Effect of Block Polyether as an Interfacial Dispersant on the Properties of Nanosilica/Natural Rubber Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Nanosilica/Natural Rubber Composites

2.3. Characterization

3. Results and Discussion

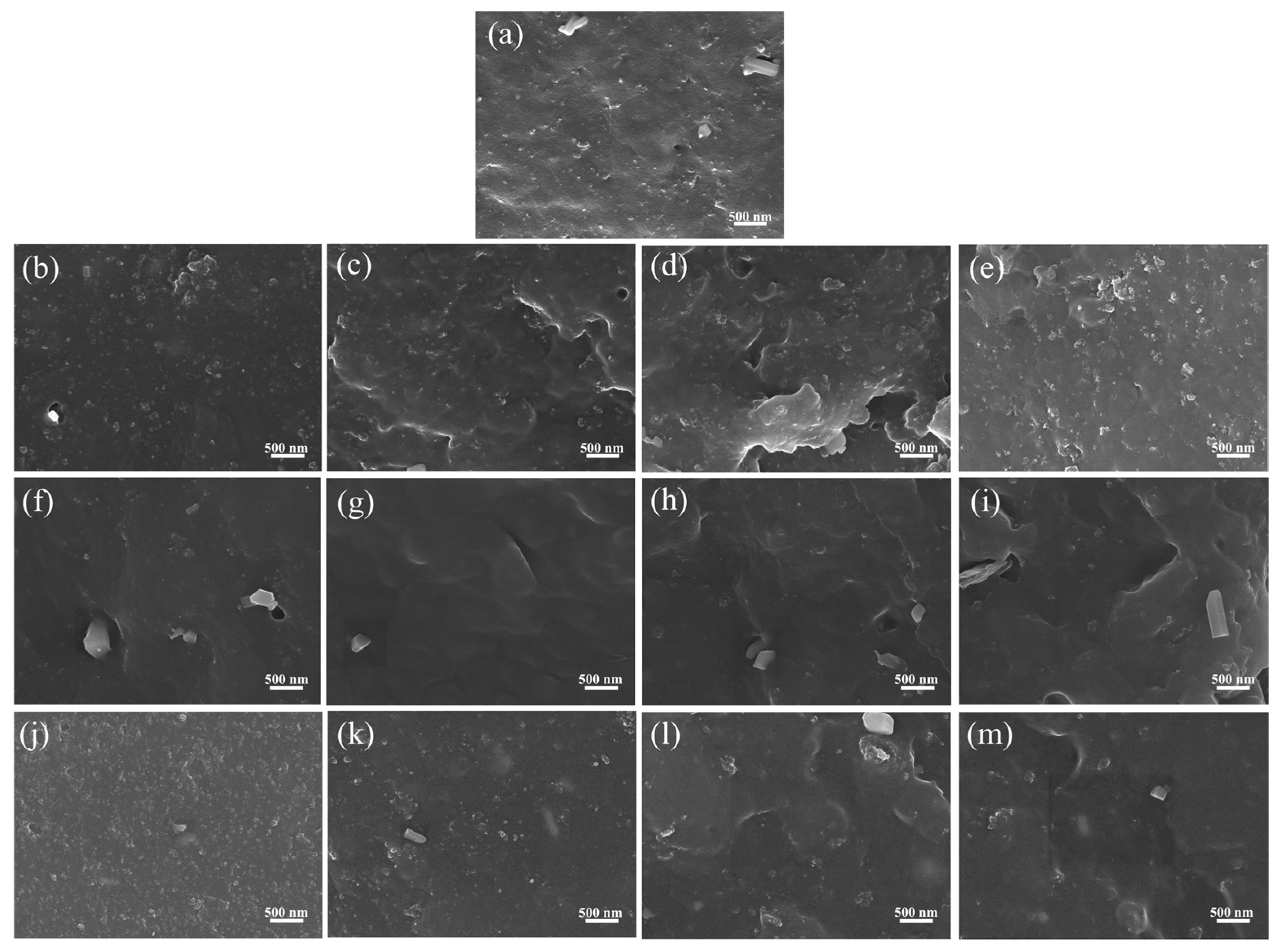

3.1. Effect of HLB Value of Block Polyethers on Silica Dispersion in SiO2/NR Composites

