Short Term Cotton Lint Yield Improvement with Cover Crop and No-Tillage Implementation

Abstract

1. Introduction

2. Materials and Methods

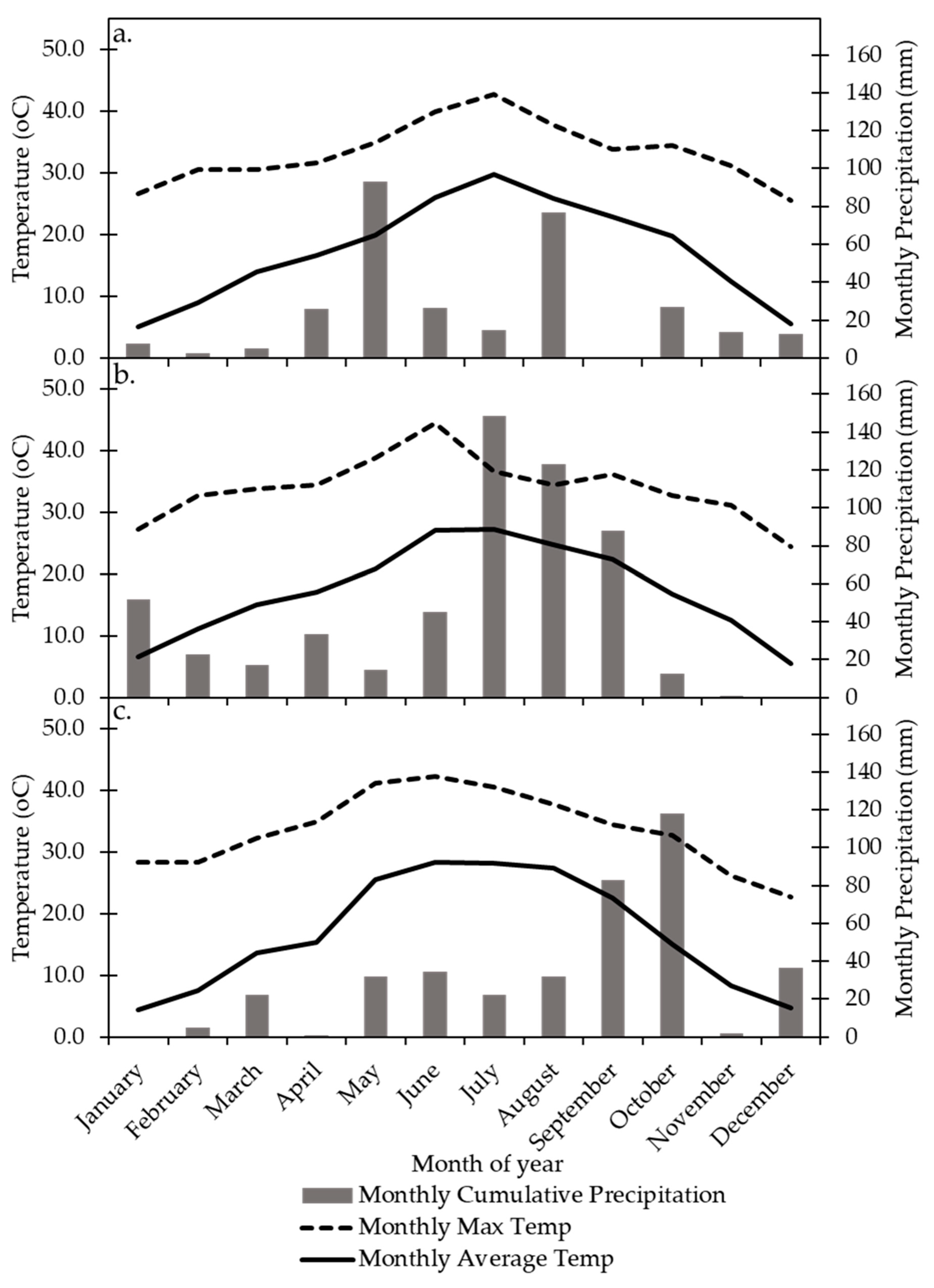

2.1. Site Descriptions

2.1.1. Experimental Design and Treatments

2.1.2. Field Management

2.2. Soil Characterization

2.3. Plant Nitrogen Analysis

2.4. Nitrogen Use Efficiency

2.5. Statistical Approach

3. Results

3.1. Cover Crop Biomass

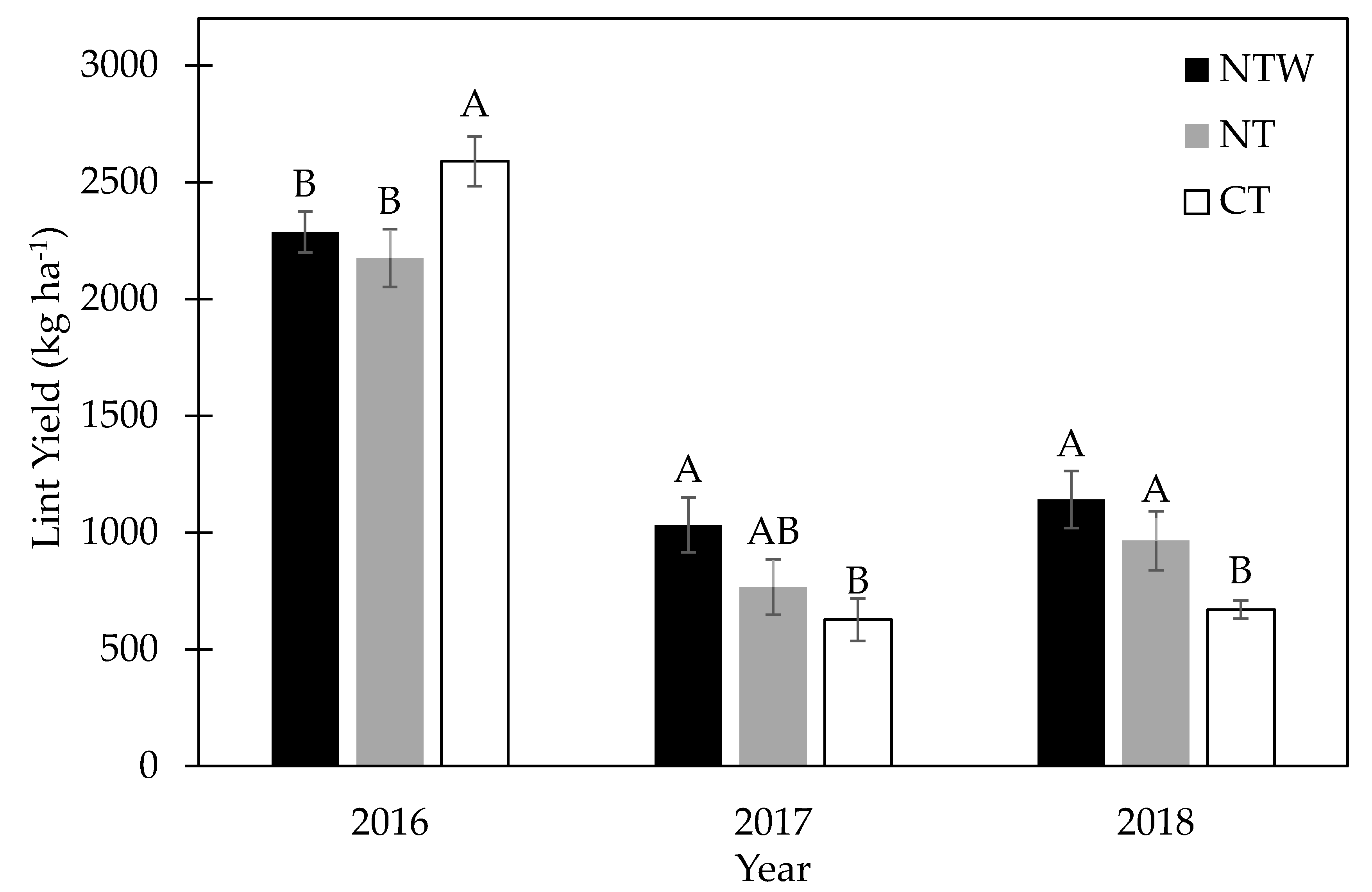

3.2. Cotton Lint Yield

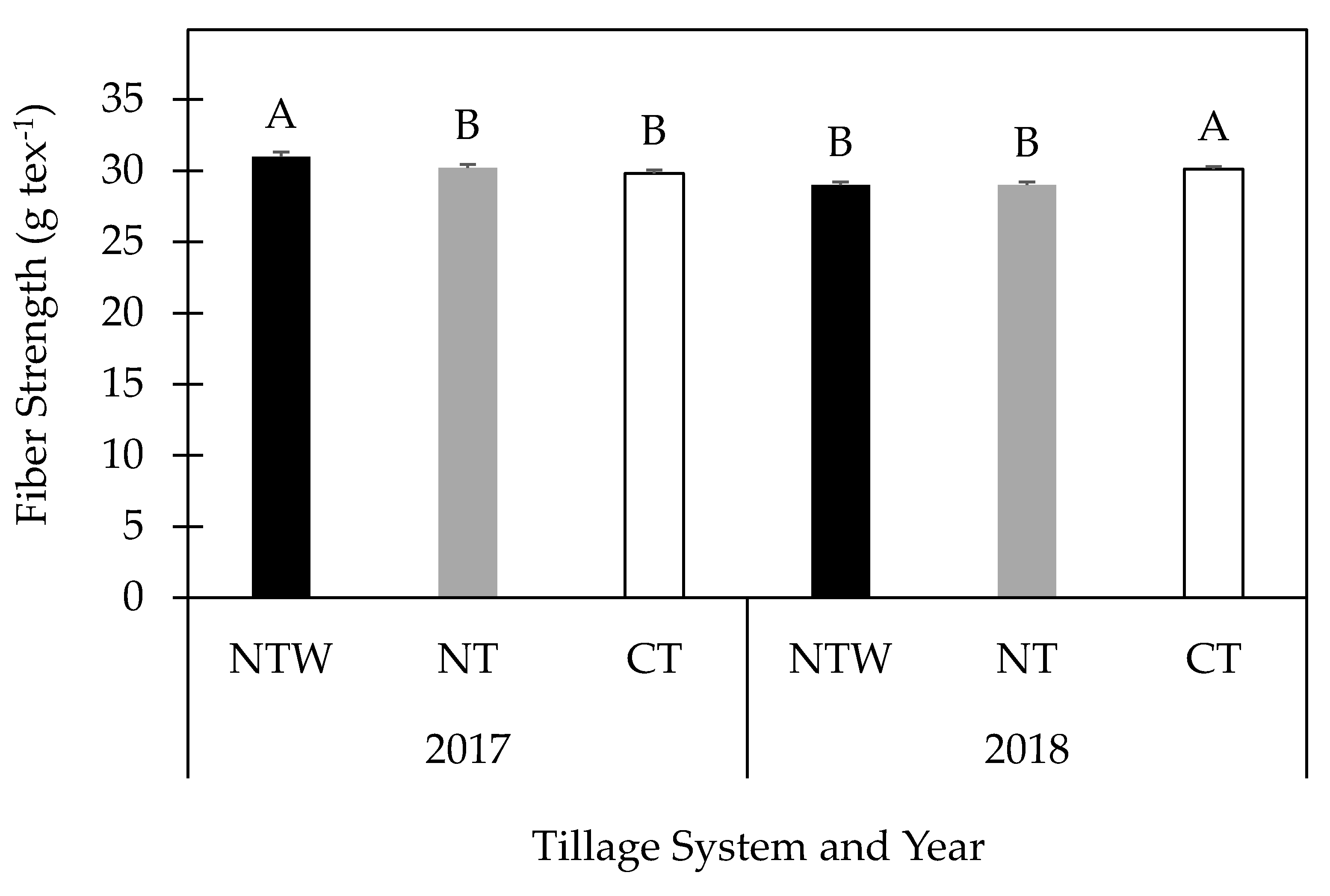

3.3. Fiber Quality

3.4. Agronomic Use Efficiency

3.5. Plant Seed N

4. Discussion

4.1. Cover Crop Biomass

4.2. Cotton Lint Yield

4.3. Fiber Quality

4.4. Plant Seed N

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- National Resource Conservation Service. Land resource regions and major land resource areas of the United