Optimization of Water Plugging Characteristics and Mechanical Properties of Acrylate Grouting Materials Based on Composite Crosslinking Strategy

Abstract

1. Introduction

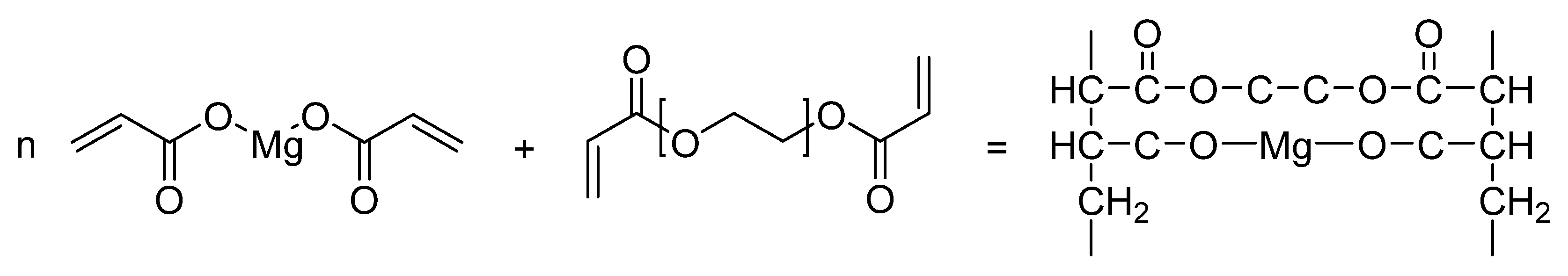

2. Materials and Methods

2.1. Raw Materials

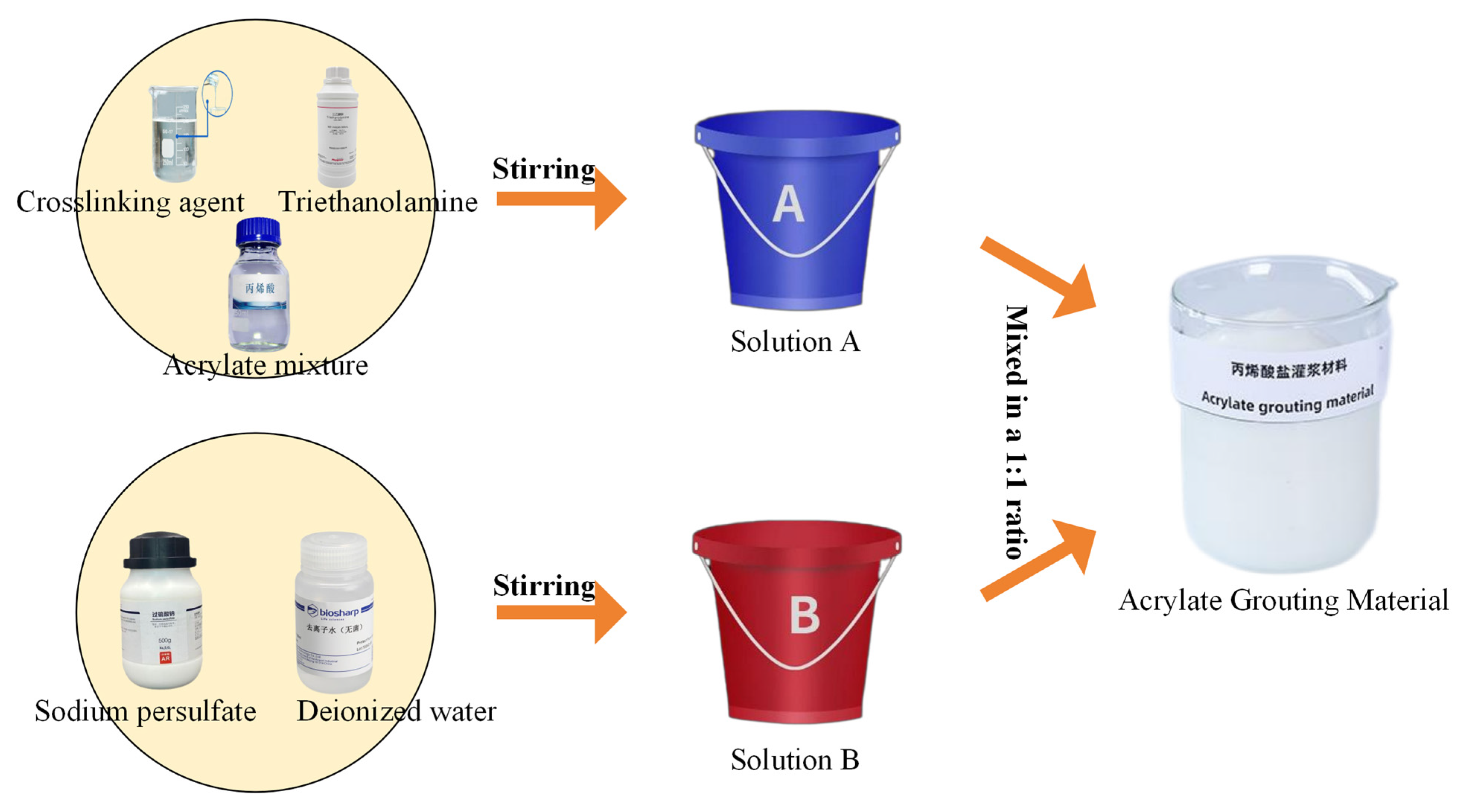

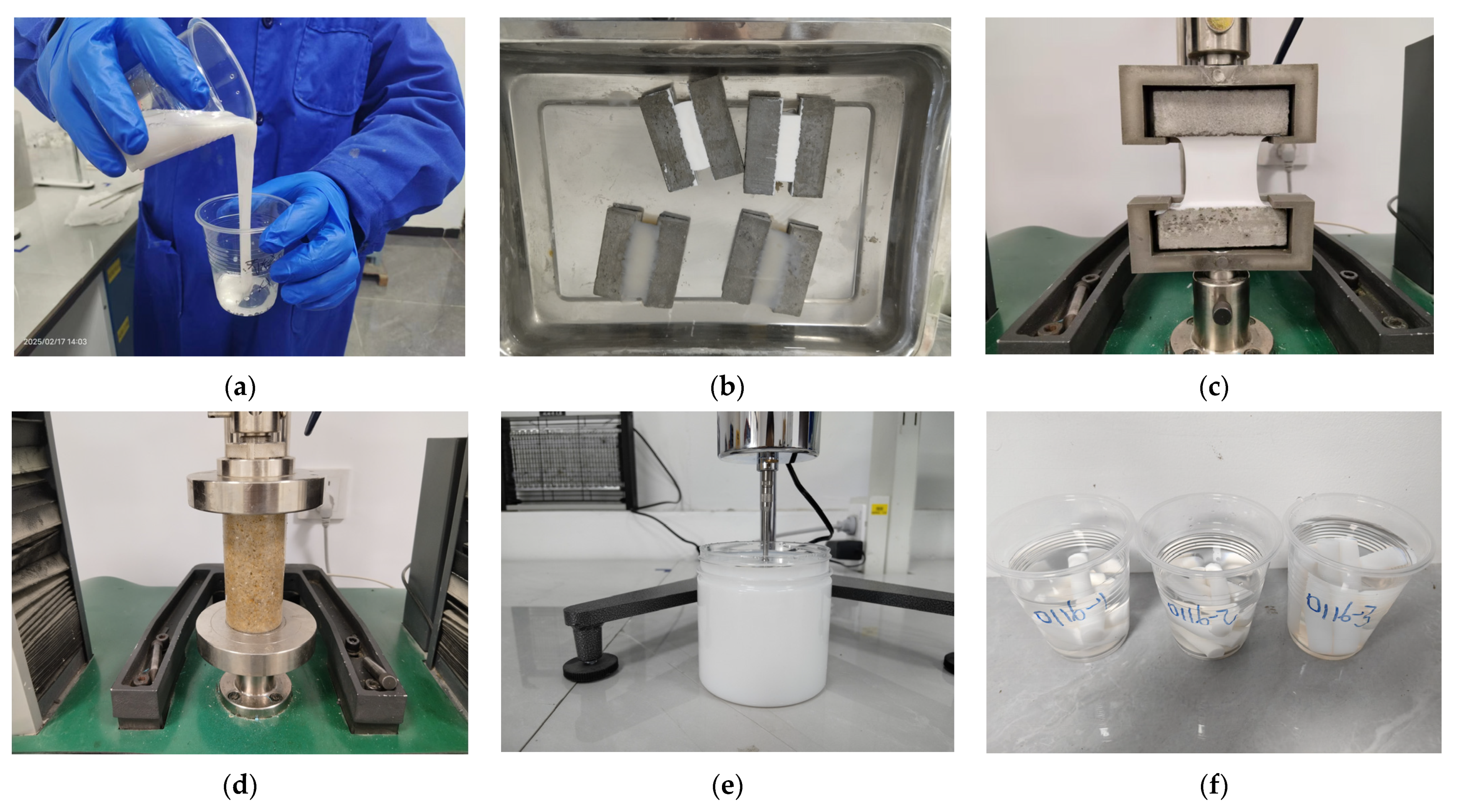

2.2. Sample Preparation

2.3. Performance Testing

3. Results and Discussion

3.1. Effect of Acrylate Concentration on Performance

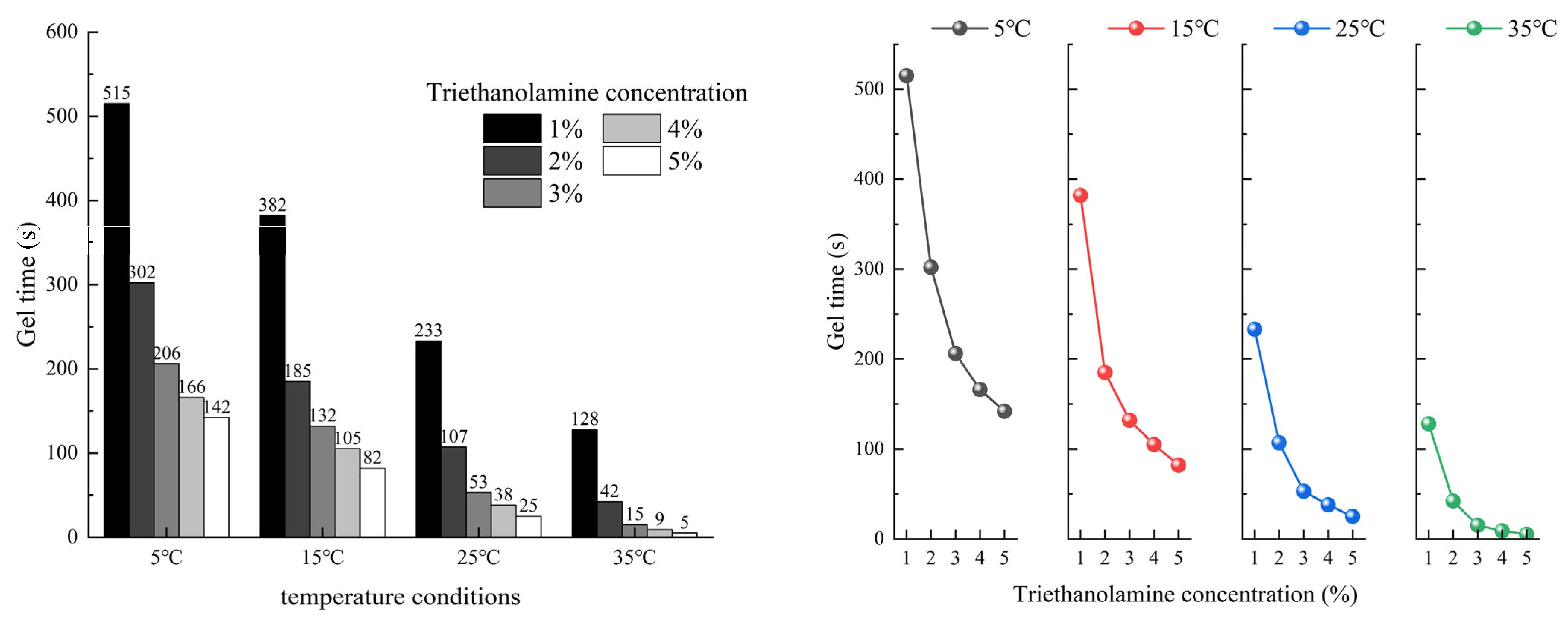

3.2. Effect of Triethanolamine on Gelation Time Under Different Temperature Conditions

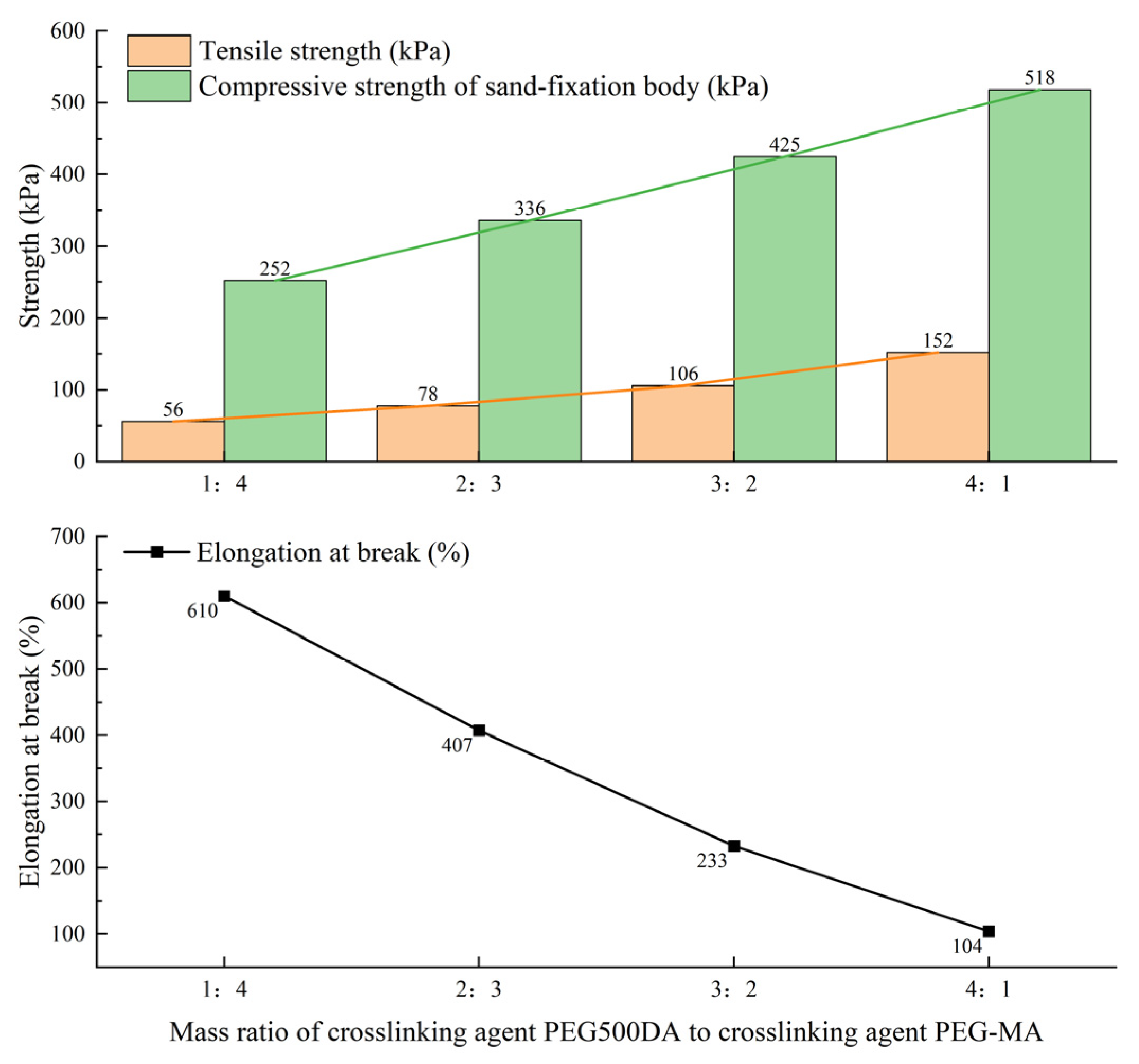

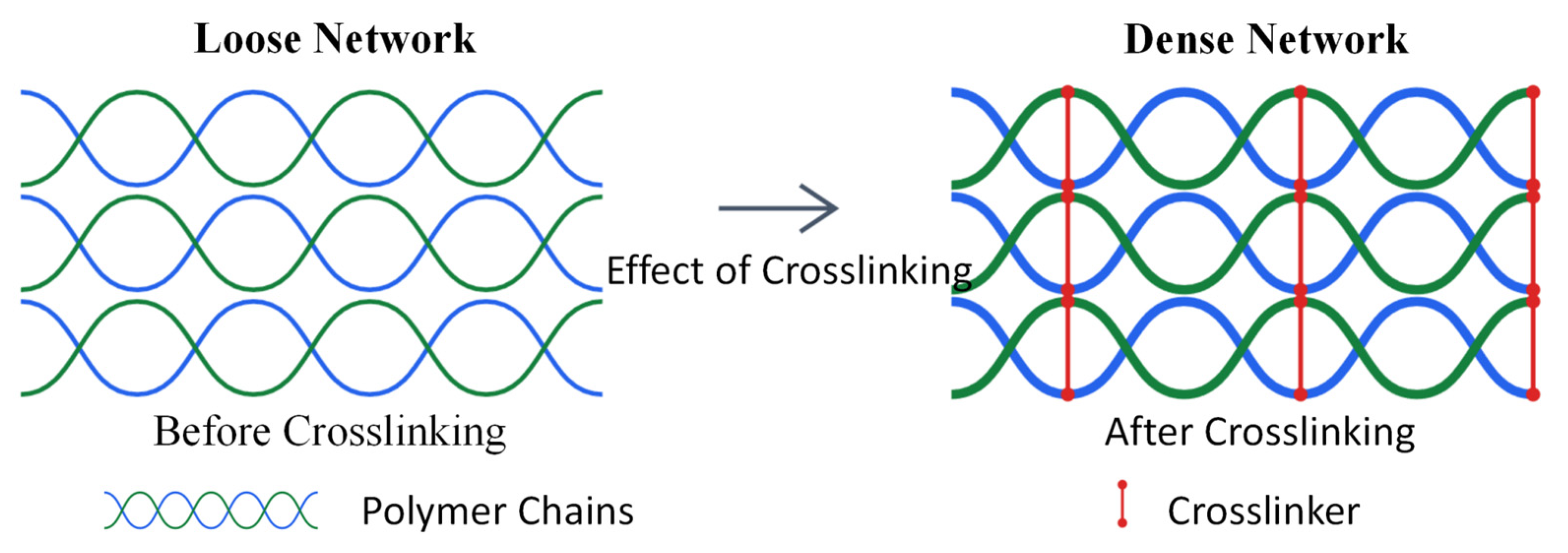

3.3. Effect of Crosslinker Ratio on Mechanical Properties

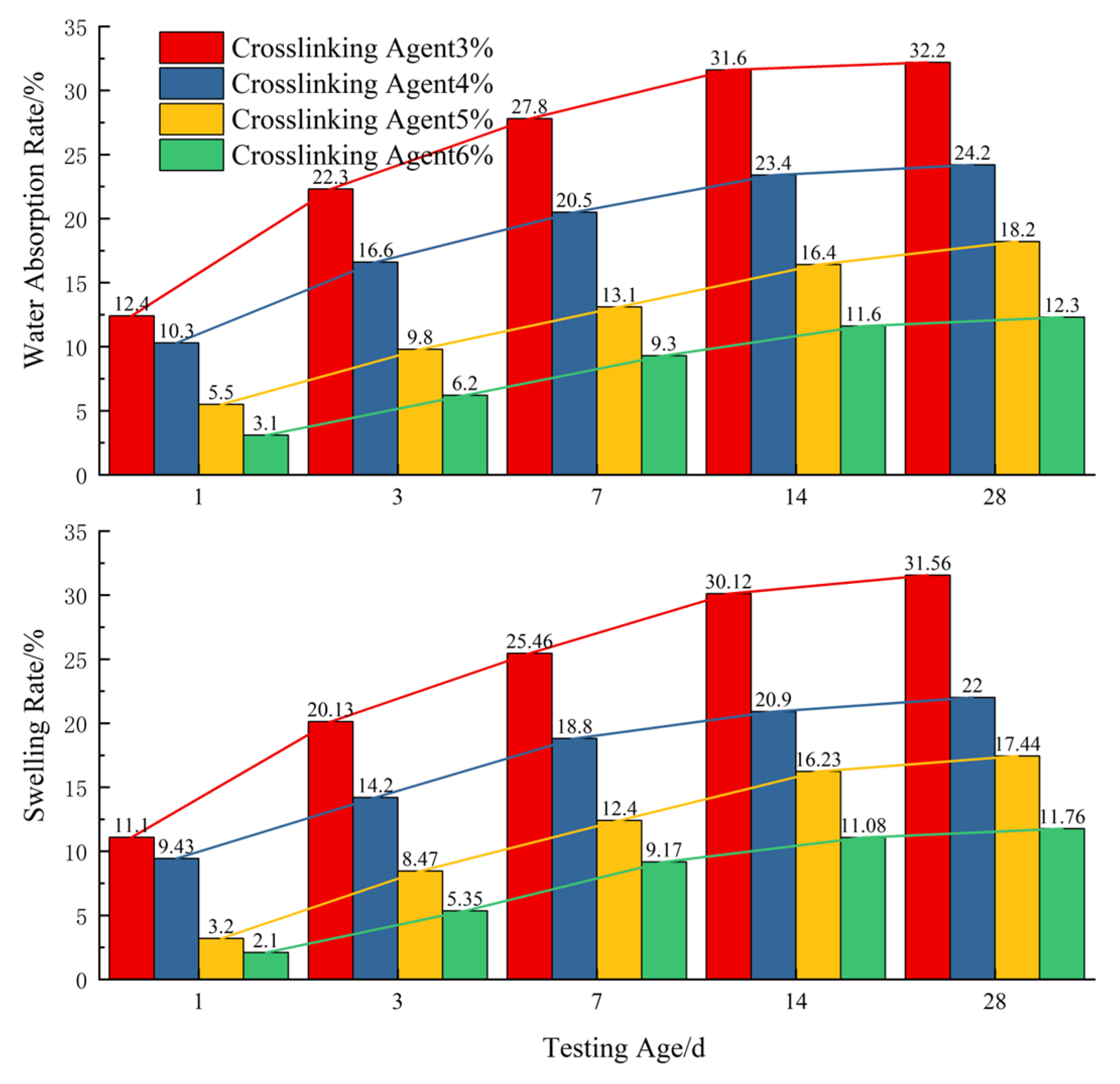

3.4. Analysis of Factors Affecting Water Absorption and Swelling

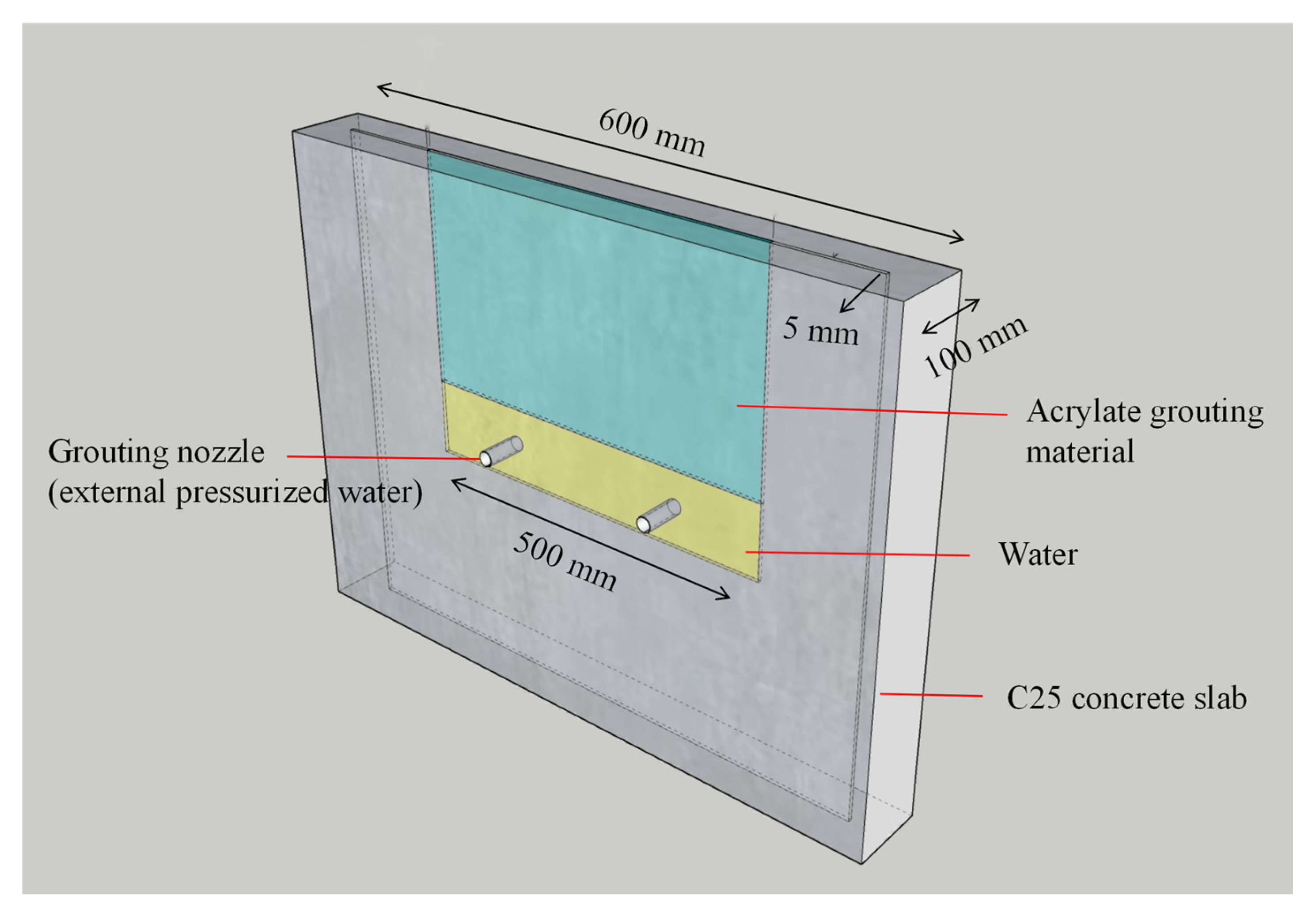

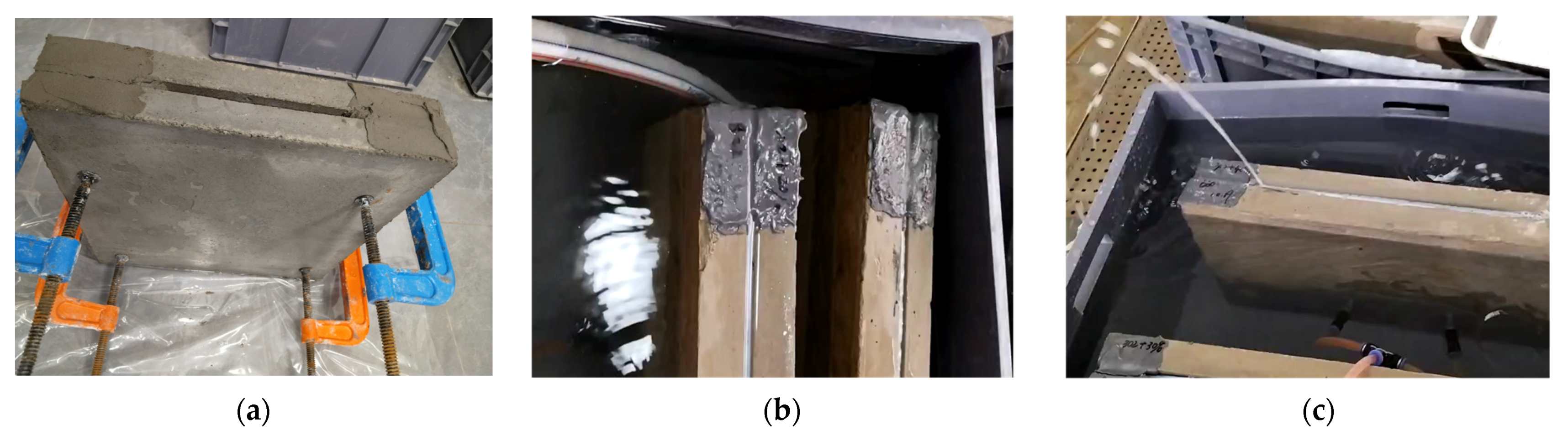

3.5. Anti-Extrusion Performance Test

3.6. Comparative Analysis with Previous Studies

