Characterization of Wood-Plastic Composites Made with Different Lignocellulosic Materials that Vary in Their Morphology, Chemical Composition and Thermal Stability

Abstract

:1. Introduction

2. Experimental

2.1. Materials

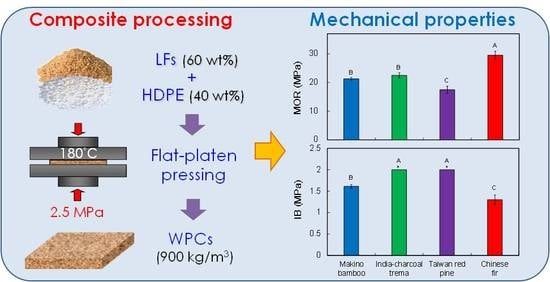

2.2. Composite Processing

2.3. Morphological Characteristics of the Lignocellulosic Materials

2.4. Chemical Composition Analysis of Lignocellulosic Materials

2.5. Determination of Composite Properties

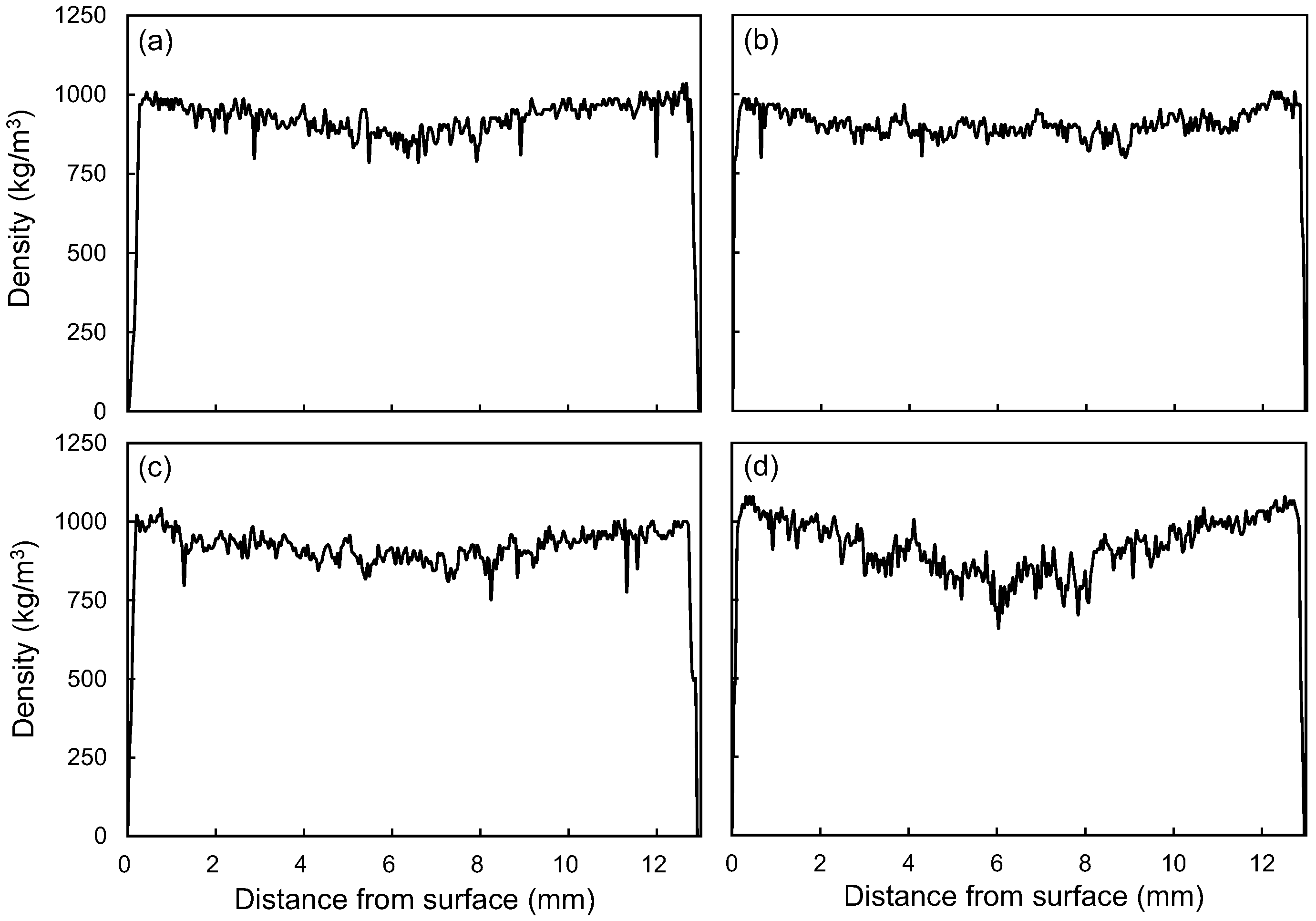

