Abstract

The amount of energy used in agricultural production, processing and distribution is constantly increasing. During the winter months in the greenhouse production industry, the supplemental lighting required to keep up production levels results in high expenditure. Current technology uses broadband high-pressure sodium (HPS) lamps, which is not the most efficient light source for crop production. Recent breakthroughs in the development of light source technologies have led to new opportunities for the use of sustainable and highly efficient light sources in the form of LEDs (light-emitting diodes) for greenhouse lighting. The aim of the study was to evaluate the efficiency of using photosynthetically active radiation (PAR) light for cucumber yielding, production processes and its influence on the variable costs in the cultivation of cucumbers using three different types of lighting. The research was carried out using three individual greenhouse growing area compartments, whereby the plants contained within were lit using three combinations: 1. HPS standard illumination from top HPS sodium lamps—control, 2. HPS-LED—HPS toplighting and LED interlighting, and 3. LED-LED—100% LED lighting, both toplighting and interlighting with LED. The research was conducted in two independent winter crop cycles. The results of the research conducted indicate that the efficiency of light use was the highest in the LED-LED combination and the lowest in HPS, and the use of supplemental lamp lighting in the LED-LED combination (interlighting and toplighting) gives the most favorable surplus of all the variable costs over the value of production to be obtained. Despite the highest absolute level of variable costs in this type of supplemental lighting, the production value was higher by as much as 32.55% in relation to the HPS combination, which also translated into a gross margin that was higher by about ¾. However, it is worth pointing out that, in the HPS-LED combination, the share of lighting and heating costs in the total value of production was the lowest. It is also a combination currently recommended in the literature as being the most beneficial in greenhouse production.

1. Introduction

The possible solutions of the problems regarding sustainable development, which are of a global character, significantly differ from the viewpoint of the state and the concrete possibilities in particular parts of the world [1]. Agriculture is one of the economic sectors that affects climate change by contributing to greenhouse gas emissions directly and indirectly, and in many countries greenhouse farming is a growing industry within this sector. However, it is a very expensive way to produce greenhouse crops and there are many variables to consider (such as energy consumption and location) before any farmer decides to take this route. Moreover, the amount of energy used in agricultural production, processing and distribution is significantly high. At the same time, there is a trend in agriculture towards the reduction in greenhouse gas emissions, but any moves in this direction should not negatively affect farm productivity and economics because this would limit its implementation, due to the high global food and feed demand and the competitive environment in this sector.

Choosing the best location is essential for crop planning and cultivation, however, the studies conducted so far have only related to patterns in the use of energy and the resources present in vegetable production have been very limited [2]. On a more positive note, it should be noted that precise agricultural practices using high-tech equipment have the ability to reduce agricultural inputs by site-specific applications as these have a greater capacity to target inputs to the spatial and temporal needs of the fields, which can result in lower greenhouse gas emissions [3,4,5].

The cucumber is an economically important vegetable grown in over 80 countries worldwide [6], and its annual production is estimated to be about 80 million tons, including about 3 million tons grown in the European Union (EU 28) [7]. High temperatures, humidity, light intensity and nutrient availability are ideal conditions for this typical subtropical plant, which is highly sensitive to adverse environmental conditions [8]. Characterized by their tenderness, these plants thrive in a temperature range between 18.3 to 23.9 °C, with a minimum temperature of 15.6 °C and a maximum of 32.2 °C. Germination of the cucumber takes place in soil that has a temperature range from 15.6 to 35 °C. However, germination is substantially impeded below 15.6 °C [9].

In the cultivation of cucumber, as with other plant growth, the energy provided by light is a significant consideration and temperature control has to be considered within the context of light intensity. The total plant leaf area, carbohydrate production and, consequently, productivity are all affected by radiation. Low supplies of carbohydrates and a reduced productivity in the winter months may cause many plants to fail. As a result, the quality of the vegetable is directly influenced by light. The crops cultivated in such reduced low light levels constitute less dry matter, and the color when harvested is light green but easily turns yellow when on the shelf. The sensitivity of these young vegetables to a low light intensity is greater than that of the older vegetables from the same plant [8]. The use of dynamic supplemental lighting models in greenhouse crop production has become an increasing necessity for growers globally [10]. In northern latitudes, where solar light levels (daily light integral) are inadequate in autumn and winter and even on overcast summer days, high pressure sodium (HPS) supplemental lighting is employed throughout the year and it is typical for cucumbers to be cultivated in greenhouses [11,12,13,14]. Despite the fact that the broad-spectrum high-pressure sodium (HPS) lamps currently being used are outstanding sources of luminous light, they are, however, not the most efficient light source for plant production. Moreover, because of their high operating temperature, HPS lamps can only be used as toplighting when placed well above the crop canopy, which has resulted in an uneven vertical light distribution in tall crops such as cucumbers [13]. An alternative solution seems to be light-emitting diode (LED) lighting. LEDs used in horticulture usually contain combinations of red (peak ≈ 660 nm), blue (peak ≈ 450 nm), white, and/or far-red (peak ≈ 730 nm). The available research results indicate that the current possible performance levels of LED fixtures could be as high as 3.4 µmol J−1 for white and red fixtures, and 4.1 µmol J−1 for blue and red fixtures. LEDs can be used not only as a toplighting but also as interlighting, which directs and focuses growth-stimulating light on the on the most vital part of the crop [15]. Research conducted by Hao et al. [16] indicated that all LED interlighting treatments improved the fruit visual quality, and they also increased the fruit yield beyond the increase in photosynthetic active radiation (more than 10%) in the early production period.

