Advances in Crack-Based Strain Sensors on Stretchable Polymeric Substrates: Crack Mechanisms, Geometrical Factors, and Functional Structures

Abstract

1. Introduction

2. Mechanisms of Crack-Based Strain Sensors

| Crack Type | Conductive Layer Material | GFmax | Working Range (%) | Repeatability (Cycle) | Response Time (ms) | Ref. |

|---|---|---|---|---|---|---|

| Straight | Pt | 2000 | 2 | 5000 | 100 | [23] |

| MWCNT | 593.3 | 5 | 10,000 | 50 | [76] | |

| AgNW | 874.1 | 160 | 500 | N/A | [77] | |

| * GNWs | 8.6 × 104 | 4 | 800 | N/A | [50] | |

| Ag/AgNPs | 1870 | 1.2 | 2000 | 0.252 | [51] | |

| Ti/Au | 9327 | 10 | 3000 | 72 | [52] | |

| Au | 15,000 | 18 | 12,000 | 11 | [53] | |

| Network | Pt | 30 | 150 | 100 | 30 | [61] |

| Pt/AgNW/** DS | 493.2 | 75 | 1000 | 205 | [78] | |

| CNTs | 83,982.8 | 300 | 10,000 | 70 | [79] | |

| *** MXene-AgNW | 224 | 60 | 6000 | 30 | [80] | |

| AgNPs | >10 | 55 | 8000 | 16.3 | [81] | |

| Au/Ti | 113.7 | 120 | 1000 | 86.4 | [47] | |

| CNTs | 87 | 100 | 1500 | 65 | [82] | |

| Ti3C2Tx MXene | 45 | 50 | 1000 | N/A | [54] | |

| CNTs/CB | 1516 | 500 | 1000 | 80 | [83] | |

| CNT ink | 8.9 × 104 | 630 | 10,000 | 120 | [84] | |

| AgNWs/CNTs | 244.3 | 380 | 1000 | 80 | [55] | |

| MXene/CNT | 8089.7 | 450 | 10,000 | 40 | [85] | |

| **** LSG | 2692 | 120 | 11,000 | N/A | [56] | |

| AgNWs/Au | 6.1 | 350 | 1000 | N/A | [57] | |

| Kirigami | MXene | 29.1 | 5000 | 1000 | 17 | [36] |

| Conductive hydrogel | 26.9 | 25 | N/A | N/A | [58] | |

| AuNP-MWCNT | 220 | 180 | 100 | 10,000 | [48] | |

| CB/MWCNT-TPU | 5705.53 | 150 | 6000 | 220 | [86] | |

| Pt | 1220.71 | 2 | 5000 | 1700 | [87] | |

| LIG | 1.6 × 103 | 30 | 1000 | 220 | [88] | |

| Conductive hydrogel | 80 | 215 | 10,000 | 85 | [59] | |

| Meta | Mo/MoO3/PBAT/PLA | 12,331 | 0.34 | 6400 | N/A | [49] |

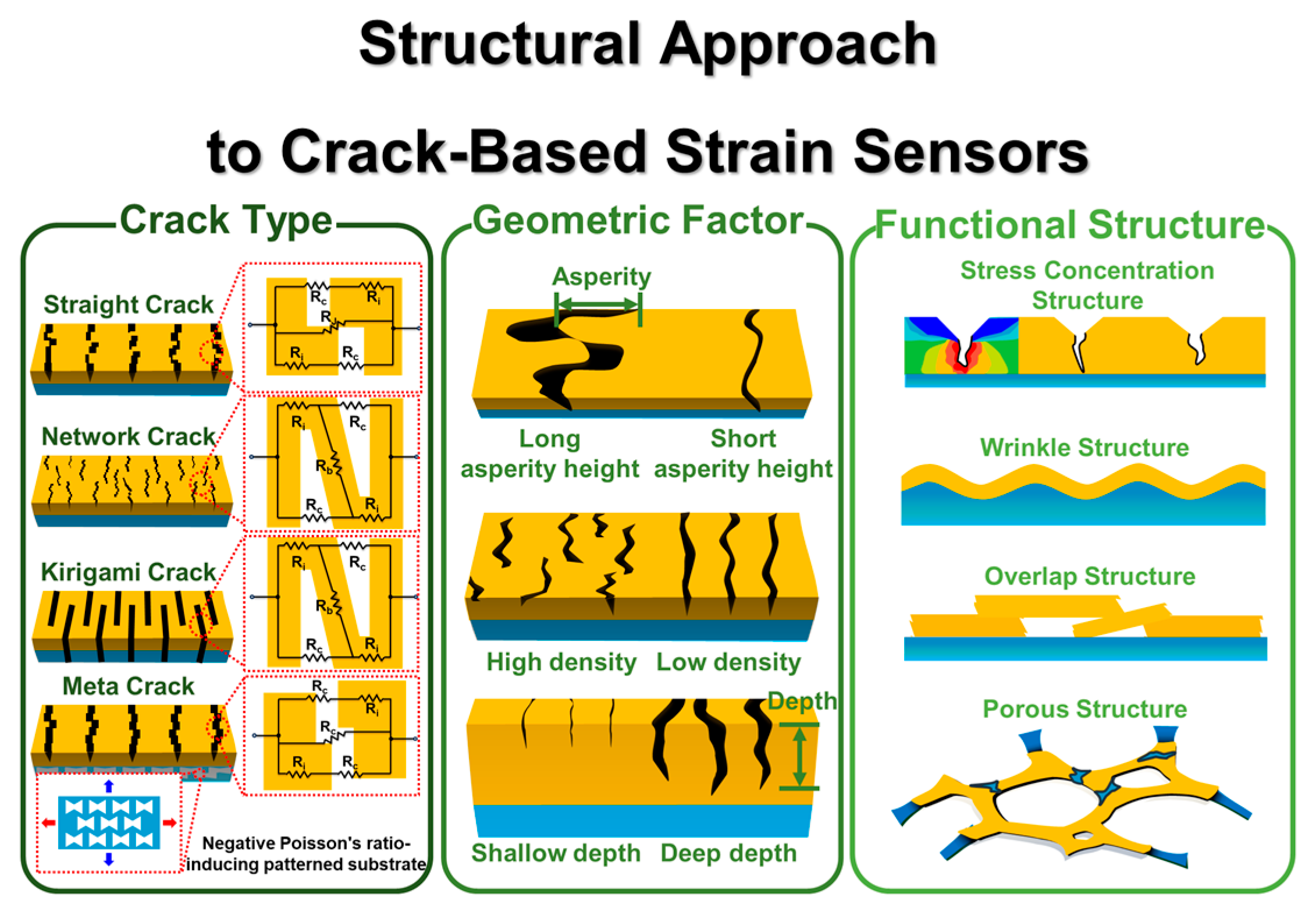

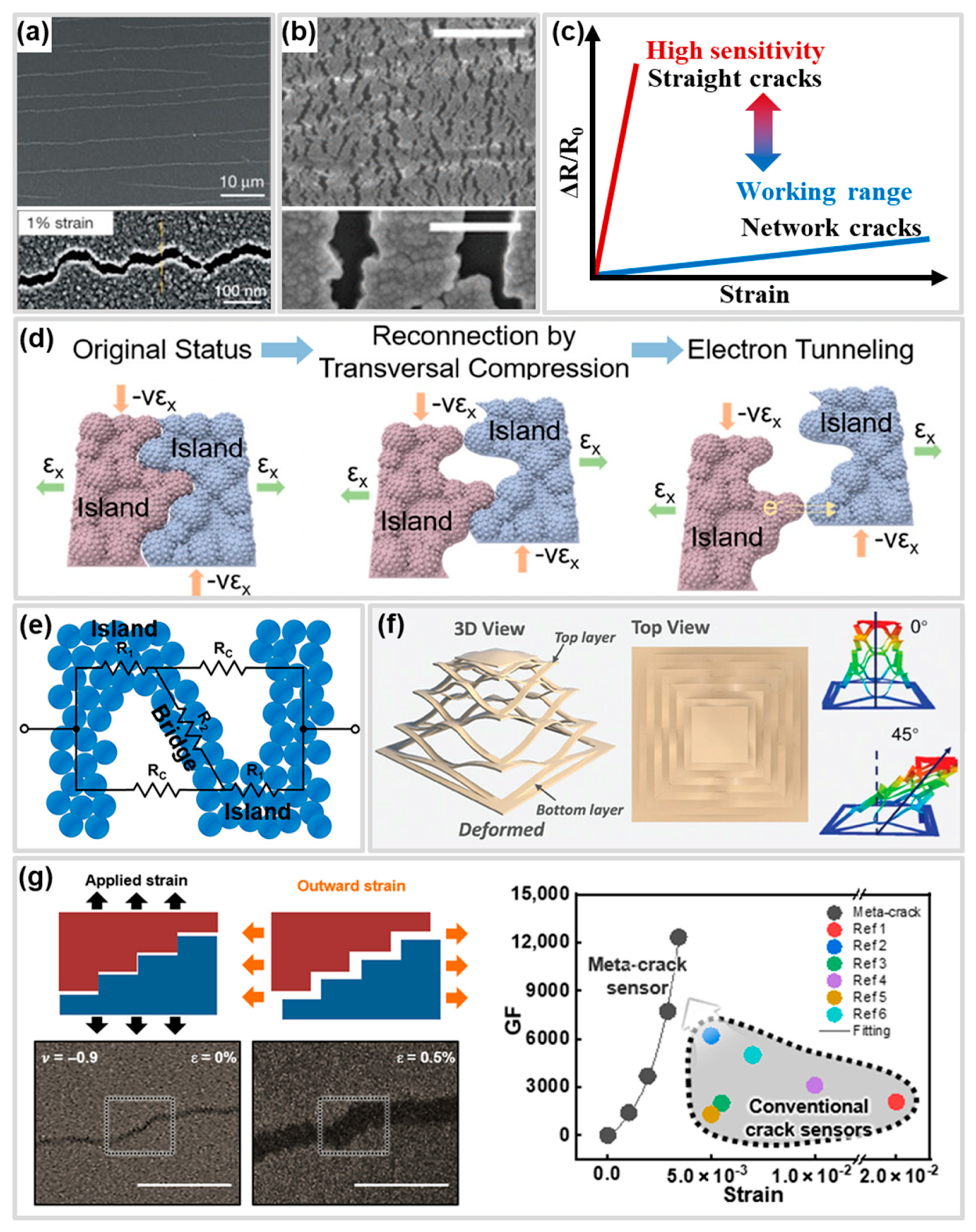

2.1. Straight Cracks

2.2. Network Cracks

2.3. Advanced Cracks

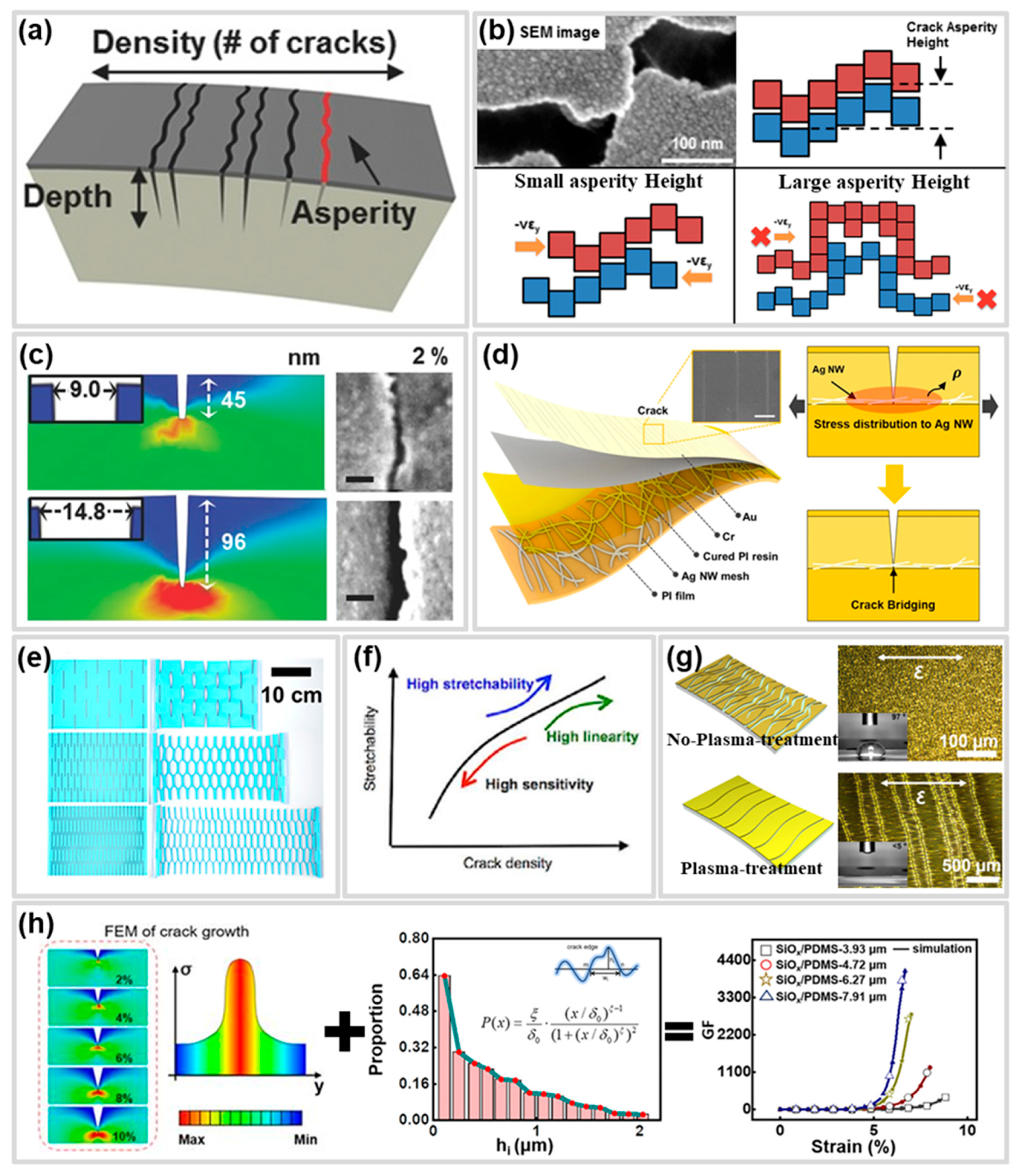

3. Effect of Geometrical Factors on Crack-Based Strain Sensors

| Geometric Factor | Crack Type | Conductive Layer Material | GFmax | Working Range (%) | Repeatability (Cycle) | Response Time (ms) | Ref. |

