Biodegradation of Halloysite Nanotubes-Polyester Nanocomposites Exposed to Short Term Seawater Immersion

Abstract

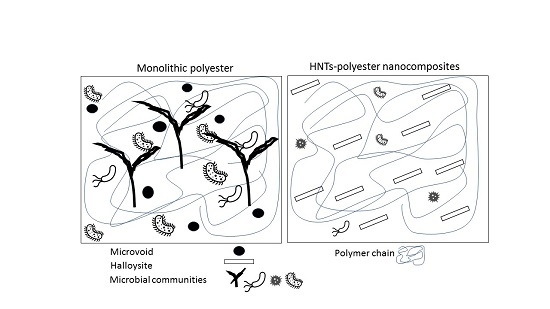

1. Introduction

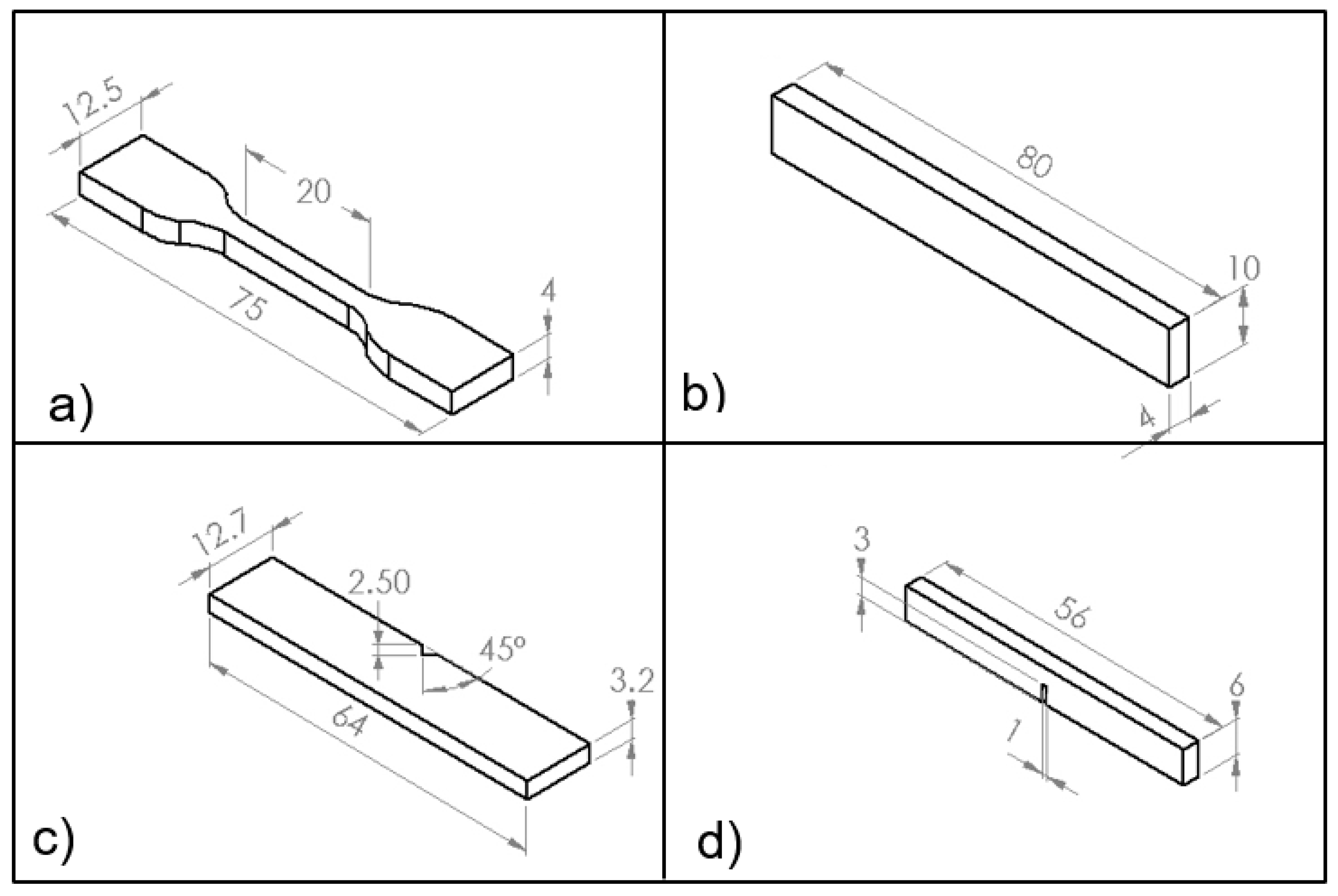

2. Materials and Methods

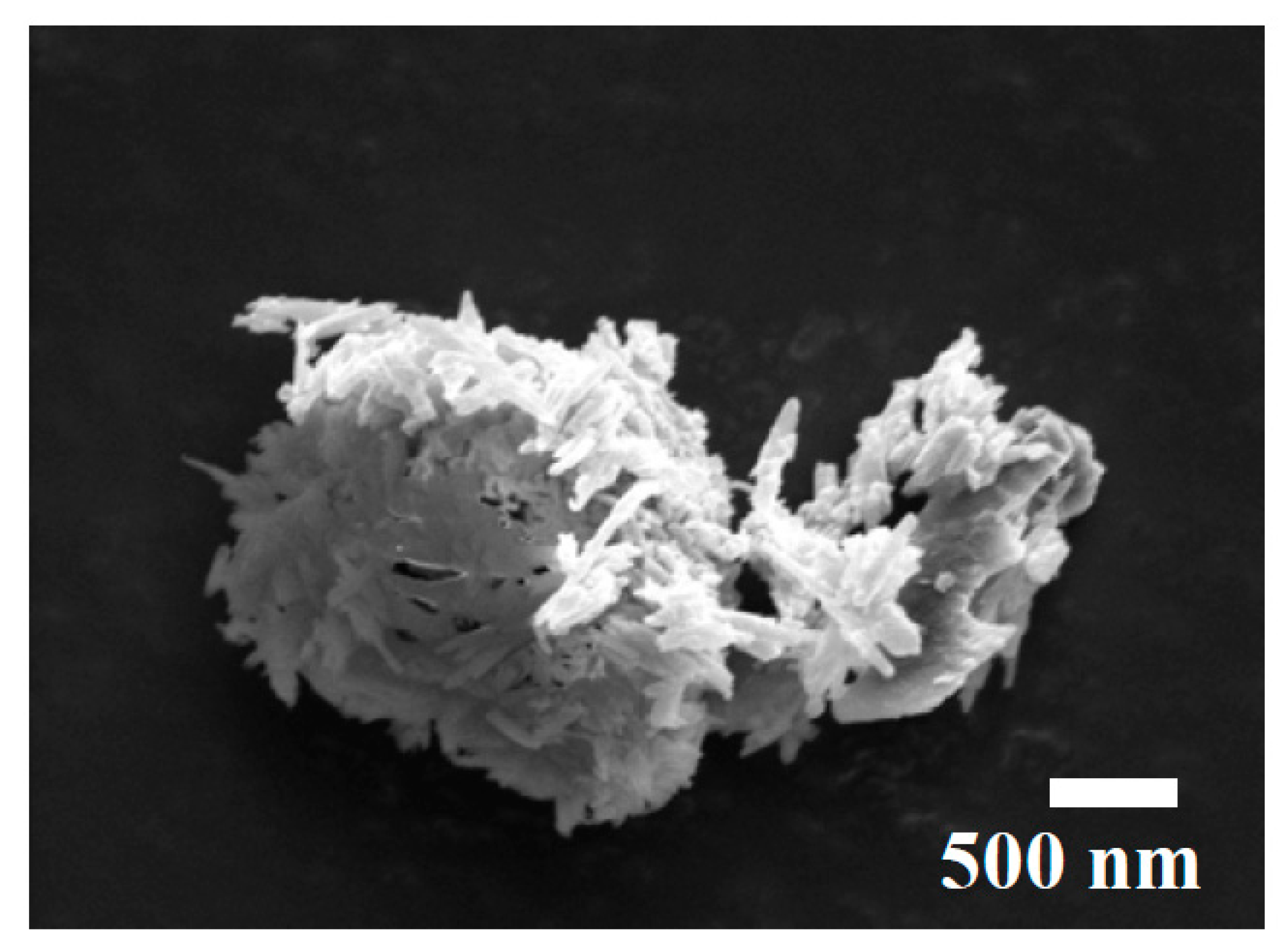

Characterization

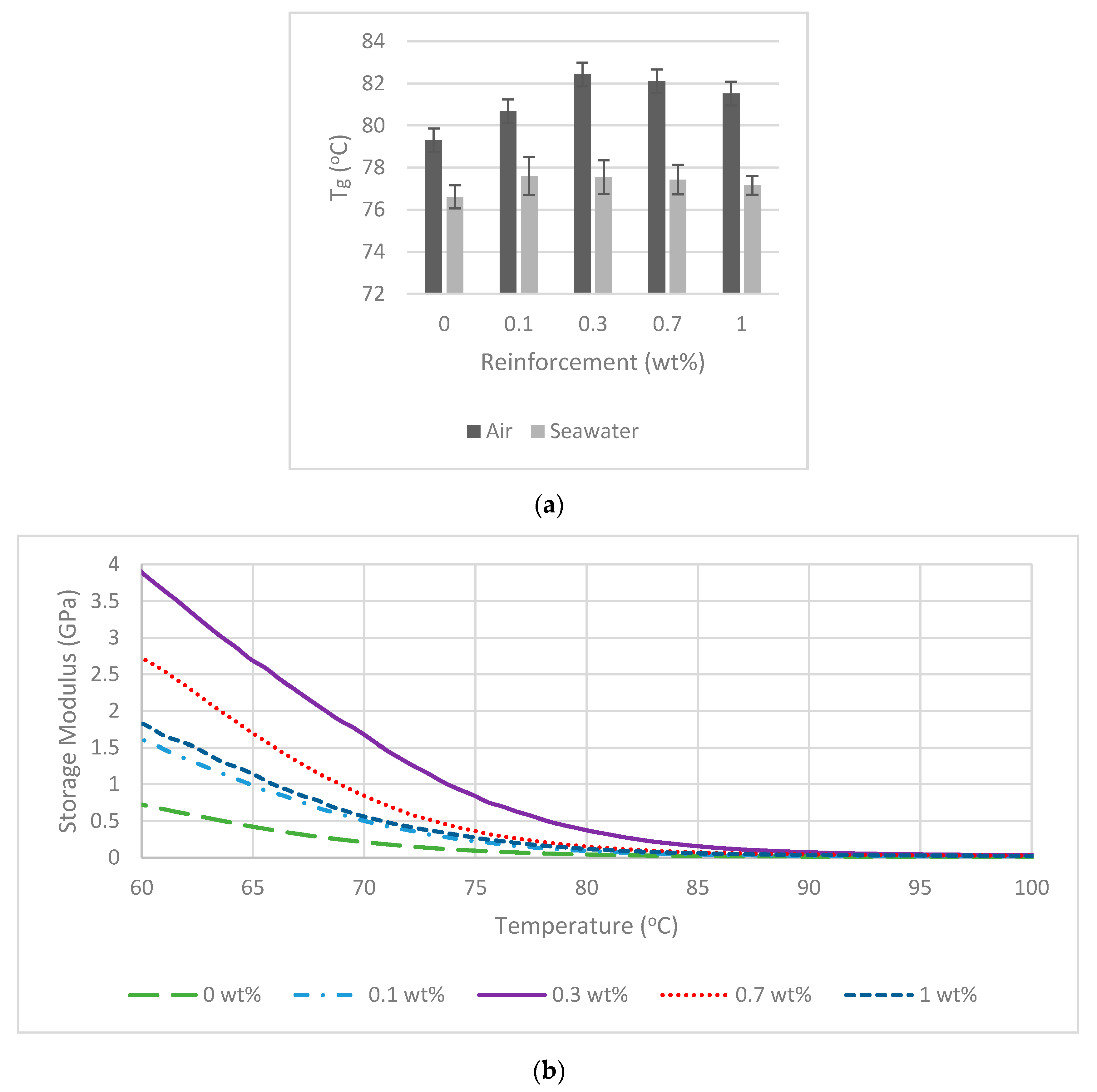

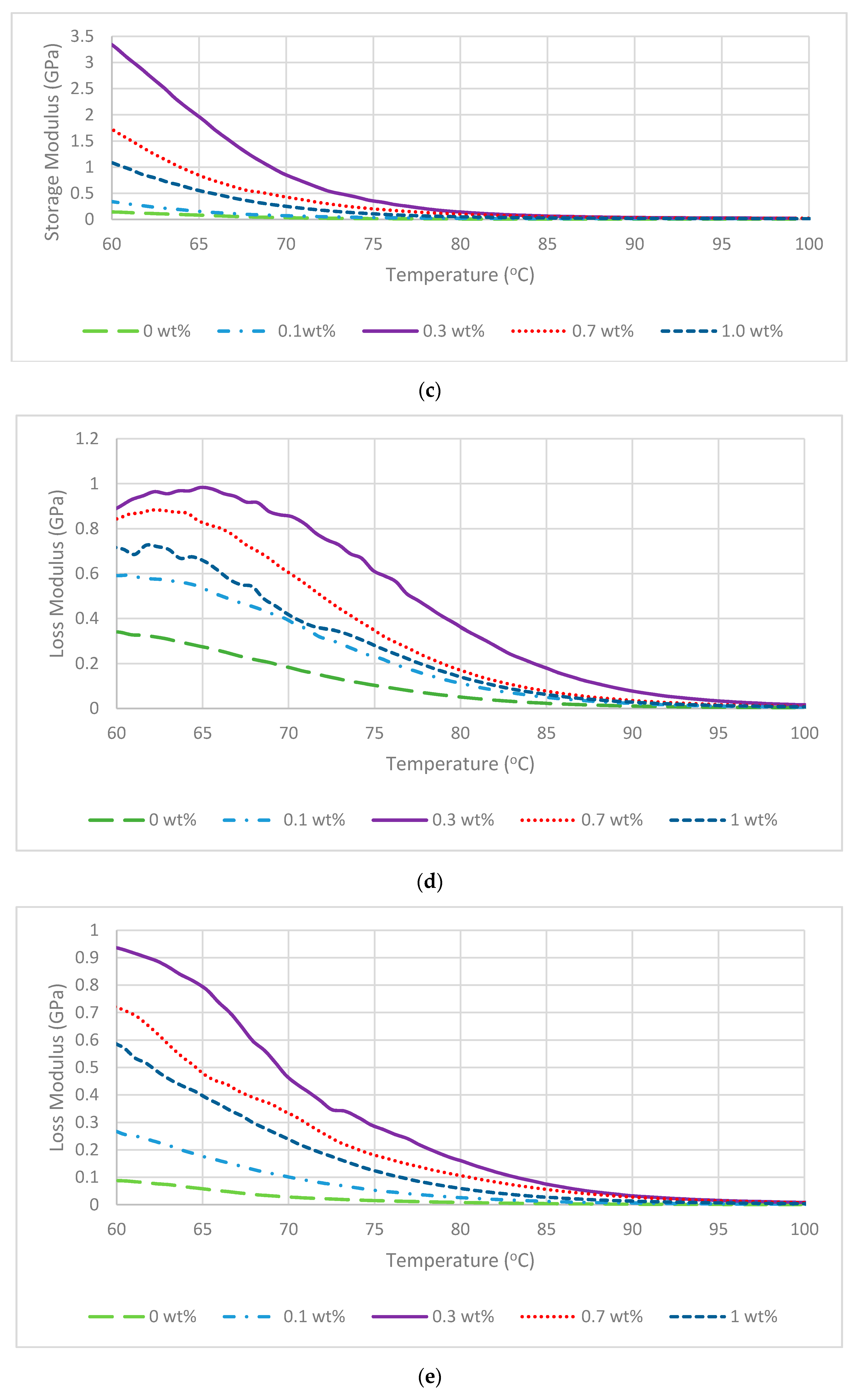