In practice, in the northern countries, such as Poland, located at latitudes above 50° N, in the autumn–winter period and early spring, it is necessary to use assimilation lighting in plant production due to the low solar radiation and shortage of natural sunlight.

Therefore, plant lighting from an artificial light source has been used for many years, although this is an expensive means of intensifying greenhouse crop production. Expenditure on heat and electrical energy in Poland accounts for up to 30% of the total costs of covered crop production, and most of the energy consumed in greenhouse production, in Poland, is still obtained from the combustion of fossil fuels, which has a negative impact on the natural environment [17,18].

The aim of the study was to evaluate the efficiency of using photosynthetically active radiation (PAR) light for cucumber yielding, production processes and its influence on the variable costs in the cultivation of cucumbers using three different types of lighting.

2. Materials and Methods

2.1. Parameters of the Greenhouse Experiment

The research was conducted in two independent winter crop cycles in 2015 and 2016. Both experiments were carried out in a greenhouse at Warsaw University of Life Sciences—SGGW (longitude 21° E, latitude 51°15′ N) as a part of a scientific project conducted with Philips Lighting Holding B.V. [19,20]. The greenhouse facility is a complex of detached modular hothouses with a 12 m aisle width and a 6 m wide gap between modules. The height of the side columns is 3.5 m, and the overall height is 6.72 m. The roofs and interior partition walls are covered with single float glass 4 mm thick and 74/100 wide. The exterior sidewalls are covered with double glass of the same type.

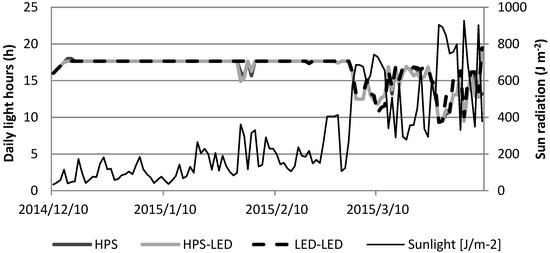

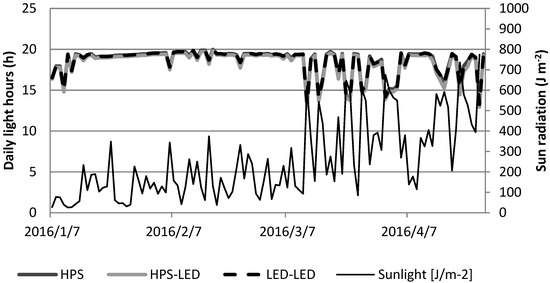

Light was measured with Li-Cor Light meter LI-250A, and quantum sensor LI-190. A daily light exposure equaled 18 h. The lamps were turned off when natural light intensity reached the level of 300 W m−2 and when the internal temperature exceeded 30 °C. The inter-row lighting worked independently of the conditions. Figure 1 and Figure 2 show the number of hours the lamps were switched on and the daily sum of solar radiation in each year of the study. The efficiency of light use for the production of 1 kg of cucumber fruit was calculated depending on the lighting combination. The sum of PAR light energy and cucumber yields in the analyzed cultivation cycles were compared.

Figure 1.

The number of hours of lamp switching on per day in tested combinations in relation to the daily sum of solar radiation in the 2015 growing cycle. Source: own elaboration.

Figure 2.

The number of hours of lamp switching on per day in tested combinations in relation to the daily sum of solar radiation in the 2016 growing cycle. Source: own elaboration.

