3.1. Influence of Interactions (χN and μN) and β on the Phase Behavior

Previous studies reveal that β has little effect on the phase diagram of rod-coil diblock copolymer systems when the orientational interaction (μ

N) dominates, such as μ

N = 4χ

N [

9,

12]. In this case, we found lamellae including smectic A and smectic C occupy most of the area of the phase diagram [

31], and hexagonal cylinders with elliptical cross-sections formed by rods only occur at relatively high coil fractions and strong orientational interactions between rods [

29]. When the orientational interaction between rods decreases to be comparable with χ

N, however, the effect of β on the phase behavior can be manifested as the orientational interaction being weak near the ODT and the liquid crystal behavior hardly observed. For example, Tang

et al. reported a series of non-lamellar structures including body-centered cubic, A15, hexagonal and Gyroid phases by ignoring μ

N in the rod-coil diblock copolymer systems [

32]. They also calculated these OOT phase boundaries at several different β values [

32]. Therefore, non-lamellae structures can be obtained depending on the β and μ

N. In order to distinguish the effect of the relation between μ

N and β on the phase behavior, we first calculate the phase diagram of χ

N versus β at

f = 0.5 and

f = 0.65 under the condition of μ

N = χ

N. For each certain fixed composition, the phase diagram is calculated by plotting the free energy curves of various competitive phases by varying χ

N with the increment of Δχ

N = 0.1. The corresponding χ

N of the intersection point of these curves is set as the phase boundary point. Although different initial fields, including hexagonal cylinders, four structures such as complex bicontinuous structures (Gyroid), tetragonal cylinders, body-centered spheres and A15, found by Tang

et al. in the absence of interactions between rods [

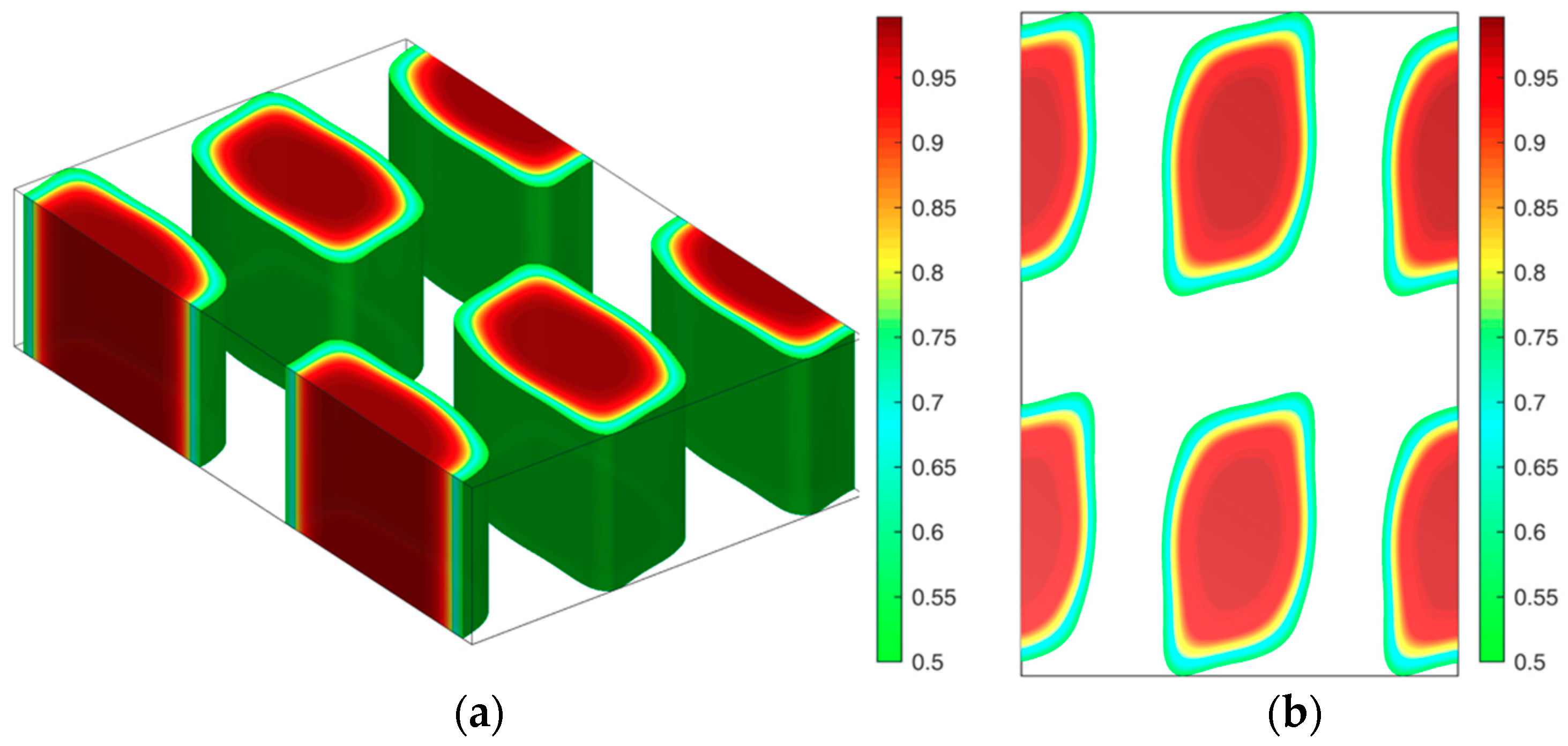

32] and lamellae are included during calculations, only HEX (coil), HEX (rod) phases, and lamellae (LAM) in this work are obtained by altering β. The HEX (coil) structure is hexagonal cylinders formed by coil blocks, LAM represents lamellae and HEX (rod) is hexagonal cylinders formed by rod blocks. With further increasing β, puck cylinders with tetragonal symmetry formed by rods, shown in

Figure 1, occur in a quite narrow area of the phase diagram, as shown in

Table 1. This is similar to the tetragonal cylinders found in our previous study and the puck phase found by us and Pryamitsyn and Ganesan [

9,

13,

14].

