Modified SC Resin Pre-Coating Treatment for Rapid and Robust Repair of CFRP Laminates with Sharp Delamination Cracks

Abstract

1. Introduction

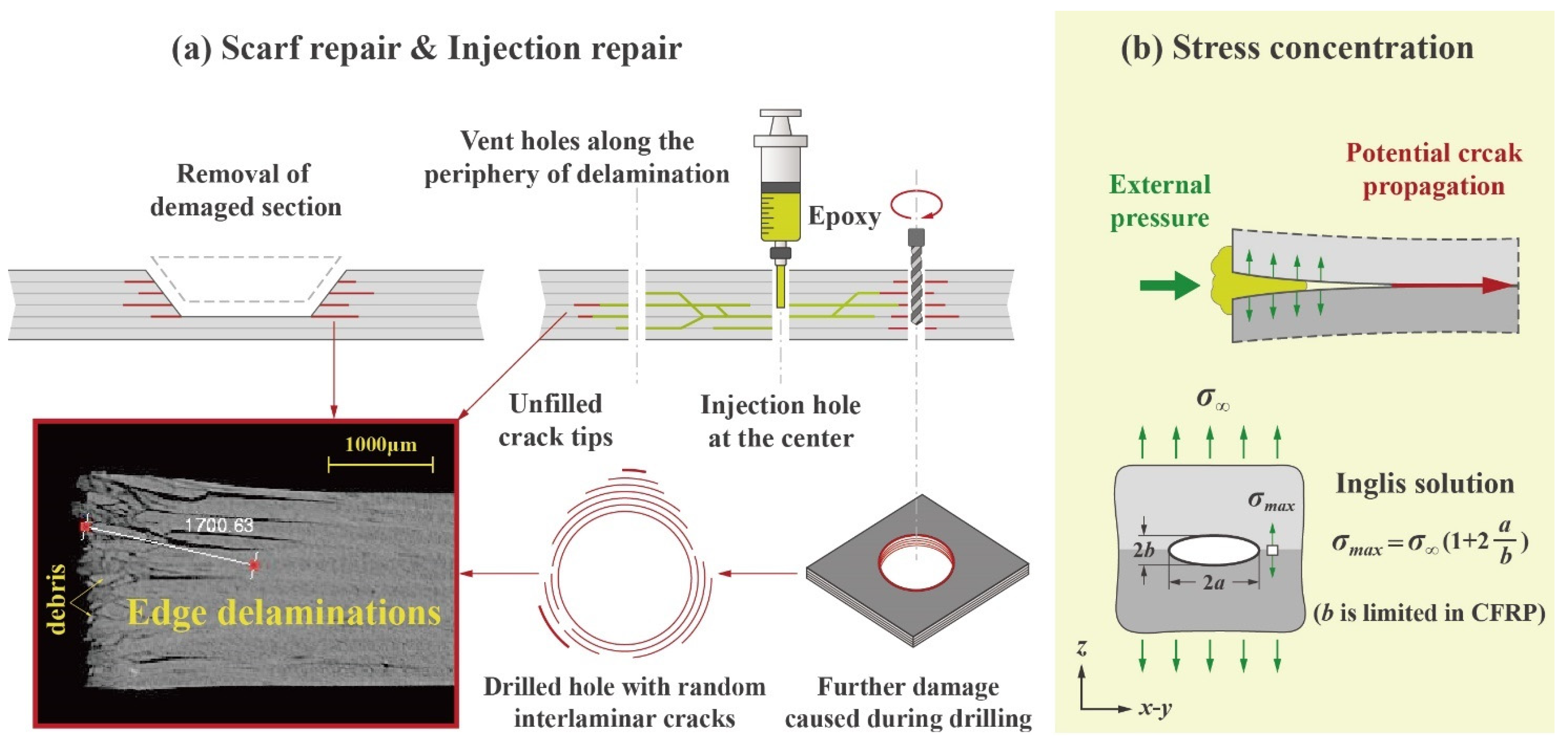

2. Mechanisms for Repair of Sharp Delamination Cracks

2.1. Crack/Delamination Propagation Under Internal Stress