2.6. Evaluation of the Vertical Density Profile

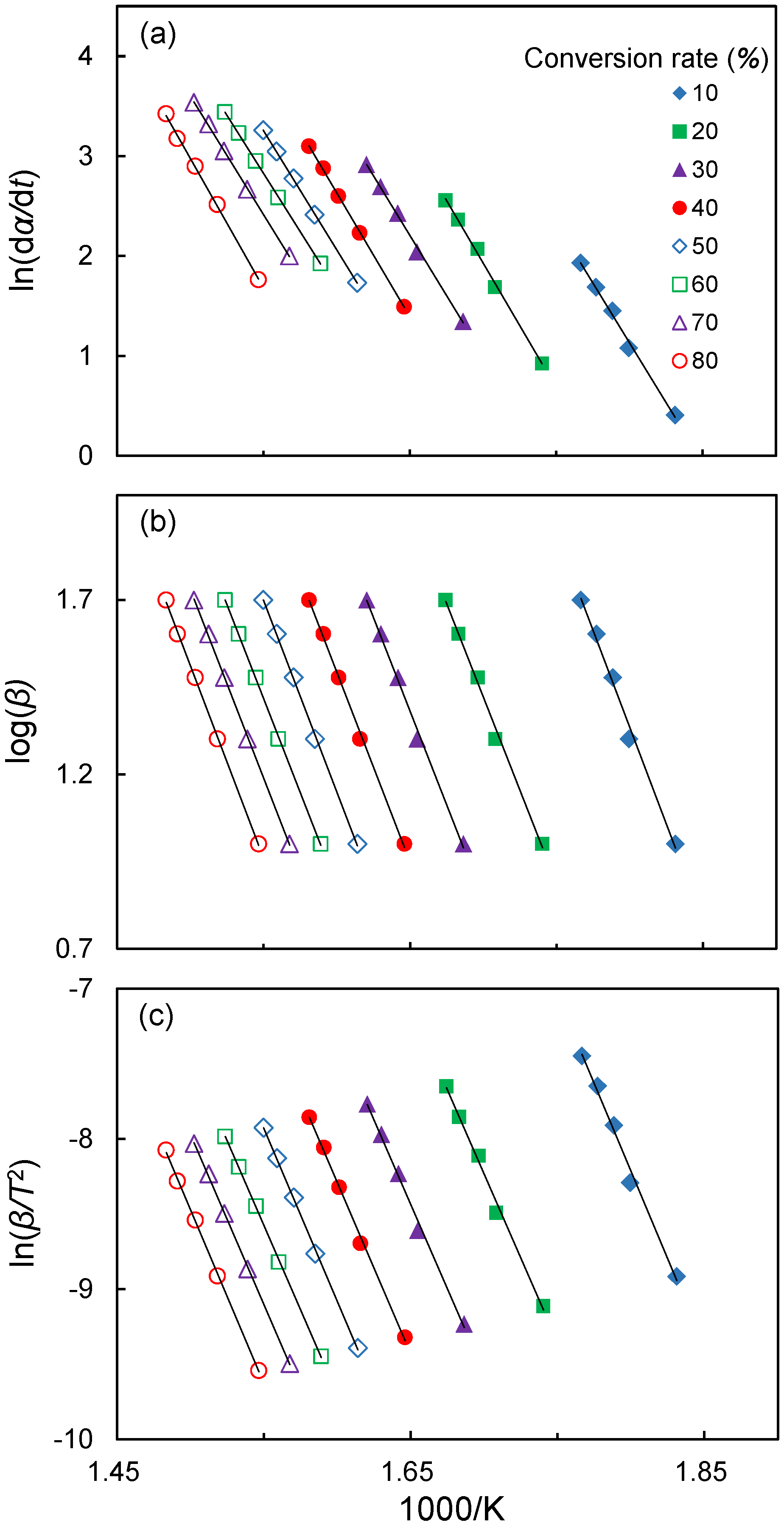

2.7. Thermal Decomposition Kinetics Analysis

2.8. Analysis of Variance

3. Results and Discussion

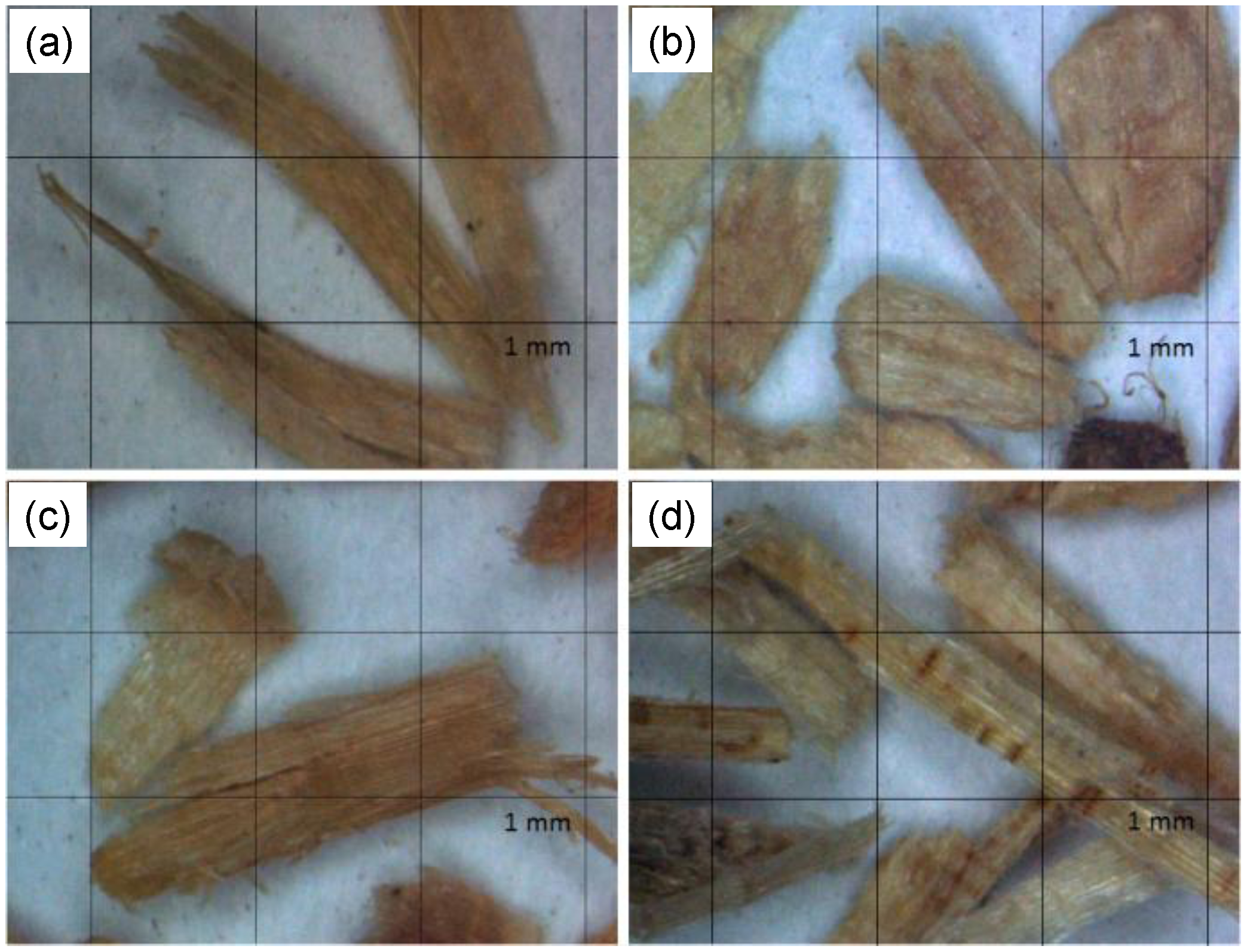

3.1. Morphological Characteristics and Chemical Compositions of Different LFs

3.2. Effect of Different LFs on Physical Properties of the WPCs

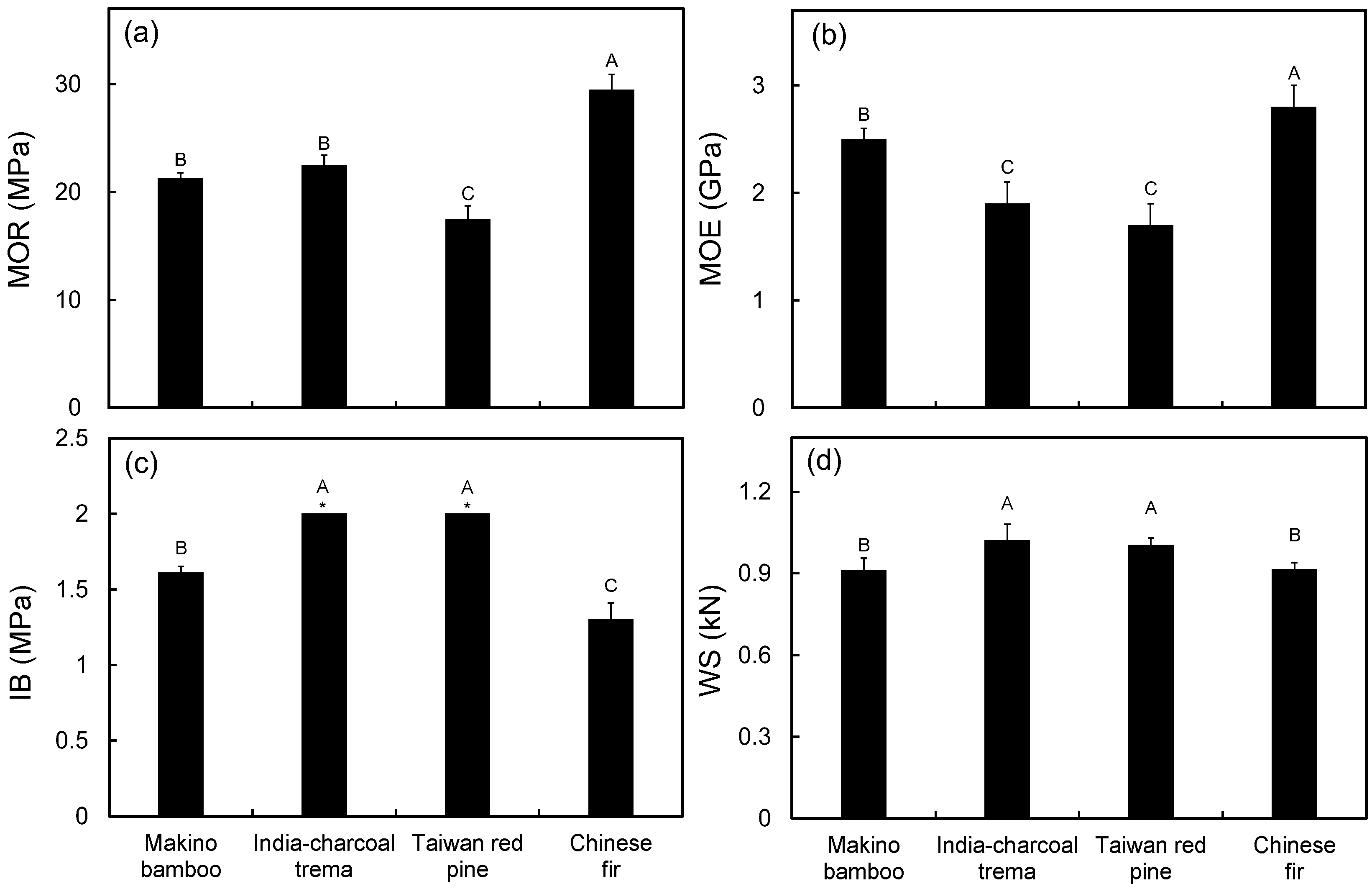

3.3. Effect of Different LFs on Mechanical Properties of the WPC