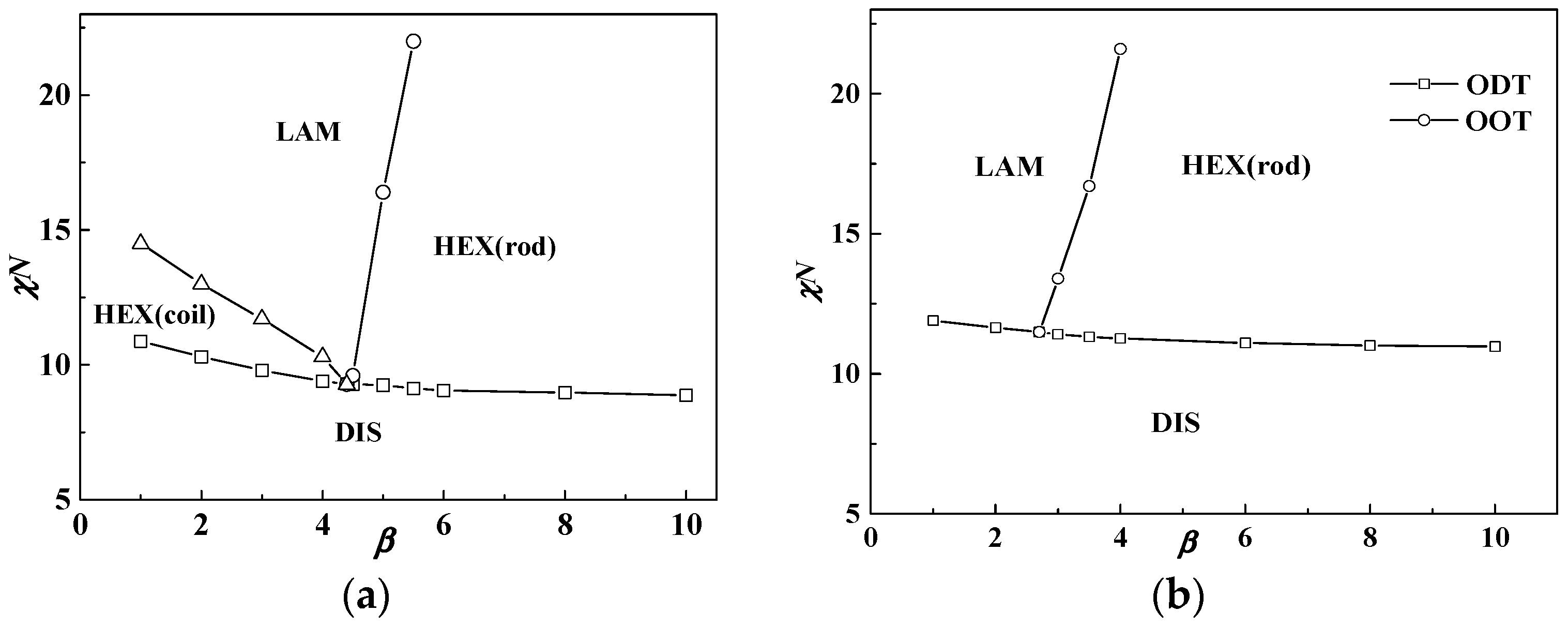

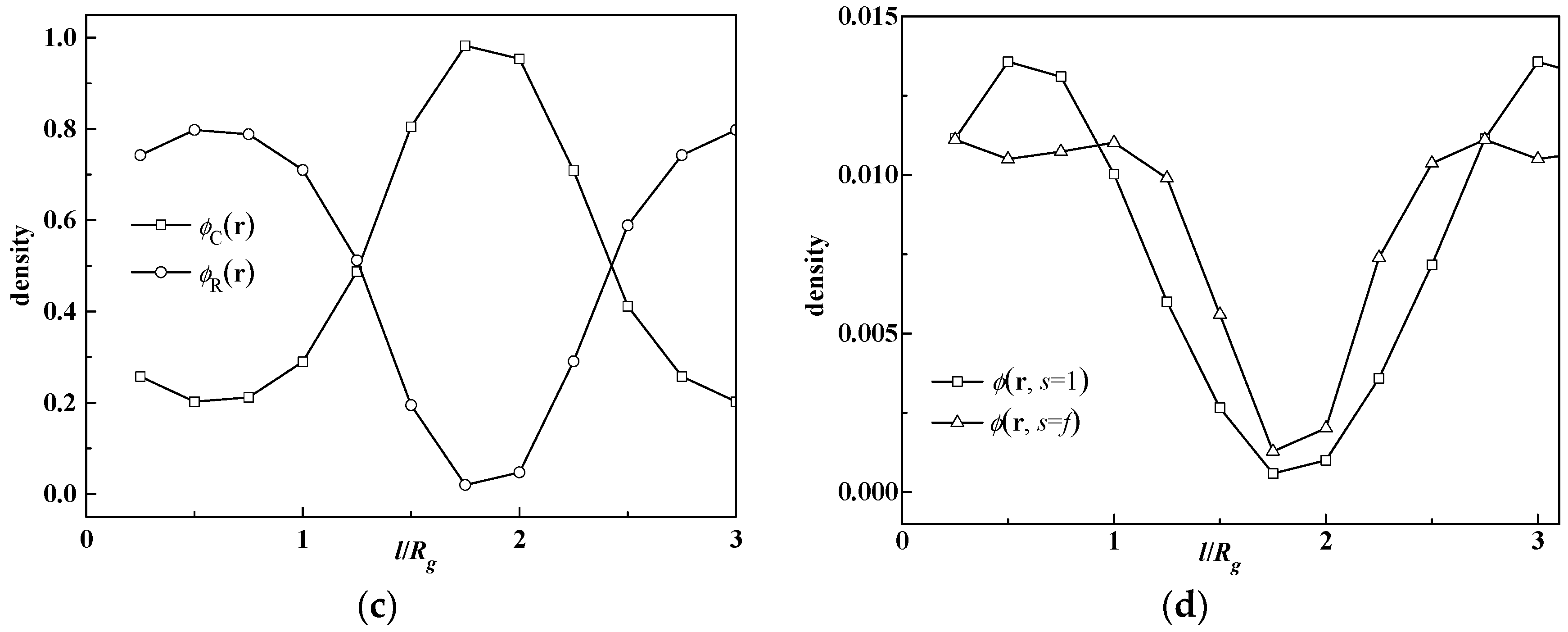

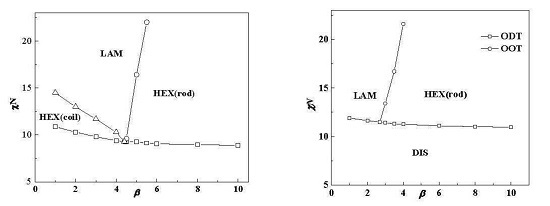

Figure 2a shows the phase diagram at coil volume fraction

f = 0.5, in which condition coil-coil diblock copolymers develop into the lamellar phase with χ

NODT = 10.5 [

10,

11,

33]. We note that the phase diagram is only within the range of β ≤ 10 for saving computational tasks, and puck cylinders with tetragonal symmetry in

Figure 1 formed by rods occur only in a narrow area of the phase diagram with a further increasing β (see

Table 1). The triple point where lamellar, cylinder and disordered phases coexist in equilibrium is located at about β = 4.4 with χ

NODT = 9.3. When β > 2, the χ

NODT < 10.5. This is due to the fact that rods do not have conformation entropy so the introduction of rod blocks will decrease the system energy and thus decrease χ

NODT, compared to the coil blocks. Therefore, the χ

NODT of rod-coil blocks is between 10.5 for coil-coil blocks and 6.1 for rod-rod blocks [

34]. Interestingly, we note that the χ

NODT continuously increases as β decreases and even exceeds 10.5 of the coil-coil diblock copolymer system when β < 2. For example, the χ

NODT at β = 1 and

f = 0.5 is 10.9, larger than 10.5 of the coil-coil diblock copolymer system at the same volume fraction. In this case, the short, stumpy rod can provide a larger interfacial area per chain for coils to release stretching entropy, thus showing a slightly higher χ

NODT than that of coil-coil blocks. This can be further illustrated by comparing the domain period near the ODT in different cases including coil-coil, rod-coil and rod-rod diblock copolymers. The domain period from rod-coil blocks is

D = 0.75

bN = 3.25

aN0.5 when β = 4.4,

f = 0.5 and χ

NODT = 9.5, which is smaller than that of rod-rod diblock copolymers (

D = 0.91

bN) but much larger than that of coil-coil diblock copolymers (

D = 1.32

aN0.5) [

33,

34].

In addition, when the coil volume fraction is increased to

f = 0.65, the phase diagram changes a lot as illustrated in