|---|---|---|---|---|---|---|---|

| Asperity | Straight | Pt | 2000 | 2 | 5000 | 100 | [23] |

| Straight | ITO | 4000 | 2 | 5000 | 1 | [103] | |

| Straight | PtNPs/Al2O3 | 2 × 104 | 1 | 1200 | 100 | [104] | |

| Straight | PtNPs/Al2O3 | 2.6 × 108 | 7.2 | 1000 | N/A | [44] | |

| Straight | PEDOT:PSS | 280 | 8 | 2000 | N/A | [105] | |

| Straight | Cu-Al | 43,152 | 2 | 10 | <100 | [18] | |

| Network | MoO3/Mo | 1355 | 2 | 10,000 | N/A | [17] | |

| Depth | Straight | Pt | 16,000 | 2 | 10,000 | N/A | [20] |

| Straight | Au/Cr/MoO3 | 10,000 | 2 | 15,000 | 5 | [106] | |

| Straight | Carbon paste | 43.79 | 3.27 | 100,000 | N/A | [107] | |

| N/A | CNT | 43.8 | 200 | 1000 | 100 | [108] | |

| Straight | Au/Cr/AgNWs | 2000 | 44.4 | 200,000 | 0.2 | [109] | |

| Density | Network | Pt | 30 | 150 | N/A | 30 | [61] |

| Straight | Au | 5000 | 1 | 1000 | N/A | [94] | |

| Straight | SWCNT | 4.2 × 104 | 153 | 5000 | N/A | [110] | |

| Straight | CNTs | 1020.2 | 100 | 10,000 | N/A | [111] | |

| Network | MXene/CNT | 89.72 | 100 | 10,000 | 353 | [112] | |

| Straight | Au | 10,000 | 120 | 5000 | N/A | [113] | |

| Straight | Au | 2448 | 59 | 3000 | 69 | [114] | |

| Network | Ag | 4570.6 | 50 | 1000 | N/A | [21] | |

| Straight | Laser-induced graphene (LIG) | 191.55 | 50 | 1500 | 70 | [115] |

3.1. Crack Asperity Height

3.2. Crack Depth

3.3. Crack Density

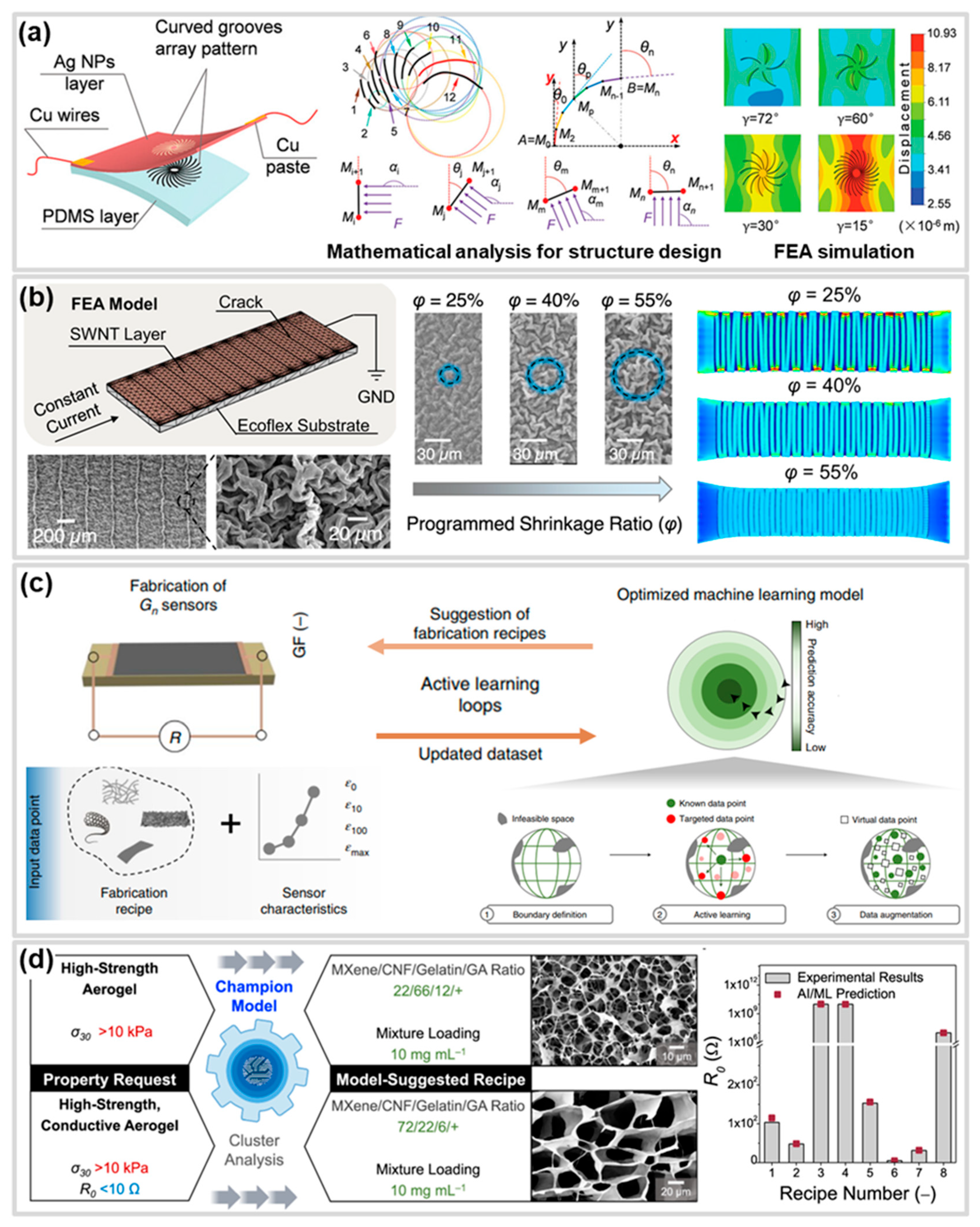

3.4. Performance Control Through Numerical Analysis of Cracks Geometrical Factor

4. Functional Structures for Performance Improvement

| Functional Structure | GFmax | Working Range (%) | Repeatability (Cycle) | Response Time (ms) | Material | Ref. |

|---|---|---|---|---|---|---|

| Stress concentration structure | 2.0 × 106 | 10 | 5000 | 100 | Pt/Cr/PUA | [125] |

