Bioengineering the Future: Tomato Peel Cutin as a Resource for Medical Textiles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Solutions Preparation

2.3. Solutions Characterization

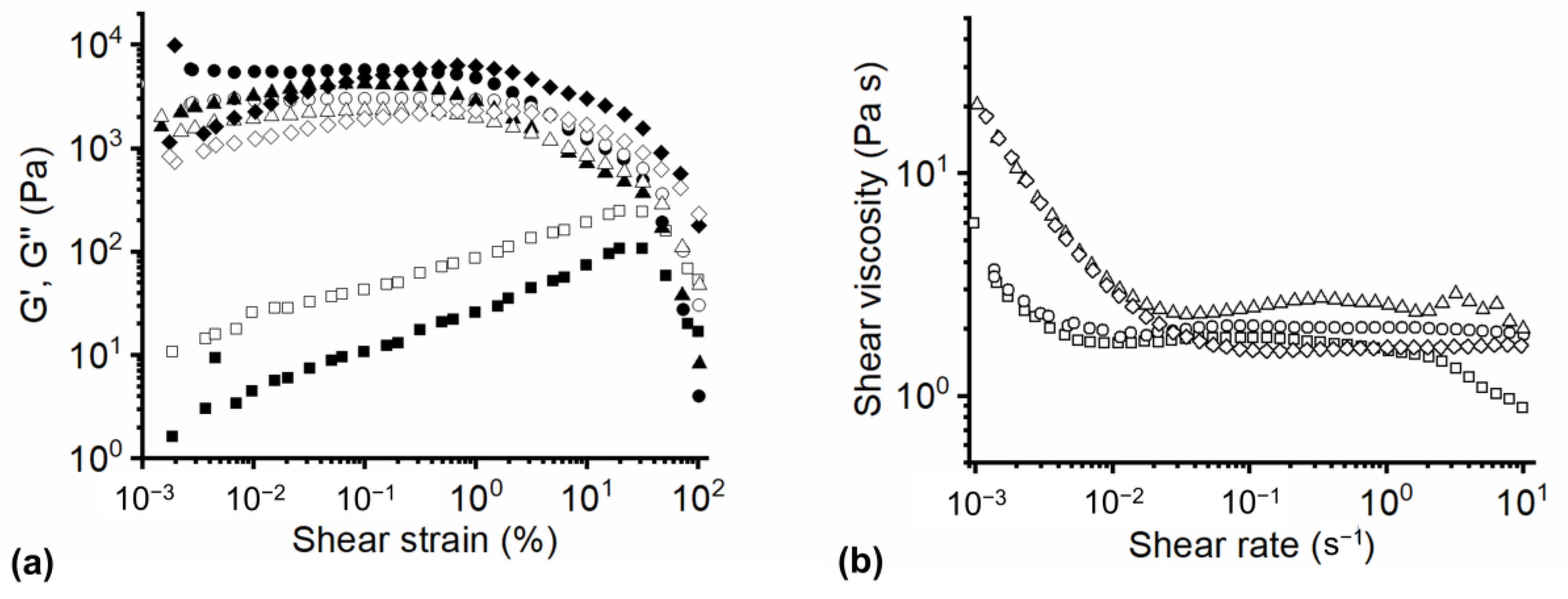

2.3.1. Rheological Measurements

2.3.2. Measurement of Surface Tension

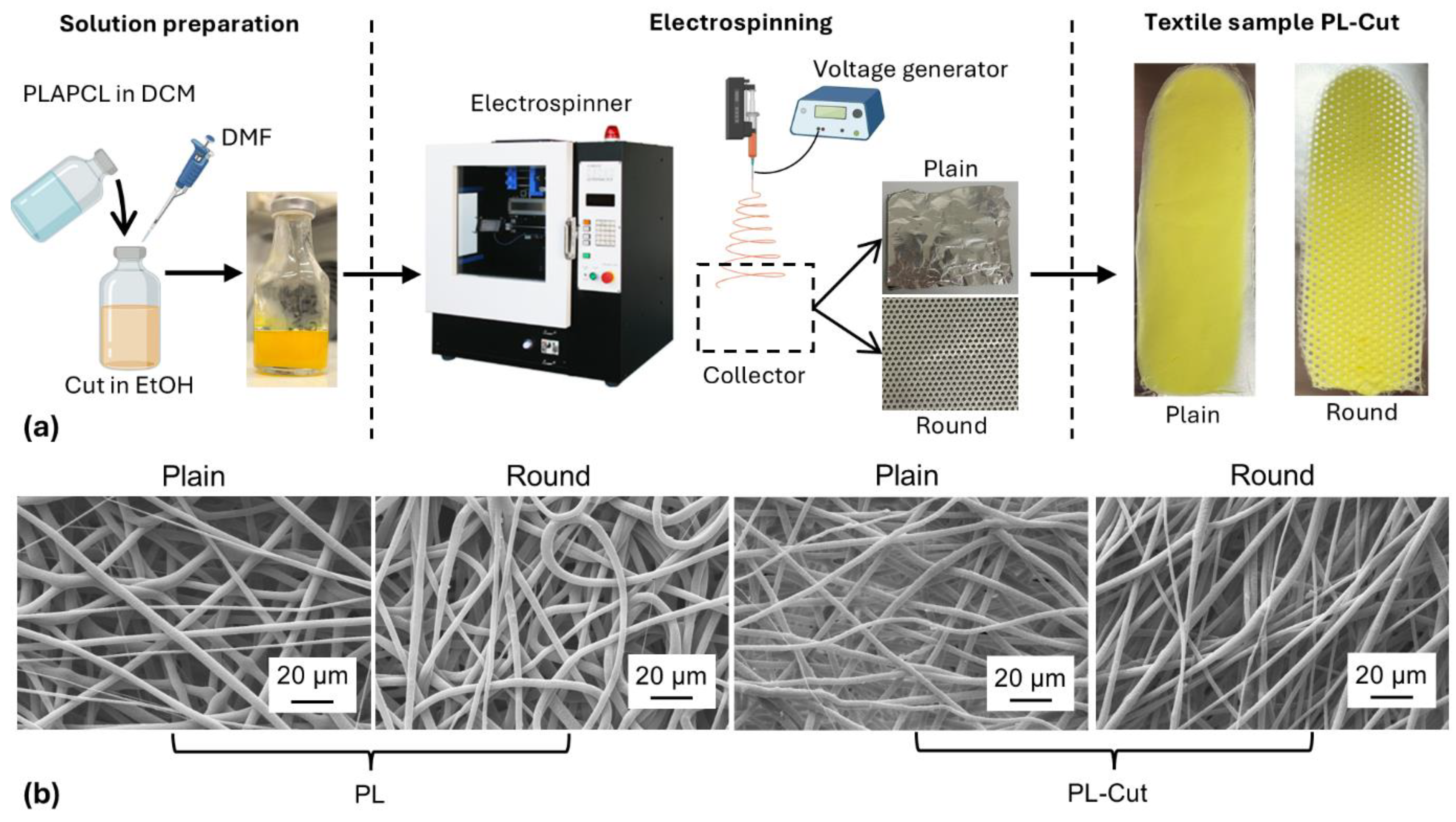

2.4. Fabrication of PLAPCL–Cut Fibers Through Electrospinning

2.5. Scanning Electron Microscopy

2.6. Determination of Encapsulation Efficiency

2.7. Gel Permeation Chromatography

2.8. Thermogravimetric Analysis

2.9. Differential Scanning Calorimetry

2.10. γ-Sterilization

2.11. Contact Angle Measurement

2.12. Tensile Test

2.13. Biological Characterization

2.13.1. Cell Culture

2.13.2. MTT Assay

2.13.3. Morphological Characterization

2.14. Preliminary Analysis of the Life Cycle of Greenhouse Gas (GHG) Emissions

2.15. Statistical Analysis

3. Results and Discussion

