Multi-Angle Crack Detection in CFRP Based on Line Laser Infrared Thermography Scanning Technology

Abstract

1. Introduction

2. Theoretical Foundation

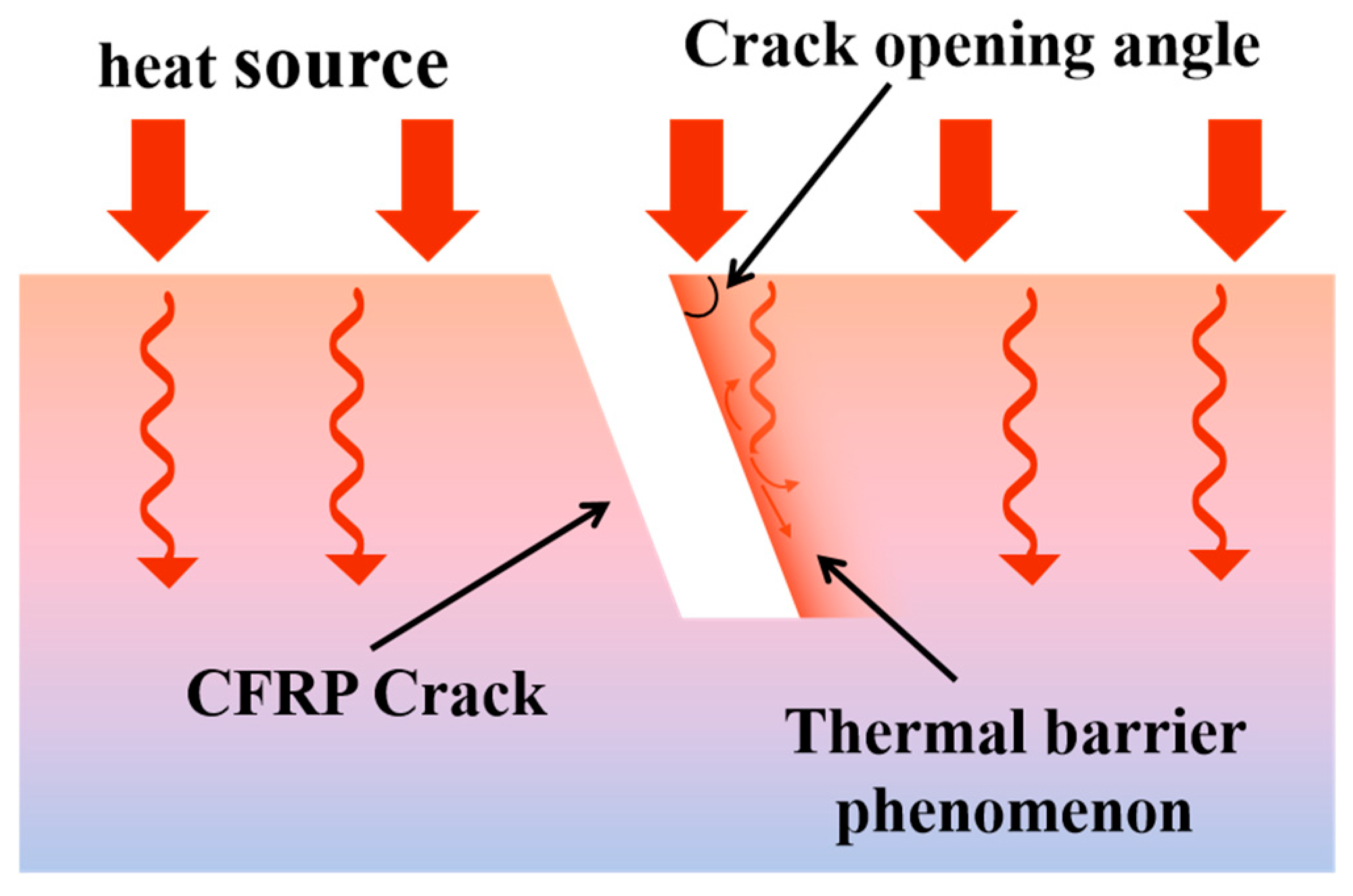

2.1. Line Laser Scanning for Heat Transfer Principle

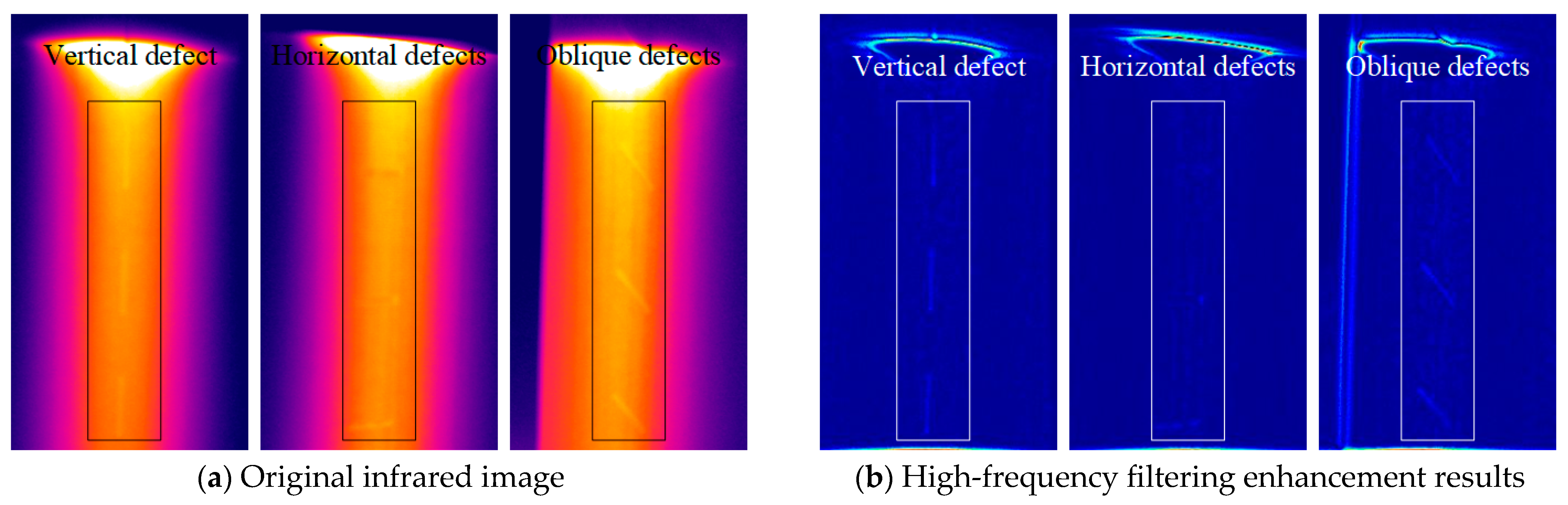

2.2. Principle of Image Enhancement by High-Frequency Filtering

3. Experimental Setup

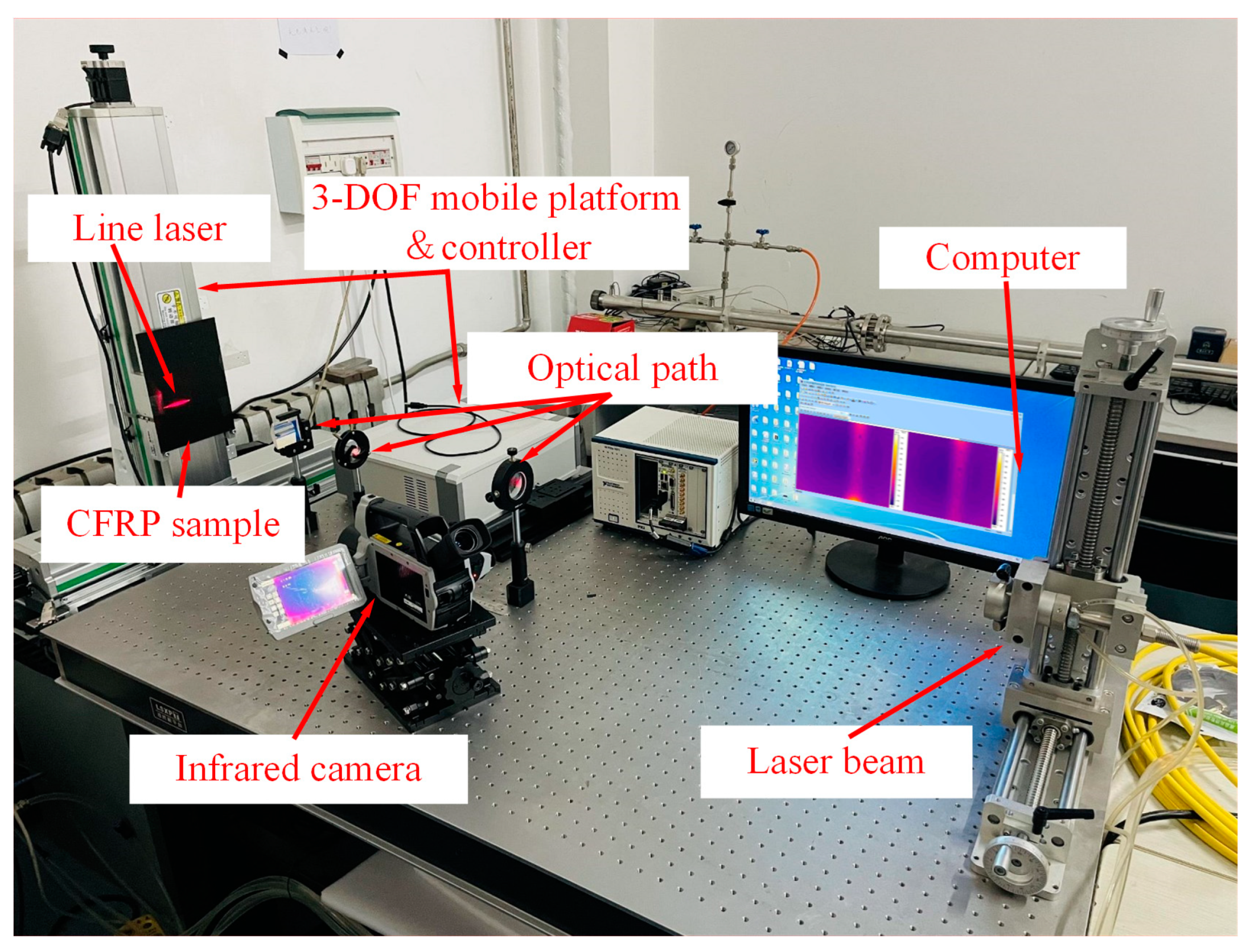

3.1. Experimental System

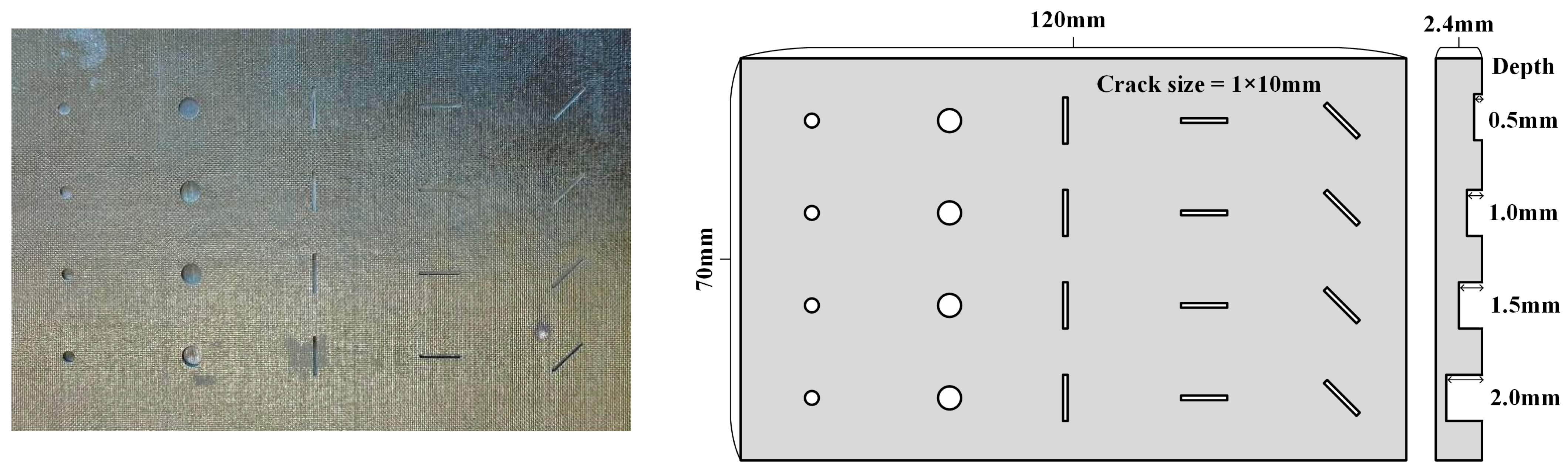

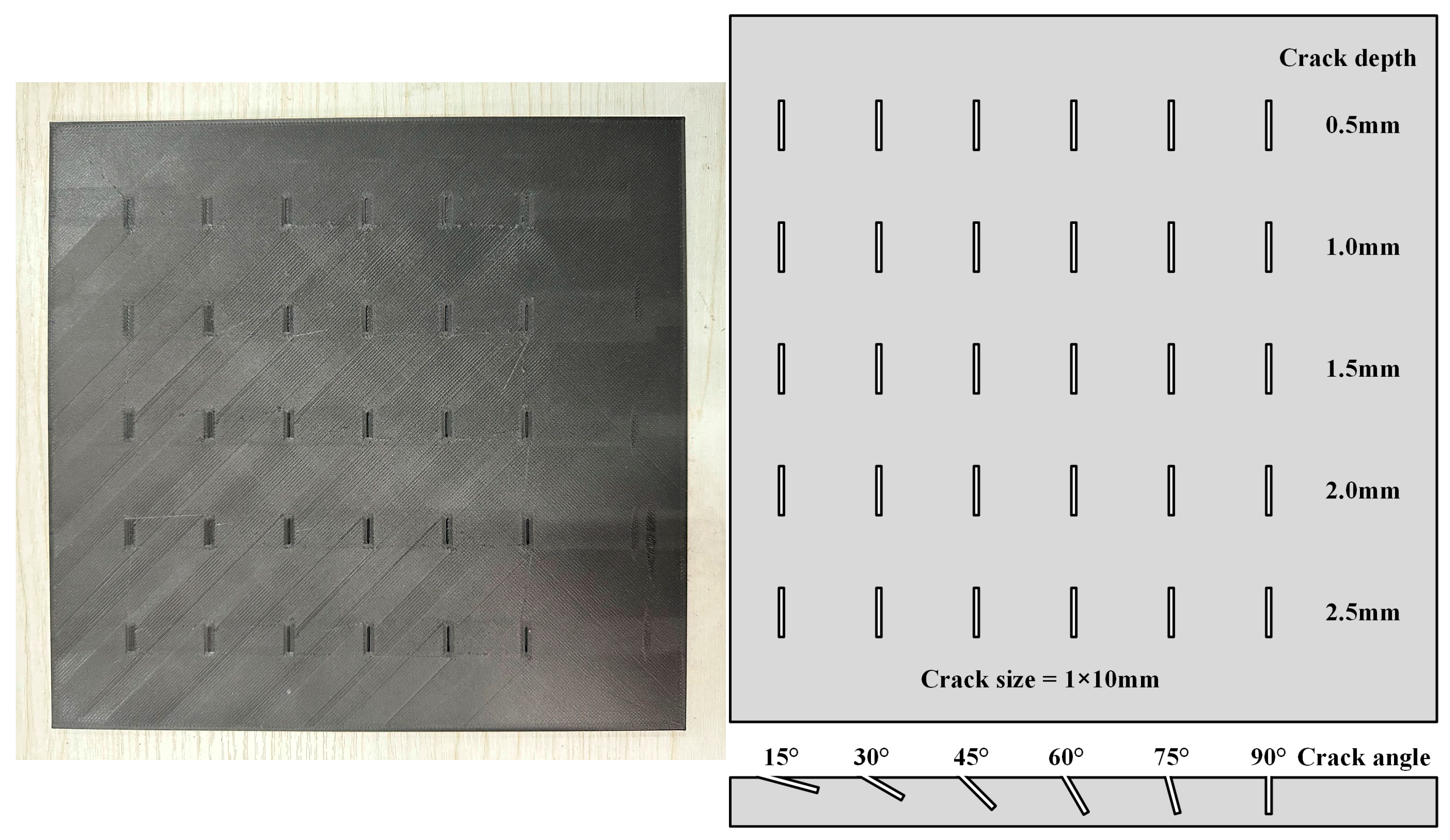

3.2. CFRP Sample

4. Experimental Results and Analysis

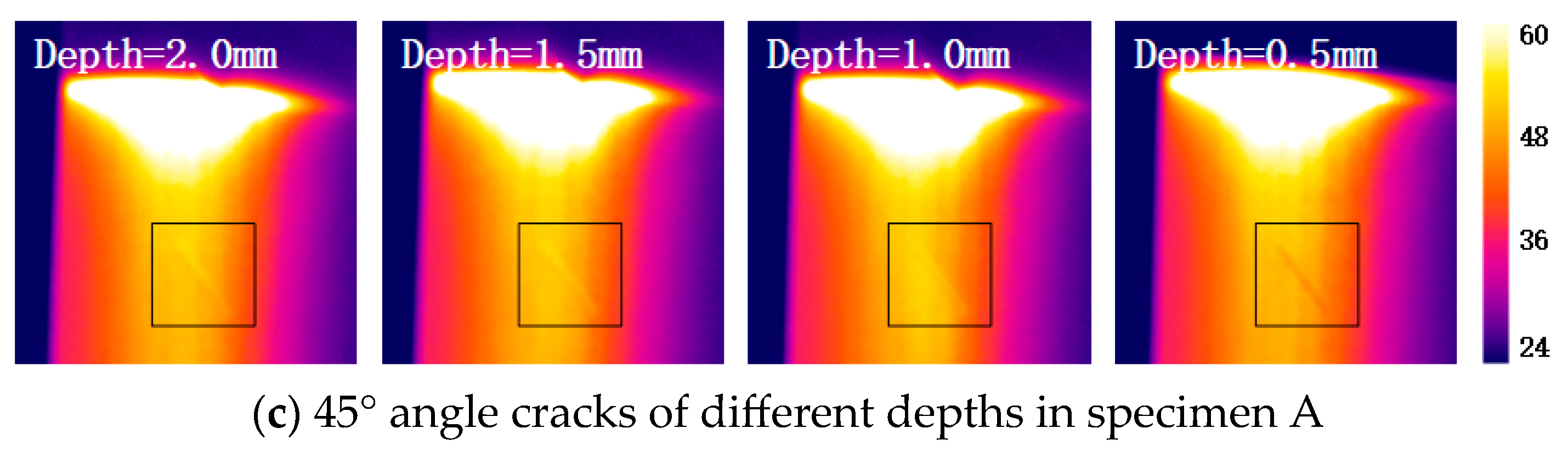

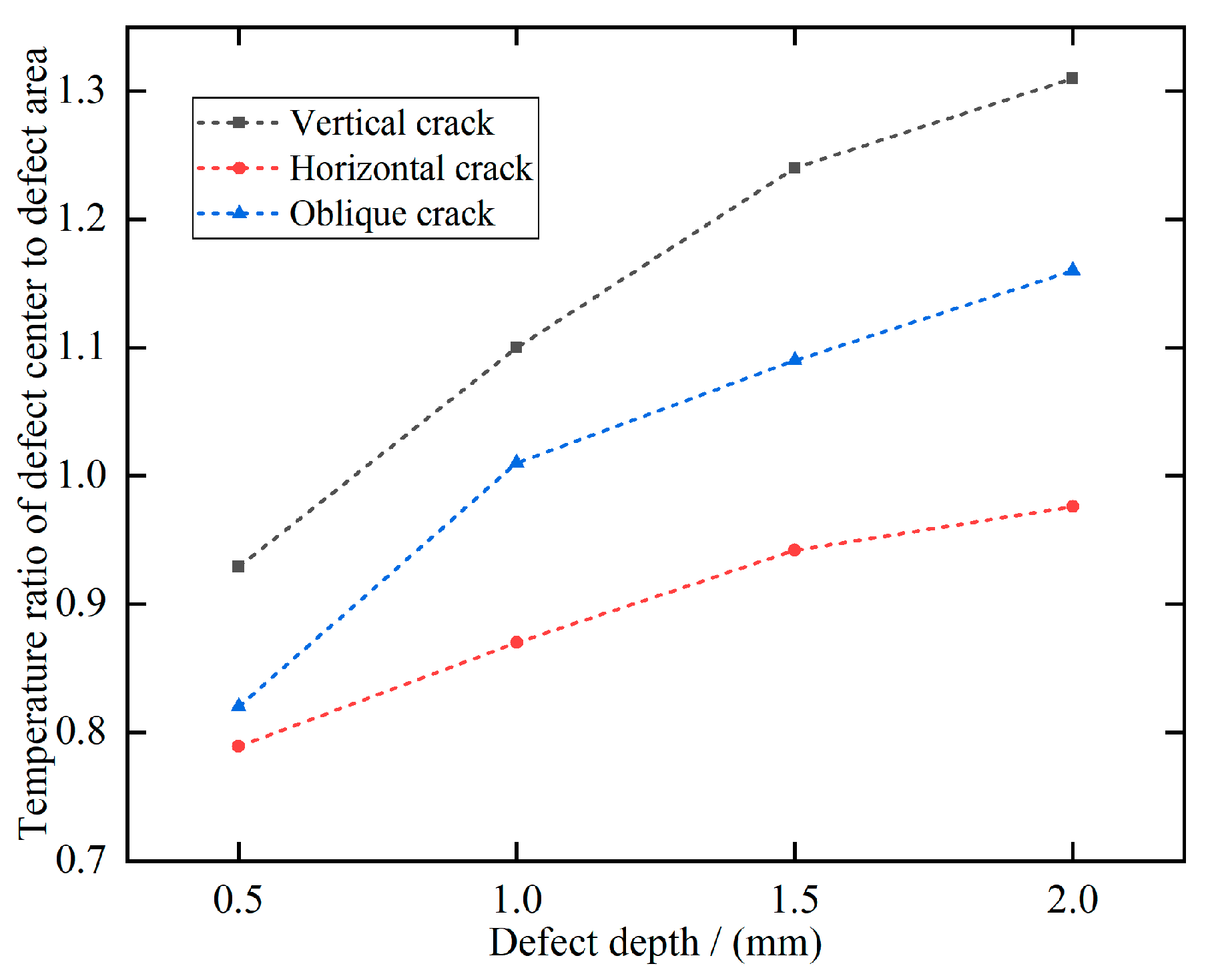