| 670 | 0.3 | 20,000 | N/A | Au/Cr/Cu/PUA | [62] | |

| 74 | 100 | 1000 | N/A | SWCNT/PDMS | [126] | |

| 4570.6 | 50 | 1000 | N/A | Ag/cPDMS * | [21] | |

| 1084.16 | 100 | 1000 | 489 | Ecoflex-GNPs/PDMS | [127] | |

| 18,000 | 0.65 | 7000 | 258 | AgNPs/PDMS | [128] | |

| 150,000 | 60 | 30,000 | N/A | AgNWs/PDMS | [129] | |

| 184.88 | 1.67 | 500 | 145 | Pt/TPU | [130] | |

| 1.42e8 | 0.085 | 1000 | N/A | Au/Cr/PDMS | [131] | |

| Wrinkle structure | 167,665.6 | 300 | 10,000 | 90 | Au/rGO/VHB/PDMS | [132] |

| 1.1 × 109 | 125 | 3500 | 0.13 | Ag/rGO/ PDMS | [45] | |

| 1071 | 15 | 150 | 200 | GNC/PDMS | [133] | |

| 287.6 | 100 | 10,000 | 489 | CNT-GO/ Elastic tape | [134] | |

| 750 | 24 | 20,000 | 90 | GNPs/TPU/ PDMS | [135] | |

| 2000 | 100 | 1000 | 30 | SWNT/GO/ PDMS | [136] | |

| 2585 | 66.5 | 1000 | N/A | Au/PDMS | [137] | |

| 1344.1 | 200 | 10,000 | 88 | CNTs/PU yarn | [32] | |

| 2 | 600 | 10,000 | 153 | CNT/SEBS rubber elastomer | [63] | |

| 136,124.4 | 300 | 10,500 | 140 | MXene/rGO | [138] | |

| Overlap structure | 30,000 | 3 | 1000 | N/A | GNPs/PDMS | [119] |

| 2369.1 | 80 | 2500 | 600 | MXene/PANIF/ Elastic rubber | [139] | |

| 58.5 | 200 | 5000 | 42 | CNTs/AgNPs/ Spandex fiber | [140] | |

| 42,300 | 145 | 1000 | N/A | CNT/Ecoflex | [141] | |

| 150 | 25 | 1000 | 70 | GnPs/PU | [142] | |

| 1.0 × 107 | 300 | 1000 | 158 | Au/PDMS | [143] | |

| 64.08 | 500 | 1000 | 56 | CNT/Ecoflex | [144] | |

| 4000 | 1 | 1000 | N/A | AgNWs/GO/TPU | [145] | |

| 150 | 82 | 5000 | N/A | rGO/elastic tape | [146] | |

| 475 | 14.5 | 500 | N/A | AgNPs/rGO/PDMS | [147] | |

| Porous structure | 0.039 | 900 | 2000 | 60 | CNTs/TPU | [64] |

| 97.1 | 320 | 9700 | <200 | MWCNTs/TPU | [148] | |

| 3405 | 83 | 1000 | 60 | MXene/CNC/TPU | [149] | |

| 0.8 | 80 | 500 | 46 | MXene/PU | [150] | |

| 66,600 | 520 | 5000 | ~60 | CNTs/TPU fiber | [151] | |

| Hierarchical structure | 57.2 | 530 | 1000 | 200 | CNTs/TPU fiber | [152] |

| 5.9 | 150 | 1000 | 192 | GO/rubber band | [153] | |

| 2352.8 | 50 | 11,000 | 125.4 | a-C **/PDMS | [154] | |

| 2557.71 | 45 | 10,000 | <130 | Au/PDMS | [155] |

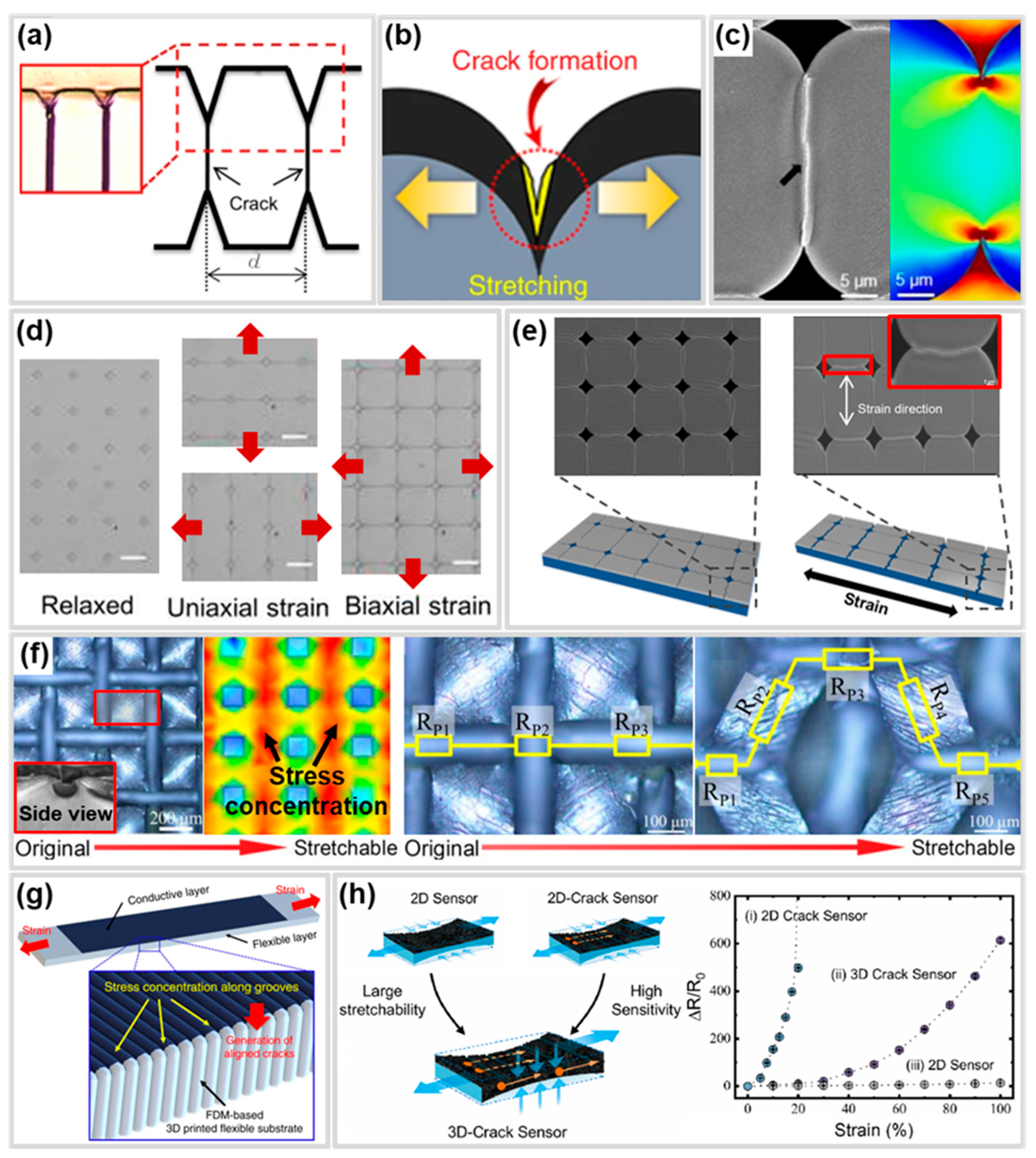

4.1. Stress Concentration Structure

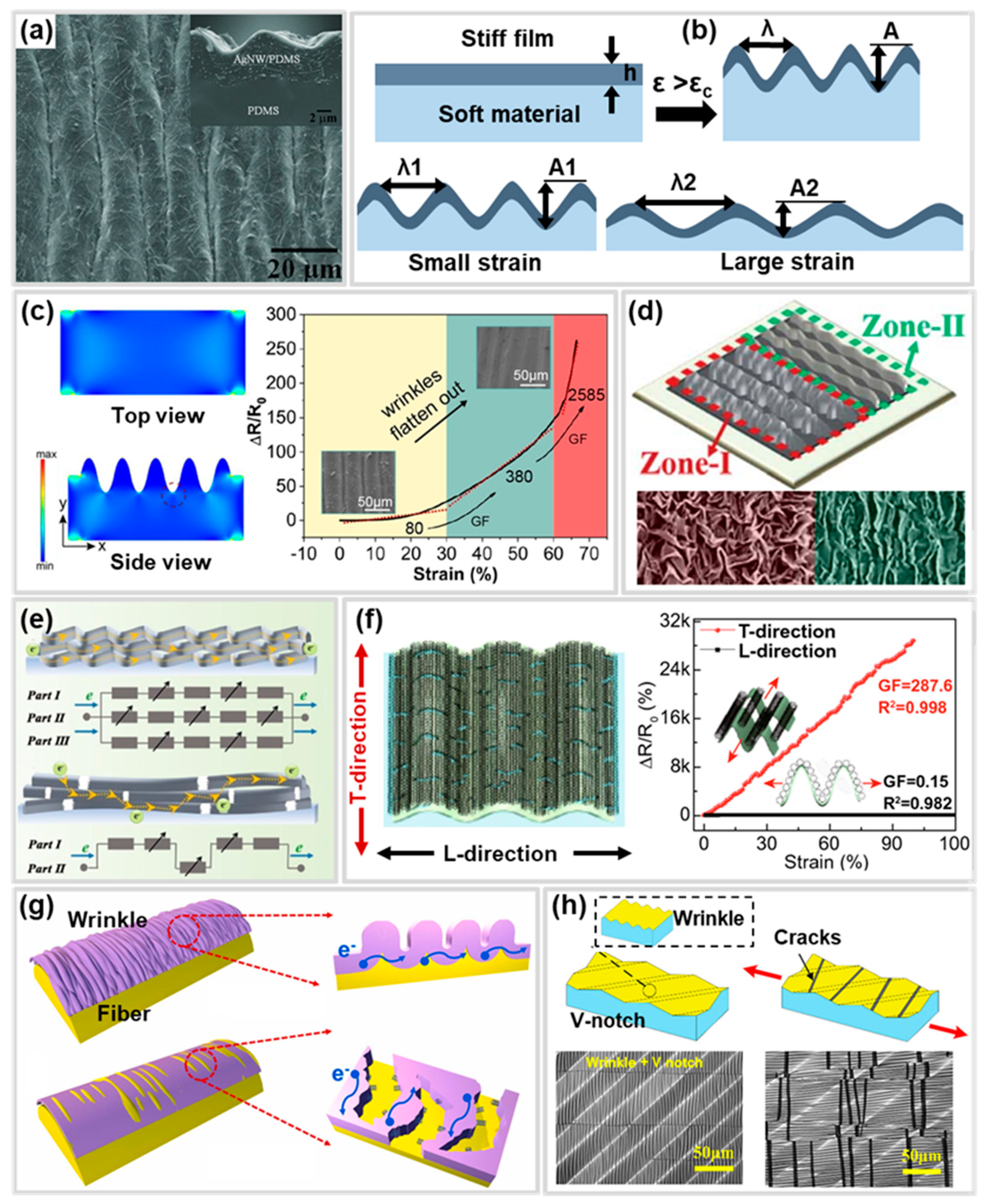

4.2. Wrinkle Structure

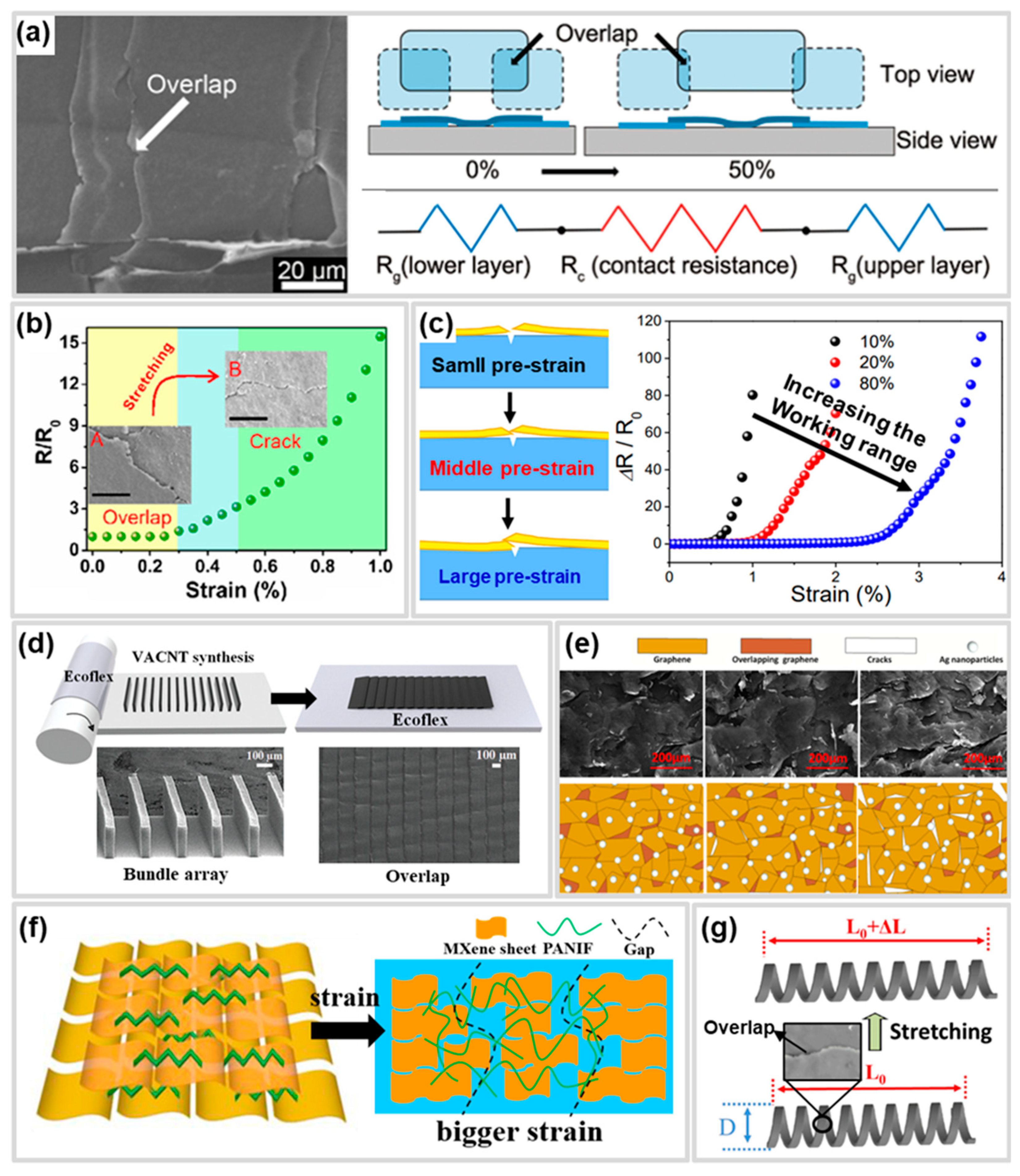

4.3. Overlap Structure

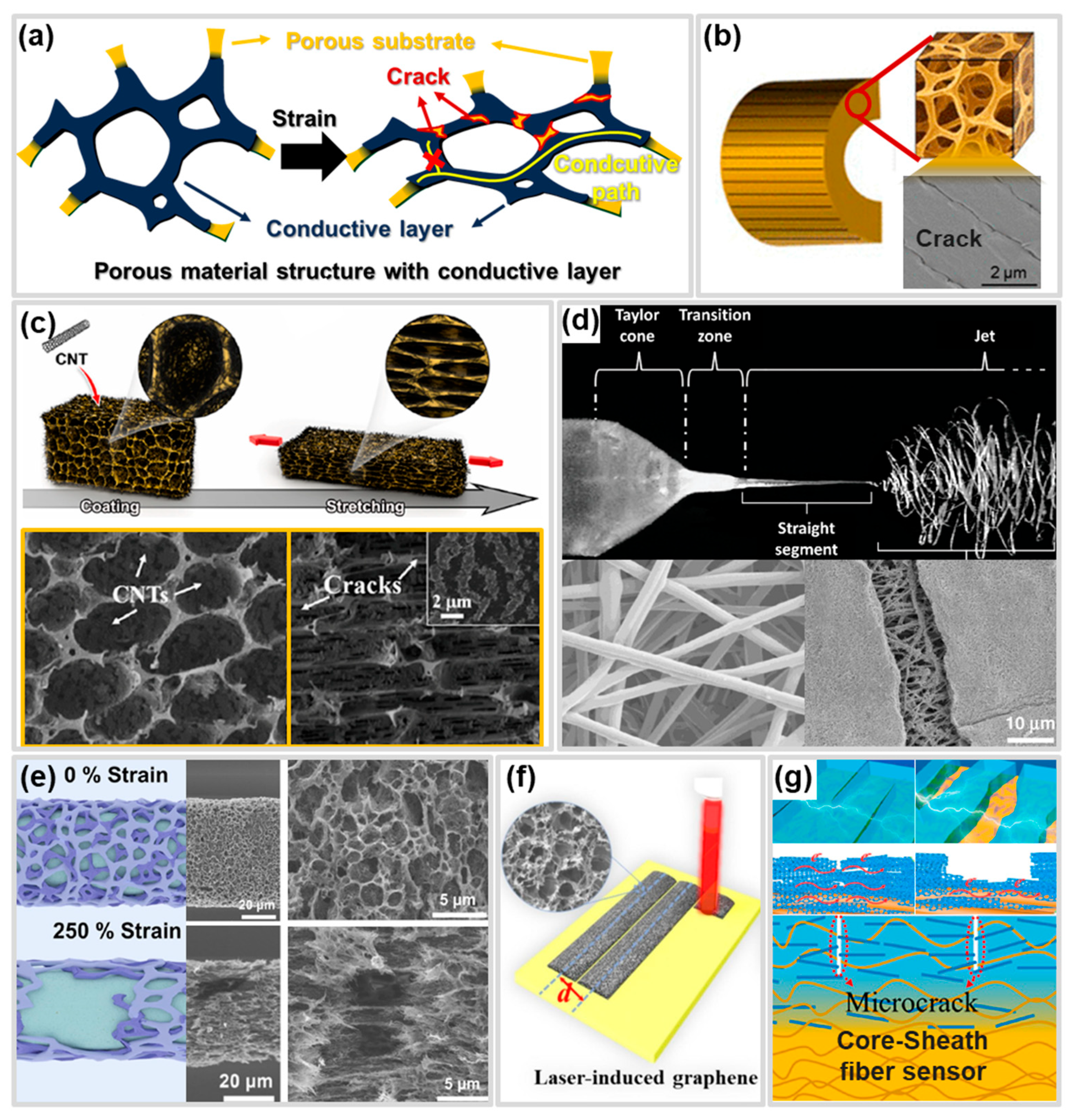

4.4. Porous Structure

4.5. Performance Control Through Numerical Analysis of Functional Structure

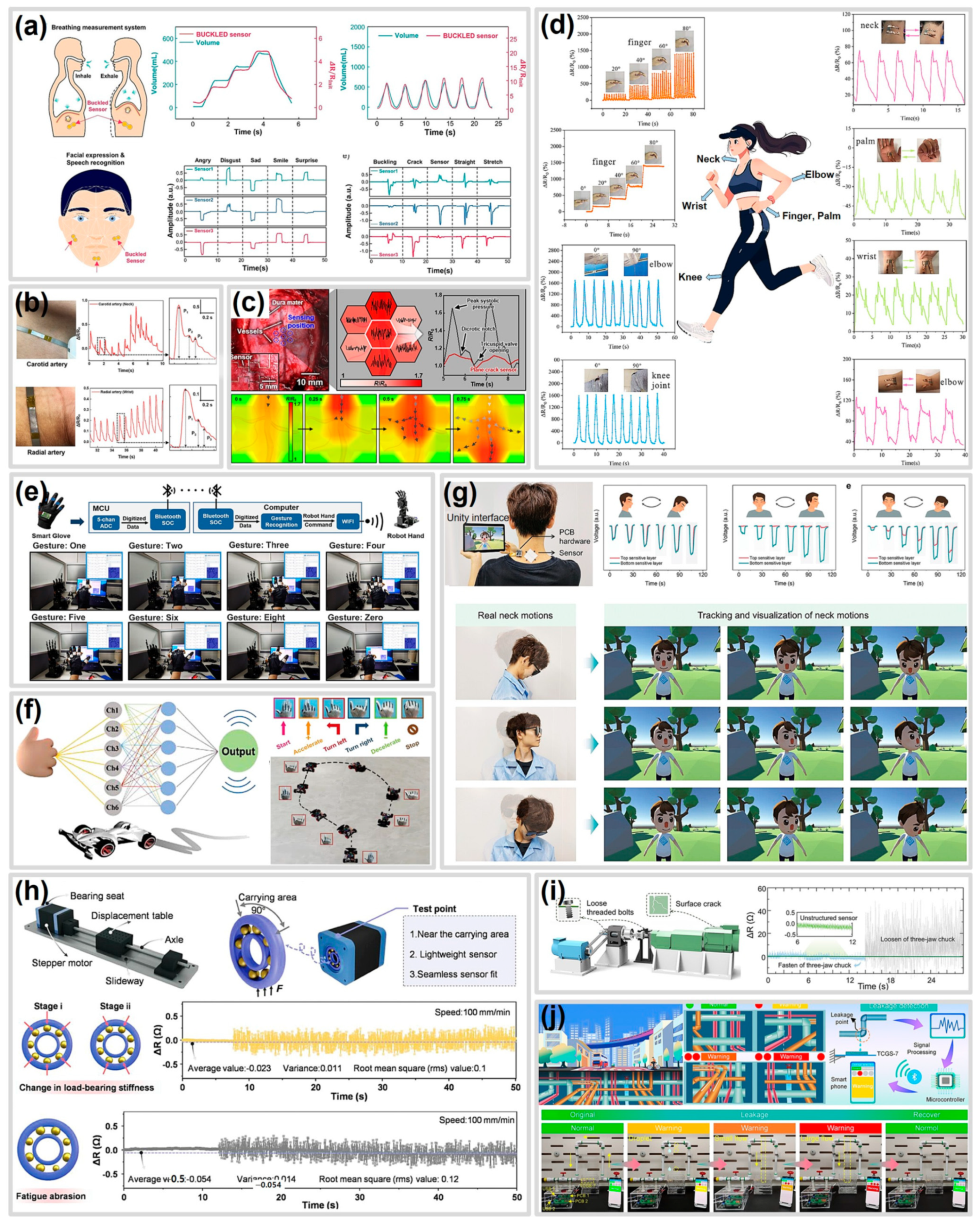

5. Application of Crack-Based Strain Sensors

5.1. Physiology and Motion Monitoring

5.2. Human–Machine Interface

5.3. Structural Health Monitoring

6. Challenges and Future Perspectives

6.1. Challenges in Crack-Based Strain Sensors

6.1.1. Long-Term Stability and Durability

6.1.2. Fabrication Process and Scalability

6.1.3. Integration with Electronic Devices

6.2. Future Perspectives

6.2.1. Advanced Cracks

6.2.2. Hierarchical Cracks

6.2.3. Hierarchical Structures

6.2.4. Optimization Using Numerical Analysis and Data-Driven Methods

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| a-C | Amorphous carbon |

| AgNW | Silver nanowires |

| Al2O3 | Aluminum oxide |

| Au | Gold |

| CBSS | Crack-based strain sensors |

| CNT | Carbon nanotube |

| Cr | Chromium |

| DS | Dragon skin |

| FA | Fluorescent agent |

| FEA | Finite element analysis |

| FE | Finite element |

| fPCB | Flexible printed circuit board |

| FSR | Fluorosilicone rubber |

| GF | Gauge factor |

| GnP | Graphene platelets |

| GO | Graphene oxide |

| LIG | Laser-induced graphene |

| LTP | Laser transmission pyrolysis |

| MEMS- | Microelectromechanical systems |

| Mo | Molybdenum |

| MoO3 | Molybdenum trioxide |

| MXene | New intriguing family of 2D transition metal carbides, nitrides, and carbonitrides |

