Abstract

The increased interest in artificial intelligence in manufacturing has driven the adoption of machine learning to optimize processes and improve efficiency. A key challenge in injection molding is the variability of recycled materials, which affects part quality and processing stability. This study presents a novel closed-loop process control approach for injection molding, leveraging machine learning to adaptively predict processing inputs and quality outcomes. The methodology was tested on five blends of recycled polypropylene (rPP), using artificial neural networks (ANNs), linear regression, and polynomial regression to model the relationships between material properties and process parameters. The dataset was split 80/20 into training and testing sets. The ANN model was implemented using TensorFlow and Keras, with six hidden layers of 32 neurons per layer, ReLU activation, and an Adam optimizer. Empirical tuning and early stopping were used to optimize performance and prevent overfitting. Predictions were evaluated based on mean absolute error (MAE), mean squared error (MSE), and percentage error. The results showed that yield stress, ultimate elongation, and part weight were accurately predicted within a 5% error for linear and polynomial regression models and within a 10% error for the ANN. However, modulus predictions were less reliable, with errors of ~11% for ANN and linear regression and ~40% for polynomial regression, reflecting the inherent variability of this property in rPP blends. Predictions of processing inputs had errors ranging from 3% to 25%, depending on the model and response variable. No single modeling approach was consistently superior across all responses, highlighting the complexity of the relationship between material properties, process parameters, and quality metrics. Overall, the work demonstrates that closed-loop process control, powered by machine learning, can effectively predict key quality parameters in injection molding of recycled materials. The proposed approach can improve process stability and material utilization, facilitating increased adoption of sustainable materials.

1. Introduction

The rise of Industry 4.0 has led to increased technological advancements throughout most manufacturing industries. Injection molding is the largest plastics manufacturing industry in the world, with a total market size of 261.8 billion in 2021 [1], and it has been heavily influenced by this technological uprising [1]. This has increased production efficiency by reducing scrap rates, reducing material consumption, and minimizing cycle times. In this context, the use of machine and mold sensors [2], as well as machine learning, offer opportunities for advanced process control strategies [3,4].

Ensuring product quality while minimizing the cost of injection molded parts has been an area of focus in the industry since its inception. However, current practices involve the setting of processing variables by process engineers. The influence of these process settings on overall product quality has been researched extensively, and therefore, the overall product quality is heavily influenced by the expertise of the process engineer [5,6]. Hence, current research has focused on reducing reliance on processing expertise [7]. A tool often used for process optimization is multivariate regression analysis, as regression is an effective statistical method for determining a relationship between multiple dependent and independent variables [8]. Multivariate regression models are often used in injection molding to predict the significance of processing factors on part quality metrics (dimensional stability, weight) [9,10] and part performance metrics (mechanical properties) [11,12]. Regression modeling involves selecting one or more independent variables that will influence the response of one dependent variable. Statistical analysis is then performed to estimate the coefficients of each independent variable, resulting in the lowest error. The fit of the regression model is then validated, and the model fit is evaluated most commonly by the coefficient of determination (R2) value. The results of the model are an equation that takes the following form [13]:

where β0 is the intercept, β1, β3, and βn are the coefficients for each independent variable (X1, X2, X3, Xn), Y is the dependent variable, and is the error. The ease of application and ease of interpretation are key advantages of this method, as the coefficients attached to each predictor show how each predictor influences the final predicted response [13]. The main drawback of using linear regression modeling is that it attempts to find linear relationships between dependent and independent variables, whereas, in injection molding, the relationships are often complex and not linear [14,15]. To combat this drawback, additional regression models were evaluated, including a polynomial regression model, as follows [13]:

where the variables are the same as those in linear regression, except that the independent variable is raised to the nth degree. The polynomial regression extends linear regression by introducing polynomial terms of independent variables, making the model nonlinear in terms of relationships but still linear in its parameters.

The quick rise of artificial intelligence in all aspects of industry has led to increased focus and use of these technologies as an opportunity for increased efficiency and process improvement [7]. As a result of this rise, the use of different machine learning algorithms within the plastics industry has drawn significant interest. Additionally, it has been combined with other technologies, such as simulations, to predict the quality of injection molded parts [7]. Research has been conducted on training ANN to predict resulting weight and warpage from different combinations of processing settings and part geometry [16,17]. Other research involving ANN has shown its efficacy in predicting various materials’ mechanical properties [18,19]. Moreover, research has been performed to determine the optimal prediction model by comparing multivariate regression modeling and ANNs [20]. The results showed that ANNs effectively captured nonlinear relationships, though performance varied across different quality metrics and in some cases, regression models performed comparably or better [21]. Table 1 highlights recent research papers. It can be observed that most research has focused on virgin resins, as well as using part weight and dimensional stability as the main quality parameters. Different machine learning algorithms, such as ANN, multivariate regression, and transfer learning, have been used to improve processing consistency, minimize startup time, maximize efficiency, and improve product quality.

Table 1.

Previous research work reported on the use of machine learning in injection molding.

Research conducted on ANNs has proved to be an effective way of reducing the amount of trial and error when establishing a process and reducing the reliance on human expertise. Indeed, ANNs do not require explicit programming for their creation and can take data and use training and learning to create a model, thus reducing the setup time and increasing efficiency [22]. ANNs work well with plastic injection molding due to the neural network’s capability to model non-linear behavior, encompassing the process and its relationship with different processing parameters. A basic ANN uses computing cells (i.e., neurons) that receive inputs; each of these is multiplied by a given weight, which determines the importance of that specific input in relation to the neuron. Additionally, an adder is used to sum all the input signals with their respective weights, as well as a bias to produce an output. An activation function is used to introduce nonlinearity to limit the range of the output signal to a finite value [23]. An ANN can predict parameters from a set of inputs through training. During training, backpropagation is used to compute the gradient of the error with respect to the network’s weights, which are then adjusted by an optimization algorithm to minimize the error. This process continues iteratively until a stopping criterion is met, improving the ANN’s ability to generalize to hold-out data [24]. Proper training and setting up of the ANN are crucial for accuracy. Overfitting (memorizing noise rather than learning patterns) and underfitting (failing to capture relevant patterns) can lead to inaccuracies. Additionally, hyper-parameter tuning is important as using the correct activation function, number of hidden layers, etc., is crucial to achieving accurate predictions and preventing overfitting [25].

Alongside the technological growth in the injection molding sector, there is a push for sustainable business practices, with particular emphasis on reduced energy consumption and the push for recycled materials [26,27]. The rise in recycled material usage has led to an increased reliance on appropriate process control methodologies to combat the inherent variability of these materials. This variation arises due to a permanent breakdown of the molecular structure, which decreases molecular weight and leads to a broader molecular weight distribution [15]. Machine learning models can be used to tackle the compositional variation in recycled materials at the process control level to maximize consistency [28]. Currently, most process control strategies focus on regression analysis; hence, the introduction of machine learning models represents an opportunity for further development [29].

In this work, a process control methodology was developed for a process that automatically adjusts in response to recycled material processing variability. Different data modeling approaches are evaluated for the closed-loop process control in injection molding. The methodology involves comparing the predictive performance of an ANN, linear regression analysis, and polynomial regression analysis. The models predict key injection molding processing inputs based on different quality response variables, including tensile properties and part weight. The work focuses on recycled polypropylene (rPP), which is one of the most commonly recycled and available thermoplastic resins.

