A Self-Healing Structure Based on Monolayer Wall-Less Microvascular Network Carriers for Orthotropic Anisotropic Polymer Composites

Abstract

1. Introduction

2. Self-Healing Topology Optimization

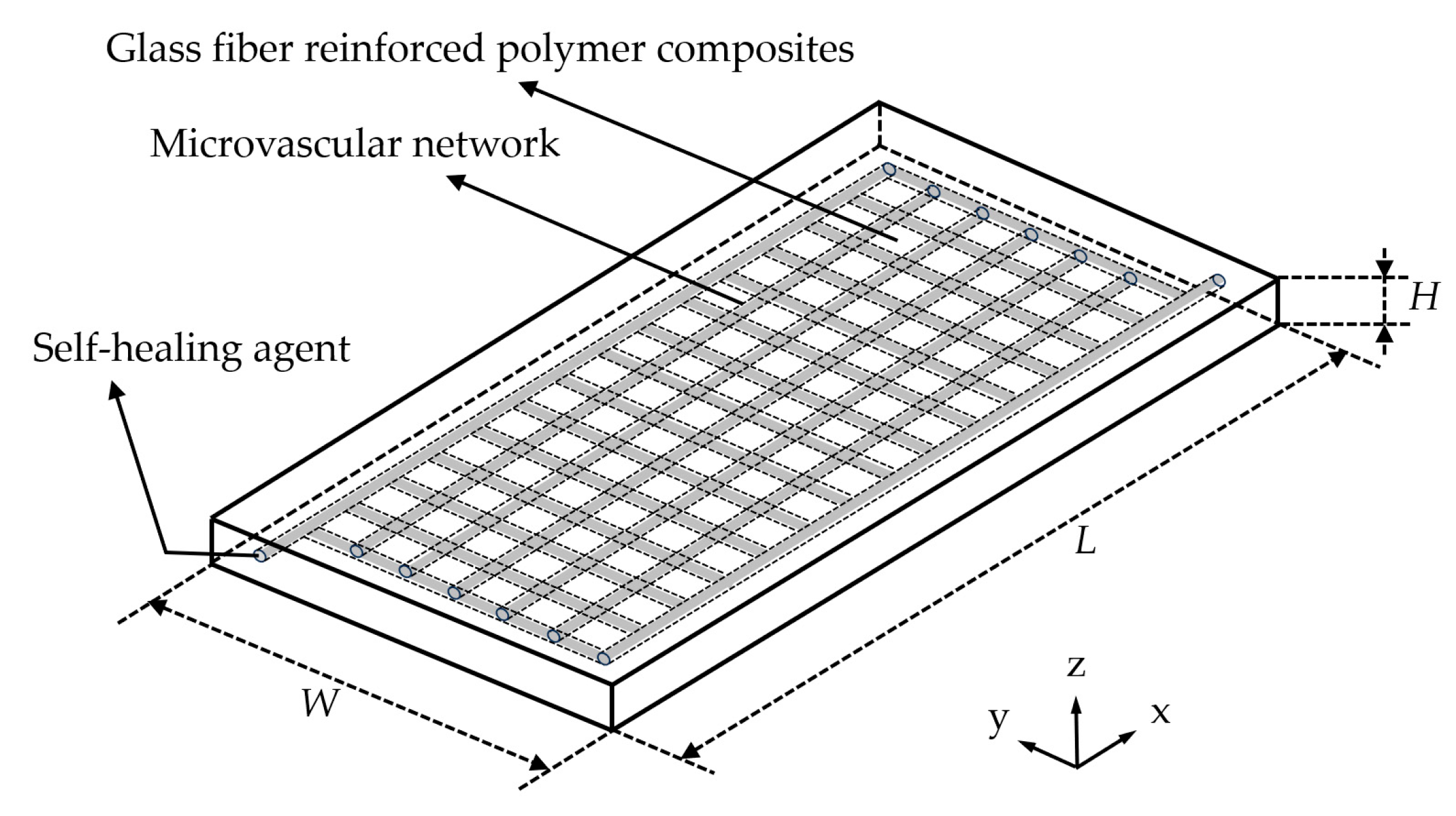

2.1. Self-Healing Structural Models for Orthotropic Anisotropic Composites

2.2. Microvascular Network Carrier Structure Optimization

2.2.1. Objective Function I: Self-Healing Structural Compliance

2.2.2. Objective Function II: Water Head Loss

2.2.3. Objective Function III: Volume Percentage of Microvascular Network

