Synthesis, Morphologies and Building Applications of Nanostructured Polymers

Abstract

1. Introduction

1.1. Polymer Nanoparticles (PNPs)

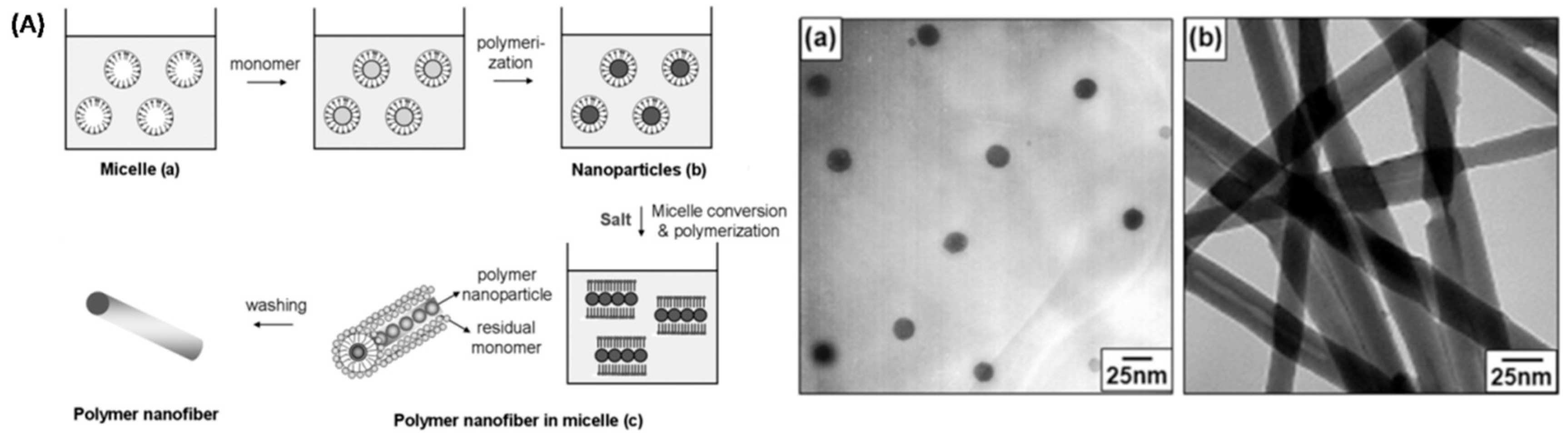

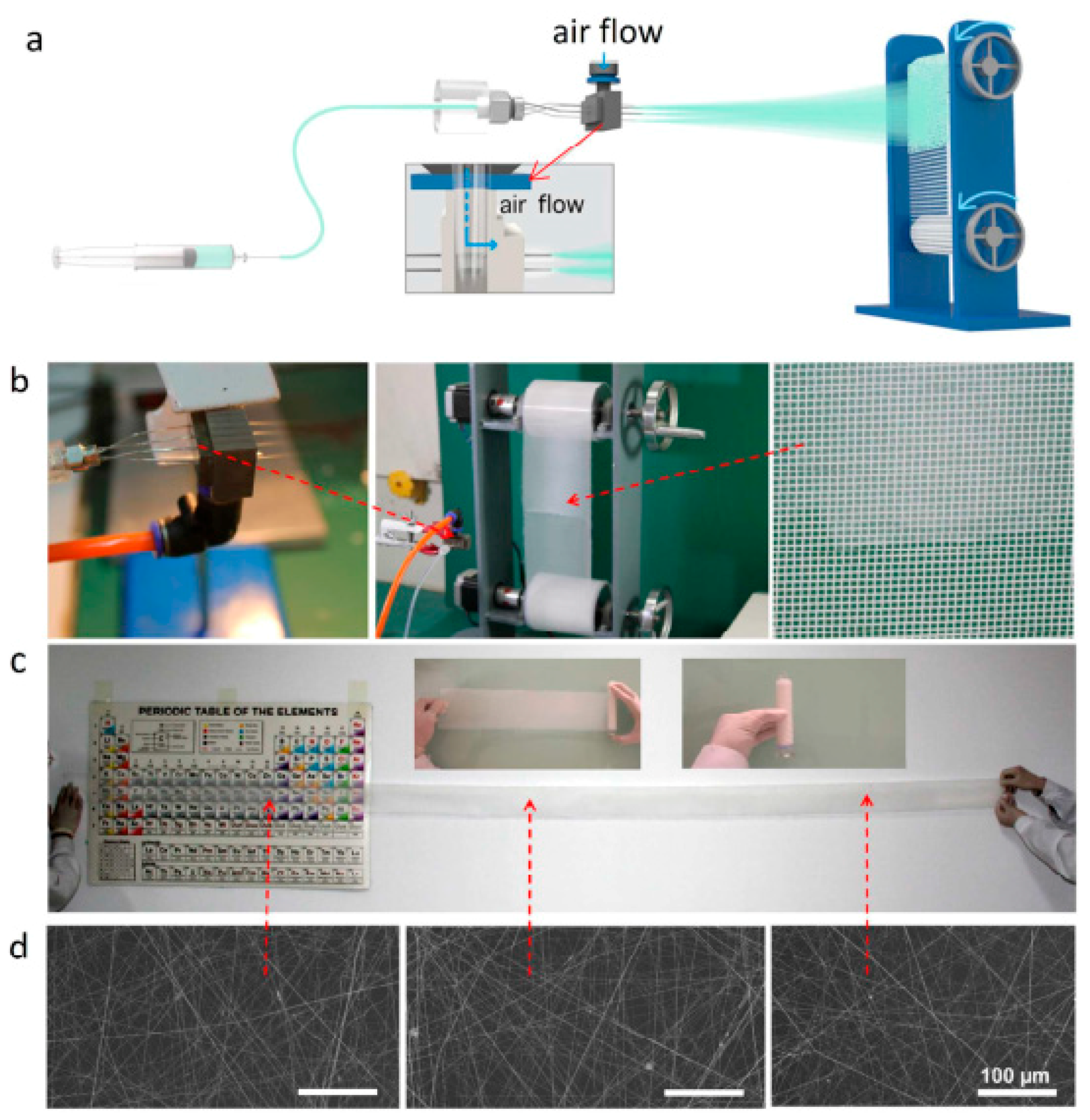

1.2. Polymer Nanofibers (PNFs)

2. Nanosynthesis of Representative Polymers Used in Construction

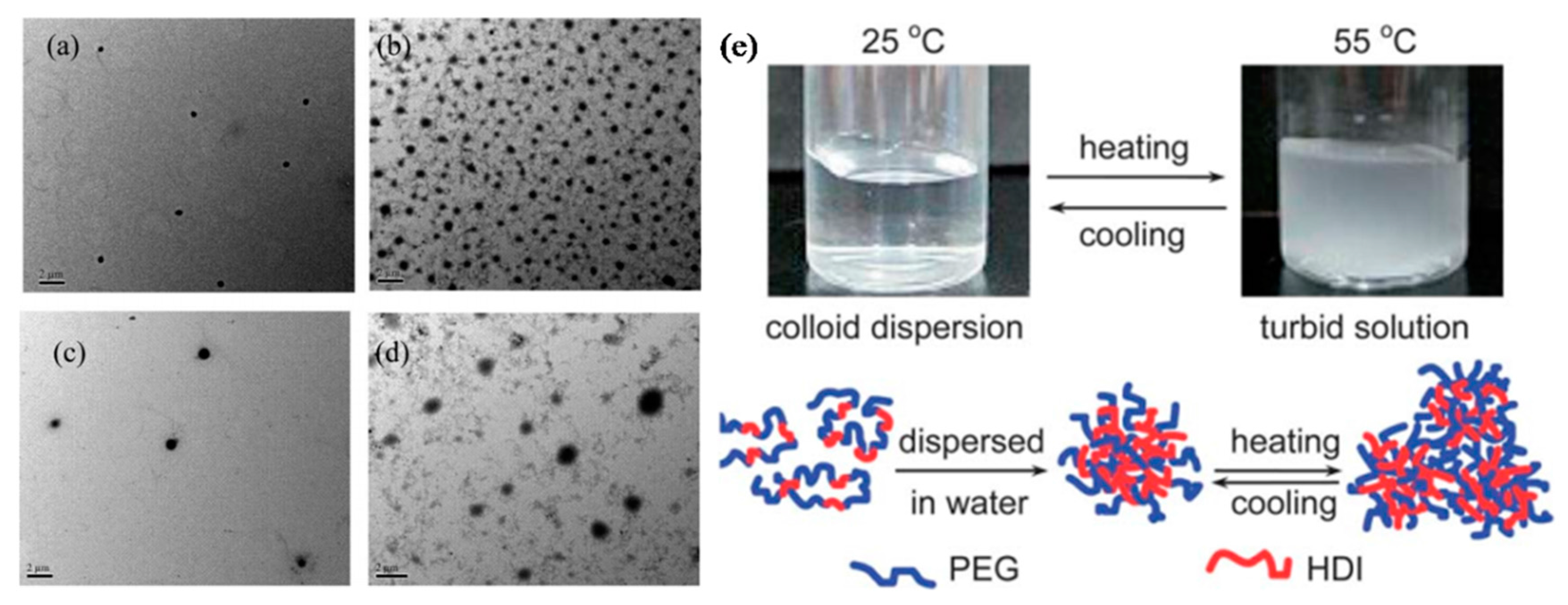

2.1. Synthesis of Nanostructured Polyurethane (NS-PU)

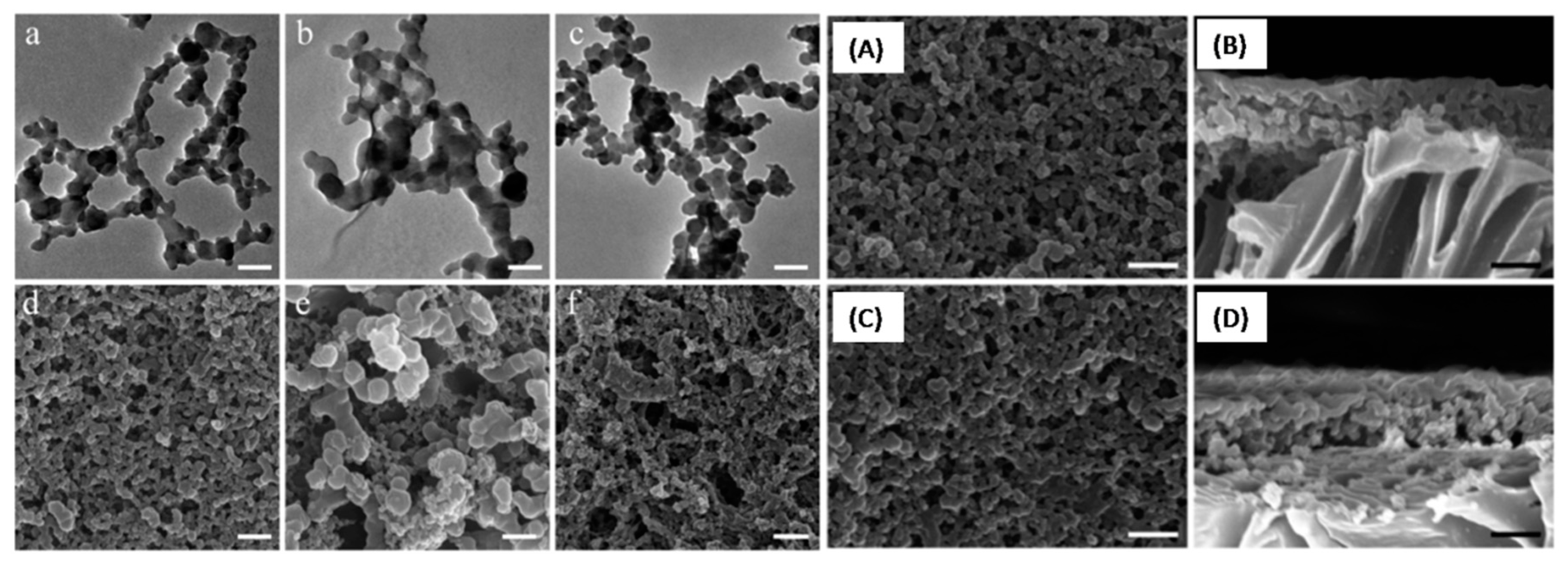

2.2. Synthesis of Nanostructured Polystyrene (NS-PS)

2.3. Synthesis of Nanostructured Polyacrylonitrile (NS-PAN)

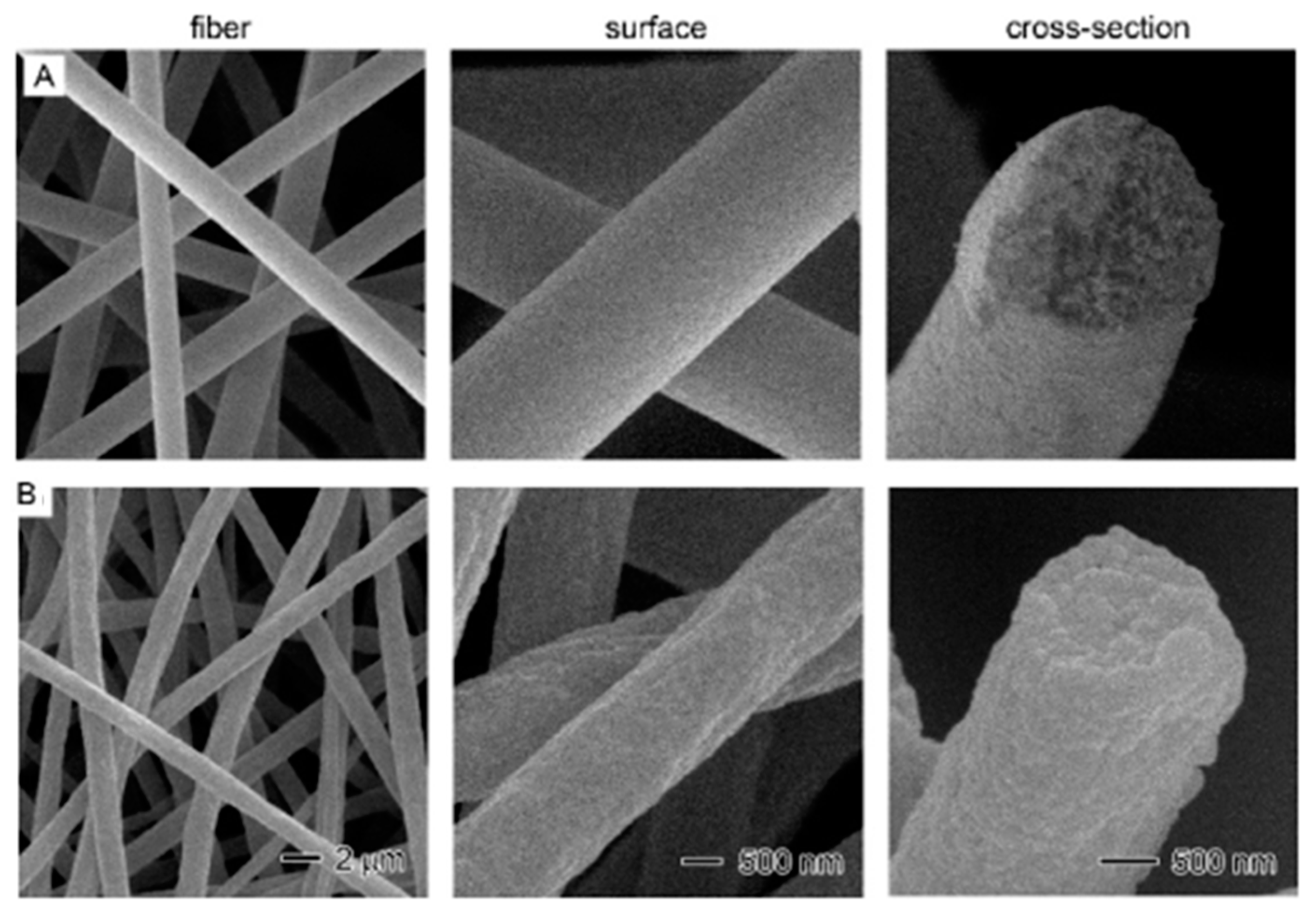

2.4. Synthesis of Nanostructured Polyvinyl Chloride (NS-PVC)

3. Building Applications of Polymers Used in Construction Industry

3.1. Air Filtration

3.2. Thermal Energy Storage

3.3. Sound Absorption

3.4. Other Applications

3.4.1. Anti-corrosion Coating

3.4.2. Metal Coating

3.4.3. Reinforced Adhesive

3.4.4. Flame Retardant

4. Outlook and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Needham, R.B.; Doe, P.H. Polymer flooding review. J. Pet. Technol. 1987, 39, 1503–1507. [Google Scholar] [CrossRef]

- Cheung, H.Y.; Lau, K.T.; Lu, T.P.; Hui, D. A critical review on polymer-based bio-engineered materials for scaffold development. Compos. Part B 2007, 38, 291–300. [Google Scholar] [CrossRef]

- Shrive, N.G. The use of fibre reinforced polymers to improve seismic resistance of masonry. Constr. Build. Mater. 2006, 20, 269–277. [Google Scholar] [CrossRef]

- Halliwell, S.M. Polymers in Building and Construction; Rapra Review Report; Rapra Technology Ltd.: Shropshire, UK, 2002; Volume 13, ISSN 0889-3144. [Google Scholar]

- Herrmann, A.S.; Nickel, J.; Riedel, U. Construction materials based upon biologically renewable resources-from components to finished parts. Polym. Degrad. Stab. 1998, 59, 251–261. [Google Scholar] [CrossRef]

- Feldman, D. Polymer nanocomposites in building, construction. J. Macromol. Sci. Part A Pure Appl. Chem. 2014, 51, 203–209. [Google Scholar] [CrossRef]