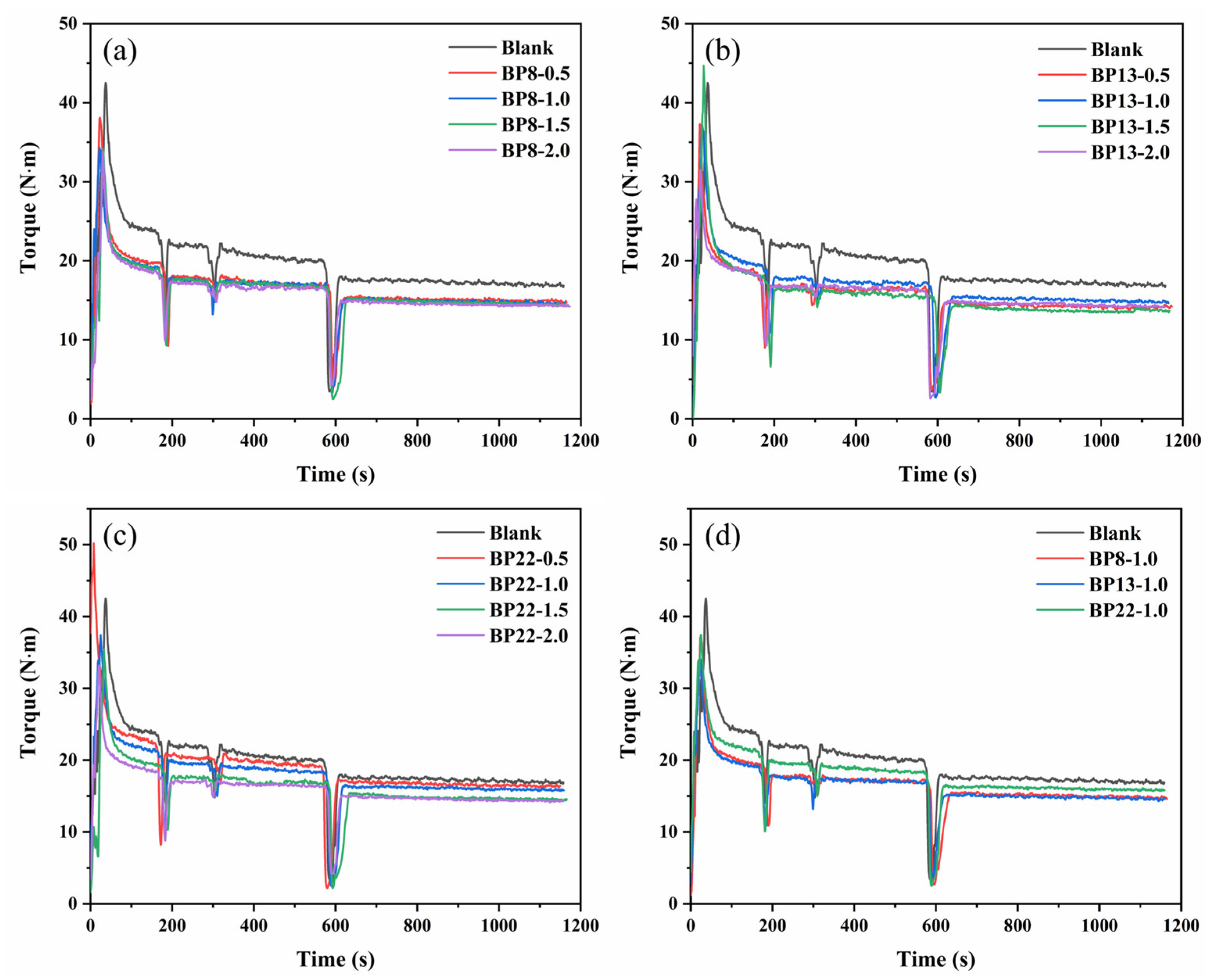

3.2. Influence of Block Polyethers on the Processing Properties of SiO2/NR Composites

3.3. Influence of Block Polyethers on the Vulcanization Characteristics of Silica/NR Composites

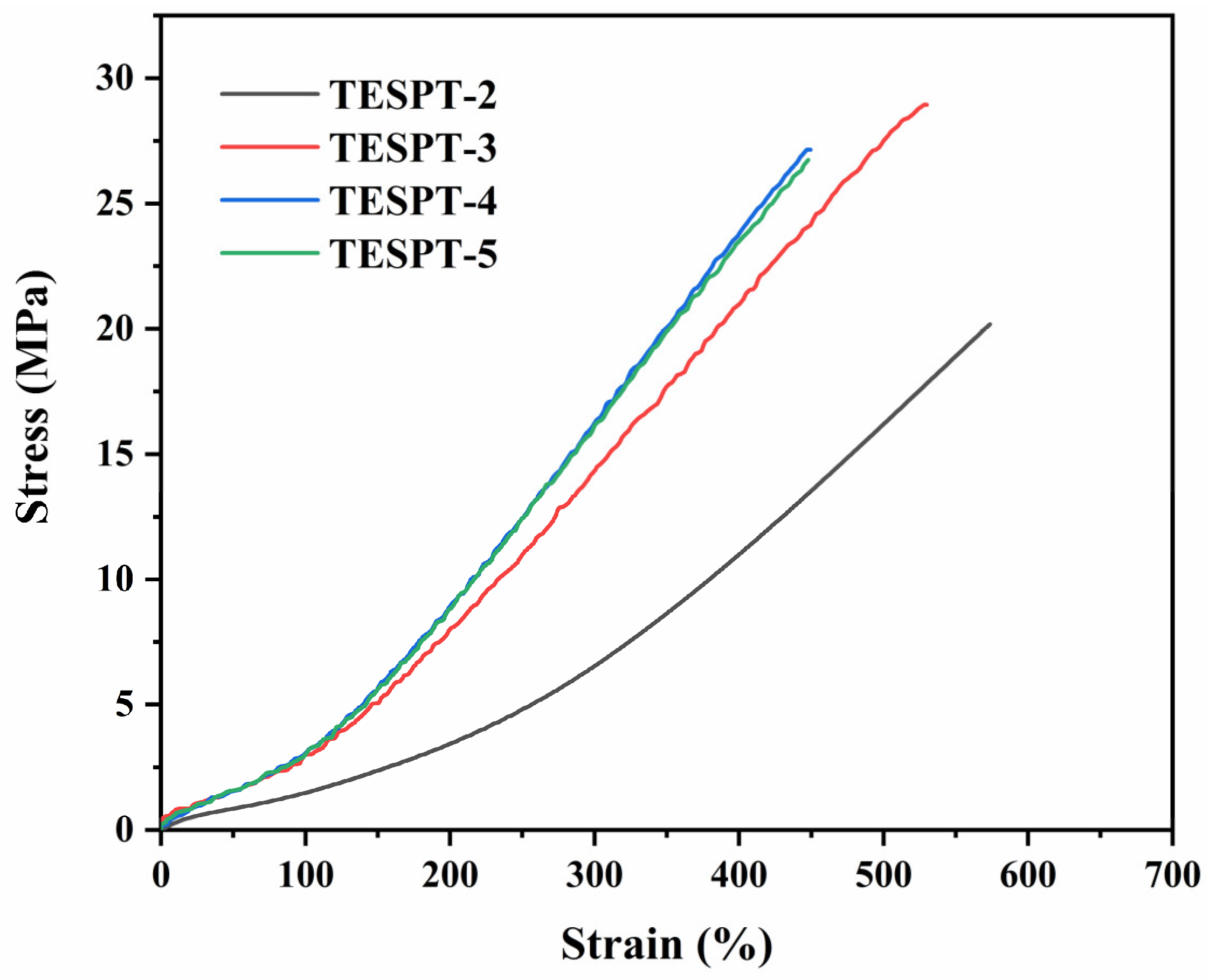

3.4. Effect of Block Polyethers on the Mechanical Properties of SiO2/NR Composites

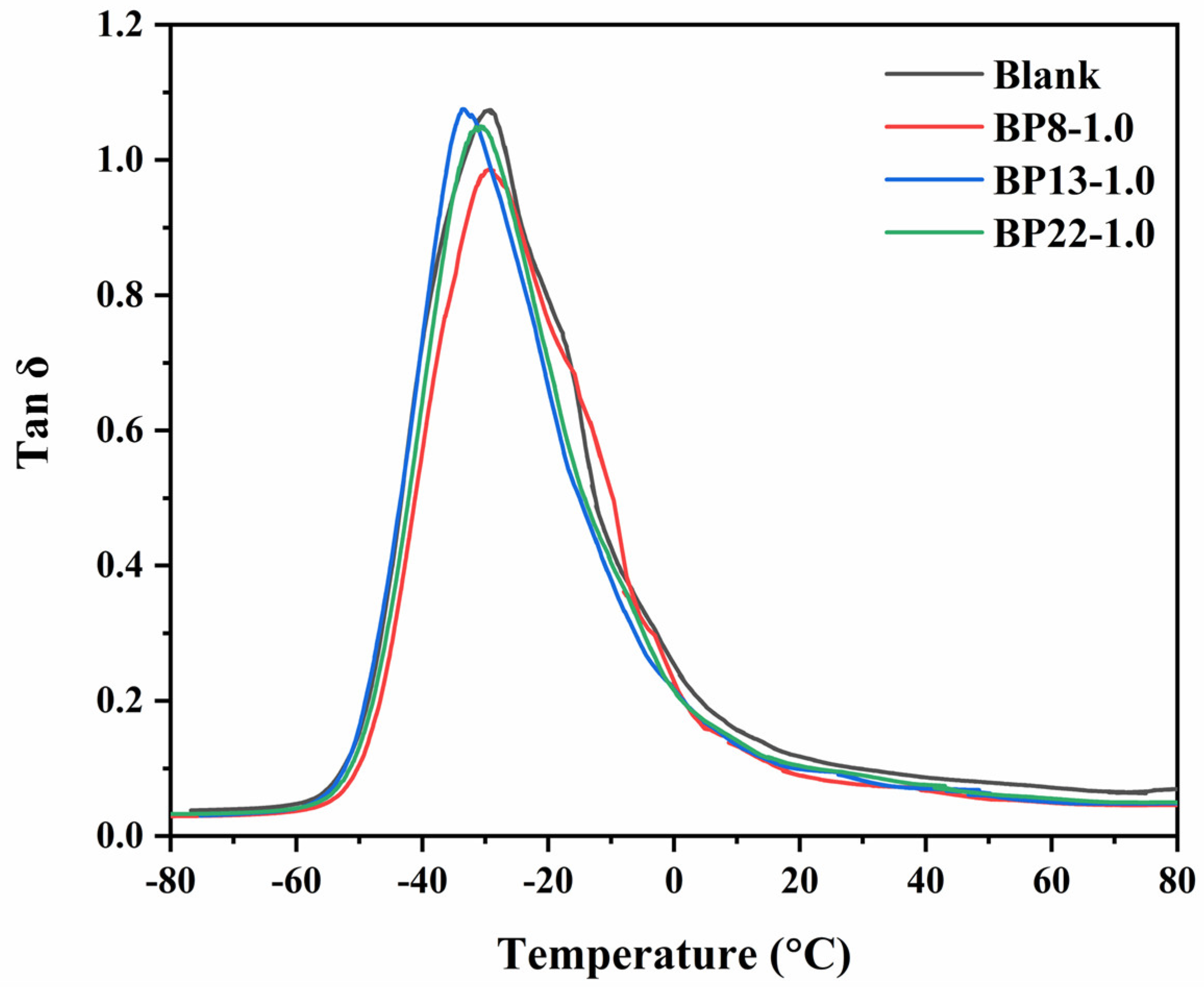

