Recent Advances in the Fabrication of Membranes Containing “Ion Pairs” for Nanofiltration Processes

Abstract

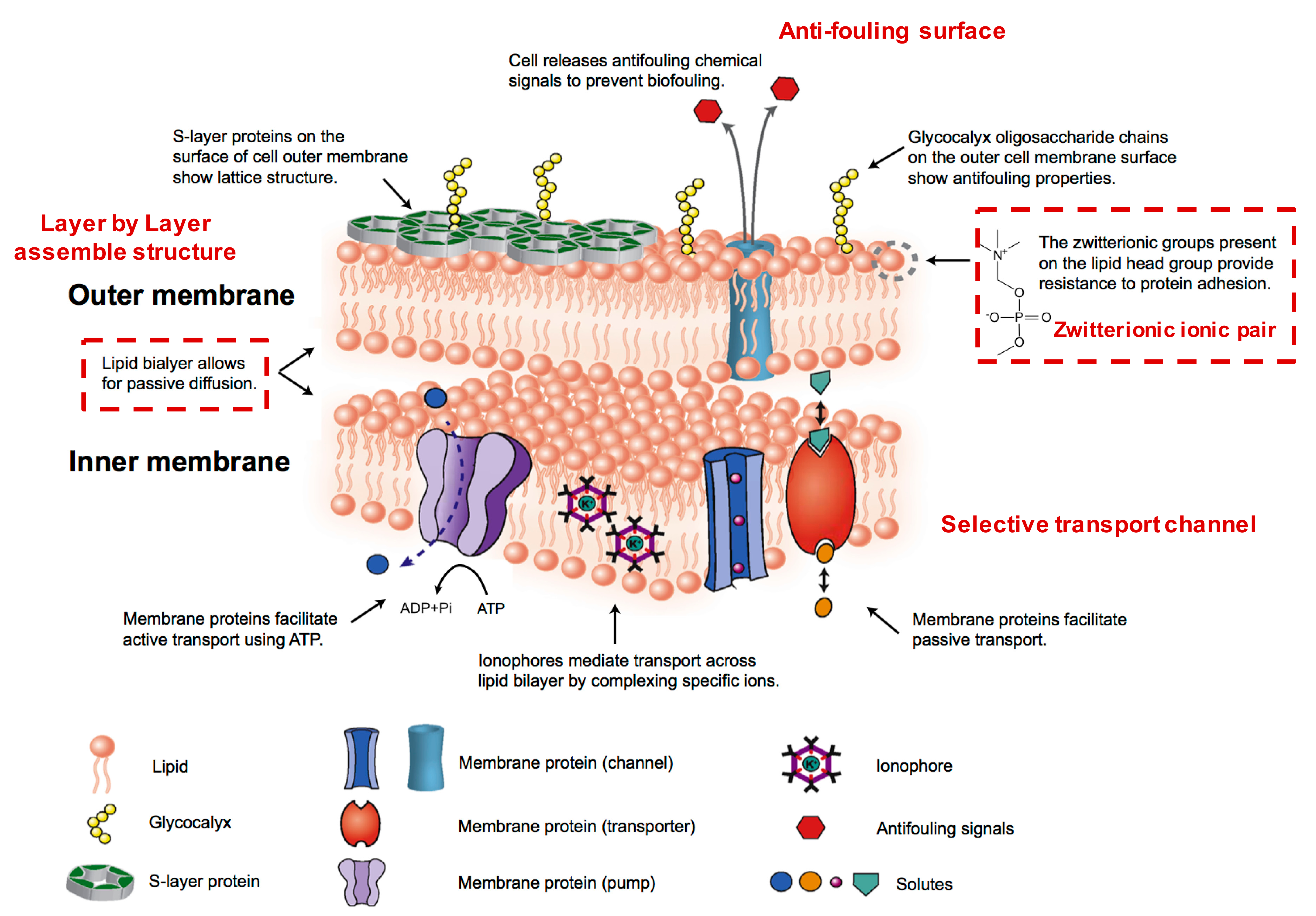

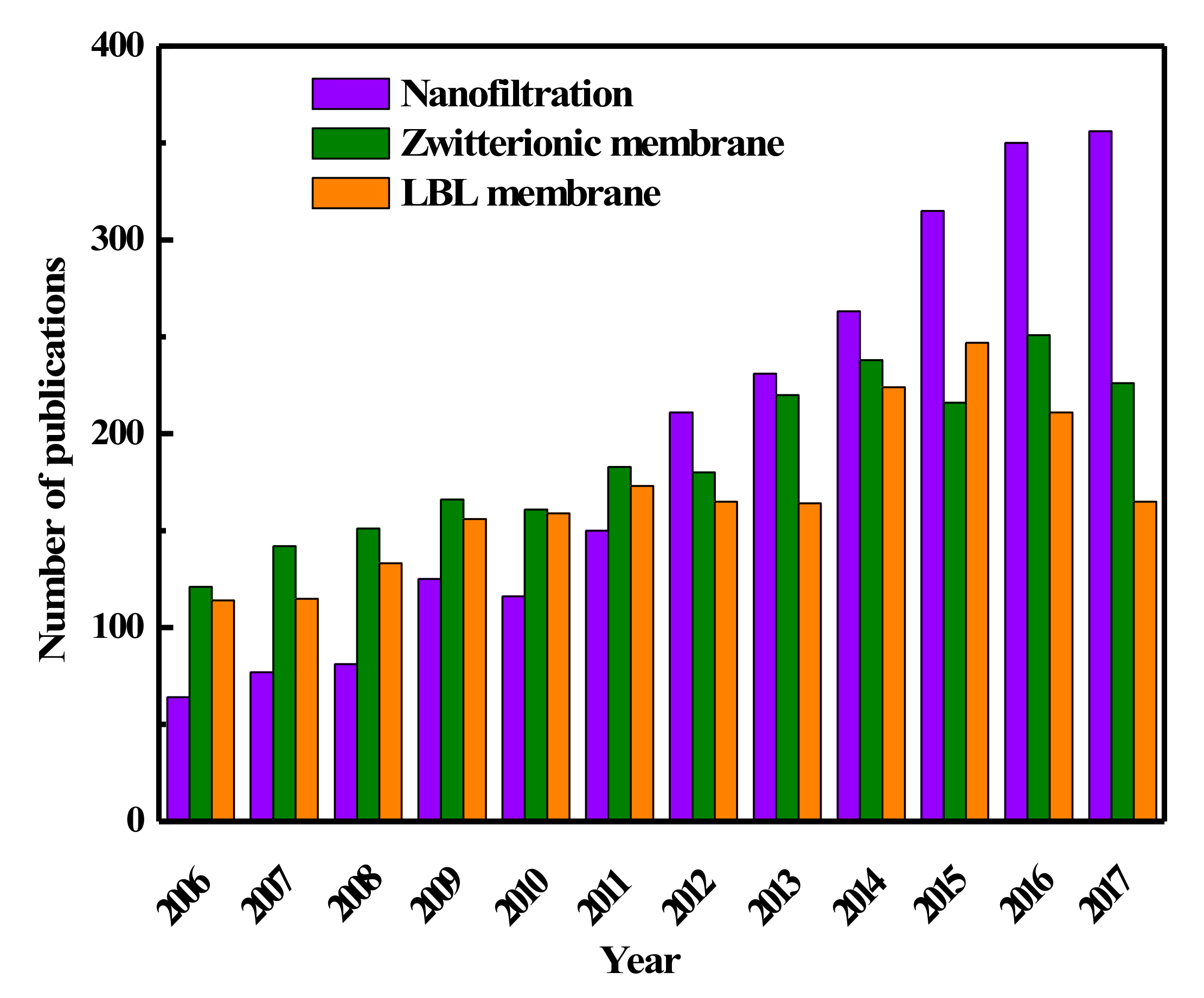

:1. Introduction

2. Influence of “Ion Pairs” Characteristic of Nanofiltration Performance

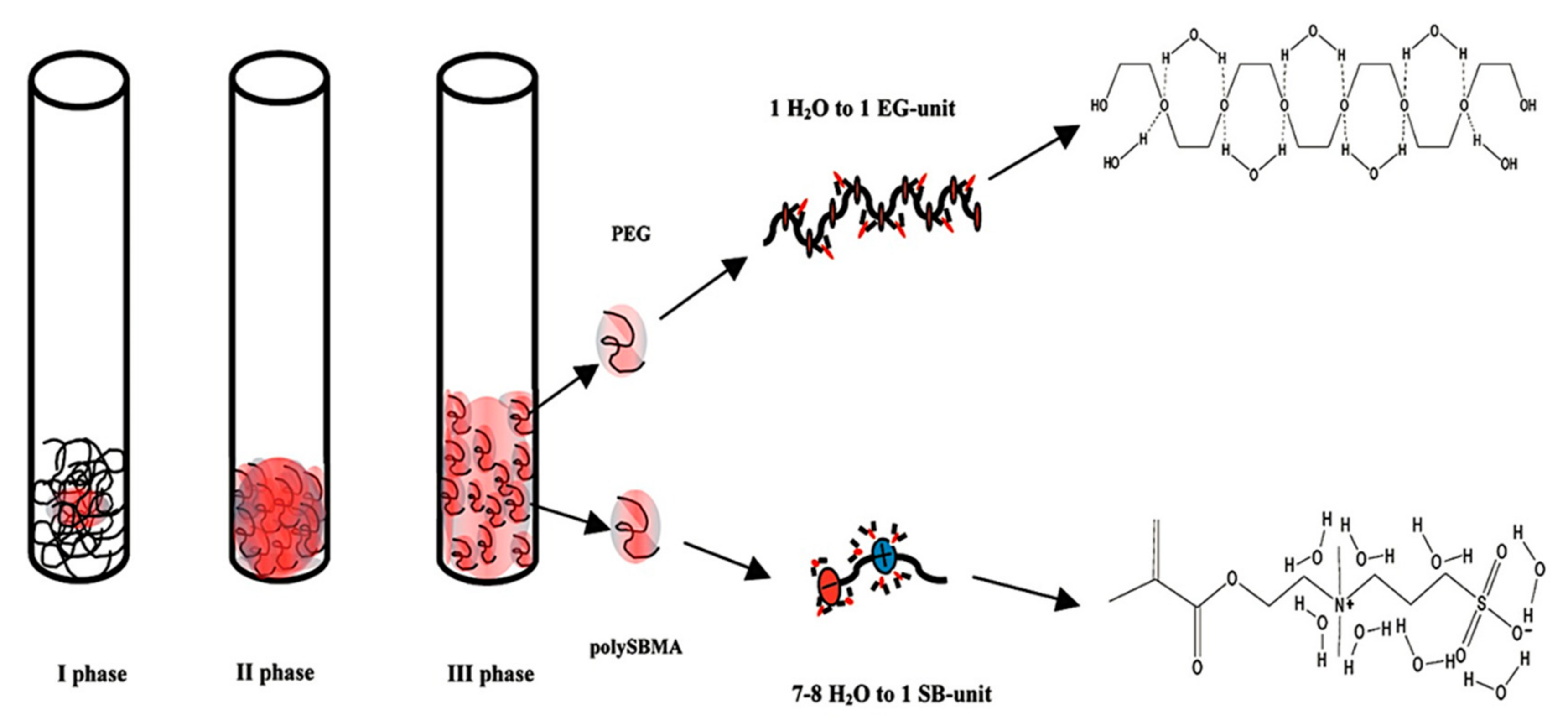

2.1. Super-Hydrophilicity of “Ion Pairs” Affects Membrane Permeation

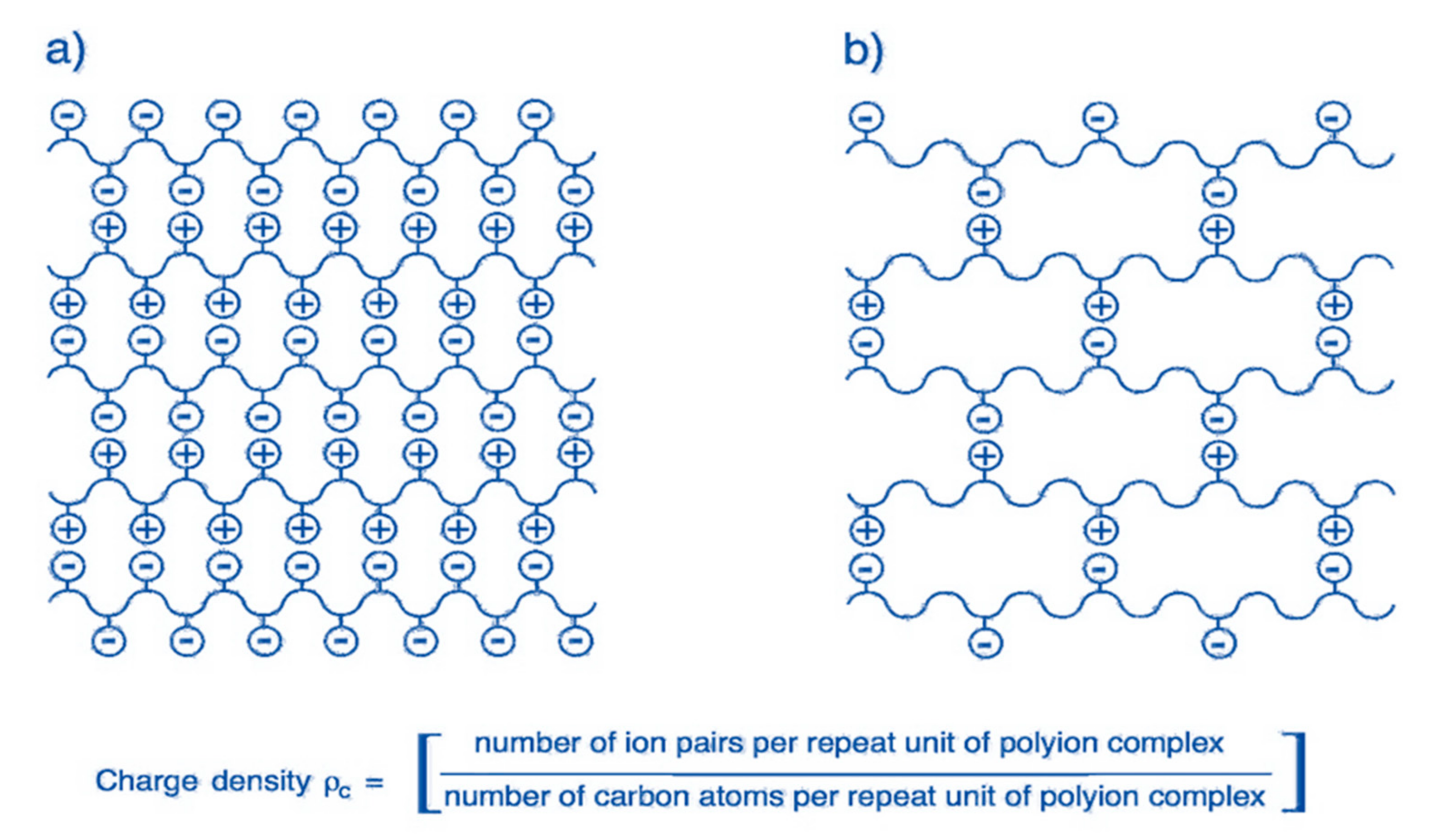

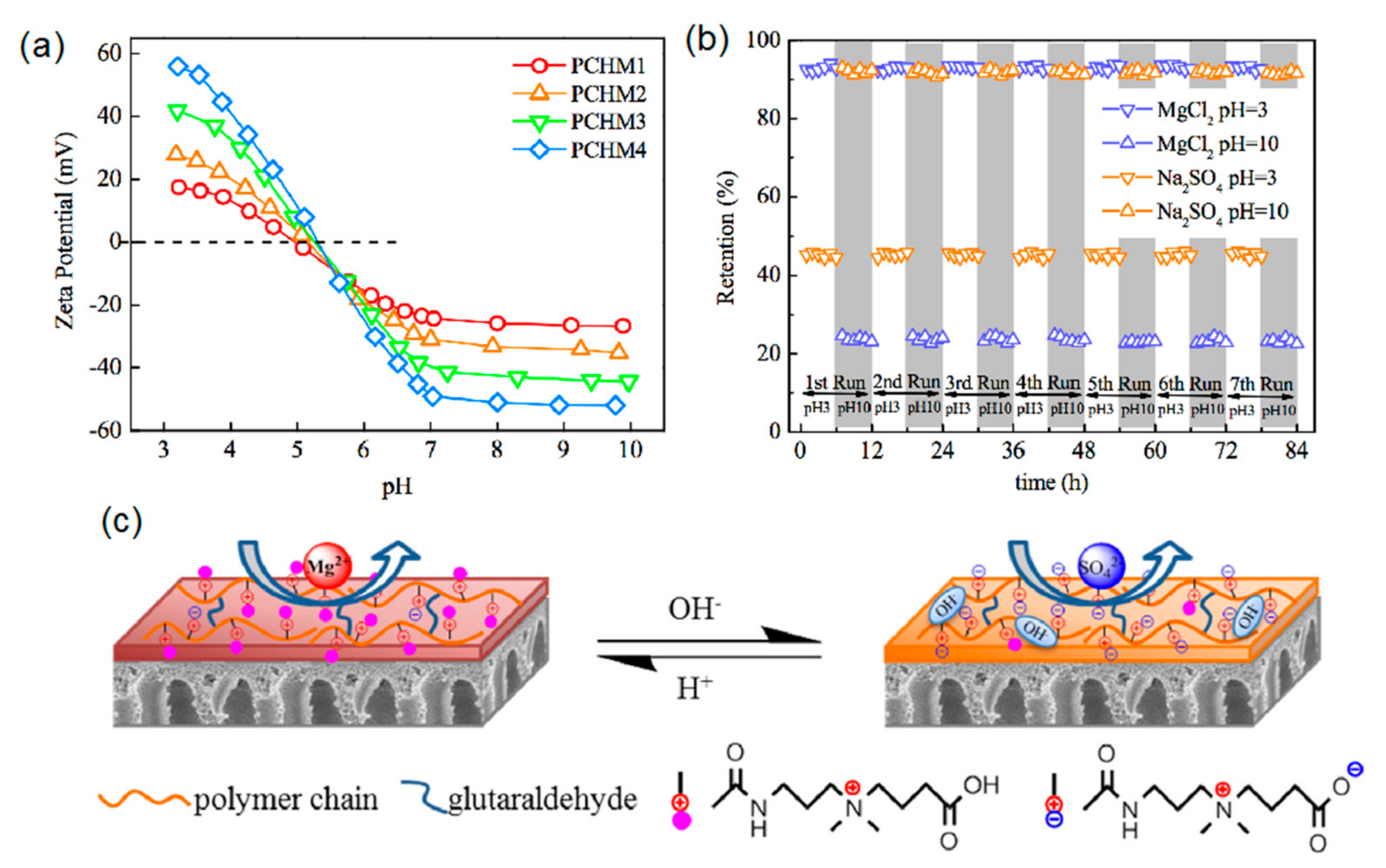

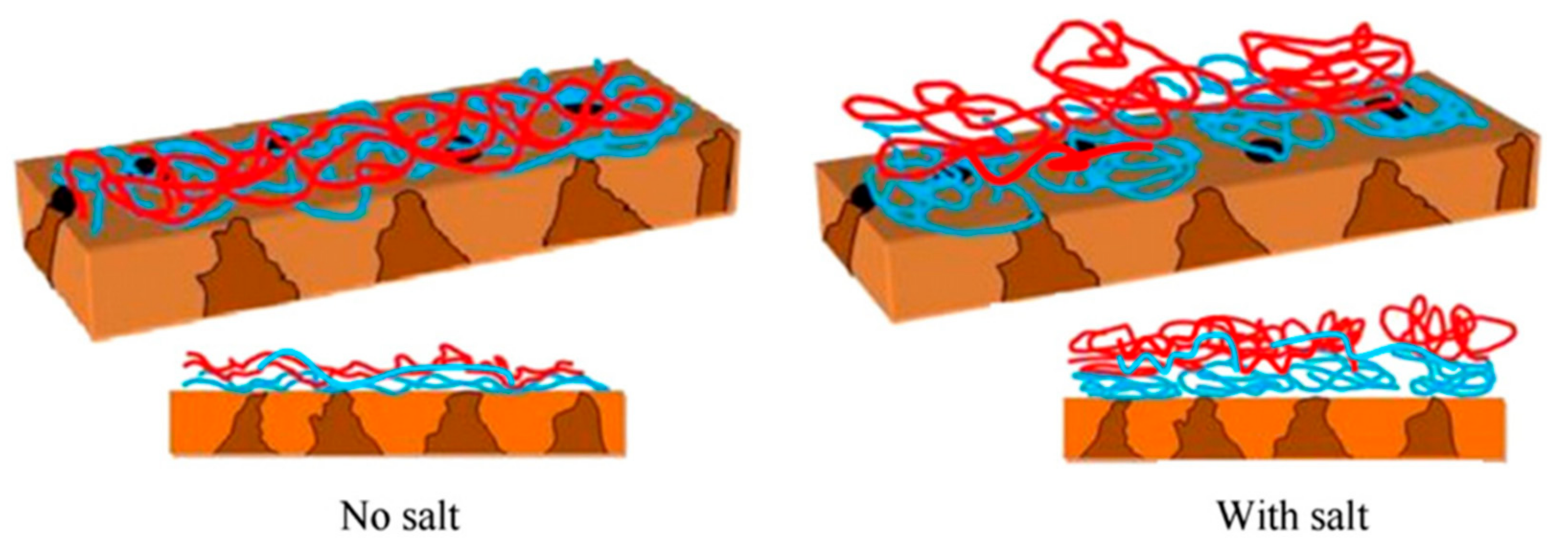

2.2. Controllable Charge Character of “Ion Pairs” Affects Membrane Separation

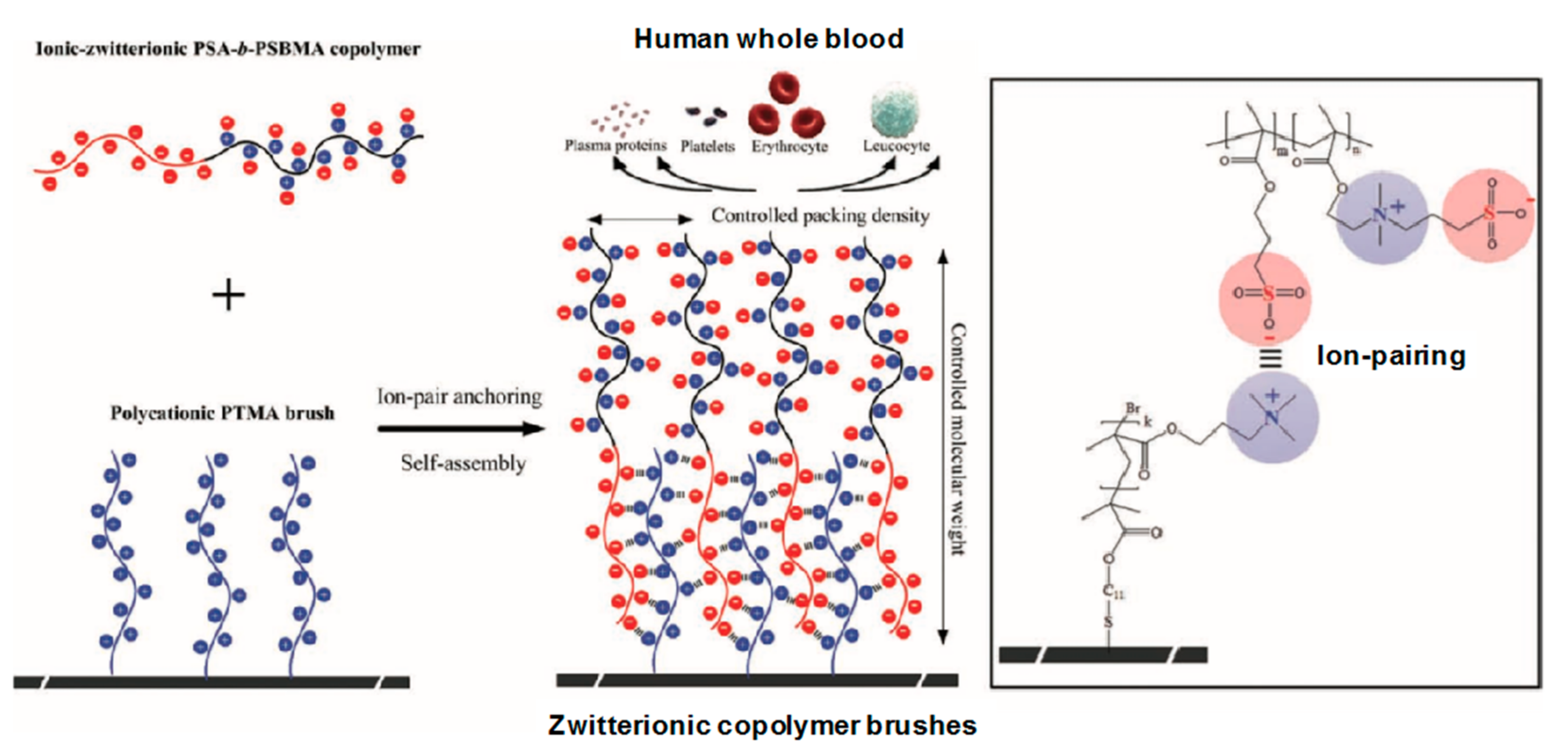

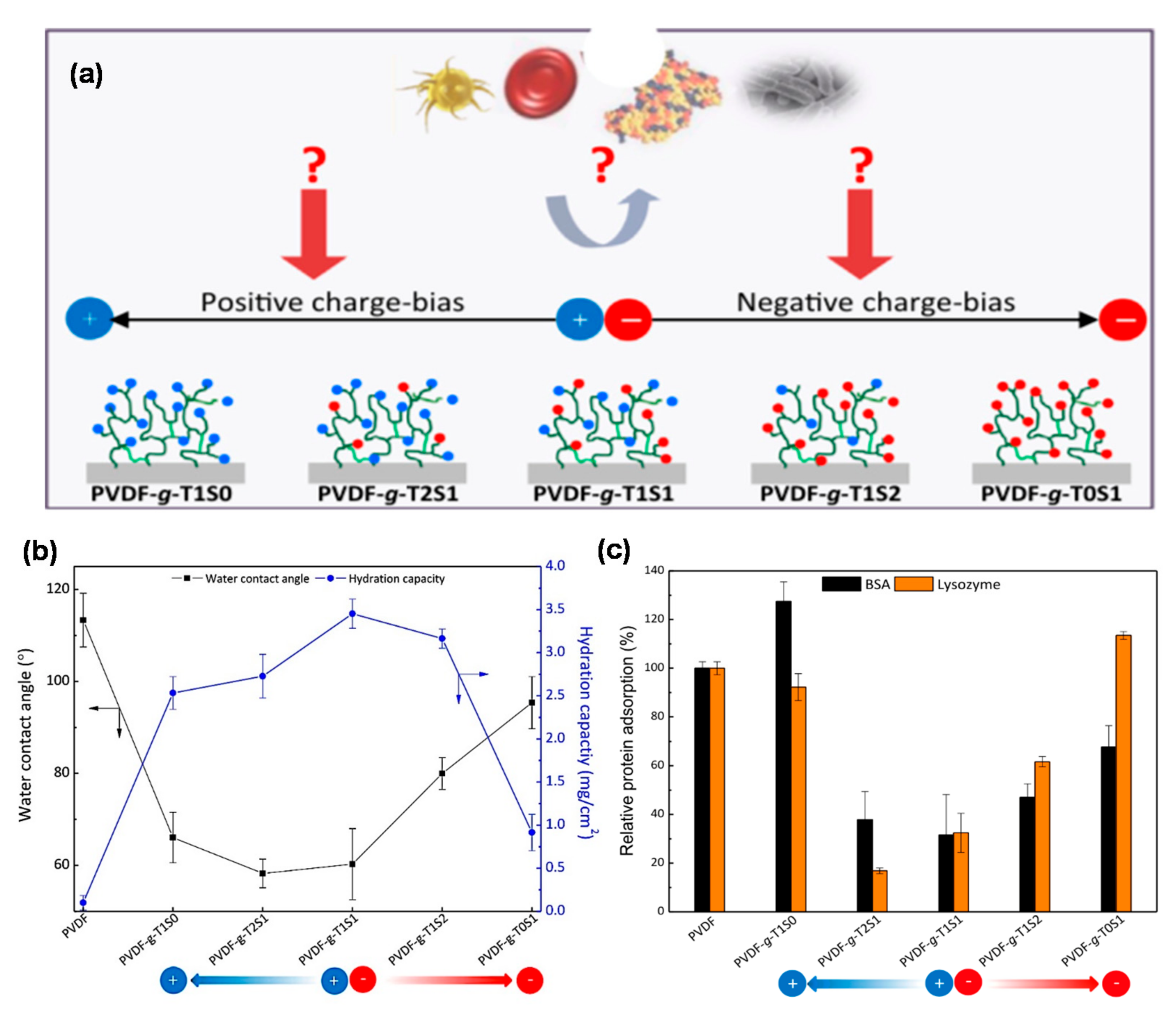

2.3. Fouling Resistance of “Ion Pairs” Affects Membrane Antifouling Performance

3. Fabrication of Nanofiltration Membranes Containing Ion Pairs

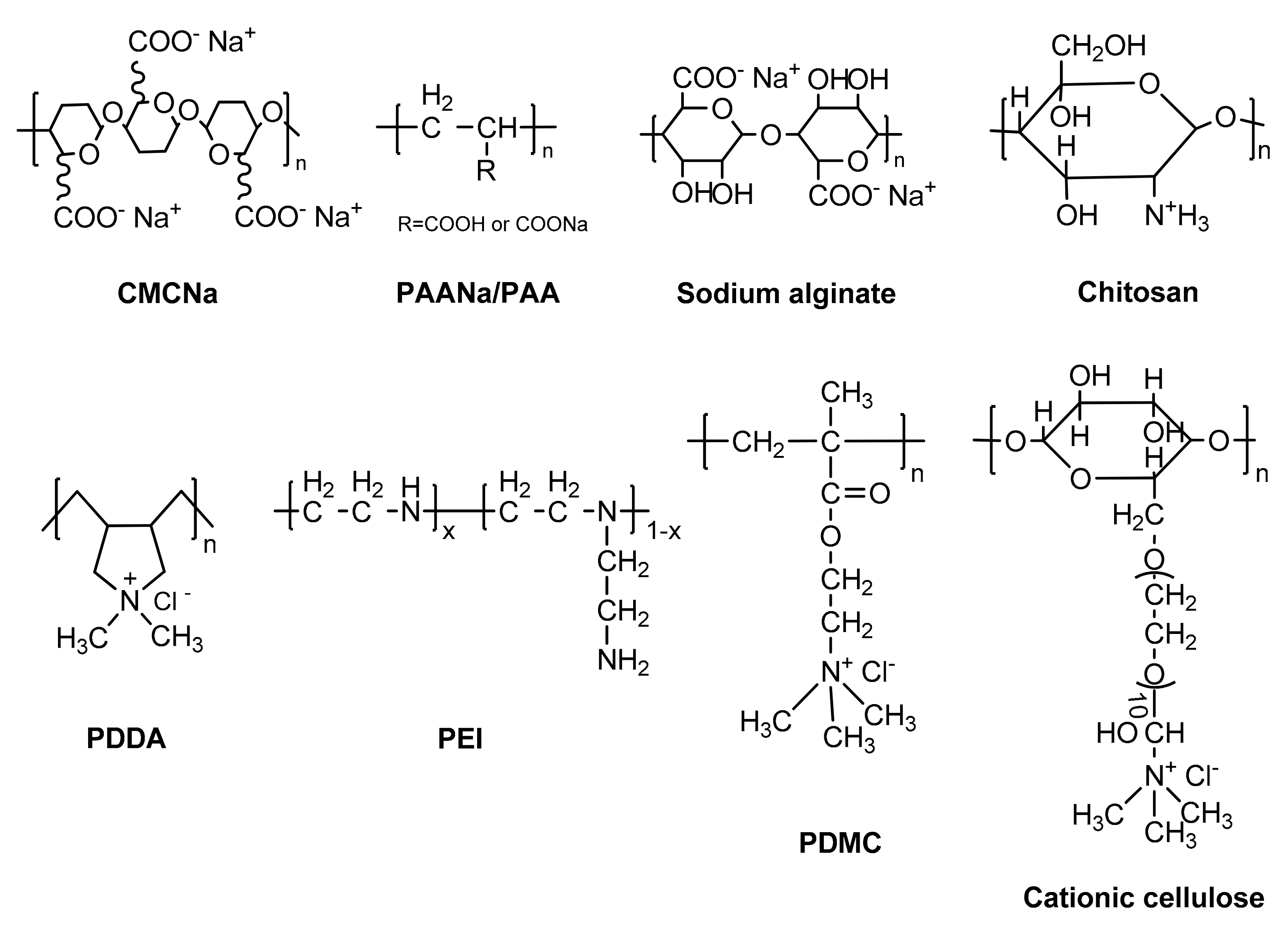

3.1. Nanofiltration Membranes Prepared with Oppositely Charged Polyelectrolytes

3.1.1. Multilayer Polyelectrolyte Membranes

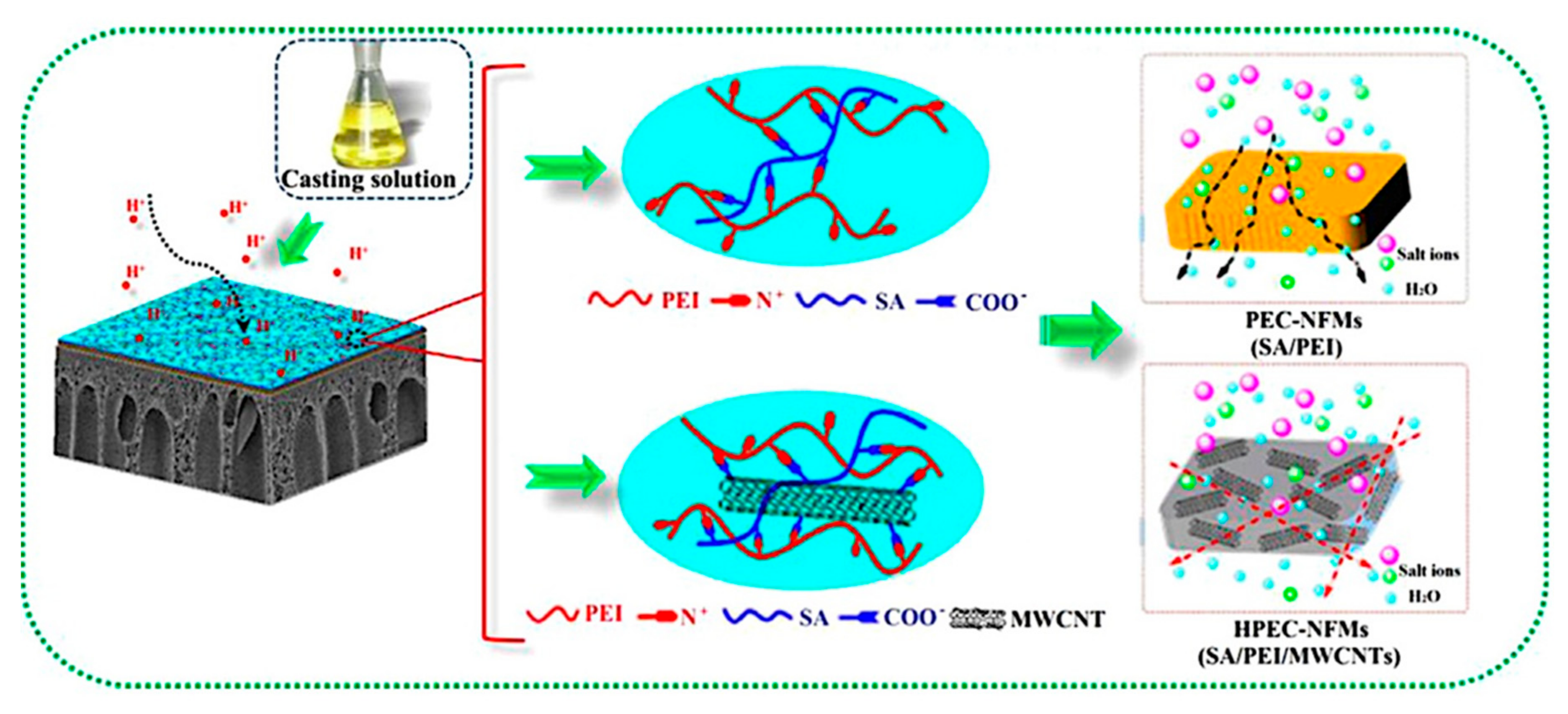

3.1.2. Homogeneous Polyelectrolyte Complex Membranes

3.2. Nanofiltration Membranes Prepared with Zwitterionic Materials

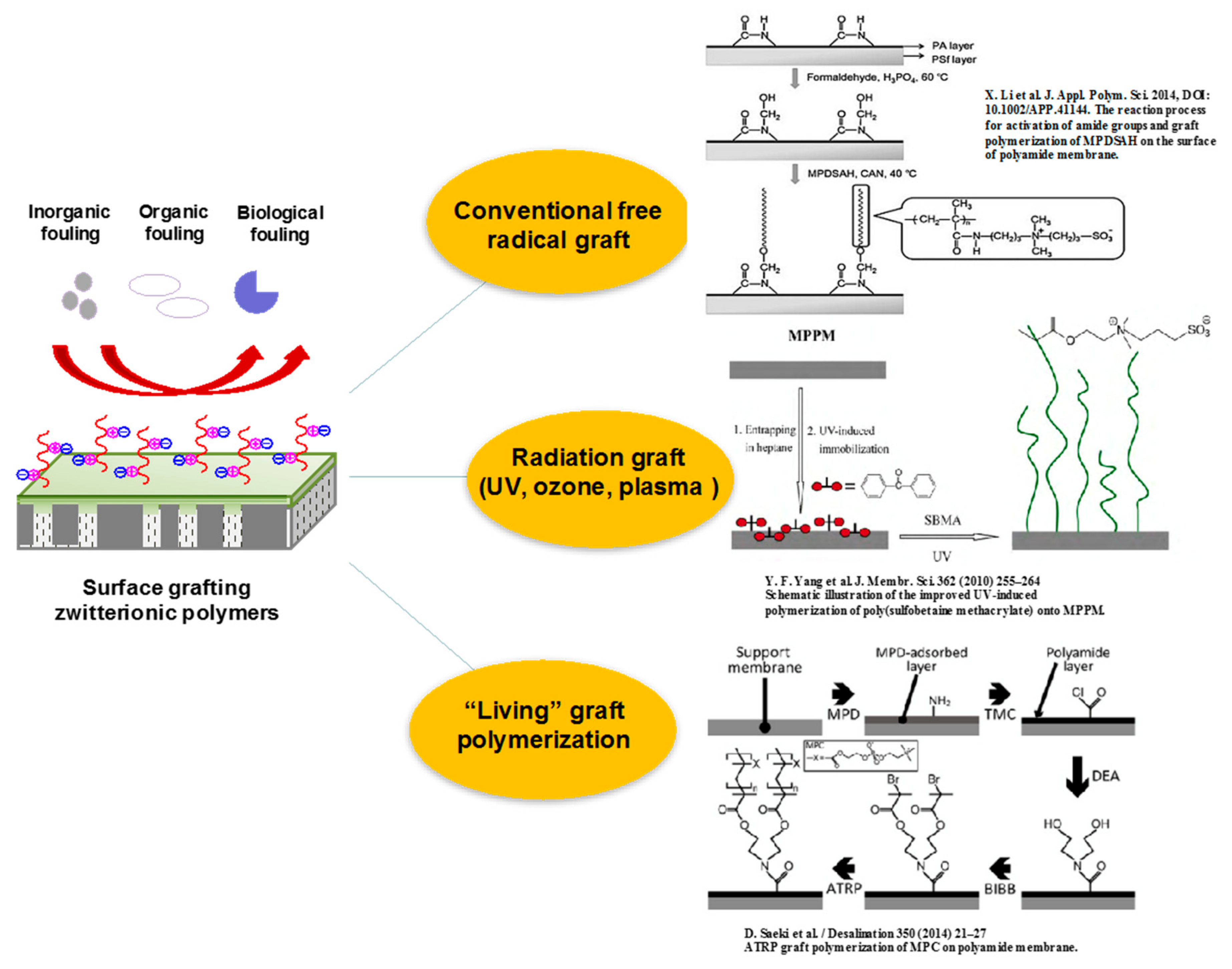

3.2.1. Surface Grafting Zwitterionic Polymer Membranes

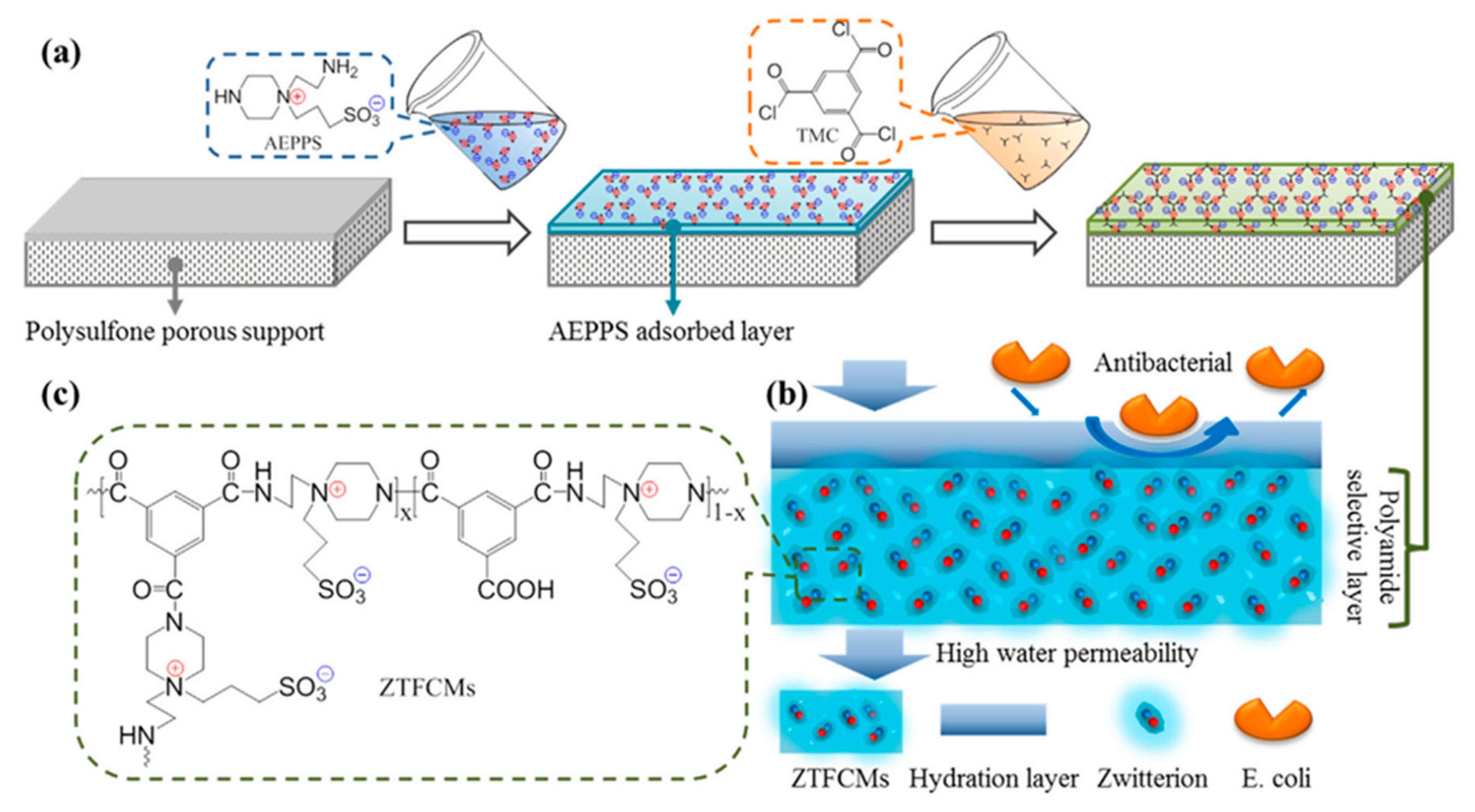

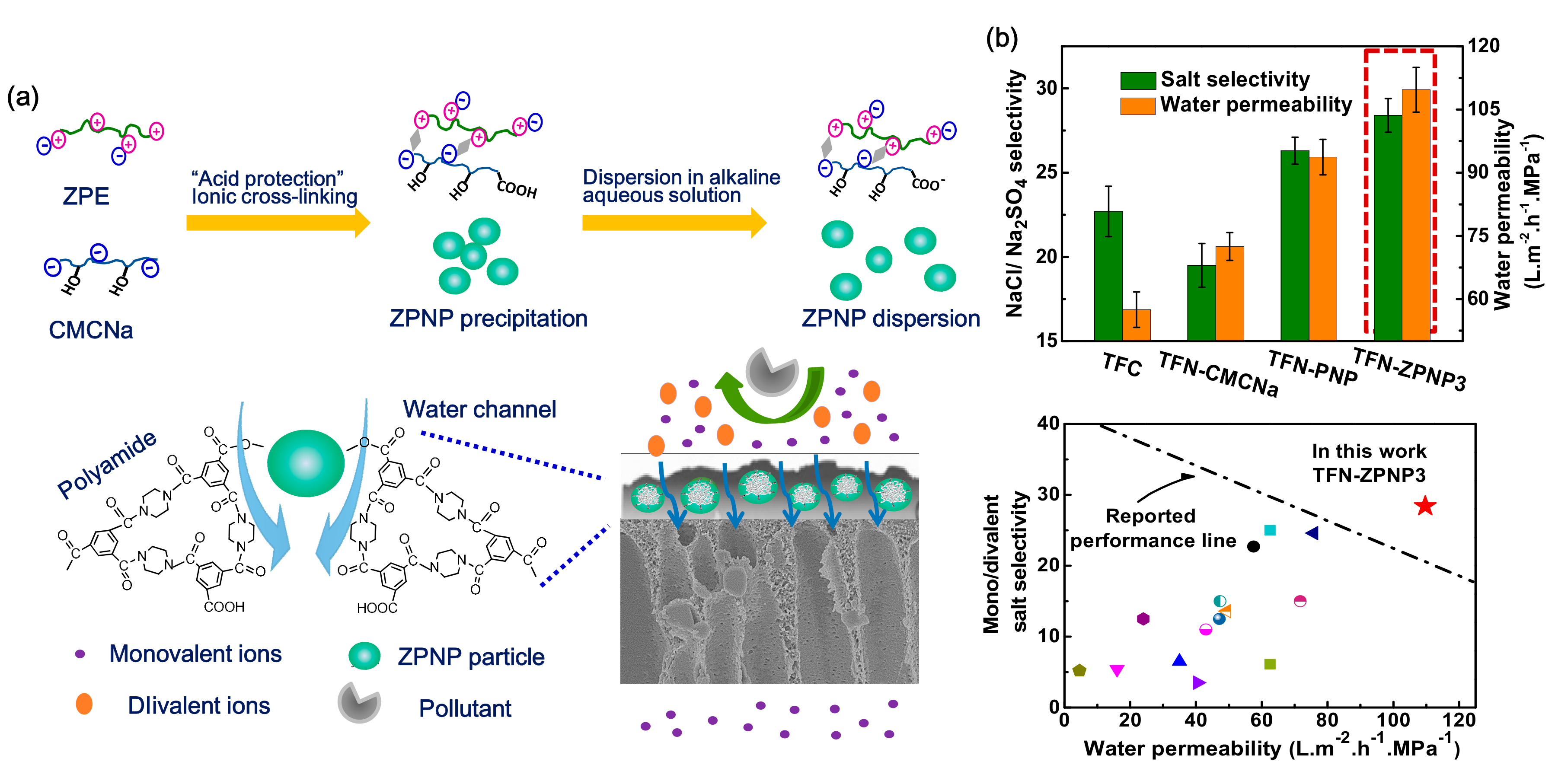

3.2.2. Interfacial Polymerization Zwitterionic Membranes

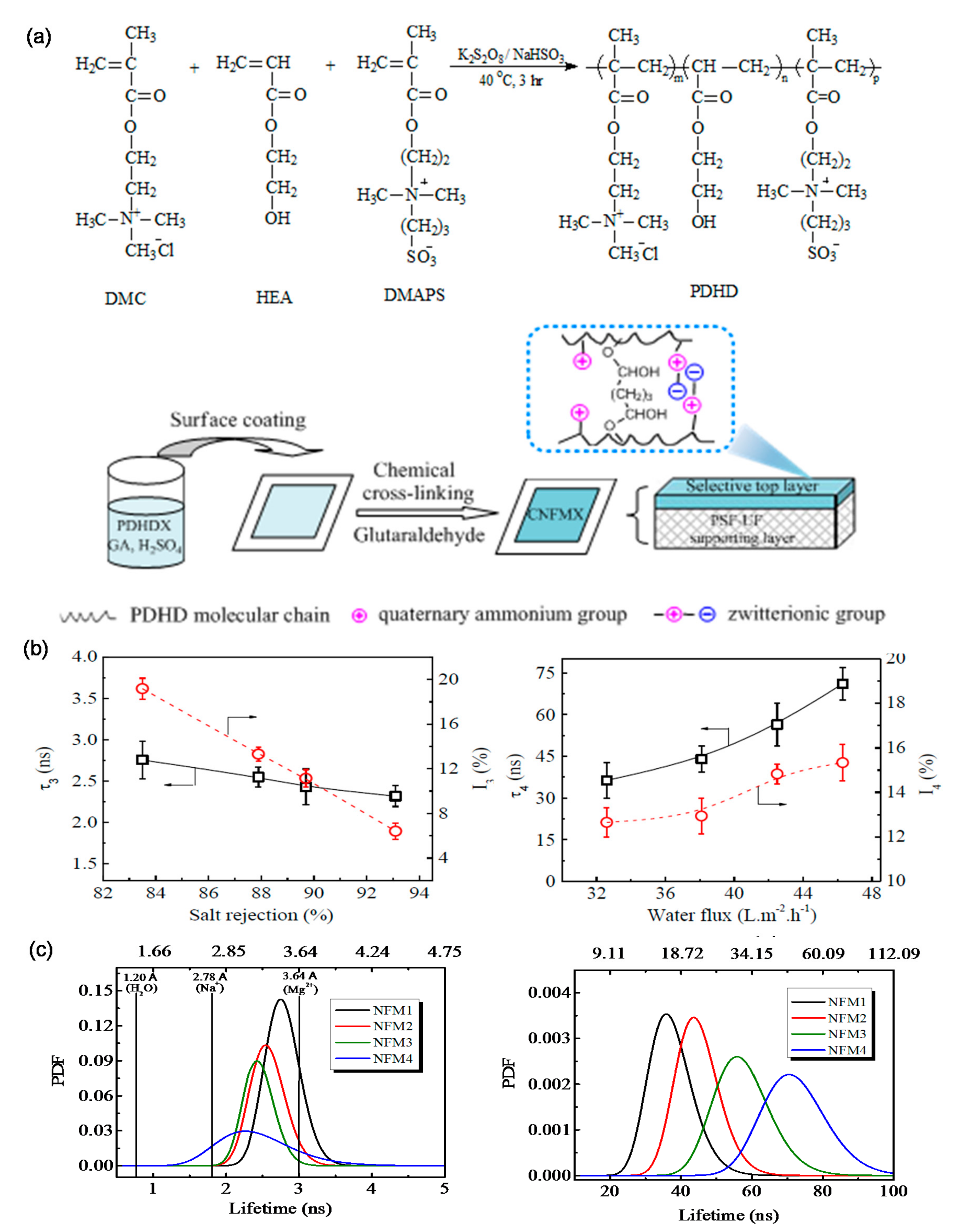

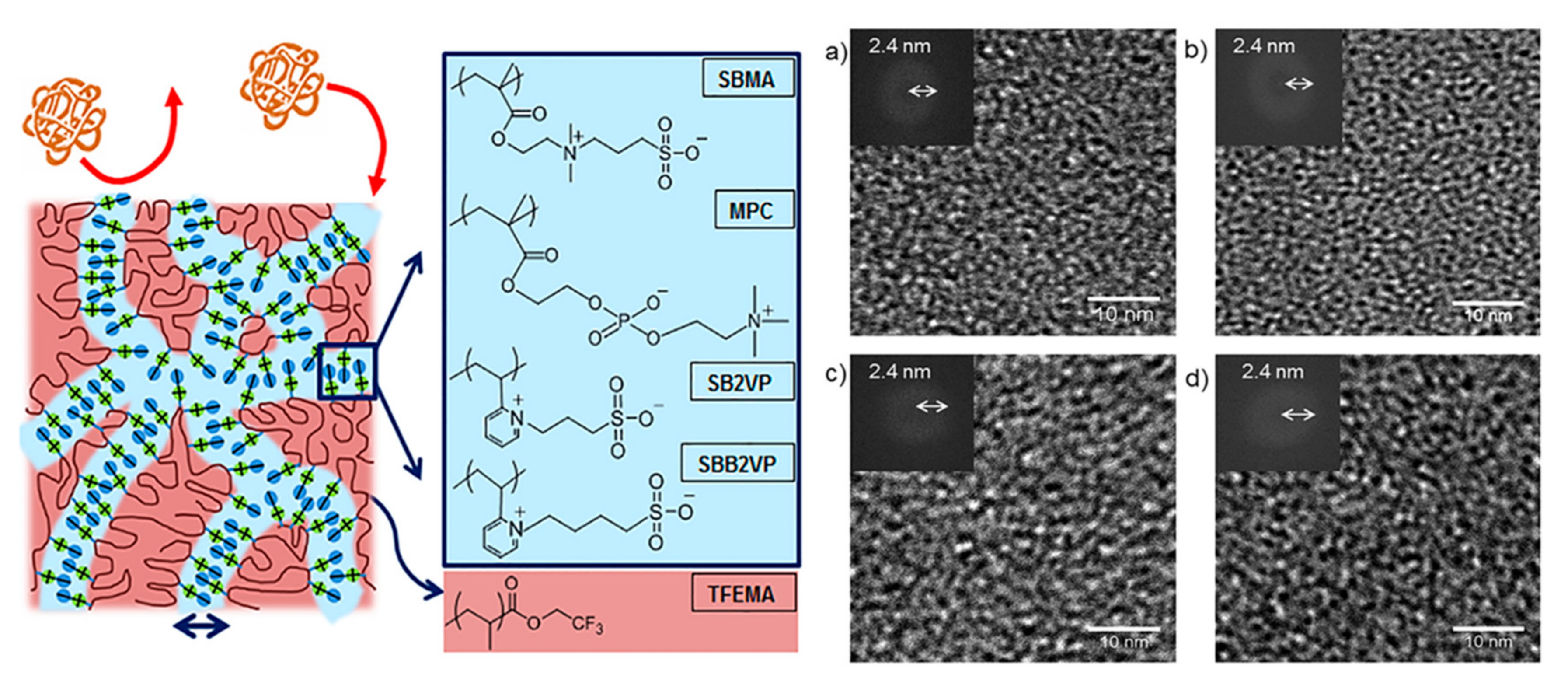

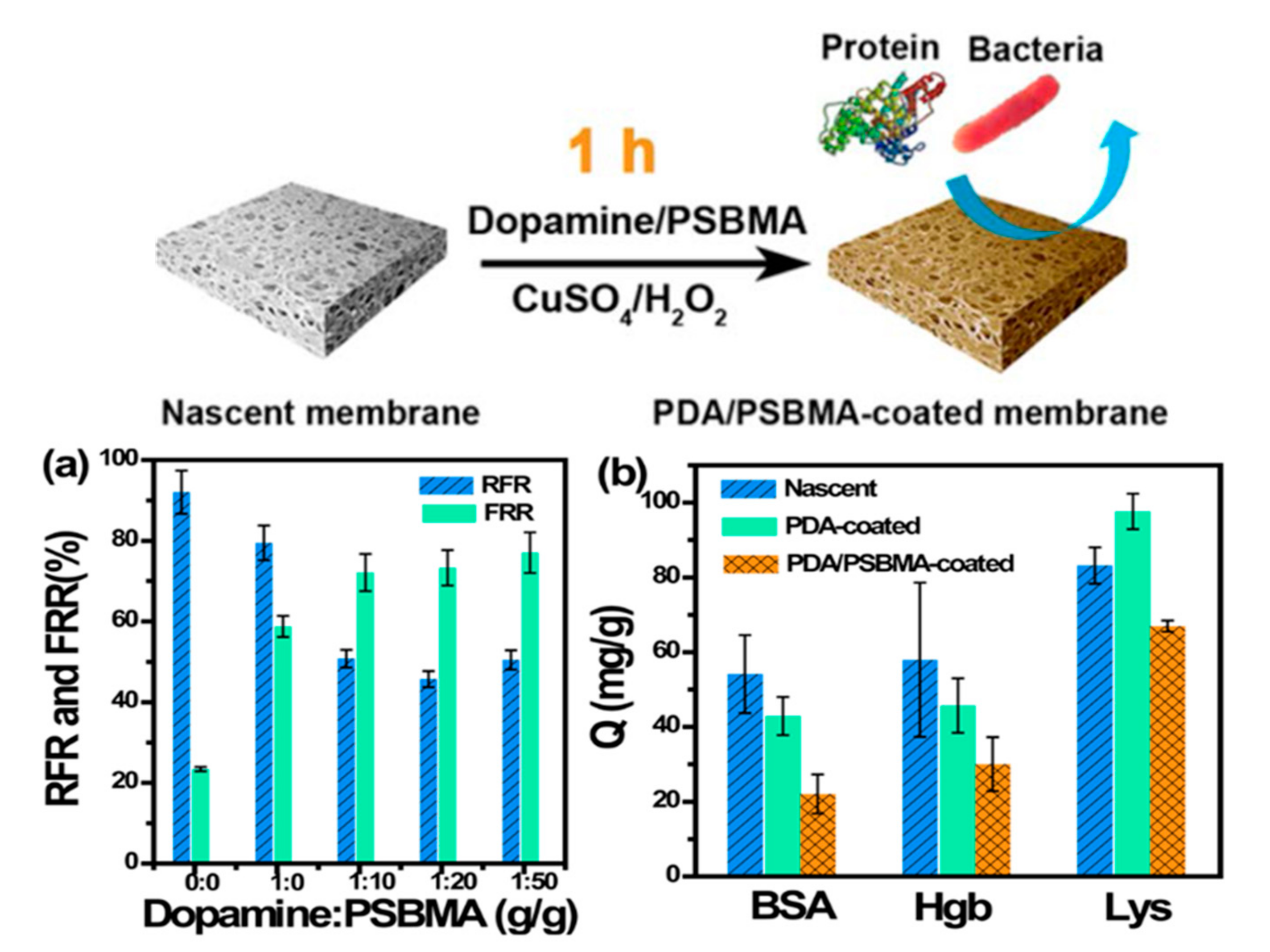

3.2.3. Surface Coating Zwitterionic Polymer Membranes

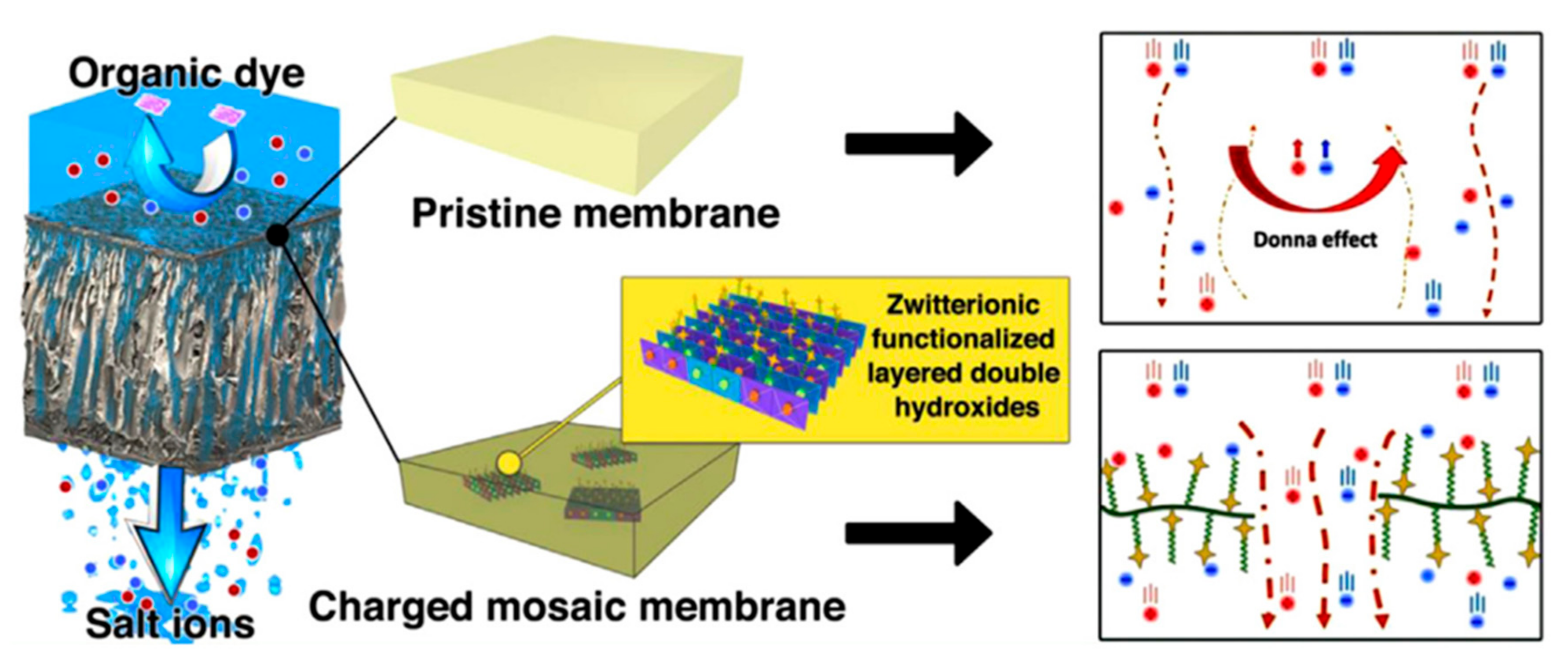

3.3. Charged Mosaic Membranes Containing “Ion Pairs”

4. Conclusions and Perspectives

Acknowledgments

Conflicts of Interest

References

- Montgomery, M.A.; Elimelech, M. Water and sanitation in developing countries: Including health in the equation. Environ. Sci. Technol. 2007, 41, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Shannon, M.A.; Bohn, P.W.; Elimelech, M.; Georgiadis, J.G.; Marinas, B.J.; Mayes, A.M. Science and technology for water purification in the coming decades. Nature 2008, 452, 301–310. [Google Scholar] [CrossRef] [PubMed]