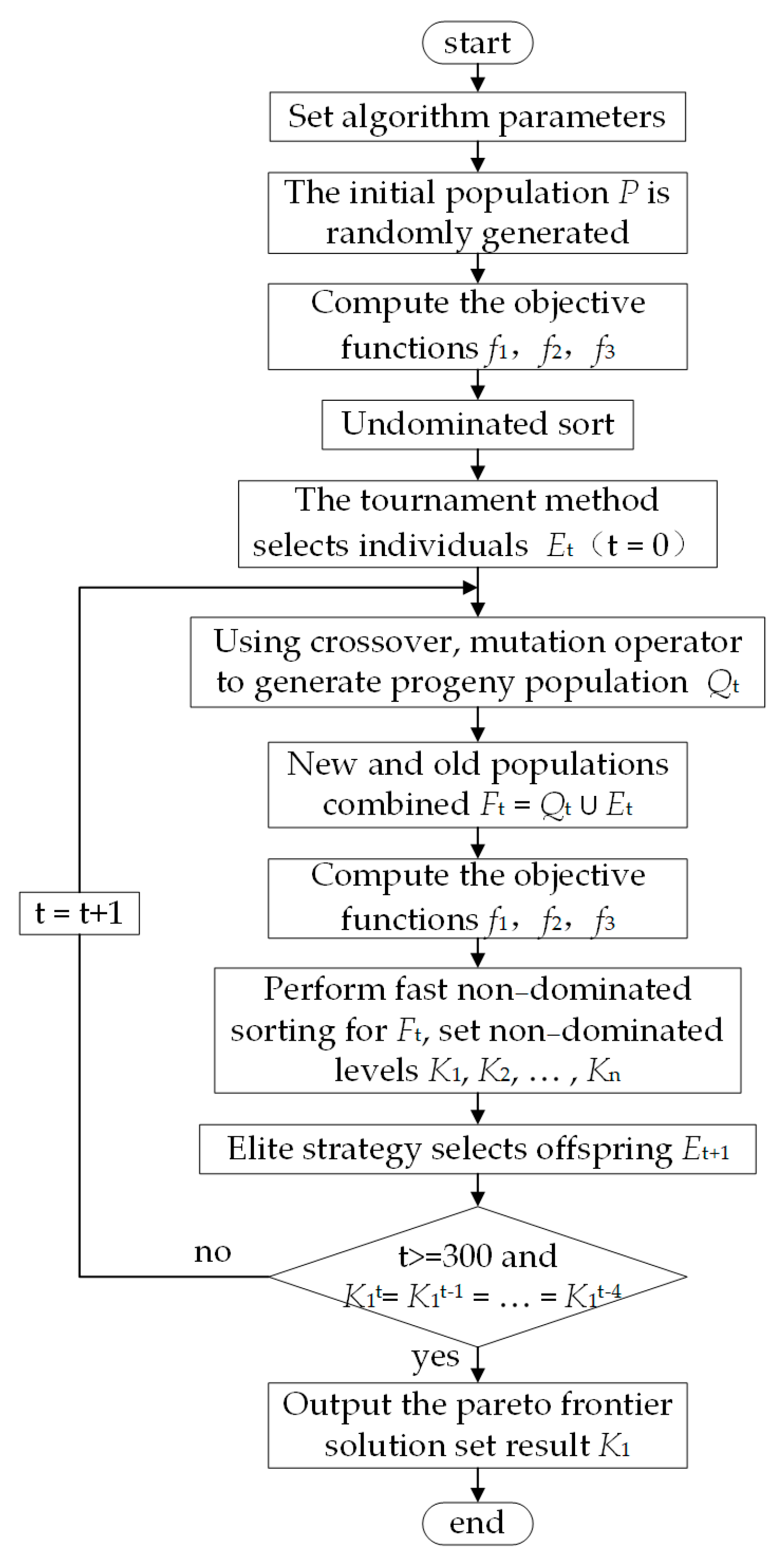

2.3. Non-Dominated Sorting Genetic Algorithm II

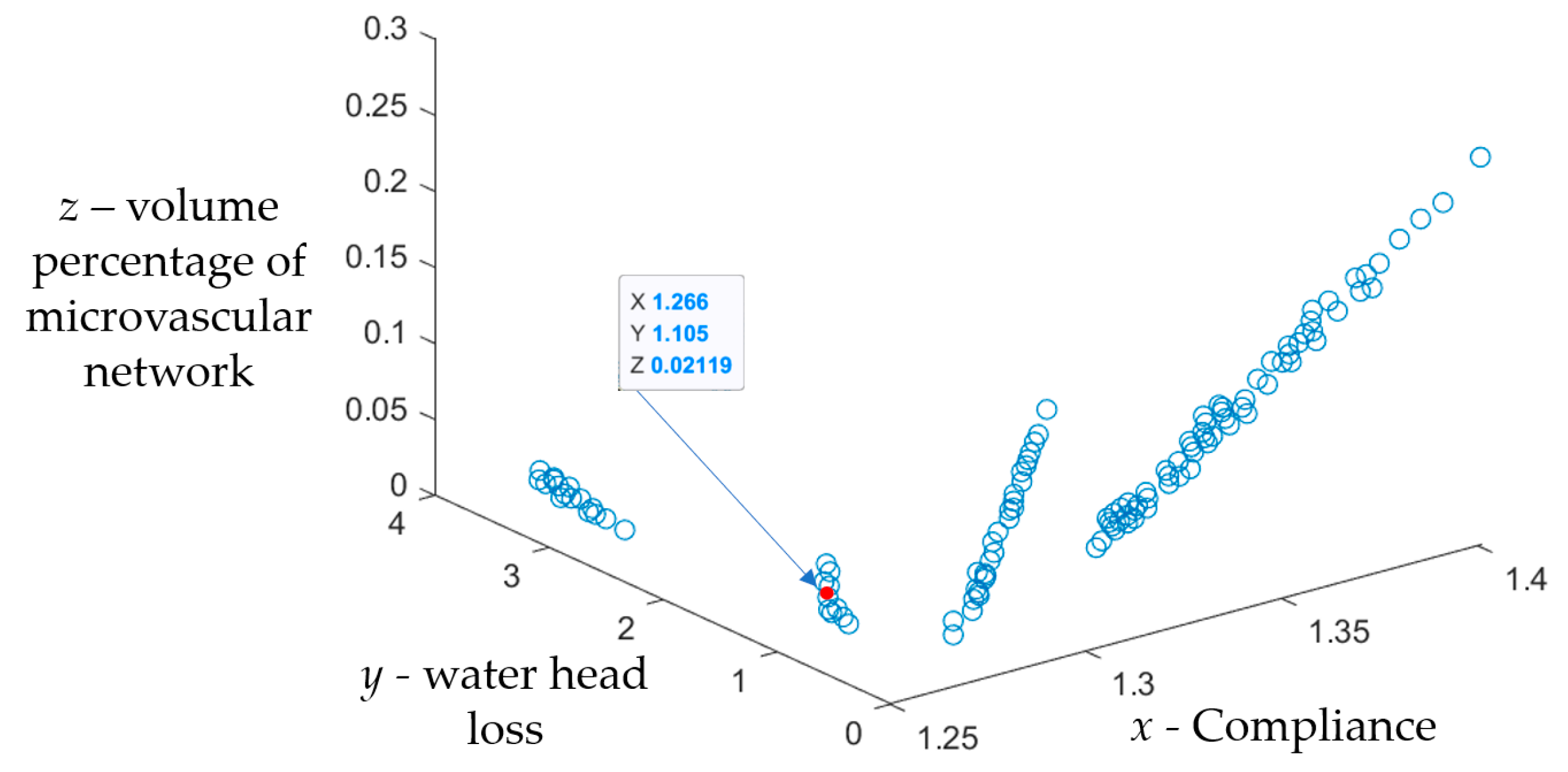

2.4. Microvascular Network Optimization Results

- (1)

- The embedding of the optimized microvascular network has little effect on the mechanical properties of the material. Compared with the material structure without a microvascular network, the compliance of the self-healing structure of the built-in monolayer wall-less microvascular network decreased to a certain extent, and the decrease ranged from 0.021% to 10.81%.

- (2)

- When the microvascular spacing parameters α and β remain unchanged, with the increase in the radius r of the microvascular structure, the overall compliance of the self-healing structure increases, the water head loss of the microvascular network decreases, and the volume percentage of the microvascular network increases.

- (3)

- When the radius r of the microvascular is unchanged, the overall compliance of the self-healing structure decreases with the increase in the microvascular spacing parameters α and β, and the water head loss and the volume percentage of the microvascular network also decrease.