- Rana1, A.K.; Rana, S.B.; Kumari, A.; Kiran, V. Significance of nanotechnology in construction engineering. Int. J. Recent Trends Eng. 2009, 4, 46–48. [Google Scholar]

- Torgala, F.P.; Jalali, S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials. Constr. Build. Mater. 2011, 25, 582–590. [Google Scholar] [CrossRef]

- Raoa, J.P.; Geckeler, K.E. Polymer nanoparticles: Preparation techniques and size-control parameters. Prog. Polym. Sci. 2011, 36, 887–913. [Google Scholar] [CrossRef]

- Zhao, B.; Deng, J. Emulsion polymerization of acetylenics for constructing optically active helical polymer nanoparticles. Polym. Rev. 2016, 1–19. [Google Scholar] [CrossRef]

- Huang, Z.M.; Zhang, Y.Z.; Kotakic, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Arinstein, A.; Zussman, E. Electrospun polymer nanofibers: Mechanical and thermodynamic perspectives. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 691–707. [Google Scholar] [CrossRef]

- Reis, C.P.; Neufeld, R.J.; Ribeiro, A.J.; Veiga, F. Nanoencapsulation I. Methods for preparation of drug-loaded polymeric nanoparticles. Nanomed. Nanotechnol. Biol. Med. 2006, 2, 8–21. [Google Scholar] [CrossRef] [PubMed]

- Jang, J.S.; Oh, J.H. Novel crystalline supramolecular assemblies of amorphous polypyrrole nanoparticles through surfactant templating. Chem. Commun. 2002, 19, 2200. [Google Scholar] [CrossRef]

- Zhang, Q.; Chuang, K.T. Adsorption of organic pollutants from effluents of a kraft pulp mill on activated carbon and polymer resin. Adv. Environ. Res. 2001, 5, 251–258. [Google Scholar] [CrossRef]

- Pal, S.L.; Jana, U.; Manna, P.K.; Mohanta, G.P.; Manavalan, R. Nanoparticle: An overview of preparation and characterization. J. Appl. Pharm. Sci. 2011, 1, 228–234. [Google Scholar]

- Julienne, V.M.C.; Benoit, J.P. Preparation, purification and morphology of polymeric nanoparticles as drug carriers. Pharm. Acta Helv. 1996, 71, 121–128. [Google Scholar] [CrossRef]

- Crucho, C.I.C.; Barros, M.T. Formulation of functionalized PLGA polymeric nanoparticles for targeted drug delivery. Polymer 2015, 68, 41–46. [Google Scholar] [CrossRef]