Figure 2b. In this condition, the HEX (coil) structure disappears and the triple point moves to about β = 3, which is smaller than that in

Figure 2a. This demonstrates that rod-coil diblocks tend to form into structures with coils at the convex interface, namely HEX (rod) near the ODT. This is because the coil conformational entropy dominates the whole free energy when the volume fraction of coils is larger than that of rods. Therefore, the HEX (coil) structure will not come up even when β is very small and is replaced by the LAM structure. Our previous study for semiflexible-coil block copolymers also found hexagonal packed elliptical domains formed by rods at a coil volume fraction of 0.7 with a strong orientational interaction by numerical implementation of SCFT in 2D space [

13]. In order to decrease the total free energy, one better way for the system is that coils stay at the convex side of the interface to decrease entropy loss. On the other hand, it also can be seen from

Figure 2 that increasing χ

N can lead the phase transition from cylinders to lamellae structures no matter what the value of β is. As in this part μ

N = χ

N, and increasing χ

N will lead rods to align with each other, thus favoring liquid crystal behavior with lamellae structure.

In conclusion, the phase diagram in

Figure 2 is quite similar to that in the plot of χ

N(μ

N)

vs. f. This demonstrates that copolymer composition

f and conformational asymmetry between two blocks β have a similar effect on the phase behavior. Therefore, non-lamellar structures for rod-coil blocks (anisotropic orientational interactions between rods favor liquid crystal behavior, thus resulting in the majority of the phase diagram being occupied by the layered structures) can also be obtained by changing β, besides

f. Except to obtain non-lamellar structures (HEX (rod)) in a large coil volume fraction condition as shown in

Figure 2b,

Figure 2a shows that changing β can also result in non-lamellar structures including HEX (coil) and especially HEX (rod) in a case of comparable volume fractions between rods and coils, and even quite large rod fractions.

