Characterization of the Transverse Distribution of Fertilizer in Coffee Plantations

Abstract

1. Introduction

2. Materials and Methods

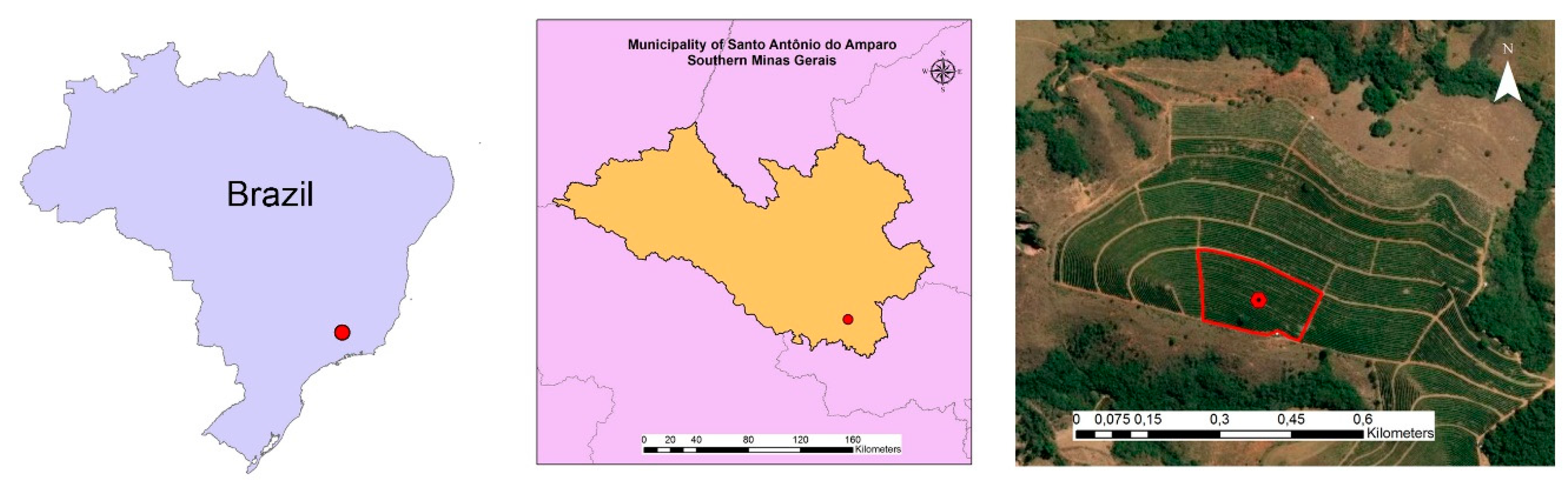

2.1. Field Characterization

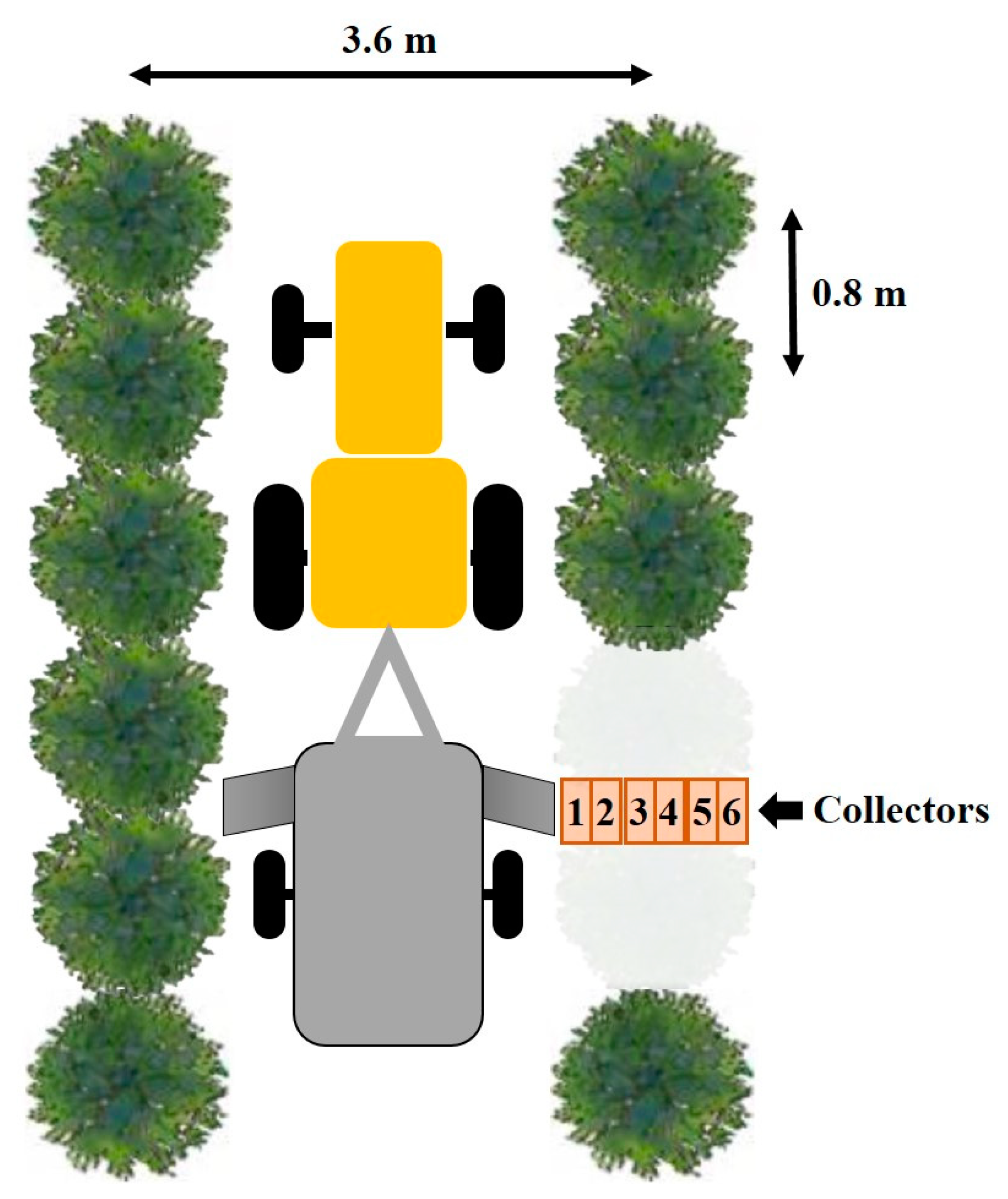

2.2. Machinery Set Specification

2.3. Experiment Description

2.4. Statistical Methods