The research was carried out using three individual 40 m2 greenhouse growing area compartments, whereby the plants contained within were lit using three combinations: 1. HPS standard illumination from top HPS lamps—control, 2. HPS-LED—HPS toplighting and LED interlighting, and 3. LED-LED—100% LED lighting—both toplighting and interlighting with LED (Table 1). HPS toplighting: HPS lamps Gavita GAN 600 W; LED toplighting: Philips Green Power LED toplighting units DR/W—LB, 195 W, and LED interlighting: 2 lines of LEDs with Philips Green Power LED interlighting unit modules 2.5 m HO DR/B 100 W. The light conditions in terms of PAR (photosynthetically active radiation) in every compartment were maintained at one level, possibly closest to ~320 µmol m−2 s−1 (PPFD—Photosynthetic Photon Flux Density). The PPFD was measured at the horizontal position above the inter-row lamps and in the middle of plants canopy. The detailed microclimate and growing conditions in experimental compartments were published by Kowalczyk et al. [19,20].

Table 1.

Characteristics of the experiment parameters.

Seedlings were planted on 22 December 2014. The first combination (with 100% HPS) comprised 125 plants whilst in the second (HPS-LED) and in the third combination (with 100% LED-LED), there were 125 cucumber plants. The total crop cycle was approximately 122 d (22 December to 24 April). This was repeated when the seedlings were planted in January 2015. The first combination (HPS) comprised 114 plants, the second (HPS-LED) 146 plants, and the third combination of (LED-LED) comprised 146 cucumber plants. The total crop duration lasted approximately 119 d (7 January to 1 May). During the stages of growth, development and production, regular measurements of the humidity, temperature, fertilizer and water consumption and yield were taken. In 2015, the cucumber production was harvested after 25 days and in 2016 after 18 days of vegetative growth.

2.2. Gross Margin Model

Calculations made during the research study revealed a surplus of variable costs over revenue. This has proved very helpful in decision making when considering incremental pricing where an entity must cover its variable costs. However, this was not completed automatically and not all of the fixed costs were covered. In the analysis, variable costs that included seedlings, production materials, fertilizer, plant protection, labor, and special costs, such as lighting, heating and additional fixed costs, were recorded in total. Figures for gross returns on total production were calculated by referring to the weekly average weighted prices from the Warsaw Agricultural-Food Wholesale Market Ltd. This is the biggest wholesale market for the sale of agricultural food products sold by agricultural producers, importers, wholesalers, retailers, wholesale units, restaurants, hotels and catering companies in Poland. Fixed costs, including the greenhouse structure and the covering materials along with the irrigation systems, were ignored in this study. The assumption was made in all combinations that the share of fixed costs was exactly the same. In addition, dependent on the cultivation technology used, the size of greenhouses may differ significantly depending on their type. However, investment expenditure related to lighting was presented separately, depending on the type, i.e., HPS, HPS-LED and LED-LED. The gross profit margin in the study was expressed in the form of a percentage following the Elum et al. [21] method, which defined it as the difference between the revenue and variable costs directly connected with the crop production divided by the revenue. Three types of lighting were calculated as presented below:

where:

- GM—gross margin expressed as a percentage,

- TR—total revenue in EUR,

- TVC—total variable cost in EUR,

- P—cumber price per kg in EUR,

- Q—cucumber quantity produced in kg.

The unit cost in EUR of the variable inputs—seedling, costs of fertigation, plant protection, special costs and labor—is represented by letters C1 to C5, whilst the respective quantities (values from 2015 and 2016) of these inputs (in their standard units of measurements) are represented by the letters X1 to X5. Coefficients of variation of costs were also calculated for the three types of lighting used in the study. The coefficients were determined for total variable costs and selected costs such as lighting and heating costs (gas heating). They show how much the costs will change if the production process/method changes by a unit. This coefficient was determined according to the following formula:

where:

- Δk—increase in costs,

- Δx—increase in production,

- K0—costs of the base period (2015),

- X0—production of the base period (2015).

The coefficient of variation of costs can take the following values:

- Wzk = 1—proportional variable cost,

- Wzk < 1—degressive variable cost,

- Wzk > 1—progressive variable cost.

3. Results

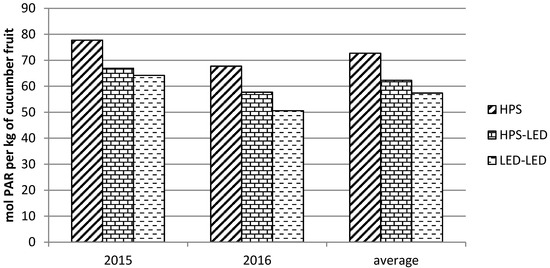

The efficiency of light use, taking into account the use of the number of PAR mols per 1 kg of cucumber fruit, was the highest in the LED-LED combination and the lowest in both cultivation cycles with the HPS lamp (Figure 3). In the 2016 cycle, this efficiency was higher than in 2015, probably due to more solar energy in this production season (Figure 1 and Figure 2). The sun is the best source of light for plant growth and yield. Artificial lighting with LED lamps proved to be a more advantageous light source than HPS. Probably the difference in the light spectrum of both lamps had an influence on the higher efficiency of LED compared to HPS. HPS lamps without blue light, despite the comparable amount of PAR light, even with the additional use of LED lamps that had blue light in their composition, were not as effective for cucumbers as the LED-LED combination. During the study, the average light intensity in both cultivation cycles was about 24 mol/m2/day.