- Bilati1, U.; Allemann, E.; Doelker, E. Development of a nanoprecipitation method intended for the entrapment of hydrophilic drugs into nanoparticles. Eur. J. Pharm. Sci. 2005, 24, 67–75. [Google Scholar] [CrossRef] [PubMed]

- Song, X. PLGA nanoparticles simultaneously loaded with vincristine sulfate and verapamil hydrochloride: Systematic study of particle size and drug entrapment efficiency. Int. J. Pharm. 2008, 350, 320–329. [Google Scholar] [CrossRef] [PubMed]

- Allemann, E.; Gurny, R.; Doelker, E. Preparation of aqueous polymeric nanodispersions by a reversible salting-out process: Influence of process parameters on particle size. Int. J. Pharm. 1992, 87, 247–253. [Google Scholar] [CrossRef]

- Jeong, Y.I.; Cho, C.S.; Kim, S.H.; Ko, K.S.; Kim, S.I.; Shim, Y.H.; Nah, J.W. Preparation of poly(dl-lactide-co-glycolide) nanoparticles without surfactant. J. Appl. Polym. Sci. 2001, 80, 2228–2236. [Google Scholar] [CrossRef]

- Thickett, S.C.; Gilbert, R.G. Emulsion polymerization: State of the art in kinetics and mechanisms. Polymer 2007, 48, 6965–6991. [Google Scholar] [CrossRef]

- Soppimath, K.S.; Aminabhavi, T.M.; Kulkarni, A.R.; Rudzinski, W.E. Biodegradable polymeric nanoparticles as drug delivery devices. J. Control. Release 2001, 70, 1–20. [Google Scholar] [CrossRef]

- Yuan, L.; Wang, Y.; Pan, M.; Rempela, G.L.; Pan, Q. Synthesis of poly(methyl methacrylate) nanoparticles via differential microemulsion polymerization. Eur. Polym. J. 2013, 49, 41–48. [Google Scholar] [CrossRef]

- Wu, M.; Dellacherie, E.; Durand, A.; Marie, E. Poly(N-butyl cyanoacrylate) nanoparticles via miniemulsion polymerization (1): Dextranbased surfactants. Colloid Surf. B 2009, 69, 141–146. [Google Scholar] [CrossRef] [PubMed]

- Hirech, K.; Payan, S.; Carnelle, G.; Brujes, L.; Legrand, J. Microencapsulation of an insecticide by interfacial polymerization. Powder Technol. 2003, 130, 324–330. [Google Scholar] [CrossRef]

- Scott, C.; Wu, D.; Ho, C.C.; Co, C.C. Liquid-core capsules via interfacial polymerization: A free-radical analogy of the nylon rope trick. J. Am. Chem. Soc. 2005, 127, 4160–4161. [Google Scholar] [CrossRef] [PubMed]

- Desgouilles, S.; Vauthier, C.; Bazile, D.; Vacus, J.; Grossiord, J.L.; Veillard, M.; Couvreur, P. The design of nanoparticles obtained by solvent evaporation: A comprehensive study. Langmuir 2003, 19, 9504–9510. [Google Scholar] [CrossRef]

- Higuchi, T.; Yabu, H.; Shimomura, M. Simple preparation of hemispherical polystyrene particles. Colloid Surf. A 2006, 284–285, 250–253. [Google Scholar] [CrossRef]

- Fessi, H.; Puisieux, F.; Devissaguet, J.P.; Ammoury, N.; Benita, S. Nanocapsule formation by interfacial polymer deposition following solvent displacement. Int. J. Pharm. 1989, 55, R1–R4. [Google Scholar] [CrossRef]

- Ganachaud, F.; Katz, J.L. Nanoparticles and nanocapsules created using the ouzo effect: Spontaneous emulsification as an alternative to ultrasonic and high-shear devices. ChemPhysChem 2005, 6, 209–216. [Google Scholar] [CrossRef] [PubMed]

- Noh, M.; Lee, D. Synthesis and characterization of PS-clay nanocomposite by emulsion polymerization. Polym. Bull. 1999, 42, 619–626. [Google Scholar] [CrossRef]

- Lu, S.; Qu, R.; Forcada, J. Preparation of magnetic polymeric composite nanoparticles by seeded emulsion polymerization. Mater. Lett. 2009, 63, 770–772. [Google Scholar] [CrossRef]

- Baji, A.; Mai, Y.W.; Wong, S.C.; Abtahi, M.; Chen, P. Electronspinning of polymer nanofibers: Effects on oriented morphology, structures and tensile properties. Compos. Sci. Technol. 2010, 70, 703–718. [Google Scholar] [CrossRef]

- Persano, L.; Camposeo, A.; Tekmen, C.; Pisignano, D. Industrial upscaling of electrospinning and applications of polymer nanofibers: A Review. Macromol. Mater. Eng. 2013, 298, 504–520. [Google Scholar] [CrossRef]

- Ondarcuhu, T.; Joachim, C. Drawing a single nanofibre over hundreds of microns. Eur. Phys. Lett. 1998, 42, 215–220. [Google Scholar] [CrossRef]

- Martin, C.R. Membrane-based synthesis of nanomaterials. Chem. Mater. 1996, 8, 1739–1746. [Google Scholar] [CrossRef]

- Nam, Y.S.; Park, T.G. Biodegradable polymeric microcellular foams by modifed thermally induced phase separation method. Biomaterials 1999, 20, 1783–1790. [Google Scholar] [CrossRef]

- Liu, G.J.; Ding, J.F.; Qiao, L.J.; Guo, A.; Dymov, B.P.; Gleeson, J.T. Polystyrene-block-poly(2-cinnamoylethyl methacrylate) nanofibers: Preparation, characterization, and liquid crystalline properties. Chem. A Eur. J. 1999, 5, 2740–2749. [Google Scholar] [CrossRef]

- Frenot, A.; Chronakis, I.S. Polymer nanofibers assembled by electrospinning. Curr. Opin. Colloid Interface Sci. 2003, 8, 64–75. [Google Scholar] [CrossRef]

- Megelski, S.; Stephens, J.S.; Rabolt, J.F.; Bruce, C.D. Micro- and nanostructured surface morphology on electrospun polymer fibers. Macromolecules 2002, 35, 8456–8466. [Google Scholar] [CrossRef]

- Lee, K.H.; Kim, H.Y.; La, Y.M.; Lee, D.R.; Sung, N.H. Influence of a mixing solvent with tetrahydrofuran and N,N-dimethylformamide on electrospun poly(vinylchloride) nonwoven mats. J. Polym. Sci Part B Polym. Phys. 2002, 40, 2259–2268. [Google Scholar] [CrossRef]

- Serkis-Rodzeń, M.; Spírková, M.; Matejícek, P.; Stepánek, M. Formation of linear and crosslinked polyurethane nanoparticles that self-assemble differently in acetone and in water. Prog. Org. Coat. 2017, 106, 119–127. [Google Scholar] [CrossRef]

- Fu, H.; Gao, H.; Wu, G.; Wang, Y.; Fan, Y.; Ma, J. Preparation and tunable temperature sensitivity of biodegradable polyurethane nanoassemblies from diisocyanate and poly(ethylene glycol). Soft Matter 2011, 7, 3546–3552. [Google Scholar] [CrossRef]

- Wang, A.; Gao, H.; Sun, Y.; Sun, Y.; Yang, Y.; Wu, G.; Wang, Y.; Fan, Y.; Ma, J. Temperature- and pH-responsive nanoparticles of biocompatible polyurethanes for doxorubicin delivery. Int. J. Pharm. 2013, 441, 30–39. [Google Scholar] [CrossRef] [PubMed]

- Ramos, B.J.Z.; Sennab, E.L.; Soldia, V.; Borsalic, R.; Cloutetc, E.; Cramail, H. Polyurethane nanoparticles from a natural polyol via miniemulsion technique. Polymer 2006, 47, 8080–8087. [Google Scholar] [CrossRef]

- Shendi, H.K.; Omrani, I.; Ahmadi, A.; Farhadian, A.; Babanejad, N.; Nabid, M.R. Synthesis and characterization of a novel internal emulsifier derived from sunflower oil for the preparation of waterborne polyurethane and their application in coatings. Prog. Org. Coat. 2017, 105, 303–309. [Google Scholar] [CrossRef]

- Zhuo, H.; Hu, J.; Chen, S.; Yeung, L. Preparation of polyurethane nanofibers by electrospinning. J. Appl. Polym. Sci. 2008, 109, 406–411. [Google Scholar] [CrossRef]