States, the Caribbean, and the Pacific Basin. In US Department of Agriculture Handbook; Agriculture, United States Department of Agriculture: Washington, DC, USA, 2006; Volume 296. [Google Scholar]

- Lal, R.; Reicosky, D.C.; Hanson, J.D. Evolution of the plow over 10,000 years and the rationale for no-till farming. Soil Till. Res. 2007, 93, 1–12. [Google Scholar] [CrossRef]

- Baumhardt, L. Dust Bowl Era. In Encyclopedia of Water Science, Second Edition (Print Version); CRC Press: Boca Raton, FL, USA, 2003; pp. 246–250. [Google Scholar] [CrossRef]

- Zobeck, T.M.; Bilbro, J.D. Crop productivity and surface soil properties of a severely wind-eroded soils. In Proceedings of the Sustaining the Global Farm. 10th International Soil Conservation Organization Conference, West Lafayette, IN, USA, 23–28 May 1999. [Google Scholar]

- Zobeck, T.M.; van Pelt, R.S. Wind Erosion. In Soil Management: Building a Stable Base for Agriculture; Hatfield, J.L., Sauer, T.J., Eds.; Soil Science Society of America: Madison, WI, USA, 2011; pp. 209–227. [Google Scholar] [CrossRef]

- National Agriculture Statistics Service. Quick Stats—Texas Land Use Practices. Available online: https://quickstats.nass.usda.gov/results/2D65C1DB-B947-370D-8DD9-82AA17CAC756 (accessed on 17 May 2018).

- United States Department of Agriculture, National Agriculture Statistics Service. Cotton Production; USDA, Ed.; National Agricultural Statistics Service: Austin, TX, USA, 2017.

- National Agriculture Statistics Service. Quick Stats—US Total Cotton Production. Available online: https://quickstats.nass.usda.gov/results/40B70CDD-296F-3192-88D3-9BB60985F40D (accessed on 21 May 2018).

- Balkcom, K.S.; Reeves, D.W.; Shaw, J.N.; Burmester, C.H.; Curtis, L.M. Cotton yield and fiber quality from irrigated tillage systems in the Tennessee Valley. Agron. J. 2006, 98, 596–602. [Google Scholar] [CrossRef]

- Boquet, D.J.; Hutchinson, R.L.; Breitenbeck, G.A. Long-term tillage, cover crop, and nitrogen rate effects on cotton: Yield and fiber properties. Agron. J. 2004, 96, 1436–1442. [Google Scholar] [CrossRef]

- Raper, R.; Reeves, D.; Burmester, C.; Schwab, E. Tillage depth, tillage timing, and cover crop effects on cotton yield, soil strength, and tillage energy requirements. Appl. Eng. Agric. 2000, 16, 379. [Google Scholar] [CrossRef]

- Daniel, J.B.; Abaye, A.O.; Alley, M.M.; Adcock, C.W.; Maitland, J.C. Winter annual cover crops in a Virginia no-till cotton production system: II. cover crop and tillage effects on soil moisture, cotton yield, and cotton quality. J. Cotton Sci. 1999, 3, 84–91. [Google Scholar]