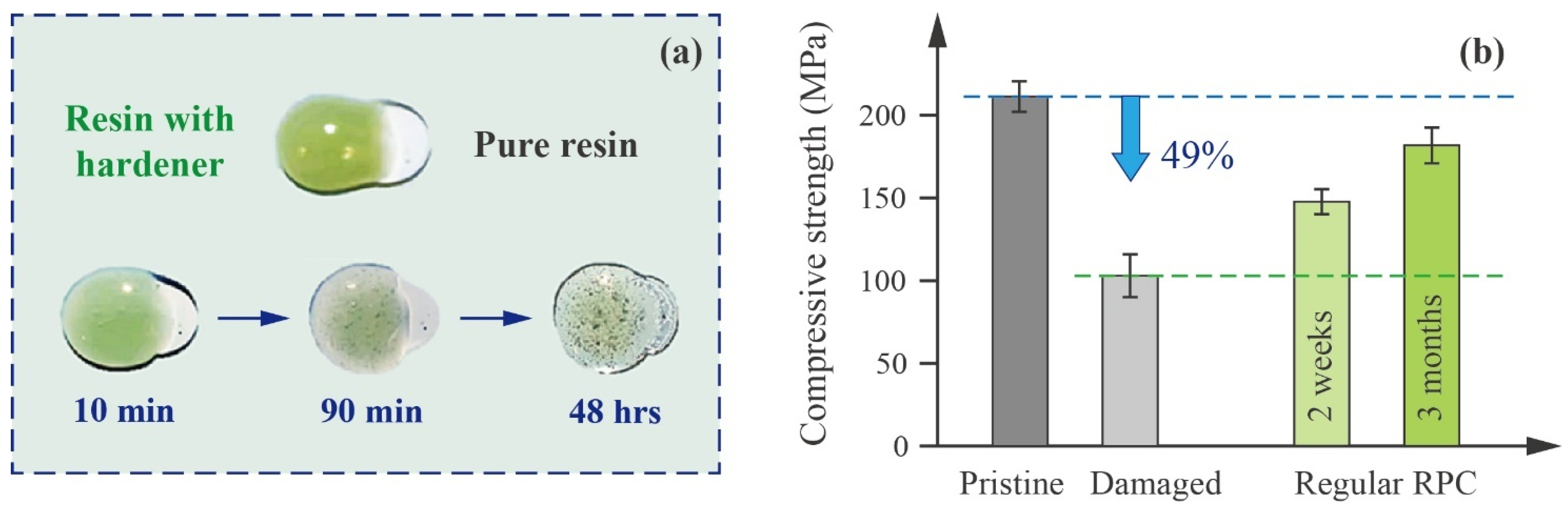

2.2. Repair and Reinforcement Mechanisms of RPC and RPC+CNT Treatments

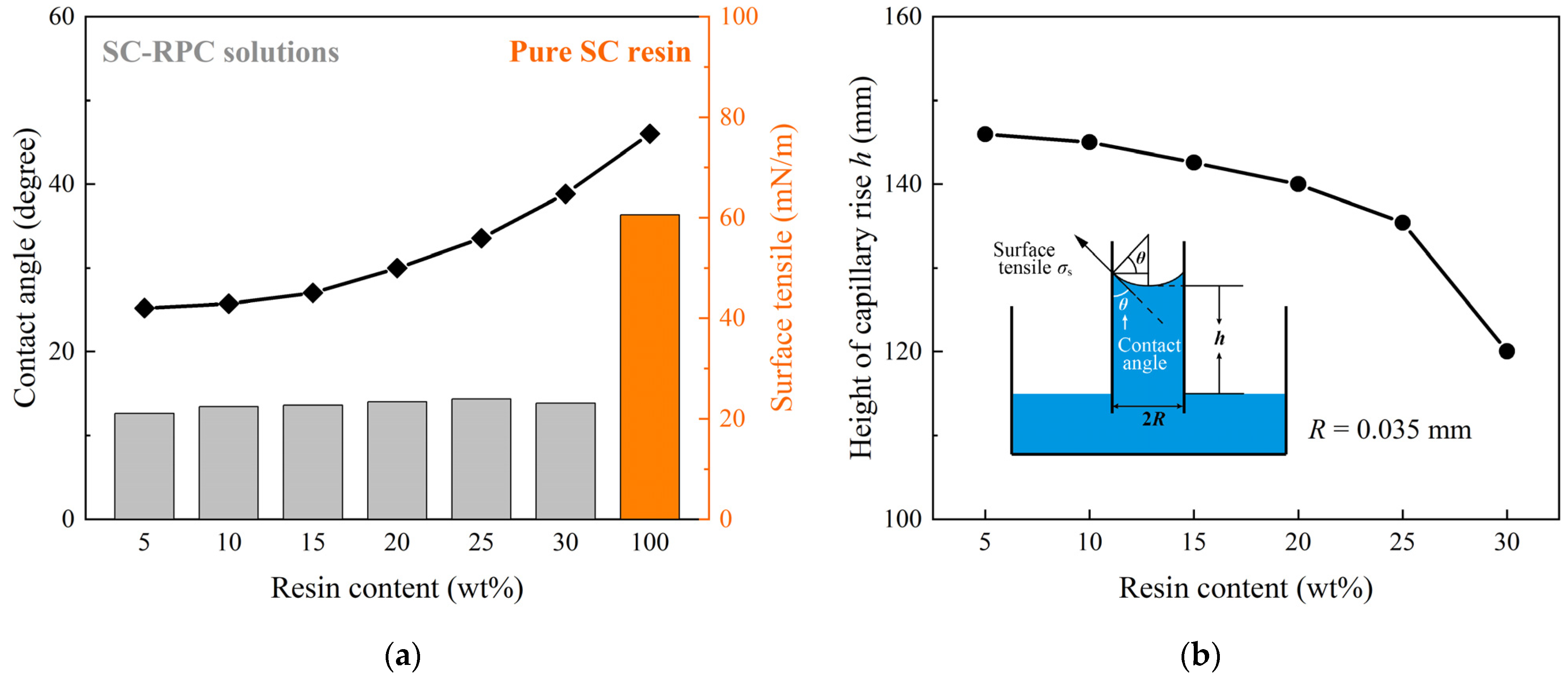

2.3. Benefits and Potential Issues of Replacing Conventional Resin with SC Resin in the RPC Repair Process

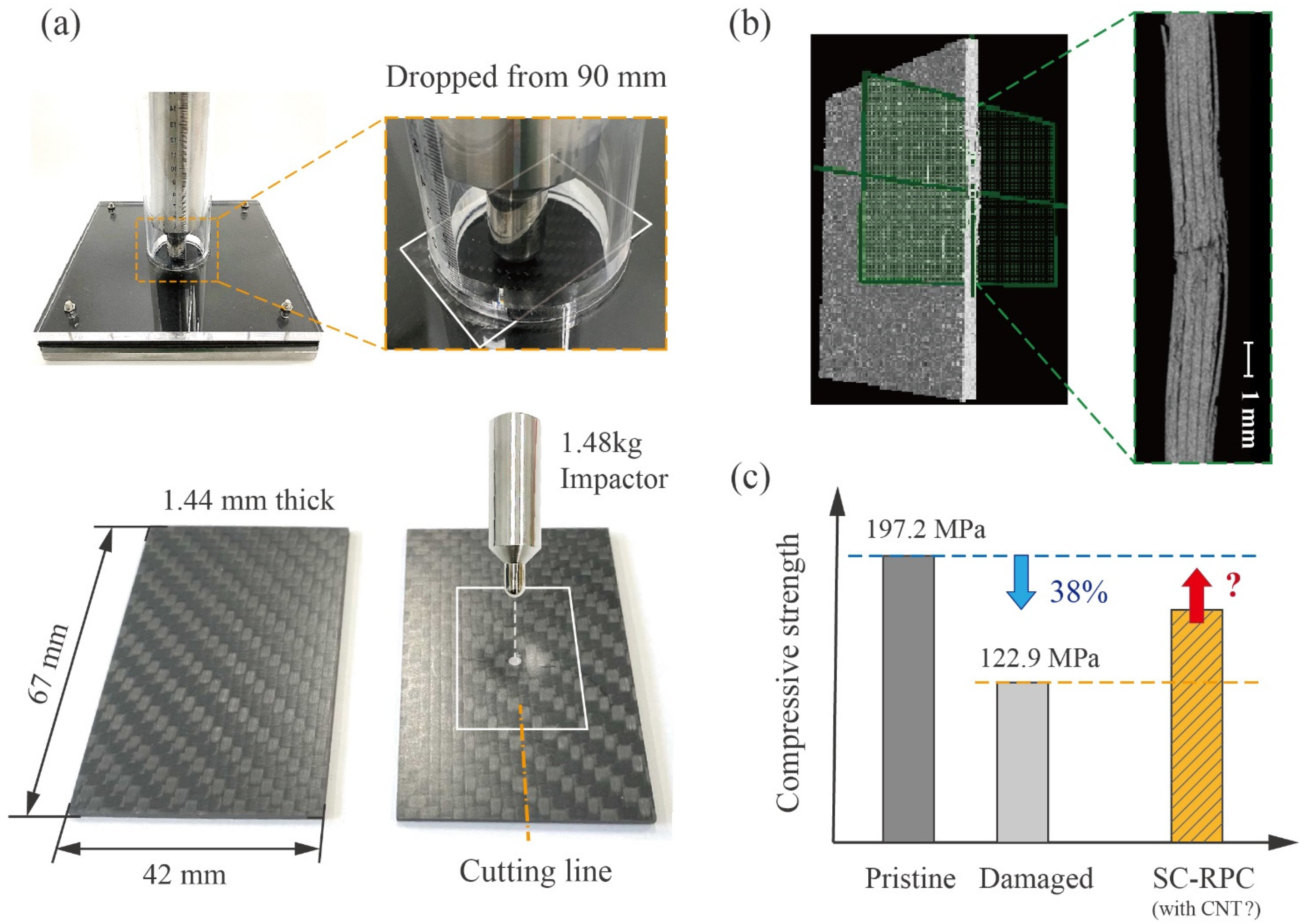