3.1. Solution Characterization

3.2. Electrospinning of PLAPCL and PLAPCL–Cut Solutions

3.3. Morphological Characterization of the Developed Patches

3.4. Cutin Encapsulation Efficiency

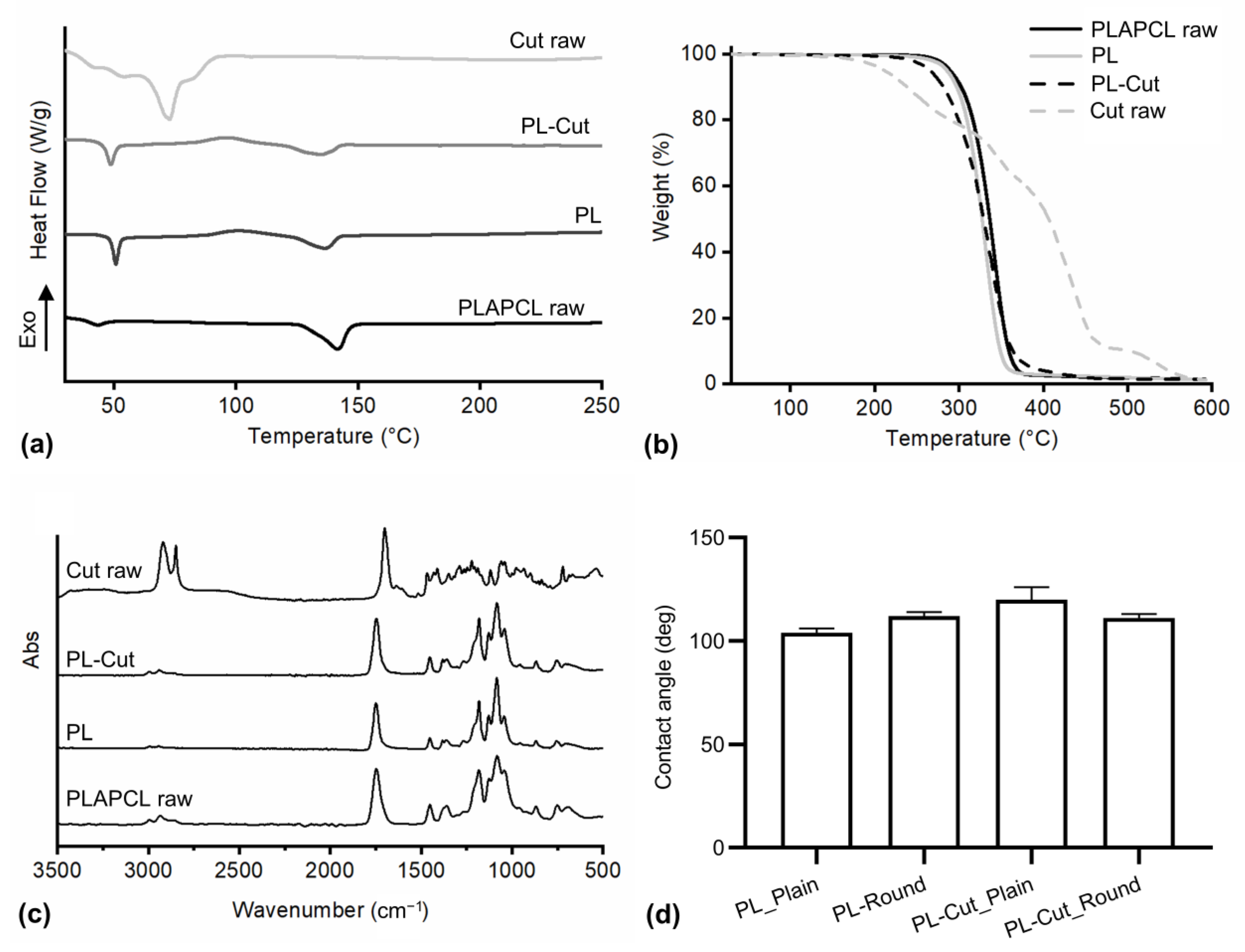

3.5. Thermal Characterization

3.6. Infrared Spectroscopy

3.7. Determination of the Wettability of the Textiles

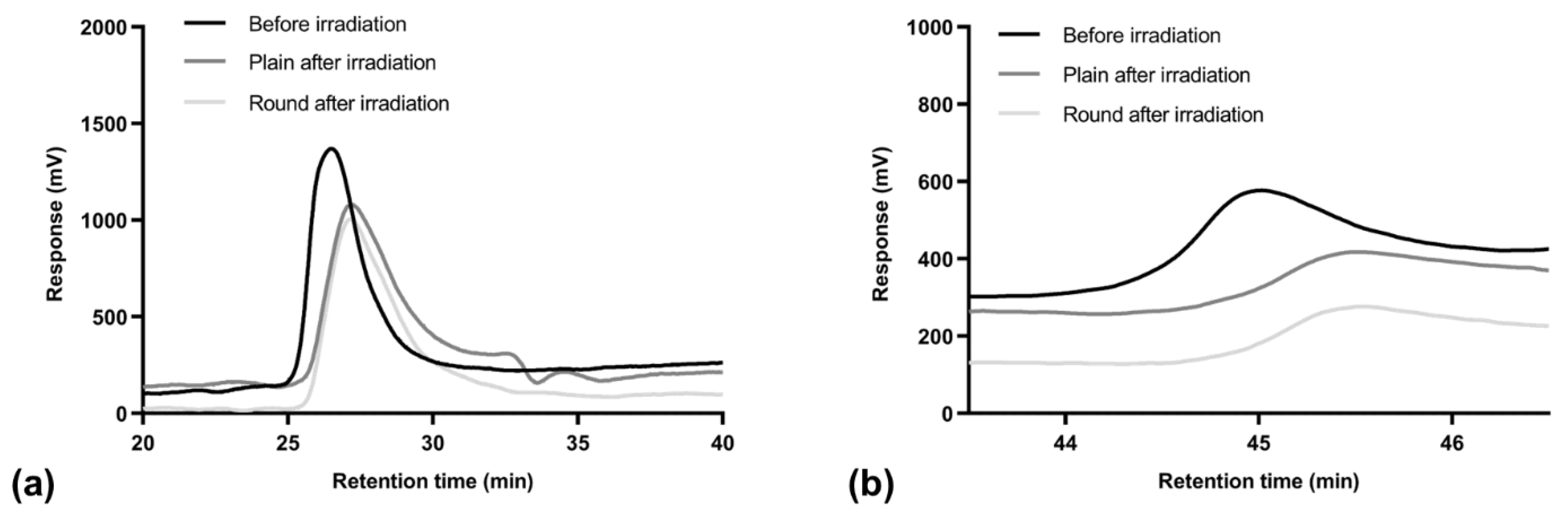

3.8. Stability After γ-Irradiation

3.9. Mechanical Characterization

3.10. Determination of Cytotoxicity

3.11. Assessing Global GHG Emissions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Das, A.K.; Islam, M.N.; Billah, M.M.; Sarker, A. COVID-19 pandemic and healthcare solid waste management strategy—A mini-review. Sci. Total Environ. 2021, 778, 146220. [Google Scholar] [CrossRef]

- Mondal, R.; Mishra, S.; Pillai, J.S.K.; Sahoo, M.C. COVID 19 Pandemic and biomedical waste management practices in healthcare system. J. Fam. Med. Prim. Care 2022, 11, 439–446. [Google Scholar] [CrossRef]

