Green-Synthesized TIO2 Nanoparticles Improve Mechanical Performance of Glass Ionomer Cements

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Hemp Extract

2.2.2. Green Synthesis of TiO2 Nanoparticles

2.2.3. Preparation of Experimental Groups

2.2.4. Surface Roughness Analysis

2.2.5. Flexural Strength Testing

2.2.6. Microhardness Measurement

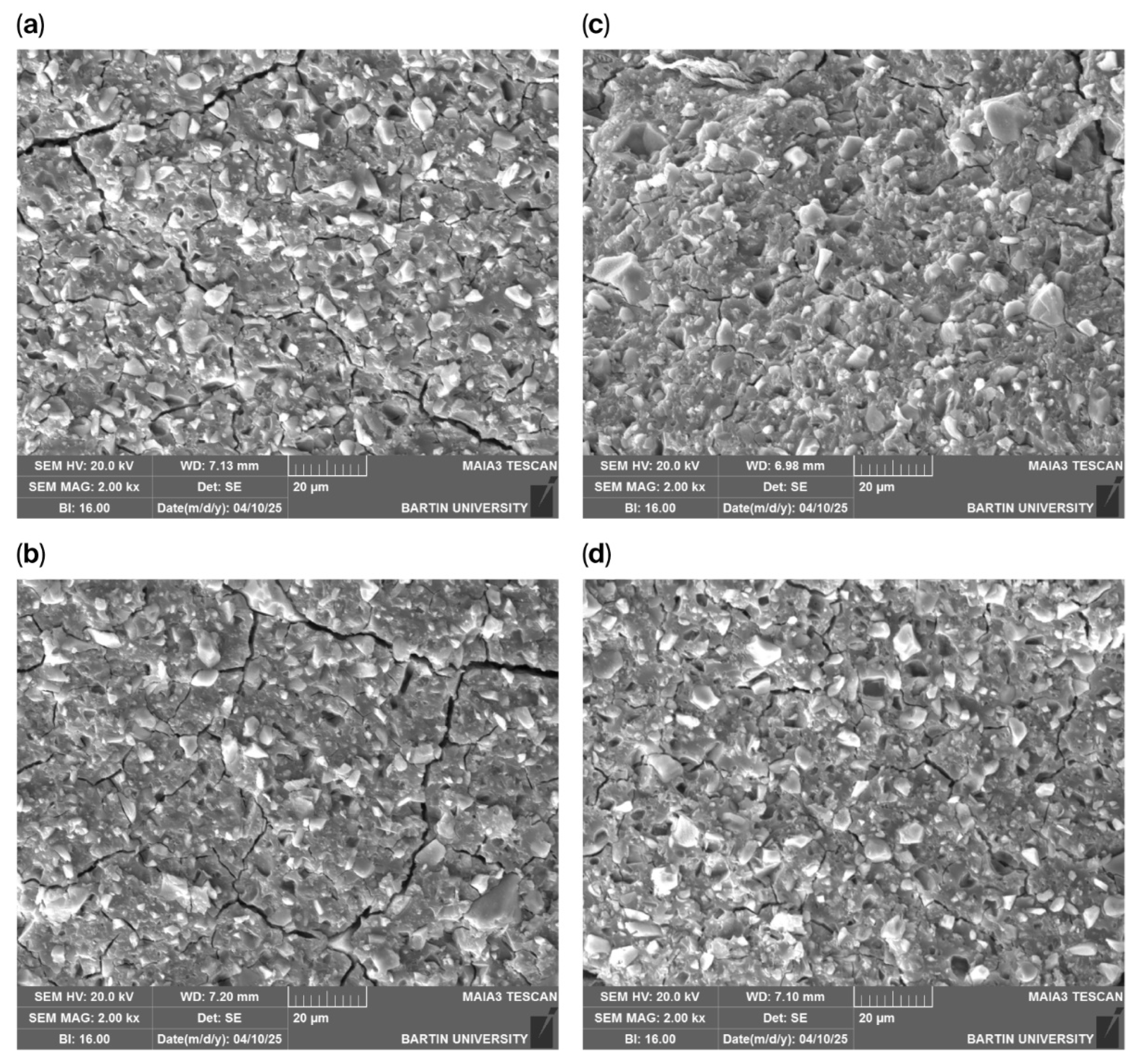

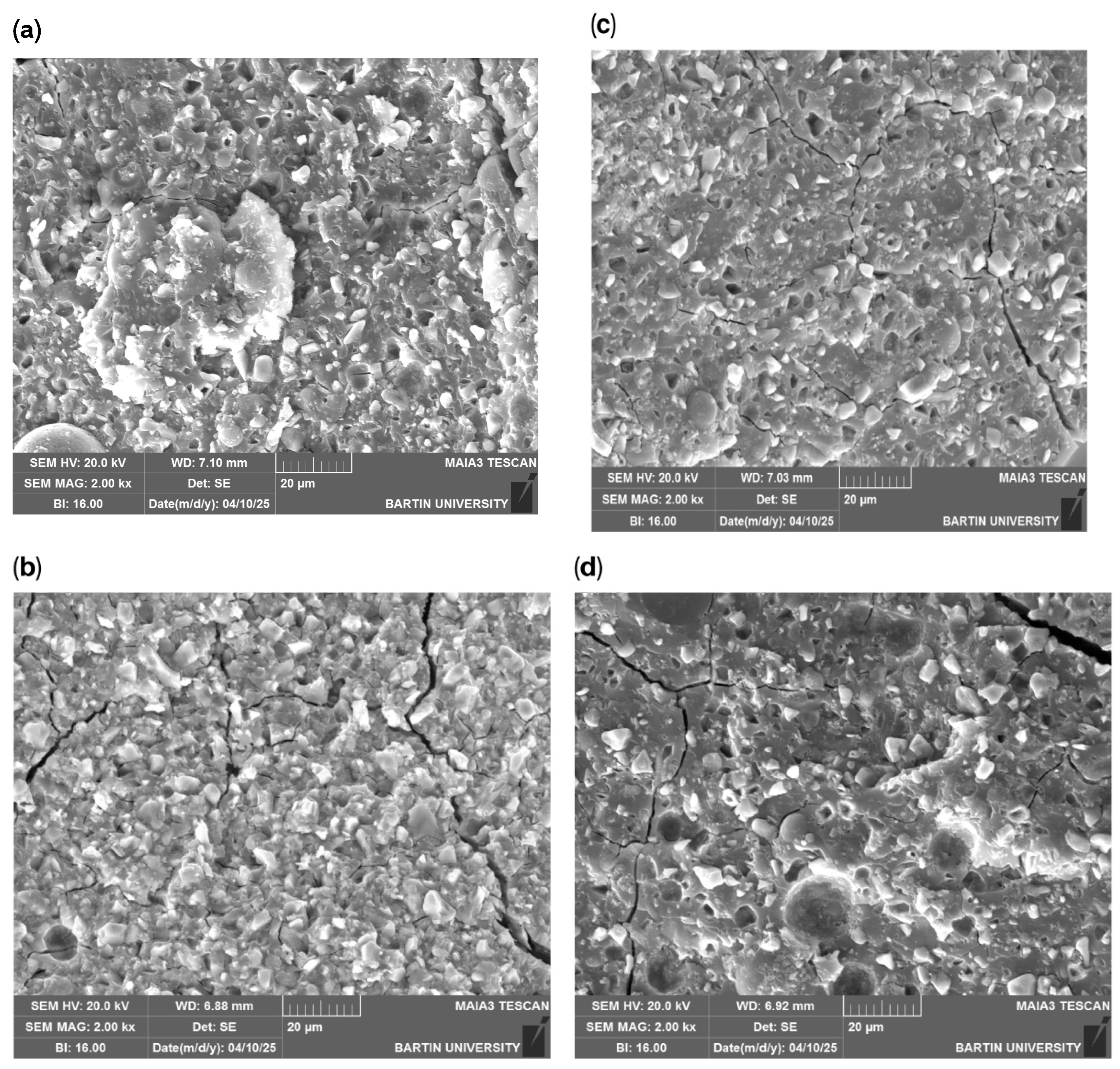

2.2.7. SEM and EDX Characterization

2.2.8. Statistical Analysis

3. Results

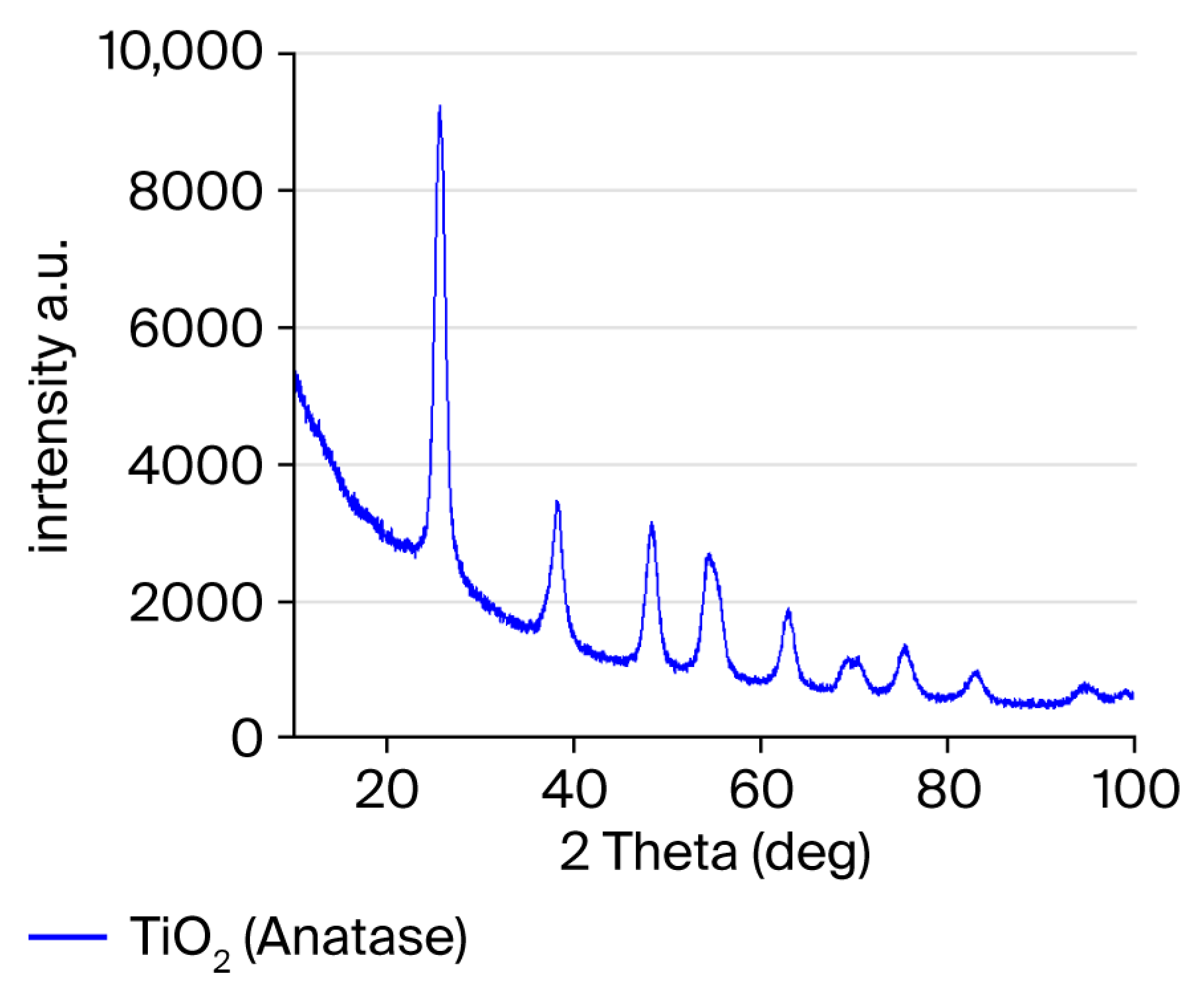

3.1. XRD Analysis of TiO2 Nanoparticles

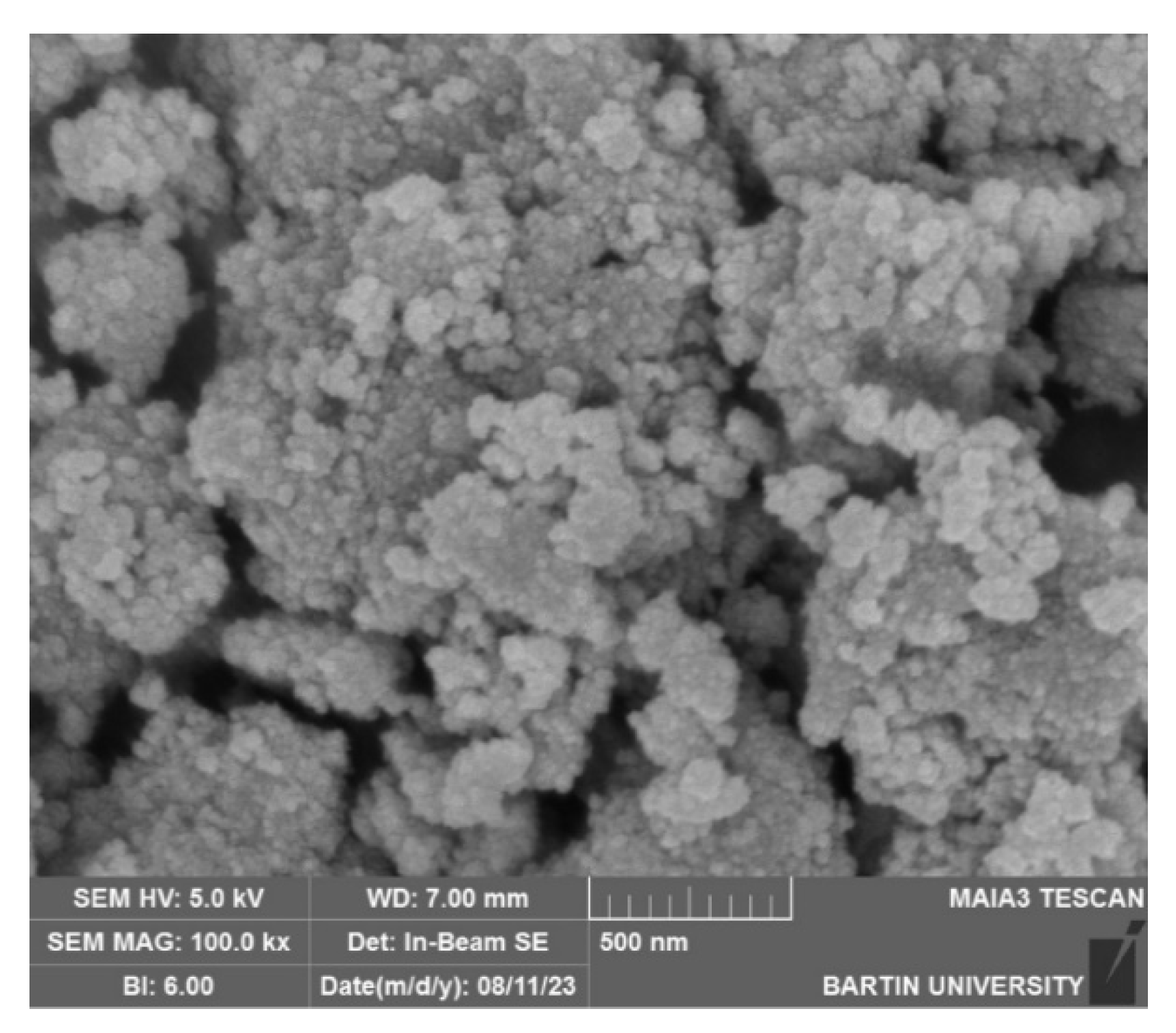

3.2. SEM Analysis of TiO2 Nanoparticles