- Elimelech, M.; Phillip, W.A. The future of seawater desalination: Energy, technology, and the environment. Science 2011, 333, 712–717. [Google Scholar] [CrossRef] [PubMed]

- Drioli, E.; Giorno, L. Membrane Operation in Molecular Separations; Elsevier (Singapore) Pte Ltd.,: Singapore, 2012. [Google Scholar]

- Razali, M.; Kim, J.F.; Attfield, M.; Budd, P.M.; Drioli, E.; Lee, Y.M.; Szekely, G. Sustainable wastewater treatment and recycling in membrane manufacturing. Green Chem. 2015, 17, 5196–5205. [Google Scholar] [CrossRef]

- Baker, R.W. Membrane Technology and Applications, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Petersen, R.J. Composite reverse-osmosis and nanofiltration membranes. J. Membr. Sci. 1993, 83, 81–150. [Google Scholar] [CrossRef]

- Jhaveri, J.H.; Jhaveri, Z.V.P.; Murthy, V. A comprehensive review on anti-fouling nanocomposite membranes for pressure driven membrane separation processes. Desalination 2016, 379, 137–154. [Google Scholar] [CrossRef]

- Vandezande, P.; Gevers, L.E.M.; Vankelecom, I.F.J. Solvent resistant nanofiltration: Separating on a molecular level. Chem. Soc. Rev. 2008, 37, 365–405. [Google Scholar] [CrossRef] [PubMed]

- Kowalczyk, S.W.; Blosser, T.R.; Dekker, C. Biomimetic nanopores: Learning from and about nature. Trends Biotechnol. 2011, 29, 607–614. [Google Scholar] [CrossRef] [PubMed]

- Zwaal, R.F.; Schroit, A.J. Pathophysiologic implications of membrane phospholipid asymmetry in blood cells. Blood 1997, 89, 1121–1132. [Google Scholar] [PubMed]

- Shen, Y.X.; Saboe, P.O.; Sines, I.T.; Erbakan, M.; Kumar, M. Biomimetic membranes: A review. J. Membr. Sci. 2014, 454, 359–381. [Google Scholar] [CrossRef]

- Sui, H.; Han, B.G.; Lee, J.K.; Walian, P.; Jap, B.K. Structural basis of water-specific transport through the AQP1 water channel. Nature 2001, 414, 872–878. [Google Scholar] [CrossRef] [PubMed]

- Kozono, D.; Yasui, M.; King, L.S.; Agre, P. Aquaporin water channels: Atomic structure and molecular dynamics meet clinical medicine. J. Clin. Investig. 2002, 109, 1395–1399. [Google Scholar] [CrossRef] [PubMed]