- Italian Institute for Environmental Protection and Research (ISPRA). 2024. Available online: https://www.isprambiente.gov.it/it (accessed on 20 November 2024).

- World Health Organization. Global Analysis of Healthcare Waste in the Context of COVID-19: Status, Impacts and Recommendations. 2022. Available online: https://www.who.int/publications/i/item/9789240039612 (accessed on 20 November 2024).

- Bala, S.; Garg, D.; Sridhar, K.; Inbaraj, B.S.; Singh, R.K.S.; Tripathi, M.; Sharma, M. Transformation of Agro-Waste into Value-Added Bioproducts and Bioactive Compounds: Micro/Nano Formulations and Application in the Agri-Food-Pharma Sector. Bioengineering 2023, 10, 152. [Google Scholar] [CrossRef]

- Chew, X.; Khaw, K.W.; Alnoor, A.; Ferasso, M.; Al Halbusi, H.; Muhsen, Y.R. Circular economy of medical waste: Novel intelligent medical waste management framework based on extension linear Diophantine fuzzy FDOSM and neural network approach. Environ. Sci. Pollut. Res. 2023, 30, 60473–60499. [Google Scholar] [CrossRef]

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef]

- Cui, X.; Ng, K.R.; Chai, K.F.; Chen, W.N. Clinically relevant materials & applications inspired by food technologies. EBioMedicine 2022, 75, 103792. [Google Scholar] [CrossRef]

- Saini, R.K.; Moon, S.H.; Keum, Y.S. An updated review on use of tomato pomace and crustacean processing waste to recover commercially vital carotenoids. Food Res. Int. 2018, 108, 516–529. [Google Scholar] [CrossRef]

- Righetti, G.I.C.; Nasti, R.; Beretta, G.; Levi, M.; Turri, S.; Suriano, R. Unveiling the Hidden Properties of Tomato Peels: Cutin Ester Derivatives as Bio-Based Plasticizers for Polylactic Acid. Polymers 2023, 15, 1848. [Google Scholar] [CrossRef]