3. Self-Healing Structure Preparation and Performance Study

3.1. Preparation of Monolayer Wall-Less Microvascular Network Self-Healing Materials

3.1.1. Raw Materials and Reagents

3.1.2. Self-Healing Material Specimen Preparation Steps

3.2. Mechanical Properties and Light Repair Properties of Self-Healing Materials

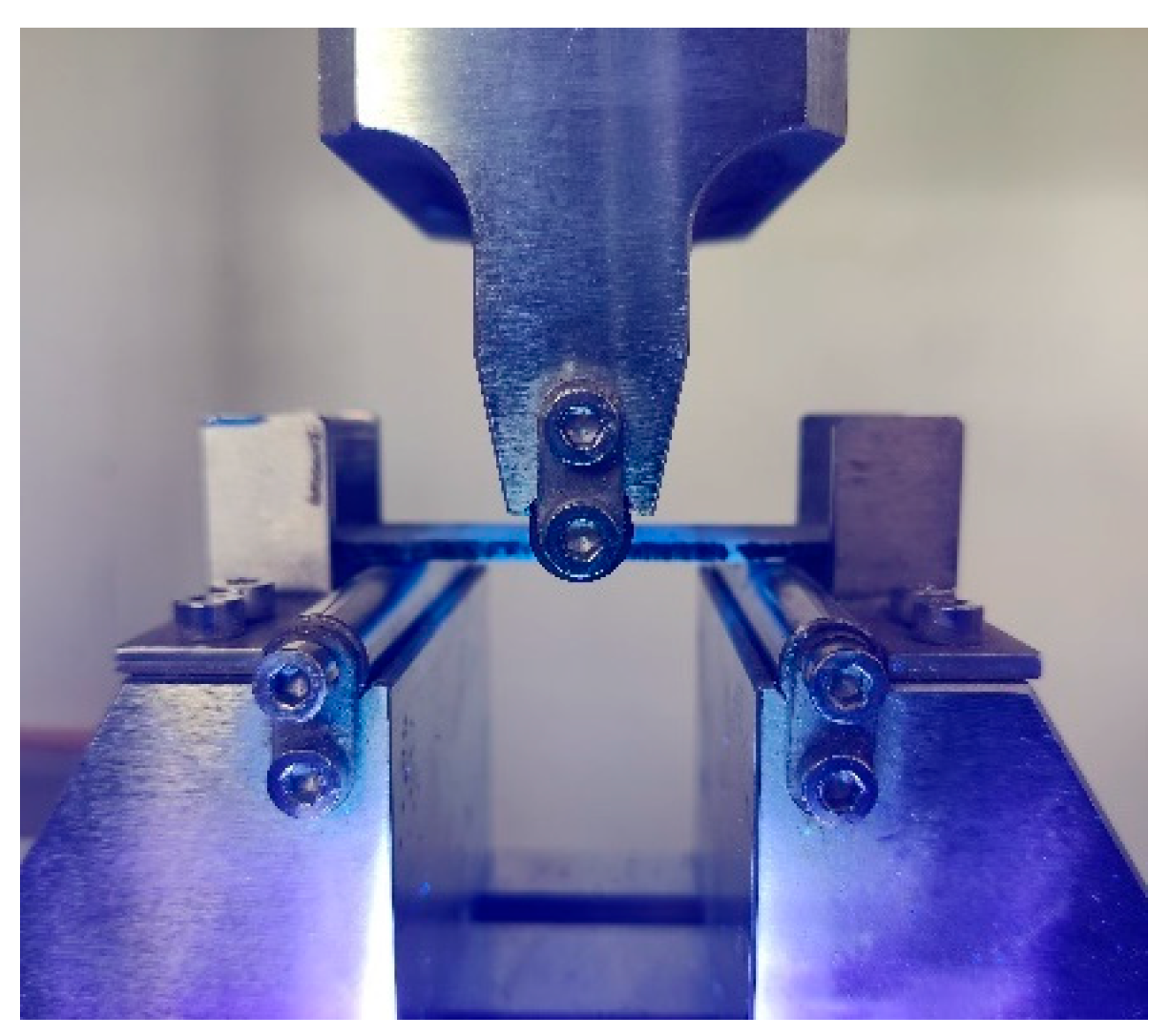

3.2.1. Mechanical Property Test

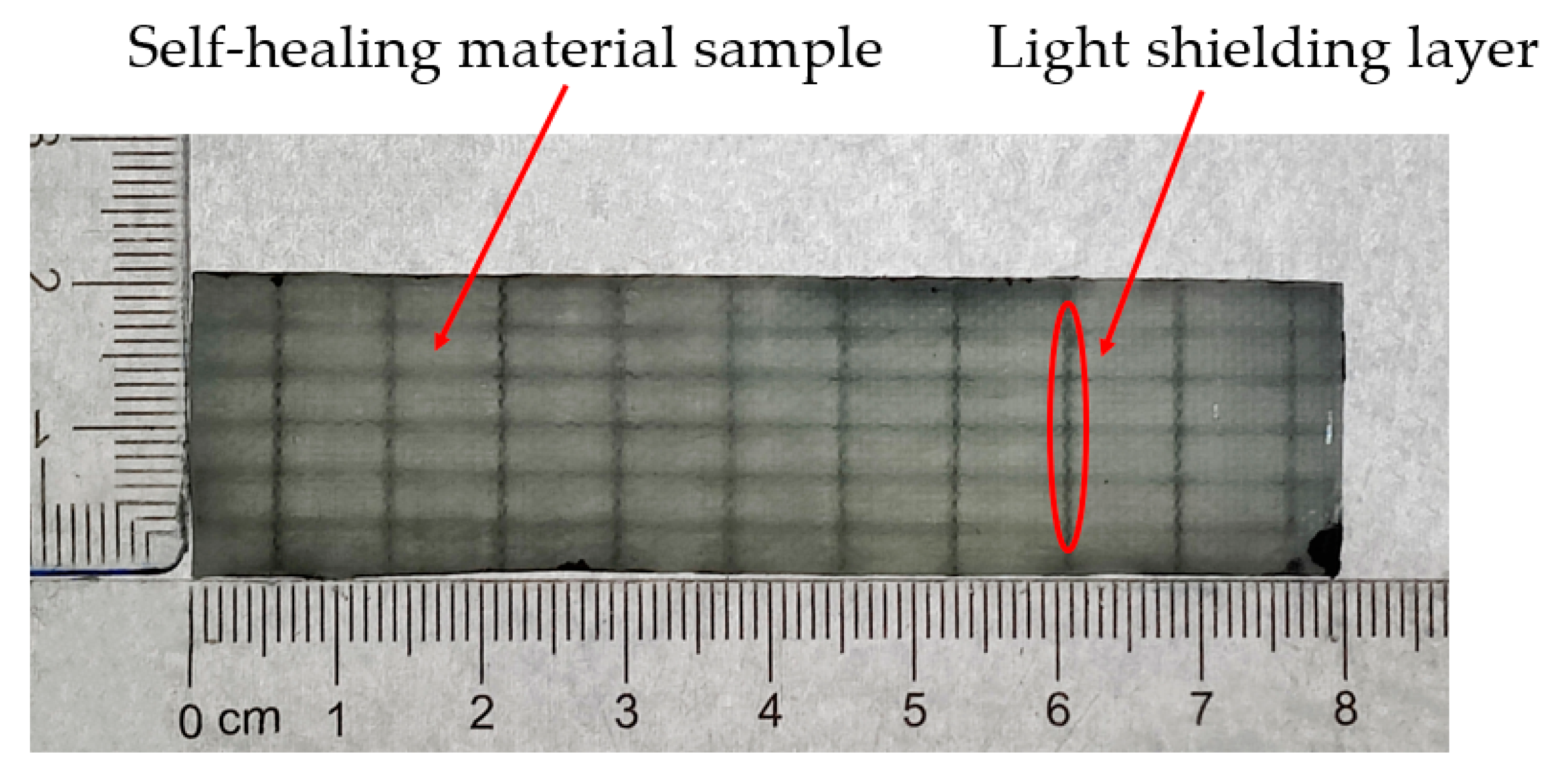

3.2.2. Light Repair Property Test

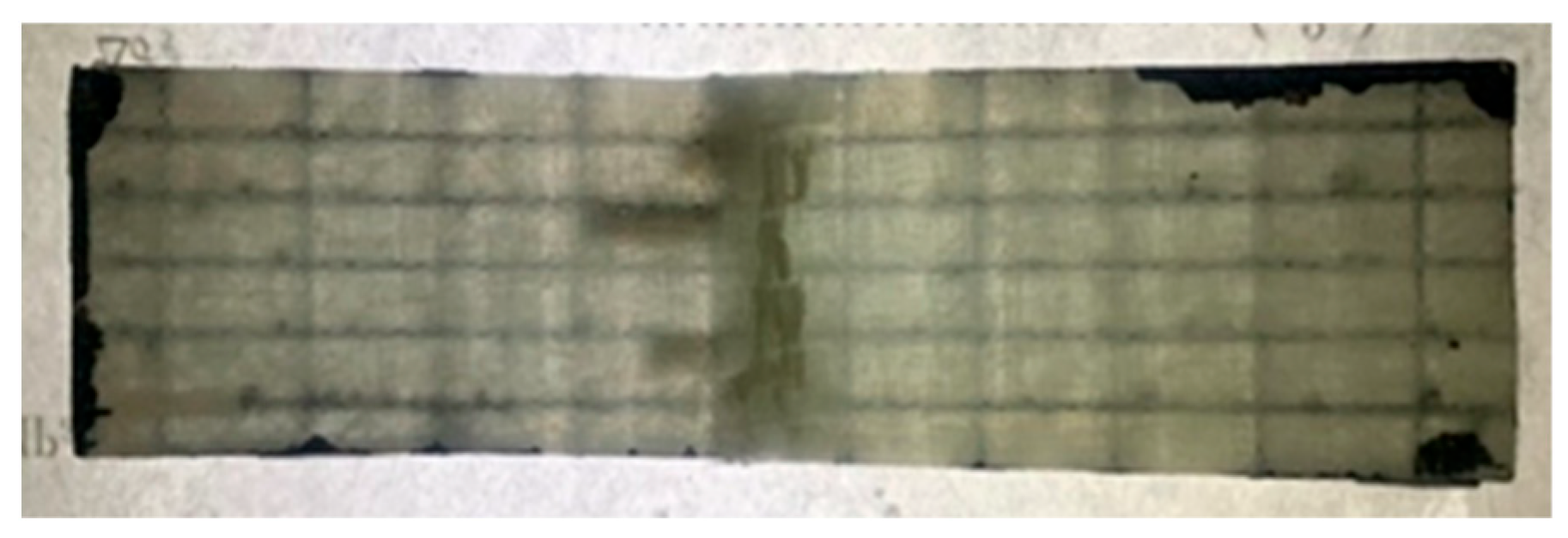

- (1)

- Figure 8 shows the sample front drawing after the test, from which it can be seen that there is an obvious curing phenomenon in the middle of the sample. This indicated that the microvascular network of the specimen at the compression site ruptured, leading to the outflow of the light repair agent. Under the irradiation of excitation light, the light repair agent produces a photochemical reaction, which causes it to cure in a short time and repairs the damaged part of the material.

