Effects of the Size and Loading of Chrome-Tanned Leather Shavings on the Properties of Styrene–Butadiene Rubber Compounds

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. LW Scrap Size Reduction

2.3. Chromium Determination in the LW

2.4. Thermogravimetric Analysis

2.5. Preparation of the Composites

2.6. Mechanical Tests

2.7. Microscopy Analysis

3. Results and Discussion

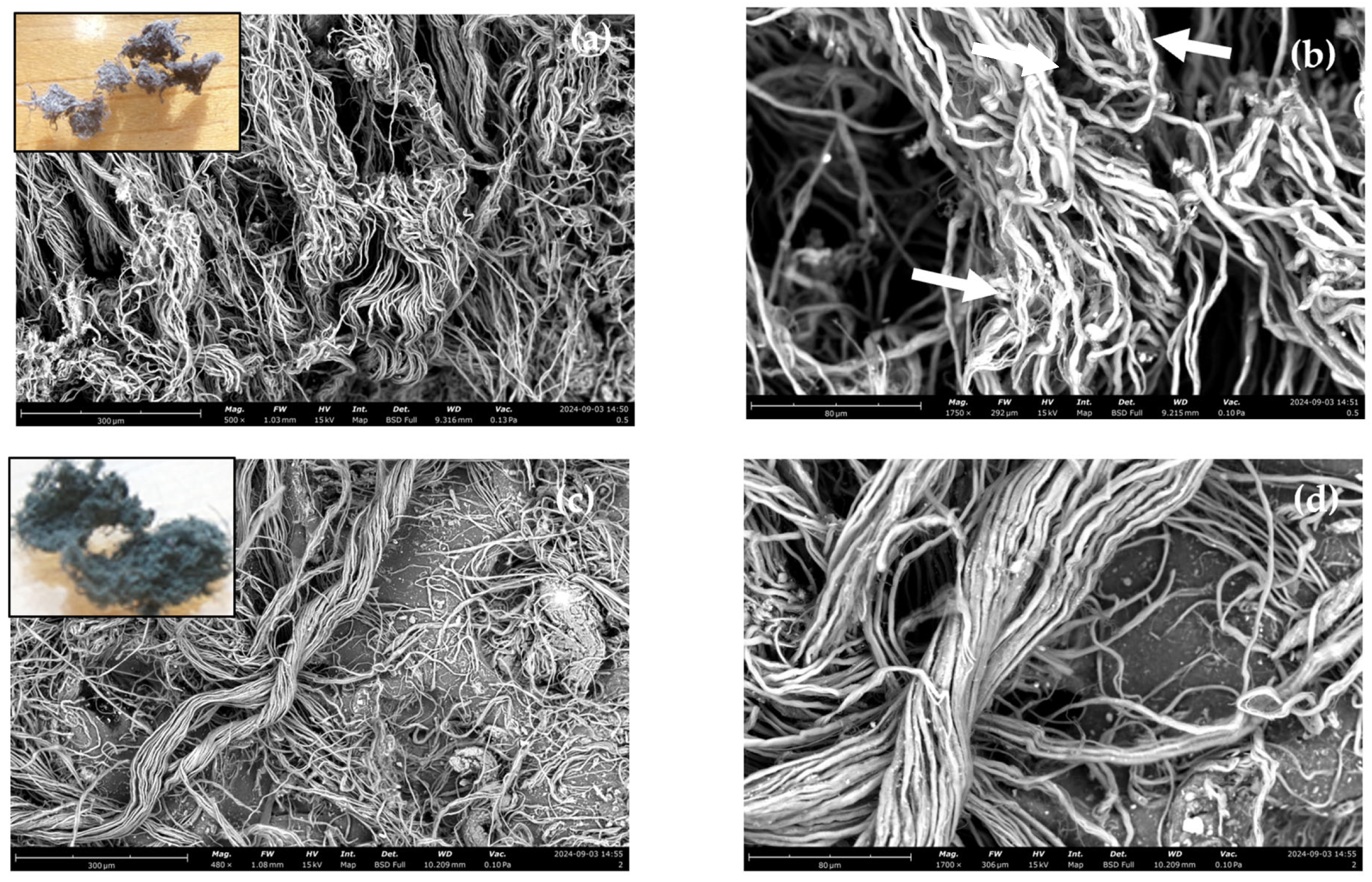

3.1. LW Characterization

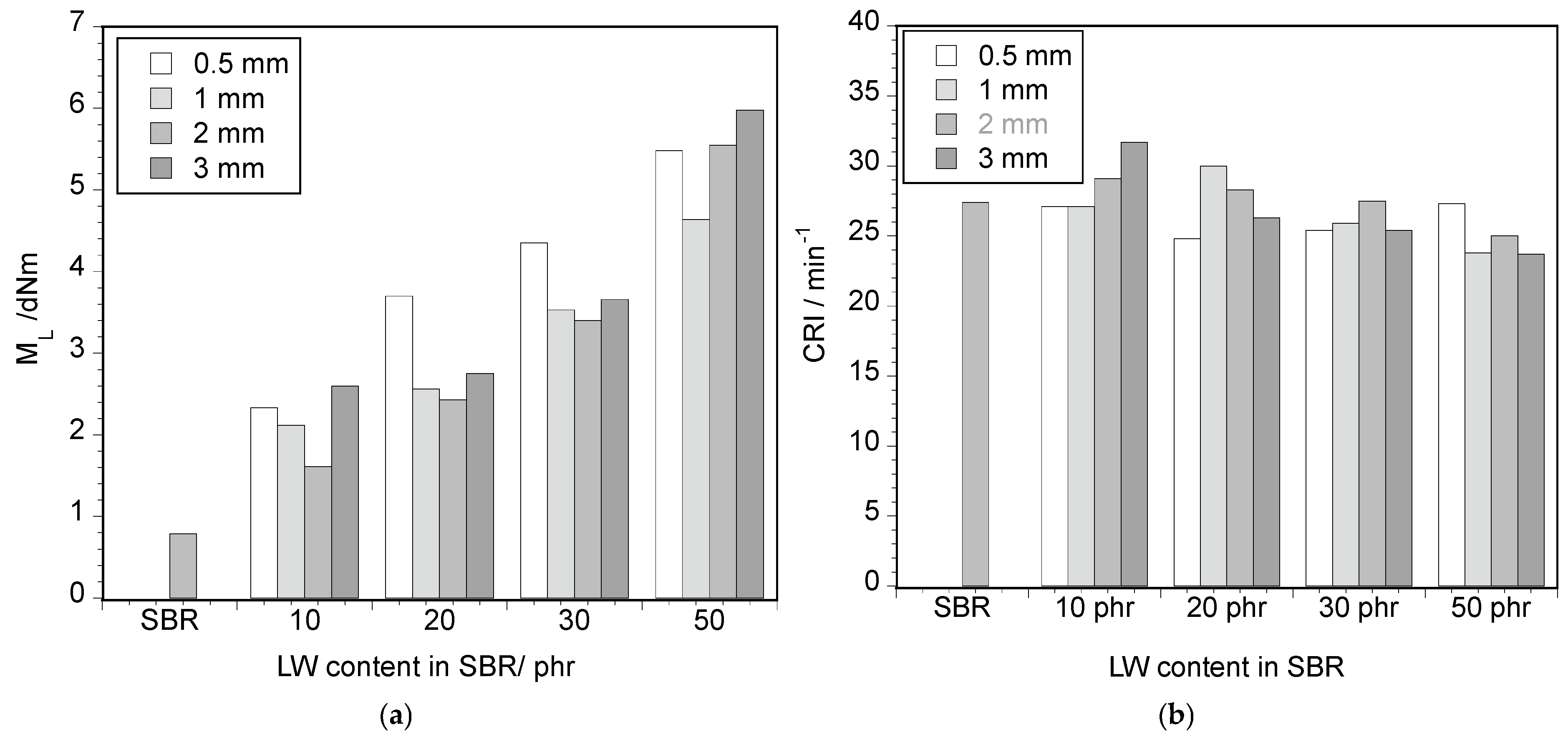

3.2. Rheological Properties of the Mixtures

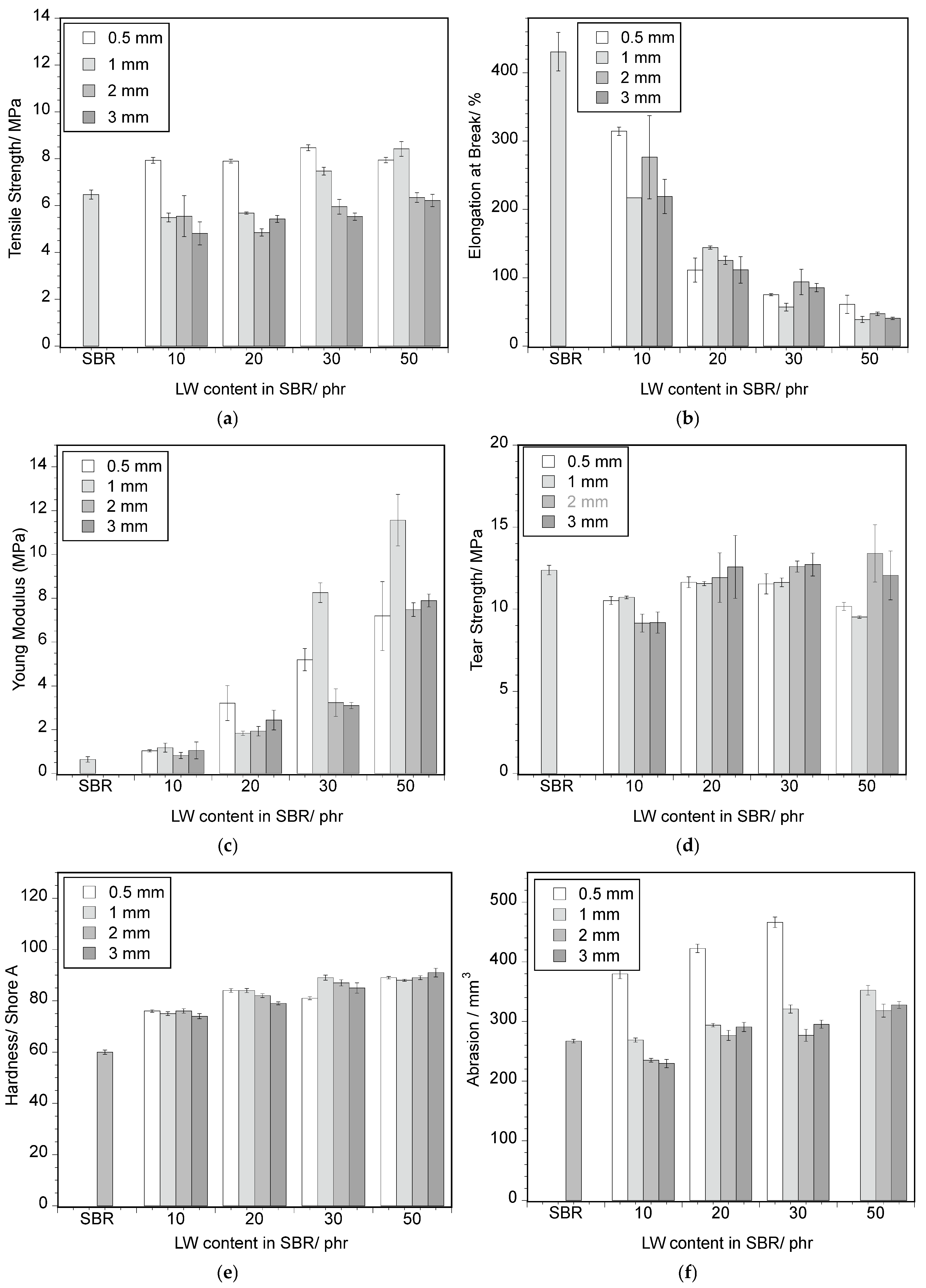

3.3. Mechanical Properties

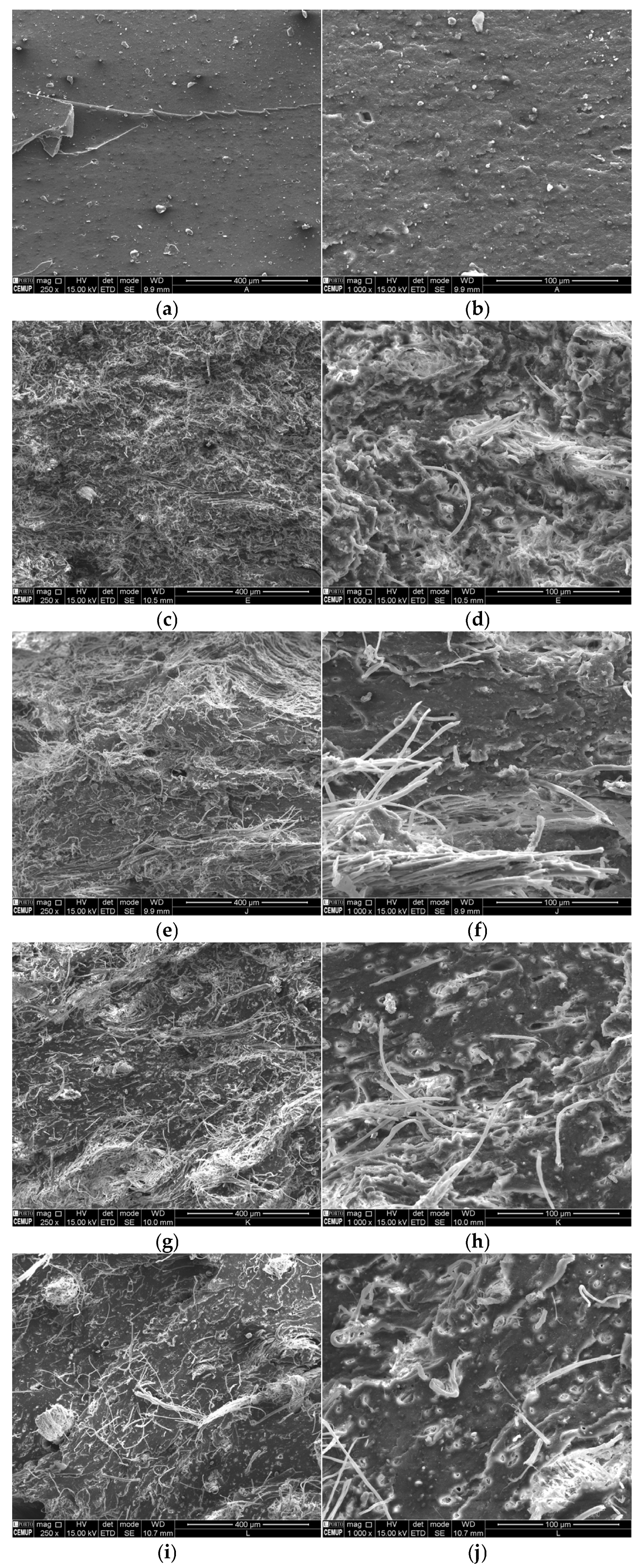

