Subjective and Objective Evaluation of Surface Properties of Flattened Bamboo and Polyurethane Self-Foaming Plastic

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Experimental Apparatus

- Colorimeter: SEGT-J portable colorimeter (Tianchuang Instrument Co., Ltd. from Zhuhai, China);

- Gloss meter: HG268 gloss meter (3nh Technology Co., Ltd. from Shenzhen, China);

- Roughness meter: TR100 pocket surface roughness meter (Horiyang Precision Measurement Co., Ltd. from Shanghai, China);

- Contact Angle Measuring Instrument (Zhongchen Digital Technology Equipment Co., Ltd. from Shanghai, China).

2.3. Experimental Methods

2.3.1. Color Test

2.3.2. Glossiness Test

2.3.3. Roughness Test

2.3.4. Surface Wettability Testing

2.3.5. Subjective Evaluation Test

- 1.

- Perceptual language pair establishment

- 2.

- Perceptual semantic evaluation

3. Results

3.1. Surface Performance Results Analysis

3.1.1. Color Test Results

3.1.2. Gloss Test Results

3.1.3. Roughness Test Results

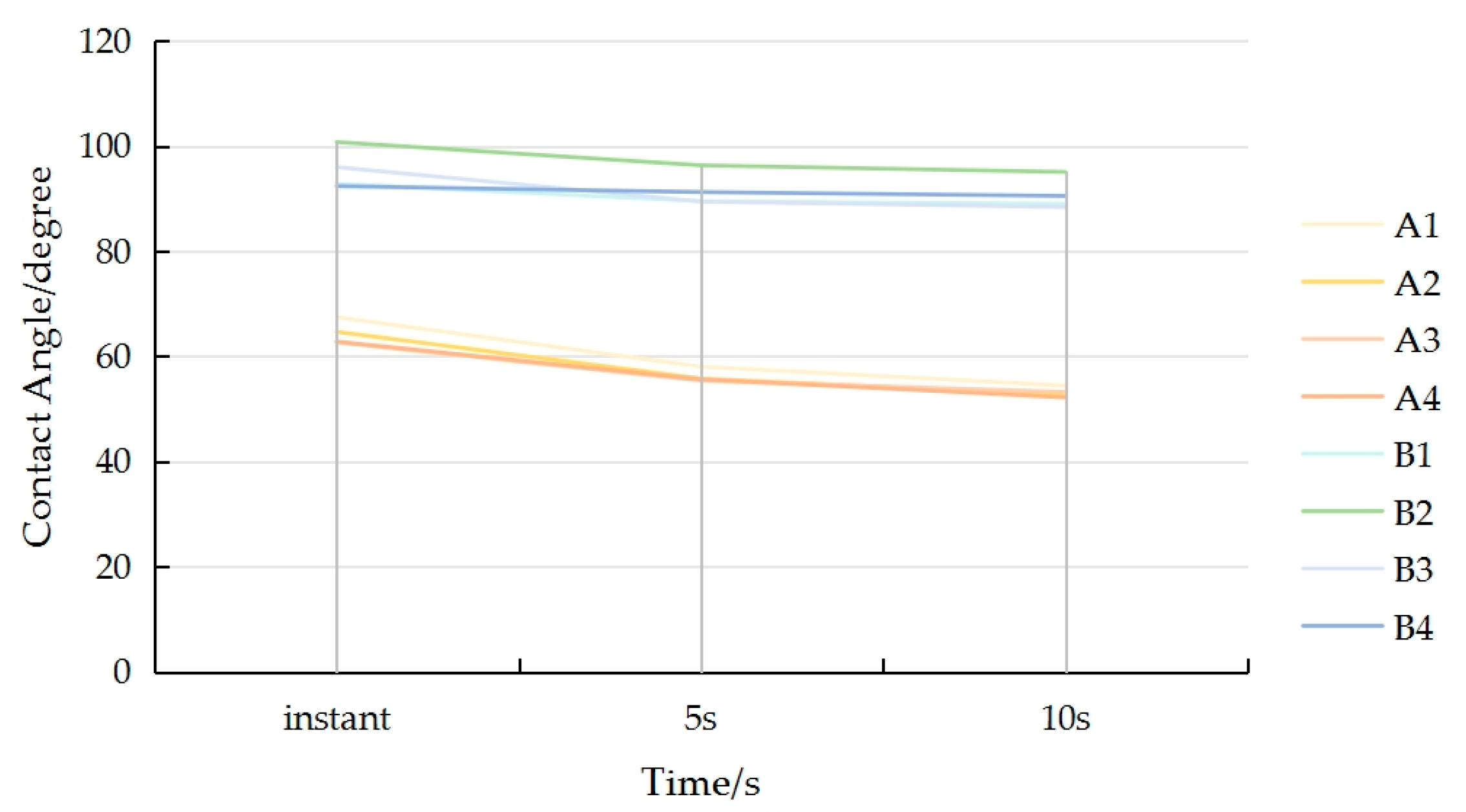

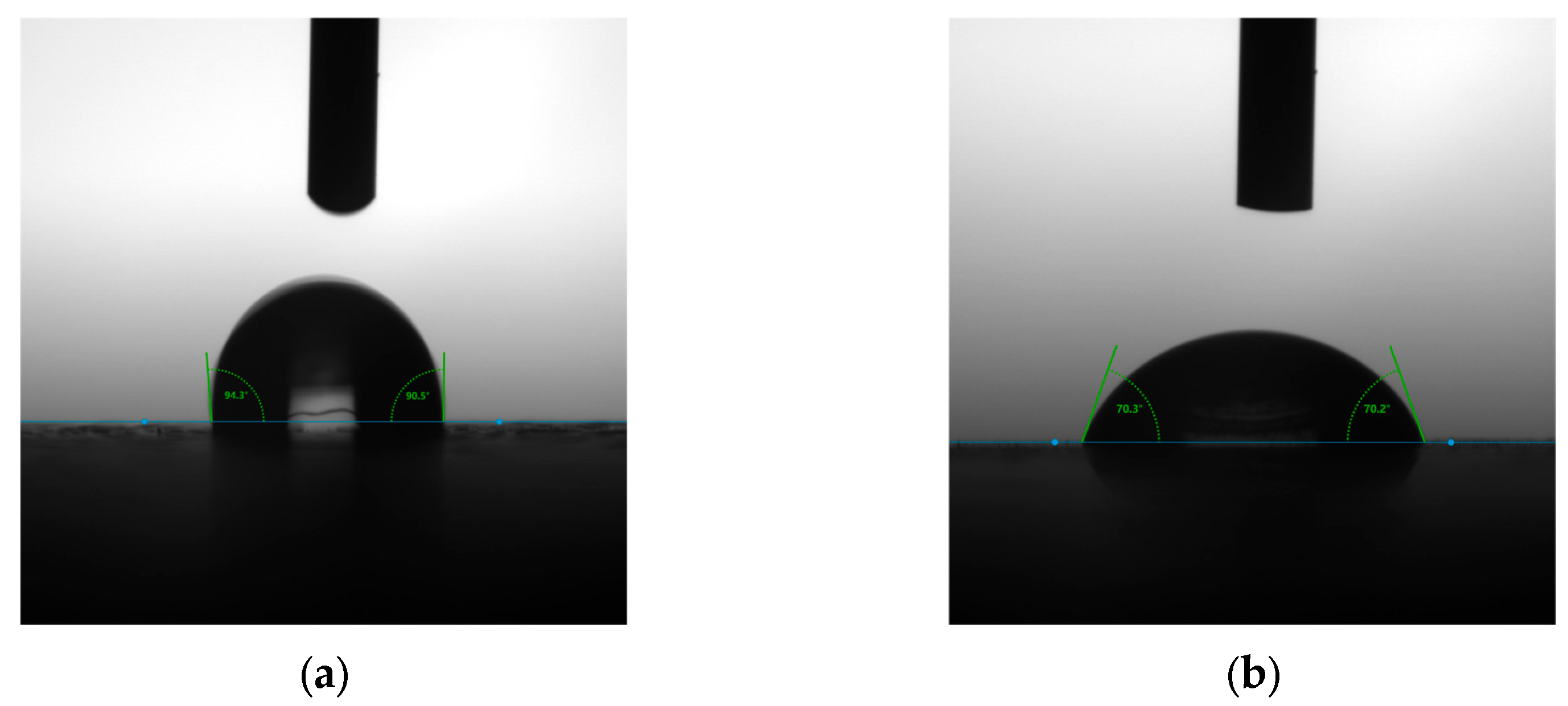

3.1.4. Surface Wettability Test Results

3.2. Analysis of the Subjective Evaluation Results

3.2.1. Perceptual Vocabulary Screening and Categorization

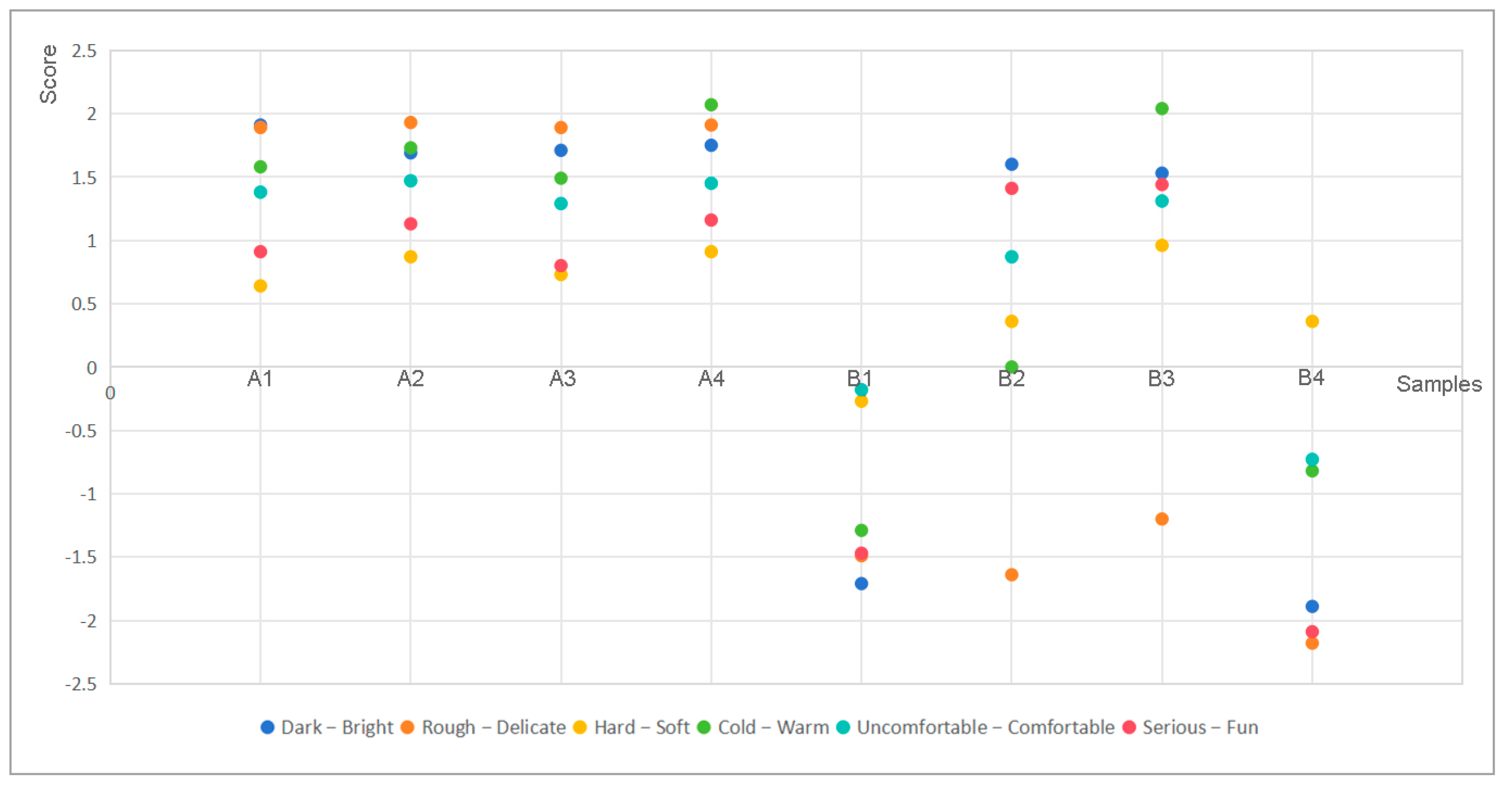

3.2.2. Subjective Evaluation Test Results

3.3. Correlation Analysis Between Surface Properties and Subjective Evaluation

4. Discussion

- Objective performance comparison

- 2.

- Subjective evaluation analysis

- 3.

- Correlation analysis between objective performance and subjective evaluation

- 4.

- Research limitations

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ates, M.; Karadag, S.; Eker, A.A. Polyurethane foam materials and their industrial applications. Polym. Int. 2022, 71, 1157–1163. [Google Scholar]

- Fu, X.Y.; Huang, Z.Y.; Lv, Q.Z.; Wang, Y.H. Sustainable Design Strategies of Educational Furniture Based on LCA Methodology. Packag. Eng. 2024, 45, 183–191. [Google Scholar]