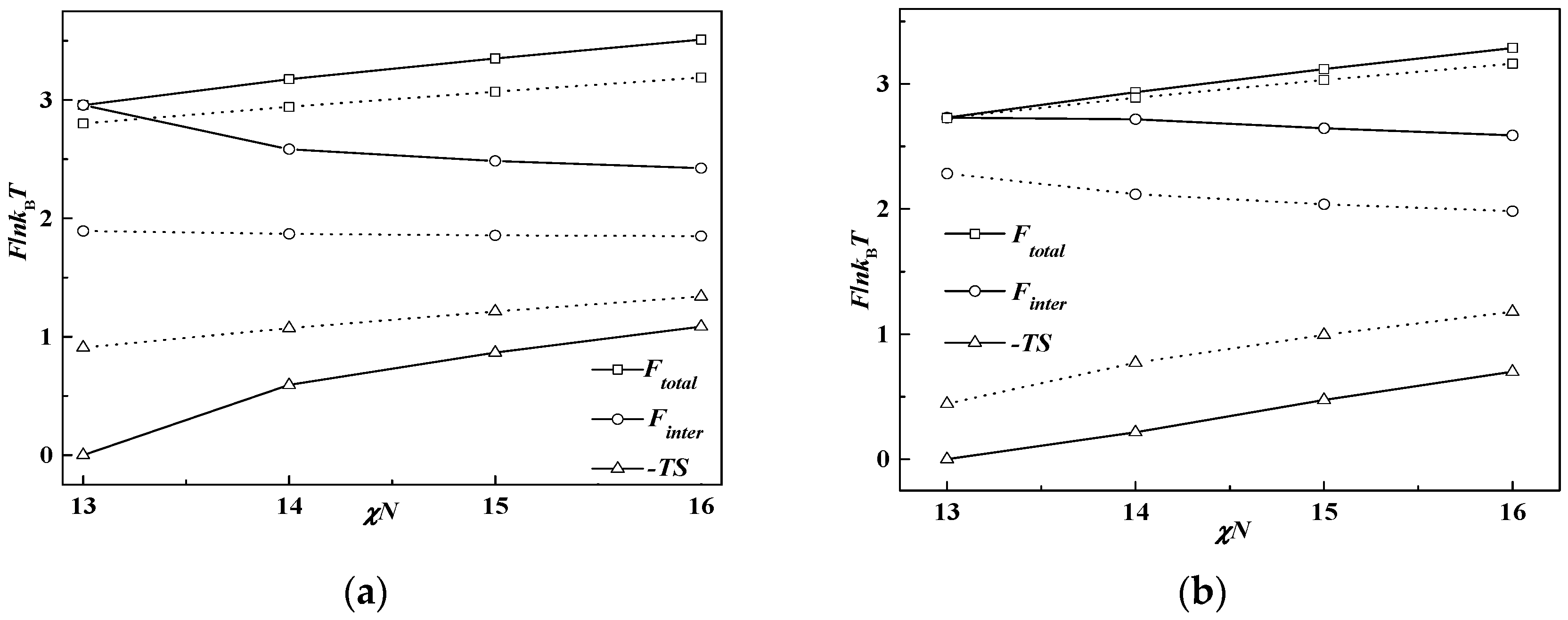

To obtain a thorough understanding of the phase behavior of the rod-coil diblock copolymer system, the free energy

Ftotal and three of its contributions mentioned in the theoretical part, the Flory–Huggins interaction

Finter, the entropy loss −

TS and the orientational interaction

Forien at χ

N = 12 as a function of β, are drawn in

Figure 3, in which

Figure 3a,b represent

f = 0.5 and

f = 0.65, respectively. It is shown that the total free energy increases with the decrease of β, which means the free energy of the lamellar phase at a smaller β is higher than that of the cylinder phase formed at a larger β. The order-disorder transition point χ

NODT is consequently increased, as discussed in

Figure 2, with increase of the total free energy. It also can be seen that the Flory-Huggins interaction energy makes the main contribution to the whole free energy of the system, especially at a smaller value of β or a larger value of the coil volume fraction, while the entropy loss behaves in a converse way. As we set μ

N = χ

N, the orientational interaction energy is close to zero to make little contribution to the free energy of the system. This is the reason that many works choose μ

N = 4χ

N to ensure liquid crystal behavior for the rod-coil diblock copolymer system.

When β decreases from 10 to 1, the rod changes from a slim conformation to a short, stumpy one. In the condition of

f = 0.65 and β = 10, rods are slim with a small diameter, thus providing narrow interfacial area for coils, resulting in coils much more stretched and far away from the rods, just like polymer brushes at the flat interface [

35,

36]. In order to decrease the system energy, coils prefer to stay at the convex side of the rod-coil interface to decrease the entropy loss, leading to the formation of rod-rich cylinders, HEX (rod). Compared with coil-coil diblocks with the same cylinder phase formed, the free energy of rod-coil diblock copolymers can be smaller due to the lack of conformation entropy of the rods. As a consequence, the χ

NODT of rod-coil blocks is lower than that of coil-coil blocks. As mentioned above, the interaction energy dominates the free energy as β decreases. Therefore, it is the main driving force to bring the increase of the χ

NODT at relatively small β. Particularly the Flory–Huggins interaction energy between rods and coils increases so much after phase transition from cylinder to lamella that the χ

NODT increases a lot and even exceeds that of the coil-coil diblock copolymer system. For example, χ

NODT = 10.9 at β = 1 and

f = 0.5 is larger than the 10.5 value of the coil-coil diblock copolymer system at the same volume fraction.

3.2. Effect of β When the Orientational Interaction Is Turned off

According to the above discussion, the decrease of geometrical asymmetry β affects the phase transition by increasing the interfacial tension for compensating the stretching entropy loss of coils. To further focus on the β influence on the phase behavior, the orientational interaction is ignored in this part. It is noted that we only consider HEX (rod) and HEX (coil) as the representative non-lamellar structures and lamellae as candidate structures for simplicity to concentrate on the β effect on the non-lamellae of the rod-coil system. Two conditions including β = 10 and β = 1 are chosen to investigate the phase behavior for rods with slim and short, stumpy conformations, respectively.