3. Results and Discussion

3.1. Fertilizer Physical Characterization

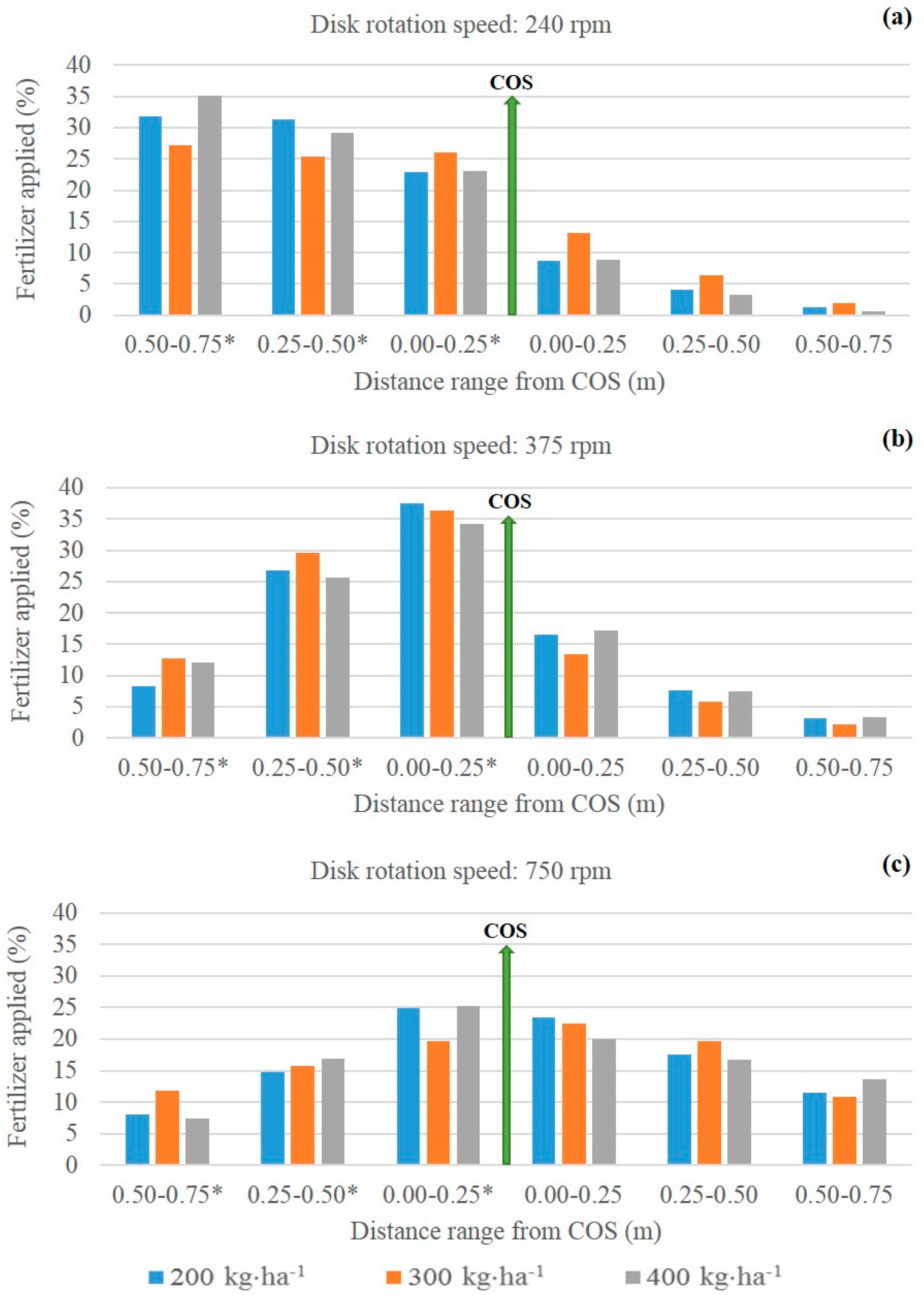

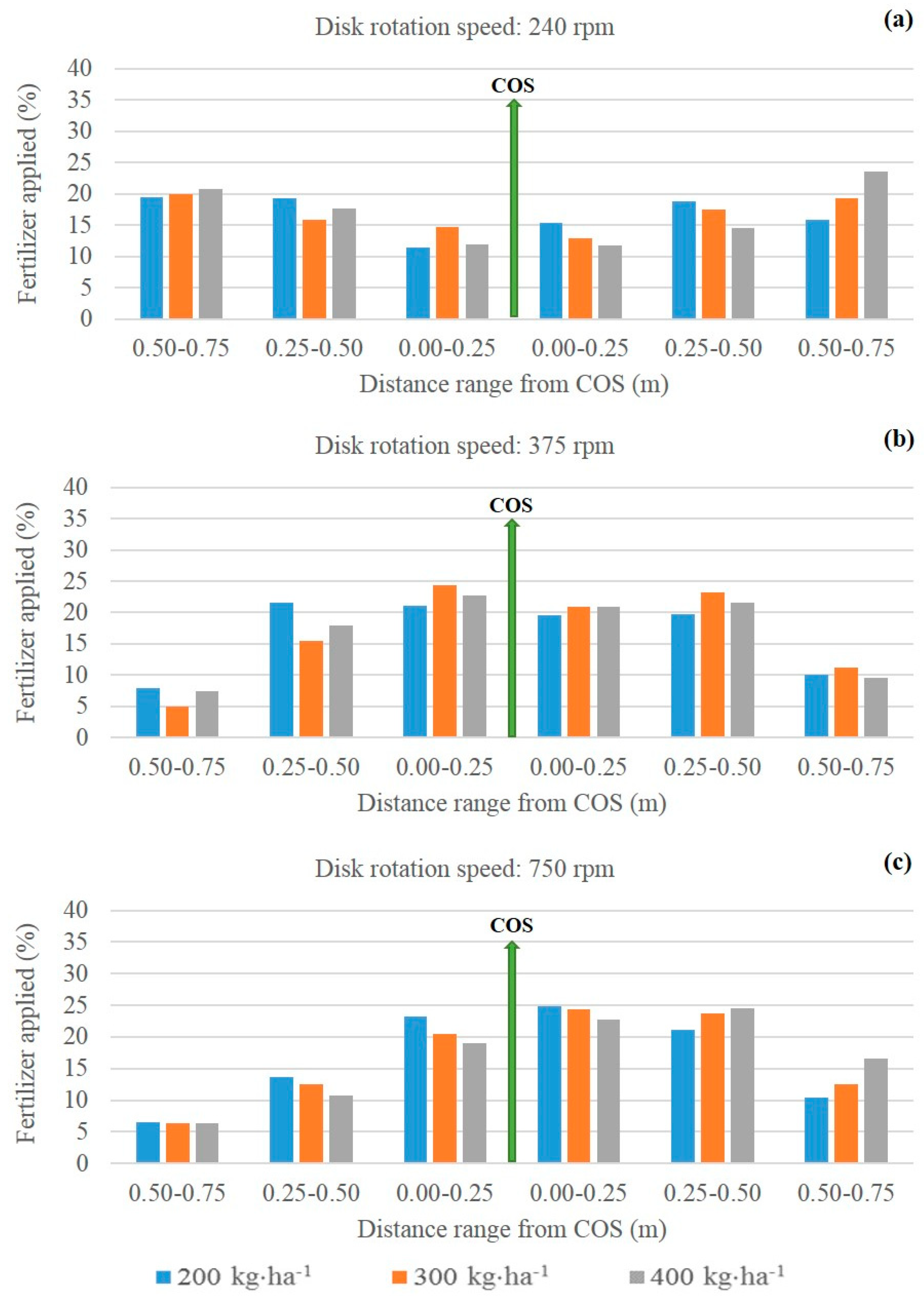

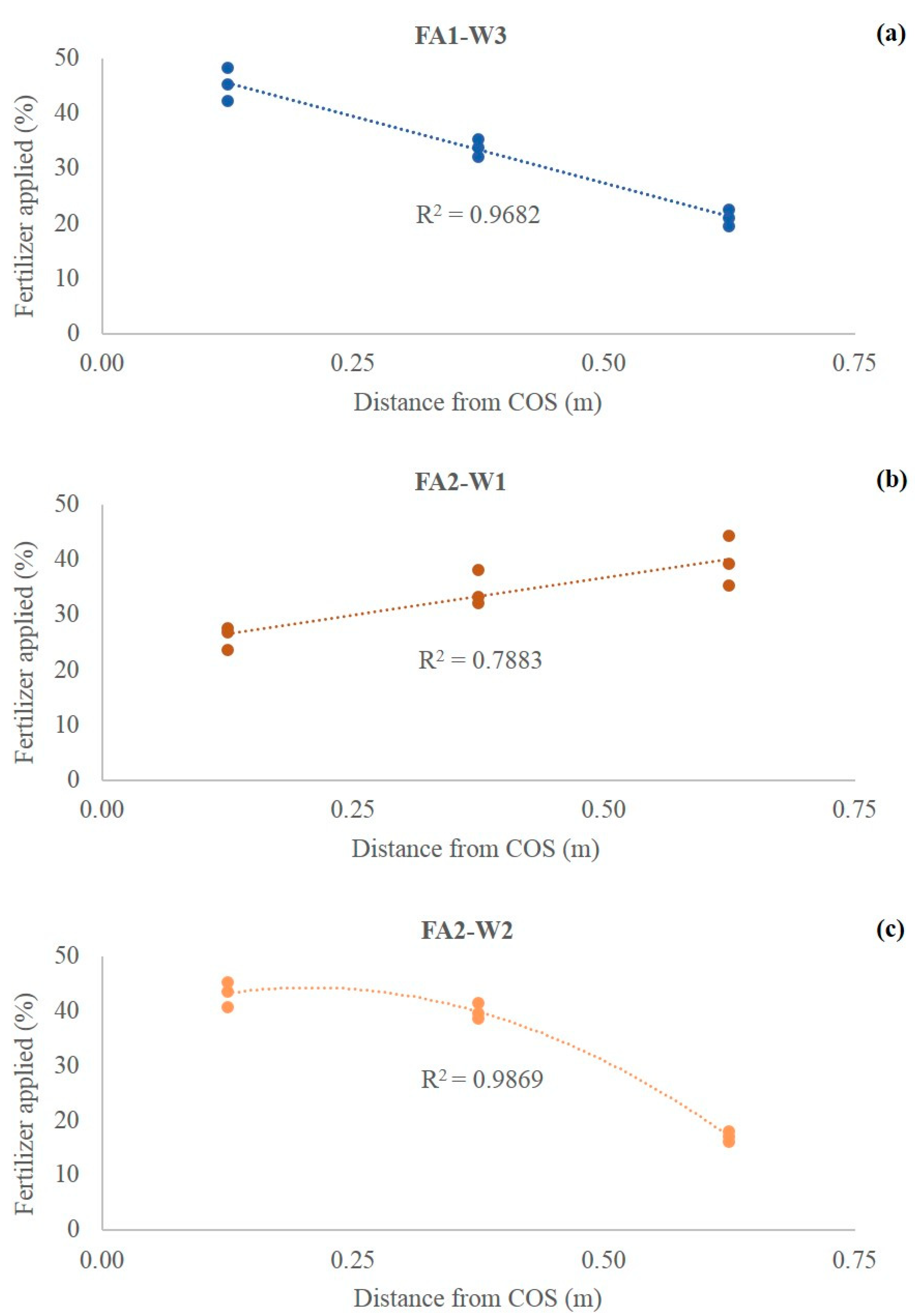

3.2. Distribution Profile

3.3. Data Analysis

3.4. Fertilizer Distribution Uniformity

3.5. Fertilizer Distribution Characterization in Coffee Plantation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rocha, H.G.; Silva, A.B.D.; Nogueira, D.A.; Miranda, J.M.; Mantovani, J.R. Mapeamento da produtividade do cafeeiro a partir de modelos matemáticos de previsão de safra. Coffee Sci. 2016, 11, 108–116. [Google Scholar]

- Molin, J.P.; Motomiya, A.V.A.; Frasson, F.R.; Faulin, G.D.C.; Tosta, W. Test procedure for variable rate fertilizer on coffee. Acta Sci. Agron. 2010, 32, 569–575. [Google Scholar] [CrossRef]

- Turco, P.H.N.; Esperancini, M.S.T.; Bueno, O.D.C.; Oliveira, M.D.M. Economic profitability in conventional and irrigated coffee production systems in three municipalities in the Marilia region of São Paulo, Brazil. Cienc. Rural 2017, 47, 1–7. [Google Scholar] [CrossRef][Green Version]

- Dalacort, R.; Stevan, S.L. Mobile helical capacitive sensor for the dynamic identification of obstructions in the distribution of solid mineral fertilizers. Sensors 2018, 18, 3991. [Google Scholar] [CrossRef] [PubMed]