- (2)

- The average maximum failure load of group B samples is 1.2886 kN, while that of group C samples is 1.3410 kN. Compared with the specimens without light repair, the average maximum failure load of the specimens with light repair was increased by 4.1%. The reason for this is that with the application of load, small cracks continue to appear in the sample, which induces the rupture of the microvascular network and the outflow of the repair agent. The repair agent cured under the light excitation, and the self-healing of the damaged crack was realized, and thus the peak load of the specimen was increased.

- (3)

- After the sample loading passed the load peak, the second peak load of group B samples was 0.5358 kN when the sample continued to be loaded until the complete fracture of the material occurred. The second peak load of group C samples was 0.6888 kN, which reached 51.36% of the average maximum failure load, and was 28.56% higher than that of group B samples.

- (4)

- Compared with group A samples, the average maximum load of group C samples is 97.88% of that of group A samples, while that of group B samples is 94.06% of that of group A samples. The experimental data show that microvascular network embedding affects the failure mechanism, and the introduction of light repair can eliminate the above effects. The data also showed the effectiveness of the optimization, and also reflected that the light repair agent had a repairing effect on the material during the test.

- (5)

- In this experiment, the whole process of self-healing was completed during a three-point test, so the real-time nature of light repair was demonstrated.

4. Conclusions

- (1)

- The study takes orthotropic anisotropic glass-fiber-reinforced polymer composites as the repair object and establishes the stress–strain relationship matrix of these orthotropic anisotropic composites. It introduces a topological descriptive function and conducts finite element analysis to solve the compliance of the structure. Taking the self-healing structural compliance, water head loss, and volume percentage of the microvascular network as the objectives, the NSGA-II algorithm was used to optimize the topology of the microvascular network, and the effectiveness of the optimization method was verified by experiments.

- (2)

- Based on the vacuum-assisted resin transfer molding process and the embedded wire removal method, the self-healing material samples with built-in monolayer wall-less microvascular network carriers were prepared, and the mechanical properties of the materials were tested by means of the three-point bending test. The results showed that the average maximum failure load of the self-healing material was 94.06% of that of the sample without carriers. The experimental data reflect the effectiveness of the microvascular network carrier optimization method, and this optimization method will help to improve the mechanical compatibility of the materials.

- (3)

- In this study, a single-component short-wave light-curing resin was used as a light repair agent to achieve the on-line and real-time self-healing of damage. Compared with other restorative agents, its light curing reaction is rapid and self-healing of material damage can be achieved quickly. The bending test results show that in the case of the introduction of real-time light energy repair, the average maximum failure load of the structure with light repair was increased by 4.1% compared to that without light repair. After passing through the peak load, the second peak load of the structure with light repair can reach 51.36% of the average maximum failure load, which is 28.56% higher than that of the structure without light repair.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, H.K. Research Progress in Mechanical Properties of Glass Fiber Reinforced Composites. Synth. Fiber China 2022, 51, 40–43+68. [Google Scholar]

- Yang, G.S.; Zhou, M.H. The Damage Analysis for Glass/Epoxy Composites. J. Natl. Univ. Def. Technol. 1988, 10, 108. [Google Scholar]

- Wu, J.Y.; Wang, W.; Yuan, L.; Gu, Y.; Liang, G. Research Progress in Self-healing Polymer Composites. Mater. Rev. 2009, 23, 39–41+49. [Google Scholar]

- Mauldin, T.C.; Kessler, M.R. Self-healing polymers and composites. Int. Mater. Rev. 2010, 55, 317–346. [Google Scholar] [CrossRef]

- Kardani, A.; Montazeri, A.; Urbassek, H.M. Strain-rate-dependent plasticity of Ta-Cu nanocomposites for therapeutic implants. Sci. Rep. 2023, 13, 15788. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Rong, M.Z.; Zhang, M.Q. Research status and prospect of self-healing polymer based on photochemical reaction. Sci. Sin. Chim. 2024, 54, 1534–1548. [Google Scholar] [CrossRef]

- Li, H.Y.; Zhang, L.B.; Li, J.; Wang, J. Research progresses in extrinsic self-healing polymer materials. Chem. Ind. Eng. Prog. 2014, 33, 133–139+164. [Google Scholar]

- Li, P.; Zhang, C.; Du, Y.; Chen, W.; Zhan, J.; Tang, G. Collaborative Optimization of Self-Healing Material Structure and Microcapsule Based on MMC. J. East China Jiaotong Univ. 2023, 40, 97–103. [Google Scholar]

- An, Z.; Cheng, X.; Zhao, D.; Ma, Y.; Guo, X.; Cheng, Y. Tensile and Compressive Properties of Woven Fabric Carbon Fiber-Reinforced Polymer Laminates Containing Three-Dimensional Microvascular Channels. Polymers 2024, 16, 665. [Google Scholar] [CrossRef]

- Li, P.; Liu, Y.; Huang, J.Y. Topology Optimization of Micro-vascular Network Based on Multi-objective Simulated Annealing Algorithms. J. East China Jiaotong Univ. 2017, 34, 125–130. [Google Scholar]