2. Materials and Methods

2.1. Process Control Approach

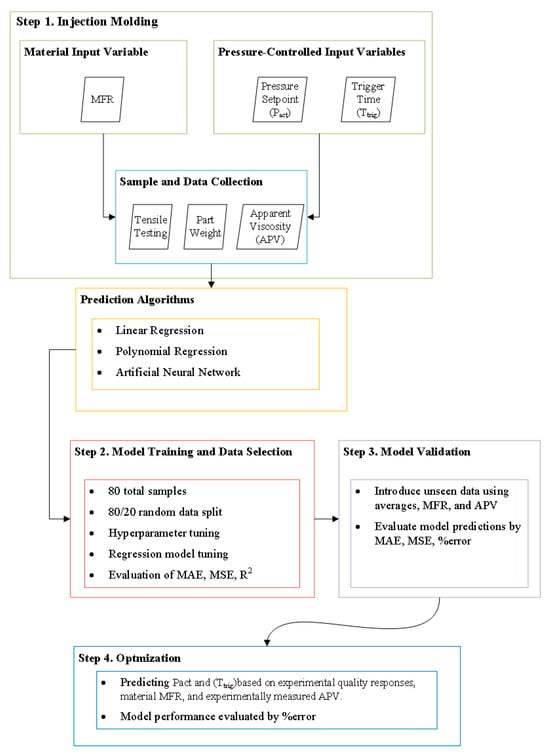

Most research on machine learning in injection molding focuses on training and validating models to predict quality metrics (most frequently weight and dimensions) from combinations of process parameters (e.g., temperature, injection velocity, packing, etc.). This work focuses on the correlation between process inputs, in-mold sensing data, and quality metrics. The goal is to develop process control strategies for recycled plastics to adjust the process from melt pressure. The methodology designed in this work follows four main steps (cf. Figure 1):

Figure 1.

Flow chart depicting the methodology followed in this work.

- Data collection from injection molding experiments and testing of the experiment specimens;

- Model setup, hyperparameter tuning, and training of each of the prediction models;

- Model validation is conducted by introducing hold-out data and evaluating each model’s ability to predict quality responses;

- Process optimization to predict the processing parameters associated with each quality response input;

- All machine learning algorithms were coded using Python version 3.10.12, with Scikit-learn version 1.3.2 used for the implementation of regression models.

2.2. Model Training and Validation

For each method, the data were split into 3 categories: training data, testing data, and data for validation. The training and testing data comprise 80% of the samples collected (80 samples, 4 different MFRs) and further split the data into 80% for training (64 samples) and 20% (16 samples) for testing. This 80/20 split follows standard machine learning practices, ensuring sufficient training data (64 samples) for robust learning while retaining an adequately sized test set (16 samples) to evaluate model performance on unseen data. Additionally, a separate validation set of 20 samples was reserved to assess model effectiveness on completely unseen material variations, further ensuring generalization. The last 20% of the data is used to measure the model’s effectiveness and comprises a combination of inputs and responses that the model has not seen before. The data were introduced into the model in two ways. The first uses the MFR values of the material, which were tested for each material lot. The second is the apparent viscosity values calculated using pressure curves and in-mold sensors for each cycle.

The first step (Step 1, Figure 1) was collecting and testing the injection-molded parts. As Step 2 (cf. Figure 1) shows, the collected data were split randomly into an 80/20 split for the model creation and training. Following the training, the models were evaluated by measuring the mean absolute error (MAE), mean squared error (MSE), and R2 values using the following equations:

where yi represents the experimental or observed value and represents the predicted value. MSE was chosen as a primary metric to penalize larger errors, while MAE was used to provide an intuitive measure of average deviation.

The trained machine learning models were then validated (Step 3, Figure 1) by evaluating their effectiveness at predicting part quality parameters (yield stress, modulus, ultimate elongation, and part weight) using hold-out data (material MFR, apparent viscosities, trigger times, and pressures) from a pressure-controlled injection molding process, as seen in step three of the flow chart. This step was crucial to determining the best material viscosity parameter (i.e., MFR or APV). When using MFR, the model did not consider the shot-to-shot variation. In contrast, when using the APV, the model measures the material flow for each cycle. The accuracy of the predicted quality response determined the model’s effectiveness compared to the actual experimental value during the validation step and the minimization of the MAE and MSE values.

Once the model was validated, the optimization component was introduced (Step 4, Figure 1). The objective of the optimization was that of predicting process parameters for a P-Control molding process (pressures, trigger time) when using an rPP of different viscosity while having specific quality parameters as a target (i.e., yield stress, modulus, ultimate elongation, part weight). The upper and lower limits of the variable inputs, Pact and ttrig, were taken as the maximum and minimum values of the 80 samples used to train the model. Additionally, the step size for the Pset variable was 5 bar (58 total Pact values ranging from 335 bar to 625 bar), and the step size for ttrig was 0.1 s (10 total ttrig values ranging from 2 s to 3 s) for a total of 638 combinations. Then, for a specific material MFR or APV and a selected quality parameter, the model computes all possibilities and produces a combination of Pact and ttrig, resulting in the lowest error. The predicted values were compared to values obtained experimentally to validate the model’s effectiveness.

2.3. Data Collection

The injection molding experiments were performed using two recycled polypropylenes with varying melt flow rates and three different blends of the same grades. The base materials were a non-woven PP (Green Isoplen Y900R, SER North America, Anderson, IN, USA) and a clear recycled BOPP (Green Isoplen C200R, SER North America, Anderson, IN, USA). More information about the materials is provided in previous research from the authors [30]. Table 2 shows the melt flow rate for each material. The injection molding experiments were performed on a fully electric 130-ton machine (Milacron-FANUC Roboshot α-S130iB, Cincinnati, OH, USA). The mold used for the experiments was a two-plate cold runner mold with a 2 mm thick spiral flow cavity. The mold was instrumented with three 2.5 mm direct pressure transducers (Kistler 6182B, Winterthur, Switzerland) flush mounted along the flow path. Additionally, a data acquisition unit integrated within the injection molding machine was used to monitor the sensor signals with a time step of 0.001 s after triggering from the screw forward movement.

Table 2.

Selected material blends and their melt flow rates.

The experiments were performed using a pressure-controlled (P-Ctrl) injection molding strategy provided by iMFLUX, Inc. (P&G, Cincinnati, OH, USA) [31,32]. Previous work from the authors has shown that pressure-controlled injection molding is a viable alternative to conventional velocity-controlled injection molding. The authors reported improved tensile parameters, reduced overall molding pressures, and decreased energy consumption [33]. The functionality of the P-Ctrl system and the injection molding experiments used as the base for this work are explained in greater detail in other works by the authors [30].

The combination of experimental runs used for the training and validation of the models can be found in Table 3. The ttrig relates to the activation of P-Ctrl’s AV feature, a trigger time of 2 s signifies that the melt must reach the target location in the cavity at 2 s, and therefore the pressure setpoint will be adjusted to reach that location at the given time. That adjusted pressure setpoint is known as Pact and is a deviation from the pressure setpoint chosen during the process setup. Table 4 shows the 20 samples used for the validation and optimization problem. These samples were fabricated using the material with an MFR of 14. This material was selected for prediction and optimization as it lay in the middle of the MFR range and would allow the machine learning algorithm to train with data surrounding it. The main difference in these 20 samples is that the first run had a faster melt front velocity due to the shorter trigger time, Trig2. In contrast, the second run had a slower melt front velocity due to a longer trigger time, Trig3, which resulted in different APV values.

