Enhancement in Post-Consumer Mechanical Recycling of Plastics: Role of Design for Recycling, Specifications, and Efficient Sorting of Packaging Material

Abstract

1. Introduction

- The Packaging and Packaging Waste Directive (94/62/EG), with its amendment in 2018, aims to harmonize the management of packaging and packaging waste within the European Union. It declares a recycling rate of at least 50% by the end of 2025 and 55% by the end of 2030 as targets and defines a hierarchy of waste (reduce, reuse, recycle, and dispose) [9];

- European Directive (2008/98) and its amendment in 2018 on waste management, extended producer responsibility (EPR), and waste prevention [10];

- European Directive (EU/2015/720) to reduce the consumption of lightweight plastic carrier bags to prevent the littering of plastic carrier bags and other items into the environment [11];

- European Directive (EU/2019/904) to reduce the impact of certain plastic products on the environment. This directive restricts the consumption of single-use plastic (SUP) items in Europe [12];

- Commission Regulation (EU/2022/1616) defines the rules and requirements for recycled plastic materials and articles intended to come into contact with food [15].

- Collection rate: accumulated losses due to incorrect sorting, streams towards incineration or landfill, and littering towards the environment;

- Sorting rate: material loss during sorting process in waste handling and recycling facilities;

- Recycling process rate: losses, off-specification, and waste production during recycling processes within recycling plants.

2. Methodology

3. Design for Recycling (DfR)

4. Specification

5. Sorting Improvements

6. Information-Based Technologies

7. Benefits of Use of Information-Based Technology and DfR

8. Discussion

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Plastics Europe. Plastics–the Facts 2022—An Analysis of European Plastics Production, Demand and Waste Data; Plastics Europe: Brussels, Belgium, 2022; p. 81. [Google Scholar]

- Lase, I.S.; Bashirgonbadi, A.; van Rhijn, F.; Dewulf, J.; Ragaert, K.; Delva, L.; Roosen, M.; Brandsma, M.; Langen, M.; De Meester, S. Material flow analysis and recycling performance of an improved mechanical recycling process for post-consumer flexible plastics. Waste Manag. 2022, 153, 249–263. [Google Scholar] [CrossRef] [PubMed]

- Kato, L.S.; Conte-Junior, C.A. Safety of Plastic Food Packaging: The Challenges about Non-Intentionally Added Substances (NIAS) Discovery, Identification and Risk Assessment. Polymers 2021, 13, 2077. [Google Scholar] [CrossRef] [PubMed]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Ellen MacArthur Foundation. The Global Commitment 2021: Progress Report; Ellen MacArthur Foundation: Cowes, UK, 2021; p. 39. Available online: https://emf.thirdlight.com/link/n1ipti7a089d-ekf9l1/@/preview/1?o (accessed on 20 June 2024).

- Kahlert, S.; Bening, C.R. Why pledges alone will not get plastics recycled: Comparing recyclate production and anticipated demand. Resour. Conserv. Recycl. 2022, 181, 106279. [Google Scholar] [CrossRef]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy; European Commission: Brussels, Belgium, 2015; p. 18.

- European Commission. A European Strategy for Plastics in a Circular Economy; European Commission: Brussels, Belgium, 2018; p. 18.

- European Parliament and Council. Directive on Packaging and Packaging Waste; European Parliament and Council: Brussels, Belgium, 1994; p. 32. [Google Scholar]

- European Parliament and Council. Directive on Waste and Repealing Certain Directives; European Parliament and Council: Brussels, Belgium, 2008; p. 28. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0098&from=EN (accessed on 27 March 2023).

- European Parliament and Council. Directive Regards Reducing the Consumption of Lightweight Plastic Carrier Bags; European Parliament and Council: Brussels, Belgium, 2015; p. 5. [Google Scholar]

- European Parliament and Council. Directive on the Reduction of the Impact of Certain Plastic Products on the Environment; European Parliament and Council: Brussels, Belgium, 2019; p. 19. [Google Scholar]

- European Parliament and Council. Regulation on Shipments of Waste; European Parliament and Council: Brussels, Belgium, 2006; p. 98. [Google Scholar]

- European Parliament and Council. Amendent to Regulation (EC) No 1013/2006 of the European Parliament and of the Council on Shipments of Waste; European Parliament and Council: Strasbourg, France, 2020; p. 5. [Google Scholar]

- European Commission. Commission Regulation on Recycled Plastic Materials and Articles Intended to Come into Contact with Foods; European Commission: Brussels, Belgium, 2022; p. 5. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32022R1616&from=EN (accessed on 27 March 2023).