- Pau, D.S.W.; Fleischmann, C.M.; Delichatsios, M.A. Apparatus for investigating the burning and dripping of vertically oriented polyurethane foams. Fire Mater. 2020, 44, 211–229. [Google Scholar]

- Wang, X.Z.; Lu, M.S.; Zeng, J.B.; Weng, Y.X.; Li, Y.D. Malleable and thermally recyclable polyurethane foam. Green Chem. 2021, 23, 307–313. [Google Scholar]

- Hakeem, K.R.; Ibrahim, S.; Ibrahim, F.H.; Tombuloglu, H. Bamboo biomass: Various studies and potential applications for value-added products. In Agricultural Biomass Based Potential Materials; Springer: Cham, Switzerland, 2015; pp. 231–243. [Google Scholar]

- Hu, Y.A.; Huang, H.; He, L.; Pan, C.Y.; He, M. Research status and development trends of “bamboo as as ubstitute for plastic” in construction and building materials. J. For. Eng. 2024, 9, 1–12. [Google Scholar]

- Zheng, Y.; Zhu, J. The application of bamboo weaving in modern furniture. BioResources 2021, 16, 5024–5035. [Google Scholar]

- National Development and Reform Commission, Ministry of Industry and Information Technology, Ministry of Finance, State Forestry and Grass Administration, etc. Accelerate the Development of “Bamboo Instead of Plastic” Three-Year Action Plan. 12 October 2023. Available online: https://www.gov.cn/zhengce/zhengceku/202311/content_6913316.htm (accessed on 16 February 2025).

- Ye, H.Z.; Fu, J.; Cheng, H.T.; Chen, F.M.; Yang, S.Y. The Current Status and Market Development Potential of Processing Technology and Products Using Bamboo as a Substitute for Plastic. Sci. Silvae Sin. 2024, 60, 129–141. [Google Scholar]

- Wan, Q.; Hu, Q.; Chen, B.; Fang, H.; Ke, Q.; Song, S. Study on the visual cognition of laminated bamboo furniture. For. Prod. J. 2021, 71, 84–91. [Google Scholar]

- Tang, T.; Fei, B.; Song, W.; Su, N.; Sun, F. Tung Oil Thermal Treatment Improves the Visual Effects of Moso Bamboo Materials. Polymers 2022, 14, 1250. [Google Scholar] [CrossRef]

- Zhang, M.; Yuan, X.F. Material Perception Experience in Furniture Product Design: A Literature Review. Furnit. Inter. Des. 2024, 31, 40–47. [Google Scholar]