- Alameen, A.A.; Al-Gaadi, K.A.; Tola, E. Development and performance evaluation of a control system for variable rate granular fertilizer application. Comput. Electron. Agric. 2019, 160, 31–39. [Google Scholar] [CrossRef]

- Reyes, J.F.; Esquivel, W.; Cifuentes, D.O.R. Field testing of an automatic control system for variable rate fertilizer. Comput. Electron. Agric. 2015, 113, 260–265. [Google Scholar] [CrossRef]

- Ferraz, G.A.S.; Silva, F.M.; Oliveira, M.S.; Avelar, R.C.; Sales, R.S. Variabilidade espacial da dose de P2O5 e K2O para adubação diferenciada e convencional em lavoura cafeeira. Coffee Sci. 2015, 10, 346–356. [Google Scholar]

- Oliveira, R.B.D.; Lima, J.S.S.; Xavier, A.C.; Passos, R.R.; Silva, S.A.; Silva, A.F. Comparação entre métodos de amostragem do solo para recomendação de calagem e adubação do cafeeiro conilon. Eng. Agrícola 2008, 28, 176–186. [Google Scholar] [CrossRef][Green Version]

- Barros, M.M.; Volpato, C.E.S.; Silva, F.C.; Palma, M.A.Z.; Spagnolo, R.T. Avaliação de um sistema de aplicação de fertilizantes a taxa variável adaptado à cultura cafeeira. Coffee Sci. 2015, 10, 223–232. [Google Scholar]

- Machado, O.D.C.; Alonçol, A.S.; Francettol, T.R.; Carpesl, D.P. Acurácia e tempos de resposta de máquinas para aplicação de defensivos agrícolas à taxa variável. Cienc. Rural 2015, 45, 440–449. [Google Scholar] [CrossRef][Green Version]

- Mialhe, L.G. Máquinas Agrícolas; Ensaios & Certificação; Shekinah: São Paulo, Brazil, 1996; 722p. [Google Scholar]

- Baio, F.H.R.; Molin, J.P.; Leal, A.J.F. Avaliação comparativa da distribuição transversal de adubos sólidos aplicados em cobertura em culturas anuais instaladas. Biosci. J. 2012, 28, 527–536. [Google Scholar]

- Barros, M.M.; Volpato, C.E.S.; Silva, F.M.; Conceição, F.G.; Corrêa, D.J.; Ribeiro, L.F. Performance of a variable-rate distribution system for simultaneous fertilizer application. Rev. Bras. Eng. Agríc. Ambient. 2016, 20, 188–192. [Google Scholar] [CrossRef]

- Rosa, D.P.; Pagnussat, L.; Alves, A.; Pesini, F.; Spagnolo, R.T. Methodology to evaluate the fertilizer distribution by helical doser from seed planter. J. Exp. Agric. Int. 2019, 31, 1–7. [Google Scholar] [CrossRef]

- Motta, A.C.V.; Nick, J.A.; Yorinori, G.T.; Serrat, B.M. Distribuição horizontal e vertical da fertilidade do solo e das raízes de cafeeiro (Coffea arabica L.) cultivar Catuaí. Acta Sci. Agron. 2006, 28, 455–463. [Google Scholar] [CrossRef]

- Ronchi, C.P.; Souza-Júnior, J.M.; Almeida, W.L.; Souza, D.S.; Silva, N.O.; Oliveira, L.B.; Moura-Guerra, A.M.N.; Ferreira, P.A. Morfologia radicular de cultivares de café arábica submetidas a diferentes arranjos espaciais. Pesq. Agropec. Bras. 2015, 50, 187–195. [Google Scholar] [CrossRef]

- Ferreira, D.F. Sisvar: A computer statistical analysis system. Ciênc. Agrotec 2011, 35, 1039–1042. [Google Scholar] [CrossRef]

- Valdez, E. Determinacion y estudio de los perfiles de distribuicion de superfosfato, hiperfosfato y urea granulados, aplicados com la fertilizadora centrifuga. Agrinter 1978, 14, 1–42. [Google Scholar]