Figure 3.

The efficiency of using light for cucumber plant yielding. Source: own elaboration.

The results of the gross margin analysis show that the gross profit of cucumber production is clearly differentiated depending on the type of lighting used (Table 2). The gross profit margin, resulted in 38.00% in the case of the HPS lighting, 45.00% in in the case of mixed HPS-LED lighting, whereas it resulted in about 50.00% in the case of LED-LED lighting. Therefore, it can be stated that regardless of the type of lighting used, over 38 eurocents are retained as gross profit on every euro of revenue, and this could then be used for other operational expenses. This gross profit, which is realized after accounting for the costs of operating the business in a production season, indicates that in examining the first level of profitability, cucumber production is highly profitable in the area researched. However, it is worth noting that despite the higher level of variable costs in absolute values in the case of LED-LED combinations, this combination proved to be the most profitable. This situation was significantly affected by the fact that, with this type of lighting, the yield from 1 m2 was higher, which in effect translated into a higher production value. Moreover, in the case of the combination using HPS lighting this was EUR 59.42, in the combination with mixed lighting (HPS-LED) this was EUR 70.62 and in the case of LED-LED combination this was as much as EUR 78.76, i.e., higher by 32.55% in relation to the HPS combination. At the same time, it should be noted that this translated into a higher, gross profit margin by about ¾.

Table 2.

Determination of the profit level in cucumber production using three types of lighting.

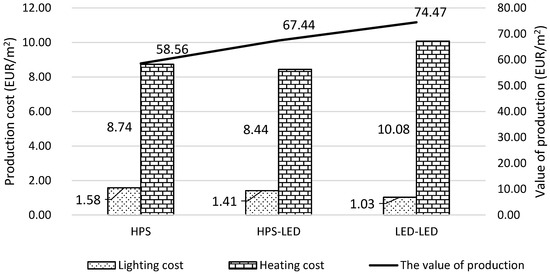

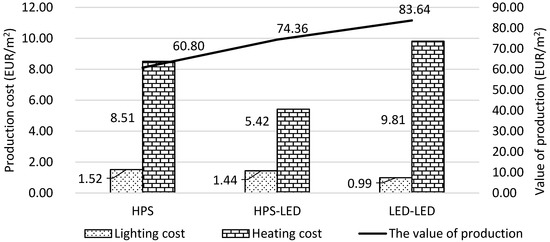

As can be seen from the table above, the specialist costs, which include the cost of heating, the energy needed for lighting in the combination of HPS and LED during the period considered were significantly different. Therefore, their impact on the value of production was more closely examined. The analyses carried out indicate that in 2015 and 2016, the lighting energy costs varied, depending on the type of lighting used. The highest cost per 1 m2 was observed in the case of the HPS combination. In 2015, 13.75 kWh was used to light 1 m2, and the cost was EUR 1.58. In 2016, 9.00 kWh with a value of EUR 1.52 was used per 1 m2, while in the case of the LED combination, 13.22 kWh with a value of EUR 1.03 and 8.62 kWh with a value of EUR 0.99 was used per 1 m2, respectively. The heating cost expressed as GJ/m2 was slightly different. The highest cost per 1m2 was observed in the case of the LED combination. In 2015, 0.98 GJ was used to heat 1 m2, and the cost was EUR 10.08. In 2016, 0.95 GJ with a value of EUR 9.85 was used per 1 m2, while in the case of the HPS combination, 0.85 GJ with a value of EUR 8.74 and 0.82 GJ with a value of EURO 8.51 was used per 1 m2 (Figure 4 and Figure 5). According to the analyses, the use of HPS lighting in moderate climate conditions during the winter results in a lower expenditure of thermal energy, due to the high heat emission of HPS lamps. In the case of LED lamp lighting, expenditures on thermal energy increase. Nonetheless, the increase in the value of production caused by the use of the LED-LED combination certainly compensates for the costs of thermal energy in this case.

Figure 4.

Selected costs and value of cucumber production from 1 m2 depending on the type of lighting used in 2015. Source: own work.

Figure 5.

Selected costs and value of cucumber production from 1 m2 depending on the type of lighting in 2016. Source: own work.