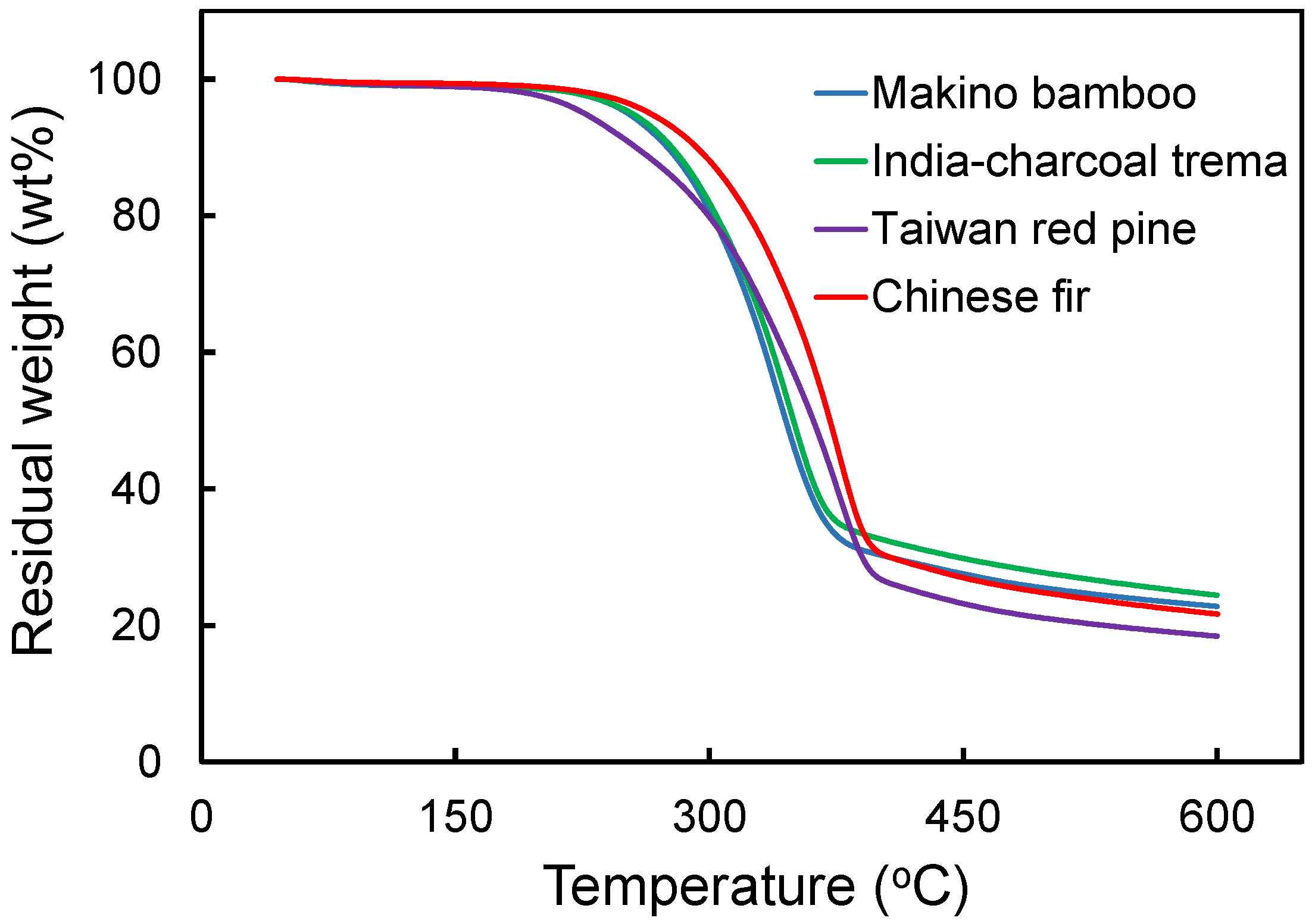

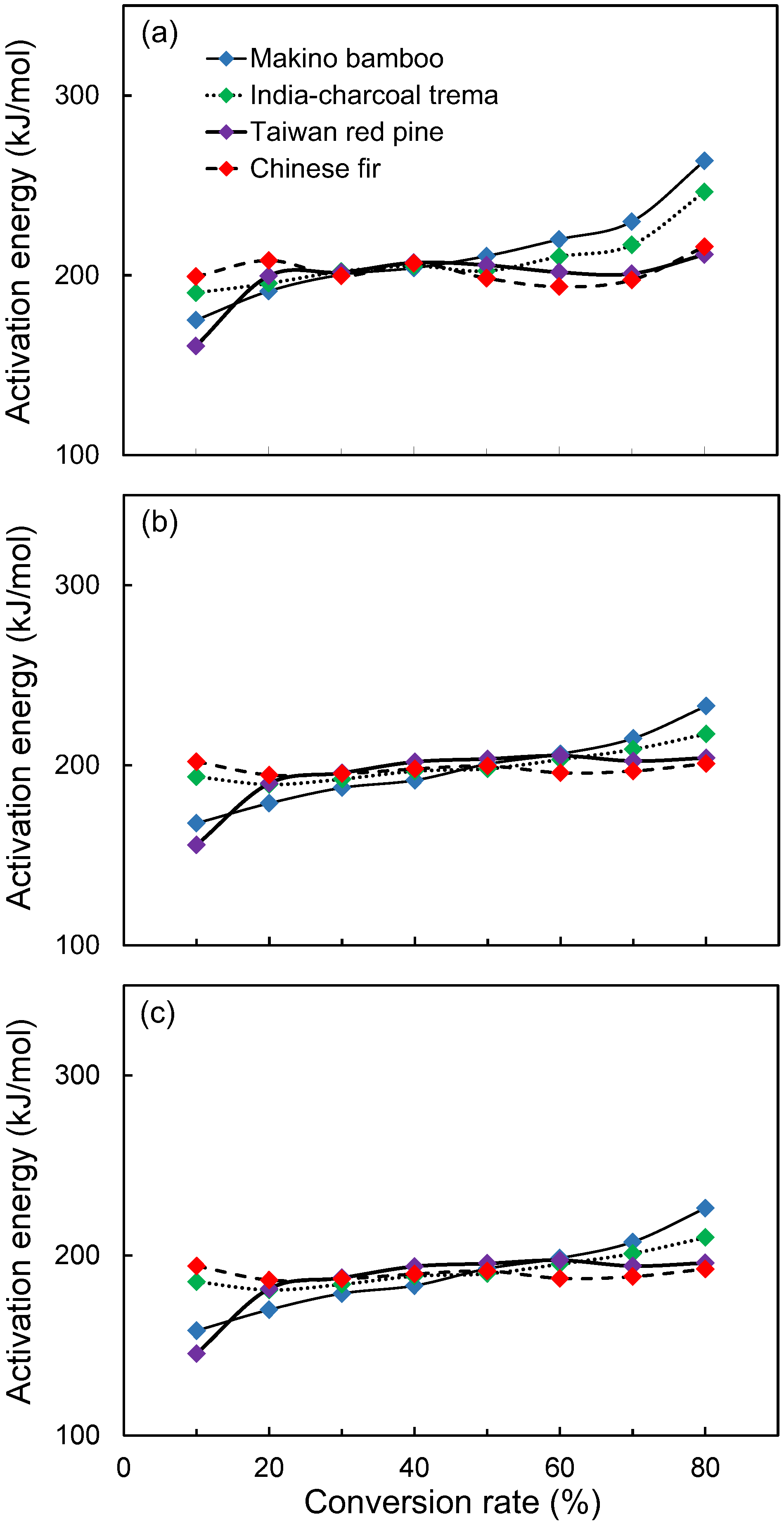

3.4. Thermal Decomposition Kinetics of Different LFs

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, Y.F.; Dong, X.Y.; Liu, Y.X.; Li, J.; Wang, F.H. Improvement of decay resistance of wood via combination treatment on wood cell wall: Swell-bonding with maleic anhydride and graft copolymerization with glycidyl methacrylate and methyl methacrylate. Int. Biodeterior. Biodegrad. 2011, 65, 1087–1094. [Google Scholar] [CrossRef]