Table 3.

Complete list of runs for training models.

Table 4.

DoE runs used for validation.

2.4. Multivariate Regression Model

Two multivariate regression models were created using the Scikit learn library in Python [34]. The first model is a linear regression model and the second one is a polynomial regression model, ranging from second to fourth degrees. For both models, the data were split as stated in step 2. For the polynomial regression model, Grid Search with 5-fold cross-validation was used to determine the optimal degree. A pipeline of polynomial feature transformation followed by linear regression was implemented, and a linear regression model was trained for each degree. The mean validation score was calculated using the R2 score, and the degree with the highest validation score was selected to balance model complexity and prediction accuracy. Following this, the coefficients for each independent variable were obtained and the model performance was assessed using R2, MSE, and MAE. The remaining 20 samples were kept separately, were arithmetically averaged based on their inputs, and were implemented similarly to the ANN for both approaches.

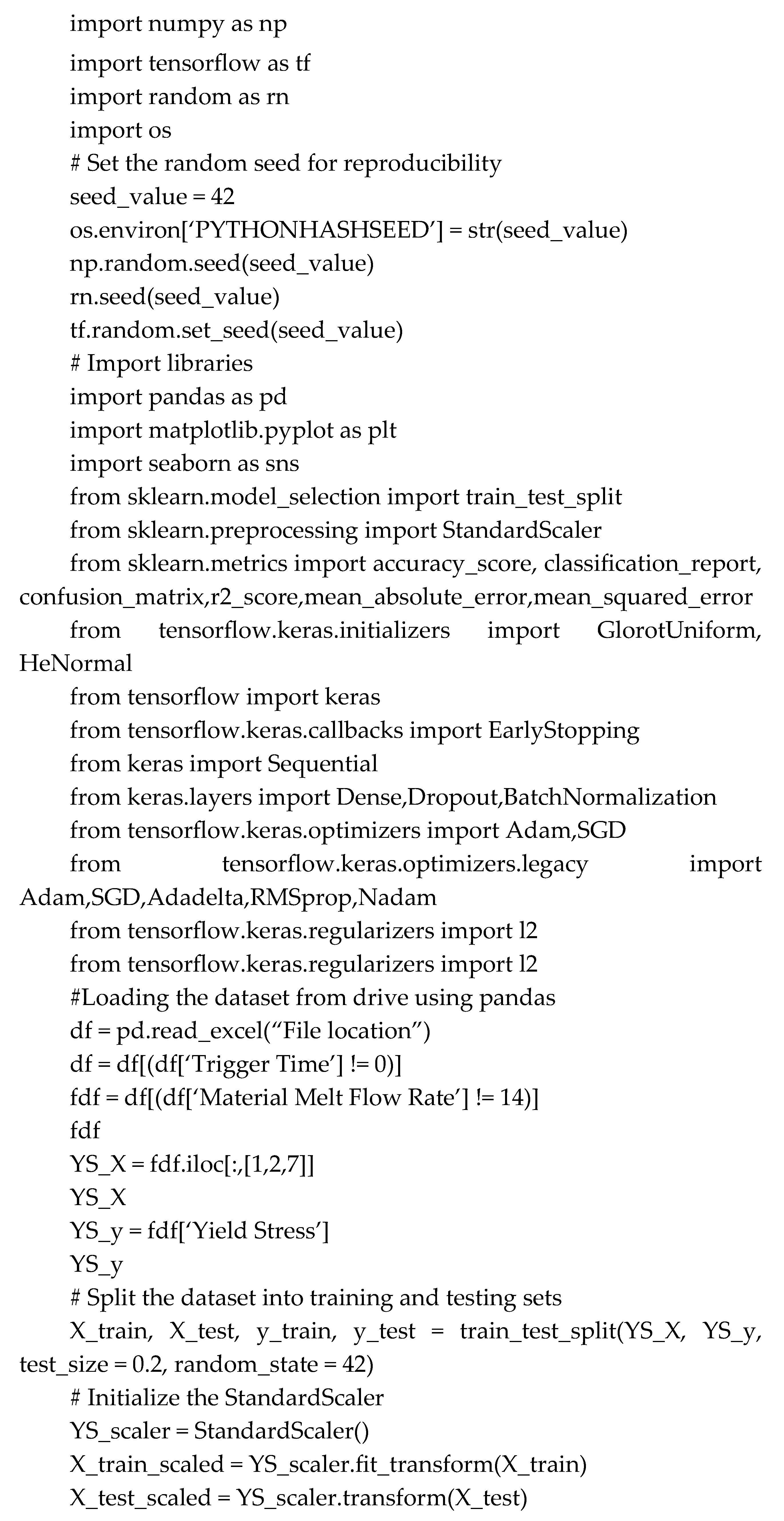

2.5. Artificial Neural Networks

In this work, the ANNs were implemented using TensorFlow version 2.15.0 and Keras version 2.15.0. The neural network architecture comprised 6 hidden layers with 32 neurons per layer. The ANN architecture was determined through empirical tuning to balance model complexity and predictive performance. A six-layer structure with 32 neurons per layer was chosen as it provided the best trade-off between accuracy and computational efficiency. Testing alternative architectures showed that fewer layers led to underfitting, while deeper networks increased the training time without meaningful performance improvements. The final architecture was selected based on validation performance, and early stopping was implemented to prevent overfitting. This configuration is consistent with prior work in ANN-based process modeling for materials science and injection molding. Additionally, a Rectified Linear Unit (ReLU) activation function was used with a ‘he_normal’ initializer and an Adaptive Moment Estimation (Adam) Optimizer with a 0.001 learning rate. The ‘he_normal’ initializer was specifically chosen because it draws weights from a normal distribution scaled by the number of input neurons. This helps maintain stable activation magnitudes throughout the network, reducing the risk of vanishing or exploding gradients. As a widely recommended method for deep networks using ReLU, it enhances convergence speed and overall training stability. Lastly, early stopping was implemented to prevent the overfitting of the models, with a patience parameter of 20, meaning training continued for up to 20 epochs without improvement before stopping. A minimum improvement threshold (min_delta) of 0.00001 was set to ensure only meaningful reductions in validation loss were considered. The mode was set to ‘auto’ to determine whether to minimize or maximize the tracked metric. Model performance was assessed on the MAE and MSE during training and validation. Specifically, the difference between the training and validation MAE and MSE was evaluated. Appendix A shows a sample script used to create and validate the ANN model.

After training the model, the data for the rPP with hol MFR, ttrig, Pact, and APV were introduced, and the hold-out quality parameter was predicted and compared to experimental values (step three). The % error, MAE, and MSE were once again evaluated to determine the model’s ability to predict hold-out data.

Following the model’s validation, the potential combinations of variable inputs and quality responses were introduced. Following this, the model calculated the error each combination would provide for each constant input, and the lowest resulting error was deemed the predicted output (step four). To evaluate the models, the %error for each predicted combination was measured.