4.1. Thermography Results of Line Laser Scanning on Cracks in Specimen A with Different Orientations

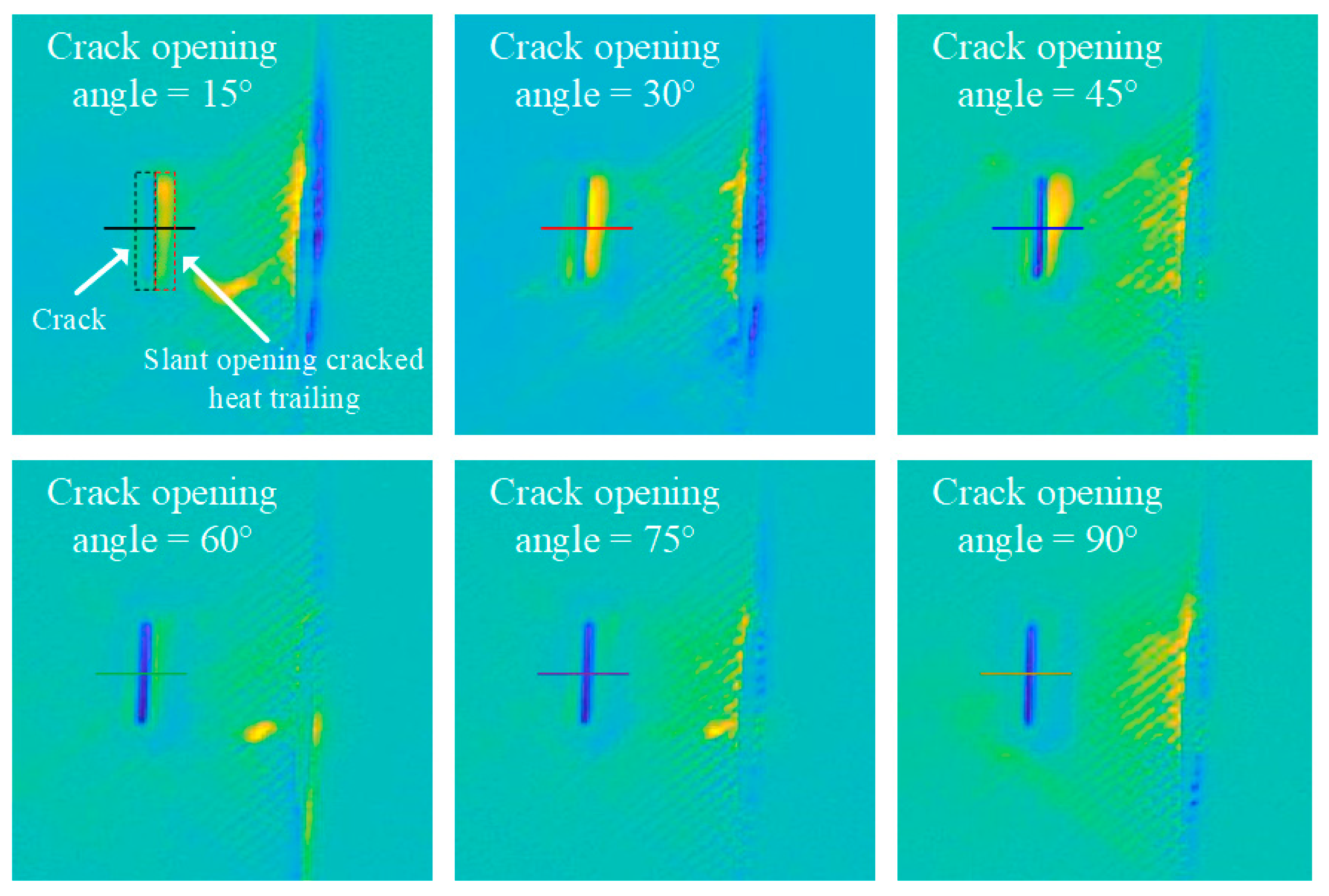

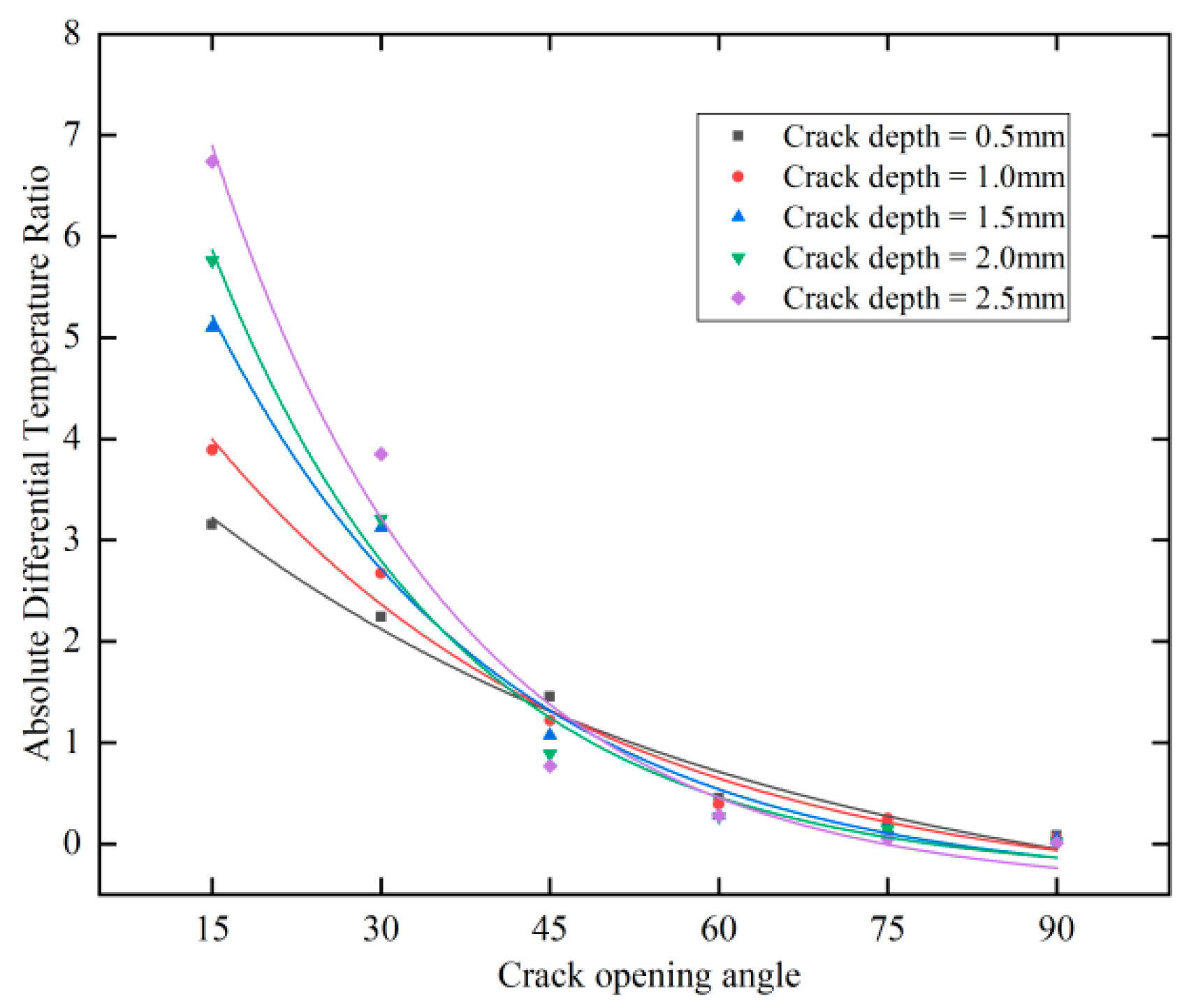

4.2. Thermography Results of Line Laser Scanning on Cracks with Different Oblique Angles in Specimen B

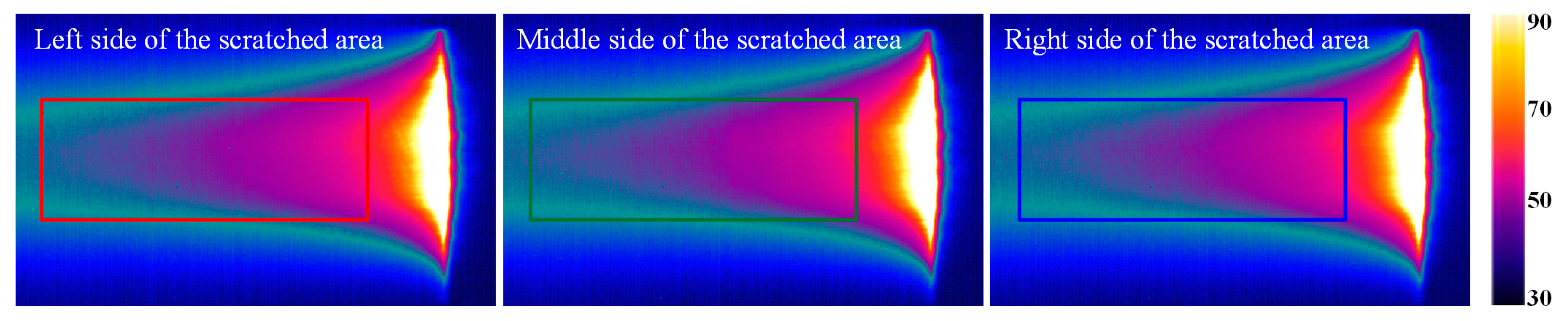

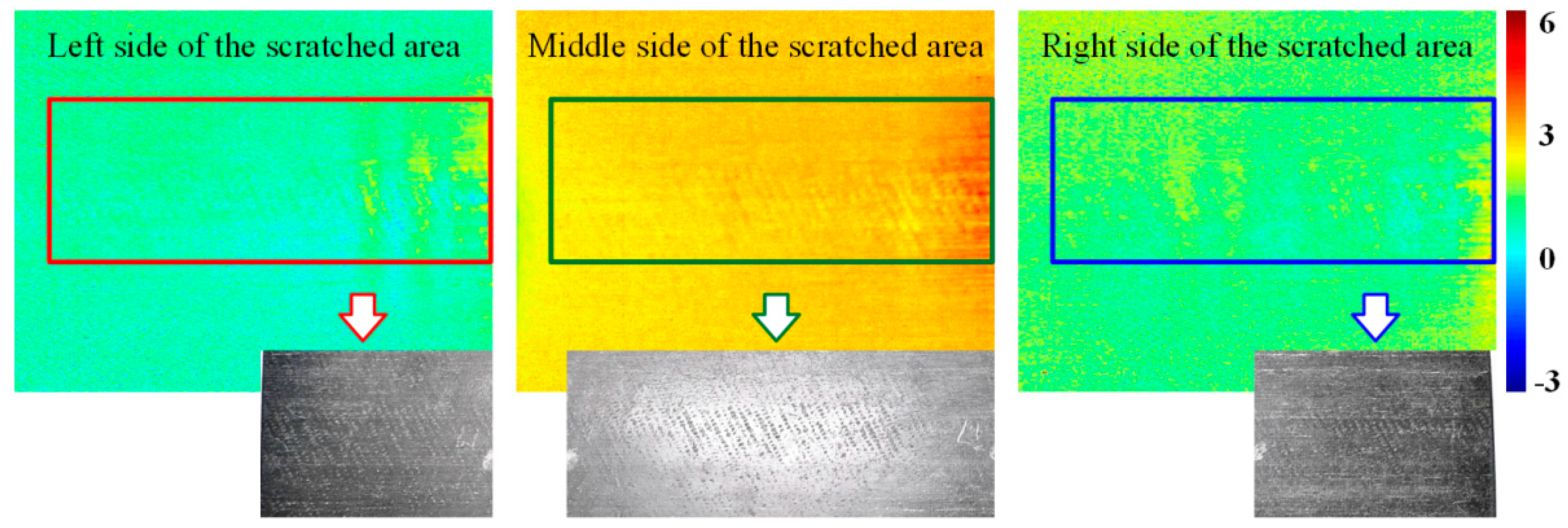

4.3. Thermography Results of Line Laser Scanning on Naturally Occurring Scratches in Specimen C

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Raišutis, R.; Kažys, R.; Žukauskas, E.; Mažeika, L.; Vladišauskas, A. Application of ultrasonic guided waves for non-destructive testing of defective CFRP rods with multiple delaminations. Ndt E Int. 2010, 43, 416–424. [Google Scholar] [CrossRef]