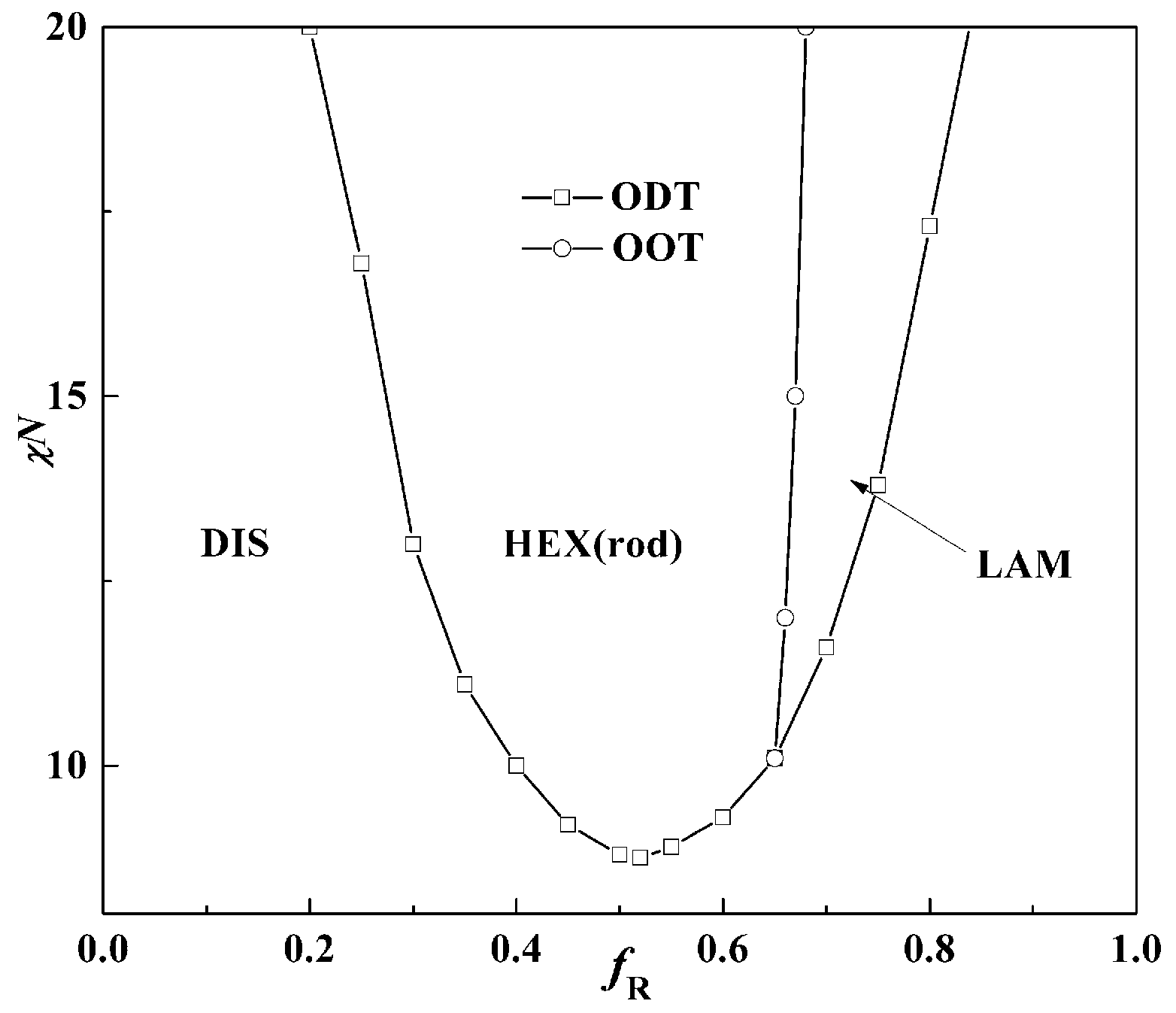

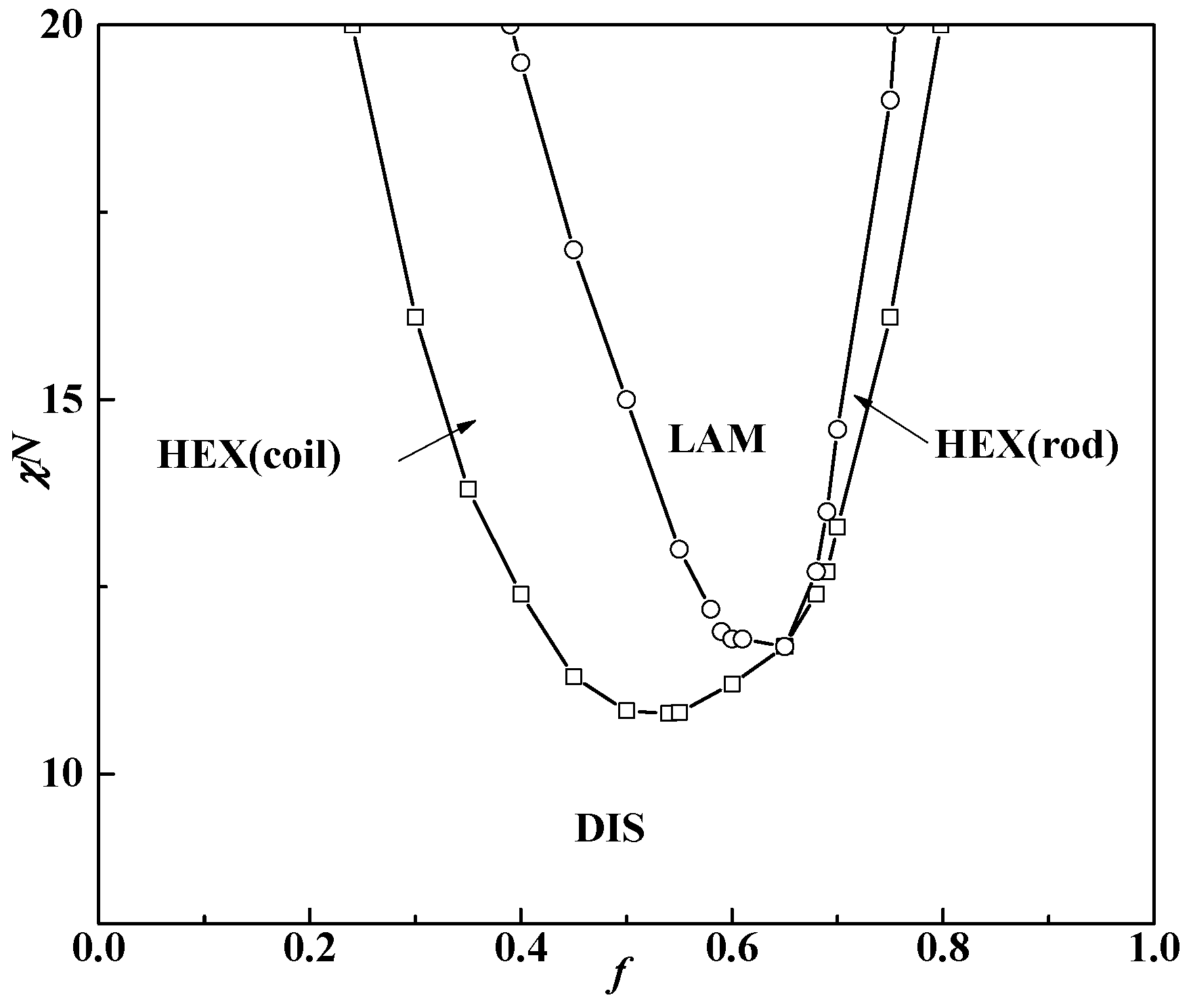

In

Figure 4, the phase diagram for β = 10 as a function of the rod volume fraction

fR and Flory-Huggins interaction χ

N is firstly presented as a comparison with the result by Müller and Schick [

20]. The phase diagram is slightly asymmetric as the critical point of χ

NODT = 8.7 is at about

f = 0.48 (

fR = 0.52), which is lower than the typical value χ

NODT = 10.5 of coil-coil diblock copolymers. Two kinds of structures: lamella (LAM) and hexagonal cylinders aggregated by rod blocks (HEX (rod)) come up at the phase diagram and the triple point where LAM, HEX (rod) and DIS coexist is located at about

f = 0.35 (

fR = 0.65). The hexagonal cylinders formed by rods occupy the majority of the phase diagram, leaving a small area for the lamellar phase. These results are almost the same as the work of Müller and Schick, who also pointed out that stable structures are only those with coils at the convex side of the rod-coil interface [

20].

Figure 2 also shows that a larger value of β can lead to the formation of HEX (rod), even at quite large rod volume fractions. Kriksin

et al. also found that only such non-lamellar structures are observed with rods forming the core and coils located at the outside convex surface [

25]. It seems that increasing β or

f can both induce the non-lamellar structure HEX (rod) and HEX (coil) formation, respectively.

The difference lies in the result that the triple point is located at about

f = 0.35 (

fR = 0.65) in our current work, while the triple point calculated by Müller and Schick coincides with the lowest point of ODT [

20]. Our calculations show that the triple point location depends on the values of β for rod-coil block copolymers. The triple point of the phase diagram is calculated as the cross point of OOT (cylinder structure to LAM) and ODT (disorder structure to LAM) by comparing the free energy of the lamella and cylinder with the disorder phase as shown in

Figure 5. Matsen even theoretically examined the effect of two coil statistical segment length ratio

on the phase behavior of the coil-coil diblock copolymers and found the triple point moved to the component side with the larger Kuhn length [

37]. When β = 10, the length ratio of the rod to coil is very large, which can be seen as the limit of the Kuhn length ratio

in the coil-coil diblock copolymer system. The interface therefore tends to curve towards the rod blocks, allowing the coil blocks to relax at the convex side for decreasing the stretching entropy penalty. Kriksin

et al. also found that the phase diagram is asymmetric and the lamellar structures exist even at quite asymmetric compositions, due to conformational asymmetry between two coil blocks [

38,

39]. Moreover, the majority component with a large Kuhn length can aggregate into micelle inner cores with a minority component-forming matrix, different from conventional coil-coil diblocks.