| O3 | Ozone |

| PANIF | Polyaniline fiber |

| PBAT | Polybutylene adipate terephthalate |

| PCAM | Programmed crack array within micro-crumples |

| PDMS | Polydimethylsiloxane |

| PDCA | Probability distribution based cellular automata method |

| PEDOT:PSS | Poly(3,4-ethylenedioxythiophene) polystyrene sulfonate |

| PLA | Polylactic acid |

| Pt | Platinum |

| PU | Polyurethane |

| PUA | Polyurethane acrylate |

| rGO | Reduced graphene oxide |

| SEBS | Styrene-ethylene-butylene-styrene |

| SiOx | Silicon oxide |

| SVM | Support vector machine |

| SWCNT | Single-walled carbon nanotube |

| UV | Ultraviolet |

| HMI | Human–machine interface |

References

- Tan, C.; Dong, Z.; Li, Y.; Zhao, H.; Huang, X.; Zhou, Z.; Jiang, J.-W.; Long, Y.-Z.; Jiang, P.; Zhang, T.-Y. A high performance wearable strain sensor with advanced thermal management for motion monitoring. Nat. Commun. 2020, 11, 3530. [Google Scholar] [PubMed]

- Sonil, N.I.; Ullah, Z.; Chen, J.; Wang, G.P. Wearable strain sensors for human motion detection and health monitoring based on hybrid graphite-textile flexible electrodes. J. Mater. Res. Technol. 2023, 26, 764–774. [Google Scholar]

- Yadav, A.; Yadav, N.; Wu, Y.; RamaKrishna, S.; Hongyu, Z. Wearable strain sensors: State-of-the-art and future applications. Mater. Adv. 2023, 4, 1444–1459. [Google Scholar]

- Kulkarni, M.B.; Rajagopal, S.; Prieto-Simón, B.; Pogue, B.W. Recent advances in smart wearable sensors for continuous human health monitoring. Talanta 2024, 272, 125817. [Google Scholar]

- Hong, Y.J.; Jeong, H.; Cho, K.W.; Lu, N.; Kim, D.H. Wearable and implantable devices for cardiovascular healthcare: From monitoring to therapy based on flexible and stretchable electronics. Adv. Funct. Mater. 2019, 29, 1808247. [Google Scholar]

- Zhou, Q.; Geng, Z.; Yang, L.; Shen, B.; Kan, Z.; Qi, Y.; Hu, S.; Dong, B.; Bai, X.; Xu, L. A Wearable Healthcare Platform Integrated with Biomimetical Ions Conducted Metal–Organic Framework Composites for Gas and Strain Sensing in Non-Overlapping Mode. Adv. Sci. 2023, 10, 2207663. [Google Scholar]

- Zhang, C.; Ouyang, W.; Zhang, L.; Li, D. A dual-mode fiber-shaped flexible capacitive strain sensor fabricated by direct ink writing technology for wearable and implantable health monitoring applications. Microsyst. Nanoeng. 2023, 9, 158. [Google Scholar] [PubMed]

- Wu, Y.; Karakurt, I.; Beker, L.; Kubota, Y.; Xu, R.; Ho, K.Y.; Zhao, S.; Zhong, J.; Zhang, M.; Wang, X. Piezoresistive stretchable strain sensors with human machine interface demonstrations. Sens. Actuators A Phys. 2018, 279, 46–52. [Google Scholar]

- Gao, Z.; Xiao, X.; Carlo, A.D.; Yin, J.; Wang, Y.; Huang, L.; Tang, J.; Chen, J. Advances in wearable strain sensors based on electrospun fibers. Adv. Funct. Mater. 2023, 33, 2214265. [Google Scholar]

- Zhao, S.; Liu, D.; Yan, F. Wearable Resistive-Type Stretchable Strain Sensors: Materials and Applications. Adv. Mater. 2025, 37, 2413929. [Google Scholar]

- Pancham, P.P.; Chiu, W.H.; Mukherjee, A.; Lo, C.Y. Strain visualization in flexible sensors with functional materials: A review. Adv. Mater. Interfaces 2023, 10, 2300029. [Google Scholar]

- Han, P.; Liang, S.; Zou, H.; Wang, X. Structure, principle and performance of flexible conductive polymer strain sensors: A review. J. Mater. Sci. Mater. Electron. 2024, 35, 775. [Google Scholar]

- Sun, Z.; Ou, Q.; Dong, C.; Zhou, J.; Hu, H.; Li, C.; Huang, Z. Conducting polymer hydrogels based on supramolecular strategies for wearable sensors. Exploration 2024, 4, 20220167. [Google Scholar] [PubMed]

- Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A.A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and stretchable strain sensors: Materials, sensing mechanisms, and applications. Adv. Intell. Syst. 2020, 2, 2000039. [Google Scholar]

- Khalid, M.A.U.; Chang, S.H. Flexible strain sensors for wearable applications fabricated using novel functional nanocomposites: A review. Compos. Struct. 2022, 284, 115214. [Google Scholar]

- Park, J.; Kim, M.; Hong, I.; Kim, T.; Lee, E.; Kim, E.A.; Ryu, J.K.; Jo, Y.; Koo, J.; Han, S.; et al. Foot Plantar Pressure Measurement System Using Highly Sensitive Crack-Based Sensor. Sensors 2019, 19, 5504. [Google Scholar] [CrossRef]

- Lee, J.H.; Bae, J.Y.; Kim, Y.N.; Chae, M.; Lee, W.J.; Lee, J.; Kim, I.D.; Hyun, J.K.; Lee, K.S.; Kang, D. A Fully Biodegradable and Ultra-Sensitive Crack-Based Strain Sensor for Biomechanical Signal Monitoring. Adv. Funct. Mater. 2024, 34, 2406035. [Google Scholar]

- Wu, X.; Chen, H.; Luo, X.; Wang, D.; Schaaf, P.; Zhang, G. Ultrasensitive Strain Sensors Based on Cu-Al Alloy Films with Voided Cluster Boundaries. Adv. Mater. Technol. 2021, 6, 2100524. [Google Scholar]

- Hou, Y.; Wang, L.; Sun, R.; Zhang, Y.; Gu, M.; Zhu, Y.; Tong, Y.; Liu, X.; Wang, Z.; Xia, J.; et al. Crack-Across-Pore Enabled High-Performance Flexible Pressure Sensors for Deep Neural Network Enhanced Sensing and Human Action Recognition. ACS Nano 2022, 16, 8358–8369. [Google Scholar] [CrossRef]

- Park, B.; Kim, J.; Kang, D.; Jeong, C.; Kim, K.S.; Kim, J.U.; Yoo, P.J.; Kim, T.I. Dramatically Enhanced Mechanosensitivity and Signal-to-Noise Ratio of Nanoscale Crack-Based Sensors: Effect of Crack Depth. Adv. Mater. 2016, 28, 8130–8137. [Google Scholar] [CrossRef]

- Zhang, S.; Fei, W.; Jiang, Q.; Jiang, J.; Shi, K.; Xue, L.; Wu, Z. Facile fabrication of sensitivity-tunable strain sensors based on laser-patterned micro-nano structures. J. Micromech. Microeng. 2021, 31, 085003. [Google Scholar]

- Zhang, Y.; Wu, H.; Liu, L.; Yang, Y.; Zhang, C.; Duan, J. Crack-Based Composite Flexible Sensor with Superhydrophobicity to Detect Strain and Vibration. Polymers 2024, 16, 2535. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.Y.; Kim, T.I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Cai, J.; Xu, J.; Gong, D. High-performance strain sensors based on Au/graphene composite films with hierarchical cracks for wide linear-range motion monitoring. ACS Appl. Mater. Interfaces 2022, 14, 39230–39239. [Google Scholar]

- Won, C.; Lee, S.; Jung, H.H.; Woo, J.; Yoon, K.; Lee, J.; Kwon, C.; Lee, M.; Han, H.; Mei, Y.; et al. Ultrasensitive and Stretchable Conductive Fibers Using Percolated Pd Nanoparticle Networks for Multisensing Wearable Electronics: Crack-Based Strain and H2 Sensors. ACS Appl. Mater. Interfaces 2020, 12, 45243–45253. [Google Scholar] [CrossRef]

- Gong, S.; Yap, L.W.; Zhu, B.; Zhai, Q.; Liu, Y.; Lyu, Q.; Wang, K.; Yang, M.; Ling, Y.; Lai, D.T.H.; et al. Local Crack-Programmed Gold Nanowire Electronic Skin Tattoos for In-Plane Multisensor Integration. Adv. Mater. 2019, 31, e1903789. [Google Scholar] [CrossRef]

- Oh, J.; Yang, J.C.; Kim, J.O.; Park, H.; Kwon, S.Y.; Lee, S.; Sim, J.Y.; Oh, H.W.; Kim, J.; Park, S. Pressure Insensitive Strain Sensor with Facile Solution-Based Process for Tactile Sensing Applications. ACS Nano 2018, 12, 7546–7553. [Google Scholar] [CrossRef]

- Pu, J.-H.; Zhao, X.; Zha, X.-J.; Li, W.-D.; Ke, K.; Bao, R.-Y.; Liu, Z.-Y.; Yang, M.-B.; Yang, W. A strain localization directed crack control strategy for designing MXene-based customizable sensitivity and sensing range strain sensors for full-range human motion monitoring. Nano Energy 2020, 74, 104814. [Google Scholar]

- Chhetry, A.; Sharma, S.; Barman, S.C.; Yoon, H.; Ko, S.; Park, C.; Yoon, S.; Kim, H.; Park, J.Y. Black phosphorus@ laser-engraved graphene heterostructure-based temperature–strain hybridized sensor for electronic-skin applications. Adv. Funct. Mater. 2021, 31, 2007661. [Google Scholar]

- Tolvanen, J.; Hannu, J.; Jantunen, H. Stretchable and Washable Strain Sensor Based on Cracking Structure for Human Motion Monitoring. Sci. Rep. 2018, 8, 13241. [Google Scholar] [CrossRef]

- Gong, X.X.; Fei, G.T.; Fu, W.B.; Fang, M.; Gao, X.D.; Zhong, B.N.; De Zhang, L. Flexible strain sensor with high performance based on PANI/PDMS films. Org. Electron. 2017, 47, 51–56. [Google Scholar]

- Sun, H.; Dai, K.; Zhai, W.; Zhou, Y.; Li, J.; Zheng, G.; Li, B.; Liu, C.; Shen, C. A Highly Sensitive and Stretchable Yarn Strain Sensor for Human Motion Tracking Utilizing a Wrinkle-Assisted Crack Structure. ACS Appl. Mater. Interfaces 2019, 11, 36052–36062. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.S.; Yang, F.; Xu, J.; Kong, Y.; Zheng, H.; Chen, L.; Chen, Y.; Wu, M.X.; Yang, B.R.; Luo, Y.; et al. Ultrasonically Patterning Silver Nanowire-Acrylate Composite for Highly Sensitive and Transparent Strain Sensors Based on Parallel Cracks. ACS Appl. Mater. Interfaces 2020, 12, 47729–47738. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Liu, P.; Tong, W.; Li, J.; Xu, G.; Teng, F.; Liu, J.; Feng, H.; Hu, R.; Yang, A. An ultra-sensitive core-sheath fiber strain sensor based on double strain layered structure with cracks and modified MWCNTs/silicone rubber for wearable medical electronics. Compos. Sci. Technol. 2023, 231, 109816. [Google Scholar]

- Kim, Y.-G.; Song, J.-H.; Hong, S.; Ahn, S.-H. Piezoelectric strain sensor with high sensitivity and high stretchability based on kirigami design cutting. NPJ Flex. Electron. 2022, 6, 52. [Google Scholar]

- Zhuo, F.; Zhou, J.; Liu, Y.; Xie, J.; Chen, H.; Wang, X.; Luo, J.; Fu, Y.; Elmarakbi, A.; Duan, H. Kirigami-Inspired 3D-Printable MXene Organohydrogels for Soft Electronics. Adv. Funct. Mater. 2023, 33, 2308487. [Google Scholar]

- Lee, G.; Lee, T.; Choi, Y.W.; Pikhitsa, P.V.; Park, S.J.; Kim, S.M.; Kang, D.; Choi, M. Metal–elastomer bilayered switches by utilizing the superexponential behavior of crack widening. J. Mater. Chem. C 2017, 5, 10920–10925. [Google Scholar]

- Gong, S.; Yap, L.W.; Zhu, Y.; Zhu, B.; Wang, Y.; Ling, Y.; Zhao, Y.; An, T.; Lu, Y.; Cheng, W. A soft resistive acoustic sensor based on suspended standing nanowire membranes with point crack design. Adv. Funct. Mater. 2020, 30, 1910717. [Google Scholar]

- Lee, J.; Kim, T.; Kim, H.; Im, S.; Park, J.; Park, I.; Park, D.H.; Han, B.; Kang, D.; Lee, G. Ultrasensitive Ultrasoft Buckled Crack-Based Sensor for Respiration Measurement and Enhanced Human–Machine Interface. Adv. Intell. Syst. 2024, 2400624. [Google Scholar] [CrossRef]

