Performance of Hybrid Reinforced Composite Substrates in Adhesively Bonded Joints Under Varied Loading Rates

Abstract

1. Introduction

2. Experimental Study Details

2.1. Materials

2.1.1. Adhesive

2.1.2. Substrates

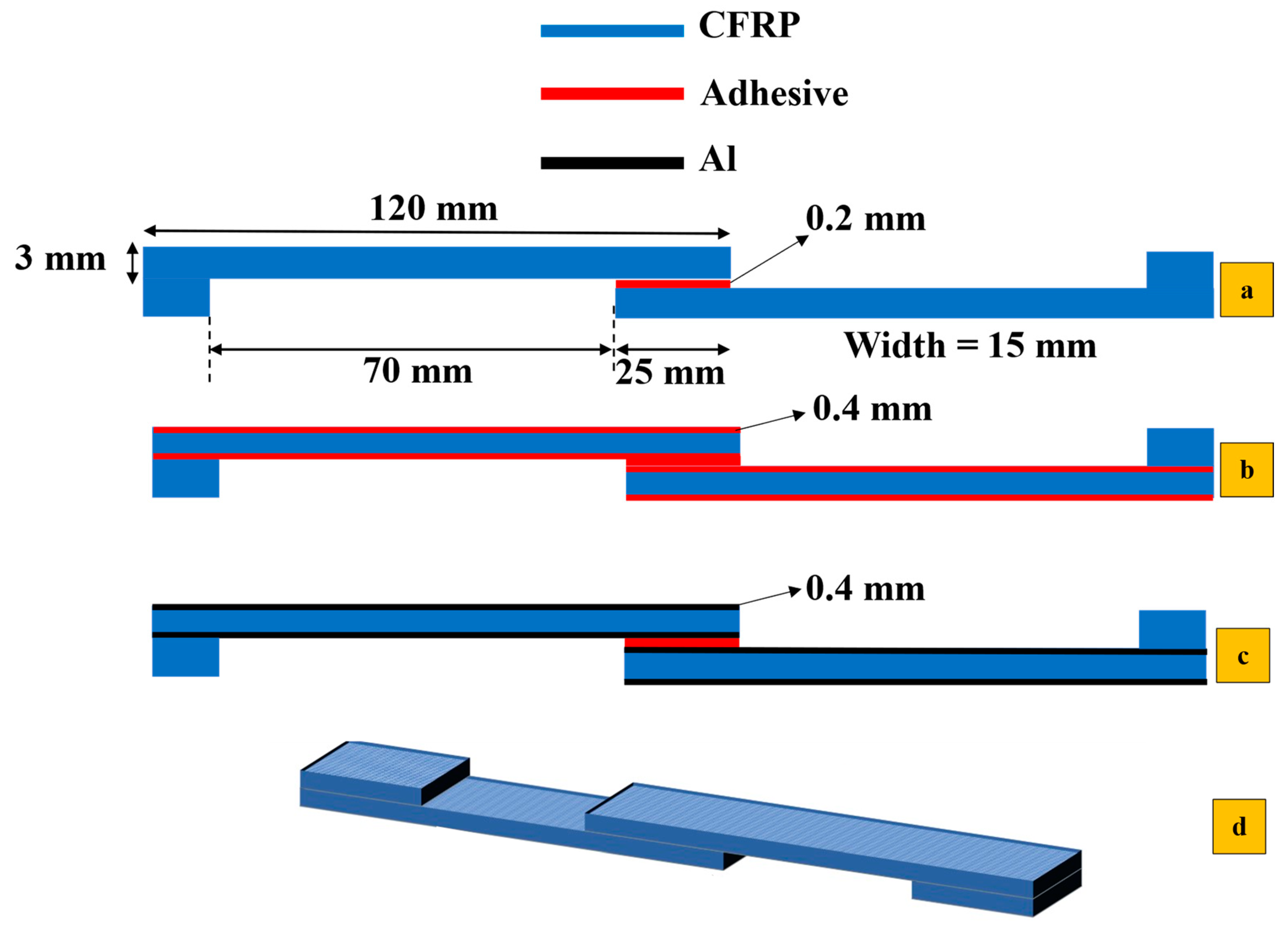