- Dobrynin, A.V.; Rubinstein, M. Theory of polyelectrolytes in solutions and at surfaces. Prog. Polym. Sci. 2005, 30, 1049–1118. [Google Scholar] [CrossRef]

- Xu, G.R.; Wang, S.H.; Zhao, H.L.; Wu, S.B.; Xu, J.M.; Li, L.; Liu, X.Y. Layer-by-layer (LBL) assembly technology as promising strategy for tailoring pressure-driven desalination membranes. J. Membr. Sci. 2015, 493, 428–443. [Google Scholar] [CrossRef]

- Zhao, Q.; An, Q.F.; Ji, Y.L.; Qian, J.W.; Gao, C.J. Polyelectrolyte complex membranes for pervaporation, nanofiltration and fuel cell applications. J. Membr. Sci. 2011, 379, 19–45. [Google Scholar] [CrossRef]

- Lowe, A.B.; McCormick, C.L. Synthesis and solution properties of zwitterionic polymers. Chem. Rev. 2002, 102, 4177–4189. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.Y.; Cao, Z.Q. Ultralow-fouling, functionalizable, and hydrolyzable zwitterionic materials and their derivatives for biological applications. Adv. Mater. 2010, 22, 920–932. [Google Scholar] [CrossRef] [PubMed]

- Xuan, F.Q.; Liu, J.S. Preparation, characterization and application of zwitterionic polymers and membranes: Current developments and perspective. Polym. Int. 2009, 58, 1350–1361. [Google Scholar] [CrossRef]

- Ostuni, E.; Chapman, R.G.; Holmlin, R.E.; Takayama, S.; Whitesides, G.M. A survey of structure-property relationships of surfaces that resist the adsorption of protein. Langmuir 2011, 17, 5605–5620. [Google Scholar] [CrossRef]

- Chen, S.F.; Li, L.Y.; Zhao, C.; Zheng, J. Surface hydration: Principles and applications toward low-fouling/nonfouling biomaterials. Polymer 2010, 51, 5283–5293. [Google Scholar] [CrossRef]

- Weinstein, J.N.; Caplan, S.R. Charge-mosaic membranes: Enhanced permeability and negative osmosis with a symmetrical salt. Science 1968, 161, 70–72. [Google Scholar] [CrossRef] [PubMed]

- Fujimoto, T.; Ohkoshi, K.; Miyaki, Y.; Nagasawa, M. A new charge-mosaic membrane from a multiblock copolymer. Science 1984, 224, 74–76. [Google Scholar] [CrossRef] [PubMed]

- Linder, C.; Kedem, O. Asymmetric ion exchange mosaic membranes with unique selectivity. J. Membr. Sci. 2001, 181, 39–56. [Google Scholar] [CrossRef]