- Séguin-Charbonneau, L.; Walter, J.; Théroux, L.-D.; Scheed, L.; Beausoleil, A.; Masson, B. Automated defect detection for ultrasonic inspection of CFRP aircraft components. NDT E Int. 2021, 122, 102478. [Google Scholar] [CrossRef]

- Petrò, S.; Reina, C.; Moroni, G. X-ray CT-Based Defect Evaluation of Continuous CFRP Additive Manufacturing. J. Nondestruct. Eval. 2021, 40, 7. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Experimental wavelet analysis of acoustic emission signal propagation in CFRP. Eng. Fract. Mech. 2019, 210, 400–407. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, Z.; Yin, W.; Chen, H.; Wang, L.; Wang, D.; Ma, H. Characterization and depth detection of internal delamination defects in CFRP based on line laser scanning infrared thermography. Struct. Health Monit. 2024, 23, 3195–3210. [Google Scholar] [CrossRef]

- Swiderski, W. Non-destructive testing of CFRP by laser excited thermography. Compos. Struct. 2019, 209, 710–714. [Google Scholar] [CrossRef]

- Peeters, J.; Ibarra-Castanedo, C.; Sfarra, S.; Maldague, X.; Dirckx, J.; Steenackers, G. Robust quantitative depth estimation on CFRP samples using active thermography inspection and numerical simulation updating. NDT E Int. 2017, 87, 119–123. [Google Scholar] [CrossRef]