- Nie, M.; Xia, Y.-h.; Yang, H.-s. A flexible and highly sensitive graphene-based strain sensor for structural health monitoring. Clust. Comput. 2019, 22, 8217–8224. [Google Scholar]

- Liao, X.; Liao, Q.; Yan, X.; Liang, Q.; Si, H.; Li, M.; Wu, H.; Cao, S.; Zhang, Y. Flexible and Highly Sensitive Strain Sensors Fabricated by Pencil Drawn for Wearable Monitor. Adv. Funct. Mater. 2015, 25, 2395–2401. [Google Scholar] [CrossRef]

- Zhang, Y.; Anderson, N.; Bland, S.; Nutt, S.; Jursich, G.; Joshi, S. All-printed strain sensors: Building blocks of the aircraft structural health monitoring system. Sens. Actuators A Phys. 2017, 253, 165–172. [Google Scholar]

- Dai, H.; Thostenson, E.T.; Schumacher, T. Processing and characterization of a novel distributed strain sensor using carbon nanotube-based nonwoven composites. Sensors 2015, 15, 17728–17747. [Google Scholar] [CrossRef]

- Aslanidis, E.; Skotadis, E.; Tsoukalas, D. Resistive crack-based nanoparticle strain sensors with extreme sensitivity and adjustable gauge factor, made on flexible substrates. Nanoscale 2021, 13, 3263–3274. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Zheng, Y.; Liu, E.; Zhao, X.; Yu, S.; Wang, J.; Han, X.; Xu, F.; Cao, Y.; Lu, C. Stretchable and ultrasensitive strain sensor based on a bilayer wrinkle-microcracking mechanism. Chem. Eng. J. 2022, 437, 135399. [Google Scholar]

- Sun, Z.; Yang, S.; Zhao, P.; Zhang, J.; Yang, Y.; Ye, X.; Zhao, X.; Cui, N.; Tong, Y.; Liu, Y. Skin-like ultrasensitive strain sensor for full-range detection of human health monitoring. ACS Appl. Mater. Interfaces 2020, 12, 13287–13295. [Google Scholar] [PubMed]

- Wang, W.; Liu, Y.; Ding, M.; Xia, T.; Gong, Q.; Zeng, X.; Cai, Z.; Hu, Y. From network to channel: Crack-based strain sensors with high sensitivity, stretchability, and linearity via strain engineering. Nano Energy 2023, 116, 108832. [Google Scholar]

- Noushin, T.; Tabassum, S. Kirigami-shaped Dual-functional Strain and Temperature Sensors for Monitoring Body Movements and Hyperthermia Toward Physiotherapy Applications. IEEE Sens. J. 2023, 24, 7253–7263. [Google Scholar]

- Lee, J.H.; Kim, Y.N.; Lee, J.; Jeon, J.; Bae, J.Y.; Lee, J.Y.; Kim, K.S.; Chae, M.; Park, H.; Kim, J.H.; et al. Hypersensitive meta-crack strain sensor for real-time biomedical monitoring. Sci. Adv. 2024, 10, eads9258. [Google Scholar] [CrossRef]

- Sun, H.; Ye, C.; Zhao, G.; Zhang, H.; Liu, Z.; Dai, W.; Wang, J.; Alam, F.E.; Yan, Q.; Li, X. Ultrasensitive micro/nanocrack-based graphene nanowall strain sensors derived from the substrate’s Poisson’s ratio effect. J. Mater. Chem. A 2020, 8, 10310–10317. [Google Scholar]

- Choi, H.J.; Ahn, J.; Jung, B.K.; Choi, Y.K.; Park, T.; Bang, J.; Park, J.; Yang, Y.; Son, G.; Oh, S.J. Highly conductive and sensitive wearable strain sensors with metal/nanoparticle double layer for noninterference voice detection. ACS Appl. Mater. Interfaces 2023, 15, 42836–42844. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Ding, Z.; Wang, W.; Hou, B.; Che, L. High-Sensitivity Flexible Strain Sensor with the Inverted Pyramid Microstructure Array Based on Stress-Induced Regular Linear Cracks. J. Electron. Mater. 2025, 54, 241–250. [Google Scholar] [CrossRef]

- Moghaddam, M.H.; Dalayoan, D.J.C.; Park, D.; Wang, Z.; Kim, H.; Im, S.; Ji, K.; Kang, D.; Das, B.; Kim, D.S. Lithographically Defined Zerogap Strain Sensors. ACS Photonics 2024, 11, 3239–3249. [Google Scholar] [CrossRef]

- Yang, R.; Song, H.; Zhou, Z.; Yang, S.; Tang, X.; He, J.; Liu, S.; Zeng, Z.; Yang, B.-R.; Gui, X. Ultra-sensitive, multi-directional flexible strain sensors based on an MXene film with periodic wrinkles. ACS Appl. Mater. Interfaces 2023, 15, 8345–8354. [Google Scholar] [CrossRef]

- Li, J.; Zhao, Y.; Zhai, W.; Zhao, X.; Dai, K.; Liu, C.; Shen, C. Highly aligned electrospun film with wave-like structure for multidirectional strain and visual sensing. Chem. Eng. J. 2024, 485, 149952. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Luo, J.; Tang, H.; Li, Y.; Liu, H.; Wu, J.; Han, F.; Liu, Z.; Guo, J. Micromesh reinforced strain sensor with high stretchability and stability for full-range and periodic human motions monitoring. InfoMat 2024, 6, e12511. [Google Scholar] [CrossRef]

- Kim, W.; Bang, J.; Yang, Y.; Ko, T.H.; Jang, M.; Cha, J.-J.; Choi, J.-I.; Oh, S.J. Highly stretchable and conductive Kirigami-like double-layer electrodes for motion-insensitive wearable electronics. Compos. Part B Eng. 2024, 283, 111655. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, Q. Design of a Highly Sensitive Ionic Conductive Hydrogel Sensor based on the Kirigami Structure. J. Phys. Conf. Ser. 2023, 2553, 012033. [Google Scholar] [CrossRef]

- Guo, Y.; Guo, H.; Han, Y.; Chen, X.; Liu, J.; Yang, M.; Lu, T.; Luo, J.; Tao, R.; Yang, Q. Multifunctional hydrogel sensor with curved macro cracks: A strategy for high sensitivity and wide detection range. Adv. Funct. Mater. 2023, 33, 2306820. [Google Scholar] [CrossRef]

- Lee, E.; Kim, T.; Suh, H.; Kim, M.; Pikhitsa, P.V.; Han, S.; Koh, J.S.; Kang, D. Effect of Metal Thickness on the Sensitivity of Crack-Based Sensors. Sensors 2018, 18, 2872. [Google Scholar] [CrossRef]

- Jeon, H.; Hong, S.K.; Kim, M.S.; Cho, S.J.; Lim, G. Omni-Purpose Stretchable Strain Sensor Based on a Highly Dense Nanocracking Structure for Whole-Body Motion Monitoring. ACS Appl. Mater. Interfaces 2017, 9, 41712–41721. [Google Scholar] [CrossRef] [PubMed]

- Chung, M.-K.; Yoo, J.-Y.; Lee, J.-S.; Jo, M.-S.; Choi, K.-W.; Kim, S.-B.; Yoon, J.-B. Ultra-sensitive strain sensor using high density self-aligned nano-cracks. In Proceedings of the 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 8–22 January 2020; pp. 20–23. [Google Scholar]

- Li, P.; Zhou, X.; Li, M.; Dong, X.; Li, L.; Yuan, N.; Ding, J. High stretch-ability and high linearity for elastic strain sensor constructed by multiple micro-cracks and complex wrinkles. Diam. Relat. Mater. 2023, 136, 110014. [Google Scholar]

- Zhu, G.; Li, H.; Peng, M.; Zhao, G.; Chen, J.; Zhu, Y. Highly-stretchable porous thermoplastic polyurethane/carbon nanotubes composites as a multimodal sensor. Carbon 2022, 195, 364–371. [Google Scholar]

- Kim, Y.-n.; Lee, J.; Kang, S.-K. Ultrasensitive crack-based strain sensors: Mechanism, performance, and biomedical applications. J. Mech. Sci. Technol. 2022, 36, 1059–1077. [Google Scholar]

- Zhou, Y.; Lian, H.; Li, Z.; Yin, L.; Ji, Q.; Li, K.; Qi, F.; Huang, Y. Crack engineering boosts the performance of flexible sensors. View 2022, 3, 20220025. [Google Scholar]

- Huang, X.; Yin, Z.; Wu, H. Structural engineering for high-performance flexible and stretchable strain sensors. Adv. Intell. Syst. 2021, 3, 2000194. [Google Scholar]

- Wu, Y.; Guo, Y.; Zhai, T.; Kang, L.; Zheng, Q.; Jiang, N. Pre-Cracked conductive networks for strain Sensing: Mechanisms, fabrication, properties and applications. Compos. Part A Appl. Sci. Manuf. 2024, 190, 108643. [Google Scholar] [CrossRef]

- Yang, H.; Ding, S.; Wang, J.; Sun, S.; Swaminathan, R.; Ng, S.W.L.; Pan, X.; Ho, G.W. Computational design of ultra-robust strain sensors for soft robot perception and autonomy. Nat. Commun. 2024, 15, 1636. [Google Scholar]

- Yang, H.; Li, J.; Lim, K.Z.; Pan, C.; Van Truong, T.; Wang, Q.; Li, K.; Li, S.; Xiao, X.; Ding, M. Automatic strain sensor design via active learning and data augmentation for soft machines. Nat. Mach. Intell. 2022, 4, 84–94. [Google Scholar] [CrossRef]

- Gu, J.; Jung, Y.; Ahn, J.; Ahn, J.; Choi, J.; Kang, B.; Jeong, Y.; Ha, J.-H.; Kim, T.; Jung, Y. Auxetic kirigami structure-based self-powered strain sensor with customizable performance using machine learning. Nano Energy 2024, 130, 110124. [Google Scholar] [CrossRef]

- Ke, J.; Liu, F.; Xu, G.; Liu, M. Data-Driven Strain Sensor Design Based on a Knowledge Graph Framework. Sensors 2024, 24, 5484. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Sun, J.; Lu, Y.; Liu, J. Nanocrack-based strain sensors. J. Mater. Chem. C 2021, 9, 754–772. [Google Scholar]

- Dinh Le, T.S.; An, J.; Huang, Y.; Vo, Q.; Boonruangkan, J.; Tran, T.; Kim, S.W.; Sun, G.; Kim, Y.J. Ultrasensitive Anti-Interference Voice Recognition by Bio-Inspired Skin-Attachable Self-Cleaning Acoustic Sensors. ACS Nano 2019, 13, 13293–13303. [Google Scholar] [CrossRef] [PubMed]

- Hong, L.; Zhang, H.; Kraus, T.; Jiao, P. Ultra-Stretchable Kirigami Piezo-Metamaterials for Sensing Coupled Large Deformations. Adv. Sci. 2024, 11, e2303674. [Google Scholar] [CrossRef]

- Chen, X.; Zeng, Q.; Shao, J.; Li, S.; Li, X.; Tian, H.; Liu, G.; Nie, B.; Luo, Y. Channel-Crack-Designed Suspended Sensing Membrane as a Fully Flexible Vibration Sensor with High Sensitivity and Dynamic Range. ACS Appl. Mater. Interfaces 2021, 13, 34637–34647. [Google Scholar] [CrossRef]

- Ha, S.-H.; Kim, J.-M. Highly sensitive and stretchable strain sensor based on self-aligned and periodic cracking of wavy metal nanowire/elastomer composite film. Smart Mater. Struct. 2021, 30, 065022. [Google Scholar]

- Noh, J.-Y.; Ha, S.-H.; Jeon, G.R.; Kim, J.-M. Geometrical and electrical modulation of cracked metal films based on metal nanowire/elastomer composites for high-performance wearable strain sensing. Compos. Sci. Technol. 2022, 230, 109738. [Google Scholar]

- Zhou, Y.; Zhan, P.; Ren, M.; Zheng, G.; Dai, K.; Mi, L.; Liu, C.; Shen, C. Significant Stretchability Enhancement of a Crack-Based Strain Sensor Combined with High Sensitivity and Superior Durability for Motion Monitoring. ACS Appl. Mater. Interfaces 2019, 11, 7405–7414. [Google Scholar] [CrossRef]

- Wang, T.; Qiu, Z.; Li, H.; Lu, H.; Gu, Y.; Zhu, S.; Liu, G.S.; Yang, B.R. High Sensitivity, Wide Linear-Range Strain Sensor Based on MXene/AgNW Composite Film with Hierarchical Microcrack. Small 2023, 19, e2304033. [Google Scholar] [CrossRef]

- Shao, H.Q.; Wei, K.D.; Gong, T.; Jia, J.; Tang, C.Y.; Zha, X.J.; Ke, K.; Bao, R.Y.; Zhang, K.; Wang, Y. Elastic Janus Microarray Film Strain Sensors with Heterogeneous Modulus and Conductivity for Healthcare and Braille Identification. Adv. Funct. Mater. 2024, 34, 2316134. [Google Scholar]

- Wang, S.; Xiao, P.; Liang, Y.; Zhang, J.; Huang, Y.; Wu, S.; Kuo, S.-W.; Chen, T. Network cracks-based wearable strain sensors for subtle and large strain detection of human motions. J. Mater. Chem. C 2018, 6, 5140–5147. [Google Scholar]

- Zhao, X.; Li, J.; Jiang, M.; Zhai, W.; Dai, K.; Liu, C.; Shen, C. Flexible strain sensor based on CNTs/CB/TPU conductive fibrous film with wide sensing range and high sensitivity for human biological signal acquisition. Polymer 2024, 302, 127049. [Google Scholar]

- Shen, T.; Liu, S.; Yue, X.; Wang, Z.; Liu, H.; Yin, R.; Liu, C.; Shen, C. High-performance fibrous strain sensor with synergistic sensing layer for human motion recognition and robot control. Adv. Compos. Hybrid Mater. 2023, 6, 127. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Chen, Z.; Shen, T.; Wang, Y.; Yin, R.; Liu, H.; Liu, C.; Shen, C. Ultrasensitive electrospinning fibrous strain sensor with synergistic conductive network for human motion monitoring and human-computer interaction. J. Mater. Sci. Technol. 2025, 213, 213–222. [Google Scholar]