3. Specimen Design and Experimental Methods

3.1. Preparation of CFRP Specimens with Edge Delamination Cracks

3.2. Preparation and Application of SC-RPC Solution

3.3. Examination of CFRP Specimens with or Without Repair

4. Results and Discussion

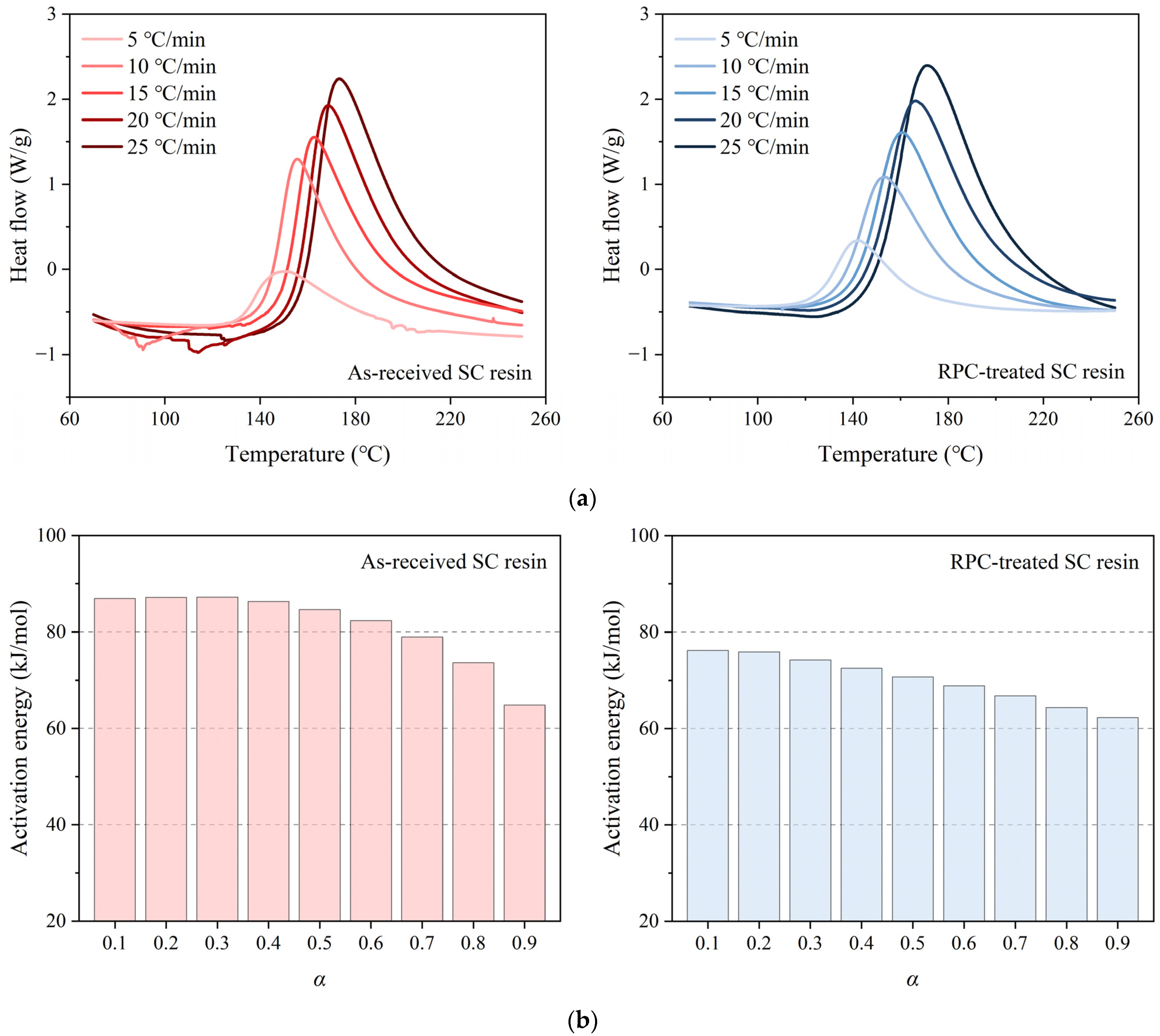