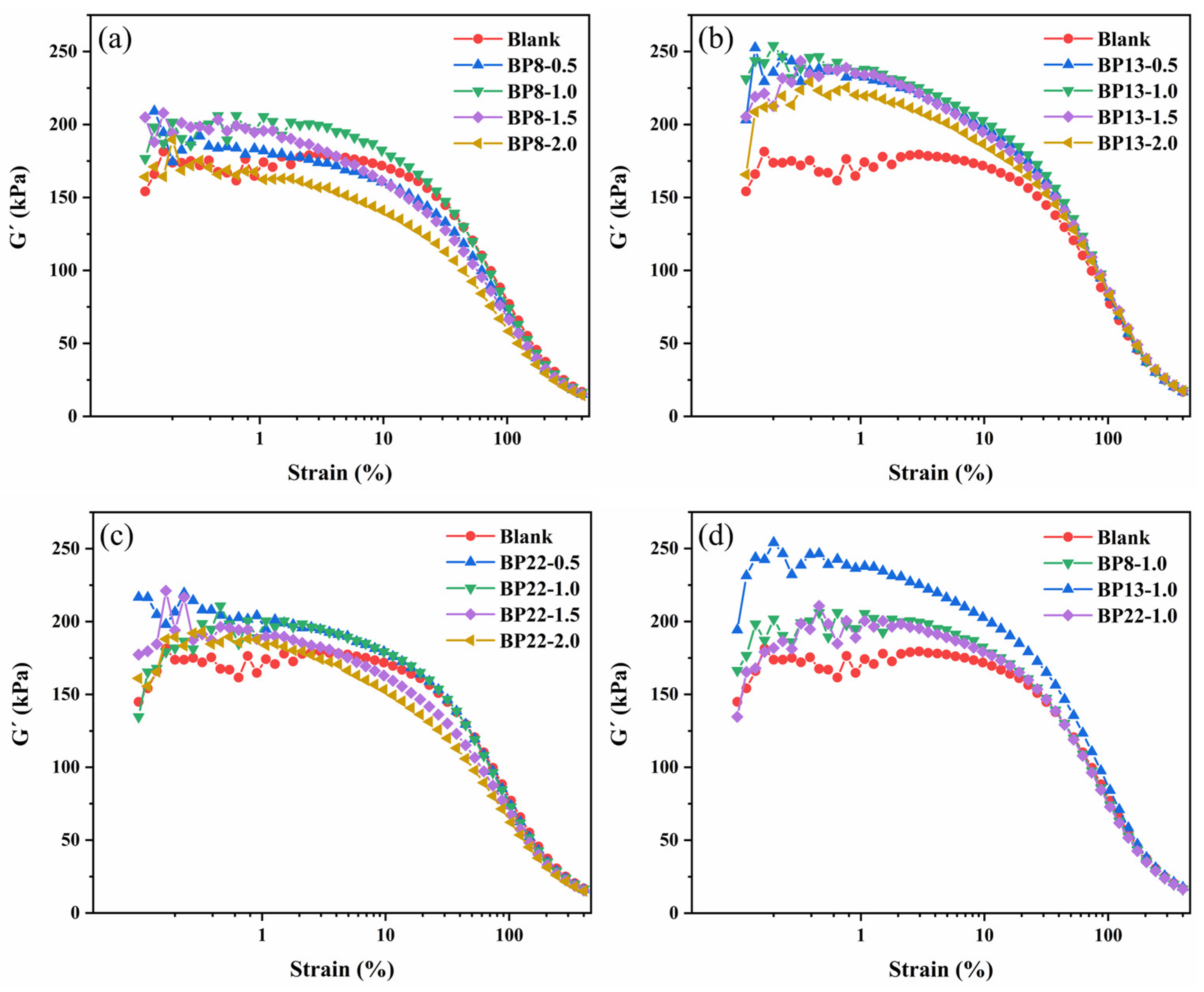

3.5. Influence of Block Polyethers on the Payne Effect in Silica/NR Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bokobza, L. Natural Rubber Nanocomposites: A Review. Nanomaterials 2018, 9, 12. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.Y.; Park, J.W.; Lee, D.Y.; Seo, K.H. Correlation between the Crosslink Characteristics and Mechanical Properties of Natural Rubber Compound via Accelerators and Reinforcement. Polymers 2020, 12, 2020. [Google Scholar] [CrossRef] [PubMed]

- Supramaniam, J.; Low, D.Y.S.; Wong, S.K.; Leo, B.F.; Goh, B.H.; Tang, S.Y. Nano-engineered ZnO/CNF-based Epoxidized Natural Rubber with Enhanced Strength for Novel Self-healing Glove Fabrication. Chem. Eng. J. 2022, 437, 135440. [Google Scholar] [CrossRef]