- Bauer, P.J.; Busscher, W.J. Winter cover and tillage influences on coastal plain cotton production. J. Prod. Agric. 1996, 9, 50–54. [Google Scholar] [CrossRef]

- DeLaune, P.B.; Sij, J.W.; Park, S.C.; Krutz, L.J. Cotton production as affected by irrigation level and transitioning tillage systems. Agron. J. 2012, 104, 991–995. [Google Scholar] [CrossRef]

- DeLaune, P.B.; Mubvumba, P.; Ale, S.; Kimura, E. Impact of no-till, cover crop, and irrigation on Cotton yield. Agric. Water Manag. 2020, 232, 106038. [Google Scholar] [CrossRef]

- DeLaune, P.B.; Mubvumba, P.; Fan, Y.; Bevers, S. Agronomic and economic impacts of cover crops in Texas Rolling Plains cotton. Agrosystems Geosci. Environ. 2020, 3, e20027. [Google Scholar] [CrossRef]

- Bronson, K.; Onken, A.; Keeling, J.; Booker, J.; Torbert, H. Nitrogen response in cotton as affected by tillage system and irrigation level. Soil Sci. Soc. Am. J. 2001, 65, 1153–1163. [Google Scholar] [CrossRef]

- Keeling, W.; Segarra, E.; Abernathy, J.R. Evaluation of conservation tillage cropping systems for cotton on the Texas Southern High Plains. J. Prod. Agric. 1989, 2, 269–273. [Google Scholar] [CrossRef]

- Lewis, K.L.; Burke, J.A.; Keeling, W.S.; McCallister, D.M.; DeLaune, P.B.; Keeling, J.W. Soil benefits and yield limitations of cover crop use in Texas High Plains cotton. Agron. J. 2018, 110, 1616–1623. [Google Scholar] [CrossRef]

- Lyons, S.E.; Ketterings, Q.M.; Godwin, G.; Cherney, J.H.; Czymmek, K.J.; Kilcer, T. Early fall planting increases growth and nitrogen uptake of winter cereals. Agron. J. 2017, 109, 795–801. [Google Scholar] [CrossRef]

- Nelson, W.L. The Effect of Nitrogen, Phosphorus, and Potash on Certain Lint and Seed Properties of Cotton1. Agron. J. 1949, 41, 289–293. [Google Scholar] [CrossRef]

- Read, J.J.; Reddy, K.R.; Jenkins, J.N. Yield and fiber quality of Upland cotton as influenced by nitrogen and potassium nutrition. Eur. J. Agron. 2006, 24, 282–290. [Google Scholar] [CrossRef]

- Singh, Y.; Rao, S.S.; Regar, P.L. Deficit irrigation and nitrogen effects on seed cotton yield, water productivity and yield response factor in shallow soils of semi-arid environment. Agric. Water Manage. 2010, 97, 965–970. [Google Scholar] [CrossRef]

- Wullschleger, S.D.; Oosterhuis, D.M. Photosynthetic carbon production and use by developing cotton leaves and bolls. Crop Sci. 1990, 30, 1259–1264. [Google Scholar] [CrossRef]

- Pettigrew, W.T.; Adamczyk, J.J. Nitrogen Fertility and Planting Date Effects on Lint Yield and Cry1Ac (Bt) Endotoxin Production. Agron. J. 2006, 98, 691–697. [Google Scholar] [CrossRef]

- Mullins, G.L.; Monks, C.D.; Delaney, D. Cotton response to source and timing of nitrogen fertilization on a sandy Coastal Plain soil. J. Plant Nutr. 2003, 26, 1345–1353. [Google Scholar] [CrossRef]

- Setatou, H.B.; Simonis, A.D. Effect of time and rate of nitrogen application on cotton. In Fertilizers and Environment: Proceedings of the International Symposium “Fertilizers and Environment”, Held in Salamanca, Spain, 26–29 September 1994; Rodriguez-Barrueco, C., Ed.; Springer: Dordrecht, The Netherlands, 1996; pp. 121–125. [Google Scholar] [CrossRef]

- National Atmospheric Deposition Program (NRSP-3); NADP Program Office, Wisconsin State Laboratory of Hygiene: Madison, WI, USA, 2020.