4.1. Influence of Acetone Dilution on the Curing Properties of SC Resin

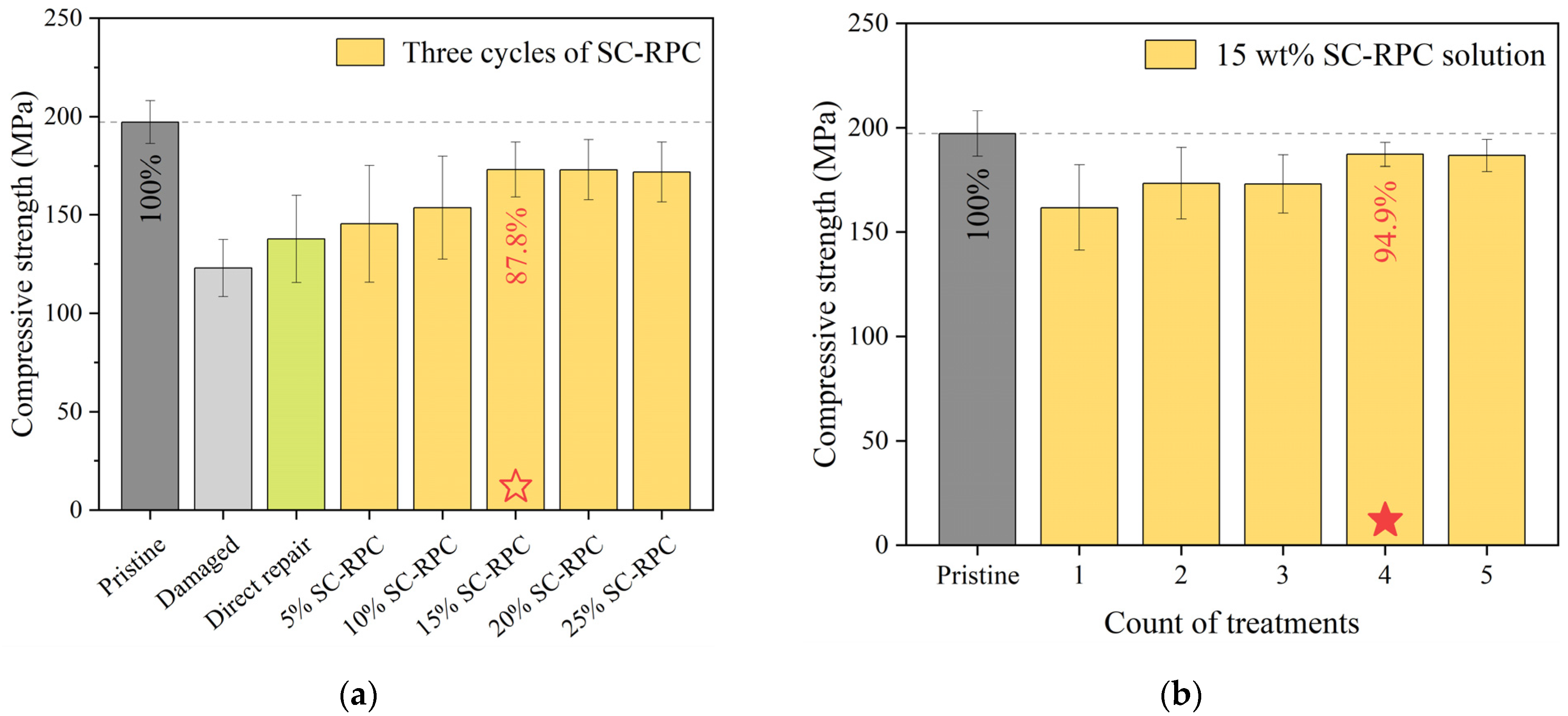

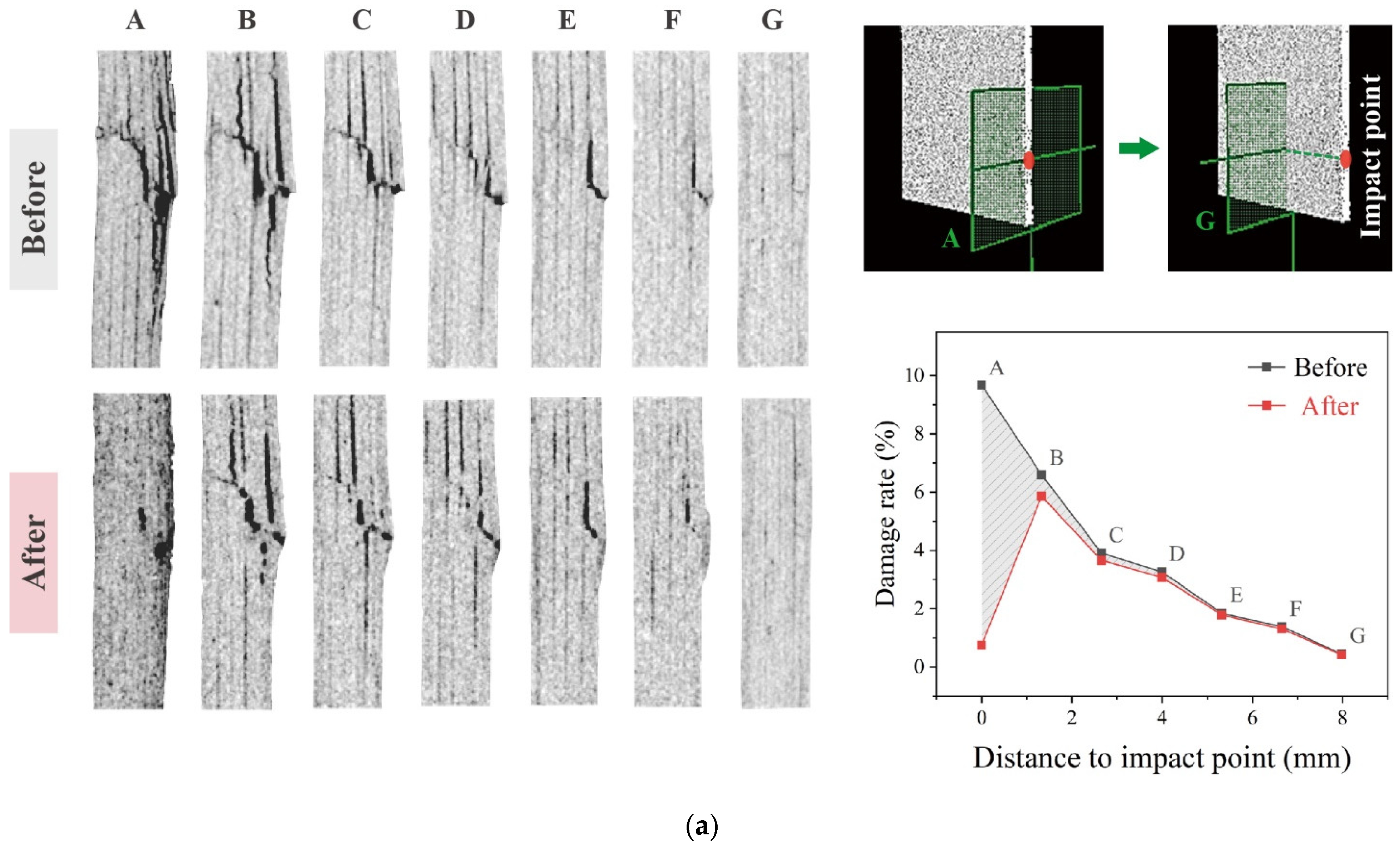

4.2. Effectiveness of SC-RPC Solutions in the Restoration of Compressive Strength of CFRP Specimens with Sharp Delamination Cracks