- Friedrich, K.; Koinig, G.; Tschiggerl, K.; Pomberger, R.; Vollprecht, D. Challenges to Increase Plastic Sorting Efficiency. Int. J. Eng. Technol. Inform. 2021, 2, 5. [Google Scholar]

- Altstoff Recycling Austria (ARA). Separate Waste Collection and Recycling—What Every One of Us Can Do to Protect the Climate. 2025. Available online: https://www.ara.at/en/waste-collection-and-recycling (accessed on 15 January 2025).

- Seier, M.; Archodoulaki, V.-M.; Koch, T.; Duscher, B.; Gahleitner, M. Polyethylene terephthalate based multilayer food packaging: Deterioration effects during mechanical recycling. Food Packag. Shelf Life 2022, 33, 100890. [Google Scholar] [CrossRef]

- Schlossnikl, J.; Pinter, E.; Jones, M.P.; Koch, T.; Archodoulaki, V.-M. Unexpected obstacles in mechanical recycling of polypropylene labels: Are ambitious recycling targets achievable? Resour. Conserv. Recycl. 2024, 200, 107299. [Google Scholar] [CrossRef]

- Maris, E.; Froelich, D.; Aoussat, A.; Naffrechoux, E. Chapter 27—From Recycling to Eco-design. In Handbook of Recycling; Worrell, E., Reuter, M.A., Eds.; Elsevier: Boston, MA, USA, 2014; pp. 421–427. [Google Scholar]

- RecyClass. RecyClass—Design for Recycling Guidelines. 2023. Available online: https://recyclass.eu/recyclability/design-for-recycling-guidelines/ (accessed on 18 April 2023).

- CEFLEX. Designing for a Circular Economy—Guidelines Summary; CEFLEX: Bergschenhoek, The Netherlands, 2020; p. 4. Available online: https://guidelines.ceflex.eu/resources/ (accessed on 6 October 2022).

- Ellen MacArthur Foundation. The Circular Design Guide. 2018. Available online: https://www.circulardesignguide.com/ (accessed on 20 April 2023).

- The UK Plastic Pact and WRAP. Defining What’s Recyclable and Best in Class Polymer Choices for Packaging; WRAP: London, UK, 2022; p. 16. Available online: https://wrap.org.uk/sites/default/files/2022-12/Polymer%20choice%20and%20recyclability%20guidance%20-%20Dec%202022.pdf (accessed on 21 April 2023).

- Tacker, M. Packaging Design for Recycling—Eine Empfehlung der ECR Austria Arbeitsgruppe “Circular Packaging Design”; The European Congress of Radiology: Vienna, Austria, 2020; p. 70. Available online: https://ecr-austria.at/arbeitsgruppen/circular-packaging-design-guideline/ (accessed on 11 November 2024).

- FH Campus Wien. Circular Packaging Design Guideline—Empfehlungen für die Gestaltung Recyclinggerechter Verpackungen. 2020. Available online: https://www.fh-campuswien.ac.at/forschung/kompetenzzentren-fuer-forschung-und-entwicklung/kompetenzzentrum-fuer-sustainable-and-future-oriented-packaging-solutions/circular-packaging-design-guideline.html (accessed on 19 April 2023).

- IK Industrievereinigung Kunststoffverpackungen e.V. Eco Design of Plastic Packaging—Round Table Management Guideline; IK Industrievereinigung Kunststoffverpackungen e.V.: Bad Homburg, Germany, 2019; p. 53. Available online: https://ecodesign-packaging.org/en/guidelines/overview/ (accessed on 19 April 2023).

- Netherlands Institute for Sustainable Packaging. Roadmap—Multilayer Flexible Packaging in a Circular Economy; The Netherlands Institute for Sustainable Packaging: The Hague, The Netherlands, 2020; p. 35. [Google Scholar]

- Bois, E.D.; Doorsselaer, K.V.; Veelaert, L. Design from Recycling—Manual; University of Antwerp: Antwerp, Belgium, 2017; p. 35. Available online: https://medialibrary.uantwerpen.be/oldcontent/container49257/files/Design%20From%20Recycling_Manual_English%20booklet.pdf?_ga=2.147801399.1448507533.1681973677-2059515463.1674715256&_gl=1*16d9574*_ga*MjA1OTUxNTQ2My4xNjc0NzE1MjU2*_ga_WVC36ZPB1Y*MTY4MjA1MTQ5Mi40LjAuMTY4MjA1MTQ5Mi42MC4wLjA (accessed on 21 April 2023).