3. Results and Discussion

3.1. Experimental Results

Table 5 shows a summary of the training data used for each model, and all of the raw data can be found in Appendix B. The table shows that a wide range of data was used for the training of the models, particularly for the yield stress and modulus. Additionally, the modulus had the overall highest variability within each of the runs and the APV value had a significant variation for a run with a material MFR of 8 and a 3 s trigger time. Indeed, the adaptive process control technology was unable to stabilize during this run, which caused significant variation within it. The reason is that a longer trigger time slows the melt front velocity down significantly, which can result in the approaching the melt front velocity approaching the Newtonian region, which makes it more susceptible to changes in shear rate, which increases shot-to-shot variation [15]. Additionally, the material with an MFR of 8 was a blend with increased content of the low MFR material added additional variation to the mix.

Table 5.

Summary of data used to train the models.

For all of the models evaluated, the experimental values for the predicted quality parameters can be found in Table 6. As seen in this table, the modulus showed the highest variation during the experimental procedure, whereas the weight and yield stress were relatively consistent. Additionally, it can be seen that the Trig3 runs showed greater variation than Trig2, similar to the results reported in Table 5.

Table 6.

Responses used as the constant input for the optimization of each model (MFR of 14).

3.2. Multivariate Regression Model Creation and Evaluation

Determining the ideal degree for the polynomial regression model was performed by assessing the mean score of each degree achieved during cross-validation. This step was crucial as selecting a degree that is too low will result in significant interactions being skipped, whereas selecting a degree that is too high can result in model overfitting and poor performance. Table 7 shows the coefficient of determination for each of the models with the different inputs. From the R2 values, the yield stress and modulus performed well for all models, with the polynomial regression model having a slightly higher R2. Ultimate elongation performed the worst for the linear regression with slightly higher performance for the polynomial regression model as the additional interactions were able to be captured by the higher order degree from the polynomial model.

Table 7.

R2 values for each of the multivariate regression models.

Comparing the MFR model to the APV model, one can see an increase in R2 for the viscosity model when looking at yield stress and modulus but a decrease in part weight R2 for the linear regression model. The reason is that when using the MFR to train the model, there is less variation within the data itself, as using the MFR essentially reduces the training data to 8 runs with 10 identical inputs Teach. This allows responses that do not have large variance across runs (such as part weight fluctuated between 13.43 g and 13.17 g across runs (c.f. Appendix B for all raw data) to have their inputs predicted as there are fewer combinations to select. On the other hand, the APV model has 80 different input combinations used during training, which, when the responses are similar, could result in uncertainty when trying to make predictions but also increase the amount of noise and outliers, which could affect the model performance.

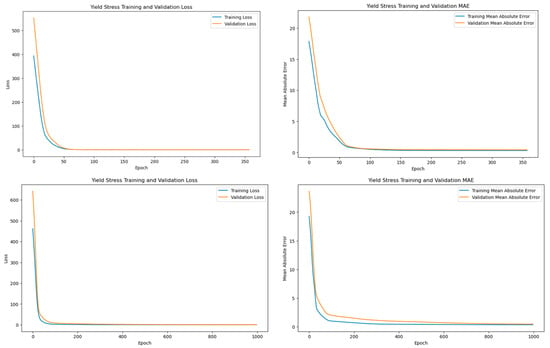

3.3. Artificial Neural Network Setup and Evaluation

A neural network model was created for each of the quality response variables; however, for simplicity, only plots for the yield stress response will be shown. Figure 2 show the training and validation loss and the training and validation mean absolute error for the yield stress response variable for the Trig2 runs using MFR (Figure 2 top row) and APV (Figure 2 bottom row). These plots highlight the importance of hyperparameter tuning and data splitting as a model that is over- or under-fit. Ideally, as the model continues to learn, the loss and the mean absolute error (MAE) decrease as the number of epochs increases while maintaining a minimum difference between the training and validation errors. A large gap between the training and validation curves could potentially signify poor model performance in the form of over- or underfitting. Additionally, as seen in the figure, both the MFR and APV models show no signs of overfitting thanks to the early stopping implemented (MFR stopped at 376 epochs, while APV stopped at 998 epochs). The significant difference in epochs reflects the complexity of the datasets, the APV model required more training cycles to capture the greater variability in viscosity-related parameters, whereas the MFR model, with more consistent data, converged more quickly. This extended training allowed the APV model to better generalize to the increased shot-to-shot variation present in the dataset. The difference in epochs means that the model with the APV underwent the training process 622 more times than the model run with the MFR data. The additional epochs allow the model to learn from the data more extensively and give the model a chance for better convergence and, thus, a better understanding of the data’s patterns. These additional epochs could have been necessary for the model to better understand the data due to the APV creating that additional variation within the dataset.

Figure 2.

Training and validation plots for the yield stress response variable for ANN using MFR (top row) and ANN using APV (bottom row).

Table 8 shows the final values for the loss and MAE for each response for both the MFR and APV models. As can be seen, the magnitude of the losses varies significantly for each response variable, and this magnitude shows the average discrepancy between the predicted response and the actual response.

Table 8.

Final validation and training losses and MAE for each response variable.

Comparing the model run using MFR and the model using APV, it can be observed that APV model performed better for the modulus and the yield stress response. However, the MFR model performed better for the ultimate elongation and part weight model. Indeed, when using the MFR to train the model, there is less variation within the data itself, as using the MFR essentially reduces the training data to 8 runs with 10 identical inputs each. This followed the same trend and reasoning as the regression models in which introducing additional variation to the dataset increased the noise.

3.4. Validation of the Models

3.4.1. Multivariate Regression Models

After evaluating the models and their coefficients, the hold-out data used for the ANN were introduced similarly for each regression model. The % error for each of the predicted quality responses and the experimental values for each regression model can be seen in Table 9. From the table, the APV model performs significantly better for the yield stress, modulus, and ultimate elongation response. A best-performing model could not be identified for the part weight response. Comparing the regression models, the linear model performs equally or better than the polynomial model. Whereas, the MFR model outperformed the linear model for the yield stress and ultimate elongation. The polynomial model notably performs very poorly at predicting the modulus when using the MFR data with errors greater than 30%. The error decreased to under 9% when using the APV data. The reason for this is that the polynomial models are known for performing quite well at predicting data that is close to the training data; however, the models tend to collapse when using data outside of the training set. When using MFR, the training data becomes limited, and therefore there are fewer unique training combinations, thus limiting the model. When using the APV, the number of unique training combinations increases, thus allowing the model to be better prepared for more variable validation data.

Table 9.

% error between predicted quality response and experimental values for each regression model.

3.4.2. Artificial Neural Network

Once the models were trained, the hold-out data were introduced (inputs c.f. Table 4). Following this, the model was re-run to predict the values of the hold-out data. Table 10 shows the average % error between the predicted quality response and the actual response seen in Table 6. As seen in the table, the Trig2 runs all fall within 10% error, whereas the Trig3 runs tend to show increased error up to 15%. This was expected due to the increased variation in experimental data (larger standard deviations in Table 6). Comparing the MFR model to the APV model, one can see that for yield stress, ultimate elongation, and modulus, there is no clear trend as to which model is most beneficial. However, the MFR model significantly reduces the % error for part weight, which was expected due to the better training results seen in Table 7. From the training results, the expected result would be a minimal increase in validation accuracy for the APV model. However, this was observed in just a few instances, likely due to the increase in training performance being insufficient to warrant a significant decrease in error percentage. Indeed, the amount of variation within each of the runs caused the model to fail to recognize certain trends in the data when training, and the creation of different combinations created additional noise.