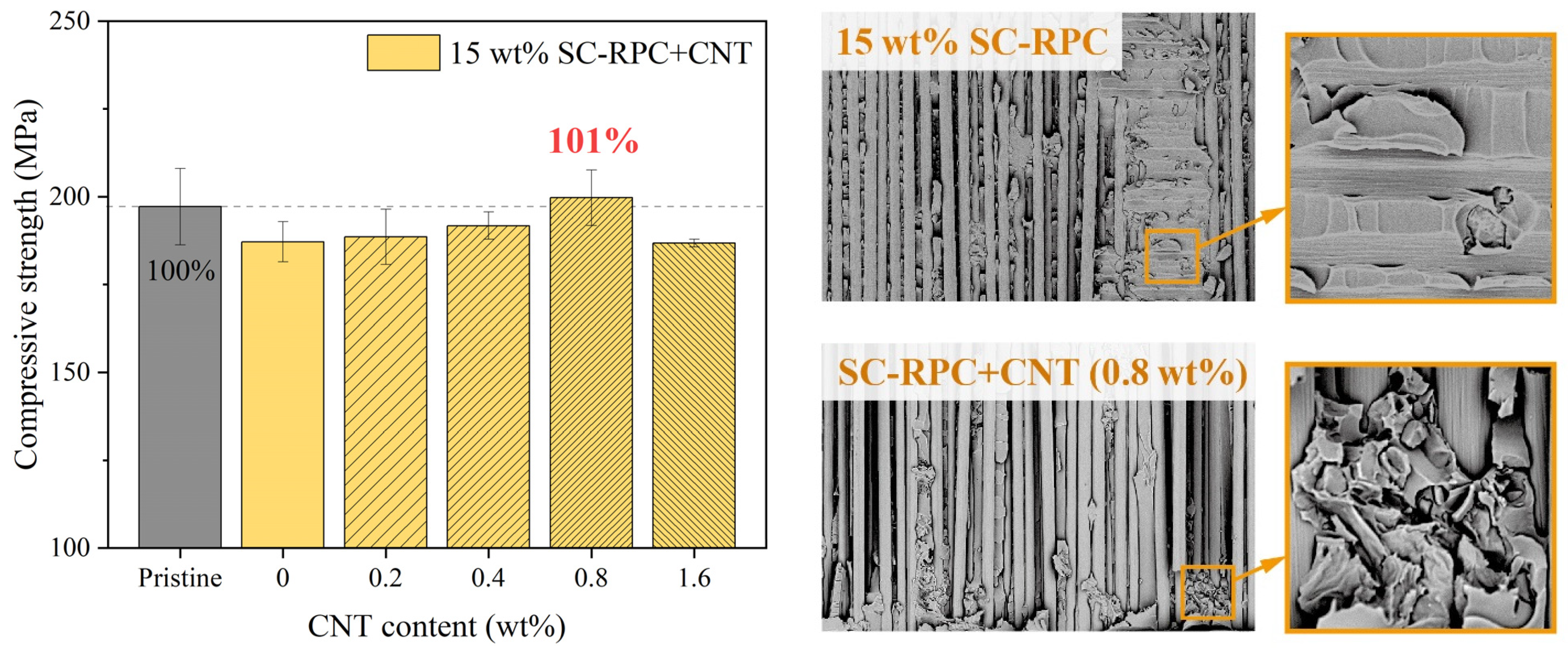

4.3. CNT Reinforcement Within Sharp Delamination Cracks Deposited Through SC-RPC Treatment, Referred to as SC-RPC+CNT

5. Conclusions

- (1)

- According to FTIR observations, acetone dilution did not pose detrimental effects on the new SC resin in terms of the molecular structure and curing properties. Conversely, it enhanced the thermal performance of the resin, smoothing the DSC curves and reducing the activation energy required for the curing reaction.

- (2)