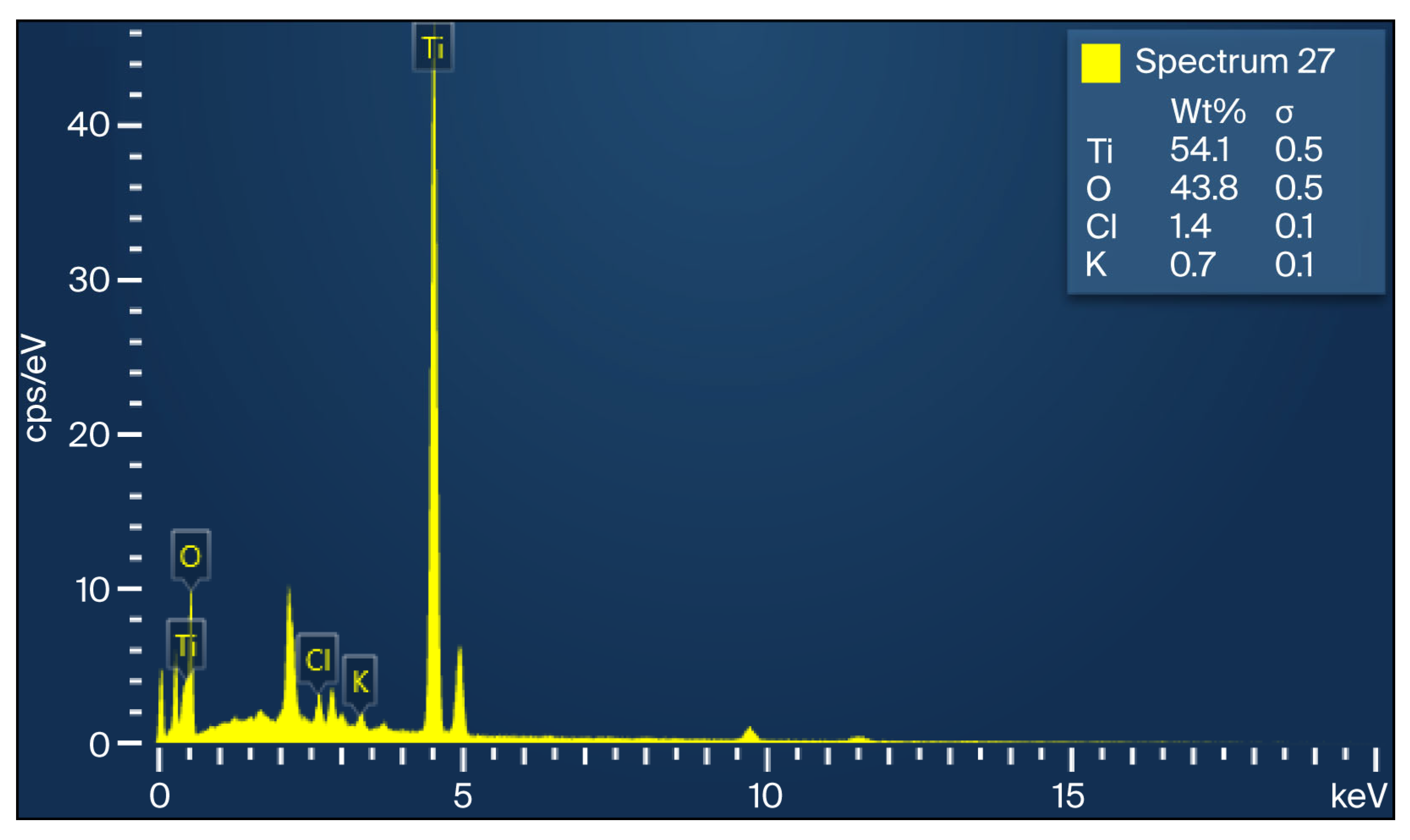

3.3. EDX Analysis of TiO2 Nanoparticles

3.4. Surface Roughness

- In Ketac™ Cem Radiopaque, the highest Ra values were recorded at 5% NP concentration.

- In Ketac™ Molar Easymix, significant increases were observed at 3% and 5% concentrations.

3.5. Flexural Strength

Vickers Microhardness

- Ketac™ Molar Easymix: Significant increases were observed at 1% and 3% TiO2, while slight reductions occurred at a 5% NP concentration.

- Ketac™ Cem Radiopaque: The highest hardness was recorded at 1% NP concentration, with decreases at higher concentrations (3% and 5%).

4. Discussion

5. Conclusions

- Hemp-mediated green synthesis enabled the successful production of TiO2 nanoparticles and their incorporation into restorative and luting glass ionomer cements.

- Low nanoparticle concentrations (1% and 3%) enhanced flexural strength and microhardness in the restorative GIC, whereas higher loading (5%) resulted in performance reduction, likely due to nanoparticle agglomeration.