- Xia, J.; He, L.; Lu, Z.; Liu, L.; Song, J.; Chen, S.; Wang, Q.; Hammad, F.A.; Tian, Y. Stretchable and sensitive strain sensors based on CB/MWCNTs–TPU for human motion capture and health monitoring. ACS Appl. Nano Mater. 2023, 6, 9736–9745. [Google Scholar]

- Kim, N.; Park, S.; Kim, M.-c.; Choi, Y.W. Auxetic crack-based wearable strain sensor designed for sustainable conformal contact. Sens. Actuators A Phys. 2025, 387, 116429. [Google Scholar]

- Fang, H.; Huang, X.; Guo, W.; Wu, H. A Prestrained Strategy Enabled Highly Sensitive Strain Sensors for Muscle Strength Assessment. ACS Appl. Mater. Interfaces 2024, 16, 66501–66513. [Google Scholar]

- Bao, M.-H. Micro Mechanical Transducers: Pressure Sensors, Accelerometers and Gyroscopes; Elsevier: Philadelphia, PA, USA, 2000. [Google Scholar]

- Xiang, Y.; Li, T.; Suo, Z.; Vlassak, J.J. High ductility of a metal film adherent on a polymer substrate. Appl. Phys. Lett. 2005, 87, 161910. [Google Scholar]

- Nam, K.H.; Park, I.H.; Ko, S.H. Patterning by controlled cracking. Nature 2012, 485, 221–224. [Google Scholar] [CrossRef]

- Han, Z.; Liu, L.; Zhang, J.; Han, Q.; Wang, K.; Song, H.; Wang, Z.; Jiao, Z.; Niu, S.; Ren, L. High-performance flexible strain sensor with bio-inspired crack arrays. Nanoscale 2018, 10, 15178–15186. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, J.; Ma, C.; Sun, J.; Tian, L.; Li, X.; Li, F.; Han, X.; Liu, C.; Shen, C. Detection of non-joint areas tiny strain and anti-interference voice recognition by micro-cracked metal thin film. Nano Energy 2017, 34, 578–585. [Google Scholar] [CrossRef]

- Yang, T.; Li, X.; Jiang, X.; Lin, S.; Lao, J.; Shi, J.; Zhen, Z.; Li, Z.; Zhu, H. Structural engineering of gold thin films with channel cracks for ultrasensitive strain sensing. Mater. Horiz. 2016, 3, 248–255. [Google Scholar]

- Simmons, J.G. Generalized formula for the electric tunnel effect between similar electrodes separated by a thin insulating film. J. Appl. Phys. 1963, 34, 1793–1803. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, G.; Wang, F.; Xu, Y.; Wang, C.; Zhu, Y.; Jiang, W. Design of flexible strain sensor with both ultralow detection limit and wide sensing range via the multiple sensing mechanisms. Compos. Sci. Technol. 2021, 213, 108932. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Moody, K.; Kollipara, A.; Zhu, Y. Highly Sensitive, Stretchable, and Robust Strain Sensor Based on Crack Propagation and Opening. ACS Appl. Mater. Interfaces 2023, 15, 1798–1807. [Google Scholar] [CrossRef]

- Meng, Q.; Chi, T.; Guo, S.; Razbin, M.; Wu, S.; He, S.; Han, S.; Peng, S. Highly sensitive strain sensors with ultra-low detection limit based on pre-defined serpentine cracks. Mater. Horiz. 2025, 12, 178–189. [Google Scholar] [CrossRef]

- Gu, J.; Ahn, J.; Jung, J.; Cho, S.; Choi, J.; Jeong, Y.; Park, J.; Hwang, S.; Cho, I.; Ko, J. Self-powered strain sensor based on the piezo-transmittance of a mechanical metamaterial. Nano Energy 2021, 89, 106447. [Google Scholar] [CrossRef]

- Lee, S.; Lee, Y.; Park, C.; Ro, Y.G.; Kwak, M.S.; Jeong, G.; Park, J.; Lee, H.; Kim, P.K.; Chung, S.I. Shape-Reconfigurable Crack-Based Strain Sensor with Ultrahigh and Tunable Sensitivity. Adv. Funct. Mater. 2025, 27, 124010. [Google Scholar] [CrossRef]

- Meng, F.; Zhou, H.; Wang, Z.; Zhang, C.; Li, S.; Zhang, L.; Kong, L. Characteristics of asperity damage and its influence on the shear behavior of granite joints. Rock Mech. Rock Eng. 2018, 51, 429–449. [Google Scholar] [CrossRef]

- Lee, T.; Choi, Y.W.; Lee, G.; Pikhitsa, P.V.; Kang, D.; Kim, S.M.; Choi, M. Transparent ITO mechanical crack-based pressure and strain sensor. J. Mater. Chem. C 2016, 4, 9947–9953. [Google Scholar] [CrossRef]

- Puyoo, E.; Brottet, S.; Rafael, R.; Malhaire, C. Ultrahigh Sensitivity to Strain of Cracked Thin Films Based on Metallic Nanoparticles in a Dielectric Matrix. IEEE Sens. Lett. 2018, 2, 1–4. [Google Scholar] [CrossRef]

- Wu, H.; Liu, Q.; Du, W.; Li, C.; Shi, G. Transparent Polymeric Strain Sensors for Monitoring Vital Signs and Beyond. ACS Appl. Mater. Interfaces 2018, 10, 3895–3901. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Lee, T.; Lee, G.; Choi, Y.W.; Kim, S.M.; Kang, D.; Choi, M. Polyimide encapsulation of spider-inspired crack-based sensors for durability improvement. Appl. Sci. 2018, 8, 367. [Google Scholar] [CrossRef]

- Guo, Z.; Yu, P.; Liu, Y.; Zhao, J. Pre-fatigue enhancing both long-term stability and sensitivity of direct-ink-writing printed sensors. Int. J. Fatigue 2023, 166, 107237. [Google Scholar]

- Hu, T.; Sheng, B. A Highly Sensitive Strain Sensor with Wide Linear Sensing Range Prepared on a Hybrid-Structured CNT/Ecoflex Film via Local Regulation of Strain Distribution. ACS Appl. Mater. Interfaces 2024, 16, 21061–21072. [Google Scholar] [CrossRef]

- Kim, T.; Hong, I.; Kim, M.; Im, S.; Roh, Y.; Kim, C.; Lim, J.; Kim, D.; Park, J.; Lee, S. Ultra-stable and tough bioinspired crack-based tactile sensor for small legged robots. NPJ Flex. Electron. 2023, 7, 22. [Google Scholar]

- Xin, Y.; Zhou, J.; Xu, X.; Lubineau, G. Laser-engraved carbon nanotube paper for instilling high sensitivity, high stretchability, and high linearity in strain sensors. Nanoscale 2017, 9, 10897–10905. [Google Scholar] [CrossRef]

- Li, Q.; Wang, K.; Gao, Y.; Tan, J.; Wu, R.; Xuan, F. Highly sensitive wearable strain sensor based on ultra-violet/ozone cracked carbon nanotube/elastomer. Appl. Phys. Lett. 2018, 112, 263501. [Google Scholar]

- Jin, Q.; Liu, Z.; Ouyang, X.; Liu, Y.; Wang, X. Superhydrophobic MXene-CNT Bridge Strain Sensors with Wide Linear-Range via Strain-isolation and Crack-synergy Effects. Chem. Eng. J. 2024, 488, 150796. [Google Scholar]

- Zhu, J.; Wu, X.; Jan, J.; Du, S.; Evans, J.; Arias, A.C. Tuning Strain Sensor Performance via Programmed Thin-Film Crack Evolution. ACS Appl. Mater. Interfaces 2021, 13, 38105–38113. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Yang, H.; Zong, Q.; Huang, Q.; Tan, C.; Gao, C.; Li, S.; Ye, H.; Zhang, G.; French, P. High-Performance Flexible Strain Sensor Fabricated Using Laser Transmission Pyrolysis. IEEE Sens. J. 2023, 24, 7521–7529. [Google Scholar] [CrossRef]

- Wang, W.; Lu, L.; Li, Z.; Lin, L.; Liang, Z.; Lu, X.; Xie, Y. Fingerprint-Inspired Strain Sensor with Balanced Sensitivity and Strain Range Using Laser-Induced Graphene. ACS Appl. Mater. Interfaces 2022, 14, 1315–1325. [Google Scholar] [CrossRef]

- Song, Z.; Li, Q.; Yan, Y.; Gao, Y.; Xuan, F. A mathematical model for predicting the electro-mechanical behavior of biomimetic crack sensors: Effect of crack depth and gap. J. Appl. Phys. 2024, 136, 194503. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, X.; Li, Y. The Role of Fracture Patterns on Crack-Based Strain Sensors. J. Eng. Mater. Technol. 2024, 146, 011004. [Google Scholar] [CrossRef]

- Jin, H.; Lu, W.-Y.; Cordill, M.; Schmidegg, K. In situ study of cracking and buckling of chromium films on PET substrates. Exp. Mech. 2011, 51, 219–227. [Google Scholar] [CrossRef]

- Huang, Y.; Xiang, Y.; Ren, W.; Li, F.; Li, C.; Yang, T. Enhancing the sensitivity of crack-based strain sensor assembled by functionalized graphene for human motion detection. Sci. China Technol. Sci. 2021, 64, 1805–1813. [Google Scholar] [CrossRef]

- Mahmoud, H.A.; Nesser, H.; Wagih, A.; Lubineau, G. Optimizing Fragmentation of Metallic Film for Cracked-Based Strain Sensor. ACS Appl. Electron. Mater. 2024, 6, 5359–5370. [Google Scholar]

- Park, J.; Kim, D.S.; Yoon, Y.; Shanmugasundaram, A.; Lee, D.W. Crack-Based Sensor by Using the UV Curable Polyurethane-Acrylate Coated Film with V-Groove Arrays. Micromachines 2022, 14, 62. [Google Scholar] [CrossRef]

- Song, Z.; Li, Q.; Yan, Y.; Gao, Y.; Xuan, F. A mathematical model for predicting the electro-mechanical behavior of crack-based flexible strain sensor. Appl. Phys. Lett. 2023, 123, 153501. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, Q.; Huang, G.; Li, G.; Wang, L.; Tian, Z.; Qin, Y.; Di, Z.; Mei, Y. Multifunctional nanocracks in silicon nanomembranes by notch-assisted transfer printing. ACS Appl. Mater. Interfaces 2018, 10, 25644–25651. [Google Scholar] [CrossRef]

- Yuan, H.; Liao, X.; Wu, K.; Chen, J.; Chen, K.; Zhu, T.; Wang, Y.; Zhang, J.; Liu, G.; Sun, J. Hierarchical Wrinkling-Cracking Architectures for Flexible Pressure Sensors. Adv. Mater. Interfaces 2023, 10, 2202169. [Google Scholar] [CrossRef]

- Choi, Y.W.; Kang, D.; Pikhitsa, P.V.; Lee, T.; Kim, S.M.; Lee, G.; Tahk, D.; Choi, M. Ultra-sensitive Pressure sensor based on guided straight mechanical cracks. Sci. Rep. 2017, 7, 40116. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Kim, D.; Yoon, J.; Joo, Y.; Hong, Y. Stamp-Perforation-Inspired Micronotch for Selectively Tearing Fiber-Bridged Carbon Nanotube Thin Films and Its Applications for Strain Classification. ACS Appl. Mater. Interfaces 2021, 13, 32307–32315. [Google Scholar] [CrossRef]

- Liu, Z.; Jin, Q.; Zhuang, C.; He, P.; Liu, Y.; Wang, X.; Ouyang, X. Three-dimensional cracks architectural design enhances the sensitivity and stretchability of superhydrophobic strain sensors. Compos. Part B Eng. 2025, 291, 111978. [Google Scholar] [CrossRef]

- Liu, L.; Niu, S.; Zhang, J.; Mu, Z.; Li, J.; Li, B.; Meng, X.; Zhang, C.; Wang, Y.; Hou, T.; et al. Bioinspired, Omnidirectional, and Hypersensitive Flexible Strain Sensors. Adv. Mater. 2022, 34, e2200823. [Google Scholar] [CrossRef]

- Liao, X.; Zhang, Z.; Kang, Z.; Gao, F.; Liao, Q.; Zhang, Y. Ultrasensitive and stretchable resistive strain sensors designed for wearable electronics. Mater. Horiz. 2017, 4, 502–510. [Google Scholar]

- Shin, S.; Ko, B.; So, H. Structural effects of 3D printing resolution on the gauge factor of microcrack-based strain gauges for health care monitoring. Microsyst. Nanoeng. 2022, 8, 12. [Google Scholar] [CrossRef]

- Ye, J.; Yang, T.; Zhang, Y.; Lin, L. Single-Crack-Activated Ultrasensitive Impedance Strain Sensor. Adv. Mater. Interfaces 2018, 5, 1800616. [Google Scholar] [CrossRef]

- Chu, Z.; Jiao, W.; Huang, Y.; Zheng, Y.; Wang, R.; He, X. Superhydrophobic gradient wrinkle strain sensor with ultra-high sensitivity and broad strain range for motion monitoring. J. Mater. Chem. A 2021, 9, 9634–9643. [Google Scholar] [CrossRef]

- Xue, P.; Chen, C.; Diao, D. Ultra-sensitive flexible strain sensor based on graphene nanocrystallite carbon film with wrinkle structures. Carbon 2019, 147, 227–235. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, D.; Lee, J.H.; Chen, H.; Kim, E.; Shen, X.; Zheng, Q.; Yang, J.; Kim, J.K. Anisotropic, Wrinkled, and Crack-Bridging Structure for Ultrasensitive, Highly Selective Multidirectional Strain Sensors. Nanomicro Lett. 2021, 13, 122. [Google Scholar] [CrossRef]

- Li, Z.-Y.; Zhai, W.; Yu, Y.-F.; Li, G.-J.; Zhan, P.-F.; Xu, J.-W.; Zheng, G.-Q.; Dai, K.; Liu, C.-T.; Shen, C.-Y. An ultrasensitive, durable and stretchable strain sensor with crack-wrinkle structure for human motion monitoring. Chin. J. Polym. Sci. 2021, 39, 316–326. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, H.; Chen, H.; Lee, J.-H.; Guo, F.; Shen, X.; Zheng, Q.; Kim, J.-K. Wrinkled, cracked and bridged carbon networks for highly sensitive and stretchable strain sensors. Compos. Part A Appl. Sci. Manuf. 2022, 163, 107221. [Google Scholar]