3.4. Microstructural Analysis

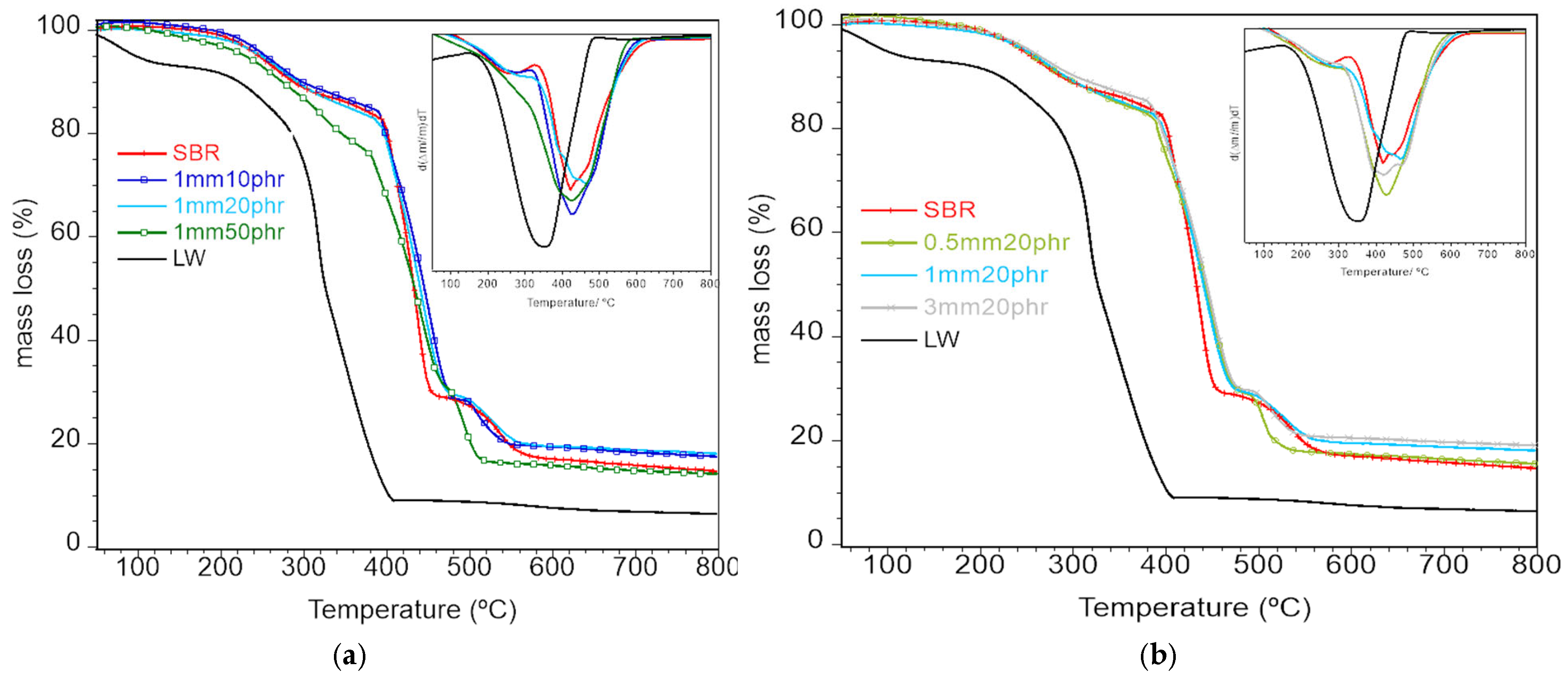

3.5. Thermal Properties

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nanni, A.; Parisi, M.; Colonna, M.; Messori, M. Thermo-mechanical and morphological properties of polymer composites reinforced by natural fibers derived from wet blue leather wastes: A comparative study. Polymers 2021, 13, 1837. [Google Scholar] [CrossRef] [PubMed]

- Parisi, M.; Nanni, A.; Colonna, M. Recycling of chrome-tanned leather and its utilization as polymeric materials and in polymer-based composites: A review. Polymers 2021, 13, 429. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.M.; Harris, J.; Busfield, J.J.C.; Bilotti, E. A review of the green chemistry approaches to leather tanning in imparting sustainable leather manufacturing. Green Chem. 2023, 25, 7441–7469. [Google Scholar] [CrossRef]

- Muthukrishnan, L. Nanotechnology for cleaner leather production: A review. Environ. Chem. Lett. 2021, 19, 2527–2549. [Google Scholar] [CrossRef]

- Ferreira, M.J.; Almeida, M.F. Recycling of Leather Waste Containing Chromium—A Review. Mater. Sci. Res. J. 2011, 5, 327. [Google Scholar]

- Muralidharan, V.; Palanivel, S.; Balaraman, M. Turning problem into possibility: A comprehensive review on leather solid waste intra-valorization attempts for leather processing. J. Clean. Prod. 2022, 367, 133021. [Google Scholar] [CrossRef]

- Ding, W.; Liao, X.P.; Zhang, W.H.; Shi, B. Dechroming of Chromium-containing Leather Waste with Low Hydrolysis Degree of Collagen. J. Soc. Leather Technol. Chem. 2015, 99, 129–133. [Google Scholar]

- Sun, D.H.; Liao, X.P.; Shi, B. Oxidative dechroming of leather shavings under ultrasound. J. Soc. Leather Technol. Chem. 2003, 87, 103–106. [Google Scholar]

- Liu, Y.; Wang, Q.; Li, L. Reuse of leather shavings as a reinforcing filler for poly (vinyl alcohol). J. Thermoplast. Compos. Mater. 2016, 29, 327–343. [Google Scholar] [CrossRef]

- Ramaraj, B. Mechanical and thermal properties of ABS and leather waste composites. J. Appl. Polym. Sci. 2006, 101, 3062–3066. [Google Scholar] [CrossRef]

- Noyon, M.A.R.; Dey, T.K.; Jamal, M.; Rathanasamy, R.; Chinnasamy, M.; Uddin, M.E. Fabrication of LLDPE based biodegradable composite incorporated with leather shavings and buffing dust: An approach for waste management. J. Appl. Polym. Sci. 2022, 139, e53184. [Google Scholar] [CrossRef]

- Ferreira, M.J.; Almeida, M.F.; Freitas, F. Formulation and characterization of leather and rubber wastes composites. Polym. Eng. Sci. 2011, 51, 1418–1427. [Google Scholar] [CrossRef]