Table 10.

% error between predicted quality response and experimental values for both ANN models.

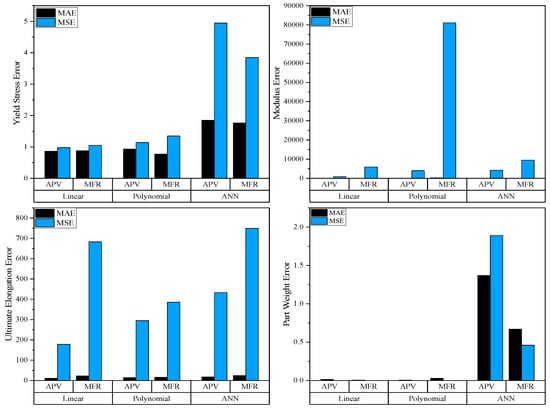

3.4.3. Comparison Between Models

The comparison between the regression models and the ANN can be seen in Figure 3, which compares the MAE and MSE between the three models and the different datasets. As seen in the figure, the MSE is significantly larger for the yield stress, modulus, and ultimate elongation, which signifies that the predictions are distributed relatively evenly amongst the true values. For the weight, however, it can be seen that the MAE is larger than the MSE for all but the ANN using MFR data. This signifies that there were a few outliers in the data that heavily influenced the model. Additionally, it can be seen that the ANN performed worse for all responses except for Modulus (Polynomial with MFR data was the worst performer). Comparing these results to the literature, it can be seen that similar results on the performance between ANN and polynomial regression were found, and the authors concluded that there was no best model for each case [22]. Additionally, they determined that hyperparameter tuning and the data selected for the training of the models were key to preventing overfitting and the best prediction behaviors. However, other authors have compared ANNs to regression analysis and their results show a clear advantage to using an ANN for predicting relationships between inputs and outputs using similar size datasets [35]. The main difference is the amount of variation within the dataset as the authors only used a single virgin polypropylene, and their response variable was dimension stability. It is hypothesized that the complex relationships between the quality responses and the processing inputs were not adequately captured, and additional data would be required to fully grasp the relationship and make more accurate predictions. However, except for part weight, the ANN performed quite similarly to the regression models, with errors below 6% for the Trig2 runs.

Figure 3.

Errors between experimental and predicted responses for all models.

The different datasets also did not seem to provide a clear trend for the ANN, as using the APV data proved advantageous for the modulus and ultimate elongation models, and the MFR data proved more accurate for the part weight and yield stress models. For the linear and polynomial regression models, the APV showed vast improvements, particularly for the polynomial model being able to reduce the MSE of the modulus model by 99.65% (from 81,000 to 280).

3.5. Process Input Optimization

Following the validation of each machine learning model, the hold-out data were reorganized for an optimization algorithm so that the quality responses would become inputs and the processing variables would be the resulting outputs. Table 11 shows the data breakdown for the machine learning optimization. Each response model created in Section 3.1 was used to predict the Ttrig and the Pact used for the hold-out material with a given MFR and a calculated APV. The ideal combination of Ttrig and the Pact was conducted by evaluating the error of each of the 638 combinations, as elaborated in Section 2.1. Table 12 shows the average combination and % error of Ttrig and Pact determined by each model for each response.

Table 11.

Model inputs for the optimization problem.

Table 12.

Predicted input parameters for each model.

From Table 12, all models show at least a 12% error in predicting the trigger time that was used to conduct the experiments. However, the models are more accurate at predicting the pressures that were seen during experiments. A conclusion cannot be drawn on which model performs the best at predicting the overall mechanical properties and part weights, as each model struggles to find the accurate processing input that was used, with errors ranging from 3% to 25% for all models. The error in the optimization of the process inputs is much larger than that seen during the validation of the models, which shows that although the models showed adequate training performance, perhaps additional feature engineering is necessary to fully capture the relationship between the inputs and the outputs. Indeed, the relationship between plastics properties and processing inputs is complex and therefore additional input data may be necessary for the model to fully understand [15].

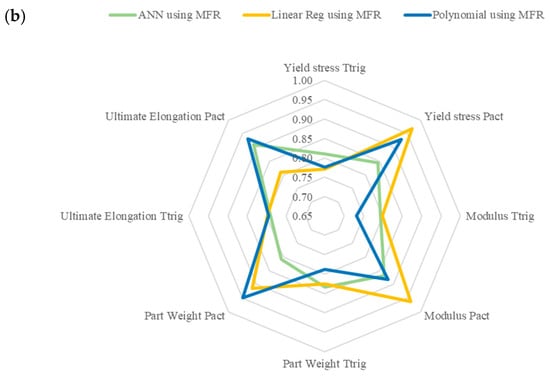

Additionally, the dataset used had no real impact on the optimization problem, as both datasets appear to perform similarly for all models. This could also signify the need for feature reassessment as the difference between the two datasets was evident during the model training and validation. Figure 4a shows a radar chart highlighting the combination of inputs that give the best performance for the APV dataset and Figure 4b for the MFR dataset. The closer to the outside of the radar, the more accurate that specific model is at predicting the response since the data plotted is one error from Table 12. As seen in the figures, the model using MFR data can more accurately predict the Pact value; however, in doing so, it is unable to predict the . The model using the APV data is more accurately able to predict the value; however, in doing so, it sacrifices accuracy in .

Figure 4.

Radar plot showing the performance of each model for each predicted input variable using (a) APV and (b) MFR data.

3.6. Validation of Input Prediction

As Section 3.5 focuses on the prediction of processing inputs based on specific mechanical properties as responses, this section focuses on determining whether the predicted inputs can indeed meet the required mechanical properties. Therefore, four additional runs were performed with the processing inputs predicted in Section 3.5 focusing on the two different datasets and with yield stress as the target mechanical property, Table 13. highlights the setup for the 4 validation runs.

Table 13.

Setup of validation runs.

The samples were fabricated following the same procedure presented in Section 2.3. After the samples were fabricated, tensile testing was performed following ASTM D638 [36], which tested five samples for each run. The yield stress values obtained using the model-suggested inputs were then compared to the original yield stress values, as seen in Table 14. The results show that using the model inputs resulted in yield stresses lower than the original yield stress values. However, the error was within ~6% across each of the datasets, which showed the resilience of the material to obtain the same mechanical properties using different processing inputs. Moreover, it showed the capabilities of machine learning to predict inputs that provide accurate responses.

Table 14.

Yield stress comparison between original inputs and the model predicted inputs.