- Mechanical Performance Enhancement: Compared with conventional acrylate materials, the compressive strength of the optimized solid sand body reaches 236–585 kPa, which is significantly higher than that of conventional acrylate materials (150–200 kPa) [2] and close to that of polyurethane-based materials (12–24 MPa) [12]. The elongation at break >376%, overcoming the brittleness problem of conventional acrylates (<100%). The comparison is shown in Table 3.

- Hydraulic Stability under Pressure: In this study, the hydrophobic crosslinking network design is significantly better than the existing materials. In terms of short-term water pressure resistance, the 1-day water pressure resistance reaches 300 kPa, which is better than that of water-soluble polyurethane and cement-based materials; in terms of long-term stability, the 28-day water pressure resistance is stabilized at 350 kPa, which is 75% higher than that of commercial acrylate products (200 kPa), and there is no strength attenuation problem commonly found (a 30% decay rate was reported by Liang et al.) [4]. The viscosity of the slurry, 8.3 mPa·s, combines low viscosity and scour resistance, which is superior to traditional acrylates (10–20 mPa·s) and polyurethanes (solvent dilution required) [6].

- Durability and Environmental Adaptability: In terms of chemical resistance, the material in this study indirectly improves the resistance to ionic penetration by reducing the water absorption (12%). In terms of environmental protection, the use of polyethylene glycol derivatives (PEG500DA/PEG-MA) avoids the toxicity of organic solvents in the case of epoxy resins and the problem of the volatilization of isocyanates in the case of polyurethanes.

4. Conclusions and Outlook

4.1. Key Findings

- Material Performance Optimization and Concentration Regulation: Using a mixed solution of magnesium, calcium, and zinc acrylate as the base, combined with the synergistic effect of a bifunctional crosslinker (PEG500DA) and a monofunctional crosslinker (D), the mechanical properties and water stability of the material were significantly improved. When the acrylate concentration was