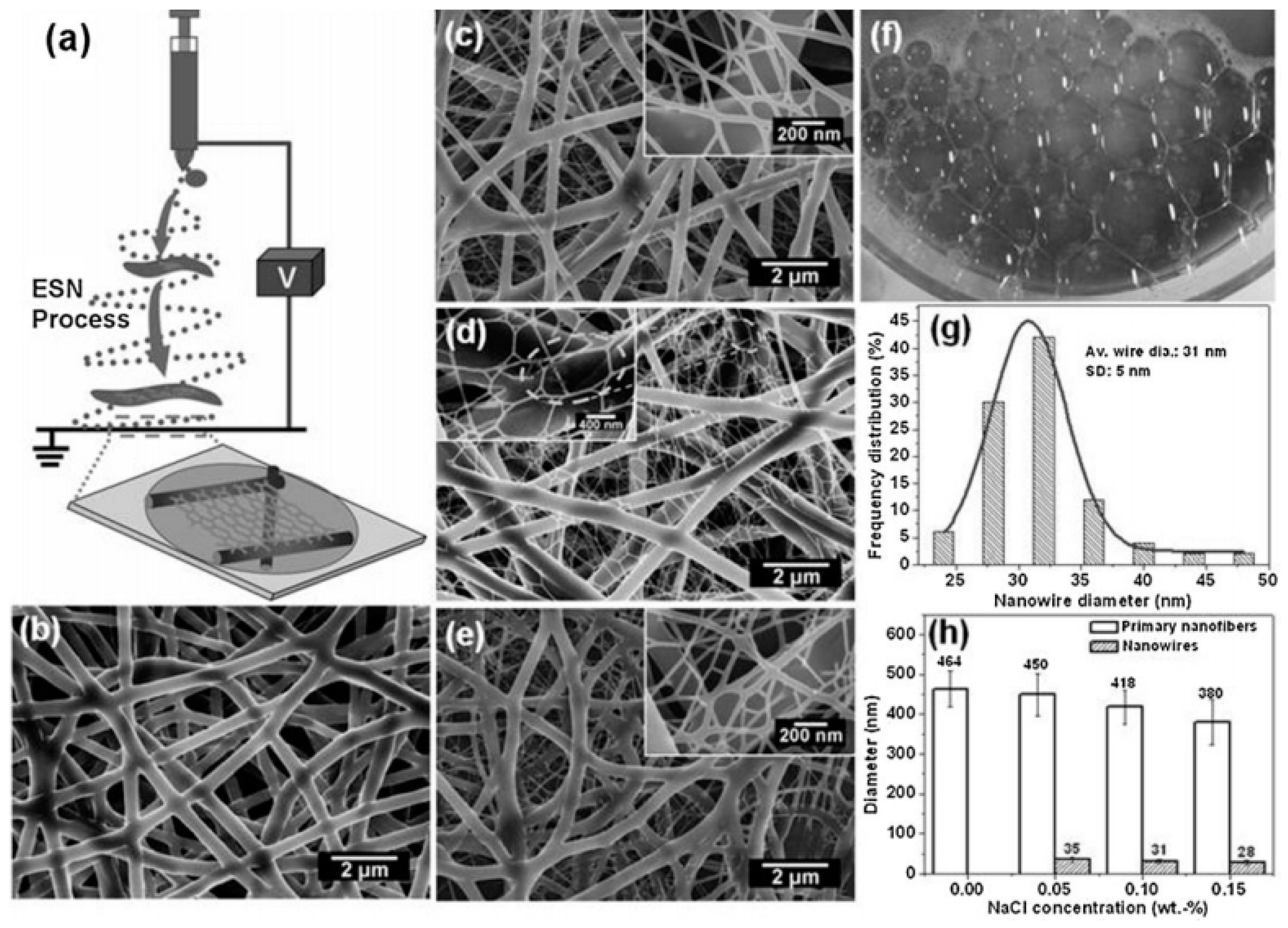

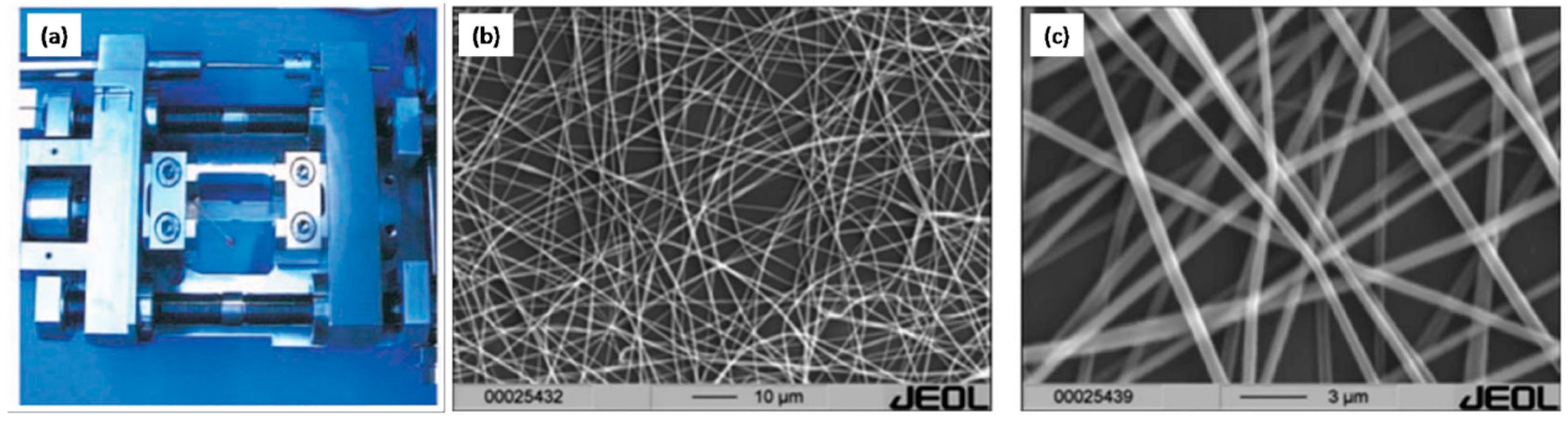

- Hu, J.; Wang, X.; Ding, B.; Lin, J.; Yu, J.; Sun, G. One-step electro-spinning/netting technique for controllably preparing polyurethane nano-fiber/net. Macromol. Rapid Commun. 2011, 32, 1729–1734. [Google Scholar] [CrossRef] [PubMed]

- Lev, J.; Holba, M.; Došek, M.; Kalhotka, L.; Mikulǎ, P.; Kimmer, D. A novel electrospun polyurethane nanofibre membrane—Production parameters and suitability for wastewater (WW) treatment. Water Sci. Technol. 2014, 69, 1496–1501. [Google Scholar] [CrossRef] [PubMed]

- Lev, J.; Holba, M.; Kalhotk, L.; Mikula, P.; Kimmer, D. Improvements in the structure of electrospun polyurethane nanofibrous materials used for bacterial removal from wastewater. Inter. J. Theor. Appl. Nanotechnol. 2012, 1, 16–20. [Google Scholar] [CrossRef]

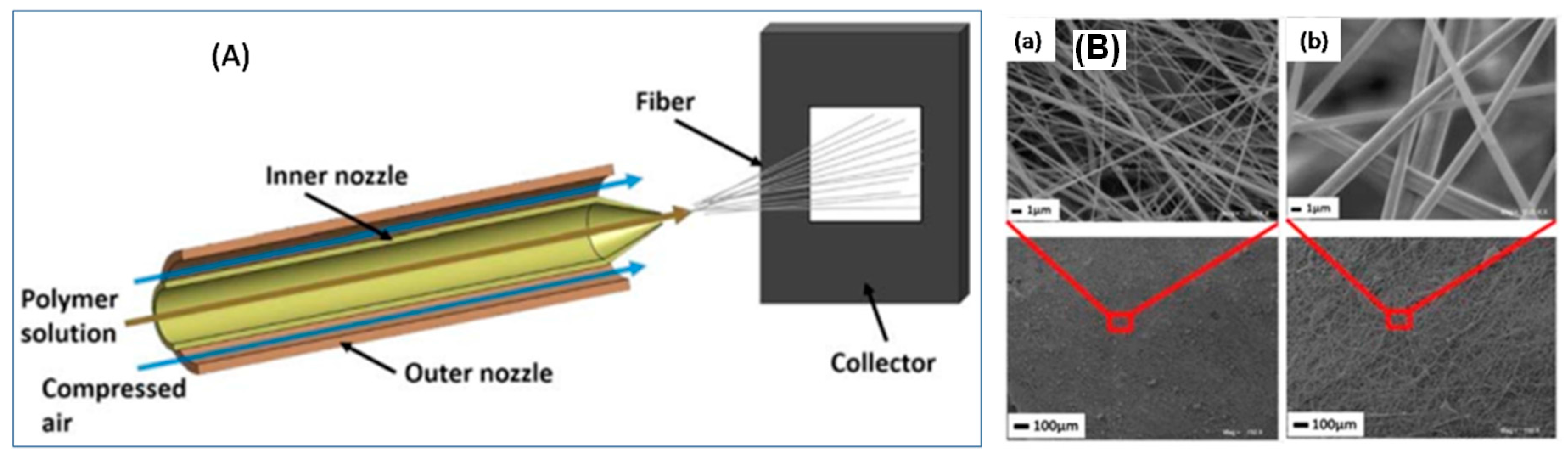

- Guan, K.; Zhuang, X.; Yan, G.; Cheng, B. Fabrication and properties of polyurethane nanofibers nonwoven by solution blowing. Adv. Mater. Res. 2011, 332–334, 1339–1342. [Google Scholar] [CrossRef]

- Polat, Y.; Pampal, E.S.; Stojanovska, E.; Simsek, R.; Hassanin, A.; Kilic, A.; Demir, A.; Yilmaz, S. Solution blowing of thermoplastic polyurethane nanofibers: A facile method to produce flexible porous materials. J. Appl. Polym. Sci. 2016, 133, 43025. [Google Scholar] [CrossRef]

- Ernawati, L.; Balgis, R.; Ogi, T.; Okuyama, K.; Takada, T. Role of acetone in the formation of highly dispersed cationic polystyrene nanoparticles. Chem. Process Eng. 2017, 38, 5–18. [Google Scholar] [CrossRef]

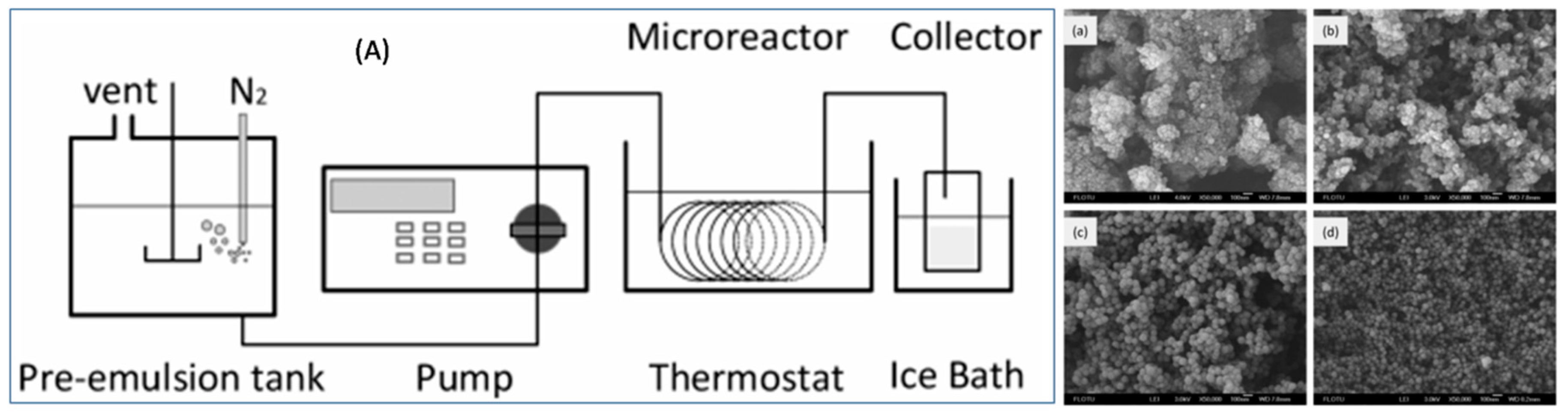

- Liu, X.; Lu, Y.; Luo, G. Continuous flow synthesis of polystyrene nanoparticles via emulsion polymerization stabilized by a mixed nonionic and anionic emulsifier. Ind. Eng. Chem. Res. 2017, 56, 9489–9495. [Google Scholar] [CrossRef]