- Surface roughness increased in a concentration-dependent manner for both materials, highlighting the importance of optimizing nanoparticle concentration to balance mechanical reinforcement and clinical surface quality.

- No significant improvement in flexural strength was observed for Ketac™ Cem Radiopaque, which may be attributed to material-specific compositional and matrix-related factors.

- The reinforcing efficiency of TiO2 nanoparticles was strongly dependent on cement formulation and nanoparticle dispersion within the matrix.

- Although antibacterial activity and advanced mechanical properties were not directly evaluated, future studies incorporating tensile behavior, fracture-related parameters, antibacterial assays, and environmental impact analyses are warranted to further elucidate the multifunctional and sustainable potential of green-synthesized TiO2-reinforced glass ionomer cements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wilson, A.D.; Kent, B.E. A new translucent cement for dentistry. Br. Dent. J. 1972, 132, 133–135. [Google Scholar] [CrossRef] [PubMed]

- Anusavice, K.J.; Shen, C.; Rawls, H.R. Phillips’ Science of Dental Materials, 12th ed.; Elsevier Health Sciences: St. Louis, MI, USA, 2012. [Google Scholar]

- Baig, M.S.; Fleming, G.J. Conventional glass-ionomer materials: A review of the developments in glass powder, polyacid liquid and the strategies of reinforcement. J. Dent. 2015, 43, 897–912. [Google Scholar] [CrossRef]

- Sidhu, S.K.; Nicholson, J.W. A review of glass-ionomer cements for clinical dentistry. J. Funct. Biomater. 2016, 7, 16. [Google Scholar] [CrossRef] [PubMed]

- François, P.; Fouquet, V.; Attal, J.P.; Dursun, E. Commercially available fluoride-releasing restorative materials: A review and a proposal for classification. Materials 2020, 13, 2313. [Google Scholar] [CrossRef] [PubMed]

- Kuşçu, S.; Baysan, F.D.; Korkmaz, N.; Kuşçu, A.İ.; Karadağ, A. Enhancing mechanical properties of glass-ionomer cement with hemp fiber: A sustainable approach for dental restorations. BMC Oral Health 2025, 25, 369. [Google Scholar] [CrossRef] [PubMed]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Scheibe, M.; Urbania, M.; Bledzki, A. Application of natural (plant) fibers particularly hemp fiber as reinforcement in hybrid polymer composites—Part II. J. Nat. Fibers 2023, 20, 2276715. [Google Scholar] [CrossRef]

- Cibim, D.D.; Saito, M.T.; Giovani, P.A.; Borges, A.F.S.; Pecorari, V.G.A.; Gomes, O.P.; Lisboa-Filho, P.N.; Nociti-Junior, F.H.; Puppin-Rontani, R.M.; Kantovitz, K.R. Novel nanotechnology of TiO2 improves physical-chemical and biological properties of glass ionomer cement. Int. J. Biomater. 2017, 2017, 7123919. [Google Scholar] [CrossRef] [PubMed]

- De Caluwé, T.; Vercruysse, C.W.J.; Fraeyman, S.; Verbeeck, R.M.H. The influence of particle size and fluorine content of aluminosilicate glass on the glass ionomer cement properties. Dent. Mater. 2014, 30, 1029–1038. [Google Scholar] [CrossRef] [PubMed]

- Guilger-Casagrande, M.; de Lima, R. Synthesis of silver nanoparticles mediated by fungi: A review. Front. Bioeng. Biotechnol. 2019, 7, 287. [Google Scholar] [CrossRef] [PubMed]

- Iravani, S. Green synthesis of metal nanoparticles using plants. Green Chem. 2011, 13, 2638–2650. [Google Scholar] [CrossRef]

- Malhotra, S.P.K.; Alghuthaymi, M.A. Biomolecule-Assisted Biogenic Synthesis of Metallic Nanoparticles. In Agri-Waste and Microbes for Production of Sustainable Nanomaterials, 1st ed.; Springer: Cham, Switzerland, 2022; pp. 139–163. [Google Scholar]

- ISO 9917-1:2025; Dentistry—Water-Based Cements—Part 1: Acid-Base Cements. International Organization for Standardization: Geneva, Switzerland, 2025.