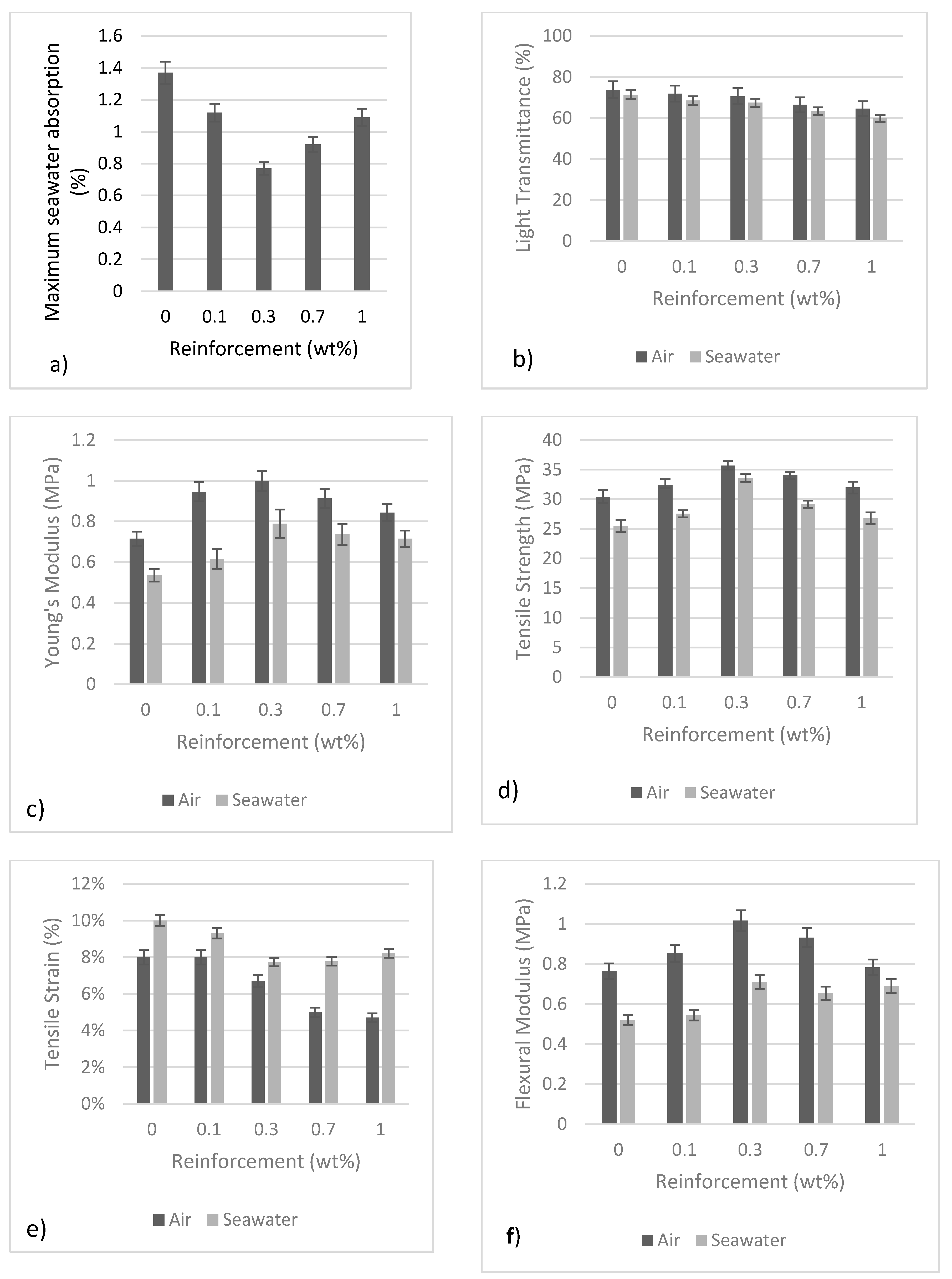

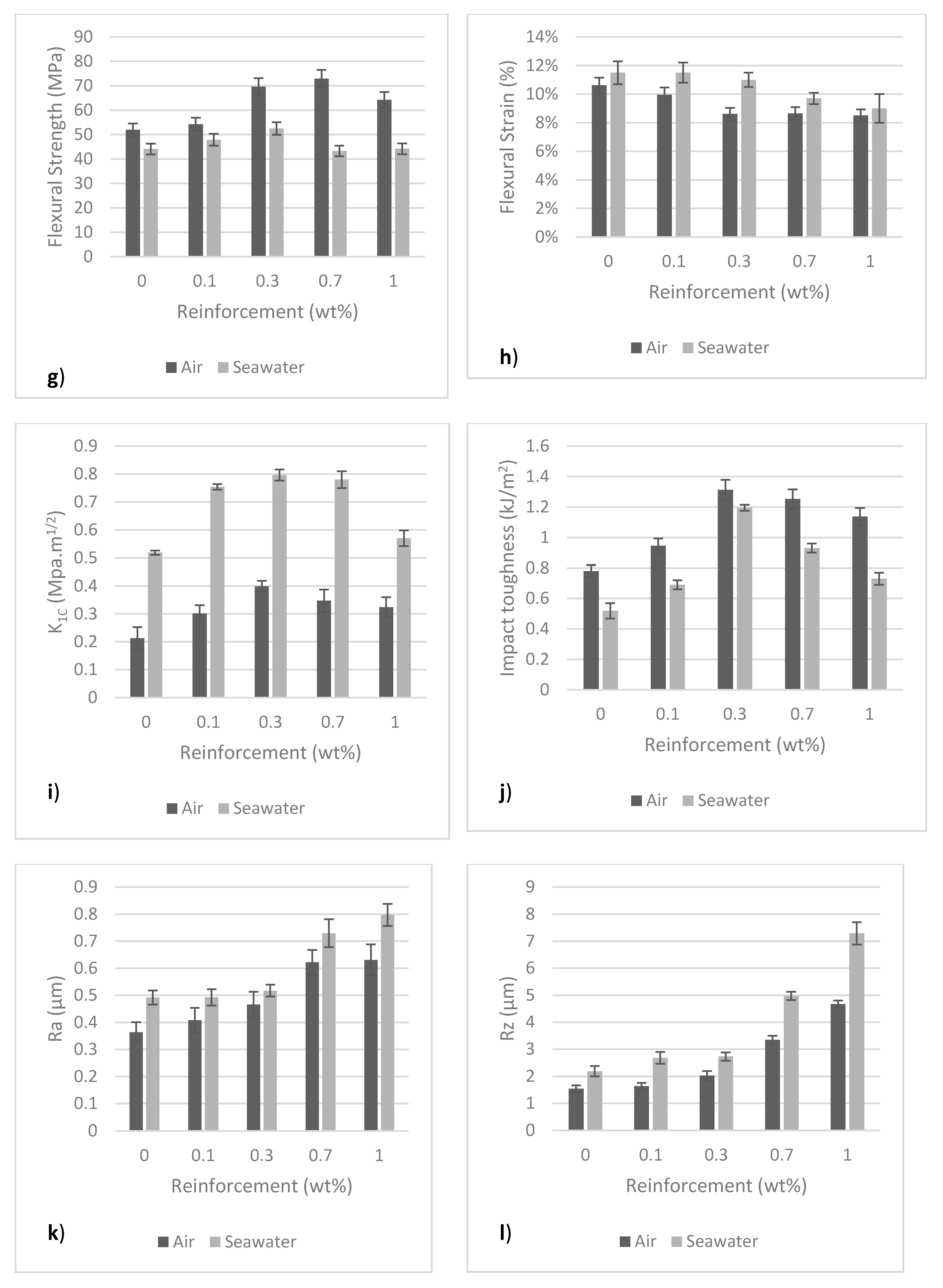

3. Results and Discussion

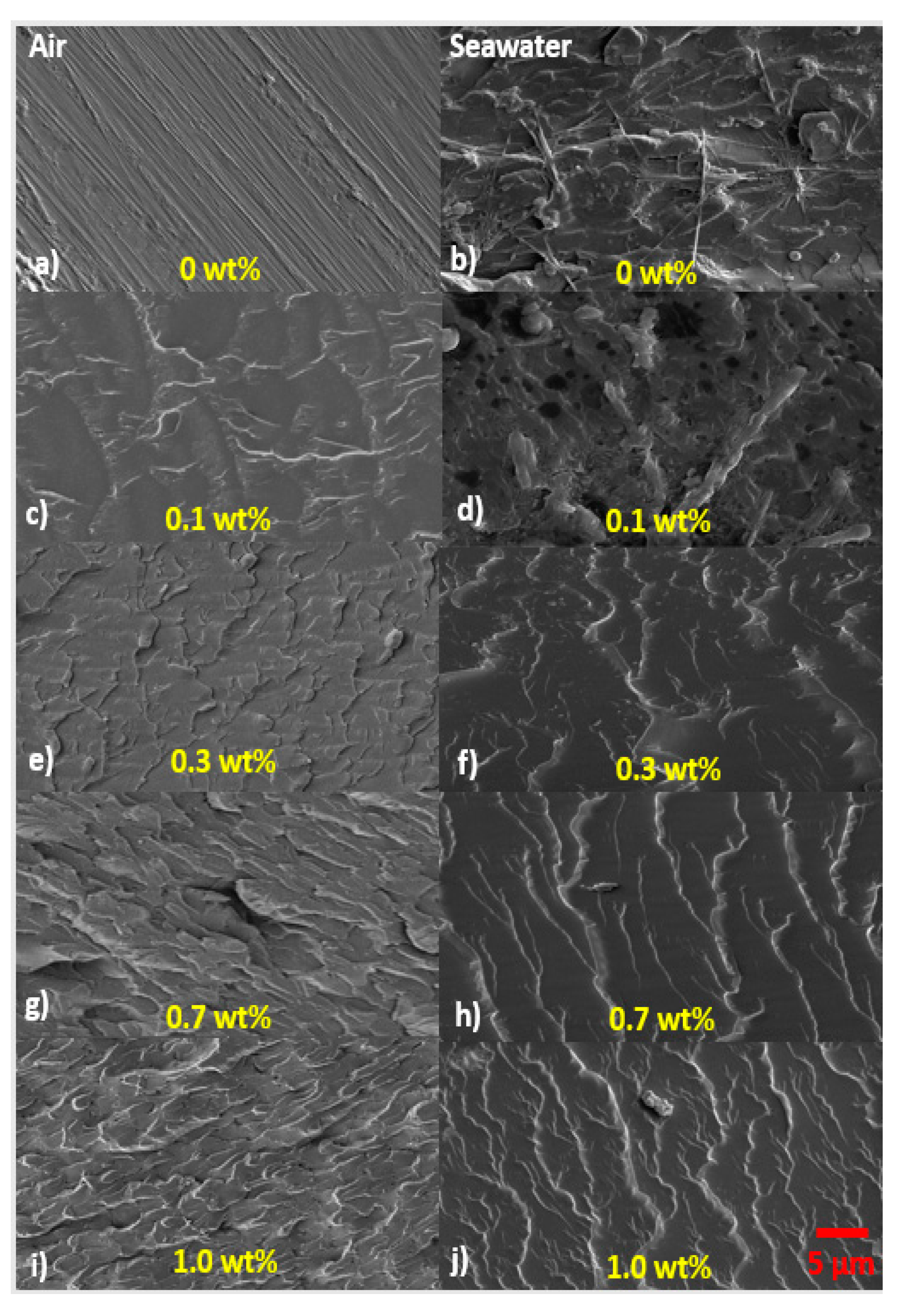

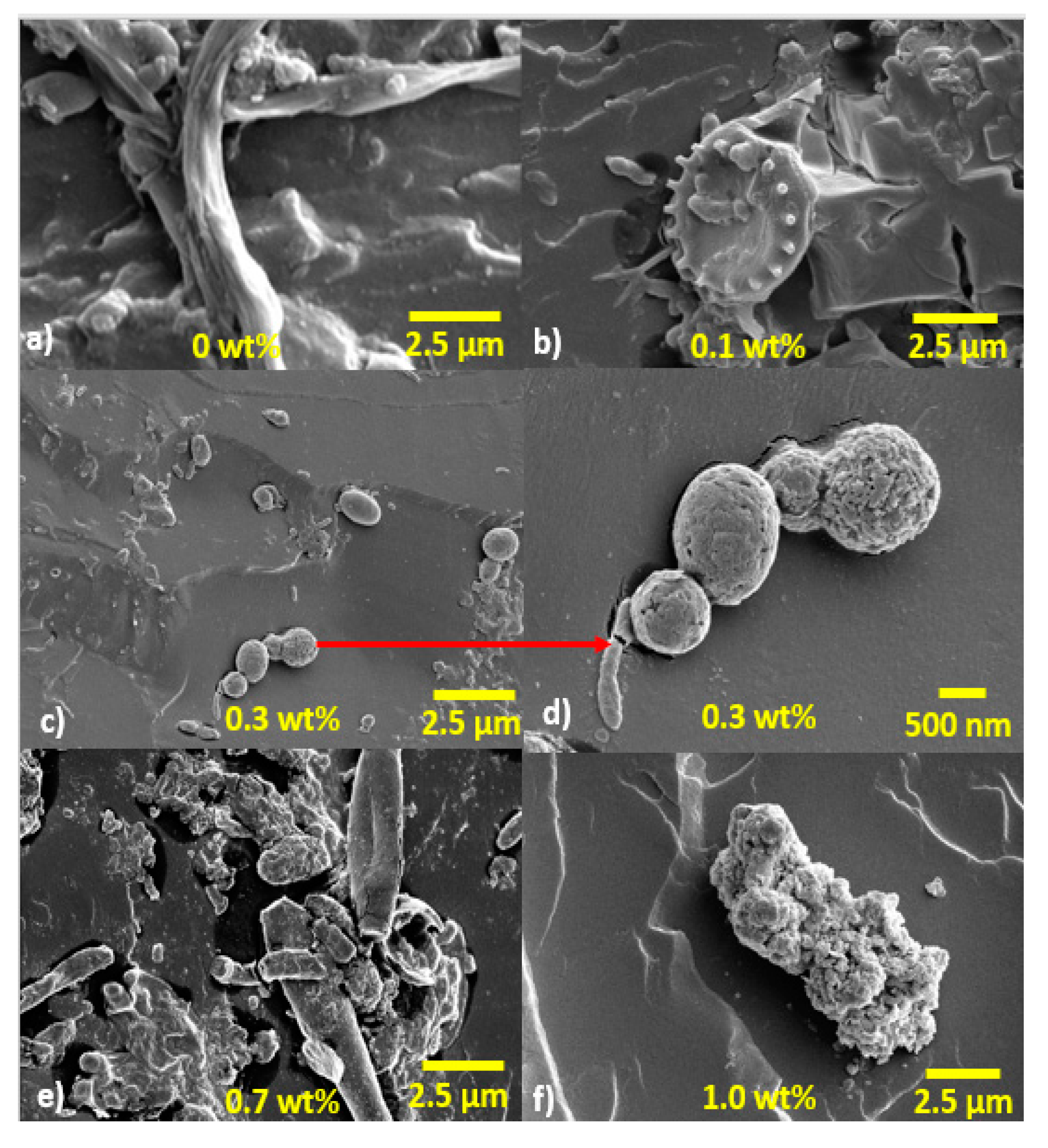

SEM Images

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Saharudin, M.S.; Shyha, I.; Inam, F. The effect of methanol exposure on the flexural and tensile properties of halloysite nanoclay polyester. In Proceedings of the IRES-17th International Conference on Innovative Engineering Technologies, London, UK, 21 November 2015; pp. 40–44. [Google Scholar]