- Cifarelli, A.; Cigognini, I.M.; Bolzoni, L.; Montanari, A. Physical-Chemical Characteristics of Cutin Separated from Tomato Waste for the Preparation of Bio-Lacquers. Adv. Sci. Eng. 2019, 11, 33–45. [Google Scholar] [CrossRef]

- Escorcio, R.; Bento, A.; Tome, A.S.; Correia, V.G.; Rodrigues, R.; Moreira, C.J.S.; Marion, D.; Bakan, B.; Silva Pereira, C. Finding a Needle in a Haystack: Producing Antimicrobial Cutin-Derived Oligomers from Tomato Pomace. ACS Sustain. Chem. Eng. J. 2022, 10, 11415–11427. [Google Scholar] [CrossRef]

- Ruffini, E.; Bianchi Oltolini, A.; Magni, M.; Beretta, G.; Cavallaro, M.; Suriano, R.; Turri, S. Crosslinked Polyesters as Fully Biobased Coatings with Cutin Monomer from Tomato Peel Wastes. Polymers 2024, 16, 682. [Google Scholar] [CrossRef]

- Manrich, A.; Moreira, F.K.; Otoni, C.G.; Lorevice, M.V.; Martins, M.A.; Mattoso, L.H. Hydrophobic edible films made up of tomato cutin and pectin. Carbohydr. Polym. 2017, 164, 83–91. [Google Scholar] [CrossRef]

- Simoes, A.; Coelhoso, I.M.; Alves, V.D.; Brazinha, C. Recovery and Purification of Cutin from Tomato By-Products for Application in Hydrophobic Films. Membranes 2023, 13, 261. [Google Scholar] [CrossRef]

- Xing, J.; Zhang, M.; Liu, X.; Wang, C.; Xu, N.; Xing, D. Multi-material electrospinning: From methods to biomedical applications. Mater. Today Bio 2023, 21, 100710. [Google Scholar] [CrossRef]

- Rostamitabar, M.; Abdelgawad, A.M.; Jockenhoevel, S.; Ghazanfari, S. Drug-Eluting Medical Textiles: From Fiber Production and Textile Fabrication to Drug Loading and Delivery. Macromol. Biosci. 2021, 21, e2100021. [Google Scholar] [CrossRef]

- Dziemidowicz, K.; Sang, Q.; Wu, J.; Zhang, Z.; Zhou, F.; Lagaron, J.M.; Mo, X.; Parker, G.J.M.; Yu, D.G.; Zhu, L.M.; et al. Electrospinning for healthcare: Recent advancements. J. Mater. Chem. B 2021, 9, 939–951. [Google Scholar] [CrossRef]

- Liu, Z.; Yin, F.; Ruan, N.; Gao, Z. Mapping the knowledge domains of medical textiles: A review. Medicine 2023, 102, e35956. [Google Scholar] [CrossRef]

- Medical Textiles: Properties, Classifications. 2024. Available online: https://www.jasonmills.com/blog/medical-textiles/ (accessed on 20 November 2024).

- Tian, W.; Huang, K.; Zhu, C.; Sun, Z.; Shao, L.; Hu, M.; Feng, X. Recent progress in biobased synthetic textile fibers. Front. Mater. 2022, 9, 1098590. [Google Scholar] [CrossRef]

- Visco, A.; Scolaro, C.; Facchin, F.; Brahimi, S.; Belhamdi, H.; Gatto, V.; Beghetto, V. Agri-Food Wastes for Bioplastics: European Prospective on Possible Applications in Their Second Life for a Circular Economy. Polymers 2022, 14, 2752. [Google Scholar] [CrossRef]

- Zuiderveen, E.A.R.; Kuipers, K.J.J.; Caldeira, C.; Hanssen, S.V.; van der Hulst, M.K.; de Jonge, M.M.J.; Vlysidis, A.; van Zelm, R.; Sala, S.; Huijbregts, M.A.J. The potential of emerging bio-based products to reduce environmental impacts. Nat. Commun. 2023, 14, 8521. [Google Scholar] [CrossRef]

- Hartanto, B.W.; Mayasari, D.S. Environmentally friendly non-medical mask: An attempt to reduce the environmental impact from used masks during COVID 19 pandemic. Sci. Total Environ. 2021, 760, 144143. [Google Scholar] [CrossRef] [PubMed]