- Gong, Y.; Putnam, E.; You, W.; Zhao, C. Investigation into circular economy of plastics: The case of the UK fast moving consumer goods industry. J. Clean. Prod. 2020, 244, 118941. [Google Scholar] [CrossRef]

- Seier, M.; Archodoulaki, V.-M.; Koch, T.; Duscher, B.; Gahleitner, M. Prospects for Recyclable Multilayer Packaging: A Case Study. Polymers 2023, 15, 2966. [Google Scholar] [CrossRef]

- Carullo, D.; Casson, A.; Rovera, C.; Ghaani, M.; Bellesia, T.; Guidetti, R.; Farris, S. Testing a coated PE-based mono-material for food packaging applications: An in-depth performance comparison with conventional multi-layer configurations. Food Packag. Shelf Life 2023, 39, 101143. [Google Scholar] [CrossRef]

- Maga, D.; Hiebel, M.; Aryan, V. A Comparative Life Cycle Assessment of Meat Trays Made of Various Packaging Materials. Sustainability 2019, 11, 5324. [Google Scholar] [CrossRef]

- DIN SPEC 91446:2021; Classification of Recycled Plastics by Data Quality Levels for Use and (Digital) Trading. DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 2021; p. 37.

- DIN SPEC 91009:2015; Recycled Plastics—Determination of Marker Compounds in Food Grade Recycled Poly(ethylene terephthalate) (PET). DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 2015; p. 27.

- DIN SPEC 91011:2013; Recycled Plastics—Sample Preparation. DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 2013; p. 26.

- Welle, F. Twenty years of PET bottle to bottle recycling—An overview. Resour. Conserv. Recycl. 2011, 55, 865–875. [Google Scholar] [CrossRef]

- Aerospace Industries Association (AIA). The Future of Aerospace Standardization; AIA: Arlington, VA, USA, 2022; p. 81. Available online: https://www.aia-aerospace.org/wp-content/uploads/Future-of-Aero-Standardization-2022-3-17-2022.pdf (accessed on 1 July 2024).

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Neo, E.R.K.; Yeo, Z.; Low, J.S.C.; Goodship, V.; Debattista, K. A review on chemometric techniques with infrared, Raman and laser-induced breakdown spectroscopy for sorting plastic waste in the recycling industry. Resour. Conserv. Recycl. 2022, 180, 106217. [Google Scholar] [CrossRef]

- Sarc, R.; Curtis, A.; Kandlbauer, L.; Khodier, K.; Lorber, K.E.; Pomberger, R. Digitalisation and intelligent robotics in value chain of circular economy oriented waste management—A review. Waste Manag. 2019, 95, 476–492. [Google Scholar] [CrossRef]

- Wilts, H.; Garcia, B.R.; Garlito, R.G.; Gómez, L.S.; Prieto, E.G. Artificial Intelligence in the Sorting of Municipal Waste as an Enabler of the Circular Economy. Resources 2021, 10, 28. [Google Scholar] [CrossRef]

- Konstantinidis, F.K.; Sifnaios, S.; Tsimiklis, G.; Mouroutsos, S.G.; Amditis, A.; Gasteratos, A. Multi-sensor cyber-physical sorting system (CPSS) based on Industry 4.0 principles: A multi-functional approach. Procedia Comput. Sci. 2023, 217, 227–237. [Google Scholar] [CrossRef]

- Heikkilä, S.; Malahat, G.; Deviatkin, I. Chapter 29—From waste to value: Enhancing circular value creation in municipal solid waste management ecosystem through artificial intelligence-powered robots. In Sustainable and Circular Management of Resources and Waste Towards a Green Deal; Vara Prasad, M.N., Smol, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 415–428. [Google Scholar]

- Altstoff Recycling Austria (ARA). Rohstoff Kunststoff-Ressourcen und Kreislaufwirtschaft Neu Denken. und Machen; Altstoff Recycling Austria AG: Vienna, Austria, 2023; p. 28. Available online: https://www.ara.at/uploads/Dokumente/EU-Kreislaufwirtschaftspaket/Kunststoffbroschuere/ARA_Kunststoffbroschuere.pdf (accessed on 10 April 2024).