- Aravind, M.; Amalanathan, M.; Mary, M.S.M. Synthesis of TiO2 nanoparticles by chemical and green synthesis methods and their multifaceted properties. SN Appl. Sci. 2021, 3, 281. [Google Scholar] [CrossRef]

- Jadoun, S.; Arif, R.; Jangid, N.K.; Meena, R.K. Green synthesis of nanoparticles using plant extracts: A review. Environ. Chem. Lett. 2021, 19, 355–374. [Google Scholar] [CrossRef]

- Verma, V.; Al-Dossari, M.; Singh, J.; Rawat, M.; Kordy, M.G.; Shaban, M. A review on green synthesis of TiO2 NPs: Photocatalysis and antimicrobial applications. Polymers 2022, 14, 1444. [Google Scholar] [CrossRef] [PubMed]

- Hudlikar, M.; Joglekar, S.; Dhaygude, M.; Kodam, K. Green synthesis of TiO2 nanoparticles by using aqueous extract of Jatropha curcas L. latex. Mater. Lett. 2012, 75, 196–199. [Google Scholar] [CrossRef]

- Elbatanony, M.M.; El Shahawi, A.M. Evaluation of some mechanical and optical properties of modified glass ionomer cement with TiO2 and SiO2 nanoparticles. Bull. Natl. Res. Cent. 2024, 48, 109. [Google Scholar] [CrossRef]

- Gharechahi, M.; Moosavi, H.; Forghani, M. Effect of surface roughness and materials composition on biofilm formation. J. Biomater. Nanobiotechnol. 2012, 3, 541–546. [Google Scholar] [CrossRef]

- Ramić, B.; Marković, D.; Petrović, V.; Janković, O.; Nikolić, M.; Jovanović, D. Physical and mechanical properties assessment of glass ionomer cements modified with TiO2 and Mg-doped hydroxyapatite nanoparticles. J. Dent. Sci. 2024, 19, 210–218. [Google Scholar] [CrossRef] [PubMed]

- Panahandeh, N.; Hasani, E.; Safa, S.; Hashemi, M.; Torabzadeh, H. Effects of incorporation of titanium dioxide nanoparticles on mechanical properties of conventional glass ionomer cement. J. Iran. Med. Counc. 2024, 7, 99–106. [Google Scholar] [CrossRef]

- Wassel, M.O.; Allam, G.G. Anti-bacterial effect, fluoride release, and compressive strength of a glass ionomer containing silver and titanium nanoparticles. Indian J. Dent. Res. 2022, 33, 75–79. [Google Scholar] [CrossRef] [PubMed]

| Material | Group | Mean Ra (µm) | Standard Deviation (µm) | Minimum Ra (µm) | Maximum Ra (µm) |

|---|---|---|---|---|---|

| Ketac™ Cem Radiopaque | Control (No NP) | 0.42 | 0.29 | 0.01 | 0.84 |

| 1% TiO2 NP | 0.69 | 0.34 | 0.22 | 1.16 | |

| 3% TiO2 NP | 0.74 | 0.38 | 0.26 | 1.24 | |

| 5% TiO2 NP | 0.98 | 0.40 | 0.58 | 1.38 | |

| Ketac™ Molar Easymix | Control (no NPs) | 0.80 | 0.45 | 0.01 | 1.60 |

| 1% TiO2 NP | 1.10 | 0.38 | 0.56 | 1.42 | |

| 3% TiO2 NP | 1.20 | 0.42 | 0.50 | 1.74 | |

| 5% TiO2 NP | 1.18 | 0.44 | 0.48 | 1.72 |

| No. | Group | p-Value | Significance | Mean Flexural Strength (MPa) | Std Dev Flexural Strength (MPa) |

|---|---|---|---|---|---|

| 1 | 0.0 vs. 0.01 | 0.0281 | Significant | 1.3324 | 0.1864 |

| 2 | 0.0 vs. 0.03 | 0.0206 | Significant | 0.7123 | 0.1582 |

| 3 | 0.0 vs. 0.05 | 0.0207 | Significant | 0.6818 | 0.2224 |

| 4 | 0.01 vs. 0.03 | 0.743 | Not Significant | 0.6834 | 0.1279 |

| 5 | 0.01 vs. 0.05 | 0.7209 | Not Significant | 0.8042 | 0.1584 |

| 6 | 0.03 vs. 0.05 | 0.673 | Not Significant | 1.0248 | 0.1733 |

| No. | Group | p-Value | Significance | Mean Flexural Strength (MPa) | Std Dev Flexural Strength (MPa) |