- Xue, G.; Guo, Z.; Xie, Z. Using Kansei Engineering for the Design Thinking Framework: Bamboo Pen Holder Product Design. Sustainability 2022, 14, 10556. [Google Scholar] [CrossRef]

- Yang, Y.N.; Li, J.; Guo, M.Y.; Wei, X.; Huang, Z.L.; Liu, Y.; Guo, H.W. Quantitative Evaluation of Visual Perception Semantic Fractal Dimension of Wood Materials. Packag. Eng. 2023, 44, 210–219. [Google Scholar]

- Su, N.; Fang, C.; Zhou, H.; Tang, T.; Zhang, S.; Wang, X.; Fei, B. Effect of Rosin Modification on the Visual Characteristics of Round Bamboo Culm. Polymers 2021, 13, 3500. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Zeng, Z.; Li, Q.; Hu, C. The effects of ACQ and water glass on the color change and decay resistance of carbonized bamboo. Wood Res. 2022, 67, 731–743. [Google Scholar] [CrossRef]

- Yan, X.; Chang, Y.; Qian, X. Effect of Concentration of Thermochromic Ink on Performance of Waterborne Finish Films for the Surface of Cunninghamia Lanceolata. Polymers 2020, 12, 552. [Google Scholar] [CrossRef]

- Ken, S. Conversion from Measured Values by Machine to Visual Values: Transformation from the L*, a*, b* Color System to Munsell. Wood Ind. 1985, 40, 16–20. [Google Scholar]

- ISO 2813:2014; Paints and Varnishes—Determination of Gloss Value at 20 Degrees, 60 Degrees and 85 Degrees, CEN/TC 139—Paints and Varnishes. International Organization for Standardization: Geneva, Switzerland, 2014.

- Lin, X.Y.; Zhang, Q.H.; Huang, Y.H.; Huang, Q.F.; Yang, X. Painting technology and adhesion mechanism of waterborne paint based on bamboo laminated lumber. J. Beijing For. Univ. 2022, 44, 158–164. [Google Scholar]

- Dagher, R.; Stevanovic, T.; Landry, V. Wood color modification with iron salts aqueous solutions: Effect on wood grain contrast and surface roughness. Holzforschung 2023, 77, 356–367. [Google Scholar] [CrossRef]

- Jiang, J.C.; Li, J.; Zhang, J.Y.; Wang, B.Q.; Zhan, J.F. Effect of Oil Wax Heat Treatment on Physical Properties and Dimensional Stability of Wood. For. Eng. 2024, 40, 106–113. [Google Scholar]

- Zhang, Y.; Guo, Y.; Wei, P.; He, Z.; Yi, S.; Zhao, G. Effect of changes in surface visual properties of heat-treated wood on the psychological preference. BioResources 2024, 19, 4652–4669. [Google Scholar] [CrossRef]

- Nagai, T.; Matsushima, T.; Koida, K.; Tani, Y.; Kitazaki, M.; Nakauchi, S. Temporal properties of material categorization and material rating: Visual vs non-visual material features. Vis. Res. 2015, 115, 259–270. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Bai, R.; Jin, Y.; Xiao, W.; Xue, C. Aesthetic Cognitive Computing Clues of Materials Based on Multidimensional Perception. J. Test. Eval. 2023, 51, 64–84. [Google Scholar] [CrossRef]

- Lian, C.; Wang, X.; Chen, H.; Fei, B.; Pang, X.; Lian, J.; Wu, Z. Using Statistical Methods to Comparatively Analyze the Visual Characteristics of Flattened Bamboo Boards in Different Bamboo Culms. Polymers 2022, 14, 4327. [Google Scholar] [CrossRef] [PubMed]

- Leung, M.Y.; Famakin, I.O.; Wang, C. Developing an integrated indoor built environment-quality of life model for the elderly in public and subsidized housing. Eng. Constr. Archit. Manag. 2019, 26, 1498–1517. [Google Scholar] [CrossRef]