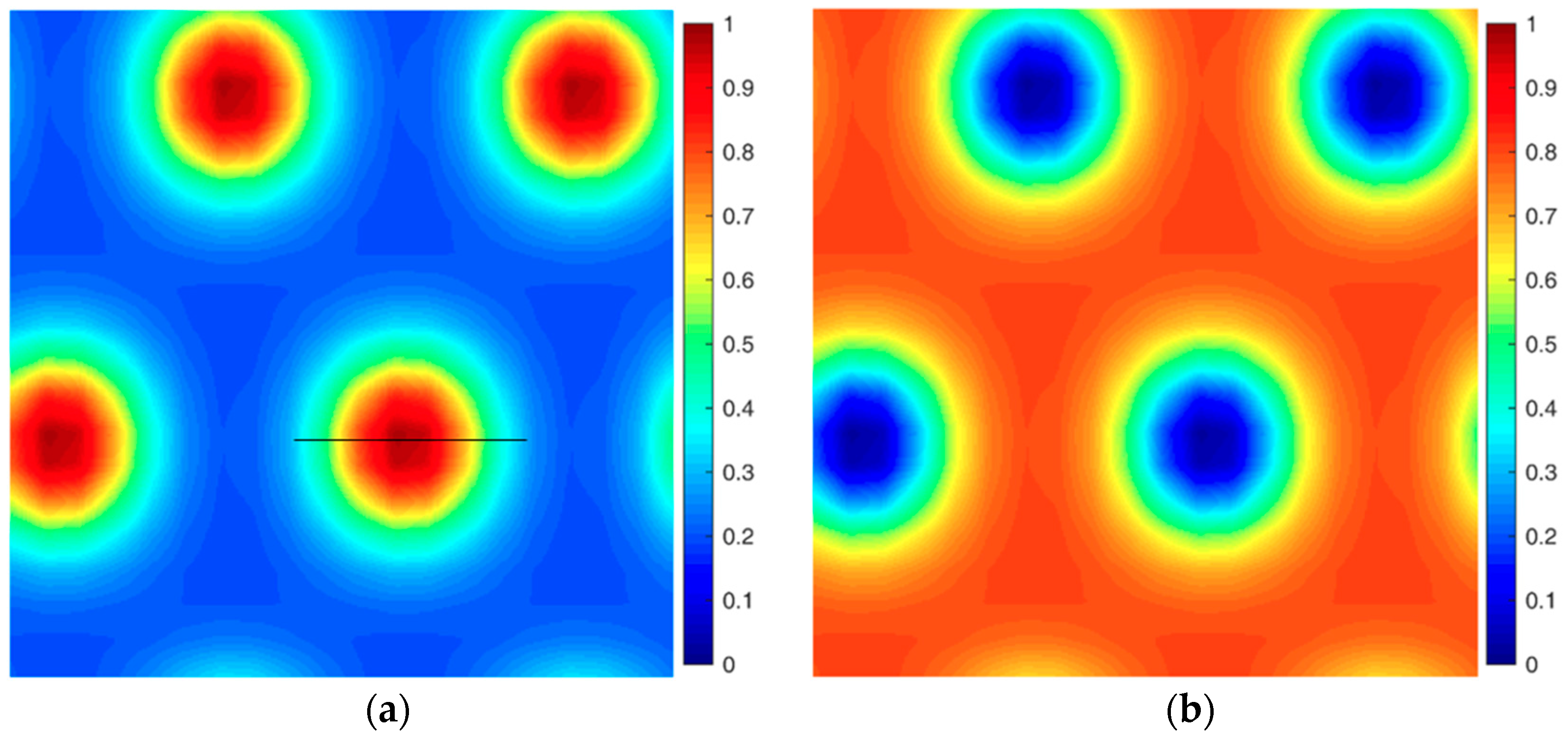

To illustrate the cylinder structure, the morphology and the density profile are given in

Figure 6 at β = 10 and

f = 0.7.

Figure 6a,b show the 3D structure and the cross-section at the XZ plane, respectively. The lattice corresponding to the lowest energy here is 5

Rg × 8.5

Rg which means the structure is in hexagonal asymmetry. To show this structure in more detail, the density profile of the rod and coil component, across one rod domain as well as the rod terminal

and junction points

, are also shown in

Figure 6c,d. It can be seen that the rod blocks aggregate in the center of the rod-rich domain, leaving the link distributed at the rod-coil interface. The domain size in this parameter is 2.75

Rg, while the rod length can be calculated from the equation as

lR =

NbfR = β

RgfR = 3

Rg. We can calculate the orientational tensor field

and its maximum eigenvalue

, the latter of which shows the orientation degree of the rod block. Thus,

is 0.002 at the point with the largest rod density, which means rods do not show long-range orientation due to the ignorance of the orientational interaction between rods. Therefore, the domain morphology cross-section develops into the same circle, such as in the case of the coil-coil block copolymer system. In the study of the 2D puck phase of coil-semiflexible diblock copolymers, Gao

et al. pointed out that the orientation of semiflexible blocks resulted in the ellipse domain morphology [

29]. Our results reconfirm that the puck phase is due to the anisotropic orientational interaction between semiflexible blocks. In the rod-coil diblock copolymer system, orientational interaction will generally decrease the whole system energy by aligning rod blocks so as to form a flat interface such as smectic A or smectic C, which are obtained in many works and in our previous work [

12,

13,

14,

29]. When the orientational interaction is ignored, the geometrical asymmetry effect on the phase behavior of the rod-coil diblock copolymer system is manifested. For β = 10, the rod is long and thin so the interface between the rod and coil blocks per chain is small. Coils are thus much more stretched away from the interface, leading to more entropy penalty. In this condition, rod-rich cylinders with coils at the convex side of the interface can provide more space for coils to relax. The consequence is that a large area in the phase diagram comes with rod-rich cylinders.

When β decreases to 1, however, the phase diagram changes a lot. As illustrated in

Figure 7, the whole phase diagram is shifted with the lowest

χNODT point at

f = 0.54 and

χNODT = 10.8, which is slightly higher than the value of coil-coil diblock copolymers. This is also in accordance with the result in the condition of μ

N = χ

N, as discussed in

Figure 2 when β = 1. It is widely thought that rod-coil diblock copolymers have relatively strong phase-separation abilities so χ

NODT should be lower than that of coil-coil diblock copolymers in the same volume fraction. Our result, however, shows a different phenomenon: that the rod-coil diblock copolymer with extremely small β is more difficult to phase-separate than coil-coil diblock copolymers. As mentioned above, a smaller β means the rods are in short, stumpy conformation. Compared with β = 10, in this case rods can provide enough interface for coils with much more flexible conformation. The entropy penalty with a small β is therefore less than that with a large β, but the Flory–Huggins interaction becomes very large. The order-disorder transition behavior of the rod-coil diblock copolymer system is thus much more similar to the coil-coil diblock copolymer system.

Besides the above two structures LAM and HEX formed by rods, cylinders formed by coil blocks (HEX (coil)) come up when both

f and χ

N are small. The triple point moves to about

f = 0.65 and χ

NODT = 11.8. The lamellar and cylinder phases formed by coil blocks occupy the most area of the phase diagram and the cylinder phase formed by rod blocks only comes up in a relatively small area. Stupp and coworkers have observed rod-rich hexagonal cylinder and lamella phases in thin films of rod-coil diblock molecules by TEM and found the transition between the two ordered phases to occur at lower rod contents [

40].