- Nasti, R.; Beretta, G.; Trasatti, S.; Dorati, R.; Conti, B.; Genta, I. Process for the preparation of a cutin-based material and biomedical applications thereof. WIPO Patent WO/2024/241267, 28 November 2024. [Google Scholar]

- Herzyk, F.; Piłakowska-Pietras, D.; Korzeniowska, M. Supercritical Extraction Techniques for Obtaining Biologically Active Substances from a Variety of Plant Byproducts. Foods 2024, 13, 1713. [Google Scholar] [CrossRef]

- Tottoli, E.M.; Chiesa, E.; Ceccarelli, G.; Pisani, S.; Bruni, G.; Genta, I.; Conti, B.; Dorati, R. BioFiber: An advanced fibrous textured dressing to manage exudate in severe wounds. Int. J. Pharm. 2022, 625, 122073. [Google Scholar] [CrossRef]

- ASTM D882-18; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Lee, A.W.L.; Neo, E.R.K.; Khoo, Z.Y.; Yeo, Z.; Tan, Y.S.; Chng, S.; Yan, W.; Lok, B.K.; Low, J.S.C. Life cycle assessment of single-use surgical and embedded filtration layer (EFL) reusable face mask. Resour. Conserv. Recycl. 2021, 170, 105580. [Google Scholar] [CrossRef]

- Pisani, S.; Dorati, R.; Conti, B.; Modena, T.; Bruni, G.; Genta, I. Design of copolymer PLA-PCL electrospun matrix for biomedical applications. React. Funct. Polym. 2018, 124, 77–89. [Google Scholar] [CrossRef]

- Pisani, S.; Genta, I.; Dorati, R.; Modena, T.; Chiesa, E.; Bruni, G.; Benazzo, M.; Conti, B. A Design of Experiment (DOE) approach to correlate PLA-PCL electrospun fibers diameter and mechanical properties for soft tissue regeneration purposes. J. Drug Deliv. Sci. Technol. 2022, 68, 103060. [Google Scholar] [CrossRef]

- Haider, A.; Haider, S.; Kang, I.-K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Tottoli, E.M.; Benedetti, L.; Chiesa, E.; Pisani, S.; Bruni, G.; Genta, I.; Conti, B.; Ceccarelli, G.; Dorati, R. Electrospun Naringin-Loaded Fibers for Preventing Scar Formation during Wound Healing. Pharmaceutics 2023, 15, 15030747. [Google Scholar] [CrossRef] [PubMed]

- Ming, H.; Guan, Y.; Geng, C.; Gao, Y.; Meng, J.; Liang, J. Rheological behavior of particle-filled polymer suspensions and its influence on surface structure of the coated electrodes. E-Polymers 2024, 24, 20230133. [Google Scholar] [CrossRef]

- Liu, Z.; Ramakrishna, S.; Ahmed, I.; Rudd, C.; Liu, X. Rheological, Surface Tension and Conductivity Insights on the Electrospinnability of Poly(lactic-co-glycolic acid)-hyaluronic Acid Solutions and Their Correlations with the Nanofiber Morphological Characteristics. Polymers 2022, 14, 4411. [Google Scholar] [CrossRef]

- Han, T.; Yarin, A.L.; Reneker, D.H. Viscoelastic electrospun jets: Initial stresses and elongational rheometry. Polymer 2008, 49, 1651–1658. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Eticha, A.K.; Akgul, Y.; Pakolpakcil, A.; Unlu, O.K.; Ahmed, S.B.; Cug, H.; Kilic, A. Biodegradable Biconstituent Melt-Blown Nonwovens for Air Filtration: Fabrication and Characterization. Fibers Polym. 2024, 25, 2855–2873. [Google Scholar] [CrossRef]

- Signori, F.; Coltelli, M.-B.; Bronco, S. Thermal degradation of poly(lactic acid) (PLA) and poly(butylene adipate-co-terephthalate) (PBAT) and their blends upon melt processing. Polym. Degrad. Stab. 2009, 94, 74–82. [Google Scholar] [CrossRef]

- Khan, J.E.N.; Mariatti, M.; Vilay, V.; Todo, M. A comprehensive review on facemask manufacturing, testing, and its environmental impacts. J. Ind. Text. 2022, 52, 15280837221111175. [Google Scholar] [CrossRef]