- Ahmed, H.T.; Aly, A.M. Recycled Waste Materials in Landscape Design for Sustainable Development (Al-Ahsa as a Model). Sustainability 2023, 15, 11705. [Google Scholar] [CrossRef]

- Yu, X.N.; Liu, S.; Chen, B.X.; Bao, X.D.; Guan, X.; Lin, J.G. Study on Effect of Sanding Treatment on Surface Properties of Zenia insigins Wood. China For. Prod. Ind. 2024, 61, 14–19. [Google Scholar]

- Lan, P.; Qiao, L.L.; Liao, A.P.; Nong, Y.; Qin, R.D.; Liu, Q.; Li, H.B.; Chen, H. Effect of lanthanum ricinoleate on the performance of water-blownintegral skin polyurethane foams. Chem. Ind. Eng. Prog. 2015, 34, 1993–1997. [Google Scholar]

- Członka, S.; Sienkiewicz, N.; Kairytė, A.; Vaitkus, S. Colored polyurethane foams with enhanced mechanical and thermal properties. Polym. Test. 2019, 78, 105986. [Google Scholar]

- Lu, S.W.; Jian, Y.L.; San, H.; Liu, Y.G.; Chai, X.J.; Xu, K.M.; Xie, L.K. Silylation of Moso Bamboo(Phyllostachys Edulis) Surface and Preventable Wettability and Penetration for Water and Oil. Surf. Technol. 2022, 51, 443–451+459. [Google Scholar]

- Ding, M.; Cheng, Y.; Huang, X.G.; Zhao, L.Y. Status and progress of kansei engineering design method. J. Mach. Des. 2020, 37, 121–127. [Google Scholar]

- Choi, J. Material selection: Exploring the reliability of material perception data and its relevance to materials. Met. Mater. Int. 2019, 27, 1599–1604. [Google Scholar]

- Wan, Q.; Li, X.; Zhang, Y.; Song, S.; Ke, Q. Visual perception of different wood surfaces: An event-related potentials study. Ann. For. Sci. 2021, 78, 25. [Google Scholar]

- Liang, S.; Pan, C.R.; Cen, X.Q.; Lin, H.; Li, Q. Assessment of the Color Difference and Decay Resistance Performance of Moso Bamboo and Carbonized Moso Bamboo Treatments with Different Painting. For. Eng. 2022, 38, 52–57. [Google Scholar]