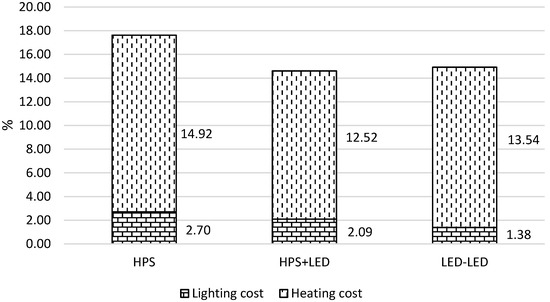

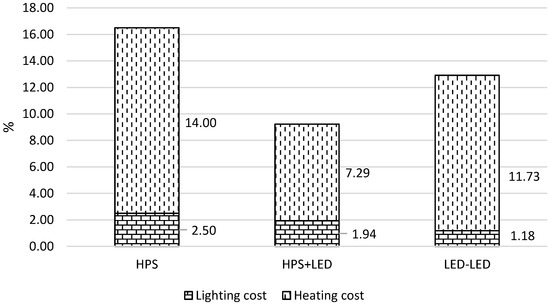

The study also determines the share of lighting and heating costs in the value of production. The share of lighting costs in the value of production in the case of the LED-LED combination in both 2015 and 2016 was the lowest of all combinations, and was 1.38 and 1.18%, respectively. In the case of the HPS combination, it was 2.70 and 2.50%. The heating costs, which in the case of the LED-LED combination constituted 13.54 and 11.73% of the production value in 2015 and 2016, respectively, had a much larger share in this case. For comparison, in the HPS combination, they were 14.92 and 14.00%, respectively. It is worth noting that in 2016, the share of lighting and heating costs in the HPS-LED combination was 1.94 and 7.29% (Figure 6 and Figure 7).

Figure 6.

Share of lighting and heating costs in the value of cucumber production from 1 m2 depending on the type of lighting used in 2015. Source: own work.

Figure 7.

Share of lighting and heating costs within the value of cucumber production from 1 m2 depending on the type of lighting used in 2016. Source: own work.

Based on the calculated cost variability indices, it was found that the total variable costs presented in the combinations are described are progressive. Their value over the period analyzed exceeded the threshold value of 1, which meant that the increase in costs between 2015 and 2016 was faster than the growth of production. The progressive character of production costs was also observed in the case of lighting costs in the LED-LED combination (cost variability coefficient = 1.02) (Table 3).

Table 3.

Cost variability coefficient depending on the particular type of lighting.

Referring to the evaluation of costs of assimilation lighting with HPS and LED lamps for the cucumber, it is impossible to ignore the aspects of expenditure on investment related to the application of each type of technology. The previous part of the study focused only on variable costs. The table below contains a summary of operational parameters and expenses related to the installation of lighting used in the tests. The use of HPS lighting (600 W lamps) found only in the first greenhouse compartment requires the lamps to be replaced after 8000 h, and in the case of the third compartment, after 35,000 h (both for interlighting and toplighting). In the case of HPS lamps, the increased power consumption and the lack of power regulation is also significant. Flickering of the source/lamps also occurs.

The total investment expenditure including the use of a combination of different lamps, for each greenhouse department within an area of 40 m2 was: EUR 6192.34 for the first one (HPS), EUR 7452.88 for the second (HPS-LED), and EUR 15,370.09 for the third (LED-LED) (Table 4). However, considering the life of lamps in the LED-LED combination, it is over three times longer than in the case of lamps in the HPS combination, and power consumption is more than twice lower. This goes on to confirm the aforementioned benefits of this type of lighting, even when considering a higher overall level of expenditure on investment.

Table 4.

Comparison of the costs of installation and operation of lamps needed for lighting a compartment within a growing area of 40 m2.

4. Discussion

Solar radiation, the natural source of light, is insufficient in certain areas and this has led to the use of supplementary sources in order to provide conditions for optimal growth. High-pressure sodium lamps and other metal halide lamps, which hitherto have been the traditional sources of light, are inefficient and also produce high levels of radiant heat [22]. The reduced daylight hours of the winter months mean that there is, as a result, a substantial expenditure on additional lighting, however this does enable growers to increase production [23]. Consequently, in order to produce energy-efficient greenhouse lighting, there has been a call for the development of alternative, innovative systems [24]. To give an example, in certain Nordic countries, in order to achieve an economically viable production and reduce the industry’s carbon footprint, energy-efficient greenhouse cultivation is vital. The quantity of light-emitting diode (LED) horticultural luminaires coming onto the market has greatly increased in recent years. When comparing lights such as the high-pressure sodium lights (HPS lights) currently in use, it should be noted that LEDs also demonstrate other benefits such as the ability to vary the color, intensity and location of the light source relative to the plants. Hereby, the efficiency of lighting would be substantially improved, thus enabling enhanced plant growth resulting in higher quality produce [25]. Generally speaking, LED lighting is considered to be beneficial in the following ways: a small size, long lifetime, fire safety, (as excess heat is not produced), and slow voltage rates, ensuring safety and enabling the use of battery-powered devices while their low energy consumption is paramount [11,26,27].