- Santos, R.J.; Agostini, D.L.S.; Cabrera, F.C.; Budemberg, E.R.; Job, A.E. Recycling leather waste: Preparing and studying on the microstructure, mechanical, and rheological properties of leather waste/rubber composite. Polym. Compos. 2015, 36, 2275–2281. [Google Scholar] [CrossRef]

- Hang, L.T.; Viet, D.Q.; Linh, N.P.D.; Doan, V.A.; Dang, H.L.T.; Dao, V.D.; Tuan, P.A. Utilization of leather waste fibers in polymer matrix composites based on acrylonitrile-butadiene rubber. Polymers 2021, 13, 117. [Google Scholar] [CrossRef]

- Şaşmaz, S.; Karaağaç, B.; Uyanık, N. Utilization of chrome-tanned leather wastes in natural rubber and styrene-butadiene rubber blends. J. Mater. Cycles Waste Manag. 2019, 21, 166–175. [Google Scholar] [CrossRef]

- El-Sabbagh, S.H.; Mohamed, O.A. Recycling of chrome-tanned leather waste in acrylonitrile butadiene rubber. J. Appl. Polym. Sci. 2011, 121, 979–988. [Google Scholar] [CrossRef]

- Ravichandran, K.; Natchimuthu, N. Natural Rubber—Leather Composites. Polímeros 2005, 15, 102–108. [Google Scholar] [CrossRef]

- Yepes, W.U.; Cardona, N.; Velasquez, S.M.; Vásquez, D.H.G.; Posada, J.C. Mechanical and rheometric properties of natural rubber composites filled with untreated and chemically treated leather wastes. J. Compos. Mater. 2019, 53, 1475–1487. [Google Scholar] [CrossRef]

- Ferreira, M.J.; Freitas, F.; Almeida, M.F. The Effect of leather fibers on the properties of rubber-leather composites. J. Compos. Mater. 2010, 44, 2801–2817. [Google Scholar] [CrossRef]

- Shabani, I.; Arani, A.J.; Dakhel, H.R.; Iranmehr, G. Using of leather fibers as an additive in elastomeric compounds: Its effect on curing behavior and physico-mechanical properties. J. Appl. Polym. Sci. 2009, 111, 1670–1675. [Google Scholar] [CrossRef]

- Prochon, M.; Marzec, A.; Dzeikala, O. Hazardous waste management of buffing dust collagen. Materials 2020, 13, 1498. [Google Scholar] [CrossRef] [PubMed]

- Hayeemasae, N.; Waesateh, K.; Soontaranon, S.; Masa, A. The effect of mastication time on the physical properties and structure of natural rubber. J. Elastomers Plast. 2021, 53, 228–240. [Google Scholar] [CrossRef]

- Natchimuthu, N.; Radhakrishnan, G.; Palanivel, K.; Ramamurthy, K.; Anand, J.S. Vulcanization Characteristics and Mechanical Properties of Nitrile Rubber Filled with Short Leather Fibers. Polym. Int. 1994, 33, 329–333. [Google Scholar] [CrossRef]

- Cardona, N.; Velásquez, S.; Giraldo, D. Characterization of Leather Wastes from Chrome Tanning and its Effect as Filler on the Rheometric Properties of Natural Rubber Compounds. J. Polym. Environ. 2017, 25, 1190–1197. [Google Scholar] [CrossRef]

- Li, S.; Wang, Y.; Xu, W.; Shi, B. Natural Rubber-Based Elastomer Reinforced by Chemically Modified Multiscale Leather Collagen Fibers with Excellent Toughness. ACS Sustain. Chem. Eng. 2020, 8, 5091–5099. [Google Scholar] [CrossRef]

- ISO 11466:1995; Soil Quality—Extraction of Trace Elements Soluble in Aqua Regia. ISO: Geneva, Switzerland, 1995.

- ISO 22654:2002; Footwear—Test Methods for Outsoles—Tensile Strength and Elongation. ISO: Geneva, Switzerland, 2002.

- ISO 20871:2018; Footwear—Test Methods for Outsoles—Abrasion Resistance. ISO: Geneva, Switzerland, 2018.

- ISO 20872:2018; Test Methods for Outsoles—Tear Strength. ISO: Geneva, Switzerland, 2018.