increased to 35%, the slurry viscosity (8.3 mPa·s) and mechanical properties (tensile strength of 76 kPa, compressive strength of sand-solidified body of 440 kPa) reached an optimal balance, while maintaining excellent permeability, meeting the needs of complex engineering environments.

- Precise Control of Gelation Time: By adjusting the triethanolamine content and construction temperature, the gelation time can be flexibly controlled. At room temperature (25 °C), a triethanolamine content of 2–3% can stabilize the gelation time at 60–120 s, while under high-temperature or high-content conditions, it can be further shortened to 25 s, providing adaptive solutions for different construction scenarios (such as emergency water stoppage or low-temperature environments).

- Crosslinker Ratio and Water Stability: The ratio of crosslinkers PEG500DA to D directly affects the strength–toughness balance of the material. When the ratio is 2:3, the material exhibits both high tensile strength (78 kPa) and excellent ductility (elongation at break >407%). At the same time, when the total crosslinker content reaches 5%, the 28-day water absorption rate (12%) and volume expansion rate (11%) are significantly reduced, indicating that the material can maintain a stable structure under long-term immersion.

- Breakthrough in Anti-Water Extrusion Performance: Through simulated pressurized water environment tests, the anti-water pressure strength of the modified acrylate grouting material reached 300 kPa after 1 day and stabilized at 350 kPa after 28 days, far exceeding that of commercially available products (<200 kPa). The failure mode is mainly internal gel failure, with excellent interfacial bonding strength, effectively resisting the risk of leakage under high-water-pressure environments, providing reliable long-term anti-seepage and water stoppage protection for underground engineering.

4.2. Study Limitations

- Lack of Microstructural Characterization: The polymer network’s crystallinity, crosslinking density, and interfacial bonding mechanisms (e.g., gel–aggregate interactions) were not analyzed using XRD, SEM-EDS, or FTIR. This omission hinders a mechanistic understanding of how crosslinker ratios regulate chain arrangements and phase-interface properties.

- Narrowed Environmental Testing: While hydraulic stability was validated under controlled laboratory conditions, the material’s performance in extreme environments (e.g., high salinity, dynamic water flow) remains untested, limiting direct extrapolation to field applications.

- Limited Multi-Factor Interaction Analysis: The single-factor experimental design identified dominant trends but did not systematically quantify synergistic or antagonistic effects between components, potentially underestimating optimization potential.

4.3. Future Directions

- Microstructural Analysis: Employ XRD to quantify crosslinker-induced crystallinity changes and polymer chain alignment. Use SEM-EDS to map elemental distributions at gel–aggregate interfaces, elucidating bonding enhancement mechanisms. Apply in situ FTIR to track chemical bond evolution during polymerization, refining reaction kinetic models.