- Park, H.B.; Kamcev, J.; Robeson, L.M.; Elimelech, M.; Freeman, B.D. Maximizing the right stuff: The trade-off between membrane permeability and selectivity. Science 2017, 356, 1137–1148. [Google Scholar] [CrossRef] [PubMed]

- Stevens, D.M.; Shu, J.Y.; Reichert, M.; Roy, A. Next-generation nanoporous materials: Progress and prospects for reverse osmosis and nanofiltration. Ind. Eng. Chem. Res. 2017, 56, 10526–10551. [Google Scholar] [CrossRef]

- Sin, M.C.; Chen, S.H.; Chang, Y. Hemocompatibility of zwitterionic interfaces and membranes. Polym. J. 2014, 46, 436–443. [Google Scholar] [CrossRef]

- Wu, J.; Lin, W.F.; Wang, Z.; Chen, S.F. Investigation of the hydration of nonfouling material poly(sulfobetaine methacrylate) by low-field nuclear magnetic resonance. Langmuir 2012, 28, 7436–7441. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, M.; Hayashi, T.; Morita, S. The roles of water molecules at the biointerface of medical polymers. Polym. J. 2013, 45, 701–710. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Wee, K.H.; Bai, R. Highly hydrophilic and low-protein-fouling polypropylene membrane prepared by surface modification with sulfobetaine-based zwitterionic polymer through a combined surface polymerization method. J. Membr. Sci. 2010, 362, 326–333. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Wang, J.X.; Wang, S.C. Improving the water flux and bio-fouling resistance of reverse osmosis (RO) membrane through surface modification by zwitterionic polymer. J. Membr. Sci. 2015, 493, 188–199. [Google Scholar] [CrossRef]

- An, Q.F.; Sun, W.D.; Zhao, Q.; Ji, Y.L.; Gao, C.J. Study on a novel nanofiltration membrane prepared by interfacial polymerization with zwitterionic amine monomers. J. Membr. Sci. 2013, 431, 171–179. [Google Scholar] [CrossRef]

- Ma, R.; Ji, Y.L.; Weng, X.D.; An, Q.F.; Gao, C.J. High-flux and fouling-resistant reverse osmosis membrane prepared with incorporating zwitterionic amine monomers via interfacial polymerization. Desalination 2016, 381, 100–110. [Google Scholar] [CrossRef]