- Fabiyi, J.S.; McDonald, A.G. Effect of wood species on property and weathering performance of wood plastic composites. Compos. Part A 2010, 41, 1434–1440. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Reihmane, S.; Gassan, J. Thermoplastics reinforced with wood fillers: A literature review. Polym. Plast. Technol. Eng. 1998, 37, 451–468. [Google Scholar] [CrossRef]

- Alsaeed, T.; Yousif, B.F.; Ku, H. The potential of using date palm fibres as reinforcement for polymeric composites. Mater. Des. 2013, 43, 177–184. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Characterization of weathered wood-plastic composite surfaces using FTIR spectroscopy, contact angle, and XPS. Polym. Degrad. Stabil. 2007, 92, 1883–1890. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Perré, P.; Riedl, B. Effects of wood fiber surface chemistry on strength of wood-plastic composites. Appl. Surf. Sci. 2015, 343, 11–18. [Google Scholar] [CrossRef]

- Simonsen, J. Efficiency of reinforcing materials in filled polymer composites. For. Prod. J. 1997, 47, 74–81. [Google Scholar]

- Bouafif, H.; Koubaa, A.; Perré, P.; Cloutier, A. Effects of fiber characteristics on the physical and mechanical properties of wood plastic composites. Compos. Part A 2009, 40, 1975–1981. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Reinforced polypropylene composites: Effects of chemical compositions and particle size. Bioresour. Technol. 2010, 101, 2515–2519. [Google Scholar] [CrossRef] [PubMed]