- Neto, W.P.F.; Mariano, M.; da Silva, I.S.V.; Silvério, H.A.; Putauxe, J.L.; Otaguro, H.; Pasquini, D.; Dufresne, A. Mechanical properties of natural rubber nanocomposites reinforced with high aspect ratio cellulose nanocrystals isolated from soy hulls. Carbohydr. Polym. 2016, 153, 143–152. [Google Scholar] [CrossRef]

- Sreelekshmi, R.V.; Sudha, J.D.; Menon, A.R.R. Novel organomodified kaolin/silica hybrid fillers in natural rubber and its blend with polybutadiene rubber. Polym. Bull. 2017, 74, 783–801. [Google Scholar] [CrossRef]

- Wang, D.; Tang, Z.; Fang, S.; Wu, S.; Zeng, H.; Wang, A.; Guo, B. The use of inverse vulcanised polysulfide as an intelligent interfacial modifier in rubber/carbon black composites. Carbon 2021, 184, 409–417. [Google Scholar] [CrossRef]

- Song, Y.; Huang, D. Linear Rheology of Natural Rubber Compounds Filled with Silica, short Nylon Fiber or both. Polymer 2018, 134, 71–74. [Google Scholar] [CrossRef]

- Fan, Y.; Fowler, G.D.; Zhao, M. The past, present and future of carbon black as a rubber reinforcing filler—A review. J. Clean. Prod. 2020, 247, 119115. [Google Scholar] [CrossRef]

- Dileep, P.; Narayanankutty, S.K. Styrenated phenol modified nanosilica for improved thermo-oxidative and mechanical properties of natural rubber. Polym. Test. 2020, 82, 106302. [Google Scholar]

- Wei, Z.; Hou, Y.; Ning, N.; Zhang, L.; Tian, M.; Mi, J. Theoretical Insight into Dispersion of Silica Nanoparticles in Polymer Melts. J. Phys. Chem. B 2015, 119, 9940–9948. [Google Scholar] [CrossRef]

- Brinke, J.W.t.; Debnath, S.C.; Reuvekamp, L.A.E.M.; Noordermeer, J.W.M. Mechanistic aspects of the role of coupling agents in silica–rubber composites. Compos. Sci. Technol. 2003, 63, 1165–1174. [Google Scholar] [CrossRef]

- Palraj, S.; Selvaraj, M.; Maruthan, K.; Rajagopal, G. Corrosion and wear resistance behavior of nano-silica epoxy composite coatings. Prog. Org. Coat. 2015, 81, 132–139. [Google Scholar] [CrossRef]

- Prasertsri, S.; Rattanasom, N. Mechanical and damping properties of silica/natural rubber composites prepared from latex system. Polym. Test. 2011, 30, 515–526. [Google Scholar] [CrossRef]

- Sokolnicki, T.; Franczyk, A.; Janowski, B.; Walkowiak, J. Synthesis of Bio-Based Silane Coupling Agents by the Modification of Eugenol. Adv. Synth. Catal. 2021, 363, 5493–5500. [Google Scholar] [CrossRef]

- Inphonlek, S.; Bureewong, N.; Jarukumjorn, K.; Chumsamrong, P.; Ruksakulpiwat, C.; Ruksakulpiwat, Y. Preparation of Poly(acrylic acid-co-acrylamide)-Grafted Deproteinized Natural Rubber and Its Effect on the Properties of Natural Rubber/Silica Composites. Polymers 2022, 14, 4602. [Google Scholar] [CrossRef]

- Sengloyluan, K.; Sahakaro, K.; Dierkes, W.K.; Noordermeer, J.W.M. Silica-reinforced tire tread compounds compatibilized by using epoxidized natural rubber. Eur. Polym. J. 2014, 51, 69–79. [Google Scholar] [CrossRef]

- Pang, S.; Yu, Y.; Zhang, L.; Wu, Y. Adjusting silica/rubber interfacial interactions and properties via the click reactions between liquid polybutadiene and silane. Compos. Sci. Technol. 2021, 213, 108903. [Google Scholar] [CrossRef]

- Li, Y.; Han, B.; Wen, S.; Lu, Y.; Yang, H.; Zhang, L.; Liu, L. Effect of the temperature on surface modification of silica and properties of modified silica filled rubber composites. Compos. Part A 2014, 62, 52–59. [Google Scholar] [CrossRef]

- Zhong, B.; Zeng, X.; Chen, W.; Luo, Q.; Hu, D.; Jia, Z.; Jia, D. Nonsolvent-assisted surface modification of silica by silane and antioxidant for rubber reinforcement. Polym. Test. 2019, 78, 105949. [Google Scholar] [CrossRef]

- Phumnok, E.; Khongprom, P.; Ratanawilai, S. Preparation of Natural Rubber Composites with High Silica Contents Using a Wet Mixing Process. ACS Omega 2022, 7, 8364–8376. [Google Scholar] [CrossRef]

- Dohi, H.; Horiuchi, S. Locating a Silane Coupling Agent in Silica-Filled Rubber Composites by EFTEM. Langmuir 2007, 23, 12344–12349. [Google Scholar] [CrossRef] [PubMed]