- Joseph, N.; Ahmadiannamini, P.; Hoogenboom, R.; Vankelecom, I.F.J. Layer-by-layer preparation of polyelectrolyte multilayer membranes for separation. Polym. Chem. 2014, 5, 1817–1831. [Google Scholar] [CrossRef]

- Malaisamy, R.; Bruening, M.L. High-flux nanofiltration membranes prepared by adsorption of multilayer polyelectrolyte membranes on polymeric supports. Langmuir 2005, 21, 10587–10592. [Google Scholar] [CrossRef] [PubMed]

- Li, X.F.; Feyter, S.D.; Chen, D.J.; Aldea, S.; Vandezande, P.; Prez, F.D.; Vankelecom, I.F.J. Solvent-resistant nanofiltration membranes based on multilayered polyelectrolyte complexes. Chem. Mater. 2008, 20, 3876–3883. [Google Scholar] [CrossRef]

- Farhat, T.R.; Schlenoff, J.B. Ion transport and equilibria in polyelectrolyte multilayers. Langmuir 2001, 17, 1184–1192. [Google Scholar] [CrossRef]

- Kim, D.; Tzeng, P.; Barnett, K.J.; Yang, Y.H.; Wilhite, B.A.; Grunlan, J.C. Highly size-selective ionically crosslinked multilayer polymer films for light gas separation. Adv. Mater. 2014, 26, 746–751. [Google Scholar] [CrossRef] [PubMed]

- Jin, W.Q.; Toutianoush, A.; Tieke, B. Use of polyelectrolyte layer-by-layer assemblies as nanofiltration and reverse osmosis membranes. Langmuir 2003, 19, 2550–2553. [Google Scholar] [CrossRef]

- Tieke, B.; Toutianoush, A.; Jin, W.Q. Selective transport of ions and molecules across layer-by-layer assembled membranes of polyelectrolytes, p-sulfonato-calix[n]arenes and prussian blue-type complex salts. Adv. Colloid Interface Sci. 2005, 116, 121–131. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.U.; Miller, M.D.; Bruening, M.L. Removal of dyes, sugars, and amino acids from NaCl solutions using multilayer polyelectrolyte nanofiltration membranes. Ind. Eng. Chem. Res. 2006, 45, 6284–6288. [Google Scholar] [CrossRef]

- Zhang, Z.; Vaisocherova, H.; Cheng, G.; Yang, W.; Xue, H.; Jiang, S.Y. Nonfouling behavior of polycarboxybetaine-grafted surfaces: Structural and environmental effects. Biomacromolecules 2008, 9, 2686–2692. [Google Scholar] [CrossRef] [PubMed]

- Keating, J.J.; Imbrogno, J.; Belfort, G. Polymer brushes for membrane separations: A review. ACS Appl. Mater. Interfaces 2016, 8, 28383–28399. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.H.; Wee, K.H.; Bai, R. A novel electrolyte-responsive membrane with tunable permeation selectivity for protein purification. ACS Appl. Mater. Interfaces 2010, 2, 203–211. [Google Scholar] [CrossRef] [PubMed]

- Niu, A.Z.; Liaw, D.J.; Sang, H.C.; Wu, C. Light-scattering study of a zwitterionic polycarboxybetaine in aqueous solution. Macromolecules 2000, 33, 3492–3494. [Google Scholar] [CrossRef]

- Weng, X.D.; Bao, X.J.; Jiang, H.D.; Chen, L.; Ji, Y.L.; An, Q.F.; Gao, C.J. pH-responsive nanofiltration membranes containing carboxybetaine with tunable ion selectivity for charge-based separations. J. Membr. Sci. 2016, 520, 294–302. [Google Scholar] [CrossRef]

- Ilyas, S.; Abtahi, S.M.; Akkilic, N.; Roesink, H.D.W.; Vos, W.M. Weak polyelectrolyte multilayers as tunable separation layers for micro-pollutant removal by hollow fiber nanofiltration membranes. J. Membr. Sci. 2017, 537, 220–228. [Google Scholar] [CrossRef]

- Dai, J.H.; Jensen, A.W.; Mohanty, D.K.; Erndt, J.; Bruening, M.L. Controlling the permeability of multilayered polyelectrolyte films through derivatization, cross-linking, and hydrolysis. Langmuir 2001, 17, 931–937. [Google Scholar] [CrossRef]

- Adusumilli, M.; Bruening, M.L. Variation of ion-exchange capacity, ζ potential, and ion-transport selectivities with the number of layers in a multilayer polyelectrolyte film. Langmuir 2009, 25, 7478–7485. [Google Scholar] [CrossRef] [PubMed]

- Weinstein, J.N.; Bunow, B.J.; Caplan, S.R. Transport properties of charge mosaic membranes. I. Theoretical models. Desalination 1972, 11, 341–377. [Google Scholar] [CrossRef]

- Yamauchi, A.; Fukuda, T. Material transport through charged mosaic membrane. Ann. N. Y. Acad. Sci. 2003, 984, 256–266. [Google Scholar] [CrossRef] [PubMed]

- Higa, M.; Masuda, D.; Kobayashi, E.; Nishimura, M.; Sugio, Y.; Kusudou, T.; Fujiwara, N. Charge mosaic membranes prepared from laminated structures of PVA-based charged layers 1. Preparation and transport properties of charged mosaic membranes. J. Membr. Sci. 2008, 310, 466–473. [Google Scholar] [CrossRef]

- Liu, J.S.; Xu, T.W.; Fu, Y.X. Fundamental studies of novel inorganic-organic charged zwitterionic hybrids. 2. Preparation and characterisations of hybrid charged zwitterionic membranes. J. Membr. Sci. 2005, 252, 165–173. [Google Scholar] [CrossRef]

- Edidin, M. Timeline-lipids on the frontier: A century of cell-membrane bilayers. Nat. Rev. Mol. Cell Biol. 2003, 4, 414–418. [Google Scholar] [CrossRef] [PubMed]

- Singer, S.J.; Nicolson, G.L. The fluid mosaic model of the structure of cell membranes. Science 1972, 175, 720–731. [Google Scholar] [CrossRef] [PubMed]

- Lewis, A.L. Phosphorylcholine-based polymers and their use in the prevention of biofouling. Colloids Surf. B 2000, 18, 261–275. [Google Scholar] [CrossRef]

- Zhao, X.T.; Chen, W.J.; Su, Y.L.; Zhu, W.; Peng, J.M.; Jiang, Z.Y.; Kong, L.; Li, Y.F.; Liu, J.Z. Hierarchically engineered membrane surfaces with superior antifouling and self-cleaning properties. J. Membr. Sci. 2013, 441, 93–101. [Google Scholar] [CrossRef]

- Liu, C.H.; Lee, J.H.; Ma, J.; Elimelech, M. Antifouling thin-film composite membranes by controlled architecture of zwitterionic polymer brush layer. Environ. Sci. Technol. 2017, 51, 2161–2169. [Google Scholar] [CrossRef] [PubMed]

- Kaner, P.; Hu, X.R.; Thomas, S.W.; Asatekin, A. Self-cleaning membranes from comb-shaped copolymers with photoresponsive side groups. ACS Appl. Mater. Interfaces 2017, 9, 13619–13631. [Google Scholar] [CrossRef] [PubMed]

- Wei, Q.; Becherer, T.; Angioletti-Uberti, S.; Dzubiella, J.; Wischke, C.; Neffe, A.T.; Lendlein, A.; Ballauff, M.; Haag, R. Protein interactions with polymer coatings and biomaterials. Angew. Chem. Int. Ed. 2014, 53, 8004–8031. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.J.; Hu, H.Y.; Guo, J.F.; Li, Y.B. Preparation of polymethacrylic acid-grafted HEMA/PVP microspheres and preliminary study on basic protein adsorption. Colloids Surf. B 2010, 77, 206–213. [Google Scholar] [CrossRef] [PubMed]

- Chang, Y.; Shi, Y.J.; Lai, C.J.; Kung, H.H.; Jiang, S.Y. Blood-inert surfaces via ion-pair anchoring of zwitterionic copolymer brushes in human whole blood. Adv. Funct. Mater. 2013, 23, 1100–1110. [Google Scholar] [CrossRef]

- Park, N.; Kwon, B.; Kim, I.S.; Cho, J.W. Biofouling potential of various NF membranes with respect to bacteria and their soluble microbial products (SMP): Characterizations, flux decline, and transport parameters. J. Membr. Sci. 2005, 258, 43–54. [Google Scholar] [CrossRef]

- Bernstein, R.; Belfer, S.; Freger, V. Bacterial attachment to RO membranes surface-modified by concentration-polarization-enhanced graft polymerization. Environ. Sci. Technol. 2011, 45, 5973–5980. [Google Scholar] [CrossRef] [PubMed]

- Hadidi, M.; Zydney, A.L. Fouling behavior of zwitterionic membranes: Impact of electrostatic and hydrophobic interactions. J. Membr. Sci. 2014, 452, 97–103. [Google Scholar] [CrossRef]

- Chen, S.F.; Zheng, J.; Li, L.Y.; Jiang, S.Y. Strong resistance of phosphorylcholine self-assembled monolayers to protein adsorption: Insights into nonfouling properties of zwitterionic materials. J. Am. Chem. Soc. 2005, 127, 14473–14478. [Google Scholar] [CrossRef] [PubMed]

- Venault, A.; Wei, T.C.; Shih, H.L.; Yeh, C.C.; Chinnathambi, A.; Alharbi, S.A.; Carretier, S.; Aimar, P.; Lai, J.Y.; Chang, Y. Antifouling pseudo-zwitterionic poly(vinylidene fluoride) membranes with efficient mixed-charge surface grafting via glow dielectric barrier discharge plasma-induced copolymerization. J. Membr. Sci. 2016, 516, 13–25. [Google Scholar] [CrossRef]

- Chang, Y.; Higuchi, A.; Shih, Y.J.; Li, P.T.; Chen, W.Y.; Tsai, E.M.; Hsiue, G.H. Bioadhesive control of plasma proteins and blood cells from umbilical cord blood onto the interface grafted with zwitterionic polymer brushes. Langmuir 2012, 28, 4309–4317. [Google Scholar] [CrossRef] [PubMed]

- Jeon, S.I.; Lee, J.H.; Andrade, J.D.; Gennes, P.G.D. Protein-surface interactions in the presence of polyethylene oxide. J. Colloid Interface Sci. 1991, 142, 149–158. [Google Scholar] [CrossRef]

- Li, X.; Cao, Y.M.; Kang, G.D.; Yu, H.J.; Jie, X.M.; Yuan, Q. Surface modification of polyamide nanofiltration membrane by grafting zwitterionic polymers to improve the antifouling property. J. Appl. Polym. Sci. 2015, 131, 205–212. [Google Scholar] [CrossRef]

- Sin, M.C.; Sun, Y.M.; Chang, Y. Zwitterionic-based stainless steel with well-defined polysulfobetaine brushes for general bioadhesive control. ACS Appl. Mater. Interfaces 2014, 6, 861–873. [Google Scholar] [CrossRef] [PubMed]

- Decher, G. Fuzzy nanoassemblies: Toward layered polymeric multicomposites. Science 1997, 277, 1232–1237. [Google Scholar] [CrossRef]

- Bergbreiter, D.E.; Liao, K.S. Covalent layer-by-layer assembly-an effective, forgiving way to construct functional robust ultrathin films and nanocomposites. Soft Matter 2008, 5, 23–28. [Google Scholar] [CrossRef]

- Schlenoff, J.B.; Ly, H.; Li, M. Charge and mass balance in polyelectrolyte multilayers. J. Am. Chem. Soc. 1998, 120, 7626–7634. [Google Scholar] [CrossRef]

- Schlenoff, J.B.; Dubas, S.T. Mechanism of polyelectrolyte multilayer growth: Charge overcompensation and distribution. Macromolecules 2001, 34, 592–598. [Google Scholar] [CrossRef]

- Miller, M.D.; Bruening, M.L. Controlling the nanofiltration properties of multilayer polyelectrolyte membranes through variation of film composition. Langmuir 2004, 20, 11545–11551. [Google Scholar] [CrossRef] [PubMed]

- Stanton, B.W.; Harris, J.J.; Miller, M.D.; Bruening, M.L. Ultrathin, multilayered polyelectrolyte films as nanofiltration membranes. Langmuir 2003, 19, 7038–7042. [Google Scholar] [CrossRef]

- Hong, S.U.; Malaisamy, R.; Bruening, M.L. Optimization of flux and selectivity in Cl−/SO42−, separations with multilayer polyelectrolyte membranes. J. Membr. Sci. 2006, 283, 366–372. [Google Scholar] [CrossRef]

- Goh, P. S.; Matsuura, T.; Ismail, A. F.; Hilal, N. Recent trends in membranes and membrane processes for desalination. Desalination 2016, 391, 43–60. [Google Scholar] [CrossRef]

- Mohammad, A.W.; Teow, Y.H.; Ang, W.L.; Chung, Y.T.; Oatley-Radcliffe, D.L.; Hilal, N. Nanofiltration membranes review: Recent advances and future prospects. Desalination 2015, 356, 226–254. [Google Scholar] [CrossRef]

- Fane, A.G.; Wang, R.; Hu, M.X. Synthetic membranes for water purification: Status and future. Angew. Chem. Int. Ed. 2015, 54, 3368–3386. [Google Scholar] [CrossRef] [PubMed]

- Lu, O.; Malaisamy, R.; Bruening, M.L. Multilayer polyelectrolyte films as nanofiltration membranes for separating monovalent and divalent cations. J. Membr. Sci. 2008, 310, 76–84. [Google Scholar]

- Ahmadiannamini, P.; Li, X.F.; Goyens, W.; Meesschaert, B.; Vankelecom, I.I.F.J. Multilayered PEC nanofiltration membranes based on SPEEK/PDDA for anion separation. J. Membr. Sci. 2010, 360, 250–258. [Google Scholar] [CrossRef]

- Izumrudov, V.; Kharlampieva, E.; Sukhishvili, S.A. Salt-induced multilayer growth: Correlation with phase separation in solution. Macromolecules 2004, 37, 8400–8406. [Google Scholar] [CrossRef]

- Salomäki, M.; Kankare, J. Specific anion effect in swelling of polyelectrolyte multilayers. Macromolecules 2008, 41, 4423–4428. [Google Scholar] [CrossRef]

- Li, X.F.; Goyens, W.; Ahmadiannamini, P.; Vanderlinden, W.; Feyter, S.D. Morphology and performance of solvent-resistant nanofiltration membranes based on multilayered polyelectrolytes: Study of preparation conditions. J. Membr. Sci. 2010, 358, 150–157. [Google Scholar] [CrossRef]

- Hong, S.U.; Malaisamy, R.; Bruening, M.L. Separation of fluoride from other monovalent anions using multilayer polyelectrolyte nanofiltration membranes. Langmuir 2007, 23, 1716–1722. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.X.; Zhang, G.J.; Ji, S.L.; Qin, Z.P.; Liu, Z.Z. The salt-, pH- and oxidant-responsive pervaporation behaviors of weak polyelectrolyte multilayer membranes. J. Membr. Sci. 2010, 354, 14–22. [Google Scholar] [CrossRef]

- Ilyas, S.; Grooth, J.D.; Nijmeijer, K.; Vos, W.M.D. Multifunctional polyelectrolyte multilayers as nanofiltration membranes and as sacrificial layers for easy membrane cleaning. J. Colloid Interface Sci. 2015, 446, 386–393. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Park, J.; Kim, S.H.; Cho, J.; Bang, J. Desalination membranes from pH-controlled and thermally-crosslinked layer-by-layer assembled multilayers. J. Mater. Chem. 2010, 20, 2085–2091. [Google Scholar] [CrossRef]

- Shi, J.F.; Zhang, W.Y.; Su, Y.L.; Jiang, Z.Y. Composite polyelectrolyte multilayer membranes for oligosaccharides nanofiltration separation. Carbohydr. Polym. 2013, 94, 106–113. [Google Scholar] [CrossRef] [PubMed]

- Deng, H.Y.; Xu, Y.Y.; Zhu, B.K.; Wei, X.Z.; Liu, F.; Cui, Z.Y. Polyelectrolyte membranes prepared by dynamic self-assembly of poly (4-styrenesulfonic acid-co-maleic acid) sodium salt (PSSMA) for nanofiltration (I). J. Membr. Sci. 2008, 323, 125–133. [Google Scholar] [CrossRef]

- Hong, S.U.; Bruening, M.L. Separation of amino acid mixtures using multilayer polyelectrolyte nanofiltration membranes. J. Membr. Sci. 2006, 280, 1–5. [Google Scholar] [CrossRef]

- Buonomenna, M.G.; Bae, J. Organic solvent nanofiltration in pharmaceutical industry. Sep. Purif. Rev. 2015, 44, 157–182. [Google Scholar] [CrossRef]

- Marchetti, P.; Solomon, M.F.J.; Szekely, G.; Livingston, A.G. Molecular separation with organic solvent nanofiltration: A critical review. Chem. Rev. 2014, 114, 10735–10806. [Google Scholar] [CrossRef] [PubMed]

- Amirilargani, M.; Sadrzadeh, M.; Sudhölter, E.; Smet, L.D. Surface modification methods of organic solvent nanofiltration membranes. Chem. Eng. J. 2016, 289, 562–582. [Google Scholar] [CrossRef]

- Ahmadiannamini, P.; Li, X.F.; Goyens, W.; Joseph, N.; Meesschaert, B.; Vankelecom, I.F.J. Multilayered polyelectrolyte complex based solvent resistant nanofiltration membranes prepared from weak polyacids. J. Membr. Sci. 2012, 394–395, 98–106. [Google Scholar] [CrossRef]