Lighting with LEDs (light-emitting diodes) in commercial greenhouse production has already been researched in several studies [24,28,29,30]. At Purdue University, scientists conducted comparative experiments by using LEDs with year-round tomato production in comparison with supplemental light vs. traditional overhead HPS lighting vs. high intensity red and blue LEDs. An energy saving of 25% in comparison with traditional lighting can be obtained by greenhouse growers cultivating tomatoes under LED lights while achieving the same yields [24]. Cucumber and lettuce crops have achieved similar results [13,31]. The results presented in this paper also indicate energy savings when using LED-LED combinations for plant lighting, because the share of lighting costs in the production value in both examined years was definitely lower than in the case of lighting with HPS lamps or in the HPS-LED combination.

The heat produced by HPS lamps reduces the demand from the greenhouse heating system. Reducing heating costs is a major challenge for greenhouses producers, especially those located in cold regions. Several techniques are used to reduce greenhouse heating costs in the winter season. However, it is important to consider the trade-offs between the agronomic need of plants and energy-saving potential of various energy-saving methods, also the economic feasibility of energy saving systems in greenhouses production [32]. A few experiences have shown that the radiative heat from HPS lamps helps maintain the desired crop temperature, and that greenhouses equipped with LEDs require higher inputs from the heating system [33]. Additional thermal radiation is useful in warming during the heating season, but is detrimental if is too warm. When sunlight supplies an adequate PPFD, supplemental lighting is usually turned off. According to Nelson and Bugbee (2014) [34], precision lighting can improve electrical efficiency. LEDs differ from HPS lamps, because they operate at lower temperatures, emit mostly convective heat and relatively little radiative heat, and can be more efficient at converting electricity to photosynthetically active radiation (PAR) [33]. LED lamps are more energy-efficient than HPS lamps, but the capital cost for LED is extremely high compared to other lamps and also provides no heating contribution in greenhouses [24].

The advantage of using LED rather than traditional (HPS) lamps is the optimization and conversion of energy into usable light—traditional (HPS) lamps being only able to convert 30% into usable light but at the same time using 30% in the form of heat. LEDs can convert up to 50%, and furthermore, can be optimized to a variety of wavelengths. In the case of LED lamp lighting, expenditures on thermal energy increase. Nonetheless, the increase in the value of production caused by the use of the LED-LED combination certainly compensates for the costs of thermal energy in this case. In terms of expenditure on thermal energy, the best results were obtained with the HPS-LED configuration, which allows lower renovation costs by leaving some of the previously used HPS lamps and supplementing them with LEDs. Therefore, it makes economic sense to use HPS lamps as an overhead light. A properly designed hybrid light system using overhead HPS with LED interlighting can reduce the cost-associated supplemental light, and also allow the growers to improve crop productivity at the same time. Substantial economizations of energy and, consequently, financial savings in the greenhouse industry have enabled growers to remain competitive by keeping production costs to a minimum. One key aspect slowing down the practice of LED technology in greenhouse lighting is the high capital outlay required for LED lighting systems. The available research results indicate the high capital cost—a five-year cost of LED fixtures is more than double that of HPS fixtures [34]. Despite this drawback, due to the strong, widespread demand in the current and potential greenhouse industry, technological innovation and a large-scale production are expected to lower the capital and operating cost in the future considerably.

5. Conclusions

The efficiency of light use was the highest in the LED-LED combination and the lowest in HPS, which confirms that artificial lighting with LED lamps proved to be a more advantageous light source for cucumber in the winter growing cycle than HPS.

Taking into account the variable costs of cucumber production in greenhouses, the application of supplemental lamp lighting in the LED-LED combination (top and interlighting) allows us to obtain the most favorable surplus of variable costs over the value of production. Despite the highest absolute level of variable costs in this type of supplemental lighting, the production value was higher by as much as 32.55% in relation to the HPS combination, which also translated into a gross margin that was higher by about ¾. However, it is worth pointing out that in the HPS-LED combination, the share of lighting and heating costs in the total value of production was the lowest. It is also a combination currently recommended in the literature as being the most beneficial in greenhouse production.

The above research results may turn out to be extremely important for producers from Central European countries. So far, relatively little attention has been paid to this type of research in the literature for this region. In the conditions of increasing energy prices and the simultaneous increase in competition, they can be a valuable source of information in the investment and management process.