- Zou, Q.; Zheng, J.; Su, Q.; Wang, W.; Gao, W.; Ma, Z. A wave-inspired ultrastretchable strain sensor with predictable cracks. Sens. Actuators A Phys. 2019, 300, 111658. [Google Scholar]

- Guo, H.; Chu, Z.; Fu, L.; Lv, Y.; Liu, X.; Fan, X.; Zhang, W. Thickness-induced gradient micro-wrinkle PDMS/MXene/rGO wearable strain sensor with high sensitivity and stretchability for human motion detection. Chem. Eng. J. 2024, 495, 153684. [Google Scholar]

- Chao, M.; Wang, Y.; Ma, D.; Wu, X.; Zhang, W.; Zhang, L.; Wan, P. Wearable MXene nanocomposites-based strain sensor with tile-like stacked hierarchical microstructure for broad-range ultrasensitive sensing. Nano Energy 2020, 78, 105187. [Google Scholar] [CrossRef]

- Lei, D.; Zhang, H.; Liu, N.; Zhang, Q.; Su, T.; Wang, L.; Ren, Z.; Zhang, Z.; Su, J.; Gao, Y. Tensible and flexible high-sensitive spandex fiber strain sensor enhanced by carbon nanotubes/Ag nanoparticles. Nanotechnology 2021, 32, 505509. [Google Scholar]

- Lee, J.; Pyo, S.; Kwon, D.S.; Jo, E.; Kim, W.; Kim, J. Ultrasensitive Strain Sensor Based on Separation of Overlapped Carbon Nanotubes. Small 2019, 15, e1805120. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, Z.; Han, S.; Xu, L.; Araby, S.; Cai, R.; Zhao, Y.; Lu, S.; Liu, T. A facile approach to fabricate highly sensitive, flexible strain sensor based on elastomeric/graphene platelet composite film. J. Mater. Sci. 2019, 54, 10856–10870. [Google Scholar]

- Chen, S.; Liu, D.; Chen, W.; Chen, H.; Li, J.; Wang, J. Ultrasensitive and ultrastretchable metal crack strain sensor based on helical polydimethylsiloxane. Beilstein J. Nanotechnol. 2024, 15, 270–278. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Lee, J.; Jo, E.; Sim, S.; Kim, J. Patterned carbon nanotube bundles as stretchable strain sensors for human motion detection. ACS Appl. Nano Mater. 2020, 3, 11408–11415. [Google Scholar]

- Chen, S.; Wei, Y.; Wei, S.; Lin, Y.; Liu, L. Ultrasensitive Cracking-Assisted Strain Sensors Based on Silver Nanowires/Graphene Hybrid Particles. ACS Appl. Mater. Interfaces 2016, 8, 25563–25570. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Chen, J.; Li, Y.; Shi, G. High-Performance Strain Sensors with Fish-Scale-Like Graphene-Sensing Layers for Full-Range Detection of Human Motions. ACS Nano 2016, 10, 7901–7906. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, D.Y.; Pang, Y.; Li, Y.X.; Wang, Q.; Zhang, T.Y.; Wang, J.B.; Liu, X.; Yang, Y.Y.; Jian, J.M.; et al. Simultaneously Detecting Subtle and Intensive Human Motions Based on a Silver Nanoparticles Bridged Graphene Strain Sensor. ACS Appl. Mater. Interfaces 2018, 10, 3948–3954. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Sun, H.; Yue, X.; Yu, Y.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. A highly stretchable carbon nanotubes/thermoplastic polyurethane fiber-shaped strain sensor with porous structure for human motion monitoring. Compos. Sci. Technol. 2018, 168, 126–132. [Google Scholar]

- Li, Q.; Yin, R.; Zhang, D.; Liu, H.; Chen, X.; Zheng, Y.; Guo, Z.; Liu, C.; Shen, C. Flexible conductive MXene/cellulose nanocrystal coated nonwoven fabrics for tunable wearable strain/pressure sensors. J. Mater. Chem. A 2020, 8, 21131–21141. [Google Scholar] [CrossRef]

- Kang, F.; Zhang, W.; Liu, M.; Liu, F.; Jia, Z.; Jia, D. Highly flexible and sensitive Ti3C2 MXene@ polyurethane composites for piezoresistive pressure sensor. J. Mater. Sci. 2022, 57, 12894–12902. [Google Scholar]

- Qu, X.; Wu, Y.; Ji, P.; Wang, B.; Liang, Q.; Han, Z.; Li, J.; Wu, Z.; Chen, S.; Zhang, G.; et al. Crack-Based Core-Sheath Fiber Strain Sensors with an Ultralow Detection Limit and an Ultrawide Working Range. ACS Appl. Mater. Interfaces 2022, 14, 29167–29175. [Google Scholar] [CrossRef]

- Zhao, X.; Guo, H.; Ding, P.; Zhai, W.; Liu, C.; Shen, C.; Dai, K. Hollow-porous fiber-shaped strain sensor with multiple wrinkle-crack microstructure for strain visualization and wind monitoring. Nano Energy 2023, 108, 108197. [Google Scholar]

- Luo, L.; Jiang, J.; Ying, N.; Liang, B.; Chen, S.; Zeng, D.; Luo, S.; Zeng, D. High sensitivity and wide sensing range graphene flexible strain sensors based on pre-stretching and layer-by-layer self-assembly. Surf. Interfaces 2024, 49, 104385. [Google Scholar]

- Zhou, J.; Guo, P.; Cui, L.; Yan, C.; Xu, D.; Li, F.; Zhang, C.; Wang, A. Wrinkled and cracked amorphous carbon film for high-performance flexible strain sensors. Diam. Relat. Mater. 2023, 132, 109619. [Google Scholar]

- Ji, J.; Zhang, C.; Yang, S.; Liu, Y.; Wang, J.; Shi, Z. High Sensitivity and a Wide Sensing Range Flexible Strain Sensor Based on the V-Groove/Wrinkles Hierarchical Array. ACS Appl. Mater. Interfaces 2022, 14, 24059–24066. [Google Scholar] [CrossRef]

- Kim, B.C.; Matsuoka, T.; Moraes, C.; Huang, J.; Thouless, M.D.; Takayama, S. Guided fracture of films on soft substrates to create micro/nano-feature arrays with controlled periodicity. Sci. Rep. 2013, 3, 3027. [Google Scholar] [CrossRef]

- Kim, M.; Kim, D.-J.; Ha, D.; Kim, T. Cracking-assisted fabrication of nanoscale patterns for micro/nanotechnological applications. Nanoscale 2016, 8, 9461–9479. [Google Scholar]

- Kim, B.C.; Moraes, C.; Huang, J.; Matsuoka, T.; Thouless, M.; Takayama, S. Fracture-based fabrication of normally closed, adjustable, and fully reversible microscale fluidic channels. Small 2014, 10, 4020–4029. [Google Scholar] [PubMed]

- Ban, S.; Lee, H.; Chen, J.; Kim, H.-S.; Hu, Y.; Cho, S.J.; Yeo, W.-H. Recent Advances in Implantable Sensors and Electronics Using Printable Materials for Advanced Healthcare. Biosens. Bioelectron. 2024, 257, 116302. [Google Scholar]

- Xu, F.; Zhu, Y. Highly conductive and stretchable silver nanowire conductors. Adv. Mater. 2012, 24, 5117–5122. [Google Scholar] [CrossRef]

- Ryu, H.; Cho, S.J.; Kim, B.; Lim, G. A stretchable humidity sensor based on a wrinkled polyaniline nanostructure. RSC Adv. 2014, 4, 39767–39770. [Google Scholar]

- Zhang, X.; Li, Z.; Liu, C.; Shan, J.; Guo, X.; Zhao, X.; Ding, J.; Yang, H. High-performance fingerprint bionic Ecoflex@ AgNW/graphite/Pt hybrid strain sensor. J. Mater. 2024, 10, 7–16. [Google Scholar]

- Zhang, Y.; Xiao, Y.; Xu, Y.; Zhang, S.; Qu, C.; Liu, H.; Huang, K.; Shao, H. Wrinkle Clamp Down on Structure Crack Strain Sensor Based on High Poisson’s Ratio Material for Home Health Monitoring and Human–Machine Interaction. ACS Appl. Mater. Interfaces 2023, 15, 31729–31739. [Google Scholar] [PubMed]

- Ji, J.; Zhang, C.; Liang, Y.; Zhang, N.; Wang, J. Anisotropic v-groove/wrinkle hierarchical arrays for multidirectional strain sensors with high sensitivity and exceptional selectivity. ACS Appl. Mater. Interfaces 2024, 16, 29410–29420. [Google Scholar] [PubMed]

- Jung, H.; Park, C.; Lee, H.; Hong, S.; Kim, H.; Cho, S.J. Nano-Cracked Strain Sensor with High Sensitivity and Linearity by Controlling the Crack Arrangement. Sensors 2019, 19, 2834. [Google Scholar] [CrossRef]

- Tian, H.; Shu, Y.; Cui, Y.-L.; Mi, W.-T.; Yang, Y.; Xie, D.; Ren, T.-L. Scalable fabrication of high-performance and flexible graphene strain sensors. Nanoscale 2014, 6, 699–705. [Google Scholar]

- Wang, D.-Y.; Tao, L.-Q.; Liu, Y.; Zhang, T.-Y.; Pang, Y.; Wang, Q.; Jiang, S.; Yang, Y.; Ren, T.-L. High performance flexible strain sensor based on self-locked overlapping graphene sheets. Nanoscale 2016, 8, 20090–20095. [Google Scholar] [PubMed]

- Cui, X.; Xie, H.; Jiang, Y.; Xu, Z.; Sui, G.; Yang, X. Porous structure induced crack redistribution in surface conductive layer for high-performance fiber-based flexible strain and pressure sensors. Polym. Adv. Technol. 2023, 34, 3011–3021. [Google Scholar]

- Chen, H.; Zhou, J.; Long, X.; Zhuo, F.; Liu, Y.; Zhao, Y.; Xie, J.; Duan, H.; Fu, Y. Fibrous mats based skin sensor with ultra-sensitivity and anti-overshooting dynamic stability enhanced with artificial intelligence. Chem. Eng. J. 2023, 473, 145054. [Google Scholar]

- Zhao, B.; Li, X.; Gu, C.; Wang, Y.; Liu, H.; Guo, X.; Zhang, Y.; Tian, H.; Qin, W.; Yin, S. Highly stretchable and strain sensitive MXene/MXene: MWCNTs@ TPU fiber with hierarchical conductive layers and porous elastic core structure. Colloids Surf. A Physicochem. Eng. Asp. 2024, 690, 133821. [Google Scholar]

- Wu, Y.H.; Liu, H.Z.; Chen, S.; Dong, X.C.; Wang, P.P.; Liu, S.Q.; Lin, Y.; Wei, Y.; Liu, L. Channel Crack-Designed Gold@PU Sponge for Highly Elastic Piezoresistive Sensor with Excellent Detectability. ACS Appl. Mater. Interfaces 2017, 9, 20098–20105. [Google Scholar] [CrossRef]

- Xu, B.; Ye, F.; Chen, R.; Luo, X.; Chang, G.; Li, R. A wide sensing range and high sensitivity flexible strain sensor based on carbon nanotubes and MXene. Ceram. Int. 2022, 48, 10220–10226. [Google Scholar]

- He, J.; Zou, X.; Wang, W.; Chen, M.; Jiang, S.; Cui, C.; Tang, H.; Yang, L.; Guo, R. Highly stretchable, highly sensitive, and antibacterial electrospun nanofiber strain sensors with low detection limit and stable CNT/MXene/CNT sandwich conductive layers for human motion detection. Ind. Eng. Chem. Res. 2023, 62, 8327–8338. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, J.; Huang, Z.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Flexible electrically resistive-type strain sensors based on reduced graphene oxide-decorated electrospun polymer fibrous mats for human motion monitoring. Carbon 2018, 126, 360–371. [Google Scholar] [CrossRef]

- Jia, Y.; Yue, X.; Wang, Y.; Yan, C.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Multifunctional stretchable strain sensor based on polydopamine/reduced graphene oxide/electrospun thermoplastic polyurethane fibrous mats for human motion detection and environment monitoring. Compos. Part B Eng. 2020, 183, 107696. [Google Scholar] [CrossRef]

- Han, T.; Reneker, D.H.; Yarin, A.L. Buckling of jets in electrospinning. Polymer 2007, 48, 6064–6076. [Google Scholar] [CrossRef]

- Kim, H.; Hong, S.K.; Lee, H.; Jeong, Y.; Cho, S.J. A reusable nanofibrous air filter with anti-wetting microbead coating. J. Clean. Prod. 2023, 382, 134972. [Google Scholar] [CrossRef]

- Jeon, H.; Hong, S.K.; Cho, S.J.; Lim, G. Fabrication of a highly sensitive stretchable strain sensor utilizing a microfibrous membrane and a cracking structure on conducting polymer. Macromol. Mater. Eng. 2018, 303, 1700389. [Google Scholar]

- Sun, H.; Fang, X.; Fang, Z.; Zhao, L.; Tian, B.; Verma, P.; Maeda, R.; Jiang, Z. An ultrasensitive and stretchable strain sensor based on a microcrack structure for motion monitoring. Microsyst. Nanoeng. 2022, 8, 111. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, R.; Li, D.; Zhang, L.; Ren, G.; Wang, L.; Liu, J.; Wang, D.; Tang, Z.; Lu, G. High-performance foam-shaped strain sensor based on carbon nanotubes and Ti3C2T x MXene for the monitoring of human activities. ACS Nano 2021, 15, 9690–9700. [Google Scholar] [CrossRef]

- Xia, Q.; Wang, S.; Zhai, W.; Shao, C.; Xu, L.; Yan, D.; Yang, N.; Dai, K.; Liu, C.; Shen, C. Highly linear and low hysteresis porous strain sensor for wearable electronic skins. Compos. Commun. 2021, 26, 100809. [Google Scholar] [CrossRef]

- Pang, K.; Song, X.; Xu, Z.; Liu, X.; Liu, Y.; Zhong, L.; Peng, Y.; Wang, J.; Zhou, J.; Meng, F. Hydroplastic foaming of graphene aerogels and artificially intelligent tactile sensors. Sci. Adv. 2020, 6, eabd4045. [Google Scholar] [CrossRef]

- Zheng, S.; Wu, X.; Huang, Y.; Xu, Z.; Yang, W.; Liu, Z.; Huang, S.; Xie, B.; Yang, M. Highly sensitive and multifunctional piezoresistive sensor based on polyaniline foam for wearable Human-Activity monitoring. Compos. Part A Appl. Sci. Manuf. 2019, 121, 510–516. [Google Scholar]