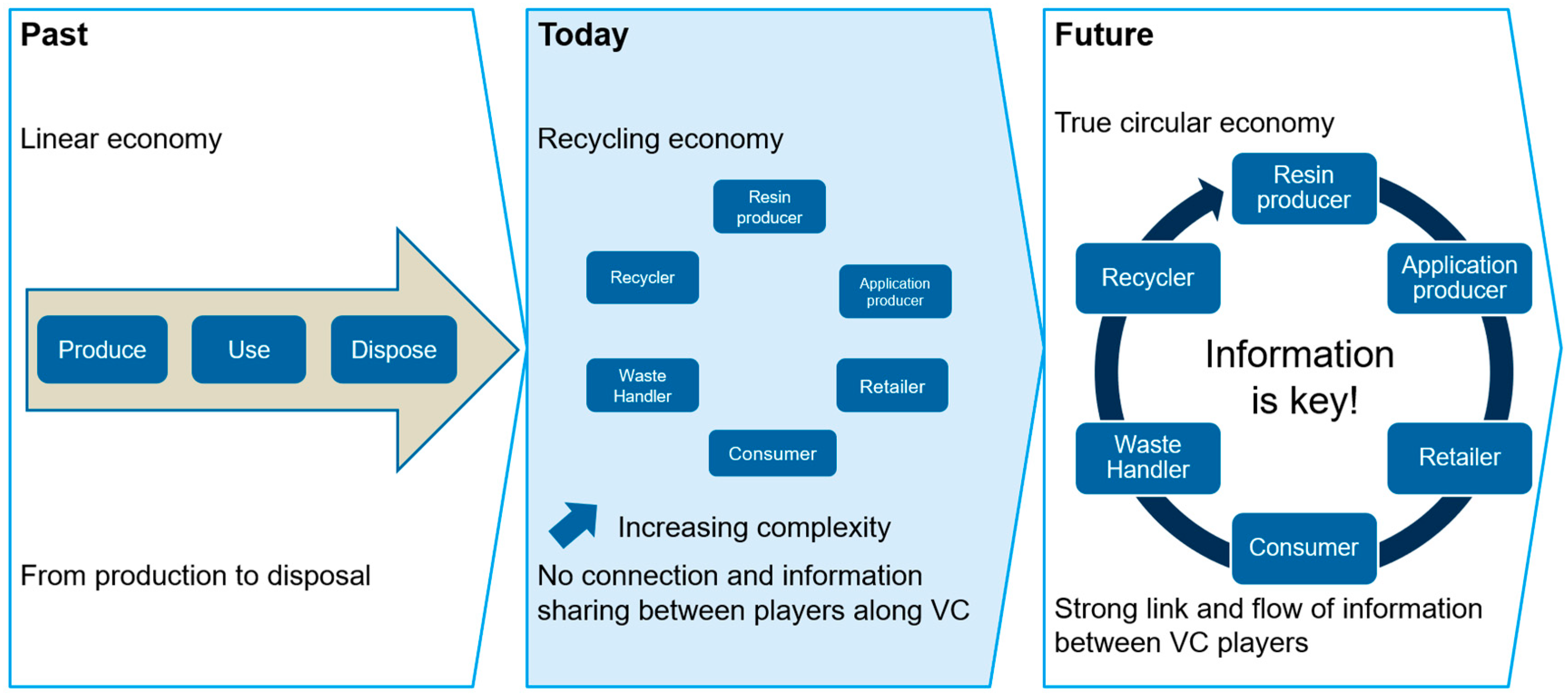

- Rumetshofer, T.; Fischer, J. Information-Based Plastic Material Tracking for Circular Economy—A Review. Polymers 2023, 15, 1623. [Google Scholar] [CrossRef]

- European Brand association (AIM). HolyGrail 2.0. 2021. Available online: https://www.digitalwatermarks.eu/ (accessed on 1 September 2022).

- European Brand association (AIM). Holy Grail 2.0-Intelligent Sorting-Pioneering Digital Watermarks for Smart Packaging Recycling in the EU; European Brand Association: Brussels, Belgium, 2021; p. 45. Available online: https://www.digitalwatermarks.eu/ (accessed on 24 April 2023).