Taking into account the higher costs of lighting installation in the LED-LED combination and the long life of this system, it can be assumed that in the near future, the use of this technology will be one of the basic factors of price and cost competitiveness in greenhouse cucumber production under moderate climate conditions. It will also contribute to the reduction in the demand for electricity in this type of production, which will have a significant impact on the sustainable development of agriculture and environmental protection.

Author Contributions

This study was designed and written principally by K.K. and D.O., K.K., J.G.-W. and M.M. involved in conducting the greenhouse experiment. D.O. prepared the cost analyses. All of the authors participated in the description of the methodology, results and discussion and approved the final manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research were partially funded by Philips Lighting Holding B.V.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Svatoš, M. Global consequences of sustainable development of agriculture. Agric. Econ. Czech 2005, 51, 20–26. [Google Scholar] [CrossRef]

- Canakci, M.; Akinci, I. Energy use pattern analyses of greenhouse vegetable production. Energy 2006, 31, 1243–1256. [Google Scholar] [CrossRef]

- Mohammadi, A.; Omid, M. Economical analysis and relation between energy inputs and yield of greenhouse cucumber production in Iran. Appl. Energy 2010, 87, 191–196. [Google Scholar] [CrossRef]

- Heidari, M.D.; Omid, M. Energy use patterns and econometric models of major greenhouse vegetable productions in Iran. Energy 2011, 36, 220–225. [Google Scholar] [CrossRef]

- Balafoutis, A.; Beck, B.; Fountas, S.; Vangeyte, J.; Wal, T.; van der Soto, I.; Gómez-Barbero, M.; Barnes, A.; Eory, V. Precision agriculture technologies positively contributing to GHG emissions mitigation, farm productivity and economics. Sustainability 2017, 9, 1339. [Google Scholar] [CrossRef]

- Adhikari, B.N.; Savory, E.A.; Vaillancourt, B.; Childs, K.L.; Hamilton, J.P.; Day, B.; Buell, C.R. Expression profiling of Cucumis sativus in response to infection by Pseudoperonospora cubensis. PLoS ONE 2012, 7, e34954. [Google Scholar] [CrossRef]

- FAOSTAT-Crops. 2018. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 5 May 2020).

- Gruda, N.; Sallaku, G.; Balliu, A. Crop Technologies: Cucumber. FAO Plant Prod. Prot. Pap. 2017, 230, 287–300. [Google Scholar]

- Schrader, W.L.; Aguiar, J.L.; Mayberry, K.S. Cucumber production in California. UC ANR 2002, 8050, 1–8. [Google Scholar] [CrossRef]

- Clutter, M.L. An Economic Assessment of Dynamic Led Supplemental Lighting Installations in Greenhouse Production. Master’s Thesis, The University of Georgia, Athens, GA, USA, 2014. [Google Scholar]

- Hovi, T.; Nakkila, J.; Tahvonen, R. Intra-canopy lighting improves production of year-round cucumber. Sci. Hortic. 2004, 102, 283–294. [Google Scholar] [CrossRef]

- Nederhoff, E.M. LEDs for greenhouse lighting. Pract. Hydroponics Greenh. 2010, 110, 32–40. [Google Scholar]

- Kumar, K.G.S.; Hao, X.; Khosla, S.; Guo, X.; Bennett, N. Comparison of HPS lighting and hybrid lighting with top HPS and intra-canopy LED lighting for high-wire mini-cucumber production. Acta Hortic. 2016, 1134, 111–117. [Google Scholar] [CrossRef]

- Särkkä, L.E.; Jokinen, K.; Ottosen, C.O.; Kaukoranta, T. Effects of HPS and LED lighting on cucumber leaf photosynthesis, light quality penetration and temperature in the canopy, plant morphology and yield. Agric. Food Sci. 2017, 26, 101–109. [Google Scholar] [CrossRef]

- Kusuma, P.; Pattison, P.M.; Bugbee, B. From physics to fixtures to food: Current and potential LED efficacy. Hortic. Res. 2020, 7. [Google Scholar] [CrossRef]

- Hao, X.; Zheng, J.; Little, C.; Khosla, S. LED inter-lighting in year-round greenhouse mini-cucumber production. Acta Hortic 2012, 956, 335–340. [Google Scholar] [CrossRef]

- Mitchell, C.A.; Both, A.J.; Bourget, M.C.; Burr, J.F.; Kubota, C.; Lopez, R.G.; Morrow, R.C.; Runkle, E.S. LEDs: The future of greenhouse lighting! Chron. Horticult. 2012, 52, 6–12. [Google Scholar]

- Klamkowski, K.; Treder, W.; Wójcik, K.; Puternicki, A.; Lisak, E. Influence of supplementary lighting on growth and photosynthetic activity of tomato transplants. Infrastruct. Ecol. Rural Areas 2014, IV/3, 1377–1385. [Google Scholar]