- Han, W.; Chen, S.; Campbell, J.; Zhang, X.; Tang, Y. Fracture toughness and wear properties of nanosilica/epoxy composites under marine environment. Mater. Chem. Phys. 2016, 177, 1–9. [Google Scholar] [CrossRef]

- Lima Sobrinho, L.; Ferreira, M.; Bastian, F.L. The effects of water absorption on an ester vinyl resin system. Mater. Res. 2009, 12, 353–361. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Wei, J.; Shyha, I.; Inam, F. Environmental Stress Cracking Resistance of Halloysite Nanoclay-Polyester Nanocomposites. World J. Eng. Technol. 2017, 5, 389–403. [Google Scholar] [CrossRef]

- Saharudin, M.; Wei, J.; Shyha, I.; Inam, F. The degradation of mechanical properties in halloysite nanoclay-polyester nanocomposites exposed in seawater environment. J. Nanomater. 2016, 2016. [Google Scholar] [CrossRef]

- Bora, C.; Gogoi, P.; Baglari, S.; Dolui, S.K. Preparation of polyester resin/graphene oxide nanocomposite with improved mechanical strength. J. Appl. Polym. Sci. 2013, 129, 3432–3438. [Google Scholar] [CrossRef]

- Wei, J.; Saharudin, M.S.; Vo, T.; Inam, F. N,N-Dimethylformamide (DMF) Usage in Epoxy/Graphene Nanocomposites: Problems Associated with Reaggregation. Polymers 2017, 9, 193. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Atif, R.; Shyha, I.; Inam, F. The degradation of mechanical properties in polymer nano-composites exposed to liquid media—A review. RSC Adv. 2016, 6, 1076–1089. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Shyha, I.; Inam, F. Viscoelastic and mechanical properties of multi-layered-graphene polyester composites. In Proceedings of the 2nd International Conference on Advances in Mechanical Engineering, Istanbul, Turkey, 10–13 May 2016; pp. 41–45. [Google Scholar]

- Saharudin, M.S.; Jumahat, A.; Kahar, A.Z.; Ahmad, S. The Influence of Alumina Filler on Impact Properties of Short Glass Fiber Reinforced Epoxy. Appl. Mech. Mater. 2013, 393, 88–93. [Google Scholar] [CrossRef]

- Gao, F. Clay/polymer composites: The story. Mater. Today 2004, 7, 50–55. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Effect of water absorption on the mechanical properties of nano-filler reinforced epoxy nanocomposites. Mater. Des. 2012, 42, 214–222. [Google Scholar] [CrossRef]

- Albdiry, M.T.; Yousif, B.F.; Ku, H. Fracture toughness and toughening mechanisms of unsaturated polyester-based clay nanocomposites. In Proceedings of the 13th International Conference on Fracture, Beijing, China, 16–21 June 2013; pp. 1–10. [Google Scholar]

- Zainuddin, S.; Hosur, M.V.; Zhou, Y.; Kumar, A.; Jeelani, S. Durability studies of montmorillonite clay filled epoxy composites under different environmental conditions. Mater. Sci. Eng. A 2009, 507, 117–123. [Google Scholar] [CrossRef]

- Fakhrullina, G.I.; Akhatova, F.S.; Lvov, M.; Fakhrullin, R.F. Environmental Science Nano Toxicity of halloysite clay nanotubes in vivo: A Caenorhabditis elegans study. Environ. Sci. Nano 2015, 2, 54–59. [Google Scholar] [CrossRef]

- Lvov, Y.; Abdullayev, E. Functional polymer-clay nanotube composites with sustained release of chemical agents. Prog. Polym. Sci. 2013, 38, 1690–1719. [Google Scholar] [CrossRef]

- Kamble, R.; Ghag, M.; Gaikawad, S.; Panda, B.K. Review article halloysite nanotubes and applications: A review. J. Adv. Sci. Res. 2012, 3, 25–29. [Google Scholar]

- Bhuvana, S.; Prabakaran, M. Synthesis and Characterisation of Polyamide/Halloysite Nanocomposites Prepared by Solution Intercalation Method. Nanosci. Nanotechnol. 2014, 4, 44–51. [Google Scholar] [CrossRef]

- Gabr, M.H.; Phong, N.T.; Abdelkareem, M.A.; Okubo, K.; Uzawa, K.; Kimpara, I.; Fujii, T. Mechanical, thermal, and moisture absorption properties of nano-clay reinforced nano-cellulose biocomposites. Cellulose 2013, 20, 819–826. [Google Scholar] [CrossRef]

- Albdiry, M.; Yousif, B.; Ku, H.; Lau, K. A critical review on the manufacturing processes in relation to the properties of nanoclay/polymer composites. J. Compos. Mater. 2012, 47, 1093–1115. [Google Scholar] [CrossRef]

- Liu, W.; Hoa, S.V.; Pugh, M. Fracture toughness and water uptake of high-performance epoxy/nanoclay nanocomposites. Compos. Sci. Technol. 2005, 65, 2364–2373. [Google Scholar] [CrossRef]

- Carli, L.N.; Crespo, J.S.; Mauler, R.S. PHBV nanocomposites based on organomodified montmorillonite and halloysite: The effect of clay type on the morphology and thermal and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1601–1608. [Google Scholar] [CrossRef]

- Pavlidou, S.; Papaspyrides, C.D. A review on polymer-layered silicate nanocomposites. Prog. Polym. Sci. 2008, 33, 1119–1198. [Google Scholar] [CrossRef]

- Lobelle, D.; Cunliffe, M. Early microbial biofilm formation on marine plastic debris. Mar. Pollut. Bull. 2011, 62, 197–200. [Google Scholar] [CrossRef] [PubMed]