- Hauffe, A.; Hähnel, F.; Wolf, K. Comparison of algorithms to quantify the damaged area in CFRP ultrasonic scans. Compos. Struct. 2020, 235, 111791. [Google Scholar] [CrossRef]

- AbouelNour, Y.; Gupta, N. Assisted defect detection by in-process monitoring of additive manufacturing using optical imaging and infrared thermography. Addit. Manuf. 2023, 67, 103483. [Google Scholar] [CrossRef]

- Lee, K.-J.; Jeon, M.-S.; Lee, J.-R. Evaluation of manufacturing defects in 3D printed carbon fiber reinforced cylindrical composite structure based on laser ultrasonic testing. NDT E Int. 2023, 135, 102802. [Google Scholar] [CrossRef]

- Montinaro, N.; Cerniglia, D.; Pitarresi, G. A Numerical Study on Interlaminar Defects Characterization in Fibre Metal Laminates with Flying Laser Spot Thermography. J. Nondestruct. Eval. 2018, 37, 41. [Google Scholar] [CrossRef]

- Wei, J.; Wang, F.; Liu, J.; Wang, Y.; He, L. A laser arrays scan thermography (LAsST) for the rapid inspection of CFRP composite with subsurface defects. Compos. Struct. 2019, 226, 111201. [Google Scholar] [CrossRef]

- Liu, Z.; Jiao, D.; Shi, W.; Xie, H. Linear laser fast scanning thermography NDT for artificial disbond defects in thermal barrier coatings. Opt. Express 2017, 25, 31789–31800. [Google Scholar] [CrossRef]

- Li, C.; Zhu, J.; Zhuo, L.; Li, J.; Zhang, D. Continuous laser-line scanning thermography with data-processing algorithm for rapid and accurate defect inspection. NDT E Int. 2024, 142, 103028. [Google Scholar] [CrossRef]

- Ahmadi, S.; Thummerer, G.; Breitwieser, S.; Mayr, G.; Lecompagnon, J.; Burgholzer, P.; Jung, P.; Caire, G.; Ziegler, M. Multidimensional Reconstruction of Internal Defects in Additively Manufactured Steel Using Photothermal Super Resolution Combined With Virtual Wave-Based Image Processing. IEEE Trans. Ind. Inform. 2021, 17, 7368–7378. [Google Scholar] [CrossRef]

- Hwang, S.; An, Y.-K.; Sohn, H. Continuous-wave line laser thermography for monitoring of rotating wind turbine blades. Struct. Health Monit. 2018, 18, 1010–1021. [Google Scholar] [CrossRef]