- Ahmadiannamini, P.; Li, X.F.; Goyens, W.; Meesschaert, B.; Vanderlinden, W.; Feyter, S.D.; Vankelecom, I.F.J. Influence of polyanion type and cationic counter ion on the SRNF performance of polyelectrolyte membranes. J. Membr. Sci. 2012, 403–404, 216–226. [Google Scholar] [CrossRef]

- Karan, S.; Jiang, Z.W.; Livingston, A.G. Sub-10 nm polyamide nanofilms with ultrafast solvent transport for molecular separation. Science 2015, 348, 1347–1351. [Google Scholar] [CrossRef] [PubMed]

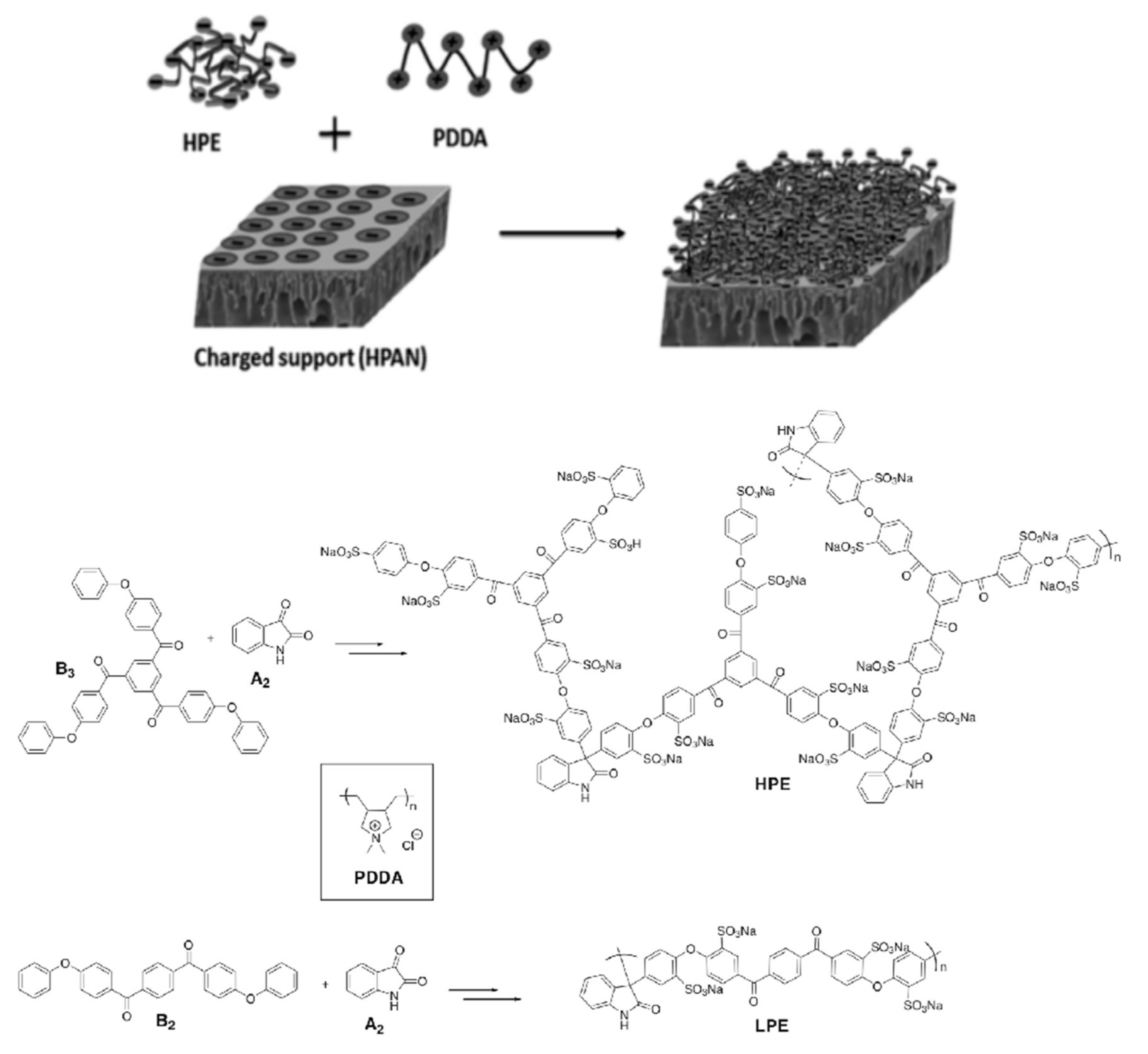

- Joseph, N.; Thomas, J.; Ahmadiannamini, P.; Gorp, H.V.; Bernstein, R.; Feyter, S.; Smet, M.; Dehaen, W.; Hoogenboom, R.; Vankelecom, I.F.J. Ultrathin single bilayer separation membranes based on hyperbranched sulfonated poly(aryleneoxindole). Adv. Funct. Mater. 2017, 27, 1605068–1605075. [Google Scholar] [CrossRef]

- Thunemann, A.F.; Muller, M.; Dautzenberg, H.; Joanny, J.F.; Luwen, H. Polyelectrolyte complexes. Adv. Polym. Sci. 2004, 166, 113–171. [Google Scholar]

- Choi, J.; Rubner, M.F. Influence of the degree of ionization on weak polyelectrolyte multilayer assembly. Macromolecules 2005, 38, 116–124. [Google Scholar] [CrossRef]

- Kim, S.G.; Lee, K.H. Polyelectrolyte complex composite gel membranes based on two cationic polymers for the separation of methyl tertbutyl ether and methanol mixtures. Curr. Appl. Phys. 2009, 9, 47–50. [Google Scholar] [CrossRef]

- Rachipudi, P.S.; Kittur, A.A.; Choudhari, S.K.; Varghese, J.G.; Kariduraganavar, M.Y. Development of polyelectrolyte complexes of chitosan and phosphotungstic acid as pervaporation membranes for dehydration of isopropanol. Eur. Polym. J. 2009, 45, 3116–3126. [Google Scholar] [CrossRef]

- Shieh, J.J.; Huang, R.Y.H. Pervaporation with chitosan membranes II. Blend membranes of chitosan and polyacrylic acid and comparison of homogeneous and composite membrane based on polyelectrolyte complexes of chitosan and polyacrylic acid for the separation of ethanol-water mixtures. J. Membr. Sci. 1997, 127, 185–202. [Google Scholar] [CrossRef]

- Hu, C.L.; Li, B.; Guo, R.L.; Wu, H.; Jiang, Z.Y. Pervaporation performance of chitosan-poly(acrylic acid) polyelectrolyte complex membranes for dehydration of ethylene glycol aqueous solution. Sep. Purif. Technol. 2007, 55, 327–334. [Google Scholar] [CrossRef]

- Ji, Y.L.; An, Q.F.; Zhao, Q.; Chen, H.L.; Qian, J.W.; Gao, C.J. Fabrication and per-formance of a new type of charged nanofiltration membrane based on polyelectrolyte complex. J. Membr. Sci. 2010, 357, 80–89. [Google Scholar] [CrossRef]

- Zhao, Q.; Ji, Y.L.; Wu, J.K.; Shao, L.L.; An, Q.F.; Gao, C.J. Polyelectrolyte complex nanofiltration membranes: Performance modulation via casting solution pH. RSC Adv. 2014, 4, 52808–52814. [Google Scholar] [CrossRef]

- Zhao, Q.; Qian, J.W.; An, Q.F.; Yang, Q.; Zhang, P. A facile route for fabricating novel polyelectrolyte complex membrane with high pervaporation performance in isopropanol dehydration. J. Membr. Sci. 2008, 320, 8–12. [Google Scholar] [CrossRef]

- Zhao, Q.; Qian, J.W.; An, Q.F.; Yang, Q.; Gui, Z.L. Synthesis and characterization of solution-processable polyelectrolyte complexes and their homogeneous membranes. ACS Appl. Mater. Interfaces 2009, 1, 90–96. [Google Scholar]

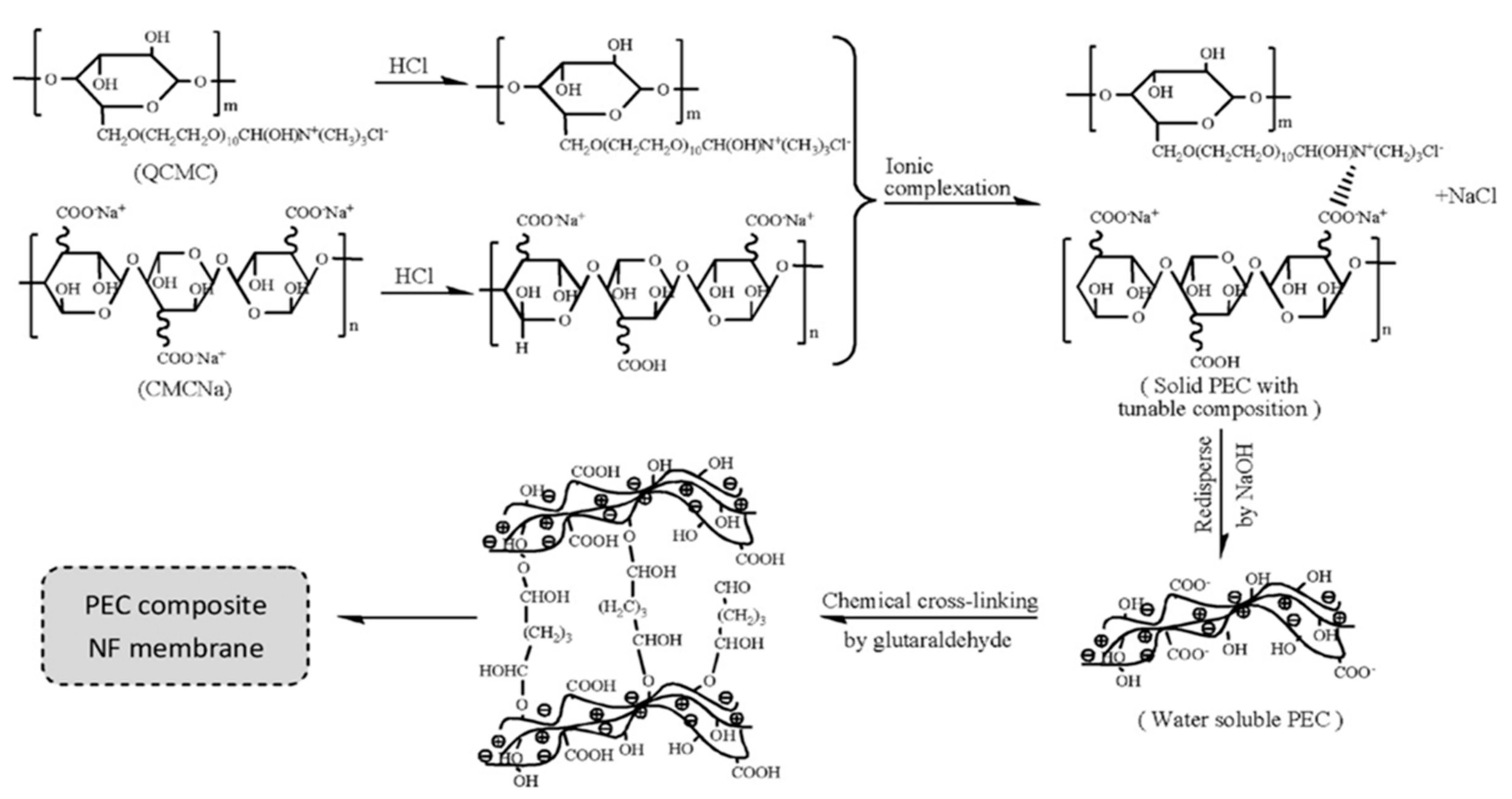

- Zhao, Q.; Qian, J.W.; Gui, Z.L.; An, Q.F.; Zhu, M.H. Interfacial self-assembly of cellulose-based polyelectrolyte complexes: Pattern formation of fractal “trees”. Soft Matter 2010, 6, 1129–1137. [Google Scholar] [CrossRef]

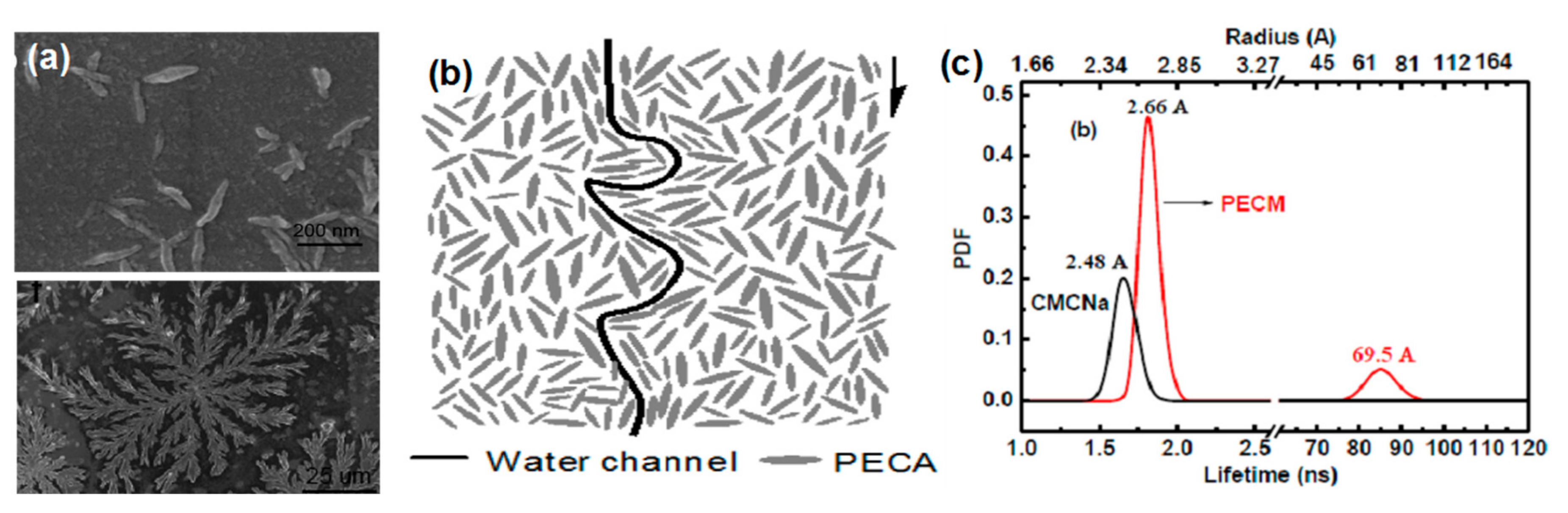

- Zhao, Q.; An, Q.F.; Sun, Z.W.; Qian, J.W.; Lee, K.R.; Gao, C.J.; Lai, J.Y. Studies on structures and ultrahigh permeability of novel polyelectrolyte complex membranes. J. Phys. Chem. B 2010, 114, 8100–8106. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.S.; Ji, Y.L.; Zheng, P.Y.; An, Q.F.; Zhao, Q.; Lee, K.R.; Qian, J.W.; Gao, C.J. Engineering novel polyelectrolyte complex membranes with improved mechanical properties and separation performance. J. Mater. Chem. A 2015, 3, 7296–7303. [Google Scholar] [CrossRef]

- Ye, C.C.; Zhao, F.Y.; Wu, J.K.; Weng, X.D.; Zheng, P.Y.; Mi, Y.F.; An, Q.F.; Gao, C.J. Sulfated polyelectrolyte complex nanoparticles structured nanoflitration membrane for dye desalination. Chem. Eng. J. 2017, 307, 526–536. [Google Scholar] [CrossRef]

- Zhao, Q.; Yin, M.J.; Zhang, A.P.; Prescher, S.; Antonietti, M.; Yuan, J.Y. Hierarchically structured nanoporous poly(ionic liquid) membranes: Facile preparation and application in fiber-optic pH sensing. J. Am. Chem. Soc. 2013, 135, 5549–5552. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.Q.; Zhang, Q.F.; Li, S.H.; Zhang, S.B. Preparation and characterization of porous polyelectrolyte complex membranes for nanofiltration. RSC Adv. 2015, 5, 3567–3573. [Google Scholar] [CrossRef]

- Zhao, Q.; Qian, J.W.; Zhu, C.X.; An, Q.F.; Xu, T.Q.; Zheng, Q.; Song, Y.H. A novel method for fabricating polyelectrolyte complex/inorganic nanohybrid membranes with high isopropanol dehydration performance. J. Membr. Sci. 2009, 345, 233–241. [Google Scholar] [CrossRef]

- Zhao, Q.; Qian, J.W.; Zhu, M.H.; An, Q.F. Facile fabrication of polyelectrolyte complex/carbon nanotube nanocomposites with improved mechanical properties and ultra-high separation performance. J. Mater. Chem. 2009, 19, 8732–8740. [Google Scholar] [CrossRef]

- Liu, T.; An, Q.F.; Zhao, Q.; Wu, J.K.; Song, Y.H.; Zhu, B.K.; Gao, C.J. Synergistic strengthening of polyelectrolyte complex membranes by functionalized carbon nanotubes and metal ions. Sci. Rep. 2015, 5, 7782–7788. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; An, Q.F.; Liu, T.; Chen, J.S.; Chen, F.; Lee, K.R.; Gao, C.J. Bio-inspired polyelectrolyte complex/graphene oxide nanocomposite membranes with enhanced tensile strength and ultra-low gas permeability. Polym. Chem. 2013, 4, 4298–4302. [Google Scholar] [CrossRef]

- Zhao, F.Y.; An, Q.F.; Ji, Y.L.; Gao, C.J. A novel type of polyelectrolyte complex/MWCNT hybrid nanofiltration membranes for water softening. J. Membr. Sci. 2015, 492, 412–421. [Google Scholar] [CrossRef]