- U.S. Department of Agriculture. National Resource Conservation Service Acuff Soil Series. Available online: https://soilseries.sc.egov.usda.gov/OSD_Docs/A/ACUFF.html (accessed on 17 May 2018).

- McDonald, M.D.; Lewis, K.L.; Ritchie, G.L.; DeLaune, P.B.; Casey, K.D.; Slaughter, L.C. Carbon dioxide mitigation potential of conservation agriculture in a semi-arid agricultural region. Aims Agric. Food 2019, 4, 206–222. [Google Scholar] [CrossRef]

- McGeehan, S.L.; Naylor, D.V. Automated instrumental analysis of carbon and nitrogen in plant and soil samples. Commun. Soil Sci. Plant Anal 1988, 19, 493. [Google Scholar] [CrossRef]

- Schulte, E.E.; Hopkins, B.G. Estimation of Soil Organic Matter by Weight by Weight Loss-on-Ignition. In Soil Organic Matter: Analysis and Interpretation; Magdoff FR, T.M., Hanlon, E.A., Jr., Eds.; Soil Science Society of America: Madison, WI, USA, 1996; pp. 21–32. [Google Scholar]

- Storer, D.A. A simple high volume ashing procedure for determining soil organic matter. Commun. Soil Sci. Plan. 1984, 15, 759–772. [Google Scholar] [CrossRef]

- Snyder, C.S.; Bruulsema, T.W. Nutrient Use Efficiency and Effectiveness in North America: Indices of Agronomic and Environmental Benefit; International Plant Nutrition Insititue (IPNI): Norcross, GA, USA, 2007. [Google Scholar]

- SAS Institute. SAS/STAT Software—The GLIMMIX Procedure. Available online: https://support.sas.com/rnd/app/stat/procedures/glimmix.html (accessed on 26 April 2018).

- SAS Institute. Base SAS® 9.4 Procedures Guide: Statistical Procedures, 2nd ed.; SAS Institute Inc.: Cary, NC, USA, 2013. [Google Scholar]

- Pittelkow, C.M.; Linquist, B.A.; Lundy, M.E.; Liang, X.; van Groenigen, K.J.; Lee, J.; van Gestel, N.; Six, J.; Venterea, R.T.; van Kessel, C. When does no-till yield more? A global meta-analysis. Field Crop. Res. 2015, 183, 156–168. [Google Scholar] [CrossRef]

- National Agriculture Statistcs Service. Quick Stats—Texas Southern High Plains Cotton Production, Irrigated. Available online: https://quickstats.nass.usda.gov/results/37C9EFA1-8E99-34FD-BA1B-BB6EA819481A (accessed on 3 April 2019).

- DeLaune, P.; Trostle, C. Nitrates in irrigation water: An asset for crop production. Texas AgriLife Extension Service. E-619; Texas A&M AgriLife Communications: College Station, TX, USA, 2012. [Google Scholar]

- Hanson, R.G.; Ewing, E.C.; Ewing, E.C., Jr. Effect of environmental factors on fiber properties and yield of deltapine cottons. Agron. J. 1956, 48, 573–581. [Google Scholar] [CrossRef]

- Bauer, P.J.; Roof, M.E. Nitrogen, aldicarb, and cover crop effects on cotton yield and fiber properties. Agron. J. 2004, 96, 369–376. [Google Scholar] [CrossRef]

- United States Department of Agriculture. Agriculture Marketing Service, Upland Season Mike Classing Office by State, Lubbock, 2017; USDA: Washington, DC, USA, 2017.