- Puthiyaveettil, N.; Thomas, K.R.; Unnikrishnakurup, S.; Myrach, P.; Ziegler, M.; Balasubramaniam, K. Laser line scanning thermography for surface breaking crack detection: Modeling and experimental study. Infrared Phys. Technol. 2020, 104, 103141. [Google Scholar] [CrossRef]

- Pech-May, N.W.; Lecompagnon, J.; Hirsch, P.; Ziegler, M. Robot-assisted crack detection on complex shaped components using constant-speed scanning infrared thermography with laser line excitation. Appl. Res. 2025, 4, e202400007. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Z.; Yin, W.; Zhou, G.; Wang, L.; Li, Y.; Zhao, C.; Wang, C. Shape characterization and depth recognition of metal cracks based on laser infrared thermography and machine learning. Expert Syst. Appl. 2024, 238, 122083. [Google Scholar] [CrossRef]

- Hu, B.; Gao, B.; Woo, W.L.; Ruan, L.; Jin, J.; Yang, Y.; Yu, Y. A Lightweight Spatial and Temporal Multi-Feature Fusion Network for Defect Detection. IEEE Trans. Image Process. 2021, 30, 472–486. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Zhang, Z.; Yin, W.; Chen, H.; Wang, D.e.; Yang, J.; Ma, H.; Fu, Y. Research of laser width variability in line laser infrared thermal wave inspection of CFRP laminates and defect reconstruction method for mobile detection. Measurement 2025, 242, 116298. [Google Scholar] [CrossRef]

- Liu, H.; Du, W.; Yazdani Nezhad, H.; Starr, A.; Zhao, Y. A dissection and enhancement technique for combined damage characterisation in composite laminates using laser-line scanning thermography. Compos. Struct. 2021, 271, 114168. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, Z.; Yin, W.; Chen, H.; Wang, L.; Wang, D.; Ma, H. Surface defect detection of CFRP materials based on infrared thermography and Attention U-Net algorithm. Nondestruct. Test. Eval. 2024, 39, 238–257. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Z.; Wu, S.; Zhao, Z.; Lei, H. Cryogenic thermal conductivity of carbon fiber reinforced polymer composite laminates. Int. J. Heat Mass Transf. 2024, 226, 125521. [Google Scholar] [CrossRef]

- Dong, K.; Liu, K.; Zhang, Q.; Gu, B.; Sun, B. Experimental and numerical analyses on the thermal conductive behaviors of carbon fiber/epoxy plain woven composites. Int. J. Heat Mass Transf. 2016, 102, 501–517. [Google Scholar] [CrossRef]

- Hashimoto, K.; Shiotani, T. Sonic-IR imaging technique for detection of crack interfaces in cementitious materials. Constr. Build. Mater. 2023, 386, 131549. [Google Scholar] [CrossRef]

- Zhou, G.; Ong, Z.C.; Zhang, Z.; Yin, W.; Chen, H.; Ma, H.; Fu, Y. Defect detection of carbon fiber deflectors based on laser infrared thermography and experimental modal analysis. Mech. Syst. Signal Process. 2024, 221, 111763. [Google Scholar] [CrossRef]

| Parameter Name | Value |

|---|---|

| Specimen A type | T800 |

| Specimen A crack horizontal angle | 0°/45°/90° |

| Specimen A size (L × W × H) (mm) | 70 × 120 × 2.4 |

| Specimen A molding method | Manually layered 0° unidirectional |

| Specimen B type | PolyMide™ PA6-CF |

| Specimen B crack opening angle | 15°/30°/45°/60°/75° |

| Specimen B size (L × W × H) (mm) | 300 × 300 × 3 |

| Specimen B molding method | 3D printing |

| Crack size (L × W) (mm) | 10 × 1 |

| Specimen C type | T300 |

| Specimen C size (L × W × H) (mm) | 300 × 200 × 2.7 |

| Crack Depth (mm) | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 |

|---|---|---|---|---|---|

| Function | y = A1 × exp(−x/t1) + y0 | ||||

| y0 | −0.95 | −0.56 | −0.44 | −0.34 | −0.47 |

| A1 | 5.67 | 7.09 | 10.15 | 12.27 | 14.71 |

| t1 | 48.98 | 33.90 | 25.68 | 21.99 | 21.67 |

| Mean square error | 0.0426 | 0.0652 | 0.1145 | 0.1254 | 0.2957 |

| R-square | 0.9834 | 0.9837 | 0.9844 | 0.9859 | 0.9767 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, G.; Zhang, Z.; Yin, W.; Fu, Y.; Wang, D. Multi-Angle Crack Detection in CFRP Based on Line Laser Infrared Thermography Scanning Technology. Polymers 2025, 17, 508. https://doi.org/10.3390/polym17040508

Zhou G, Zhang Z, Yin W, Fu Y, Wang D. Multi-Angle Crack Detection in CFRP Based on Line Laser Infrared Thermography Scanning Technology. Polymers. 2025; 17(4):508. https://doi.org/10.3390/polym17040508

Chicago/Turabian StyleZhou, Guangyu, Zhijie Zhang, Wuliang Yin, Yu Fu, and Ding’erkai Wang. 2025. "Multi-Angle Crack Detection in CFRP Based on Line Laser Infrared Thermography Scanning Technology" Polymers 17, no. 4: 508. https://doi.org/10.3390/polym17040508

APA StyleZhou, G., Zhang, Z., Yin, W., Fu, Y., & Wang, D. (2025). Multi-Angle Crack Detection in CFRP Based on Line Laser Infrared Thermography Scanning Technology. Polymers, 17(4), 508. https://doi.org/10.3390/polym17040508