- Sun, J.Z.; Liu, X.; Xie, J.; Shang, X.; Zhang, H. Research Progress of Self-Healing Polymer Materials. Mod. Plast. Process. Appl. 2022, 34, 52–55. [Google Scholar]

- Toohey, K.S.; Sottos, N.R.; Lewis, J.A.; Moore, J.S.; White, S.R. Self-healing materials with microvascular networks. Nat. Mater. 2007, 6, 581–585. [Google Scholar] [CrossRef] [PubMed]

- Toohey, K.S.; Sottos, N.R.; White, S.R. Characterization of Microvascular-Based Self-healing Coatings. Exp. Mech. 2009, 49, 707–717. [Google Scholar] [CrossRef]

- Postiglione, G.; Alberini, M.; Leigh, S.; Levi, M.; Turri, S. Effect of 3D-Printed Microvascular Network Design on the Self-Healing Behavior of Cross-Linked Polymers. ACS Appl. Mater. Interfaces 2017, 9, 14371. [Google Scholar] [CrossRef]

- Hansen, C.J.; White, S.R.; Sottos, N.R.; Lewis, J.A. Accelerated Self-Healing Via Ternary Interpenetrating Microvascular Networks. Adv. Funct. Mater. 2011, 21, 4320–4326. [Google Scholar] [CrossRef]

- Nguyen AT, T.; Orifici, A.C. Structural assessment of microvascular self-healing laminates using progressive damage finite element analysis. Compos. Part A 2012, 43, 1886–1894. [Google Scholar] [CrossRef]

- Li, P.; Du, Y.B.; Huang, P.W.; Ding, Y.; Liu, G. Light-energy Self-healing Composites Based on Wall-less Microvasculature. Mater. Rev. 2022, 36, 204–208. [Google Scholar]

- Williams, G.; Trask, R.; Bond, I. A self-healing carbon fibre reinforced polymer for aerospace applications. Compos. Part A 2007, 38, 1525–1532. [Google Scholar] [CrossRef]

- Pang, W.J.; Bond, P.I. A hollow fibre reinforced polymer composite encompassing self-healing and enhanced damage visibility. Compos. Sci. Technol. 2005, 65, 1791–1799. [Google Scholar] [CrossRef]

- Wu, X.F.; Rahman, A.; Zhou, Z.; Pelot, D.D.; Sinha-Ray, S.; Chen, B.; Payne, S.; Yarin, A.L. Electrospinning core-shell nanofibers for interfacial toug hening and self-healing of carbon-fiber/epoxy composites. J. Appl. Polym. Sci. 2013, 129, 1383–1393. [Google Scholar] [CrossRef]

- Min, W.L.; Sam, S.Y.; Alexander, L.Y. Solution-blown core-shell self-healing nano-and microfibers. ACS Appl. Mater. Interfaces 2016, 8, 4955–4962. [Google Scholar]

- Hansen, C.J.; Wu, W.; Toohey, K.S.; Sottos, N.R.; White, S.R.; Lewis, J.A. Self-Healing Materials with Interpenetrating Microvascular Networks. Adv. Mater. 2009, 21, 4143–4147. [Google Scholar] [CrossRef]

- Vidinejevs, S.; Aniskevich, A. The system of carbon fibre-reinforced plastics micro-tubes for self-healing of glass fibre-reinforced plastics laminates. J. Compos. Mater. 2017, 51, 1717–1727. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, W.; Yu, D. Preparation and Coating Self-Healing Properties of UV-Initiated Self-Healing Microcapsules. Polym. Mater. Sci. Eng. 2018, 34, 116–120. [Google Scholar]

- Gong, W.; Cheng, J.; Yan, W.; Zou, H.; Gao, C.; Liu, X.; Wang, L. Preparation and performance study of photo-initiated self-healing self-warning microencapsulated coated fabrics. Prog. Org. Coat. 2024, 192, 108530. [Google Scholar] [CrossRef]

- Zhang, K.; Tang, W.H.; Ran, X.W. Constitutive relationship of anisotropic CFRP material and its application in planar plate impact simulation. J. Vib. Shock 2019, 38, 101–106+129. [Google Scholar]

- Li, P.; Wang, S.; Fan, B.; Zhao, Y.; Yu, S. Measurement of anisotropic elastic constants of glass fiber reinforced resin matrix composite laminates. J. Phys. Conf. Ser. 2025, 2951, 012106. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, W.; Zhang, J.; Yuan, J. Explicit structural topology optimization based on moving morphable components (MMC) with curved skeletons. Comput. Methods Appl. Mech. Eng. 2016, 310, 711–748. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, W.S.; Zhong, W.L. Doing Topology Optimization Explicitly and Geometrically—A New Moving Morphable Components Based Framework. J. Appl. Mech. 2014, 81, 31. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, B. Analysis of elastic constitutive Relationship of orthotropic materials. Aeroengine 1997, 1, 20–25. [Google Scholar]

- Li, H.Y. Structure Optimization of Fiber Reinforced Composites Based on MMC Method. Master’s Thesis, Dalian University of Technology, Dalian, China, 2021. [Google Scholar]

