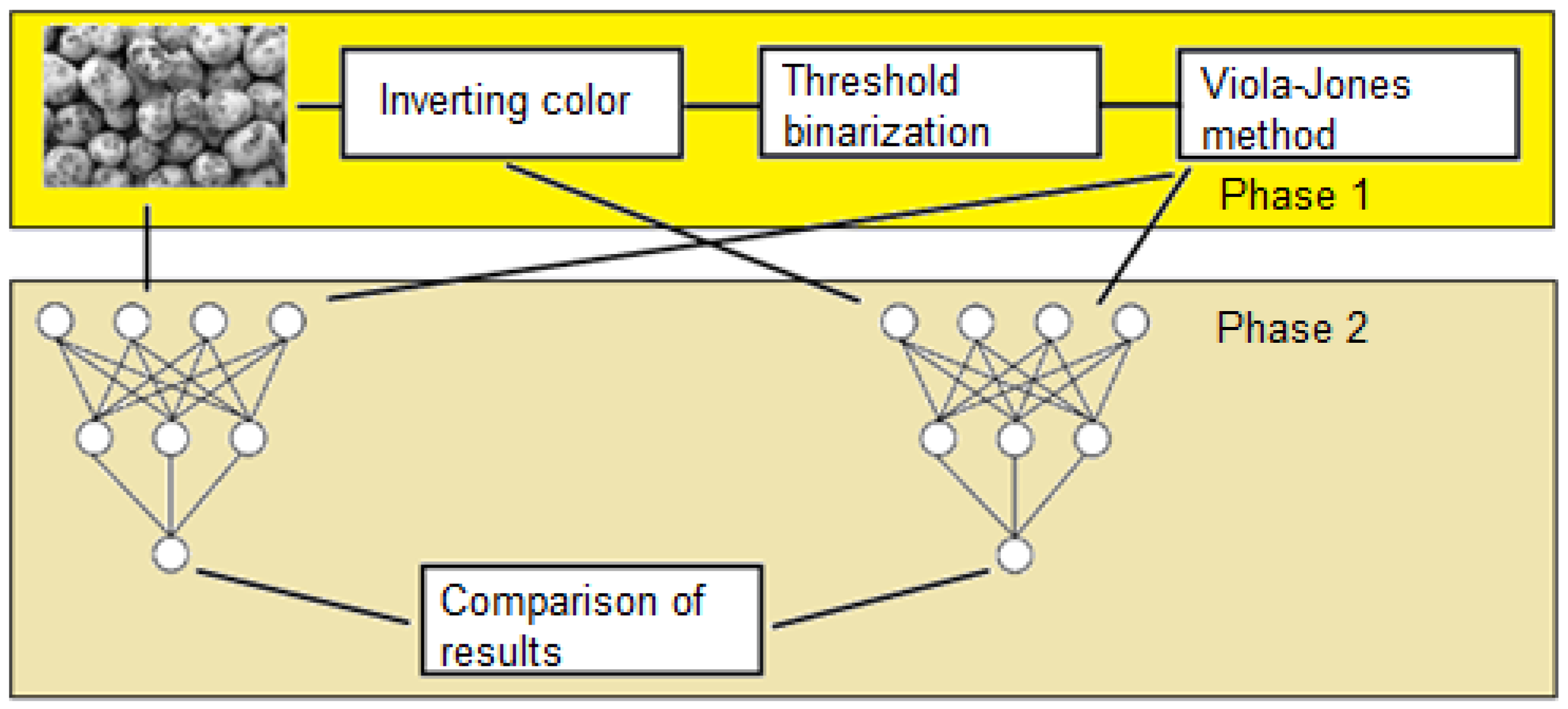

| Preprocessing Methods and Descriptors | Used Classifiers | Result |

| SIFT | SVM | 52–95% depending on damage types |

| HOG | CNN | 67–75% |

| HOG-BOVW | BPNN | 80–95% |

| Otsu threshold binarization | CNN | 85–97% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korchagin, S.A.; Gataullin, S.T.; Osipov, A.V.; Smirnov, M.V.; Suvorov, S.V.; Serdechnyi, D.V.; Bublikov, K.V. Development of an Optimal Algorithm for Detecting Damaged and Diseased Potato Tubers Moving along a Conveyor Belt Using Computer Vision Systems. Agronomy 2021, 11, 1980. https://doi.org/10.3390/agronomy11101980

Korchagin SA, Gataullin ST, Osipov AV, Smirnov MV, Suvorov SV, Serdechnyi DV, Bublikov KV. Development of an Optimal Algorithm for Detecting Damaged and Diseased Potato Tubers Moving along a Conveyor Belt Using Computer Vision Systems. Agronomy. 2021; 11(10):1980. https://doi.org/10.3390/agronomy11101980

Chicago/Turabian StyleKorchagin, Sergey Alekseevich, Sergey Timurovich Gataullin, Aleksey Viktorovich Osipov, Mikhail Viktorovich Smirnov, Stanislav Vadimovich Suvorov, Denis Vladimirovich Serdechnyi, and Konstantin Vladimirovich Bublikov. 2021. "Development of an Optimal Algorithm for Detecting Damaged and Diseased Potato Tubers Moving along a Conveyor Belt Using Computer Vision Systems" Agronomy 11, no. 10: 1980. https://doi.org/10.3390/agronomy11101980

APA StyleKorchagin, S. A., Gataullin, S. T., Osipov, A. V., Smirnov, M. V., Suvorov, S. V., Serdechnyi, D. V., & Bublikov, K. V. (2021). Development of an Optimal Algorithm for Detecting Damaged and Diseased Potato Tubers Moving along a Conveyor Belt Using Computer Vision Systems. Agronomy, 11(10), 1980. https://doi.org/10.3390/agronomy11101980