|---|---|---|---|---|---|

| 1 | 0.0 vs. 0.01 | 0.152 | Not Significant | 0.8745 | 0.1116 |

| 2 | 0.0 vs. 0.03 | 0.9182 | Not Significant | 1.4507 | 0.2732 |

| 3 | 0.0 vs. 0.05 | 0.152 | Not Significant | 1.232 | 0.2202 |

| 4 | 0.01 vs. 0.03 | 0.0745 | Not Significant | 1.0987 | 0.2416 |

| 5 | 0.01 vs. 0.05 | 0.8785 | Not Significant | 0.656 | 0.1041 |

| 6 | 0.03 vs. 0.05 | 0.0592 | Not Significant | 0.656 | 0.294 |

| Material | Group | Measurement 1 | Measurement 2 | Measurement 3 | Mean ± SD |

|---|---|---|---|---|---|

| Easymix | Control (0% NP) | 48.6 | 38.4 | 42.6 | 43.2 ± 5.1 |

| 0-2 | 34.9 | 34.2 | 38.2 | 35.8 ± 2.1 | |

| 1-1 (%1 NP) | 38.4 | 37.1 | 39.7 | 38.4 ± 1.3 | |

| 1-2 (%1 NP) | 40.8 | 46.0 | 42.9 | 43.2 ± 2.6 | |

| 3-1 (%3 NP) | 41.5 | 39.7 | 45.8 | 42.3 ± 3.1 | |

| 3-2 (%3 NP) | 44.4 | 44.7 | 46.4 | 45.2 ± 1.0 | |

| 5-1 (%5 NP) | 30.2 | 38.8 | 36.4 | 35.1 ± 4.3 | |

| 5-2 (%5 NP) | 34.8 | 35.7 | 30.5 | 33.7 ± 2.6 | |

| Cem Radiopak | Control (0% NP) | 52.1 | 43.5 | 48.0 | 47.9 ± 4.3 |

| 0-2 | 38.7 | 50.8 | 47.4 | 45.6 ± 6.1 | |

| 1-1 (%1 NP) | 75.8 | 87.9 | 80.8 | 81.5 ± 6.1 | |

| 1-2 (%1 NP) | 69.4 | 73.8 | 75.8 | 73.0 ± 3.2 | |

| 3-1 (%3 NP) | 70.4 | 41.0 | 72.3 | 61.2 ± 16.7 | |

| 5-1 (%5 NP) | 58.3 | 64.1 | 73.0 | 65.1 ± 7.4 | |

| 5-2 (%5 NP) | 53.8 | 64.1 | 58.0 | 58.6 ± 5.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Karamüftüoğlu, N.; Kuşçu, S.; Kuşçu, İ.; Korkmaz, N. Green-Synthesized TIO2 Nanoparticles Improve Mechanical Performance of Glass Ionomer Cements. Polymers 2026, 18, 295. https://doi.org/10.3390/polym18020295

Karamüftüoğlu N, Kuşçu S, Kuşçu İ, Korkmaz N. Green-Synthesized TIO2 Nanoparticles Improve Mechanical Performance of Glass Ionomer Cements. Polymers. 2026; 18(2):295. https://doi.org/10.3390/polym18020295

Chicago/Turabian StyleKaramüftüoğlu, Nevra, Süha Kuşçu, İpek Kuşçu, and Nesrin Korkmaz. 2026. "Green-Synthesized TIO2 Nanoparticles Improve Mechanical Performance of Glass Ionomer Cements" Polymers 18, no. 2: 295. https://doi.org/10.3390/polym18020295

APA StyleKaramüftüoğlu, N., Kuşçu, S., Kuşçu, İ., & Korkmaz, N. (2026). Green-Synthesized TIO2 Nanoparticles Improve Mechanical Performance of Glass Ionomer Cements. Polymers, 18(2), 295. https://doi.org/10.3390/polym18020295