- Kowalczyk, K.; Gajc-Wolska, J.; Mirgos, M.; Geszprych, A.; Kowalczyk, W.; Sieczko, L.; Niedzińska, M.; Gajewski, M. Mineral nutrients needs of cucumber and its yield in protected winter cultivation, with HPS and LED supplementary lighting. Sci. Hortic. 2020, 265, 109217. [Google Scholar] [CrossRef]

- Kowalczyk, K.; Gajc-Wolska, J.; Bujalski, D.; Mirgos, M.; Niedzińska, M.; Mazur, K.; Żołnierczyk, P.; Szatkowski, D.; Cichoń, M.; Łęczycka, N. The effect of supplemental assimilation lighting with HPS and LED lamps on the cucumber yielding and fruit quality in autumn crop. Acta Sci. Pol. Hortorum Cultus 2018, 17, 193–200. [Google Scholar] [CrossRef]

- Elum, Z.A.; Etowa, E.B.; Ogonda, A.U. Economics of cucumber production in rivers state, Nigeria. Agro-Sci. 2016, 15, 48–53. [Google Scholar] [CrossRef]

- Cuce, E.; Harjunowibowo, D.; Cuce, P.M. Renewable and sustainable energy saving strategies for greenhouse systems: A comprehensive review. Renew. Sust. Energy Rev. 2016, 64, 34–59. [Google Scholar] [CrossRef]

- Deram, P. Light-emitting-Diode (LED) Lighting for Greenhouse Tomato Production. Ph.D. Thesis, McGill University, Montréal, QC, Canada, 2013. [Google Scholar]

- Singh, D.; Basu, C.; Meinhardt-Wollweber, M.; Roth, B. LEDs for energy efficient greenhouse lighting. Renew. Sustain. Energy Rev. 2015, 49, 139–147. [Google Scholar] [CrossRef]

- Marcelis, L.F.M. LED lighting can significantly reduce energy consumption in greenhouse horticulture. Wageningen University and Research Centre. ScienceDaily. 2014, 31. Available online: www.sciencedaily.com/releases/2014/10/141031082025.htm (accessed on 5 May 2020).

- Mantere, T.; Harju, T.; Välisuo, P.; Alander, J.T. Using the LED lighting in the greenhouses–a pre-study. In Proceedings of the Next 2007—The 4th Conference on New Exploratory Technologies, Seoul, Korea, 25–27 October 2007; pp. 292–295. [Google Scholar]

- Savage, L. LEDs lower costs, boost crops inside greenhouses. Photonics Spectra. 2012, pp. 50–53. Available online: http://leds.hrt.msu.edu/assets/Uploads/LEDsInsideGreenhouses.pdf (accessed on 16 November 2019).

- Dueck, T.A.; Janse, J.; Eveleens, B.A.; Kempkes, F.L.K.; Marcelis, L.F.M. Growth of tomatoes under hybrid LED and HPS lighting. Acta Hortic. 2012, 952, 335–342. [Google Scholar] [CrossRef]

- Kong, Y.; Llewellyn, D.; Zheng, Y. Response of growth, yield, and quality of pea shoots to supplemental light-emitting diode lighting during winter greenhouse production. Can. J. Plant Sci. 2018, 98, 732–740. [Google Scholar] [CrossRef]

- Paucek, I.; Pennisi, G.; Pistillo, A.; Appolloni, E.; Crepaldi, A.; Calegari, B.; Spinelli, F.; Cellini, A.; Gabarrell, X.; Orsini, F.; et al. Supplementary LED interlighting improves yield and precocity of greenhouse tomatoes in the Mediterranean. Agronomy 2020, 10, 1002. [Google Scholar] [CrossRef]

- Loconsole, D.; Cocetta, G.; Santoro, P.; Ferrante, A. Optimization of LED lighting and quality evaluation of Romaine lettuce grown in an innovative indoor cultivation system. Sustainability 2019, 11, 841. [Google Scholar] [CrossRef]

- Ahamed, S.; Guo, H.; Tanino, K. Energy saving techniques for reducing the heating cost of conventional greenhouse. Biosyst. Eng. 2019, 178, 9–33. [Google Scholar] [CrossRef]

- Katzin, D.; van Mourik, S.; Kempkes, F.; van Henten, E.J. GreenLight—An open source model for greenhouses with supplemental lighting: Evaluation of heat requirements under LED and HPS lamps. Biosyst. Eng. 2020, 194, 61–81. [Google Scholar] [CrossRef]

- Nelson, J.A.; Bugbee, B. Economic analysis of greenhouse lighting: Light Emitting Diodes vs. High Intensity Discharge Fixtures. PLoS ONE 2014, 9, e99010. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).