- You, B.; Jin, S. Preparation of Hydrophobic Modified Silica with Si69 and Its Reinforcing Mechanical Properties in Natural Rubber. Materials 2024, 17, 3131. [Google Scholar] [CrossRef] [PubMed]

- Pattanawanidchai, S.; Loykulnant, S.; Sae-oui, P.; Maneevas, N.; Sirisinha, C. Development of eco-friendly coupling agent for precipitated silica filled natural rubber compounds. Polym. Test. 2014, 34, 58–63. [Google Scholar] [CrossRef]

- Surya, I.; Ismail, H.; Azura, A.R. The comparison of alkanolamide and silane coupling agent on the properties of silica-filled natural rubber (SMR-L) compounds. Polym. Test. 2014, 40, 24–32. [Google Scholar] [CrossRef]

- Xiao, Y.; Zou, H.; Zhang, L.; Ye, X.; Han, D. Surface modification of silica nanoparticles by a polyoxyethylene sorbitan and silane coupling agent to prepare high-performance rubber composites. Polym. Test. 2020, 81, 106195. [Google Scholar] [CrossRef]

- Ye, N.; Zheng, J.; Ye, X.; Xue, J.; Han, D.; Xu, H.; Wang, Z.; Zhang, L. Performance enhancement of rubber composites using VOC-Free interfacial silica coupling agent. Compos. Part B 2020, 202, 108301. [Google Scholar] [CrossRef]

- Sae-oui, P.; Sirisinha, C.; Thepsuwan, U.; Hatthapanit, K. Roles of silane coupling agents on properties of silica-filled polychloroprene. Eur. Polym. J. 2006, 42, 479–486. [Google Scholar] [CrossRef]

- Xu, T.; Jia, Z.; Wu, L.; Chen, Y.; Luo, Y.; Jia, D.; Peng, Z. Influence of acetone extract from natural rubber on the structure and interface interaction in NR/silica composites. Appl. Surf. Sci. 2017, 423, 43–52. [Google Scholar] [CrossRef]

- Hartyányi, M.; Bejczi, R.; Nagy, R.; Demcsák, N.; Bartha, L.; Puskás, S. An improved method for determining the water number for surfactants. MethodsX 2024, 12, 102671. [Google Scholar] [CrossRef]

- Vold, R.D. Emulsions: Theory and practice. J. Chem. Educ. 1965, 42, 692. [Google Scholar] [CrossRef]

- Pitto-Barry, A.; Barry, N.P.E. Pluronic® block-copolymers in medicine: From chemical and biological versatility to rationalisation and clinical advances. Polym. Chem. 2014, 5, 3291–3297. [Google Scholar] [CrossRef]

- Zarrintaj, P.; Ramsey, J.D.; Samadi, A.; Atoufic, Z.; Yazdi, M.K.Y.; Ganjali, M.R.; Amirabad, L.M.; Zangene, E.; Farokhi, M.; Formela, K.; et al. Poloxamer: A versatile tri-block copolymer for biomedical applications. Acta Biomater. 2020, 110, 37–67. [Google Scholar] [CrossRef] [PubMed]

- ISO 37:2024; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. ISO: Geneva, Switzerland, 2024.

- ISO 48-4:2018; Rubber, Vulcanized or Thermoplastic—Determination of Hardness Part 4: Indentation Hardness by Durometer Method (Shore Hardness). ISO: Geneva, Switzerland, 2018.

- ISO 6502-1:2018; Rubber—Measurement of Vulcanization Characteristics Using Curemeters Part 1: Introduction. ISO: Geneva, Switzerland, 2018.

- ISO 23794:2023; Rubber, Vulcanized or Thermoplastic—Abrasion Testing—Guidance. ISO: Geneva, Switzerland, 2023.

- ISO 2781:2018; Rubber, Vulcanized or Thermoplastic—Determination of Density. ISO: Geneva, Switzerland, 2018.

- Wolff, S.; Wang, M.-J.; Tan, E.-H. Filler-Elastomer Interactions. Part VII. Study on Bound Rubber. Rubber Chem. Technol. 1993, 66, 163–177. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J. Statistical Mechanics of Cross-Linked Polymer Networks II. Swelling. J. Chem. Phys. 1943, 11, 521–526. [Google Scholar] [CrossRef]

- Jain, S.R.; Sekkar, V.; Krishnamurthy, V.N. Mechanical and swelling properties of HTPB-based copolyurethane networks. J. Appl. Polym. Sci. 1993, 48, 1515–1523. [Google Scholar] [CrossRef]

- Algaily, B.; Kaewsakul, W.; Sarkawi, S.S.; Kalkornsurapranee, E. Alleviating Molecular-Scale Damages in Silica-Reinforced Natural Rubber Compounds by a Self-Healing Modifier. Polymers 2020, 13, 39. [Google Scholar] [CrossRef]

- Yu, K.; Hodges, C.; Biggs, S.; Cayre, O.J.; Harbottle, D. Polymer Molecular Weight Dependence on Lubricating Particle–Particle Interactions. Ind. Eng. Chem. Res. 2018, 57, 2131–2138. [Google Scholar] [CrossRef]