- Expanded Environmental Testing: Conduct field trials under extreme hydrogeological conditions (e.g., saline groundwater and a turbulent flow) to validate long-term stability and adaptability.

- Multi-Component Interaction Modeling: Apply response surface methodology (RSM) coupled with genetic algorithms (GAs) to resolve nonlinear interactions among key variables (e.g., the acrylate concentration, the crosslinker ratio, and the initiator/promoter content).

- Material Optimization: Explore ternary crosslinking systems or hybrid organic–inorganic networks to further balance strength and ductility while reducing production costs.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PEG500DA | Polyethylene glycol diacrylate |

| PEG-MA | Monofunctional crosslinker (experimental code) |

| TEA | Triethanolamine |

| SPS | Sodium persulfate |

References

- Wang, J.; Zhang, H.; Zhu, Y.; Yan, Z.; Chai, H. Acrylamide in-situ polymerization of toughened sulphoaluminate cement-based grouting materials. Constr. Build. Mater. 2022, 319, 126105. [Google Scholar] [CrossRef]

- Lu, H.; Dong, Q.; Yan, S.; Chen, X.; Wang, X. Development of flexible grouting material for cement-stabilized macadam base using response surface and genetic algorithm optimization methodologies. Constr. Build. Mater. 2023, 409, 133823. [Google Scholar] [CrossRef]

- Chai, H.; Liu, S.; Zhao, L.; Tian, Y.; Guo, Z.; Zhang, H. Enhancing sulfate resistance of sulfate-aluminate cement grouting material through acrylamide in-situ polymerization modification. Constr. Build. Mater. 2023, 408, 133799. [Google Scholar] [CrossRef]

- Liang, X.; Feng, K.; Wang, C.; Hu, Z.; He, C. Evaluation of rheology and washout resistance of cement-based grouts in water-rich strata. Tunn. Undergr. Space Technol. 2025, 157, 106334. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Liu, X.; Guan, X.; Zhang, C. Flexible and stretchable polyurethane/waterglass grouting material. Constr. Build. Mater. 2017, 138, 240–246. [Google Scholar] [CrossRef]

- Wu, L.; Wu, Z.; Weng, L.; Liu, Y.; Liu, Q. Investigation on basic properties and microscopic mechanisms of polyacrylate latex modified cement grouting material for water blocking and reinforcement. Constr. Build. Mater. 2023, 409, 133872. [Google Scholar] [CrossRef]

- Wu, L.; Wu, Z.; Weng, L.; Liu, Y.; Chu, Z.; Xu, X. Investigation on the pore size characteristics and mechanical properties of grouting materials scoured by flow water. Int. J. Rock Mech. Min. Sci. 2024, 183, 105923. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, G.; Zhang, P.; Zhou, B.; Zhang, P.; Xu, P.; Qiu, Z.; Xie, Z.; Mei, L. Modified castor oil-based UV/thermal dual-curing polyurethane acrylate coatings with outstanding comprehensive properties. Mater. Today Commun. 2024, 41, 110978. [Google Scholar] [CrossRef]

- Chen, Z.; Qiao, J.; Yang, X.; Sun, Y.; Sun, D. A review of grouting materials for pouring semi-flexible pavement: Materials, design and performance. Constr. Build. Mater. 2023, 379, 131235. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, S.-A.; Yu, K.; Guo, J.-Z.; Wang, Y.-X.; Li, B. Adsorption of lead ions and methylene blue on acrylate-modified hydrochars. Bioresour. Technol. 2023, 379, 129067. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, J.; Li, Z.; Luo, J.; Wang, S.; Tang, J.; Wang, X.; Hu, X.; Zhang, F. UV-curable organic silicone grafting modified waterborne polyurethane acrylate: Preparation and properties. Int. J. Adhes. Adhes. 2024, 129, 103583. [Google Scholar] [CrossRef]

- Ha, Y.-M.; Cho, E.; Lim, H.T.; Won, J.C.; Kim, Y.H.; Kim, Y.S.; Kim, J. Ultraviolet-curable optically clear resins using novel fluorinated imide-modified urethane acrylates. Mater. Today Commun. 2022, 33, 104370. [Google Scholar] [CrossRef]

- Zhang, H.; Yao, S.; Wang, J.; Zhou, R.; Zhu, Y.; Zou, D. Tensile Properties of sulfoaluminate cement-based grouting materials toughened by in-situ polymerization of acrylamide. Constr. Build. Mater. 2023, 375, 130885. [Google Scholar] [CrossRef]

- Chen, J.; Qiao, M.; Gao, N.; Wu, J.; Shan, G.; Zhu, B.; Ran, Q. Acrylate based post-acting polymers as novel viscosity modifying admixtures for concrete. Constr. Build. Mater. 2021, 312, 125414. [Google Scholar] [CrossRef]

- Cui, Y.; Tan, Z.; An, C. Research and application of multi-functional acrylic resin grouting material. Constr. Build. Mater. 2022, 359, 129381. [Google Scholar] [CrossRef]

- Shu, X.; Zhao, Y.; Liu, Z.; Zhao, C. A Study on the mix proportion of fiber-polymer composite reinforced cement-based grouting material. Constr. Build. Mater. 2022, 328, 127025. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Liu, M.; Yu, X. Comparative study on the mechanical properties of solidified silty-fine sand reinforced by permeable polymer and traditional grouting materials. Constr. Build. Mater. 2024, 419, 135485. [Google Scholar] [CrossRef]

- Li, S.; Ma, C.; Liu, R.; Chen, M.; Yan, J.; Wang, Z.; Duan, S. Super-absorbent swellable polymer as grouting material for treatment of karst water inrush. Int. J. Min. Sci. Technol. 2021, 31, 753–763. [Google Scholar] [CrossRef]