- Ou, R.; Xie, Y.; Wolcott, M.P.; Sui, S.; Wang, Q. Morphology, mechanical properties, and dimensional stability of wood particle/high density polyethylene composites: Effect of removal of wood cell wall composition. Mater. Des. 2014, 58, 339–345. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Sperber, V.E.; Faruk, O. Natural and wood fiber reinforcement in polymers. Rapra Rev. Rep. 2002, 13, 1–144. [Google Scholar]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Yao, F.; Wu, Q.; Lei, Y.; Guo, W.; Xu, Y. Thermal decomposition kinetics of natural fibers: Activation energy with dynamic thermogravimetric analysis. Polym. Degrad. Stabil. 2008, 93, 90–98. [Google Scholar] [CrossRef]

- Lee, C.-H.; Hung, K.-C.; Chen, Y.-L.; Wu, T.-L.; Chien, Y.-C.; Wu, J.-H. Effects of polymeric matrix on accelerated UV weathering properties of wood–plastic composites. Holzforschung 2012, 66, 981–987. [Google Scholar] [CrossRef]

- Hung, K.-C.; Chen, Y.-L.; Wu, J.-H. Natural weathering properties of acetylated bamboo plastic composites. Polym. Degrad. Stabil. 2012, 97, 1680–1685. [Google Scholar] [CrossRef]

- Hung, K.-C.; Wu, T.-L.; Chen, Y.-L.; Wu, J.-H. Assessing the effect of wood acetylation on mechanical properties and extended creep behavior of wood/recycled-polypropylene composites. Constr. Build. Mater. 2016, 108, 139–145. [Google Scholar] [CrossRef]

- Hung, K.-C.; Wu, J.-H. Mechanical and interfacial properties of plastic composite panels made from esterified bamboo particles. J. Wood Sci. 2010, 56, 189–209. [Google Scholar] [CrossRef]

- Gai, C.; Dong, Y.; Zhang, T. The kinetic analysis of the pyrolysis of agricultural residue under non-isothermal conditions. Bioresour. Technol. 2013, 127, 298–305. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Du, L.; Kai, C.; Huang, R.; Wu, Q. Bamboo and high density polyethylene composite with heat-treated bamboo fiber: Thermal decomposition properties. Bioresources 2013, 8, 900–912. [Google Scholar] [CrossRef]

- Lu, J.J.; Lin, K.C.; Cheng, Y.S. Terpenoids from oleoresin of Pinus taiwanensis. Phytochemistry 1975, 14, 1375–1377. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Dimensional stability and mechanical behaviour of wood-plastic composites based on recycled and virgin high-density polyethylene (HDPE). Compos. Part B 2008, 39, 807–815. [Google Scholar] [CrossRef]

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Wolcott, M.P. Effects of processing method and fiber size on the structure and properties of wood-plastic composites. Compos. Part A 2009, 40, 80–85. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Mechanical behavior of agro-residue reinforced polyethylene composites. J. Appl. Polym. Sci. 2009, 111, 2616–2620. [Google Scholar] [CrossRef]

- Chen, Y.-L.; Lin, C.-Y.; Wu, T.-L.; Chung, M.-J.; Chen, T.-Y.; Yang, T.-H.; Chen, H.-C.; Wu, J.-H. Evaluation and application of the invasive weed Mikania micrantha as an alternative reinforcement in recycled high density polyethylene. Bioresources 2012, 7, 2403–2417. [Google Scholar] [CrossRef]

- Ali, A.; Shaker, K.; Nawab, Y.; Jabbar, M.; Hussain, T.; Militky, J.; Baheti, V. Hydrophobic treatment of natural fibers and their composites‒A review. J. Ind. Text. 2016, 1–33. [Google Scholar] [CrossRef]

- Wong, E.D.; Zhang, M.; Wang, Q.; Kawai, S. Formation of the density profile and its effects on the properties of particleboard. Wood Sci. Technol. 1999, 33, 327–340. [Google Scholar] [CrossRef]