- Wang, Y.C.; Kumar, R.; Shih, C.M.; Hung, W.S.; An, Q.F.; Hsu, H.C.; Huang, S.H.; Lue, S.J. High permeance nanofiltration thin film composites with a polyelectrolyte complex top layer containing graphene oxide nanosheets. J. Membr. Sci. 2017, 540, 391–400. [Google Scholar] [CrossRef]

- Ulbricht, M. Advanced functional polymer membranes. Polymer 2006, 47, 2217–2262. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, L.J.; Mao, S.M.; Rohani, S.; Ching, C.; Lu, J. Zwitterionic chitosan-silica-PVA hybrid ultrafiltration membranes for protein separation. Sep. Purif. Technol. 2015, 152, 55–63. [Google Scholar] [CrossRef]

- Liu, J.S.; Zhan, Y.; Xu, T.W.; Shao, G.Q. Preparation and characterizations of novel zwitterionic membranes. J. Membr. Sci. 2008, 325, 325,495–502. [Google Scholar] [CrossRef]

- Meng, J.Q.; Cao, Z.; Lei, N.; Zhang, Y.F.; Wang, X.Y.; Zhang, X.; Liu, E.H. A novel salt-responsive TFC RO membrane having superior antifouling and easy-cleaning properties. J. Membr. Sci. 2014, 461, 123–129. [Google Scholar] [CrossRef]

- Yu, H.J.; Cao, Y.M.; Kang, G.D.; Liu, J.H.; Li, M.; Yuan, Q. Enhancing antifouling property of polysulfone ultrafiltration membrane by grafting zwitterionic copolymer via UV-initiated polymerization. J. Membr. Sci. 2009, 342, 6–13. [Google Scholar] [CrossRef]

- Razi, F.; Sawada, I.; Ohmukai, Y.; Maruyama, T.; Matsuyama, H. The improvement of antibiofouling efficiency of polyethersulfone membrane by functionalization with zwitterionic monomers. J. Membr. Sci. 2012, 401–402, 292–299. [Google Scholar] [CrossRef]

- Tirado, M.L.M.; Bass, M.; Piatkovsky, M.; Ulbricht, M.; Herzberg, M.; Freger, V. Assessing biofouling resistance of a polyamide reverse osmosis membrane surface-modified with a zwitterionic polymer. J. Membr. Sci. 2016, 520, 490–498. [Google Scholar] [CrossRef]

- Yang, Y.F.; Li, Y.; Li, Q.L.; Wan, L.S.; Xu, Z.K. Surface hydrophilization of microporous polypropylene membrane by grafting zwitterionic polymer for anti-biofouling. J. Membr. Sci. 2010, 362, 255–264. [Google Scholar] [CrossRef]

- Birkner, M.; Ulbricht, M. Ultrafiltration membranes with markedly different pH- and ion-responsivity by photografted zwitterionic polysulfobetain or polycarbobetain. J. Membr. Sci. 2015, 494, 57–67. [Google Scholar] [CrossRef]

- Ko, Y.G.; Kim, Y.H.; Park, K.D.; Lee, H.J.; Lee, W.K.; Park, H.D.; Kim, S.H.; Lee, G.S.; Ahn, D.J. Immobilization of poly(ethylene glycol) or its sulfonate onto polymer surfaces by ozone oxidation. Biomaterials 2001, 22, 2115–2123. [Google Scholar] [CrossRef]

- Li, X.; Hu, X.F.; Cai, T. Construction of hierarchical fouling resistance surfaces onto poly(vinylidene fluoride) membranes for combating membrane biofouling. Langmuir 2017, 33, 4477–4489. [Google Scholar] [CrossRef] [PubMed]

- Imbrogno, J.; Williams, M.D.; Belfort, G. A new combinatorial method for synthesizing, screening, and discovering antifouling surface chemistries. ACS Appl. Mater. Interfaces 2015, 7, 2385–2392. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.S.; Chen, Q.; Wu, S.S.; Shen, J.; Lin, S.C. Surface modification of cellulose membranes with zwitterionic polymers for resistance to protein adsorption and platelet adhesion. J. Membr. Sci. 2010, 350, 387–394. [Google Scholar] [CrossRef]

- Ran, J.; Wu, L.; Zhang, Z.H.; Xu, T.W. Atom transfer radical polymerization (ATRP): A versatile and forceful tool for functional membranes. Prog. Polym. Sci. 2014, 39, 124–144. [Google Scholar] [CrossRef]

- Saeki, D.; Tanimoto, T.; Matsuyama, H. Anti-biofouling of polyamide reverse osmosis membranes using phosphorylcholine polymer grafted by surface-initiated atom transfer radical polymerization. Desalination 2014, 350, 21–27. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Tian, J.Y.; Gao, S.S.; Shi, W.X.; Zhang, Z.B.; Cui, F.Y.; Zhang, S.M.; Guo, S.N.; Yang, X.N.; Xie, H.; et al. Surface functionalization of TFC FO membranes with zwitterionic polymers: Improvement of antifouling and salt-responsive cleaning properties. J. Membr. Sci. 2017, 544, 368–377. [Google Scholar] [CrossRef]

- Li, D.; Yan, Y.S.; Wang, H.T. Recent advances in polymer and polymer composite membranes for reverse and forward osmosis processes. Prog. Polym. Sci. 2016, 61, 104–155. [Google Scholar] [CrossRef]

- Chiang, Y.C.; Chang, Y.; Chuang, C.J.; Ruaan, R.C. A facile zwitterionization in the interfacial modification of low bio-fouling nanofiltration membranes. J. Membr. Sci. 2012, 389, 76–82. [Google Scholar] [CrossRef]

- Mi, Y.F.; Zhao, Q.; Ji, Y.L.; An, Q.F.; Gao, C.J. A novel route for surface zwitterionic functionalization of polyamide nanofiltration membranes with improved performance. J. Membr. Sci. 2015, 490, 311–320. [Google Scholar] [CrossRef]

- Weng, X.D.; Ji, Y.L.; Zhao, F.Y.; An, Q.F.; Gao, C.J. Tailoring the structure of polyamide thin film composite membrane with zwitterions to achieve high water permeability and antifouling property. RSC Adv. 2015, 5, 98730–98739. [Google Scholar] [CrossRef]

- Weng, X.D.; Ji, Y.L.; Ma, R.; Zhao, F.Y.; An, Q.F.; Gao, C.J. Superhydrophilic and antibacterial zwitterionic polyamide nanofiltration membranes for antibiotics separation. J. Membr. Sci. 2016, 510, 122–130. [Google Scholar] [CrossRef]

- Ma, T.Y.; Su, Y.L.; Li, Y.F.; Zhang, R.N.; Liu, Y.N.; He, M.R.; Li, Y.; Dong, N.X.; Wu, H.; Jiang, Z.Y. Fabrication of electro-neutral nanofiltration membranes at neutral pH with antifouling surface via interfacial polymerization from a novel zwitterionic amine monomer. J. Membr. Sci. 2016, 503, 101–109. [Google Scholar] [CrossRef]

- Yin, J.; Deng, B.L. Polymer-matrix nanocomposite membranes for water treatment. J. Membr. Sci. 2015, 479, 256–275. [Google Scholar] [CrossRef]

- Lau, W.J.; Gray, S.; Matsuura, T.; Emadzadeh, D.; Chen, J.P.; Ismail, A.F. A review on polyamide thin film nanocomposite (TFN) membranes: History, applications, challenges and approaches. Water Res. 2015, 80, 306–324. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Sotto, A.; Li, J.S.; Bruggen, B.V.D. Progress and perspectives for synthesis of sustainable antifouling composite membranes containing in situ, generated nanoparticles. J. Membr. Sci. 2017, 524, 502–528. [Google Scholar] [CrossRef]

- Ji, Y.L.; An, Q.F.; Guo, Y.S.; Hung, W.S.; Lee, K.R.; Gao, C.J. Bio-inspired fabrication of high perm-selectivity and anti-fouling membranes based on zwitterionic polyelectrolyte nanoparticles. J. Mater. Chem. A 2016, 4, 4224–4231. [Google Scholar] [CrossRef]

- Ji, Y.L.; Zhao, Q.; An, Q.F.; Shao, L.L.; Lee, K.R.; Xu, Z.K.; Gao, C.J. Novel separation membranes based on zwitterionic colloid particles: Tunable selectivity and enhanced antifouling property. J. Mater. Chem. A 2013, 1, 12213–12220. [Google Scholar] [CrossRef]

- Ma, R.; Ji, Y.L.; Guo, Y.S.; Mi, Y.F.; An, Q.F.; Gao, C.J. Fabrication of antifouling reverse osmosis membranes by incorporating zwitterionic colloids nanoparticles for brackish water desalination. Desalination 2017, 416, 35–44. [Google Scholar] [CrossRef]

- Chan, W.F.; Chen, H.Y.; Surapathi, A.; Taylor, M.G.; Shao, X.H.; Marand, E.; Johnson, J.K. Zwitterion functionalized carbon nanotube/polyamide nanocomposite membranes for water desalination. ACS Nano 2013, 7, 5308–5319. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.S.; Mi, Y.F.; Zhao, F.Y.; An, Q.F.; Gao, C.J. High-Flux Nanofiltration Membranes Filled with Zwitterion-Poly(dopamine) Modified Multiwall Carbon Nanotubes; ICOM: San Francisco, CA, USA, 2017. [Google Scholar]

- Zhu, J.Y.; Tian, M.M.; Hou, J.W.; Wang, J.; Lin, J.Y.; Zhang, Y.T.; Liu, J.D.; Bruggen, B.V.D. Surface zwitterionic functionalized graphene oxide for a novel loose nanofiltration membrane. J. Mater. Chem. A 2015, 4, 1980–1990. [Google Scholar] [CrossRef]

- Ji, Y.L.; An, Q.F.; Zhao, Q.; Sun, W.D.; Lee, K.R.; Chen, H.L.; Gao, C.J. Novel composite nanofiltration membranes containing zwitterions with high permeate flux and improved anti-fouling performance. J. Membr. Sci. 2012, 390, 243–253. [Google Scholar] [CrossRef]

- An, Q.F.; Ji, Y.L.; Hung, W.S.; Lee, K.R.; Gao, C.J. AMOC positron annihilation study of zwitterionic nanofiltration membranes: Correlation between fine structure and ultrahigh permeability. Macromolecules 2013, 46, 2228–2234. [Google Scholar] [CrossRef]

- Kharlampieva, E.; Izumrudov, V.A.; Sukhishvili, S.A. Electrostatic layer-by-layer self-assembly of poly(carboxybetaine)s: Role of zwitterions in film growth. Macromolecules 2007, 40, 3663–3668. [Google Scholar] [CrossRef]

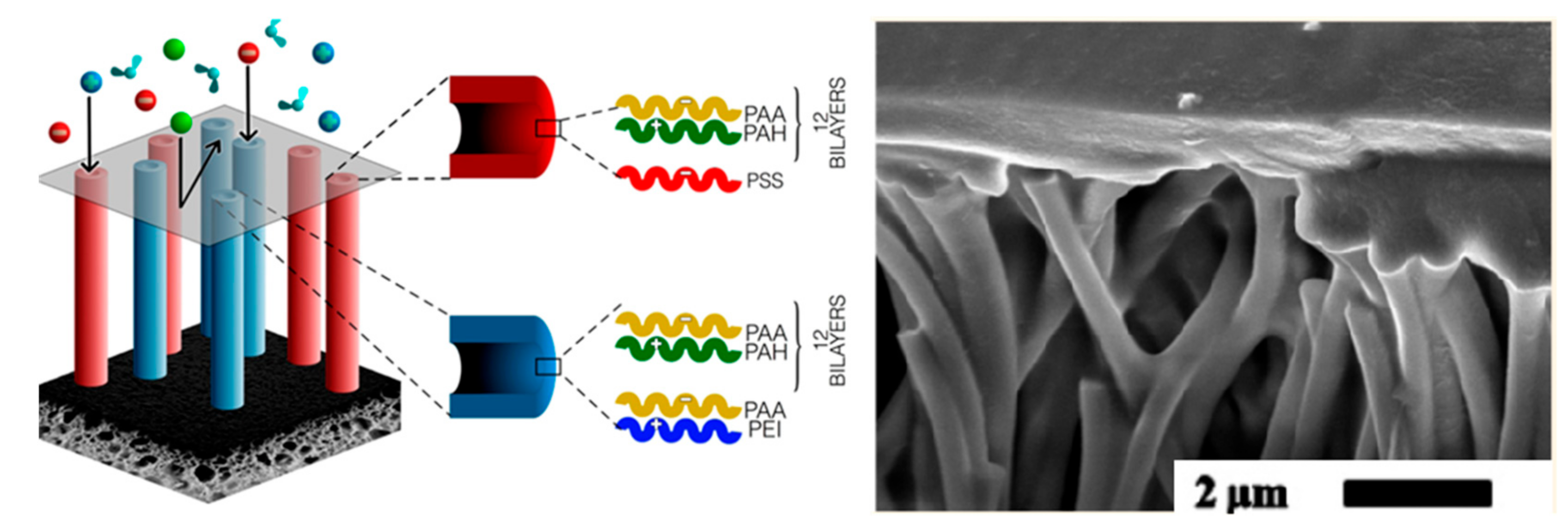

- Grooth, J.D.; Reurink, D.M.; Ploegmakers, J.; Vos, W.M.D.; Nijmeije, K. Charged micropollutant rremoval with hollow fiber nanofiltration membranes based on polycation/polyzwitterion/polyanion multilayers. ACS Appl. Mater. Interfaces 2014, 6, 17009–17017. [Google Scholar] [CrossRef] [PubMed]

- Grooth, J.D.; Dong, M.; Vos, W.M.D.; Nijmeijer, K. Building polyzwitterion-based multilayers for responsive membranes. Langmuir 2014, 30, 5152–5161. [Google Scholar] [CrossRef] [PubMed]

- Tenhaeff, W.E.; Gleason, K.K. Initiated and oxidative chemical vapor deposition of polymeric thin films: iCVD and oCVD. Adv. Funct. Mater. 2008, 18, 979–992. [Google Scholar] [CrossRef]

- Yang, R.; Xu, J.J.; Ozaydinince, G.; Wong, S.Y.; Gleason, K.K. Surface-tethered zwitterionic ultrathin antifouling coatings on reverse osmosis membranes by initiated chemical vapor deposition. Chem. Mater. 2011, 23, 1263–1271. [Google Scholar] [CrossRef]

- Yang, R.; Jang, H.C.; Stocker, R.; Gleason, K.K. Synergistic prevention of biofouling in seawater desalination by zwitterionic surfaces and low-level chlorination. Adv. Mater. 2014, 26, 1711–1718. [Google Scholar] [CrossRef] [PubMed]

- Bengani, P.; Kou, Y.; Asatekin, A. Zwitterionic copolymer self-assembly for fouling resistant, high flux membranes with size-based small molecule selectivity. J. Membr. Sci. 2015, 493, 755–765. [Google Scholar] [CrossRef]

- Benganilutz, P.; Converse, E.; Cebe, P.; Asatekin, A. Self-assembling zwitterionic copolymers as membrane selective layers with excellent fouling resistance: Effect of zwitterion chemistry. ACS Appl. Mater. Interfaces 2017, 9, 20859–20872. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Dellatore, S.M.; Miller, W.M.; Messersmith, P.B. Mussel-inspired surface chemistry for multifunctional coatings. Science 2007, 318, 426–430. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.C.; Luo, J.Q.; Lv, Y.; Shen, P.; Xu, Z.K. Surface engineering of polymer membranes via mussel-inspired chemistry. J. Membr. Sci. 2015, 483, 42–59. [Google Scholar] [CrossRef]

- Azari, S.; Zou, L. Using zwitterionic amino acid l-DOPA to modify the surface of thin film composite polyamide reverse osmosis membranes to increase their fouling resistance. J. Membr. Sci. 2012, 401–402, 68–75. [Google Scholar] [CrossRef]

- Zhou, R.; Ren, P.F.; Yang, H.C.; Xu, Z.K. Fabrication of antifouling membrane surface by poly(sulfobetaine methacrylate)/polydopamine co-deposition. J. Membr. Sci. 2014, 466, 18–25. [Google Scholar] [CrossRef]

- Zhang, C.; Li, H.N.; Du, Y.; Ma, M.Q.; Xu, Z.K. CuSO4/H2O2 triggered polydopamine/poly(sulfobetaine methacrylate) coatings for antifouling membrane surfaces. Langmuir 2017, 33, 1210–1216. [Google Scholar] [CrossRef] [PubMed]

- Bolto, B.; Hoang, M.; Tran, T. Review of piezodialysis—Salt removal with charge mosaic membranes. Desalination 2010, 254, 1–5. [Google Scholar] [CrossRef]

- Fujimoto, T.; Ohkoshi, K.; Miyaki, Y.; Nagasawa, M. Artificial membranes from multiblock copolymers. I. Fabrication of a charge-mosaic membrane and preliminary tests of dialysis and piezodialysis. J. Membr. Sci. 1984, 20, 313–324. [Google Scholar] [CrossRef]

- Miyaki, Y.; Nagamatsu, H.; Iwata, M.; Ohkoshi, K.; Se, K.; Fujimoto, T. Artificial membranes from multiblock copolymers. 3. Preparation and characterization of charge-mosaic membranes. Macromolecules 1984, 17, 2231–2236. [Google Scholar] [CrossRef]

- Ishizu, K.; Amemiya, M. Transport of electrolytes through charge mosaic composite membranes. J. Membr. Sci. 1992, 65, 129–140. [Google Scholar] [CrossRef]

- Ishizu, K.; Iwade, M.; Kiniwa, H.; Watanabe, J. Transport of organic and inorganic solutes through charged mosaic composite membranes. J. Membr. Sci. 1996, 109, 35–42. [Google Scholar] [CrossRef]