- Asran, A.S.; Seydewitz, V.; Michler, G.H. Micromechanical properties and ductile behavior of electrospun polystyrene nanofibers. J. Appl. Polym. Sci. 2012, 125, 1663–1673. [Google Scholar] [CrossRef]

- Hashemifard, N.; Shariati, S. Electrospun polystyrene nanofiber as an adsorbent for solid-phase extraction of disulfine blue from aqueous samples. Arab. J. Sci. Eng. 2016, 41, 2487–2492. [Google Scholar] [CrossRef]

- Liu, F.; Song, D.; Huang, X.; Xu, H. Electrospun polystyrene nanofibers as a novel adsorbent to transfer an organic phase from an aqueous phase. J. Sep. Sci. 2016, 39, 1326–1330. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.W.; An, S.; Latthe, S.S.; Lee, C.; Hong, S.; Yoon, S.S. Electrospun polystyrene nanofiber membrane with superhydrophobicity and superoleophilicity for selective separation of water and low viscous oil. ACS Appl. Mater. Interfaces 2013, 5, 10597–10604. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Zhang, Q.; Guo, N.; Zhu, A.; Liu, Q. Ultrafine polystyrene nanofibers and its application in nanofibrous membranes. Chem. Eng. J. 2015, 264, 329–335. [Google Scholar] [CrossRef]

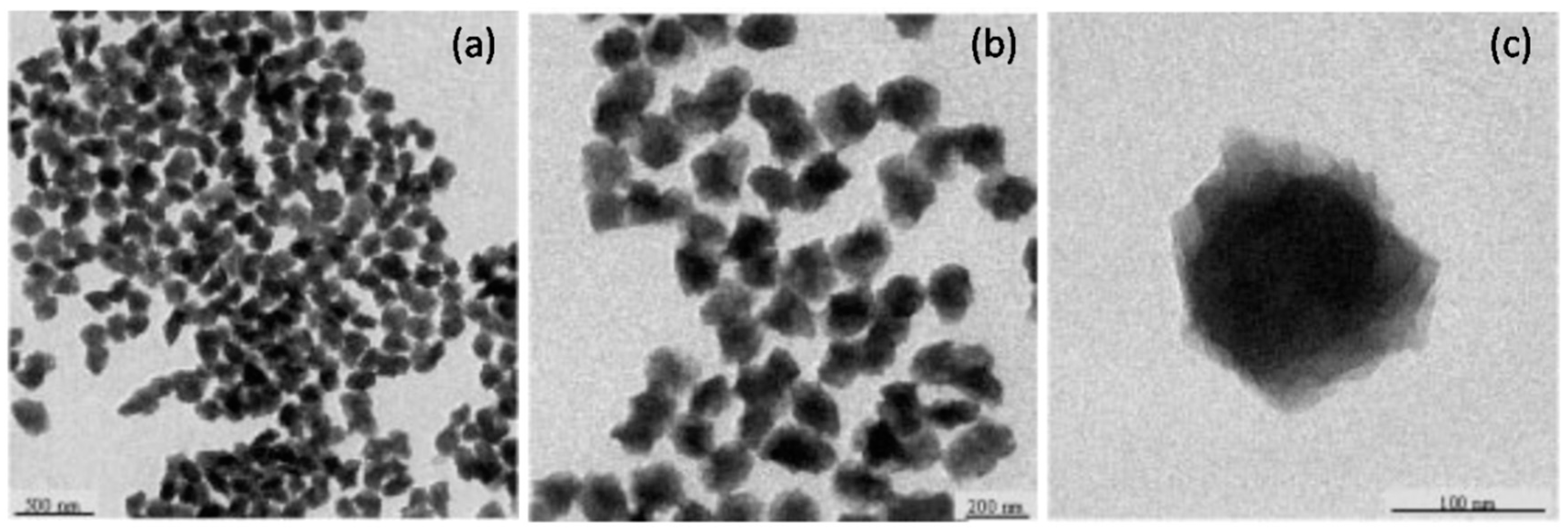

- Landfester, K.; Antonietti, M. The polymerization of acrylonitrile in miniemulsions: “Crumpled latex particles” or polymer nanocrystals. Macromol. Rapid Commun. 2000, 21, 820–824. [Google Scholar] [CrossRef]

- Jeon, H.J.; You, Y.; Yoon, M.J.; Youk, J.H. Preparation of polyacrylonitrile nanoparticles via dispersion polymerization of acrylonitrile using a poly(N-vinyl pyrrolidone)-cobalt complex in an aqueous system. Polymer 2011, 52, 3905–3911. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhuang, X.; Gu, W.; Zhao, J. Synthesis of polyacrylonitrile nanoparticles at high monomer concentrations by AIBN-initiated semi-continuous emulsion polymerization method. Eur. Polym. J. 2015, 67, 57–65. [Google Scholar] [CrossRef]

- Lee, I.; Kim, S.; Kim, S.; Jang, Y.; Jan, J. Highly fluorescent amidine/schiff base dual-modified polyacrylonitrile nanoparticles for selective and sensitive detection of copper ions in living cells. ACS Appl. Mater. Interfaces 2014, 6, 17151–17156. [Google Scholar] [CrossRef] [PubMed]

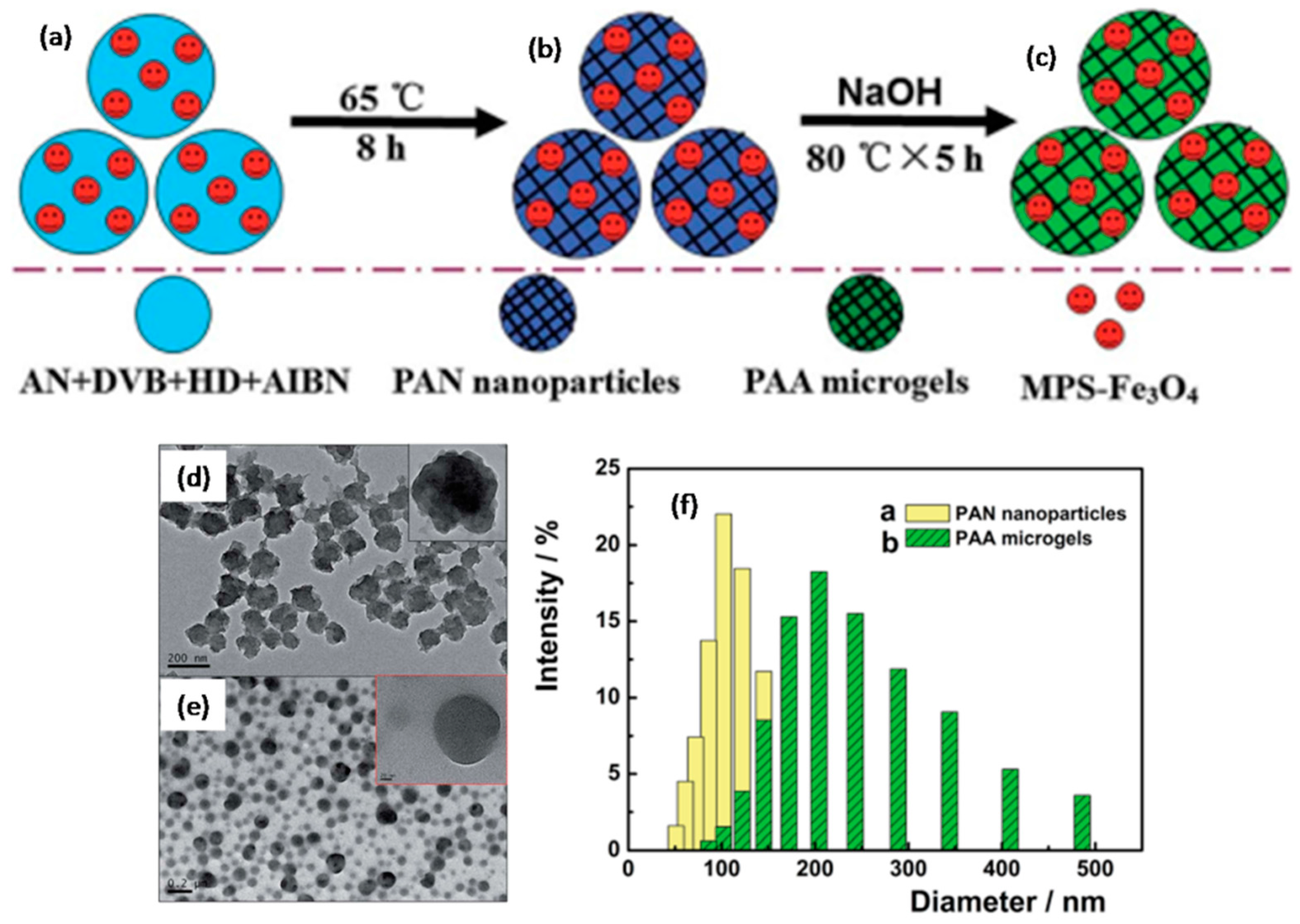

- Zhang, J.; Lu, Z.; Wu, M.; Wu, Q.; Yang, J. Large-scale synthesis and characterization of magnetic poly(acrylic acid) nanogels via miniemulsion polymerization. RSC Adv. 2015, 5, 58889–58894. [Google Scholar] [CrossRef]

- Youm, J.S.; Kim, J.H.; Kim, C.H.; Kim, J.C.; Kim, Y.A.; Yang, K.S. Densifying and strengthening of electrospun polyacrylonitrile-based nanofibers by uniaxial two-step stretching. J. Appl. Polym. Sci. 2016, 133, 43945. [Google Scholar] [CrossRef]