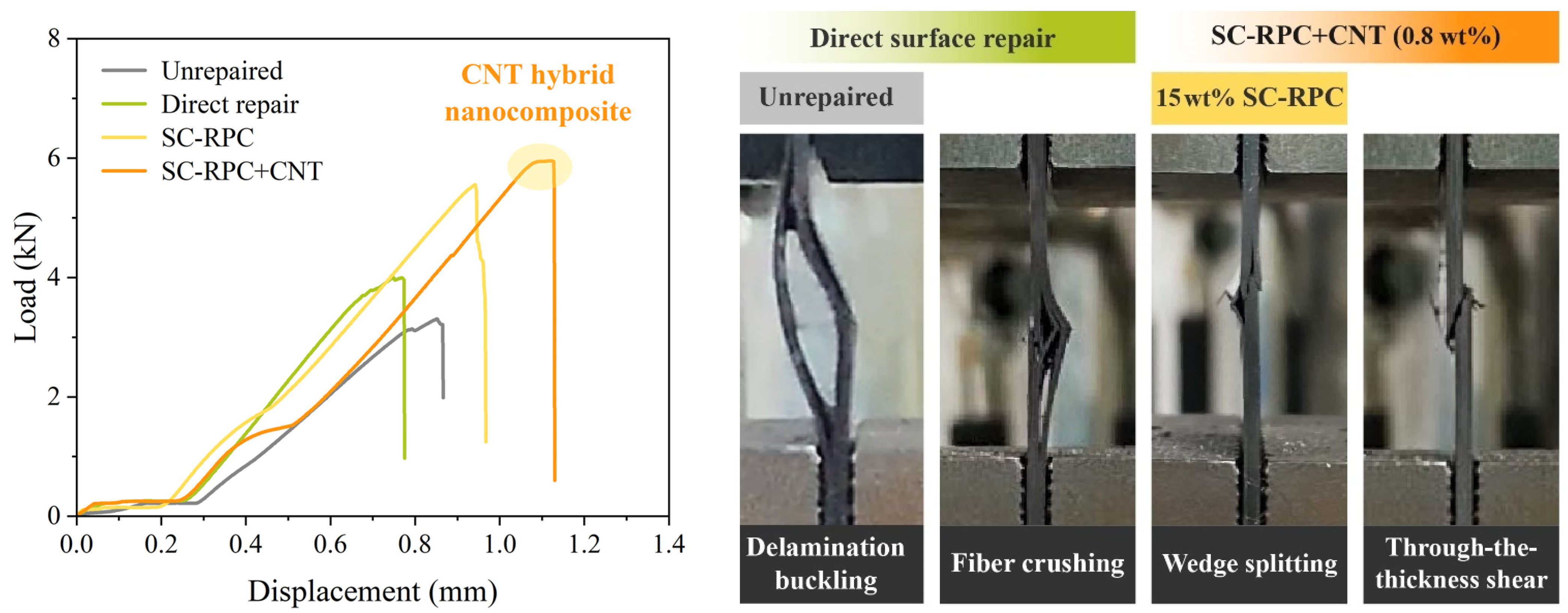

- As the primary control group, direct surface repair did prevent widespread buckling of the CFRP specimens. However, it fell short of addressing the subsurface defects and the associated stress concentration issues, resulting in a limited restoration of compressive strength (about 10%). Even low-concentration SC-RPC solutions brought further improvements, as they managed to penetrate delamination cracks (up to 8 mm in length, but only a few microns in width).

- (3)

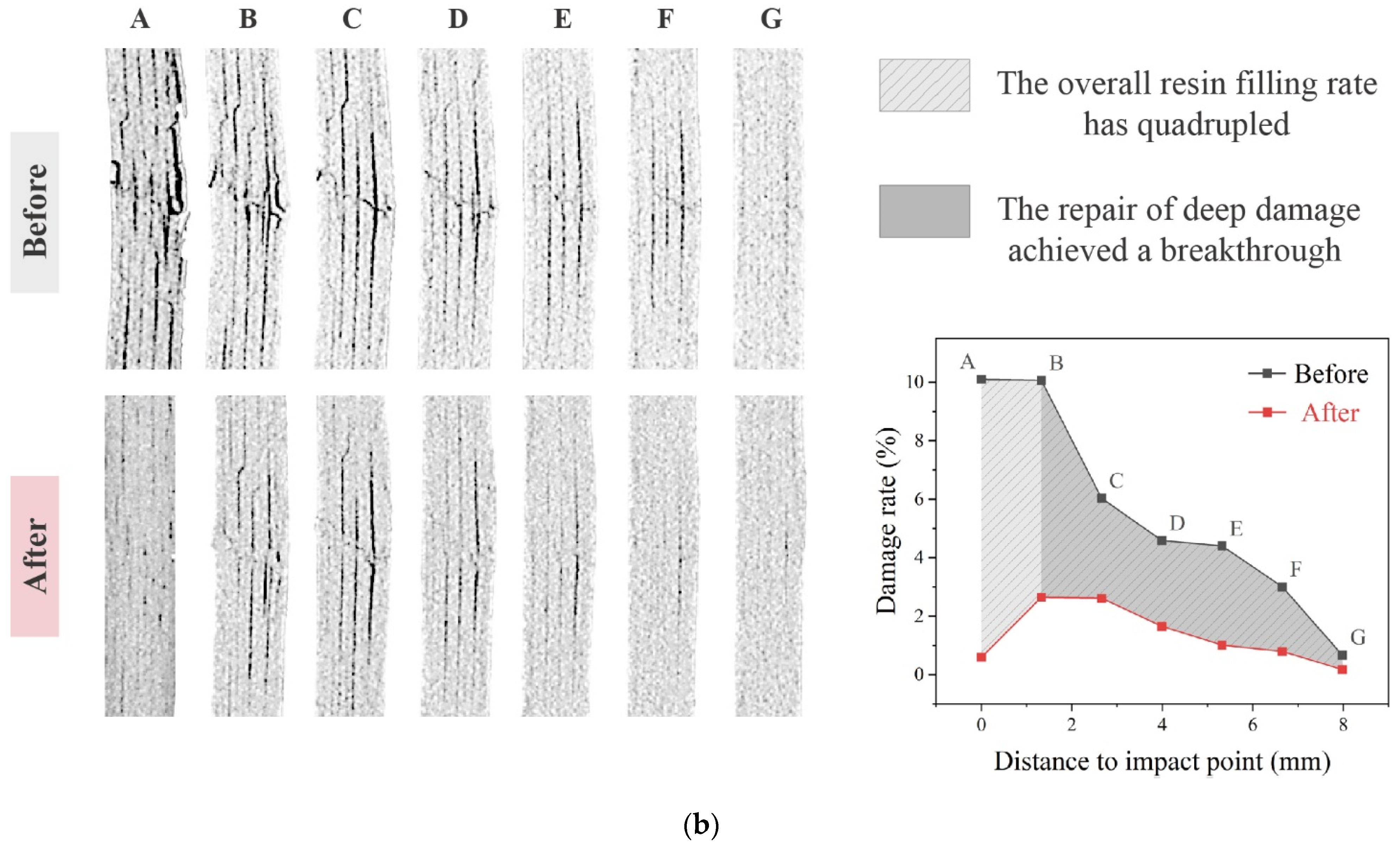

- Through a series of comparative experiments, it was observed that after four cycles of 15 wt% SC-RPC treatment, the compressive strength of the CFRP specimens reached a peak point, approximately 95% of the original strength. The repair rate was tripled compared to the control group, with a significant breakthrough in the coverage of deep damages, as revealed by CT images.

- (4)

- A 100% restoration was achieved by incorporating a tiny amount of CNTs (0.8 wt%) into the SC-RPC solution. Hybrid adhesive joints, with interlaced carbon nanotubes and carbon fibers, strengthened mechanical interlocking at the interfaces. As uniform stress transmission was re-established, typical failure modes, e.g., wedge splitting and through-the-thickness shear, reappeared on the repaired CFRP specimens. Note that our example did not fully reflect the potential of SC-RPC+CNT, as the fresh fractures initiated away from the repair regions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| # | Group Description | Count of Specimens | Count of SC-RPC Treatment Cycles | Compressive Strength (MPa) | |