Figure 8 presents the density profile for the cylinder phase formed by coil blocks. The domain size of the cylinder is calculated at about 1

Rg, the same as the coil size in scale of the whole molecular weight

N. Although coils aggregate into ordered cylinder phases, there is still a certain amount of coils in the rod domains. This means that in this condition, rods do not align very closely so that coils can be dispersed around rods. This kind of structure has been also reported recently by Shi

et al. in PDMS-

b-PMPCS rod-coil diblock copolymers [

16]. The copolymer is annealed at 125 °C lower than the liquid crystalline formation temperature, and namely the orientational interaction is weak. In that condition, the rod block PMPCS is amorphous and the coils would rather form hexagonal cylinders. Matsen also reported that a significant concentration of coil segments accumulated at the center of the rod domains when he studied the liquid crystal phase behavior of rod-coil diblock copolymers in 1D space [

8]. This is because the interface between the rod and coil block per chain will increase as β decreases, and the coils would prefer to be absorbed near the surface rather than extended far away for less conformation entropy loss. Alternative ways of reducing the high interfacial energy are to include a finite compressibility or another component in the system, such as a selective solvent for the rod blocks.

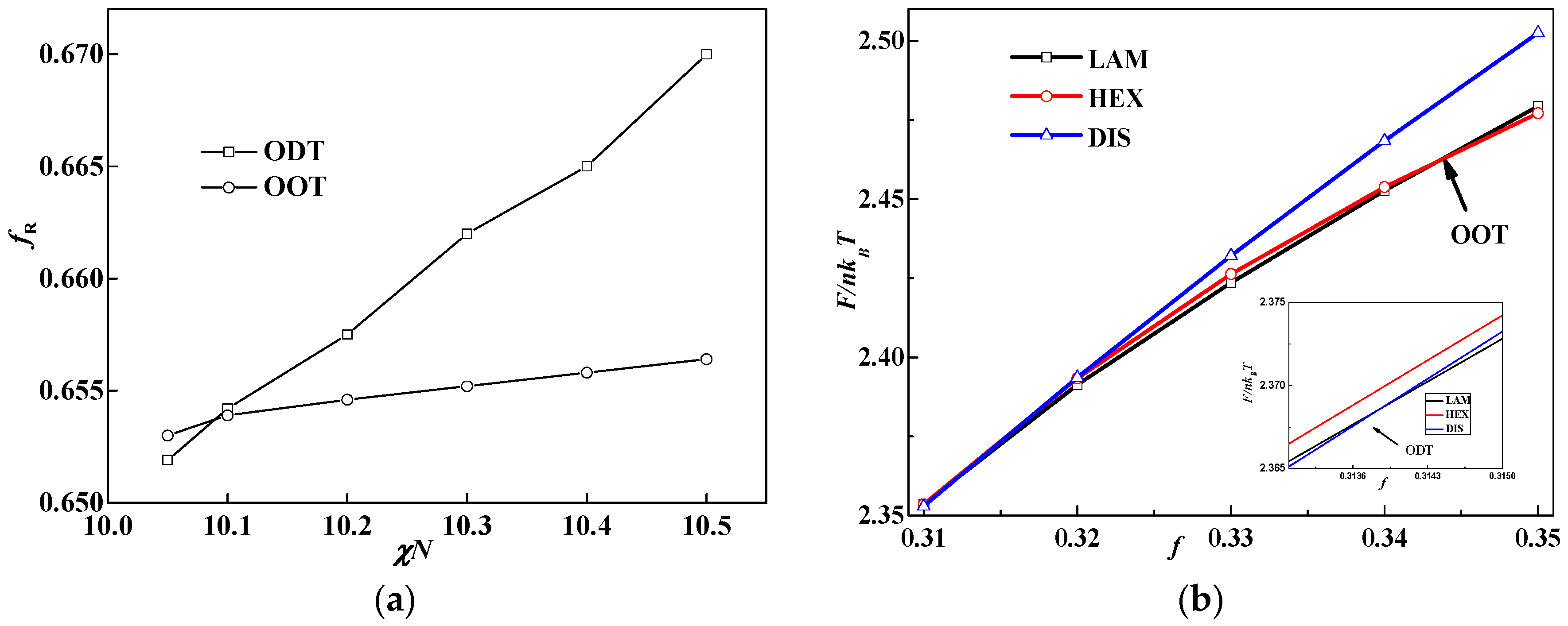

If the rod has a large diameter

d, providing larger interfacial area per chain and thus favoring the coil, it is easy to fulfill the conformation with little entropy loss. In contrast, if the rod is slim with a small diameter

d, the coil block will be excluded much further from the interface, resulting in a larger coil conformation entropy loss. To illustrate the effect of β, the order-disorder transitions at β = 1,6,10 are shown in

Figure 9a. It can be seen that the ODT increases as β decreases, especially when the rod volume fraction dominates. This phenomenon is also demonstrated in

Figure 9b by comparing χ

NODT at different values of

f and β. For example, when the rod volume fraction is large,

fR = 0.65, and the χ

NODT will increase dramatically at small β.

As the orientational interaction is set as 0, the total energy

Ftotal is composed of the Flory-Huggins interaction energy

Finter and the coil conformation entropy −

TS. In

Figure 10,

Ftotal,

Finter and −

TS are plotted as a function of

χN at

f = 0.35 and

f = 0.7 for the two different β values, respectively. It can be seen that decreasing β will increase the whole system energy and the gap between two β values will be enlarged if the rod block volume fraction is larger than that of the coil block. We also observe that the interaction energy contributes much more to the whole free energy, demonstrating that in this condition, the system is dominated by the interfacial area between rod and coil blocks. This is because when β is small, short, stumpy rods offer large interfacial area for decreasing the coil’s stretching entropy loss. The Flory-Huggins interaction in this way becomes large, but with small entropic penalty. As χ

N becomes large, coils need to stretch much more in a larger interfacial area per rod chain than that with a large β with a small interface. This accordingly results in the phase separation at a much higher value of χ

N.