- Hung, K.-C.; Yang, C.-N.; Yang, T.-C.; Wu, T.-L.; Chen, Y.-L.; Wu, J.-H. Characterization and thermal stability of acetylated slicewood production by alkali-catalyzed esterification. Materials 2017, 10, 393. [Google Scholar] [CrossRef] [PubMed]

| Characteristics of Lignocellulosic Fiber | Lignocellulosic Materials | |||

|---|---|---|---|---|

| Makino Bamboo | India-Charcoal Trema | Taiwan Red Pine | Chinese Fir | |

| Morphology | ||||

| Length (mm) | 3.1 ± 0.9 A | 2.0 ± 0.4 C | 2.5 ± 0.7 B | 3.2 ± 0.8 A |

| Width (mm) | 0.8 ± 0.3 A | 0.7 ± 0.2 A | 0.8 ± 0.2 A | 0.6 ± 0.2 B |

| Aspect ratio | 4.4 ± 1.8 B | 2.9 ± 1.3 C | 3.3 ± 1.5 C | 6.3 ± 2.7 A |

| Chemical composition | ||||

| Holocellulose (%) | 71.0 ± 0.8 B | 73.7 ± 0.2 A | 61.0 ± 1.3 D | 66.4 ± 0.3 C |

| α-Cellulose (%) | 43.7 ± 0.4 A | 42.6 ± 0.9 A | 37.7 ± 1.1 B | 45.1 ± 1.0 A |

| Lignin (%) | 20.9 ± 3.8 B | 25.4 ± 3.1 B | 28.3 ± 0.9 B | 37.1 ± 1.5 A |

| Extractives (%) | 4.0 ± 0.2 B | 4.4 ± 0.2 B | 11.7 ± 0.3 A | 4.0 ± 0.1 B |

| Lignocellulosic Materials | Density (kg/m3) | Moisture Content (%) | 24 h Soaking | |

|---|---|---|---|---|

| Water Absorption (%) | Thickness Swelling (%) | |||

| Makino bamboo | 911 ± 17 A | 4.5 ± 0.2 A | 12.2 ± 1.5 B | 4.1 ± 0.3 B |

| India-charcoal trema | 904 ± 15 A | 4.3 ± 0.2 A | 9.0 ± 1.7 BC | 4.5 ± 0.3 B |

| Taiwan red pine | 914 ± 12 A | 4.4 ± 0.2 A | 7.3 ± 1.2 C | 3.6 ± 0.8 B |

| Chinese fir | 915 ± 21 A | 4.3 ± 0.1 A | 15.4 ± 2.1 A | 6.8 ± 0.8 A |

| Lignocellulosic Materials | Friedman | F-W-O | Modified C-R | |||

|---|---|---|---|---|---|---|

| Ea (kJ/mol) | R2 | Ea (kJ/mol) | R2 | Ea (kJ/mol) | R2 | |

| Makino bamboo | 175 | 0.9890 | 168 | 0.9895 | 158 | 0.9870 |

| India-charcoal trema | 190 | 0.9984 | 194 | 0.9958 | 185 | 0.9949 |

| Taiwan red pine | 161 | 0.9941 | 156 | 0.9836 | 146 | 0.9794 |

| Chinese fir | 199 | 0.9955 | 202 | 0.9931 | 194 | 0.9917 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, K.-C.; Yeh, H.; Yang, T.-C.; Wu, T.-L.; Xu, J.-W.; Wu, J.-H. Characterization of Wood-Plastic Composites Made with Different Lignocellulosic Materials that Vary in Their Morphology, Chemical Composition and Thermal Stability. Polymers 2017, 9, 726. https://doi.org/10.3390/polym9120726

Hung K-C, Yeh H, Yang T-C, Wu T-L, Xu J-W, Wu J-H. Characterization of Wood-Plastic Composites Made with Different Lignocellulosic Materials that Vary in Their Morphology, Chemical Composition and Thermal Stability. Polymers. 2017; 9(12):726. https://doi.org/10.3390/polym9120726

Chicago/Turabian StyleHung, Ke-Chang, Heng Yeh, Teng-Chun Yang, Tung-Lin Wu, Jin-Wei Xu, and Jyh-Horng Wu. 2017. "Characterization of Wood-Plastic Composites Made with Different Lignocellulosic Materials that Vary in Their Morphology, Chemical Composition and Thermal Stability" Polymers 9, no. 12: 726. https://doi.org/10.3390/polym9120726

APA StyleHung, K.-C., Yeh, H., Yang, T.-C., Wu, T.-L., Xu, J.-W., & Wu, J.-H. (2017). Characterization of Wood-Plastic Composites Made with Different Lignocellulosic Materials that Vary in Their Morphology, Chemical Composition and Thermal Stability. Polymers, 9(12), 726. https://doi.org/10.3390/polym9120726