- Yang, J.; Xian, B.; Li, H.; Zhang, L.; Han, D. Preparation of silica/natural rubber masterbatch using solution compounding. Polymer 2022, 244, 124661. [Google Scholar] [CrossRef]

- Qiao, H.; Chao, M.; Hui, D.; Liu, J.; Zheng, J.; Lei, W.; Zhou, X.; Wang, R.; Zhang, L. Enhanced interfacial interaction and excellent performance of silica/epoxy group-functionalized styrene-butadiene rubber (SBR) nanocomposites without any coupling agent. Compos. Part B 2017, 114, 356–364. [Google Scholar] [CrossRef]

- Robertson, C.G.; Roland, C.M. Glass transition and interfacial segmental dynamics in polymer-particle composites. Rubber Chem. Technol. 2008, 81, 506–522. [Google Scholar] [CrossRef]

- Zhang, C.; Tang, Z.; Guo, B.; Zhang, L. Significantly improved rubber-silica interface via subtly controlling surface chemistry of silica. Compos. Sci. Technol. 2018, 156, 70–77. [Google Scholar] [CrossRef]

- Li, B.; Xiao, Y.; Huang, Y.; Gong, Z.; Chen, Y.; Li, S.; Wang, C.; Bian, H. Application of low-molecular-weight polyethylene glycol-modified silica in natural rubber composites. Polym. Eng. Sci. 2024, 64, 5154–5165. [Google Scholar] [CrossRef]

- Huang, L.; Yu, F.; Liu, Y.; Lu, A.; Song, Z.; Liu, W.; Xiong, Y.; He, H.; Li, S.; Zhao, X.; et al. Structural analyses of the bound rubber in silica-filled silicone rubber nanocomposites reveal mechanisms of filler-rubber interaction. Compos. Sci. Technol. 2023, 233, 109905. [Google Scholar] [CrossRef]

- Xu, T.; Lin, J.; Luo, Y.; Fu, W.; Jia, Z.; Jia, D.; Peng, Z. Quantitative analysis of the higher fatty acids in acetone solutes (AS) from raw natural rubber and their impacts on the structure and properties of NR/silica composites. Ind. Crops Prod. 2018, 121, 80–89. [Google Scholar] [CrossRef]

- Jantachum, P.; Khumpaitool, B.; Utara, S. Effect of silane coupling agent and cellulose nanocrystals loading on the properties of acrylonitrile butadiene rubber/natural rubber nanocomposites. Ind. Crops Prod. 2023, 195, 116407. [Google Scholar] [CrossRef]

| Ingredients (phr a) | NR | Silica | TESPT | Block Polyether P104 | Block Polyether P123 | Block Polyether F127 | Other Additives b |

|---|---|---|---|---|---|---|---|

| Blank | 100 | 50 | 3 | 0 | 0 | 0 | 17.8 |

| BP8-0.5 | 100 | 50 | 3 | 0 | 0.5 | 0 | 17.8 |

| BP8-1.0 | 100 | 50 | 3 | 0 | 1 | 0 | 17.8 |

| BP8-1.5 | 100 | 50 | 3 | 0 | 1.5 | 0 | 17.8 |

| BP8-2.0 | 100 | 50 | 3 | 0 | 2 | 0 | 17.8 |

| BP13-0.5 | 100 | 50 | 3 | 0.5 | 0 | 0 | 17.8 |

| BP13-1.0 | 100 | 50 | 3 | 1 | 0 | 0 | 17.8 |

| BP13-1.5 | 100 | 50 | 3 | 1.5 | 0 | 0 | 17.8 |

| BP13-2.0 | 100 | 50 | 3 | 2 | 0 | 0 | 17.8 |

| BP22-0.5 | 100 | 50 | 3 | 0 | 0 | 0.5 | 17.8 |

| BP22-1.0 | 100 | 50 | 3 | 0 | 0 | 1 | 17.8 |

| BP22-1.5 | 100 | 50 | 3 | 0 | 0 | 1.5 | 17.8 |

| BP22-2.0 | 100 | 50 | 3 | 0 | 0 | 2 | 17.8 |

| Properties | tc10 (min:s) | tc90 (min:s) | ML (dNm) | MH (dNm) | MH-ML (dNm) |

|---|---|---|---|---|---|

| Blank | 3:15 | 5:34 | 1.44 | 12.76 | 11.32 |

| BP8-0.5 | 3:38 | 5:54 | 1.42 | 13.81 | 12.39 |

| BP8-1.0 | 3:56 | 5:56 | 1.64 | 16.40 | 14.76 |

| BP8-1.5 | 3:52 | 5:59 | 1.74 | 17.29 | 15.55 |

| BP8-2.0 | 3:51 | 6:02 | 1.65 | 16.87 | 15.22 |

| BP13-0.5 | 4:22 | 6:46 | 1.18 | 14.22 | 13.04 |

| BP13-1.0 | 3:53 | 5:58 | 1.57 | 16.29 | 14.72 |

| BP13-1.5 | 4:02 | 6:03 | 1.23 | 16.23 | 15.00 |

| BP13-2.0 | 4:06 | 5:56 | 1.09 | 15.55 | 14.46 |

| BP22-0.5 | 3:49 | 6:06 | 1.26 | 14.87 | 13.61 |

| BP22-1.0 | 3:43 | 5:43 | 1.64 | 16.18 | 15.17 |

| BP22-1.5 | 4.01 | 6:02 | 1.07 | 15.33 | 14.26 |

| BP22-2.0 | 3:38 | 5:33 | 1.40 | 17.66 | 16.26 |

| Properties | Tensile Strength (MPa) | Elongation at Break (%) | Modulus at 100% Elongation (MPa) | Modulus at 300% Elongation (MPa) | Shore A Hardness | Abrasion Loss (cm3) |