- Alvarez-Zeferino, J.C.; Beltrán-Villavicencio, M.; Vázquez-Morillas, A. Degradation of Plastics in Seawater in Laboratory. Open J. Polym. Chem. 2015, 5, 55–62. [Google Scholar] [CrossRef]

- Heimowska, A.; Krasowska, K.; Rutkowska, M. Degradability of Different Packaging Polymeric Materials in Seawater. In Proceedings of the 12th Annual General Assembly IAMU, St. Johns, NL, Canada, 15–17 October 2012; pp. 153–163. [Google Scholar]

- Andrady, A.L. Microplastics in the marine environment. Mar. Pollut. Bull. 2011, 62, 1596–1605. [Google Scholar] [CrossRef] [PubMed]

- Gewert, B.; Plassmann, M.M.; MacLeod, M. Pathways for degradation of plastic polymers floating in the marine environment. Environ. Sci. Process. Impacts 2015, 17, 1513–1521. [Google Scholar] [CrossRef] [PubMed]

- Albdiry, M.T.; Ku, H.; Yousif, B.F. Impact fracture behaviour of silane-treated halloysite nanotubes-reinforced unsaturated polyester. Eng. Fail. Anal. 2013, 35, 718–725. [Google Scholar] [CrossRef]

- Lin, Y.; Ng, K.M.; Chan, C.-M.; Sun, G.; Wu, J. High-impact polystyrene/halloysite nanocomposites prepared by emulsion polymerization using sodium dodecyl sulfate as surfactant. J. Colloid Interface Sci. 2011, 358, 423–429. [Google Scholar] [CrossRef] [PubMed]

- Chozhan, C.K.; Rajasekaran, R.; Alagar, M.; Gnanasundaram, P. Thermomechanical Behavior of Vinyl Ester Oligomer-Toughened Epoxy-Clay Hybrid Nanocomposites. Int. J. Polym. Mater. 2008, 57, 319–337. [Google Scholar] [CrossRef]

- Ye, Y.; Chen, H.; Wu, J.; Ye, L. High impact strength epoxy nanocomposites with natural nanotubes. Polymer 2007, 48, 6426–6433. [Google Scholar] [CrossRef]

- Sancaktar, E.; Kuznicki, J. Nanocomposite adhesives: Mechanical behavior with nanoclay. Int. J. Adhes. Adhes. 2011, 31, 286–300. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Q.; Berglund, L.A.; Fan, J.; Qi, Z. Polyamide 6-clay nanocomposites/polypropylene-grafted-maleic anhydride alloys. Polymer 2001, 42, 8235–8239. [Google Scholar] [CrossRef]

- Lepoittevin, B.; Devalckenaere, M.; Pantoustier, N.; Alexandre, M.; Kubies, D.; Calberg, C.; Jérôme, R.; Dubois, P. Poly(ε-caprolactone)/clay nanocomposites prepared by melt intercalation: Mechanical, thermal and rheological properties. Polymer 2002, 43, 4017–4023. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Microstructural, mechanical, and thermal characteristics of recycled cellulose fiber-halloysite-epoxy hybrid nanocomposites. Polym. Compos. 2012, 33, 589–600. [Google Scholar] [CrossRef]

- Manfredi, L.B.; De Santis, H.; Vázquez, A. Influence of the addition of montmorillonite to the matrix of unidirectional glass fibre/epoxy composites on their mechanical and water absorption properties. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1726–1731. [Google Scholar] [CrossRef]

- Ji, Q.; Wetzel, B.; Friedrich, K.; Al, N. Tribological properties of surface modified nano-alumina/epoxy composites. J. Mater. Sci. 2004, 9, 6487–6493. [Google Scholar] [CrossRef]

- Vahedi, V.; Pasbakhsh, P. Instrumented impact properties and fracture behaviour of epoxy/modified halloysite nanocomposites. Polym. Test. 2014, 39, 101–114. [Google Scholar] [CrossRef]

- Atif, R.; Inam, F. Influence of macro-topography on damage tolerance and fracture toughness of 0.1 wt % multi-layer graphene/clay-epoxy nanocomposites. Polymers 2016, 8, 335–360. [Google Scholar] [CrossRef]

- John, B.; Nair, C.P.R.; Ninan, K.N. Effect of nanoclay on the mechanical, dynamic mechanical and thermal properties of cyanate ester syntactic foams. Mater. Sci. Eng. A 2010, 527, 5435–5443. [Google Scholar] [CrossRef]

- Mourad, A.H.I.; Beckry Mohamed, A.M.; El-Maaddawy, T. Effect of seawater and warm environment on glass/epoxy and glass/polyurethane composites. Appl. Compos. Mater. 2010, 17, 557–573. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Wei, J.; Shyha, I.; Inam, F. Flexural Properties of Halloysite Nanotubes-Polyester Nanocomposites Exposed to Aggressive Environment. Int. J. Chem. Mol. Nucl. Mater. Metall. Eng. 2017, 11, 292–296. [Google Scholar]

- Tan, B.; Thomas, N.L. A review of the water barrier properties of polymer/clay and polymer/graphene nanocomposites. J. Membr. Sci. 2016, 514, 595–612. [Google Scholar] [CrossRef]

- Picard, E.; Gérard, J.-F.; Espuche, E. Water transport properties of polyamide 6 based nanocomposites prepared by melt blending: On the importance of the clay dispersion state on the water transport properties at high water activity. J. Membr. Sci. 2008, 313, 284–295. [Google Scholar] [CrossRef]

- Bharadwaj, R.K.; Mehrabi, A.R.; Hamilton, C.; Trujillo, C.; Murga, M. Structure property relationships in cross-linked polyester clay nanocomposites. Polymer 2002, 43, 3699–3705. [Google Scholar] [CrossRef]

- Wei, J.; Atif, R.; Vo, T.; Inam, F. Graphene Nanoplatelets in Epoxy System: Dispersion, Reaggregation, and Mechanical Properties of Nanocomposites. J. Nanomater. 2015, 2015, 374. [Google Scholar] [CrossRef]

- Maurin, R.; Perrot, Y.; Bourmaud, A.; Davies, P.; Baley, C. Seawater ageing of low styrene emission resins for marine composites: Mechanical behaviour and nano-indentation studies. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1024–1032. [Google Scholar] [CrossRef]