- Yuan, J. Topology Optimization Method Based on Moving Morphable Components (MMC) Framework. Master’s Thesis, Dalian University of Technology, Dalian, China, 2016. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Li, P.; Liu, G.; Liu, Y.; Huang, J. Microvascular network optimization of self-healing materials using non-dominated sorting genetic algorithm II and experimental validation. Sci. Prog. 2020, 103, 003685041988354. [Google Scholar] [CrossRef] [PubMed]

- Srinivas, N.; Deb, K. Multiobjective Optimization Using Nondominated Sorting in Genetic Algorithms. Evol. Comput. 1994, 2, 221–248. [Google Scholar] [CrossRef]

- Deb, K.; Agrawal, S.; Pratap, A.; Meyarivan, T. A Fast Elitist Non-Dominated Sorting Genetic Algorithm for Multi-Objective Optimization: NSGA-II; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

| Modulus of Elasticity/GPa | Poisson’s Ratio | Shear Modulus/GPa |

|---|---|---|

| E1 = 16.3 | μ12 = 0.058 | G12 = 1.49 |

| E2 = 16.6 | μ23 = 0.282 | G23 = 1.17 |

| E3 = 3.0 | μ13 = 0.262 | G13 = 1.20 |

| Parameters | Value |

|---|---|

| Initial population size |P| | 100 |

| Cross probability Pcross | 0.8 |

| Variation probability Pmutate | 0.2 |

| Parent and offspring population size |Et| | 50 |

| Model length L1/mm | 40 |

| Model width W1/mm | 10 |

| Model thickness H1/mm | 2 |

| Input port flow V1/mm3/s | 100 |

| Microvascular radius r/mm | {0.15, 0.2, 0.25, 0.3, 0.35, 0.4, 0.45} |

| Microvascular network spacing parameters α and β/mm | {15, 17, 19, 21, 23, 25, 27, 29, 31, 33, 35, 37, 39, 41, 43, 45} |

| α | β | r/mm | Compliance | Water Head Loss/m | Volume Percentage of Microvascular Network/% |

|---|---|---|---|---|---|

| 39 | 17 | 0.2 | 1.2662 | 1.1048 | 2.1190 |

| Name | Model Number | Production and Sales Factory |

|---|---|---|

| Epoxy resin | Bisphenol A E51 | Hangzhou Wuhuigang Adhesive Co., Ltd., Hangzhou, China |

| Modified amine epoxy curing agent | JH593 | Hangzhou Wuhuigang Adhesive Co., Ltd., Hangzhou, China |

| 0°/90° biaxial glass fiber stitched fabric | LT650-1340 | Changzhou Hualike new Material Co., Ltd., Changzhou, China |

| Light repair agent | DAZZLE-LV305 150 ± 50 mPa·s (25 °C) | Shenzhen Daye laser forming technology Co., Ltd., Shenzhen, China |

| Light screening agent | two-component epoxy paint | Shanghai Jinsi Di metal paint factory, Shanghai, China |

| Specimen Group | Maximum Failure Load Range (kN) | Average Maximum Failure Load (kN) | Second Peak Load Range (kN) | Second Peak Load Mean (kN) | Percentage of Maximum Failure Load Achieved After Fracture |

|---|---|---|---|---|---|

| A | 1.2450~1.4840 | 1.3700 | — | — | — |

| B | 1.1310~1.4700 | 1.2886 | 0.4190~0.6020 | 0.5358 | 41.58% |

| C | 1.1810~1.5380 | 1.3410 | 0.6450~0.7170 | 0.6888 | 51.36% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Li, P.; Fan, B.; Zhao, Y.; Yu, S.; Tan, J.; Zhang, C. A Self-Healing Structure Based on Monolayer Wall-Less Microvascular Network Carriers for Orthotropic Anisotropic Polymer Composites. Polymers 2025, 17, 749. https://doi.org/10.3390/polym17060749

Wang S, Li P, Fan B, Zhao Y, Yu S, Tan J, Zhang C. A Self-Healing Structure Based on Monolayer Wall-Less Microvascular Network Carriers for Orthotropic Anisotropic Polymer Composites. Polymers. 2025; 17(6):749. https://doi.org/10.3390/polym17060749

Chicago/Turabian StyleWang, Shenbiao, Peng Li, Baijia Fan, Yuan Zhao, Shenglin Yu, Jianbin Tan, and Changyou Zhang. 2025. "A Self-Healing Structure Based on Monolayer Wall-Less Microvascular Network Carriers for Orthotropic Anisotropic Polymer Composites" Polymers 17, no. 6: 749. https://doi.org/10.3390/polym17060749

APA StyleWang, S., Li, P., Fan, B., Zhao, Y., Yu, S., Tan, J., & Zhang, C. (2025). A Self-Healing Structure Based on Monolayer Wall-Less Microvascular Network Carriers for Orthotropic Anisotropic Polymer Composites. Polymers, 17(6), 749. https://doi.org/10.3390/polym17060749