- Kim, H.Y.; Kim, B.; Lee, B.C.; Koo1, Y.H.; Baeck, S.H.; Shim, S.E. Structure evolution of electrospun polyacrylonitrile nanofibers by electron beam irradiation. Fibers Polym. 2015, 16, 834–839. [Google Scholar] [CrossRef]

- Wang, W.; Liu, Y.; Wang, Y.; Chen, H.; Bai, L. A novel and convenient preparation of antibacterial polyacrylonitrile nanofibers via post-modification using nitrile click chemistry and electrospinning. Chem. Pap. 2017, 133, 1–10. [Google Scholar] [CrossRef]

- Almasiana, A.; Fardb, C.; Gashtic, M.P.; Mirjalilic, M.; Mokhtari, Z.; Shourijeh, M. Surface modification of electrospun PAN nanofibers by amine compounds for adsorption of anionic dyes. Desalin. Water Treat. 2016, 57, 10333–10348. [Google Scholar] [CrossRef]

- Dilpazir, S.; Usman, M.; Rasulband, S.; Arshad, S.N. A simple UV-Ozone surface treatment to enhance photocatalytic performance of TiO2 loaded polymer nanofiber membranes. RSC Adv. 2016, 6, 14751–14755. [Google Scholar] [CrossRef]

- Makaremi, M.; Lim, C.X.; Pasbakhsh, P.; Lee, S.M.; Goh, K.L.; Chang, H.; Chan, E.S. Electrospun functionalized polyacrylonitrile–chitosan Bi-layer membranes for water filtration applications. RSC Adv. 2016, 6, 53882–53893. [Google Scholar] [CrossRef]

- Elkhaldi, R.M.; Guclu, S.; Koyuncu, I. Enhancement of mechanical and physical properties of electrospun PAN nanofiber membranes using PVDF particles. Desalin. Water Treat. 2016, 57, 26003–26013. [Google Scholar] [CrossRef]

- Jang, J.; Bae, J.; Park, E. Polyacrylonitrile nanofibers: Formation mechanism and applications as a photoluminescent material and carbon-nanofiber precursor. Adv. Funct. Mater. 2006, 16, 1400–1406. [Google Scholar] [CrossRef]

- Vatani, Z.; Eisazadeh, H. Coating of poly(vinyl chloride) nanoparticles with a conductive polyaniline in the presence of various surfactants. J. Vinyl Addit. Technol. 2013, 19, 233–238. [Google Scholar] [CrossRef]

- Phatcharasit, K.; Taweepreda, W.; Boonkerd, K.; Kim, H.K. Preparation and properties of electrospun PVC nanofiber. Adv. Mater. Res. 2013, 770, 193–196. [Google Scholar] [CrossRef]

- Jiang, T.; Kang, W.; Cheng, B. Preparation and characterization of electrospun CPVC nanofiber nonwovens. Adv. Mater. Res. 2012, 557–559, 456–459. [Google Scholar] [CrossRef]

- Krupa, A.; Sobczyk, A.T.; Jaworek, A. Surface properties of plasma-modifed poly(vinylidene fluoride) and poly(vinyl chloride) nanofbres. Fibers Text. East. Eur. 2014, 22, 35–39. [Google Scholar]

- Guo, N.; Zhang, Q.; Li, H.; Wu, X.; Liu, Q.; Zhu, A. Facile fabrication, structure, and applications of polyvinyl chloride mesoporous membranes. Ind. Eng. Chem. Res. 2014, 53, 20068–20073. [Google Scholar] [CrossRef]

- Tauer, K.; Qoebel, K.H.; Kosmella, S.; Stahler, K.; Neelsen, J. Emulsion polymerization in the presence of polymerizible emulsifiers and surface active initiators. Macromol. Symp. 1990, 31, 107–121. [Google Scholar] [CrossRef]

- Wu, H.; Khalid, B.; Bai, X.; Wei, H.; Huang, Y.; Cui, Y. Direct blow-spinning of nanofibers on window screen for highly efficient PM2.5 removal. Nano Lett. 2017, 17, 1140–1148. [Google Scholar]

- Jing, L.; Shim, K.; Toe, C.Y.; Fang, T.; Zhao, C.; Amal, R.; Sun, K.; Kim, J.H.; Ng, Y.H. Electrospun polyacrylonitrile-ionic liquid nanofibers for superior PM2.5 capture capacity. ACS Appl. Mater. Interfaces 2016, 8, 7030–7036. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Liu, C.; Hsu, P.-C.; Zhang, C.; Liu, N.; Zhang, J.; Lee, H.R.; Lu, Y.; Qiu, Y.; Chu, S.; et al. Nanofiber air filters with high-temperature stability for efficient PM2.5 removal from the pollution sources. Nano Lett. 2016, 16, 3642–3649. [Google Scholar] [PubMed]

- Xu, J.; Liu, C.; Hsu, P.C.; Liu, K.; Zhang, R.; Liu, Y.; Cui, Y. Roll-to-Roll transfer of electrospun nanofiber film for high-efficiency transparent air filter. Nano Lett. 2016, 16, 1270–1275. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Xu, Y.; Wei, H.; Wang, X. Electrospun polycarbonate nanofibrous membrane for high efficiency particulate matter filtration. RSC Adv. 2016, 6, 65275–65281. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Yin, X.; Yu, J.; Ding, B. Anti-deformed polyacrylonitrile/polysulfone composite membrane with binary structures for effective air filtration. ACS Appl. Mater. Interfaces 2016, 8, 8086–8095. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhao, X.; Yin, X.; Yu, J.; Ding, B. Electret polyvinylidene fluoride nanofibers hybridized by polytetrafluoroethylene nanoparticles for high-efficiency air filtration. ACS Appl. Mater. Interfaces 2016, 8, 23985–23994. [Google Scholar] [CrossRef] [PubMed]

- Su, J.; Yang, G.; Cheng, C.; Huang, C.; Xu, H.; Ke, Q. Hierarchically structured TiO2/PAN nanofibrous membranes for high-efficiency air filtration and toluene degradation. J. Colloid Interface Sci. 2017, 507, 386–396. [Google Scholar] [CrossRef] [PubMed]

- Sarı, A.; Alkan, C.; Doguscu, D.K.; Kızıl, C. Micro/nano encapsulated n-tetracosane and n-octadecane eutectic mixture with polystyrene shell for low-temperature latent heat thermal energy storage applications. Sol. Energy 2015, 115, 195–203. [Google Scholar] [CrossRef]

- Fang, Y.; Kuang, S.; Gao, X.; Zhang, Z. Preparation and characterization of novel nanoencapsulated phase change materials. Energy Convers. Manag. 2008, 49, 3704–3707. [Google Scholar] [CrossRef]

- Cho, W.; Kook, J.W.; Lee, S.M.; Koh, W.G.; Kim, J.H. Modification of heat storage ability and adhesive properties of core/shell structured phase change material nanocapsules. Macromol. Res. 2016, 24, 556–561. [Google Scholar] [CrossRef]

- Lu, P.; Chen, W.; Zhu, M.; Murray, S. Embedding lauric acid into polystyrene nanofibers to make high-capacity membranes for efficient thermal energy storage. ACS Sustain. Chem. Eng. 2017, 5, 7249–7259. [Google Scholar] [CrossRef]

- Mu, S.; Guo, J.; Zhang, B.; Qia, S.; Yang, L.; Wang, D.; Zhang, S.; Yu, Y. On preparation and characterization of the phase change nanofibers from the copolymer of poly(styrene-co-acrylonitrile) and lauric acid. J. Macromol. Sci. Part A Pure Appl. Chem. 2015, 52, 699–706. [Google Scholar] [CrossRef]

- Ke, H. Electrospun methyl stearate/PET form-stable phase change composite nanofbres for storage and retrieval of thermal energy. Mater. Res. Innov. 2016. [Google Scholar] [CrossRef]

- Kook, J.W.; Cho, W.; Koh, W.G.; Cheong, I.W.; Kim, J.H. Preparation and characterization of octadecane/polyurea nanocapsule-embedded poly(ethylene oxide) nanofibers. J. Appl. Polym. Sci. 2015. [Google Scholar] [CrossRef]

- Rabbi, A.; Bahrambeygi, H.; Nasouri, K.; Shoushtari, A.M.; Babaei, M.R. Manufacturing of PAN or PU nanofiber layers/PET nonwoven composite as highly effective sound absorbers. Adv. Polym. Technol. 2014, 33, 1425. [Google Scholar] [CrossRef]

- Bahrambeygi, H.; Sabetzadeh, N.; Rabbi, A.; Nasouri, K.; Shoushtari, A.M. Nanofibers (PU and PAN) and nanoparticles (Nanoclay and MWNTs) simultaneous effects on polyurethane foam sound absorption. J. Polym. Res. 2013, 20, 72. [Google Scholar] [CrossRef]

- Xiang, H.; Tan, S.; Yu, X.; Long, Y.; Zhang, X. Sound absorption behavior of electrospun polyacrylonitrile nanofibrous membranes. Chin. J. Polym. Sci. 2011, 29, 650–657. [Google Scholar] [CrossRef]

- Wu, C.M.; Chou, M.H. Polymorphism, piezoelectricity and sound absorption of electrospun PVDF membranes with and without carbon nanotubes. Compos. Sci. Technol. 2016, 127, 127–133. [Google Scholar] [CrossRef]

- Gaballah, S.; Shehata, N.; Shaaban, M.; Nosier, S.; Hefnawy, A.; Hamed, A.; Samir, E. Corrosion inhibition of aluminum in Hydrochloric acid solution using ceria doped polyvinyl chloride nanofiber. Int. J. Electrochem. Sci. 2017, 12, 1094–1105. [Google Scholar] [CrossRef]

- Müller, K.; Klapper, M.; Müllen, K. Preparation of high molecular weight polyurethane particles by nonaqueous emulsion polyaddition. Colloid Polym. Sci. 2007, 285, 1157–1161. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Neisiany, R.E.; Ayatollahi, M.R.; Ramakrishna, S.; Khorasani, S.N.; Berto, F. Fracture assessment of polyacrylonitrile nanofiber-reinforced epoxy adhesive. Theor. Appl. Fract. Mech. 2017. [Google Scholar] [CrossRef]