4. Conclusions

This work investigated the capabilities of an ANN, linear regression, and polynomial regression model to predict quality responses based on processing inputs in injection molding. The following are the main takeaways from the work:

- Processing inputs were predicted based on material properties and quality responses for a P-Ctrl injection molding process using 5 blends of recycled polypropylene;

- The work focused on the training, validation, and optimization of these models and the ability of each of the models to predict different outputs based on complex material and processing relationships;

- The research explored tuning of the models is important to optimize the prediction of the behavior of challenging recycled materials. The proposed strategy could lead to an increase in their usage across different industries;

- Models created could accurately predict the yield stress, ultimate elongation, and part weight to within 5% error for the linear and polynomial models and 10% error for the ANN with the Trig2 run;

- The predictions for the modulus were far less accurate with a % error of ~11% for the ANN and the linear regression models and of ~40% for the polynomial model. The modulus, as shown in the data, is a property that tends to show high variation across and within each of the runs. Therefore, the models struggle to find the proper trends, leading to larger errors in the predicted data;

- The differences between models’ performances can be attributed to data variability across different features. Future work will focus on expanding the analysis for different materials to allow more in-depth analysis of the sources of error;

- The optimization problem results showed no single methodology to be superior for all responses, as specific models performed better for particular ones. However, the overall results of predicting the processing inputs, Ttrig and Pact, were much worse, with errors between 3–25% depending on the response and the model;

- Future work will focus on adding a feature reassessment to identify other combinations of inputs that could better capture the complex relationships seen during the process. Additionally, alternative machine learning methodologies will be evaluated, including ensemble methods, such as Random Forest and Gradient Boosting, which could improve generalization and better capture the complex relationships in the data.

Author Contributions

Conceptualization, D.M. and J.K.; methodology, D.M., J.K., and R.M.; software, M.A.R.; validation, J.K.; formal analysis, J.K. and M.A.R.; data curation, J.K. and M.A.R.; writing—original draft preparation, J.K.; writing—review and editing, J.L., D.M., and R.M.; visualization, M.A.R. and J.K.; supervision, D.M., R.M., and P.G.; project administration, D.M. and P.G.; funding acquisition, D.M. All authors have read and agreed to the published version of the manuscript.

Funding

This material is based upon work supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) under the Advanced Manufacturing Office Award Number DE-EE0007897. This paper was prepared from results obtained as part of a project sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Institutional Review Board Statement

Not Applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Sample Python Script

Appendix B. Raw Data

Table A1.

Raw data used for model training, validation, and optimization.

Table A1.

Raw data used for model training, validation, and optimization.

| Material MFR (g/10 min) | Trigger Time (s) | Actual Pressure (bar) | Ultimate Elongation (%) | Yield Stress (MPa) | Modulus (MPa) | Part Weight (g) | APV (Pa-s) |