- Meier, P.; Zabara, M.; Hirsch, C.; Gogos, A.; Tscherrig, D.; Richner, G.; Nowack, B.; Wick, P. Evaluation of fiber and debris release from protective COVID-19 mask textiles and in vitro acute cytotoxicity effects. Environ. Int. 2022, 167, 107364. [Google Scholar] [CrossRef]

- Arrighetti, L.; Ricci, L.; De Monte, C.; Aiello, F.; Massa, C.A.; Balzano, F.; Uccello Barretta, G.; Bronco, S. Innovative materials based on physical melt-blending of cutin from tomato waste and poly(lactic acid). Mater. Today Sustain. 2024, 27, 100852. [Google Scholar] [CrossRef]

- Garkhal, K.; Verma, S.; Jonnalagadda, S.; Kumar, N. Fast degradable poly(L-lactide-co-ε-caprolactone) microspheres for tissue engineering: Synthesis, characterization, and degradation behavior. J. Polym. Sci. Part A Polym. Chem. 2007, 45, 2755–2764. [Google Scholar] [CrossRef]

- Heredia-Guerrero, J.A.; Benitez, J.J.; Dominguez, E.; Bayer, I.S.; Cingolani, R.; Athanassiou, A.; Heredia, A. Infrared and Raman spectroscopic features of plant cuticles: A review. Front. Plant Sci. 2014, 5, 305. [Google Scholar] [CrossRef]

- Silverstein, R.; Webster, F.; Kiemle, D. Spectrometric Identification of Organic Compounds; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Masson-Meyers, D.S.; Bumah, V.V.; Enwemeka, C.S. A comparison of four methods for determining viability in human dermal fibroblasts irradiated with blue light. J. Pharmacol. Toxicol. Methods 2016, 79, 15–22. [Google Scholar] [CrossRef]

- Mohd Nizar, M.; Hamzah, M.S.A.; Abd Razak, S.I.; Mat Nayan, N.H. Thermal Stability and Surface Wettability Studies of Polylactic Acid/Halloysite Nanotube Nanocomposite Scaffold for Tissue Engineering Studies. IOP Conf. Ser. Mater. Sci. Eng. 2018, 318, 012006. [Google Scholar] [CrossRef]

- Wolansky, G.; Marmur, A. Apparent contact angles on rough surfaces: The Wenzel equation revisited. Colloids Surf. A Physicochem. Eng. Asp. 1999, 156, 381–388. [Google Scholar] [CrossRef]

- Yang, X.; Li, S.; Yao, Y.; Zhao, J.; Zhu, Z.; Chai, C. Preparation and characterization of polypropylene non-woven fabric/ZIF-8 composite film for efficient oil/water separation. Polym. Test. 2021, 100, 107263. [Google Scholar] [CrossRef]

- Wibisono, Y.; Fadila, C.R.; Saiful, S.; Bilad, M.R. Facile Approaches of Polymeric Face Masks Reuse and Reinforcements for Micro-Aerosol Droplets and Viruses Filtration: A Review. Polymers 2020, 12, 2516. [Google Scholar] [CrossRef]

- Kumar, P.; Vasita, R. Understanding the relation between structural and mechanical properties of electrospun fiber mesh through uniaxial tensile testing. J. Appl. Polym. Sci. 2017, 134, 45012. [Google Scholar] [CrossRef]

- Feng, P.; Jia, J.; Liu, M.; Peng, S.; Zhao, Z.; Shuai, C. Degradation mechanisms and acceleration strategies of poly (lactic acid) scaffold for bone regeneration. Mater. Des. 2021, 210, 110066. [Google Scholar] [CrossRef]

- Deshpande, M.V.; Girase, A.; King, M.W. Degradation of Poly(epsilon-caprolactone) Resorbable Multifilament Yarn under Physiological Conditions. Polymers 2023, 15, 3819. [Google Scholar] [CrossRef]

- Varanges, V.; Caglar, B.; Lebaupin, Y.; Batt, T.; He, W.; Wang, J.; Rossi, R.M.; Richner, G.; Delaloye, J.R.; Michaud, V. On the durability of surgical masks after simulated handling and wear. Sci. Rep. 2022, 12, 4938. [Google Scholar] [CrossRef]

- Minsart, M.; Van Vlierberghe, S.; Dubruel, P.; Mignon, A. Commercial wound dressings for the treatment of exuding wounds: An in-depth physico-chemical comparative study. Burn. Trauma 2022, 10, tkac024. [Google Scholar] [CrossRef]