- Xiao, L.; Xu, L.; Yang, Y.; Zhang, S.; Huang, Y.; Bielawski, C.W.; Geng, J. Core-shell structured polyamide 66 nanofibers with enhanced flame retardancy. ACS Omega 2017, 2, 2665–2671. [Google Scholar] [CrossRef]

| Polymer | Applications in Buildings |

|---|---|

| Polystyrene (PS) | Roof insulation and masonry wall insulation |

| Polyurethane (PU) | Wall and roof insulation, curtain wall panels, insulation of industrial pipes and storage tanks, sandwich panels. |

| Polyvinyl chloride (PVC) | Sandwich structured panel and foam layer in coated fabric flooring |

| Polyacrylonitrile (PAN) | Gas filtration membranes, outdoor awnings, fiber reinforced concrete |

| Low-density poly ethylene (LDPE) | Film (packaging, agricultural film), extrusion coating (wires and cables), utensils |

| High-density poly ethylene (HDPE) | Liquid storage (tanks, drums), containers, pipes and extruded profiles, hospital material |

| Polyester (PET) | Sandwich panel and polyester coated concrete |

| Polypropylene (PP) | Containers, electrical appliance frames, tubes and geo-membranes |

| Acrylonitrile butadiene styrene (ABS) | Tubing and conduits |

| Polyvinyl acetate (PVAc) | Thermoplastic adhesives |

| Polyvinylidene fluoride (PVDF) | Electrical wire insulation |

| Polyimide (PI) | Electrical wire insulation |

| Polyamide (PA) | High performance fibers |

| Polymers | Synthesis | Morphology | Size (nm) | Notes | Ref. |

|---|---|---|---|---|---|

| NS-PU | Condensation | Particle dispersion | 60–345 | Acetone (s), 60 °C (T), 4 h (t) | [44] |

| Nanoprecipitation; Sonication | Particle | 280–300 & 330–450 | Nanoprecipitation: Acetone (s), water (s), r.t. (T), 24 h (t) | [45] | |

| Sonication: water (s), r.t. (T), 2 min (t) | |||||

| Stirring in acid; Dialysis | Particle | 250–750 | Stirring in acid: HCl (s), r.t. (T) | [46] | |

| Dialysis: DMF (s), Water (s), r.t. (T) | |||||

| Miniemulsion | Particle | 200–300 | Water (s), 60 °C (T), 4 h (t) | [47] | |

| Emulsion | Particle | 80–130 | Water (s), 80 °C (T), 2 h (t) | [48] | |

| Electrospinning | Fiber | 50–700 | DMF (s), 3–12 wt % (c), 12–25 kV (V), 0.04–0.1 mm/min (f.r.), 15 cm (d) | [49] | |

| Electrospinning | Fiber | 418–464 | DMF (s), 7 wt % (c), 40 kV (V), 3 mL/h (f.r.), 15 cm and 25 cm (d) | [50] | |

| Electrospinning | Fiber | 80–250 | DMF (s), 75 kV (V), 21 cm (d) | [51] | |

| Electrospinning | Fiber | 250 | DMF (s), 13.5 wt % (c), 75 kV (V), 21 cm (d) | [52] | |

| Solution blowing | Fiber | 100–400 | DMF (s), 6–12 wt % (c), 0.15–0.3 MPa gas pressure, 50 °C (T) | [53] | |

| Solution blowing | Fiber | 170 ± 112 & 671 ± 136 | DMF (s), 10, 15, 20 wt % (c), 1–6 bar gas pressure, 15–50 cm (d) | [54] | |

| NS-PS | Emulsion | Particle | ~31 | Acetone/water (s), 60 °C (T), 2–14 h (t) | [55] |

| Emulsion | Particle | 52–92 | Water (s), 90–95 °C (T), 7–20 min (t) | [56] | |

| Electrospinning | Fiber | 150–800 | DMF/THF (s), 20 wt % (c), 20 kV (V), 1 mL/h (f.r.), 15 cm (d) | [57] | |

| Electrospinning | Fiber | 380–500 | DMF/THF (s), 15 wt % (c), 20 kV (V), 0.1 mL/h (f.r.), 15 cm (d) | [58] | |

| Electrospinning | Fiber | 250–1000 | DMF (s), 15 wt % (c), 20 kV (V), 0.8 mL/h (f.r.) | [59] | |

| Electrospinning | Fiber | 317 | DMF (s), 20 wt % (c), 20 kV (V), 0.18 mL/h (f.r.) | [60] | |

| Fast freeze | Fiber | 19 | DCE (s) or CH (s), 0.01 wt %, frozen in liq. N2, −50 °C (T) | [61] | |

| NS-PAN | Miniemulsion polymerization | Particle | 100–180 | Water (s), 55 °C (T), 4 h (t) | [62] |

| Dispersion polymerization | Particle | 143.5–263.5 | Water (s), 30 °C (T), 24 h (t) | [63] | |

| Emulsion polymerization | Particle | <100 | Water (s), 67 °C (T), 5 h (t) | [64] | |

| Microemulsion polymerization | Particle | 40–50 | Water (s), r.t. (T), 10 min (t) | [65] | |

| Miniemulsion polymerization | Particle | 105–230 | Water (s), 65°C (T), 8 h (t) | [66] | |

| Electrospinning | Fiber | 302–744 | DMSO (s), 12 wt % (c), 17–23 kV (V), 1 mL/h (f.r.) | [67] | |

| Electrospinning | Fiber | 575 | DMF (s), 12 wt % (c), 18 kV (V), 1 mL/h (f.r.) | [68] | |

| Electrospinning | Fiber | 50–100 | DMF (s), 6.25 wt % (c), 20 kV (V), 1.25 mL/h (f.r.), 15 cm (d) | [69] | |

| Electrospinning | Fiber | 230–330 | DMF (s), 10 wt % (c), 17 kV (V), 1.2 mL/h (f.r.), 16 cm (d) | [70] | |

| Electrospinning | Fiber | 225–335 | DMF (s), 9 wt % (c), 15 kV (V), 1.2 mL/h (f.r.), 15 cm (d) | [71] | |

| Electrospinning | Fiber | 450–550 | DMSO (s), 8 wt % (c), 13–14 kV (V), 1.4 mL/h (f.r.), 15 cm (d) | [72] | |

| Electrospinning | Fiber | 294 | DMF (s), 8 wt % (c), 27 kV (V), 4 mL/h (f.r.), 13 cm (d) | [73] | |

| Microemulsion | Fiber | 20–50 | Water (s), r.t. (T), 4.5 h (t) | [74] | |

| NS-PVC | Modification | Particle | 108–215 | H2SO4 (s), r.t. (T), 5 h (t) | [75] |

| Electrospinning | Fiber | 100 | DMF/THF (s), 10 and 15 wt % (c), 12–15 kV (V), 0.5 mL/h (f.r.), 12–18 cm (d) | [76] | |

| Electrospinning | Fiber | 100–180 | DMF/THF (s), 14–20 wt % (c), 20–29 kV (V), 0.2 mL/h (f.r.), 15 cm (d) | [77] | |

| Electrospinning | Fiber | 600–800 | DMF/THF (s), 9 wt % (c), 12 kV (V), 1 mL/h (f.r.), 12 cm (d) | [78] | |

| Freeze-extraction | Fiber | 45 | DCE (s), DMAC (s) or NMP (s), 0.01 wt % (c), frozen in liq. N2, −50 °C (T) | [79] |

| Polymers | Building Application | Synthesis | Morph. | Size (nm) | Notes | Performance | Ref. |

|---|---|---|---|---|---|---|---|

| PAN | Air filtration | Blow spinning | Fiber | 150–250 | DMF (s), 10 wt % (c) | Minimum 90.6% removal efficiency of PM 2.5 over 12 h. | [81] |

| PAN | Air filtration | Electrospinning | Fiber | 200 | DMF (s), 6 wt % (c), 18 kV (V), 4 mL/h (f.r.), 20 cm (d) | Significantly improved PM 2.5 capture capability | [82] |

| PI | Air filtration | Electrospinning | Fiber | 300 | DMF (s), 15 wt % (c) | High temperature PM 2.5 removal with high efficiency (>99.5%) | [83] |

| Nylon-6 | Air filtration | Electrospinning | Fiber | 100 | Formic acid (s), 20% (c), 15 kV (V), 0.06 mL/h (f.r.), 15 cm (d) | >99.97% removal of PM 2.5 at ~73% of transmittance | [84] |

| PC | Air filtration | Electrospinning | Fiber | 319 ± 27 | Chloroform (s), THF/DMF (s), 14% and 16% (c), 18 kV (V), 0.06 mL/h (f.r.), 20 cm (d) | high filtration efficiency of 100% | [85] |

| PAN/PSU | Air filtration | Electrospinning | Fiber | 300–500 | DMF (s), 9 wt % for PAN(c), 22 wt % for PSU, 30 kV (V), 1 mL/h (f.r.), 20 cm (d) | high filtration efficiency of 99.992% | [86] |

| PVDF | Air filtration | Electrospinning | Fiber | 510 | DMF (s), 22 wt % (c), 30 kV (V), 0.5mL/h (f.r.), 15 cm (d) | high filtration efficiency of 99.972% | [87] |

| PAN | Air filtration | Electrospinning | Fiber | 900 | DMF (s), 12 wt % (c), 12 kV (V), 60mm/min (f.r.), 12 cm (d) | high filtration efficiency of 97% | [88] |

| PS | Thermal energy storage | Emulsion polymerizaiton | Particle | 10–115 × 103 | Water (s), 70 °C (T), 6 h (t) | Good for latent heat energy storage at low temperature | [89] |

| PS | Thermal energy storage | Microemulsion polymerizaiton | Particle | 100–123 | Water (s), 65 °C (T), 5 h (t) | Good for latent heat energy storage | [90] |

| PS | Thermal energy storage | Miniemulsion polymerizaiton | Particle | 250 | Water (s), 80 °C (T), 24 h (t) | Good for thermal energy storage | [91] |

| PS | Thermal energy storage | Electrospinning | Fiber | 1300–1930 | DMF (s), 20 wt % (c), 15 kV (V), 1 mL/h (f.r.), 25 cm (d) | 78.4% energy storage capacity | [92] |

| PSAN | Thermal energy storage | Electrospinning | Fiber | - | DMF (s), 20 wt % (c), 11–17 kV (V), 0.04 mm/s (f.r.), 20–35 cm (d) | Good ability to store thermal energy | [93] |

| PET | Thermal energy storage | Electrospinning | Fiber | 282–500 | DMF (s), 12 wt % (c), 16 kV (V), 2 mL/h (f.r.) | Good storage capacity of thermal energy | [94] |

| PEO | Thermal energy storage | Electrospinning | Fiber | 200 | Water (s), 5 wt % (c), 10–11 kV (V), 0.18 mL/h (f.r.), 10 cm (d) | Thermal energy storage capacity | [95] |