|---|---|---|---|---|---|---|---|

| 5 | 2 | 624 | 334.36 | 32.64 | 1361.83 | 13.21 | 275.48 |

| 5 | 2 | 624 | 353.54 | 32.66 | 1353.72 | 13.22 | 276.97 |

| 5 | 2 | 624 | 335.73 | 32.23 | 1323.97 | 13.21 | 277.46 |

| 5 | 2 | 624 | 326.65 | 32.51 | 1320.19 | 13.21 | 275.17 |

| 5 | 2 | 624 | 347.85 | 32.66 | 1332.20 | 13.20 | 277.23 |

| 5 | 2 | 624 | 321.91 | 32.77 | 1320.84 | 13.21 | 274.91 |

| 5 | 2 | 624 | 339.89 | 32.90 | 1334.81 | 13.22 | 274.12 |

| 5 | 2 | 624 | 335.37 | 32.52 | 1318.86 | 13.21 | 277.72 |

| 5 | 2 | 624 | 335.93 | 32.75 | 1319.47 | 13.21 | 282.95 |

| 5 | 2 | 624 | 368.35 | 32.10 | 1275.79 | 13.22 | 276.37 |

| 5 | 3 | 598 | 332.31 | 33.07 | 1342.81 | 13.19 | 509.84 |

| 5 | 3 | 598 | 335.70 | 33.40 | 1341.64 | 13.19 | 494.71 |

| 5 | 3 | 598 | 349.49 | 31.15 | 1303.58 | 13.19 | 473.78 |

| 5 | 3 | 598 | 306.55 | 34.08 | 1402.71 | 13.19 | 500.30 |

| 5 | 3 | 598 | 331.19 | 32.60 | 1330.13 | 13.18 | 496.31 |

| 5 | 3 | 598 | 337.84 | 31.89 | 1338.42 | 13.19 | 497.07 |

| 5 | 3 | 598 | 324.93 | 32.91 | 1379.63 | 13.18 | 500.34 |

| 5 | 3 | 598 | 320.70 | 33.14 | 1349.97 | 13.18 | 501.40 |

| 5 | 3 | 598 | 297.53 | 33.08 | 1378.71 | 13.19 | 498.53 |

| 5 | 3 | 598 | 336.11 | 32.80 | 1367.48 | 13.18 | 493.08 |

| 8 | 2 | 563 | 347.15 | 28.42 | 1128.57 | 13.22 | 229.50 |

| 8 | 2 | 563 | 318.19 | 28.55 | 1147.12 | 13.21 | 232.38 |

| 8 | 2 | 563 | 327.12 | 28.51 | 1115.59 | 13.21 | 223.12 |

| 8 | 2 | 563 | 334.80 | 28.54 | 1155.11 | 13.21 | 226.64 |

| 8 | 2 | 563 | 341.88 | 27.72 | 1121.72 | 13.22 | 244.75 |

| 8 | 2 | 563 | 306.98 | 30.17 | 1284.43 | 13.21 | 241.79 |

| 8 | 2 | 563 | 315.01 | 29.80 | 1245.28 | 13.21 | 232.20 |

| 8 | 2 | 563 | 296.44 | 29.63 | 1217.40 | 13.21 | 227.24 |

| 8 | 2 | 563 | 291.60 | 30.72 | 1303.36 | 13.21 | 243.21 |

| 8 | 2 | 563 | 310.26 | 29.94 | 1264.10 | 13.21 | 231.96 |

| 8 | 3 | 538 | 304.85 | 30.10 | 1284.07 | 13.19 | 419.12 |

| 8 | 3 | 538 | 289.77 | 30.85 | 1280.18 | 13.19 | 442.14 |

| 8 | 3 | 538 | 320.12 | 29.82 | 1246.01 | 13.19 | 447.77 |

| 8 | 3 | 538 | 286.17 | 30.36 | 1303.06 | 13.19 | 402.20 |

| 8 | 3 | 538 | 278.10 | 30.47 | 1289.62 | 13.20 | 441.22 |

| 8 | 3 | 538 | 341.33 | 27.45 | 1047.07 | 13.18 | 969.45 |

| 8 | 3 | 538 | 339.06 | 28.16 | 1076.78 | 13.19 | 974.48 |

| 8 | 3 | 538 | 333.76 | 27.29 | 1049.93 | 13.19 | 959.64 |

| 8 | 3 | 538 | 343.27 | 26.86 | 1035.26 | 13.18 | 1091.14 |

| 8 | 3 | 538 | 351.63 | 26.96 | 1022.20 | 13.18 | 653.57 |

| 14 | 2 | 483 | 356.87 | 20.59 | 762.45 | 13.21 | 184.68 |

| 14 | 2 | 483 | 345.65 | 20.12 | 750.41 | 13.21 | 182.21 |

| 14 | 2 | 483 | 368.24 | 20.04 | 747.24 | 13.22 | 183.65 |

| 14 | 2 | 483 | 345.34 | 20.53 | 770.93 | 13.22 | 190.12 |

| 14 | 2 | 483 | 349.34 | 21.10 | 776.26 | 13.22 | 186.66 |

| 14 | 2 | 483 | 344.47 | 20.64 | 776.86 | 13.21 | 181.36 |

| 14 | 2 | 483 | 365.18 | 19.93 | 737.49 | 13.21 | 177.64 |

| 14 | 2 | 483 | 369.39 | 19.56 | 722.31 | 13.22 | 177.65 |

| 14 | 2 | 483 | 355.92 | 20.04 | 730.33 | 13.21 | 186.52 |

| 14 | 2 | 483 | 379.80 | 19.60 | 729.58 | 13.21 | 194.29 |

| 14 | 3 | 457 | 359.06 | 20.26 | 755.07 | 13.20 | 319.25 |

| 14 | 3 | 457 | 369.96 | 19.88 | 743.02 | 13.20 | 335.31 |

| 14 | 3 | 457 | 347.07 | 20.21 | 758.87 | 13.20 | 314.59 |

| 14 | 3 | 457 | 330.97 | 19.90 | 730.88 | 13.19 | 338.14 |

| 14 | 3 | 457 | 365.56 | 19.82 | 725.93 | 13.20 | 304.05 |

| 14 | 3 | 457 | 372.34 | 20.63 | 762.41 | 13.20 | 407.50 |

| 14 | 3 | 457 | 361.73 | 19.33 | 684.55 | 13.19 | 378.87 |

| 14 | 3 | 457 | 343.82 | 19.53 | 711.29 | 13.20 | 325.27 |

| 14 | 3 | 457 | 374.85 | 20.19 | 744.37 | 13.20 | 320.52 |

| 14 | 3 | 457 | 372.21 | 19.25 | 710.97 | 13.19 | 348.57 |

| 32 | 2 | 415 | 397.97 | 13.58 | 374.46 | 13.21 | 135.84 |

| 32 | 2 | 415 | 398.13 | 12.91 | 337.80 | 13.21 | 132.26 |

| 32 | 2 | 415 | 395.81 | 11.92 | 288.90 | 13.21 | 130.55 |

| 32 | 2 | 415 | 375.94 | 12.34 | 300.99 | 13.20 | 139.71 |

| 32 | 2 | 415 | 395.87 | 13.05 | 331.82 | 13.20 | 144.78 |

| 32 | 2 | 415 | 385.01 | 12.77 | 344.96 | 13.20 | 138.48 |

| 32 | 2 | 415 | 408.92 | 12.77 | 336.38 | 13.21 | 130.93 |

| 32 | 2 | 415 | 410.16 | 12.74 | 333.87 | 13.20 | 139.93 |

| 32 | 2 | 415 | 386.21 | 12.99 | 349.26 | 13.21 | 130.07 |

| 32 | 2 | 415 | 397.15 | 12.44 | 327.58 | 13.20 | 127.63 |

| 32 | 3 | 383 | 380.97 | 13.87 | 398.49 | 13.18 | 238.31 |

| 32 | 3 | 383 | 387.53 | 13.36 | 370.07 | 13.18 | 261.67 |

| 32 | 3 | 383 | 385.43 | 13.19 | 362.70 | 13.18 | 230.65 |

| 32 | 3 | 383 | 418.18 | 13.03 | 340.46 | 13.18 | 245.37 |

| 32 | 3 | 383 | 395.07 | 13.53 | 380.87 | 13.18 | 271.56 |

| 32 | 3 | 383 | 392.74 | 13.25 | 365.19 | 13.18 | 265.16 |

| 32 | 3 | 383 | 411.57 | 12.63 | 322.07 | 13.18 | 261.61 |

| 32 | 3 | 383 | 402.72 | 12.99 | 348.56 | 13.18 | 269.48 |

| 32 | 3 | 383 | 406.46 | 13.07 | 350.22 | 13.19 | 299.13 |

| 32 | 3 | 383 | 386.96 | 12.69 | 330.30 | 13.18 | 288.72 |

| 50 | 2 | 367 | 209.39 | 11.45 | 289.17 | 13.18 | 103.64 |

| 50 | 2 | 367 | 354.55 | 11.79 | 297.29 | 13.19 | 100.79 |

| 50 | 2 | 367 | 353.27 | 11.69 | 290.74 | 13.19 | 105.12 |

| 50 | 2 | 367 | 372.53 | 11.23 | 260.94 | 13.19 | 101.98 |

| 50 | 2 | 367 | 369.58 | 11.40 | 276.97 | 13.19 | 106.23 |

| 50 | 2 | 367 | 372.72 | 11.91 | 305.30 | 13.19 | 100.50 |

| 50 | 2 | 367 | 371.66 | 11.87 | 300.16 | 13.19 | 99.93 |

| 50 | 2 | 367 | 354.12 | 11.63 | 279.09 | 13.18 | 100.76 |

| 50 | 2 | 367 | 338.49 | 11.60 | 282.68 | 13.19 | 104.05 |

| 50 | 2 | 367 | 376.09 | 11.70 | 284.47 | 13.18 | 100.14 |

| 50 | 3 | 336 | 348.24 | 11.80 | 299.26 | 13.18 | 175.92 |

| 50 | 3 | 336 | 362.97 | 11.58 | 288.62 | 13.17 | 174.99 |

| 50 | 3 | 336 | 388.54 | 12.19 | 319.45 | 13.16 | 180.95 |

| 50 | 3 | 336 | 380.54 | 11.92 | 303.80 | 13.17 | 179.36 |

| 50 | 3 | 336 | 390.18 | 11.72 | 289.86 | 13.17 | 179.80 |

| 50 | 3 | 336 | 385.02 | 11.92 | 302.17 | 13.17 | 180.70 |

| 50 | 3 | 336 | 357.50 | 12.16 | 316.57 | 13.16 | 181.50 |

| 50 | 3 | 336 | 330.23 | 11.94 | 296.02 | 13.17 | 185.16 |

| 50 | 3 | 336 | 377.34 | 11.84 | 288.48 | 13.16 | 185.46 |

| 50 | 3 | 336 | 382.42 | 12.13 | 312.36 | 13.17 | 181.63 |

References

- Párizs, R.D.; Török, D.; Ageyeva, T.; Kovács, J.G. Machine Learning in Injection Molding: An Industry 4.0 Method of Quality Prediction. Sensors 2022, 22, 2704. [Google Scholar] [CrossRef]

- Ageyeva, T.; Horváth, S.; Kovács, J.G. In-Mold Sensors for Injection Molding: On the Way to Industry 4.0. Sensors 2019, 19, 3551. [Google Scholar] [CrossRef]

- Ademujimi, T.T.; Brundage, M.P.; Prabhu, V.V. A Review of Current Machine Learning Techniques Used in Manufacturing Diagnosis. In Proceedings of the IFIP International Conference on Advances in Production Management Systems (APMS), Hamburg, Germany, 3–7 September 2017; pp. 407–415. [Google Scholar]

- Aminabadi, S.S.; Tabatabai, P.; Steiner, A.; Gruber, D.P.; Friesenbichler, W.; Habersohn, C.; Berger-Weber, G. Industry 4.0 In-Line AI Quality Control of Plastic Injection Molded Parts. Polymers 2022, 14, 3551. [Google Scholar] [CrossRef]

- Kurt, M.; Kaynak, Y.; Kamber, O.S.; Mutlu, B.; Bakir, B.; Koklu, U. Influence of molding conditions on the shrinkage and roundness of injection molded parts. Int. J. Adv. Manuf. Technol. 2009, 46, 571–578. [Google Scholar] [CrossRef]

- Huang, M.; Nian, S.; Lin, G. Influence of V/P switchover point, injection speed, and holding pressure on quality consistency of injection-molded parts. J. Appl. Polym. Sci. 2021, 138, 51223. [Google Scholar] [CrossRef]

- Chen, Z.; Turng, L. A review of current developments in process and quality control for injection molding. Adv. Polym. Technol. 2005, 24, 165–182. [Google Scholar] [CrossRef]

- Sykes, A.O. An Introduction to Regression Analysis. Law and Economics, no. 20, 1993. Available online: https://chicagounbound.uchicago.edu/law_and_economics (accessed on 1 April 2024).