- ISO-10993-09; Biological Evaluation of Medical Devices—Part 5: Tests for in Vitro Cytotoxicity. International Organization for Standardization: Geneva, Switzerland, 2009.

| Solution a | PLAPCL (% w/v) | Cut (% w/v) | Cut/PLAPCL (w/w) |

|---|---|---|---|

| PLAPCL | 15.0 | - | 0.00 |

| PLAPCL–Cut5 | 15.0 | 0.75 | 0.05 |

| PLAPCL–Cut10 | 15.0 | 1.50 | 0.10 |

| PLAPCL–Cut18 | 15.0 | 2.70 | 0.18 |

| Length (mm) | Width (mm) | Thickness (mm) | Weight (mg) | Fiber’s Diameter (μm) | |

|---|---|---|---|---|---|

| PL Plain | 96.3 ± 7.2 | 22.5 ± 6.2 * | 0.24 ± 0.10 * | 76 ± 7.0 | 3.8 ± 1.4 |

| PL Round | 93.9 ± 3.7 | 26.1 ± 5.0 § | 0.21 ± 0.07 | 72 ± 14 | 3.0 ± 0.8 |

| PL–Cut Plain | 99.6 ± 3.6 | 33.8 ± 4.4 * | 0.11 ± 0.02 * | 77 ± 5.0 | 3.3 ± 0.6 |

| PL–Cut Round | 102.6 ± 7.0 | 37.0 ± 4.2 § | 0.14 ± 0.02 | 91 ± 16 | 3.1 ± 0.9 |

| GHG Emissions | Total kg CO2eq | 0.315 |

|---|---|---|

| Total phase 3 | 0.299 | |

| Phase 3 | PLAPCL | 0.00324 |

| DCM | 1.19 × 10−5 | |

| EtOH | 9.98 × 10−8 | |

| DMF | 2.11 × 10−7 | |

| Electricity | 0.289 | |

| Waste solvent mixture | 0.007 | |

| Total phase 2 | 0.0169 | |

| Phase 2 | MeOH | 0.001 |

| NaOH | 4.90 × 10−5 | |

| H2O | 8.77 × 10−7 | |

| HCl 37% | 1.30 × 10−5 | |

| DCM | 0.002 | |

| Municipal waste treatment | 2.13 × 10−6 | |

| Electricity | 7.94 × 10−6 | |

| Biowaste, treatment | 3.87 × 10−6 | |

| Solvent mixture incineration treatment | 0.008 | |

| Total phase 1 | 0.0054 | |

| Phase 1 | Dry peel tomato | 2.25 × 10−5 |

| H2O | 9.60 × 10−7 | |

| CO2 gas (green solvent) | 0.00145 | |

| Electricity | 0.00196 | |

| Waste H2O | 1.04 × 10−6 | |

| Emissions CO2 gas (green solvent) | 0.00194 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pecorini, G.; Tamburriello, M.; Tottoli, E.M.; Genta, I.; Conti, B.; Gonzalez, M.N.G.; Nasti, R.; Dorati, R. Bioengineering the Future: Tomato Peel Cutin as a Resource for Medical Textiles. Polymers 2025, 17, 810. https://doi.org/10.3390/polym17060810

Pecorini G, Tamburriello M, Tottoli EM, Genta I, Conti B, Gonzalez MNG, Nasti R, Dorati R. Bioengineering the Future: Tomato Peel Cutin as a Resource for Medical Textiles. Polymers. 2025; 17(6):810. https://doi.org/10.3390/polym17060810

Chicago/Turabian StylePecorini, Gianni, Martina Tamburriello, Erika Maria Tottoli, Ida Genta, Bice Conti, Maria Nelly Garcia Gonzalez, Rita Nasti, and Rossella Dorati. 2025. "Bioengineering the Future: Tomato Peel Cutin as a Resource for Medical Textiles" Polymers 17, no. 6: 810. https://doi.org/10.3390/polym17060810

APA StylePecorini, G., Tamburriello, M., Tottoli, E. M., Genta, I., Conti, B., Gonzalez, M. N. G., Nasti, R., & Dorati, R. (2025). Bioengineering the Future: Tomato Peel Cutin as a Resource for Medical Textiles. Polymers, 17(6), 810. https://doi.org/10.3390/polym17060810