- ISO 868:2003; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). ISO: Geneva, Switzerland, 2003.

- Garcia, N.G.; Reis, E.A.P.D.; Budemberg, E.R.; Agostini, D.L.D.S.; Salmazo, L.O.; Cabrera, F.C.; Job, A.E. Natural rubber/leather waste composite foam: A new eco-friendly material and recycling approach. J. Appl. Polym. Sci. 2015, 132, 41636. [Google Scholar] [CrossRef]

- William, D., Jr. Callister, Materials Science and Engineering, 7th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Senthil, R.; Hemalatha, T.; Kumar, B.S.; Uma, T.S.; Das, B.N.; Sastry, T.P. Recycling of finished leather wastes: A novel approach. Clean. Technol. Environ. Policy 2015, 17, 187–197. [Google Scholar] [CrossRef]

- Raksaksri, L.; Ruksakulpiwat, Y.; Udomkitpanya, T. The Properties of Tannery Waste Addition as a Filler Based on Two Types of Polymer Matrices: Poly(Butylene Adipate-Co-Terephthalate) (PBAT) and Poly(Butylene Succinate) (PBS). Adv. Polym. Technol. 2023, 2023, 8301108. [Google Scholar] [CrossRef]

| Reference | Particles Size (mm) | LW Content (phr) | |||

|---|---|---|---|---|---|

| SBRF | 0 | 0 | 0 | 0 | |

| Comp10_0.5 | ≤0.5 | 10 | 0 | 0 | 0 |

| Comp20_0.5 | 20 | 0 | 0 | 0 | |

| Comp30_0.5 | 30 | 0 | 0 | 0 | |

| Comp50_0.5 | 50 | 0 | 0 | 0 | |

| Comp10_1.0 | ≤1.0 | 0 | 10 | 0 | 0 |

| Comp20_1.0 | 0 | 20 | 0 | 0 | |

| Comp30_1.0 | 0 | 30 | 0 | 0 | |

| Comp50_1.0 | 0 | 50 | 0 | 0 | |

| Comp10_2.0 | ≤2.0 | 0 | 0 | 10 | 0 |

| Comp20_2.0 | 0 | 0 | 20 | 0 | |

| Comp30_2.0 | 0 | 0 | 30 | 0 | |

| Comp50_2.0 | 0 | 0 | 50 | 0 | |

| Comp10_3.0 | ≤3.0 | 0 | 0 | 0 | 10 |

| Comp20_3.0 | 0 | 0 | 0 | 20 | |

| Comp30_3.0 | 0 | 0 | 0 | 30 | |

| Comp50_3.0 | 0 | 0 | 0 | 50 | |

| LW content (phr) | SBR | 10 | 20 | 50 |

| T5% (°C) | 247 | 254 | 250 | 230 |

| LW size (mm) | SBR | 0.5 | 1 | 3 |

| T5% (°C) | 247 | 248 | 248 | 252 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melo de Lima, L.R.; Neves, S.; Pinho, S.; Coelho, C.; Almeida, M.F.; Lopes, M.A.; Fonseca, C. Effects of the Size and Loading of Chrome-Tanned Leather Shavings on the Properties of Styrene–Butadiene Rubber Compounds. Polymers 2025, 17, 1136. https://doi.org/10.3390/polym17091136

Melo de Lima LR, Neves S, Pinho S, Coelho C, Almeida MF, Lopes MA, Fonseca C. Effects of the Size and Loading of Chrome-Tanned Leather Shavings on the Properties of Styrene–Butadiene Rubber Compounds. Polymers. 2025; 17(9):1136. https://doi.org/10.3390/polym17091136

Chicago/Turabian StyleMelo de Lima, L. R., S. Neves, S. Pinho, C. Coelho, M. F. Almeida, M. A. Lopes, and C. Fonseca. 2025. "Effects of the Size and Loading of Chrome-Tanned Leather Shavings on the Properties of Styrene–Butadiene Rubber Compounds" Polymers 17, no. 9: 1136. https://doi.org/10.3390/polym17091136

APA StyleMelo de Lima, L. R., Neves, S., Pinho, S., Coelho, C., Almeida, M. F., Lopes, M. A., & Fonseca, C. (2025). Effects of the Size and Loading of Chrome-Tanned Leather Shavings on the Properties of Styrene–Butadiene Rubber Compounds. Polymers, 17(9), 1136. https://doi.org/10.3390/polym17091136