- Farret, I.S.; Schlosser, J.F.; Durigon, R.; Werner, V.; Knob, M. Variação da regulagem no perfil transversal de aplicação com distribuidores centrífugos. Cienc Rural 2008, 38, 1886–1892. [Google Scholar]

- Reynaldo, E.F.; Machado, T.M.; Taubinger, L.; Quadros, D. Distribuição de fertilizantes a lanço em função da qualidade do insumo. Energ. Agric. 2016, 31, 24–30. [Google Scholar] [CrossRef]

| Disk Rotation Speed (rpm) | FA1 1 | FA2 2 | ||

|---|---|---|---|---|

| Left (%) | Right (%) | Left (%) | Right (%) | |

| 240 | 83.94 | 16.06 | 50.26 | 49.74 |

| 375 | 74.40 | 25.60 | 47.76 | 52.24 |

| 750 | 48.10 | 51.90 | 39.69 | 60.31 |

| Collector Position | FA1 1 | FA2 2 | ||||

|---|---|---|---|---|---|---|

| Disk Rotation Speed (rpm) | ||||||

| 240 | 375 | 750 | 240 | 375 | 750 | |

| 1 | 9.62 d | 3.84 c | 1.97 a | 5.65 b | 2.12 a | 1.32 a |

| 2 | 8.64 d | 9.13 d | 3.46 b | 4.82 b | 5.71 c | 2.47 b |

| 3 | 7.72 d | 11.96 e | 5.06 b | 3.55 a | 6.91 c | 4.22 c |

| 4 | 3.19 c | 5.28 c | 4.73 b | 3.56 a | 6.27 c | 4.90 c |

| 5 | 1.41 b | 2.33 b | 3.90 b | 4.51 b | 6.54 c | 5.08 c |

| 6 | 0.37 a | 0.97 a | 2.63 a | 5.78 b | 3.11 b | 2.84 b |

| Fertilizer Dose (kg·ha−1) | FA1 1 | FA2 2 | ||||

|---|---|---|---|---|---|---|

| Disk Rotation Speed (rpm) | ||||||

| 240 | 375 | 750 | 240 | 375 | 750 | |

| 200 | 75.5 | 72.4 | 36.3 | 17.2 | 33.3 | 41.1 |

| 300 | 60.2 | 73.6 | 25.8 | 15.0 | 41.7 | 39.9 |

| 400 | 78.7 | 63.7 | 32.7 | 26.3 | 35.9 | 38.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrade, A.D.; Araújo e Silva Ferraz, G.; Machado de Barros, M.; De Oliveira Faria, R.; Moreira da Silva, F.; Sarri, D.; Vieri, M. Characterization of the Transverse Distribution of Fertilizer in Coffee Plantations. Agronomy 2020, 10, 601. https://doi.org/10.3390/agronomy10040601

Andrade AD, Araújo e Silva Ferraz G, Machado de Barros M, De Oliveira Faria R, Moreira da Silva F, Sarri D, Vieri M. Characterization of the Transverse Distribution of Fertilizer in Coffee Plantations. Agronomy. 2020; 10(4):601. https://doi.org/10.3390/agronomy10040601

Chicago/Turabian StyleAndrade, Alan Delon, Gabriel Araújo e Silva Ferraz, Murilo Machado de Barros, Rafael De Oliveira Faria, Fábio Moreira da Silva, Daniele Sarri, and Marco Vieri. 2020. "Characterization of the Transverse Distribution of Fertilizer in Coffee Plantations" Agronomy 10, no. 4: 601. https://doi.org/10.3390/agronomy10040601

APA StyleAndrade, A. D., Araújo e Silva Ferraz, G., Machado de Barros, M., De Oliveira Faria, R., Moreira da Silva, F., Sarri, D., & Vieri, M. (2020). Characterization of the Transverse Distribution of Fertilizer in Coffee Plantations. Agronomy, 10(4), 601. https://doi.org/10.3390/agronomy10040601