- Ni, H.M.; Ma, G.H.; Nagai, M.; Omi, S. Novel method to prepare charged mosaic membrane by using dipole-like microspheres. I. Preparation and characterization of poly(4-vinylpyridine/n-butyl acrylate) seed latex with high solid content by soap-free emulsion polymerization. J. Appl. Polym. Sci. 2000, 76, 1731–1740. [Google Scholar] [CrossRef]

- Zhang, H.Q.; Liu, J.D. Preparation of composite charge mosaic hollow fiber membrane by interfacial polymerization. Chin. Chem. Lett. 2004, 5, 609–610. [Google Scholar]

- Zhang, H.Q.; Fan, G.D.; Liu, J.D.; Fang, W.J.; Guo, X.Y. Preparation of composite charge mosaic membrane by interfacial polymerization. J. Chem. Eng. Chin. Univ. 2005, 19, 156–161. [Google Scholar]

- Zhang, J.Y.; Zhang, Y.W.; Zhang, H.Q.; Dang, J.C.; Liu, J.D. Preparation and characterization of a novel polyamide charged mosaic membrane. Chin. J. Chem. Eng. 2010, 18, 569–576. [Google Scholar] [CrossRef]

- Deng, J.M.; Liu, J.D.; Zhang, H.Q.; Zhang, Y.T.; Cheng, D. Preparation and characterization of the tri-channel hollow fiber charged mosaic membrane. Adv. Mater. Res. 2011, 150–151, 1315–1320. [Google Scholar] [CrossRef]

- Bai, X.; Zhang, Y.T.; Zhang, H.Q.; Liu, J.D. Preparation and performance optimization of a composite charged mosaic membrane via interfacial polymerization. Asian J. Chem. 2012, 24, 1959–1965. [Google Scholar]

- Cheng, J.H.; Chung, T.S. Synthesis of mosaic membranes and application for egg white protein fractionation by partitioned free-flow isoelectric focusing (FFIEF). J. Membr. Sci. 2010, 353, 94–102. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.T.; Zhu, J.Y.; Hou, J.W.; Liu, J.D.; Bruggen, B.V. Zwitterionic functionalized layered double hydroxides nanosheets for a novel charged mosaic membrane with high salt permeability. J. Membr. Sci. 2016, 510, 27–37. [Google Scholar] [CrossRef]

- Rajesh, S.; Yan, Y.; Chang, H.C.; Gao, H.; Phillip, W.A. Mixed mosaic membranes prepared by layer-by-layer assembly for ionic separations. ACS Nano 2014, 8, 12338–12345. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.L.; Cui, Y.M.; Jia, Y.S.; Zhan, K.; Zhang, H.; Chen, G.X.; Yang, Y.D.; Wu, M.; Ni, H.M. Preparation of charged mosaic membrane of sodium polystyrene sulfonate and poly(4-vinyl pyridine) by conjugate electrospinning. J. Appl. Polym. Sci. 2014, 1002, 40716–40724. [Google Scholar] [CrossRef]

- Sirringhaus, H.; Kawase, T.; Friend, R.H.; Shimoda, T.; Inbasekaran, M.; Wu, W.; Woo, E.P. High-resolution inkjet printing of all-polymer transistor circuits. Science 2000, 290, 2123–2126. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.R.; Su, M.; Zhang, C.; Gao, M.; Bao, B.; Yang, Q.; Su, B.; Song, Y.L. Fabrication of nanoscale circuits on inkjet-printing patterned substrates. Adv. Mater. 2015, 27, 3928–3933. [Google Scholar] [CrossRef] [PubMed]

- Gao, P.; Hunter, A.; Summe, M.J.; Phillip, W.A. A method for the efficient fabrication of multifunctional mosaic membranes by inkjet printing. ACS Appl. Mater. Interfaces 2016, 8, 19772–19779. [Google Scholar] [CrossRef] [PubMed]

| Membrane Material | Fabrication Method | Solvent | Permeance (L m−2 h−1 bar−1) | Solute | Rejection (%) | Ref. | |

|---|---|---|---|---|---|---|---|

| Material | Substrate | ||||||

| (PVA/PVS)60 | PAN/PET supports | LBL | Water | ~0.1 | NaCl | 93.5 | [40] |

| Na2SO4 | ~97.0 | ||||||

| MgSO4 | ~99.0 | ||||||

| MgCl2 | ~82.0 | ||||||

| (PSS/PDDA)4.5 | Porous alumina supports | LBL | Water | 18.2 | NaCl | 40.0 | [77] |

| glycerol | 18.0 | ||||||

| glucose | 64.0 | ||||||

| sucrose | 97.2 | ||||||

| raffinose | 98.9 | ||||||

| (PSS/CS)4.5 | Porous alumina supports | LBL | Water | 13.0 | glycerol | 4.0 | [77] |

| glucose | 46.0 | ||||||

| sucrose | 89.0 | ||||||

| raffinose | 97.0 | ||||||

| (PSS/PAH)4-PSS | Porous alumina supports | LBL | Water | 21.7 | NaCl | 13.0 | [78] |

| 15.6 | Na2SO4 | 95.0 | |||||

| 8.7 | MgSO4 | 90.0 | |||||

| 13.0 | CaCl2 | 48.0 | |||||

| (PAA/PAH)4PAA | Porous alumina supports | LBL | Water | 1.5 | NaClNa2SO4 | Cl−: 12.9SO42−: 93.2 | [79] |

| (PAA/PDDA)4PAA | 12.2 | Cl−: −4.4SO42−: 24.0 | |||||

| (PSS/PAH)4PSS | 20.0 | Cl−: −8.7SO42−: 78.0 | |||||

| (PSS/PDDA)4PSS | 20.8 | Cl−: −15.5SO42−: 92.3 | |||||

| (PDDA/SPEEK)10 | PAN | LBL | Water | 68.8 | NaCl | 8.95 | [84] |

| 77.1 | Na2SO | 10.5 | |||||

| 10.8 | Na2HPO4 | 55.7 | |||||

| (PSS/PDDA)4PSS | Porous alumina supports | LBL | Water | 30.4 | NaCl NaF | Cl−: 9.5F−: 73.1 | [88] |

| (PSS/PAH)4PSS | 40.8 | Cl−: 16.2F−: 21.8 | |||||

| (PAH/PAA)4PAH | PES-UF | LBL | Water | / | Na2SO4 | ~24.0 | [90] |

| NaCl | ~61.0 | ||||||

| sulfamethoxazole | ~68.0 | ||||||

| (PAH/PAA 3.5)10 | PSF-UF | LBL | Water | ~0.5 | NaCl | ~99.0 | [91] |

| (CS/PSS)3-(PAH/PSS)2 | PAN-UF | LBL | Water | ~1.2 | Glucose | 63.0 | [92] |

| Maltose | 99.2 | ||||||

| Oligosaccharides | 100.0 | ||||||

| (PAH/PSS)1-(PAH/PSSMA) | PAN-UF | Dynamic LBL | Water | 13.6 | Na2SO4 | 91.6 | [93] |

| 15.3 | NaCl | 33.1 | |||||

| 14.5 | MgSO4 | 86.4 | |||||

| 15.3 | MgCl2 | 66.2 | |||||

| (PAH/PAA)6 | Hollow Fiber Silica with a separation skin layer of PES | LBL | Water | ~3.0 | Na2SO4 | ~46.0 | [48] |

| NaCl | ~9.0 | ||||||

| CaCl2 | ~27.0 | ||||||

| Atenolol | ~76.0 | ||||||

| sulfamethoxazole | ~62.0 | ||||||

| naproxen | ~72.0 | ||||||

| atrazine | ~64.0 | ||||||

| bezafibrate | ~78.0 | ||||||

| (PSS/PAH)7 | Porous alumina supports | LBL | Water | ~11.3 | Glycine | 34.5 | [94] |

| Serine | 53.0 | ||||||

| Alanine | 62.4 | ||||||

| Glutamine | 98.7 | ||||||

| (PDDA/SPEEK)5 | PAN-UF | LBL | IPA | 2.9 | Rose Bengale | 91.0 | [37] |

| 2.0 | Acid Fuchsine | 98.0 | |||||

| 12.9 | Crystal Violet | 17.0 | |||||

| 12.5 | Methyl Orange | 50.0 | |||||

| (PDDA/PAA)20 | PAN-UF | LBL | DMF | ~0.1 | Rose Bengale | ~92.0 | [98] |

| ACN | ~2.1 | Rose Bengale | ~87.0 | ||||

| IPA | ~0.1 | Bromothymol Blue | ~58.0 | ||||

| IPA | ~0.2 | Acid Fuchsine | ~76.0 | ||||

| (PDDA/PSSH)10 | PAN-UF | LBL | IPA | ~0.1 | Rose Bengale | ~99.0 | [99] |

| Acid Fuchsine | ~99.0 | ||||||

| Bromothymol Blue | ~89.0 | ||||||

| (PDDA/PVSH)5 | PAN-UF | LBL | IPA | ~1.6 | Rose Bengale | ~99.0 | [99] |

| ~2.1 | Acid Fuchsine | ~99.0 | |||||

| ~1.4 | Bromothymol Blue | ~84.0 | |||||

| (PDDA/HPE)1 | PAN-UF | LBL | IPA | ~1.2 | Rose Bengale | ~98.0 | [101] |

| Water | ~5.4 | Rose Bengale | ~99.0 | ||||

| ACN | ~4.3 | Rose Bengale | ~94.5 | ||||

| THF | ~1.2 | Rose Bengale | ~90.0 | ||||

| QCMC/CMCNa | PSF-UF | Surface coating and chemical cross-linking | Water | ~1.4 | K2SO4 | 87.7 | [108] |

| Na2SO4 | 70.6 | ||||||

| MgSO4 | 27.6 | ||||||

| NaCl | 22.8 | ||||||

| CuCl2 | 14.7 | ||||||

| MgCl2 | 10.8 | ||||||

| XO | 98.7 | ||||||

| PDDA/CMCNa | PSF-UF | Surface coating and chemical cross-linking | Water | ~1.9 | NaCl | 24.2 | [108] |

| K2SO4 | 91.8 | ||||||

| XO | 99.3 | ||||||

| PDMC/CMCNa | PSF-UF | Surface coating and chemical cross-linking | Water | ~3.0 | NaCl | 2.0 | [109] |

| K2SO4 | 97.0 | ||||||

| Sulfated CS/DSS | PSF-UF | Surface coating and chemical cross-linking | Water | ~6.4 | Methyl Blue | 99.9 | [115] |

| Na2SO4 | 93.4 | ||||||

| K2SO4 | 92.2 | ||||||

| MgSO4 | 41.9 | ||||||

| NaCl | 13.8 | ||||||

| KCl | 13.5 | ||||||

| MgCl2 | ~10.5 | ||||||

| PCMVImTf2N/P(AA1-co-ANx) | - | Surface coating | Water | 5.4 | NaCl | 6 | [117] |

| 4.6 | Na2SO4 | 59.5 | |||||

| 6.3 | MgCl2 | 0.1 | |||||

| 16.3 | Methyl orange | 99.9 | |||||

| 14.7 | Methyl violet | 6.5 | |||||

| PEI/SA | PSF-UF | Surface coating and chemical cross-linking | Water | ~2.2 | Na2SO4 | 6.6 | [122] |

| MgSO4 | ~25 | ||||||

| NaCl | 37.9 | ||||||

| MgCl2 | 94 | ||||||

| PEI/SA-MWCNT | ~4.5 | Na2SO4 | ~37.9 | ||||

| MgSO4 | ~26 | ||||||

| NaCl | 36.9 | ||||||

| MgCl2 | 93.5 | ||||||

| PDDA/CMCNa-GO | PVDF | Surface coating and chemical cross-linking | Water | 8.2 | NaCl | 38.6 | [123] |

| 8.9 | Na2SO4 | 62.1 | |||||

| 7.0 | MgCl2 | 12.2 | |||||

| 6.9 | MgSO4 | 22.0 | |||||

| Membrane Material | Fabrication Method | Solvent | Permeance (L m−2 h−1 bar−1) | Solute | Rejection (%) | Ref. | |

|---|---|---|---|---|---|---|---|

| Material | Substrate | ||||||

| Sulfobetanine zwitterionic MPDSAH | Polyamide membrane | Conventional free radical graft polymerization | Water | 6.5 | Na2SO4 | 92.0 | [71] |

| Sulfobetanine zwitterionic PSVBP | Polyamide membrane | Conventional free radical graft polymerization | Water | 6.5 | NaCl | 99.7 | [127] |

| Carboxybetaine zwitterionic CBMA | Polyamide membrane | Conventional free radical graft polymerization | Water | 5.7 | NaCl | 98.0 | [32] |

| Phosphobetaine zwitterionic MPC | Polyamide membrane | Atom transfer radical polymerization | Water | 3.2 | NaCl | 90.0 | [138] |

| Iodopropionic/iodomethane | Polyamide membrane | N-alkylation reaction and quaternization reaction | Water | ~4.6 | MgSO4 | ~78.0 | [141] |

| Na2SO4 | ~52.0 | ||||||

| MgCl2 | ~60.0 | ||||||

| NaCl | ~45.0 | ||||||

| AEPPS-PIP/TMC | PSF-UF | Interfacial polymerization | Water | 7.2 | K2SO4 | 97.0 | [33] |

| MgSO4 | 90.0 | ||||||

| NaCl | 30.0 | ||||||

| PIP/TMC/AEPPS | PSF-UF | Two-step interfacial polymerization | Water | 9.6 | Na2SO4 | 99.5 | [142] |

| MgSO4 | 98.5 | ||||||

| NaCl | 43.9 | ||||||

| AEPPS/TMC | PSF-UF | Interfacial polymerization | Water | 8.4 | K2SO4 | 97.1 | [144] |

| erythromycin | 96.5 | ||||||

| NaCl | <20.0 | ||||||

| PEI-g-SBMA/TMC | PES-UF | Interfacial polymerization | Water | 13.2 | Na2SO4 | ~50.0 | [145] |

| MgSO4 | ~48.0 | ||||||

| MgCl2 | ~47.0 | ||||||

| NaCl | ~12.0 | ||||||

| Methylene blue | ~85.0 | ||||||

| Orange GII | ~90.0 | ||||||

| Congo red | ~96.0 | ||||||

| Methyl blue | ~100.0 | ||||||

| Zwitterionic polyelectrolyte nanoparticles (ZPNPs)-PIP/TMC | PSF-UF | Interfacial polymerization | Water | ~10.0 | Na2SO4 | ~96.5 | [149] |

| NaCl | ~10.0 | ||||||

| AEPPS-MPD/TMC | PSF-UF | Interfacial polymerization | Water | 3.6 | NaCl | 98.3 | [34] |

| Zwitterionic colloid nanoparticles (ZCPs)-MPD/TMC | PSF-UF | Interfacial polymerization | Water | ~2.5 | NaCl | 96.5 | [151] |

| Zwitterion-CNT/MPD/TMC | PES-UF | Deposition and interfacial polymerization | Water | ~1.3 | NaCl | 98.6 | [152] |

| GO-PSBMA/polyethersulfone (PES) | - | Phase inversion | Water | ~12.0 | Na2SO4 | ~10.0 | [154] |

| MgSO4 | ~9.0 | ||||||

| MgCl2 | ~7.6 | ||||||

| NaCl | ~4.0 | ||||||

| RR49 | ~97.0 | ||||||

| RB5 | 99.2 | ||||||

| Sulphobetaine tri-copolymer (PDHD) | PSF-UF | Surface coating and chemical cross-linking | Water | ~8.0 | MgCl2 | 96.5 | [155] |

| NaCl | 48.5 | ||||||

| Zwitterionic colloid particles (ZCPs) | PSF-UF | Surface coating and chemical cross-linking | Water | ~4.0 | PEG1000 | ~96.0 | [150] |

| PEG600 | ~88.0 | ||||||

| PEG200 | ~60.0 | ||||||

| Na2SO4 | ~20.0 | ||||||

| Carboxybetaine bi-copolymer (PCH) | PSF-UF | Surface coating and chemical cross-linking | Water | ~8.0 | Na2SO4 | 91.8 | [47] |

| MgSO4 | 33.3 | ||||||

| MgCl2 | 23.5 | ||||||

| NaCl | 3.6 | ||||||

| PEG800 | 93.4 | ||||||

| PDDA/PSS, PSBMA | Sulfonated PES hollow fiber silica | LBL | Water | 4.5 | Na2SO4 | ~98.0 | [158] |

| NaCl | ~40.0 | ||||||

| CaCl2 | ~20.0 | ||||||

| Zwitterionic amphiphilic copolymers PTFEMA-r-SBMA | PVDF 400R UF | Self-assembly | Water | 8.4 | Methyl Orange | ~30 | [163] |

| Brilliant Blue R | ~100 | ||||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, Y.-L.; Gu, B.-X.; An, Q.-F.; Gao, C.-J. Recent Advances in the Fabrication of Membranes Containing “Ion Pairs” for Nanofiltration Processes. Polymers 2017, 9, 715. https://doi.org/10.3390/polym9120715

Ji Y-L, Gu B-X, An Q-F, Gao C-J. Recent Advances in the Fabrication of Membranes Containing “Ion Pairs” for Nanofiltration Processes. Polymers. 2017; 9(12):715. https://doi.org/10.3390/polym9120715

Chicago/Turabian StyleJi, Yan-Li, Bing-Xin Gu, Quan-Fu An, and Cong-Jie Gao. 2017. "Recent Advances in the Fabrication of Membranes Containing “Ion Pairs” for Nanofiltration Processes" Polymers 9, no. 12: 715. https://doi.org/10.3390/polym9120715

APA StyleJi, Y.-L., Gu, B.-X., An, Q.-F., & Gao, C.-J. (2017). Recent Advances in the Fabrication of Membranes Containing “Ion Pairs” for Nanofiltration Processes. Polymers, 9(12), 715. https://doi.org/10.3390/polym9120715