| Serial Number | Sample | Name |

|---|---|---|

| 1 | Flattened bamboo 1 | A1 |

| 2 | Flattened bamboo 2 | A2 |

| 3 | Flattened bamboo 3 | A3 |

| 4 | Flattened bamboo 4 | A4 |

| 5 | PU self-foaming plastic 1 | B1 |

| 6 | PU self-foaming plastic 2 | B2 |

| 7 | PU self-foaming plastic 3 | B3 |

| 8 | PU self-foaming plastic 4 | B4 |

| Samples | L* | a* | b* | H | V | C |

|---|---|---|---|---|---|---|

| A1 | 63.7 | 14.5 | 33.1 | 8.93 YR | 5.22 | 12.71 |

| A2 | 66.57 | 14.2 | 33 | 8.89 YR | 5.51 | 12.51 |

| A3 | 63.9 | 15.0 | 32.0 | 8.60 YR | 5.24 | 12.87 |

| A4 | 62.8 | 15.15 | 32.3 | 8.65 YR | 5.13 | 13.01 |

| B1 | 42.1 | 2.2 | 2.2 | 2.37 YR | 3.06 | 1.69 |

| B2 | 68.3 | −19.1 | −14.0 | 1.59 YR | 5.68 | 14.37 |

| B3 | 56.4 | 47.7 | 45.0 | 7.75 YR | 4.49 | 35.10 |

| B4 | 44.8 | −9.03 | −0.8 | 4.53 R | 3.33 | 7.14 |

| Time | A1 | A2 | A3 | A4 | B1 | B2 | B3 | B4 |

|---|---|---|---|---|---|---|---|---|

| instant | 67.45 | 64.67 | 62.67 | 62.81 | 92.80 | 100.77 | 96.0 | 92.39 |

| 5 s | 58.04 | 55.77 | 55.38 | 55.63 | 89.53 | 96.34 | 89.45 | 91.25 |

| 10 s | 54.44 | 52.64 | 53.23 | 52.20 | 89.02 | 95.08 | 88.4 | 90.52 |

| Serial Number | Representative Perceptual Pairs | Evaluation Dimension |

|---|---|---|

| 1 | Dark–Bright | Sensory |

| 2 | Rough–Delicate | Sensory |

| 3 | Hard–Soft | Sensory |

| 4 | Cold–Warm | Psychological |

| 5 | Uncomfortable–Comfortable | Psychological |

| 6 | Serious–Fun | Psychological |

| Representative Perceptual Pairs | Score | |||||||

|---|---|---|---|---|---|---|---|---|

| A1 | A2 | A3 | A4 | B1 | B2 | B3 | B4 | |

| Dark–Bright | 1.91 | 1.69 | 1.71 | 1.75 | −1.71 | 1.6 | 1.53 | −1.89 |

| Rough–Delicate | 1.89 | 1.93 | 1.89 | 1.91 | −1.49 | −1.64 | −1.2 | −2.18 |

| Hard–Soft | 0.64 | 0.87 | 0.73 | 0.91 | −0.27 | 0.36 | 0.96 | 0.36 |

| Cold–Warm | 1.58 | 1.73 | 1.49 | 2.07 | −1.29 | 0 | 2.04 | −0.82 |

| Uncomfortable–Comfortable | 1.38 | 1.47 | 1.29 | 1.45 | −0.18 | 0.87 | 1.31 | −0.73 |

| Serious–Fun | 0.91 | 1.13 | 0.8 | 1.16 | −1.47 | 1.41 | 1.44 | −2.09 |

| GZT | GZL | Roughness | L* | a* | b* | Contact Angle | |

|---|---|---|---|---|---|---|---|

| Dark–Bright | 0.682 * | 0.647 * | −0.502 | 0.937 *** | 0.411 | 0.581 | −0.505 |

| Rough–Delicate | 0.995 *** | 0.994 *** | −0.974 *** | 0.634 * | 0.344 | 0.681 * | −0.968 *** |

| Hard–Soft | 0.618 | 0.597 | −0.43 | 0.658 * | 0.619 | 0.77 ** | −0.527 |

| Cold–Warm | 0.754 ** | 0.72 ** | −0.59 | 0.709 ** | 0.716 ** | 0.873 *** | −0.637 * |

| Uncomfortable–Comfortable | 0.747 ** | 0.714 ** | −0.601 | 0.856 *** | 0.553 | 0.714 ** | −0.593 |

| Serious–Fun | 0.527 | 0.491 | −0.342 | 0.897 *** | 0.431 | 0.521 | −0.336 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Liang, Q.; Wang, J.; Ma, X. Subjective and Objective Evaluation of Surface Properties of Flattened Bamboo and Polyurethane Self-Foaming Plastic. Polymers 2025, 17, 894. https://doi.org/10.3390/polym17070894

Chen Y, Liang Q, Wang J, Ma X. Subjective and Objective Evaluation of Surface Properties of Flattened Bamboo and Polyurethane Self-Foaming Plastic. Polymers. 2025; 17(7):894. https://doi.org/10.3390/polym17070894

Chicago/Turabian StyleChen, Yushu, Qianwei Liang, Jinjing Wang, and Xinyu Ma. 2025. "Subjective and Objective Evaluation of Surface Properties of Flattened Bamboo and Polyurethane Self-Foaming Plastic" Polymers 17, no. 7: 894. https://doi.org/10.3390/polym17070894

APA StyleChen, Y., Liang, Q., Wang, J., & Ma, X. (2025). Subjective and Objective Evaluation of Surface Properties of Flattened Bamboo and Polyurethane Self-Foaming Plastic. Polymers, 17(7), 894. https://doi.org/10.3390/polym17070894