|---|---|---|---|---|---|---|

| Blank | 25.3 ± 0.1 | 494 ± 15 | 2.6 ± 0.1 | 12.6 ± 0.4 | 60 ± 1 | 0.57 ± 0.02 |

| BP8-0.5 | 26.5 ± 0.2 | 529 ± 30 | 2.2 ± 0.3 | 12.1 ± 1.3 | 62 ± 1 | 0.56 ± 0.03 |

| BP8-1.0 | 27.6 ± 0.5 | 516 ± 7 | 2.6 ± 0.1 | 13.3 ± 0.8 | 60 ± 1 | 0.55 ± 0.01 |

| BP8-1.5 | 25.2 ± 0.5 | 512 ± 28 | 2.4 ± 0.2 | 12.5 ± 0.9 | 60 ± 1 | 0.54 ± 0.02 |

| BP8-2.0 | 23.9 ± 0.4 | 479 ± 16 | 2.4 ± 0.1 | 12.1 ± 0.3 | 58 ± 1 | 0.52 ± 0.02 |

| BP13-0.5 | 27.8 ± 0.3 | 528 ± 34 | 2.6 ± 0.3 | 13.6 ± 1.6 | 59 ± 1 | 0.50 ± 0.01 |

| BP13-1.0 | 28. 9 ± 0.1 | 523 ± 18 | 3.0 ± 0.1 | 14.6 ± 0.7 | 61 ± 1 | 0.50 ± 0.01 |

| BP13-1.5 | 26.5 ± 0.4 | 501 ± 20 | 2.6 ± 0.2 | 13.7 ± 1.0 | 61 ± 1 | 0.50 ± 0.02 |

| BP13-2.0 | 26.4 ± 0.1 | 481 ± 5 | 3.4 ± 0.1 | 14.7 ± 0.4 | 61 ± 1 | 0.50 ± 0.03 |

| BP22-0.5 | 27.4 ± 0.4 | 521 ± 8 | 2.6 ± 0.1 | 13.5 ± 0.1 | 61 ± 1 | 0.51 ± 0.01 |

| BP22-1.0 | 27.3 ± 0.3 | 494 ± 12 | 2.7 ± 0.2 | 14.0 ± 0.6 | 60 ± 1 | 0.50 ± 0.02 |

| BP22-1.5 | 25.3 ± 0.6 | 460 ± 12 | 2.3 ± 0.1 | 11.8 ± 0.1 | 58 ± 1 | 0.51 ± 0.02 |

| BP22-2.0 | 24.7 ± 0.3 | 494 ± 5 | 2.4 ± 0.1 | 11.7 ± 0.3 | 57 ± 1 | 0.52 ± 0.01 |

| Properties | Tensile Strength (MPa) | Elongation at Break (%) | Modulus at 100% Elongation (MPa) | Modulus at 300% Elongation (MPa) | Shore A Hardness |

|---|---|---|---|---|---|

| BP13-0 | 6.2 ± 0.3 | 622 ± 41 | 0.5 ± 0.1 | 1.4 ± 0.2 | 34 ± 1 |

| BP13-3 | 24.7 ± 0.4 | 647 ± 14 | 1.4 ± 0.3 | 6.1 ± 0.1 | 62 ± 1 |

| BP13-4 | 24.3 ± 0.2 | 584 ± 7 | 2.0 ± 0.1 | 7.7 ± 0.2 | 61 ± 1 |

| BP13-5 | 22.4 ± 0.3 | 582 ± 12 | 1.9 ± 0.1 | 7.0 ± 0.1 | 61 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Mei, J.; Gong, D.; Chen, Y.; Zhang, C. Effect of Block Polyether as an Interfacial Dispersant on the Properties of Nanosilica/Natural Rubber Composites. Polymers 2025, 17, 1091. https://doi.org/10.3390/polym17081091

Liu Y, Mei J, Gong D, Chen Y, Zhang C. Effect of Block Polyether as an Interfacial Dispersant on the Properties of Nanosilica/Natural Rubber Composites. Polymers. 2025; 17(8):1091. https://doi.org/10.3390/polym17081091

Chicago/Turabian StyleLiu, Ying, Jiahui Mei, Depeng Gong, Yanjun Chen, and Chaocan Zhang. 2025. "Effect of Block Polyether as an Interfacial Dispersant on the Properties of Nanosilica/Natural Rubber Composites" Polymers 17, no. 8: 1091. https://doi.org/10.3390/polym17081091

APA StyleLiu, Y., Mei, J., Gong, D., Chen, Y., & Zhang, C. (2025). Effect of Block Polyether as an Interfacial Dispersant on the Properties of Nanosilica/Natural Rubber Composites. Polymers, 17(8), 1091. https://doi.org/10.3390/polym17081091