- Rumetshofer, T.; Straka, K.; Fischer, J. How the Digital Product Passport Can Lead the Plastics Industry towards a Circular Economy—A Case Study from Bottle Caps to Frisbees. Polymers 2024, 16, 1420. [Google Scholar] [CrossRef]

- Jensen, S.F.; Kristensen, J.H.; Adamsen, S.; Christensen, A.; Waehrens, B.V. Digital product passports for a circular economy: Data needs for product life cycle decision-making. Sustain. Prod. Consum. 2023, 37, 242–255. [Google Scholar] [CrossRef]

- Nordic Innovation. Data Sharing for a Circular Economy in the Nordics; Nordic Innovation: Oslo, Norway, 2021; p. 53. [Google Scholar]

- Brunner, S.; Fomin, P.; Kargel, C. Automated sorting of polymer flakes: Fluorescence labeling and development of a measurement system prototype. Waste Manag. 2015, 38, 49–60. [Google Scholar] [CrossRef] [PubMed]

- WEF. Building Block(Chain)s for a Better Planet: Fourth Industrial Revolution for the Earth Series; World Economic Forum: Cologny, Switzerland, 2018; p. 37. [Google Scholar]

- Plociennik, C.; Pourjafarian, M.; Nazeri, A.; Windholz, W.; Knetsch, S.; Rickert, J.; Ciroth, A.; Lopes, A.D.C.P.; Hagedorn, T.; Vogelgesang, M.; et al. Towards a Digital Lifecycle Passport for the Circular Economy. Procedia CIRP 2022, 105, 122–127. [Google Scholar] [CrossRef]

- Galimberti, A.; De Mattia, F.; Losa, A.; Bruni, I.; Federici, S.; Casiraghi, M.; Martellos, S.; Labra, M. DNA barcoding as a new tool for food traceability. Food Res. Int. 2013, 50, 55–63. [Google Scholar] [CrossRef]

- Rudolph, N.; Kiesel, R.; Aumnate, C. Understanding Plastics Recycling—Economic, Ecological, and Technical Aspects of Plastic Waste Handling, 2nd ed.; Hanser Publishers: Munich, Germany, 2017. [Google Scholar]

- Bher, A.; Auras, R. Life cycle assessment of packaging systems: A meta-analysis to evaluate the root of consistencies and discrepancies. J. Clean. Prod. 2024, 476, 143785. [Google Scholar] [CrossRef]

- Perugini, F.; Mastellone, M.L.; Arena, U. A life cycle assessment of mechanical and feedstock recycling options for management of plastic packaging wastes. Environ. Prog. 2005, 24, 137–154. [Google Scholar] [CrossRef]

- Resource Recycling Inc. Curbside Plastic Prices See Varying Trends in June. 2024. Available online: https://resource-recycling.com/plastics/2024/06/12/curbside-plastic-prices-see-varying-trends-in-june/ (accessed on 12 June 2024).

- Der Grüne Punkt. Rohstofffraktionsspezifikation 324-0 Polypropylen; Der Grüne Punkt: Köln, Nordrhein-Westfalen, Germany, 2024; p. 3. Available online: https://www.gruener-punkt.de/fileadmin/Dateien/Downloads/PDFs/Rohstofffraktionsspezifikationen2024/April/DOC-23-50686_-_Rohstofffraktionsspezifikation_324-0_Polypropylen_-_v1.00.0001.pdf (accessed on 1 July 2024).

| Base Case Scenario | ||

|---|---|---|

| Feedstock cost | 144 | USD/t |

| Production cost | 306 | USD/t |

| Average yield | 54 | % |

| Incineration cost | 170 | USD/t |

| Cost for 1 t of recyclate | 979 | USD/t |

| Advanced Case Scenario | ||

|---|---|---|

| Feedstock cost | 158 | USD/t |

| Production cost | 306 | USD/t |

| Average yield | 74 | % |

| Incineration cost | 170 | USD/t |

| Cost for 1 t of recyclate | 687 | USD/t |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rumetshofer, T.; Fischer, J. Enhancement in Post-Consumer Mechanical Recycling of Plastics: Role of Design for Recycling, Specifications, and Efficient Sorting of Packaging Material. Polymers 2025, 17, 1177. https://doi.org/10.3390/polym17091177

Rumetshofer T, Fischer J. Enhancement in Post-Consumer Mechanical Recycling of Plastics: Role of Design for Recycling, Specifications, and Efficient Sorting of Packaging Material. Polymers. 2025; 17(9):1177. https://doi.org/10.3390/polym17091177

Chicago/Turabian StyleRumetshofer, Thomas, and Jörg Fischer. 2025. "Enhancement in Post-Consumer Mechanical Recycling of Plastics: Role of Design for Recycling, Specifications, and Efficient Sorting of Packaging Material" Polymers 17, no. 9: 1177. https://doi.org/10.3390/polym17091177

APA StyleRumetshofer, T., & Fischer, J. (2025). Enhancement in Post-Consumer Mechanical Recycling of Plastics: Role of Design for Recycling, Specifications, and Efficient Sorting of Packaging Material. Polymers, 17(9), 1177. https://doi.org/10.3390/polym17091177