- Song, J.; Johnson, D.W.; Huang, J.; Saslow, S. Water reactive polyurethane grouting for deep vadose zone contaminant immobilization. Eng. Geol. 2025, 347, 107945. [Google Scholar] [CrossRef]

- Li, L.; Chai, H.; Hu, Y.; He, R.; Wang, Z. Feasibility study on superabsorbent polymer (SAP) as internal curing agent for cement-based grouting material. Constr. Build. Mater. 2024, 411, 134286. [Google Scholar] [CrossRef]

- Hüsken, G.; Shamsuddoha, M.; Pirskawetz, S.; Hofmann, D.; Baeßler, M.; Kühne, H.-C. Potential of a repair system for grouted connections in offshore structures. Dev. Exp. Verification. Mar. Struct. 2021, 77, 102934. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, D.; Chen, L.; Zheng, Y.; Zheng, H.; Cui, Y.; Wu, R. Fluorinated silicone-modified epoxy acrylate amphiphobic coatings exhibiting highly efficient resistance to simulants of chemical warfare agents. Eur. Polym. J. 2025, 228, 113793. [Google Scholar] [CrossRef]

- JC/T 2037-2010; Acrylate Grouting Materials. China Building Materials Federation: Beijing, China, 2010.

- GB/T 13477.8-2017; Test Methods for Construction Sealants-Part 8: Determination of Tensile Properties. Standardization Administration of China: Beijing, China, 2017.

- SL 31–2003; Code of Water Pressure test in Borechole for Water Resources and Hydropower Engineering. China Water & Power Press: Beijing, China, 2003.

| Material Composition | Weight Ratio (%) | Functional Description | Functional Classification | Manufacturing Company | Fineness |

|---|---|---|---|---|---|

| Acrylate mixture | 25–35 | A blend of magnesium acrylate, zinc acrylate, and calcium acrylate in a specific ratio, serving as the primary matrix for bonding and mechanical performance. | Matrix material | Oriental Yuhong Waterproof Technology Co., Ltd. (Beijing, China) | 95–99 |

| PEG diacrylate (PEG500DA) | 0.5–5 | Bifunctional crosslinking agent that enhances intermolecular crosslinking density, improving mechanical strength and structural stability. | Crosslinking agent | Changxing Chemical (Qingdao, China) | 98–99 |

| PEG monoacrylate (PEG-MA) | 0.5–5 | Monofunctional crosslinking agent that regulates crosslinking degree to optimize flexibility and processability. | Crosslinking agent | Self-restraint | 95–98 |

| Triethanolamine (TEA) | 0.5–2 | Catalyzes polymerization and adjusts pH to ensure uniform and stable reaction conditions. | Curing accelerator/Promoter | Dow Chemical Company (Shanghai, China) | 99 |

| Sodium persulfate (SPS) | 0.2–2.5 | Initiates free radical polymerization of acrylate monomers to promote polymer chain formation. | Polymerization initiator | Langfang Pengcai Fine Chemical Co. (Langfang, China) | 98–99 |

| Potassium ferricyanide | 0–0.1 | Inhibits polymerization rate to prevent rapid reaction-induced inhomogeneity. | Reaction regulator | Commercially Available | 99 |

| Deionized water | 60–80 | Adjusts system concentration and fluidity for uniform dispersion and reaction efficiency. | Solvent | Commercially Available | Conductivity <1 μS/cm |

| Acrylate Concentration | 20% | 25% | 30% | 35% | 40% |

|---|---|---|---|---|---|

| Initial Viscosity (mPa·s) | 2.3 | 3.6 | 5.2 | 8.3 | 14 |

| Tensile Strength (kPa) | 21 | 38 | 62 | 76 | 88 |

| Compressive Strength of Sand-Solidified Body (kPa) | 236 | 325 | 390 | 440 | 585 |

| Elongation at Break (%) | 268 | 322 | 376 | 405 | 423 |

| Performance Indicators | Data for This Study | Conventional Acrylics | Polyurethane Materials | Cementitious Materials (Class IV) |

|---|---|---|---|---|

| Compressive strength of solid sand | 385–440 kPa | 150–200 kPa | 12–24 MPa | 65–85 MPa |

| Elongation at break | >320% | 100% | 1000–2000% | <0.5% |

| Absorption rate of 28 days of water | 12% | 25–30% (Long-term water absorption) | <5% | 15–20% |

| Resistance to water pressure (28 days) | 350 kPa | <200 kPa | ≥0.8 MPa | impermeability rating ≥ P8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, F.; Qin, L.; Han, D.; Huang, F. Optimization of Water Plugging Characteristics and Mechanical Properties of Acrylate Grouting Materials Based on Composite Crosslinking Strategy. Polymers 2025, 17, 827. https://doi.org/10.3390/polym17060827

Yu F, Qin L, Han D, Huang F. Optimization of Water Plugging Characteristics and Mechanical Properties of Acrylate Grouting Materials Based on Composite Crosslinking Strategy. Polymers. 2025; 17(6):827. https://doi.org/10.3390/polym17060827

Chicago/Turabian StyleYu, Fengxian, Langtian Qin, Deqiang Han, and Feng Huang. 2025. "Optimization of Water Plugging Characteristics and Mechanical Properties of Acrylate Grouting Materials Based on Composite Crosslinking Strategy" Polymers 17, no. 6: 827. https://doi.org/10.3390/polym17060827

APA StyleYu, F., Qin, L., Han, D., & Huang, F. (2025). Optimization of Water Plugging Characteristics and Mechanical Properties of Acrylate Grouting Materials Based on Composite Crosslinking Strategy. Polymers, 17(6), 827. https://doi.org/10.3390/polym17060827