- Chakraverty, A.P.; Mohanty, U.K.; Mishra, S.C.; Satapathy, A. Sea Water Ageing of GFRP Composites and the Dissolved salts. IOP Conf. Ser. Mater. Sci. Eng. 2015, 75, 12029. [Google Scholar] [CrossRef]

- Deng, S.; Zhang, J.; Ye, L.; Wu, J. Toughening epoxies with halloysite nanotubes. Polymer 2008, 49, 5119–5127. [Google Scholar] [CrossRef]

- Ramsaroop, A.; Kanny, K.; Mohan, T.P. Fracture Toughness Studies of Polypropylene-Clay Nanocomposites and Glass Fibre Reinfoerced Polypropylene Composites. Mater. Sci. Appl. 2010, 1, 301–309. [Google Scholar] [CrossRef]

- Al-Saidi, L.F.; Mortensen, K.; Almdal, K. Environmental stress cracking resistance. Behaviour of polycarbonate in different chemicals by determination of the time-dependence of stress at constant strains. Polym. Degrad. Stab. 2003, 82, 451–461. [Google Scholar] [CrossRef]

- Buehler, F.U.; Seferis, J.C. Effect of reinforcement and solvent content on moisture absorption in epoxy composite materials. Compos. Part A Appl. Sci. Manuf. 2000, 31, 741–748. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Atif, R.; Inam, F. Effect of Short-Term Water Exposure on the Mechanical Properties of Halloysite Nanotube-Multi Layer Graphene Reinforced Polyester Nanocomposites. Polymers 2017, 9, 27. [Google Scholar] [CrossRef]

- Scaffaro, R.; Morreale, M.; Lo Re, G.; La Mantia, F.P. Degradation of Mater-Bi/wood flour biocomposites in active sewage sludge. Polym. Degrad. Stab. 2009, 94, 1220–1229. [Google Scholar] [CrossRef]

- Muthukumar, T.; Aravinthan, A.; Lakshmi, K.; Venkatesan, R.; Vedaprakash, L.; Doble, M. Fouling and stability of polymers and composites in marine environment. Int. Biodeterior. Biodegrad. 2011, 65, 276–284. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Atif, R.; Shyha, I.; Inam, F. The degradation of mechanical properties in halloysite nanoclay-polyester nanocomposites exposed to diluted methanol. J. Compos. Mater. 2016, 51, 1–12. [Google Scholar] [CrossRef]

- Cui, Y.; Kumar, S.; Rao Kona, B.; van Houcke, D. Gas barrier properties of polymer/clay nanocomposites. RSC Adv. 2015, 5, 63669–63690. [Google Scholar] [CrossRef]

- Zettler, E.R.; Mincer, T.J.; Amaral-Zettler, L.A. Life in the “plastisphere”: Microbial communities on plastic marine debris. Environ. Sci. Technol. 2013, 47, 7137–7146. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Espinel, J.D.; Castro-Fresno, D.; Parbole Gayo, P.; Ballester-Muñoz, F. Effects of sea water environment on glass fiber reinforced plastic materials used for marine civil engineering constructions. Mater. Des. 2015, 66, 46–50. [Google Scholar] [CrossRef]

- Hamzah, E.; Hussain, M.F.; Ibrahim, Z.; Abdolahi, A. Corrosion Behaviour of Carbon Steel in Sea Water Medium in Presence of P. aeruginosa Bacteria. Arab. J. Sci. Eng. 2014, 39, 6863–6870. [Google Scholar] [CrossRef]

| Nr | Authors | Year | Reinforcement/(wt %) | Polymer | Mechanical Properties | Max Increase (%) | Ref. |

|---|---|---|---|---|---|---|---|

| 1 | Albdiry et al. | 2013 | Halloysite nanotubes/3 | Unsaturated polyester | Impact strength | 16 | [29] |

| 2 | Lin et al. | 2011 | Halloysite nanotubes/5 | Epoxy | Impact strength | 300 | [30] |

| 3 | Chozhan et al. | 2008 | Clay/3 | Epoxy | Impact strength | 19.2 | [31] |

| 4 | Ye et al. | 2007 | Halloysite nanotubes/2.3 | Epoxy | Impact strength | 413 | [32] |

| 5 | Sancaktar | 2011 | Nanoclay/1 | Epoxy | Young’s modulus | 11 | [33] |

| 6 | Carli et al. | 2011 | Halloysite nanotubes/5 | PHBV | Young’s modulus | 63 | [22] |

| 7 | Liu et al. | 2001 | Nanoclay/5 | Epoxy | Young’s modulus | 40 | [34] |

| 8 | Lepoittevin | 2002 | MMT/10 | PCL(Poly(ε-caprolactone) | Young’s modulus | 54 | [35] |

| 9 | Alamri and Low | 2012 | Halloysite/5 | Epoxy | Flexural Modulus | 88 | [36] |

| 10 | Pavlidou et al. | 2008 | MMT/5 | Epoxy | Flexural modulus | 224 | [23] |

| 11 | Manfredi et al. | 2008 | Cloisite/5 | Epoxy | Flexural modulus | 29 | [37] |

| 12 | Wetzel et al. | 2006 | MMT/10 | Epoxy | Flexural modulus | 40 | [38] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saharudin, M.S.; Wei, J.; Shyha, I.; Inam, F. Biodegradation of Halloysite Nanotubes-Polyester Nanocomposites Exposed to Short Term Seawater Immersion. Polymers 2017, 9, 314. https://doi.org/10.3390/polym9080314

Saharudin MS, Wei J, Shyha I, Inam F. Biodegradation of Halloysite Nanotubes-Polyester Nanocomposites Exposed to Short Term Seawater Immersion. Polymers. 2017; 9(8):314. https://doi.org/10.3390/polym9080314

Chicago/Turabian StyleSaharudin, Mohd Shahneel, Jiacheng Wei, Islam Shyha, and Fawad Inam. 2017. "Biodegradation of Halloysite Nanotubes-Polyester Nanocomposites Exposed to Short Term Seawater Immersion" Polymers 9, no. 8: 314. https://doi.org/10.3390/polym9080314

APA StyleSaharudin, M. S., Wei, J., Shyha, I., & Inam, F. (2017). Biodegradation of Halloysite Nanotubes-Polyester Nanocomposites Exposed to Short Term Seawater Immersion. Polymers, 9(8), 314. https://doi.org/10.3390/polym9080314