- Cui, X.; Miao, C.; Lu, S.; Liu, X.; Yang, Y.; Sun, J. Strain Sensors Made of MXene, CNTs, and TPU/PSF Asymmetric Structure Films with Large Tensile Recovery and Applied in Human Health Monitoring. ACS Appl. Mater. Interfaces 2023, 15, 59655–59670. [Google Scholar]

- Gu, C.; Qin, W.; Wang, Y.; Li, X.; Wang, J.; Tian, Z.; Yang, M.; Qiao, H.; Wu, Y.; Yin, S. Highly stretchable, durable, and superfine fiber-shaped strain sensor with a porous core-sheath microstructure. Compos. Commun. 2022, 36, 101381. [Google Scholar]

- Yen, Y.-H.; Hsu, C.-S.; Lei, Z.-Y.; Wang, H.-J.; Su, C.-Y.; Dai, C.-L.; Tsai, Y.-C. Laser-induced graphene stretchable strain sensor with vertical and parallel patterns. Micromachines 2022, 13, 1220. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Chen, Q.; Huang, Y.; Wang, D.; Li, L.; Liu, Z. In situ laser synthesis of Pt nanoparticles embedded in graphene films for wearable strain sensors with ultra-high sensitivity and stability. Carbon 2022, 190, 245–254. [Google Scholar]

- Yang, J.; Wu, S.; Yu, J.; Deng, Y.; Qiao, F.; Zhang, K. Flexible micro-strain graphene sensors enhanced by laser-induced cracks for health monitoring. Diam. Relat. Mater. 2024, 148, 111401. [Google Scholar]

- Shrestha, S.; Barvenik, K.J.; Chen, T.; Yang, H.; Li, Y.; Kesavan, M.M.; Little, J.M.; Whitley, H.C.; Teng, Z.; Luo, Y. Machine intelligence accelerated design of conductive MXene aerogels with programmable properties. Nat. Commun. 2024, 15, 4685. [Google Scholar]

- Yan, Y.; Wang, C.; He, Y.; Zhao, Q.; Huang, J.; Ran, L.; Liu, X.; Li, Y.; Li, L. A Highly Sensitive and Stretchable Strain Sensor Based on Nested Wrinkle Microstructures. J. Electron. Mater. 2025, 54, 1739–1747. [Google Scholar] [CrossRef]

- Tang, C.; Xu, M.; Yi, W.; Zhang, Z.; Occhipinti, E.; Dong, C.; Ravenscroft, D.; Jung, S.-M.; Lee, S.; Gao, S. Ultrasensitive textile strain sensors redefine wearable silent speech interfaces with high machine learning efficiency. NPJ Flex. Electron. 2024, 8, 27. [Google Scholar]

- Li, J.; Dai, Q.; Wang, Z.; Yi, Y.; Shen, Y.; Yao, Z.; Niu, S.; Han, Z.; Ren, L. Highly Robust and Self-Adhesive Soft Strain Gauge via Interface Design Engineering. Adv. Mater. 2024, 36, e2406432. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, Z.; Zhang, C.; Song, H.; Ding, H.; Li, B.; Niu, S.; Huang, X.; Chen, C.; Han, Z.; et al. A Selective-Response Hypersensitive Bio-Inspired Strain Sensor Enabled by Hysteresis Effect and Parallel Through-Slits Structures. Nanomicro Lett. 2023, 16, 26. [Google Scholar] [CrossRef] [PubMed]

- Sheng, W.; Bi, X.; Huang, Z.; Tang, L.; Sun, H.; Cao, Z.; Jiang, C. Controllable fabrication of metal microcracks on rubber by mesh-like polymer mediated electroless plating for ultrasensitive and wide-range strain sensors. Surf. Interfaces 2025, 58, 105882. [Google Scholar] [CrossRef]

- Wang, J.; Chang, X.; Gao, Y.; Wang, Y.; Wu, H.; Dong, S.; Wang, H. Trace Polymer-Bonded carbon nanotube networks for precise strain sensing in healthcare. Chem. Eng. J. 2025, 508, 161142. [Google Scholar] [CrossRef]

- Lin, K.; Gou, X.; Luo, W.; Li, P.; Zhang, C.; Lang, S.; Xie, Y.; Chang, A.; Zhao, P.; Yang, J. Island-bridge microcracks with nanofiber and carbon nanotube composites for high-performance flexible strain sensors. Compos. Part B Eng. 2025, 298, 112366. [Google Scholar] [CrossRef]

- Yang, C.; Huang, W.; Lin, Y.; Cao, S.; Wang, H.; Sun, Y.; Fang, T.; Wang, M.; Kong, D. Stretchable MXene/Carbon Nanotube Bilayer Strain Sensors with Tunable Sensitivity and Working Ranges. ACS Appl. Mater. Interfaces 2024, 16, 30274–30283. [Google Scholar] [CrossRef]

- Xu, L.; Xun, X.; Gao, F.; Fan, L.; Zhao, S.; Ren, K.; Liao, X.; Ban, X.; Wu, N.; Zhao, X.; et al. Quasi-Homogeneous Integrated Strain Vector Sensors for Natural Human–Machine Interaction. Adv. Funct. Mater. 2025, 202425212. [Google Scholar] [CrossRef]

- Zhou, W.; Du, Y.; Chen, Y.; Zhang, C.; Ning, X.; Xie, H.; Wu, T.; Hu, J.; Qu, J. Bioinspired Ultrasensitive Flexible Strain Sensors for Real-Time Wireless Detection of Liquid Leakage. Nanomicro Lett. 2024, 17, 68. [Google Scholar] [CrossRef]

- Wang, Q.; Tong, J.; Wang, N.; Chen, S.; Sheng, B. Humidity sensor of tunnel-cracked nickel@polyurethane sponge for respiratory and perspiration sensing. Sens. Actuators B Chem. 2021, 330, 129322. [Google Scholar] [CrossRef]

- Tong, J.; Wang, N.; Wang, Q.; Chen, S.; Sheng, B. Improved sensitive conductive sponge sensors with tunnel-crack broadening for pressure, humidity and temperature sensing applications. Sens. Actuators B Chem. 2022, 358, 131497. [Google Scholar] [CrossRef]

- Yu, Y.; Peng, S.; Blanloeuil, P.; Wu, S.; Wang, C.H. Wearable Temperature Sensors with Enhanced Sensitivity by Engineering Microcrack Morphology in PEDOT:PSS-PDMS Sensors. ACS Appl. Mater. Interfaces 2020, 12, 36578–36588. [Google Scholar] [CrossRef]

- Liu, H.; Sun, K.; Guo, X.L.; Liu, Z.L.; Wang, Y.H.; Yang, Y.; Yu, D.; Li, Y.T.; Ren, T.L. An Ultrahigh Linear Sensitive Temperature Sensor Based on PANI:Graphene and PDMS Hybrid with Negative Temperature Compensation. ACS Nano 2022, 16, 21527–21535. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Tang, H.; Wang, L.; Zong, Y.; Jia, J.; Sun, L.; Niu, K. Temperature-insensitive stretchable conductors based on hierarchical double-layer graphene foams/PEDOT:PSS networks. Compos. Sci. Technol. 2023, 242, 110190. [Google Scholar] [CrossRef]

- Wu, C.; Lin, F.; Pan, X.; Zeng, Y.; Chen, G.; Xu, L.; He, Y.; He, G.; Chen, Q.; Sun, D.; et al. Temperature-insensitive conductive composites for noninterference strain sensing. Chem. Eng. J. 2023, 457, 141269. [Google Scholar] [CrossRef]

- Maharjan, S.; Samoei, V.K.; Amili, O.; Sano, K.; Honma, H.; Jayatissa, A.H. Design and Fabrication of a Graphene/Polyvinylidene Fluoride Nanocomposite-Based Airflow Sensor. ACS Omega 2022, 7, 7981–7988. [Google Scholar] [CrossRef] [PubMed]

- Moshizi, S.A.; Abedi, A.; Pastras, C.J.; Peng, S.; Wu, S.; Sanaeepur, M.; Asadnia, M. Carbon nanofiber-reinforced Pt thin film-based airflow sensor for respiratory monitoring. Sens. Actuators A Phys. 2022, 347, 113969. [Google Scholar] [CrossRef]

- Hong, S.K.; Yang, S.; Cho, S.J.; Jeon, H.; Lim, G. Development of a Waterproof Crack-Based Stretchable Strain Sensor Based on PDMS Shielding. Sensors 2018, 18, 1171. [Google Scholar] [CrossRef]

- Nguyen, T.; Chu, M.; Tu, R.; Khine, M. The Effect of Encapsulation on Crack-Based Wrinkled Thin Film Soft Strain Sensors. Materials 2021, 14, 364. [Google Scholar] [CrossRef]

- Li, B.; Luo, J.; Huang, X.; Lin, L.; Wang, L.; Hu, M.; Tang, L.; Xue, H.; Gao, J.; Mai, Y.-W. A highly stretchable, super-hydrophobic strain sensor based on polydopamine and graphene reinforced nanofiber composite for human motion monitoring. Compos. Part B Eng. 2020, 181, 107580. [Google Scholar] [CrossRef]

- Liu, L.; Jiao, Z.; Zhang, J.; Wang, Y.; Zhang, C.; Meng, X.; Jiang, X.; Niu, S.; Han, Z.; Ren, L. Bioinspired, Superhydrophobic, and Paper-Based Strain Sensors for Wearable and Underwater Applications. ACS Appl. Mater. Interfaces 2021, 13, 1967–1978. [Google Scholar] [CrossRef]

- Gao, W.C.; Wu, W.; Chen, C.Z.; Zhao, H.; Liu, Y.; Li, Q.; Huang, C.X.; Hu, G.H.; Wang, S.F.; Shi, D.; et al. Design of a Superhydrophobic Strain Sensor with a Multilayer Structure for Human Motion Monitoring. ACS Appl. Mater. Interfaces 2022, 14, 1874–1884. [Google Scholar] [CrossRef]

- Tung, S.T.; Glisic, B. Sensing sheet: The response of full-bridge strain sensors to thermal variations for detecting and characterizing cracks. Meas. Sci. Technol. 2016, 27, 124010. [Google Scholar] [CrossRef]

- Mu, G.; Zhang, Y.; Yan, Z.; Yu, Q.; Wang, Q. Recent advancements in wearable sensors: Integration with machine learning for human-machine interaction. RSC Adv. 2025, 15, 7844–7854. [Google Scholar] [CrossRef]

- Kim, M.; Kim, T. Crack-photolithography for membrane-free diffusion-based micro/nanofluidic devices. Anal. Chem. 2015, 87, 11215–11223. [Google Scholar] [PubMed]

- Liang, H.-L.; Bay, M.M.; Vadrucci, R.; Barty-King, C.H.; Peng, J.; Baumberg, J.J.; De Volder, M.F.; Vignolini, S. Roll-to-roll fabrication of touch-responsive cellulose photonic laminates. Nat. Commun. 2018, 9, 4632. [Google Scholar] [PubMed]

- Chen, X.; Hou, Z.; Li, G.; Yu, W.; Xue, Y.; Niu, G.; Xin, M.; Yang, L.; Meng, C.; Guo, S. A laser-scribed wearable strain sensing system powered by an integrated rechargeable thin-film zinc-air battery for a long-time continuous healthcare monitoring. Nano Energy 2022, 101, 107606. [Google Scholar]

- Park, J.; Nam, D.; Park, S.; Lee, D. Fabrication of flexible strain sensors via roll-to-roll gravure printing of silver ink. Smart Mater. Struct. 2018, 27, 085014. [Google Scholar]

- Wang, R.; Zhu, X.; Sun, L.; Shang, S.; Li, H.; Ge, W.; Lan, H. Cost-effective fabrication of transparent strain sensors via micro-scale 3D printing and imprinting. Nanomaterials 2021, 12, 120. [Google Scholar] [CrossRef]

- Zhang, A.; Maly, J.; Ameri, S.K. Hetero phase nanocomposite based posture sensor with stretchable connector-sensor interface. Sens. Actuators A Phys. 2024, 378, 115811. [Google Scholar]

- Liu, Y.; Li, H.; Zhang, M. Wireless battery-free broad-band sensor for wearable multiple physiological measurement. ACS Appl. Electron. Mater. 2021, 3, 1681–1690. [Google Scholar]

- Kwon, K.Y.; Shin, Y.J.; Shin, J.H.; Jeong, C.; Jung, Y.H.; Park, B.; Kim, T.i. Stretchable, patch-type calorie-expenditure measurement device based on pop-up shaped nanoscale crack-based sensor. Adv. Healthc. Mater. 2019, 8, 1801593. [Google Scholar]

- Xu, Z.; Xiao, W.; Deng, K.; Zhang, Y.; Shen, T.; Liu, X.; Ding, Z.; Tan, Q.; Wu, D. Hierarchical Crack Engineering-Enabled High-Linearity and Ultrasensitive Strain Sensors. ACS Sens. 2025, 1–29. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, C.; Lee, H.; Park, C.; Lee, B.; Kim, J.; Park, C.; Lai, C.H.; Cho, S.J. Advances in Crack-Based Strain Sensors on Stretchable Polymeric Substrates: Crack Mechanisms, Geometrical Factors, and Functional Structures. Polymers 2025, 17, 941. https://doi.org/10.3390/polym17070941

Song C, Lee H, Park C, Lee B, Kim J, Park C, Lai CH, Cho SJ. Advances in Crack-Based Strain Sensors on Stretchable Polymeric Substrates: Crack Mechanisms, Geometrical Factors, and Functional Structures. Polymers. 2025; 17(7):941. https://doi.org/10.3390/polym17070941

Chicago/Turabian StyleSong, Chiwon, Haran Lee, Chan Park, Byeongjun Lee, Jungmin Kim, Cheoljeong Park, Chi Hung Lai, and Seong J. Cho. 2025. "Advances in Crack-Based Strain Sensors on Stretchable Polymeric Substrates: Crack Mechanisms, Geometrical Factors, and Functional Structures" Polymers 17, no. 7: 941. https://doi.org/10.3390/polym17070941

APA StyleSong, C., Lee, H., Park, C., Lee, B., Kim, J., Park, C., Lai, C. H., & Cho, S. J. (2025). Advances in Crack-Based Strain Sensors on Stretchable Polymeric Substrates: Crack Mechanisms, Geometrical Factors, and Functional Structures. Polymers, 17(7), 941. https://doi.org/10.3390/polym17070941