|---|---|---|---|---|---|

| Average | Standard Deviation | ||||

| 1 | Pristine | 10 | NA | 197.16 | 10.89 |

| 2 | Impacted | 10 | NA | 122.98 | 14.53 |

| 3 | Direct repair | 7 | NA | 137.82 | 22.09 |

| 4 | 5 wt% SC-RPC | 8 | 3 | 145.52 | 29.70 |

| 5 | 10 wt% SC-RPC | 8 | 3 | 153.55 | 26.15 |

| 6 | 15 wt% SC-RPC | 8 | 3 | 173.05 | 13.91 |

| 7 | 20 wt% SC-RPC | 8 | 3 | 173.00 | 15.28 |

| 8 | 25 wt% SC-RPC | 8 | 3 | 171.81 | 15.19 |

| 9 | 15 wt% SC-RPC | 8 | 1 | 161.73 | 20.47 |

| 10 | 15 wt% SC-RPC | 8 | 2 | 173.42 | 17.08 |

| 11 | 15 wt% SC-RPC | 8 | 4 | 187.19 | 5.69 |

| 12 | 15 wt% SC-RPC | 8 | 5 | 186.72 | 7.60 |

| 13 | 15 wt% SC-RPC +0.2 wt% CNT | 8 | 4 | 188.57 | 7.84 |

| 14 | 15 wt% SC-RPC +0.4 wt% CNT | 7 | 4 | 191.77 | 3.89 |

| 15 | 15 wt% SC-RPC +0.8 wt% CNT | 8 | 4 | 199.71 | 7.89 |

| 16 | 15 wt% SC-RPC +1.6 wt% CNT | 8 | 4 | 186.83 | 1.09 |

References

- Collinson, M.G.; Swait, T.J.; Bower, M.P.; Nuhiji, B.; Hayes, S.A. Development and Implementation of Direct Electric Cure of Plain Weave CFRP Composites for Aerospace. Compos. Part A Appl. Sci. Manuf. 2023, 1, 107615. [Google Scholar] [CrossRef]

- Talreja, R.; Phan, N. Assessment of Damage Tolerance Approaches for Composite Aircraft with Focus on Barely Visible Impact Damage. Compos. Struct. 2019, 219, 1–7. [Google Scholar] [CrossRef]

- Wan, M.; Li, S.E.; Yuan, H.; Zhang, W.H. Cutting Force Modelling in Machining of Fiber-Reinforced Polymer Matrix Composites (PMCs): A Review. Compos. Part A Appl. Sci. Manuf. 2019, 117, 34–55. [Google Scholar] [CrossRef]

- Lai, W.L.; Saeedipour, H.; Goh, K.L. Mechanical Properties of Low-Velocity Impact Damaged Carbon Fibre Reinforced Polymer Laminates: Effects of Drilling Holes for Resin-Injection Repair. Compos. Struct. 2020, 235, 111806. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, X.; He, Y.; Yang, S.; Chen, S.; Zhang, S.; Zhou, D. CFRP Barely Visible Impact Damage Inspection Based on an Ultrasound Wave Distortion Indicator. Compos. Part B Eng. 2019, 168, 152–158. [Google Scholar] [CrossRef]

- Sun, X.C.; Hallett, S.R. Failure Mechanisms and Damage Evolution of Laminated Composites Under Compression After Impact (CAI): Experimental and Numerical Study. Compos. Part A Appl. Sci. Manuf. 2018, 104, 41–59. [Google Scholar] [CrossRef]

- Zhang, K.; Miao, Z.; Xia, H.; Yang, X.; Tian, F.; Zhao, Y. Effects of Repair Interface Structure on Mechanical Properties of Scarf Repair for Composite Laminate Plates. Polymers 2025, 17, 511. [Google Scholar] [CrossRef]

- Rasane, A.R.; Kumar, P.; Khond, M.P. Optimizing the Size of a CFRP Patch to Repair a Crack in a Thin Sheet. J. Adhes. 2017, 93, 1064–1080. [Google Scholar] [CrossRef]

- Wang, C.H.; Duong, C.N. Bonded Joints and Repairs to Composite Airframe Structures; Academic Press: Cambridge, MA, USA, 2015; ISBN 9780124171725. [Google Scholar]

- Yoo, J.S.; Truong, V.H.; Park, M.Y.; Choi, J.H.; Kweon, J.H. Parametric Study on Static and Fatigue Strength Recovery of Scarf-Patch-Repaired Composite Laminates. Compos. Struct. 2016, 140, 417–432. [Google Scholar] [CrossRef]

- Asiliskender, A.; Peiró, J.; Lee, K.Y.; Parlamas, A.; Falzon, B.; Kazancı, Z. Predicting Filling Efficiency of Composite Resin Injection Repair. Compos. Part A Appl. Sci. Manuf. 2023, 1, 107708. [Google Scholar] [CrossRef]

- Lai, W.L.; Saeedipour, H.; Goh, K.L. Experimental Assessment of Drilling-Induced Damage in Impacted Composite Laminates for Resin-Injection Repair: Influence of Open/Blind Hole-Hole Interaction and Orientation. Compos. Struct. 2021, 271, 114153. [Google Scholar] [CrossRef]

- Lai, W.L.; Saeedipour, H.; Wong, W.L.E.; Goh, K.L. In Situ Resin-Injection Approach for Repairing Barely Visible Impact Damaged Carbon-Fiber Reinforced Epoxy Laminates: Optimizing the Repair Parameters Using Taguchi Method. Polym. Compos. 2023, 44, 3372–3386. [Google Scholar] [CrossRef]

- Omairey, S.; Jayasree, N.; Kazilas, M. Injection Repair of Advanced Composites: A Prospective Method for Delamination Damage Repair. In Sustainable Biopolymer Composites; Woodhead Publishing: Sawston, UK, 2021; pp. 183–211. ISBN 9780128222911. [Google Scholar]

- Inglis, C.E. Stresses in a Plate Due to the Presence of Cracks and Sharp Corners. Trans. Inst. Nav. Arch. 1913, 55, 219–241. [Google Scholar]

- Ji, Y.; Yuan, B.; Hu, X.; Jiang, H.; Qiao, Y. Repairing Sharp Delamination Cracks in CFRP Through Capillary Action of Acetone-Diluted Resin Solution. Compos. Sci. Technol. 2021, 219, 109249. [Google Scholar] [CrossRef]

- Ji, Y.; Chen, Y.; Yuan, B.; Hu, X.; Qiao, Y. Repair of Delamination-Cracks in CFRP Using CNT-Containing Resin Pre-Coating Solution Through Capillary Action. Compos. Part C Open Access 2022, 9, 100330. [Google Scholar] [CrossRef]

- Han, G.; Yuan, B.; Hu, X. Restoration of Compressive Strength of CFRP Plates with Edge Delamination through CNT Crack-Bridging Deposited by Resin Pre-Coating Solution. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107798. [Google Scholar] [CrossRef]