- Yang, Y.; Gao, F. Injection molding product weight: Online prediction and control based on a nonlinear principal component regression model. Polym. Eng. Sci. 2006, 46, 540–548. [Google Scholar] [CrossRef]

- Zhang, Y.; Mao, T.; Huang, Z.; Gao, H.; Li, D. A statistical quality monitoring method for plastic injection molding using machine built-in sensors. Int. J. Adv. Manuf. Technol. 2015, 85, 2483–2494. [Google Scholar] [CrossRef]

- Youssef, A.H.; Madhuranthakam, C.M.R.; Elkamel, A.; Mittal, V. Optimizing mechanical properties of injection-molded long fiber-reinforced polypropylene. J. Thermoplast. Compos. Mater. 2014, 28, 849–862. [Google Scholar] [CrossRef]

- Shie, J. Optimization of injection-molding process for mechanical properties of polypropylene components via a generalized regression neural network. Polym. Adv. Technol. 2007, 19, 73–83. [Google Scholar] [CrossRef]

- Alexander, M.T.; Montgomery, D.C.; Runger, G. Applied Statistics and Probability for Engineers. Technometrics 1995, 37, 455. [Google Scholar] [CrossRef]

- Tsai, K.-M.; Hsieh, C.-Y.; Lo, W.-C. A study of the effects of process parameters for injection molding on surface quality of optical lenses. J. Mech. Work. Technol. 2008, 209, 3469–3477. [Google Scholar] [CrossRef]

- Deanin, R. Polymer Structure and Practical Properties; Cahners Books Publishing: Boston, MA, USA, 1972. [Google Scholar]

- Yin, F.; Mao, H.; Hua, L.; Guo, W.; Shu, M. Back Propagation neural network modeling for warpage prediction and optimization of plastic products during injection molding. Mater. Des. 2010, 32, 1844–1850. [Google Scholar] [CrossRef]

- Lee, C.; Na, J.; Park, K.; Yu, H.; Kim, J.; Choi, K.; Park, D.; Park, S.; Rho, J.; Lee, S. Development of Artificial Neural Network System to Recommend Process Conditions of Injection Molding for Various Geometries. Adv. Intell. Syst. 2020, 2, 2000037. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Q.; Zhang, W.; Zhang, P. Optimization of injection molding process parameters to improve the mechanical performance of polymer product against impact. Int. J. Adv. Manuf. Technol. 2014, 76, 2199–2208. [Google Scholar] [CrossRef]

- Yousef, B.F.; Mourad, A.-H.I.; Hilal-Alnaqbi, A. Prediction of the Mechanical Properties of PE/PP Blends Using Artificial Neural Networks. Procedia Eng. 2011, 10, 2713–2718. [Google Scholar] [CrossRef]

- Ozcelik, B.; Erzurumlu, T. Comparison of the warpage optimization in the plastic injection molding using ANOVA, neural network model and genetic algorithm. J. Mech. Work. Technol. 2005, 171, 437–445. [Google Scholar] [CrossRef]

- Kenig, S.; Ben-David, A.; Omer, M.; Sadeh, A. Control of properties in injection molding by neural networks. Eng. Appl. Artif. Intell. 2001, 14, 819–823. [Google Scholar] [CrossRef]

- Heinisch, J.; Lockner, Y.; Hopmann, C. Comparison of design of experiment methods for modeling injection molding experiments using artificial neural networks. J. Manuf. Process. 2021, 61, 357–368. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks: A Comprehensive Foundation, 2nd ed.; Prentice Hall: Hoboken, NJ, USA, 1998. [Google Scholar]

- Lockner, Y.; Hopmann, C.; Zhao, W. Transfer learning with artificial neural networks between injection molding processes and different polymer materials. J. Manuf. Process. 2022, 73, 395–408. [Google Scholar] [CrossRef]

- Liao, L.; Li, H.; Shang, W.; Ma, L. An Empirical Study of the Impact of Hyperparameter Tuning and Model Optimization on the Performance Properties of Deep Neural Networks. ACM Trans. Softw. Eng. Methodol. 2022, 31, 1–40. [Google Scholar] [CrossRef]

- Roy, U.; Li, Y. Sustainability Assessment of the Injection Molding Process and the Effects of Material Selection. In Proceedings of the ASME Design Engineering Technical Conference, Buffalo, NY, USA, 17–20 August 2014; Volume 4, pp. 1–10. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pujari, D. Mainstreaming Green Product Innovation: Why and How Companies Integrate Environmental Sustainability. J. Bus. Ethic 2010, 95, 471–486. [Google Scholar] [CrossRef]

- Malloy, R. Plastic Part Design for Injection Molding—An Introduction, 2nd ed.; Hanser Publishers: Munich, Germany, 2010; Available online: https://app.knovel.com/web/toc.v/cid:kpPPDIMAI2/viewerType:toc//root_slug:plastic-part-design-injection/url_slug:linear-mold-shrinkage?b-q=malloy&include_synonyms=no&issue_id=kt011Q5BD4&hierarchy= (accessed on 9 November 2021).

- Fei, N.C.; Kamaruddin, S.; Siddiquee, A.N.; Khan, Z.A. Experimental Investigation on the Recycled HDPE and Optimization of Injection Moulding Process Parameters via Taguchi Method. 2011. Available online: https://www.researchgate.net/publication/215594743 (accessed on 1 March 2024).

- Altonen, M.; McConell, N.; Breidenbach, S.; Gergov, G. Injection Molding Machines and Methods for Accounting for Changes in Material Properties During Injection Molding Runs. CA2919376C, 5 February 2015. [Google Scholar]

- Altonen, G.; Neufarth, R.; Schiller, G.; Berg, C. Alternative Pressure Control For An Injection Molding Apparatus. U.S. Patent US9289933B2, 22 March 2016. [Google Scholar]

- Krantz, J.; Nieduzak, Z.; Kazmer, E.; Licata, J.; Ferki, O.; Gao, P.; Sobkowicz, M.J.; Masato, D. Investigation of pressure-controlled injection molding on the mechanical properties and embodied energy of recycled high-density polyethylene. Sustain. Mater. Technol. 2023, 36, e00651. [Google Scholar] [CrossRef]

- Krantz, J.; Nieduzak, Z.; Licata, J.; O’Meara, S.; Gao, P.; Masato, D. In-mold rheology and automated process control for injection molding of recycled polypropylene. Polym. Eng. Sci. 2024, 64, 4112–4127. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Lee, J.; Yang, D.; Yoon, K.; Kim, J. Effects of Input Parameter Range on the Accuracy of Artificial Neural Network Prediction for the Injection Molding Process. Polymers 2022, 14, 1724. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. American Society for Testing and Materials: West Conshohocken, PA, USA, 1998.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).