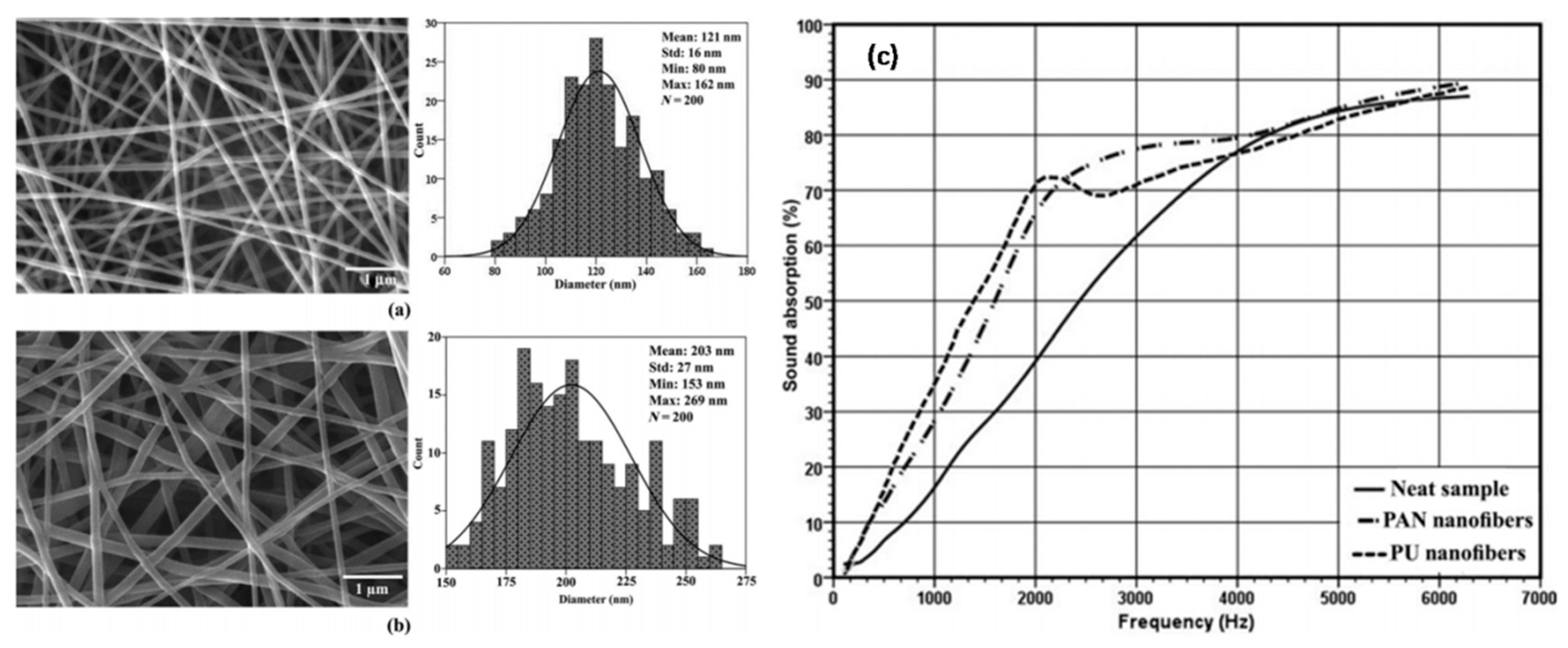

| PU & PAN | Sound absorption | Electrospinning | Fiber | 121 ± 16 & 203 ± 27 | For NS-PAN: DMF/THF (s), 10 wt % (c), 12 kV (V), for PU:NS-PAN: DMF/THF (s), 9 wt % (c), 16 kV (V), 0.25 mL/h (f.r.); 12 cm (d) | Sound absorption coefficient at low frequencies; NS-PAN preferred | [96] |

| PU & PAN | Sound absorption | Electrospinning | Fiber | - | For NS-PAN: DMF/THF (s), 10 wt % (c), 12 kV (V), for PU:NS-PAN: DMF/THF (s), 9 wt % (c), 16 kV (V), 0.25 mL/h (f.r.); 12 cm (d) | Enhancement of sound absorption coefficient at all ranges of frequencies | [97] |

| PAN | Sound absorption | Electrospinning | Fiber | 333 ± 58 | DMF (s), 8 wt % (c), 10 kV (V), 1.2 mL/h (f.r.), 13 cm (d) | Enhancement of sound absorption in low and medium frequency range | [98] |

| PVDF | Sound absorption | Electrospinning | Fiber | 138–156 | DMF (s), 18 wt % (c), 20 kV (V), 0.5 mL/h (f.r.), 20 cm (d) | Efficient for sound absorption | [99] |

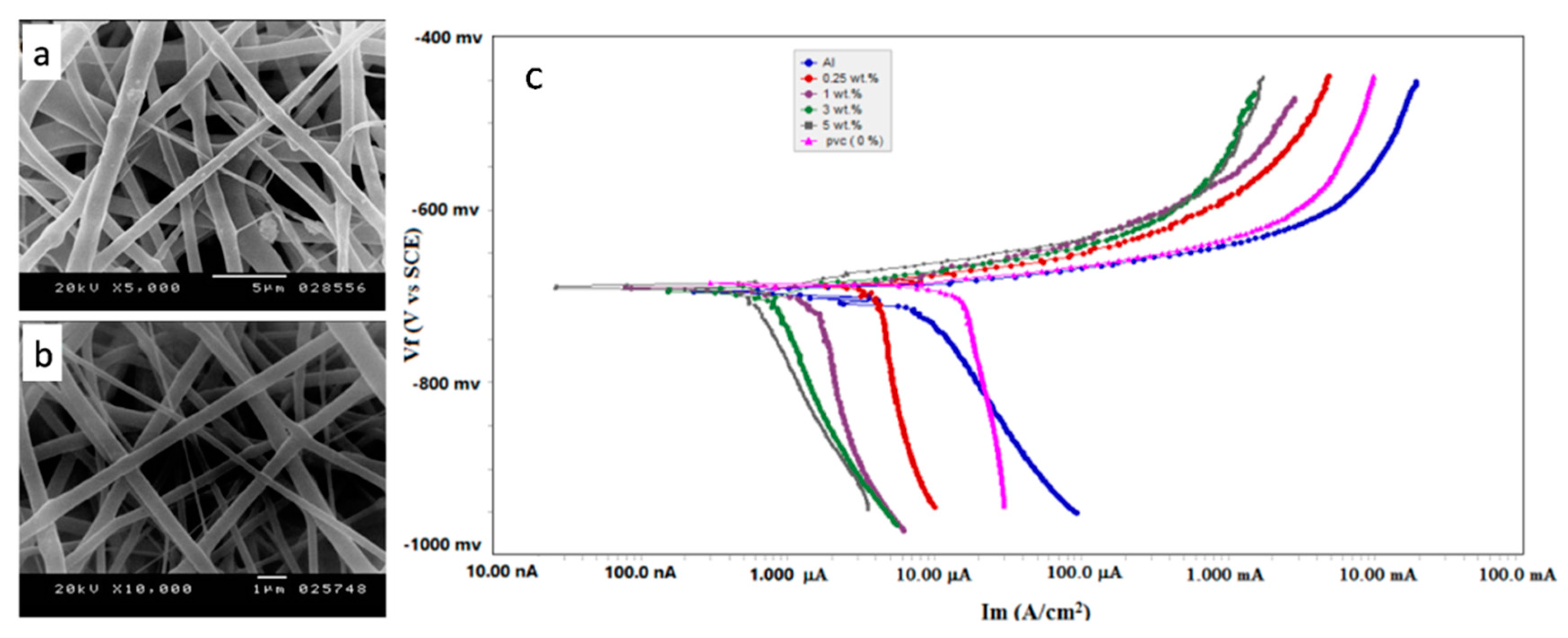

| PVC | Corrosion Inhibition | Electrospinning | Fiber | 486 & 620 | THF (s), 12 wt % (c), 20 kV (V), 9 mL/h (f.r.), 15 cm (d) | Reduction of corrosion currents and corrosion rates; enhancement of polarizationresistances | [100] |

| PU | Metal Coating | Emulsion polymerization | Particle | 35–95 | Cyclohexane(s), 45 °C (T), 8 h (t) | 25% of the material used for same application | [101] |

| PAN | Reinforced Adhesive | Electrospinning | Fiber | 362 ± 87 | THF (s), 10 wt % (c), 16 kV (V), 1 mL/h (f.r.), 15 cm (d) | Enhancement for the mechanical property | [102] |

| PA66 | Flame Retardant | Electrospinning | Fiber | 225–425 | Formic acid (s), 15–20 wt % (c), 30 kV (V), 0.5 mL/h (f.r.), 8 cm (d) | Mechanical properties and flame-retardancy improved | [103] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Shah, K.W.; Xu, J. Synthesis, Morphologies and Building Applications of Nanostructured Polymers. Polymers 2017, 9, 506. https://doi.org/10.3390/polym9100506

Lu Y, Shah KW, Xu J. Synthesis, Morphologies and Building Applications of Nanostructured Polymers. Polymers. 2017; 9(10):506. https://doi.org/10.3390/polym9100506

Chicago/Turabian StyleLu, Yong, Kwok Wei Shah, and Jianwei Xu. 2017. "Synthesis, Morphologies and Building Applications of Nanostructured Polymers" Polymers 9, no. 10: 506. https://doi.org/10.3390/polym9100506

APA StyleLu, Y., Shah, K. W., & Xu, J. (2017). Synthesis, Morphologies and Building Applications of Nanostructured Polymers. Polymers, 9(10), 506. https://doi.org/10.3390/polym9100506