- Bradow, J.M.; Davidonis, G.H. Quantitation of fiber quality and the cotton production-processing interface: A physiologist’s perspective. J. Cotton Sci. 2000, 4, 34–64. [Google Scholar]

- Bronson, K.F. Nitrogen use efficiency of cotton varies with irrigation system. Better Crop. Plant Food 2008, 92, 20–22. [Google Scholar]

- Egelkraut, T.; Kissel, D.; Cabrera, M.; Gascho, G.; Adkins, W. Nitrogen concentration in cottonseed as an indicator of N availability. Nutr. Cycl. Agroecosystems 2004, 68, 235–242. [Google Scholar] [CrossRef]

- Rochester, I.J. Using seed nitrogen concentration to estimate crop N use-efficiency in high-yielding irrigated cotton. Field Crop. Res. 2012, 127, 140–145. [Google Scholar] [CrossRef]

| Tillage System a | pH | OC b | TN c | NO3−-N | P | K | Ca | Mg | S | Na |

|---|---|---|---|---|---|---|---|---|---|---|

| g kg−1 | ------------------------------mg kg−1------------------------- | |||||||||

| NTW | 7.4 | 5.3 | 0.692 | 0.4b | 42 | 423 | 1859 | 823 | 13 | 29 |

| NT | 7.4 | 5.4 | 0.745 | 6.9a | 49 | 463 | 1993 | 809 | 14 | 36 |

| CT | 7.5 | 5.1 | 0.690 | 6.8a | 46 | 419 | 1931 | 852 | 11 | 32 |

| p-value | 0.901 | 0.264 | 0.305 | 0.028 | 0.604 | 0.188 | 0.519 | 0.337 | 0.528 | 0.217 |

| Year | Tillage System | N Treatment | Interaction |

|---|---|---|---|

| ANOVA (p-Value < 0.05) | |||

| 2016 | 0.029 | 0.387 | 0.990 |

| 2017 | 0.046 | 0.537 | 0.996 |

| 2018 | 0.016 | 0.624 | 0.996 |

| Year | Tillage System | N Treatment | Interaction |

|---|---|---|---|

| ANOVA (p-Value < 0.05) | |||

| 2016 | 0.911 | 0.617 | 0.985 |

| 2017 | 0.291 | 0.466 | 0.998 |

| 2018 | 0.884 | 0.741 | 0.961 |

| Year | Tillage System | N Treatment | Interaction |

|---|---|---|---|

| ANOVA (p-Value < 0.05) | |||

| 2016 | 0.118 | 0.277 | 0.888 |

| 2017 | 0.727 | 0.552 | 0.928 |

| 2018 | 0.903 | 0.004 | 0.357 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

McDonald, M.D.; Lewis, K.L.; Ritchie, G.L. Short Term Cotton Lint Yield Improvement with Cover Crop and No-Tillage Implementation. Agronomy 2020, 10, 994. https://doi.org/10.3390/agronomy10070994

McDonald MD, Lewis KL, Ritchie GL. Short Term Cotton Lint Yield Improvement with Cover Crop and No-Tillage Implementation. Agronomy. 2020; 10(7):994. https://doi.org/10.3390/agronomy10070994

Chicago/Turabian StyleMcDonald, Mark D., Katie L. Lewis, and Glen L. Ritchie. 2020. "Short Term Cotton Lint Yield Improvement with Cover Crop and No-Tillage Implementation" Agronomy 10, no. 7: 994. https://doi.org/10.3390/agronomy10070994

APA StyleMcDonald, M. D., Lewis, K. L., & Ritchie, G. L. (2020). Short Term Cotton Lint Yield Improvement with Cover Crop and No-Tillage Implementation. Agronomy, 10(7), 994. https://doi.org/10.3390/agronomy10070994