- Wang, B.; Hu, X.; Lu, P. Improvement of Adhesive Bonding of Grit-Blasted Steel Substrates by Using Diluted Resin as a Primer. Int. J. Adhes. Adhes. 2017, 73, 92–99. [Google Scholar] [CrossRef]

- Cheng, F.; Hu, Y.; Zhang, X.; Hu, X.; Huang, Z. Adhesive Bond Strength Enhancing Between Carbon Fiber Reinforced Polymer and Aluminum Substrates with Different Surface Morphologies Created by Three Sulfuric Acid Solutions. Compos. Part A Appl. Sci. Manuf. 2021, 146, 106427. [Google Scholar] [CrossRef]

- Han, X.; Chen, Y.; Hu, X.; Liu, W.; Li, Q.; Chen, S. Granite Strength and Toughness from Small Notched Three-Point-Bend Specimens of Geometry Dissimilarity. Eng. Fract. Mech. 2019, 216, 106482. [Google Scholar] [CrossRef]

- Han, X.; Liu, W.; Zhang, Q.; Chen, Y.; Hu, X.; Xiao, Q.; Chen, S. Effect of Resin Pre-Coating Method on Repairing Subsurface Micro-Defects in Sandstone and Granite. Constr. Build. Mater. 2020, 264, 120144. [Google Scholar] [CrossRef]

- Yu, X.; Shen, W.; Zhu, L.; Natsuki, T. The Tensile Properties and Repair Behavior of Glass Fiber Reinforced Polymer Using Resin Pre-Coating Technology. Text. Res. J. 2023, 93, 5187–5197. [Google Scholar] [CrossRef]

- Liu, W.; Xu, H.; Hu, X.; Yuan, B.; Tan, B.; Xu, F. Strengthening and Repairing of Engineered Bamboo-Steel Epoxy Adhesive Joints with Carbon Nanotube on the Basis of Resin Pre-Coating Method. Eur. J. Wood Wood Prod. 2020, 78, 313–320. [Google Scholar] [CrossRef]

- Liu, J.; Ye, Y.; Xie, X.; Zhou, X. Effect of MWNT Functionalization with Tunable-Length Block Copolymers on Dispersity of MWNTs and Mechanical Properties of Epoxy/MWNT Composites. Polymers 2022, 14, 3137. [Google Scholar] [CrossRef] [PubMed]

- Shcherbakov, A.S.; Mostovoy, A.S.; Yakovlev, N.A.; Arzamastsev, S.V. Effect of Carbon Nanotube Functionalization on the Physicochemical and Mechanical Properties of Modified Fiber-Reinforced Composites Based on an Epoxy Resin. Russ. J. Appl. Chem. 2021, 94, 1080–1087. [Google Scholar] [CrossRef]

- Rezini, D.; Khaldi, A.; Rahmani, Y. On the Boundary Value Kirsch’s Problem. J. Mech. 2015, 32, 93. [Google Scholar] [CrossRef]

- Young, T. Philosophical Transactions of the Royal Society of London; The Royal Society: London, UK, 1805. [Google Scholar]

- Laplace, P.S. Traité de Mécanique Céleste; De L’Imprimerie de Crapelet: Paris, France, 1805. [Google Scholar]

- Fries, N.; Dreyer, M. The Transition from Inertial to Viscous Flow in Capillary Rise. J. Colloid Interface Sci. 2008, 327, 125–128. [Google Scholar] [CrossRef]

- Ji, Y.; Chen, Y.; Han, X.; Hu, X.; Yuan, B.; Qiao, Y. Effect of Acetone on Mechanical Properties of Epoxy Used for Surface Treatment before Adhesive Bonding. Polym. Test. 2020, 86, 106492. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic Healing of Polymer Composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- ASTM D3410/D3410M-16e1; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading. American Society for Testing and Materials: West Conshohocken, PA, USA, 2006.

- Loos, M.R.; Coelho, L.A.F.; Pezzin, S.H.; Amico, S.C. The Effect of Acetone Addition on the Properties of Epoxy. Polimeros 2008, 18, 76–80. [Google Scholar] [CrossRef]

- Mondragon, I.; Bucknall, C.B. Effects of Residual Dichloromethane Solvent on the Cure of Epoxy Resin. Plast. Rubber Compos. Process. Appl. 1994, 21, 275–281. [Google Scholar]

- Yeh, Y.L.; Zhang, C.; Held, H.; Mebel, A.M.; Wei, X.; Lin, S.H.; Shen, Y.R. Structure of the Acetone Liquid/Vapor Interface. J. Chem. Phys. 2001, 114, 1837–1843. [Google Scholar] [CrossRef]

- Kissinger, H.E. Reaction Kinetics in Differential Thermal Analysis. Anal. Chem. 1957, 29, 1702–1706. [Google Scholar] [CrossRef]

- Zheng, T.; Xi, H.; Wang, Z.; Zhang, X.; Wang, Y.; Qiao, Y.; Wang, P.; Li, Q.; Li, Z.; Ji, C.; et al. The Curing Kinetics and Mechanical Properties of Epoxy Resin Composites Reinforced by PEEK Microparticles. Polym. Test. 2020, 91, 106781. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Ji, Y.; Cheng, F.; Hu, X. Modified SC Resin Pre-Coating Treatment for Rapid and Robust Repair of CFRP Laminates with Sharp Delamination Cracks. Polymers 2025, 17, 1079. https://doi.org/10.3390/polym17081079

Chen Y, Ji Y, Cheng F, Hu X. Modified SC Resin Pre-Coating Treatment for Rapid and Robust Repair of CFRP Laminates with Sharp Delamination Cracks. Polymers. 2025; 17(8):1079. https://doi.org/10.3390/polym17081079

Chicago/Turabian StyleChen, Yi, Yi Ji, Fei Cheng, and Xiaozhi Hu. 2025. "Modified SC Resin Pre-Coating Treatment for Rapid and Robust Repair of CFRP Laminates with Sharp Delamination Cracks" Polymers 17, no. 8: 1079. https://doi.org/10.3390/polym17081079

APA StyleChen, Y., Ji, Y., Cheng, F., & Hu, X. (2025). Modified SC Resin Pre-Coating Treatment for Rapid and Robust Repair of CFRP Laminates with Sharp Delamination Cracks. Polymers, 17(8), 1079. https://doi.org/10.3390/polym17081079