2.2. Configurations and Preparation of Specimens

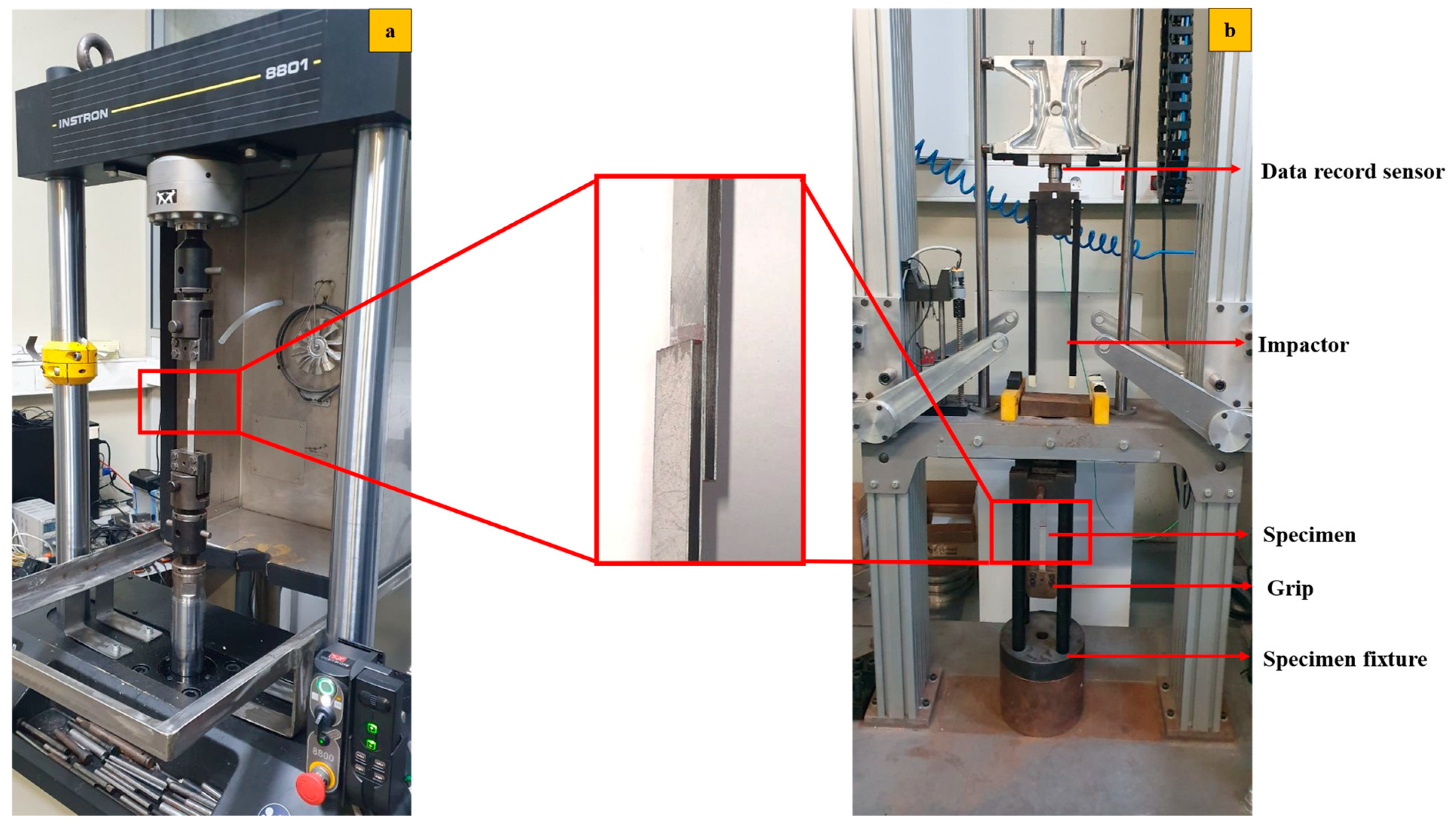

2.3. Testing Condition

3. Numerical Study Details

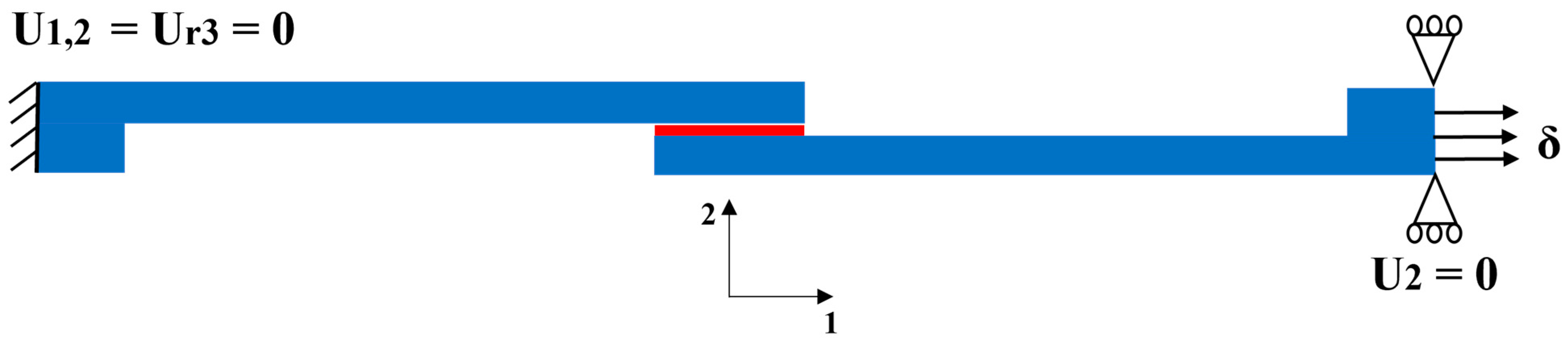

3.1. Elastic Model Analysis

3.2. CZM Analysis

4. Results and Discussions

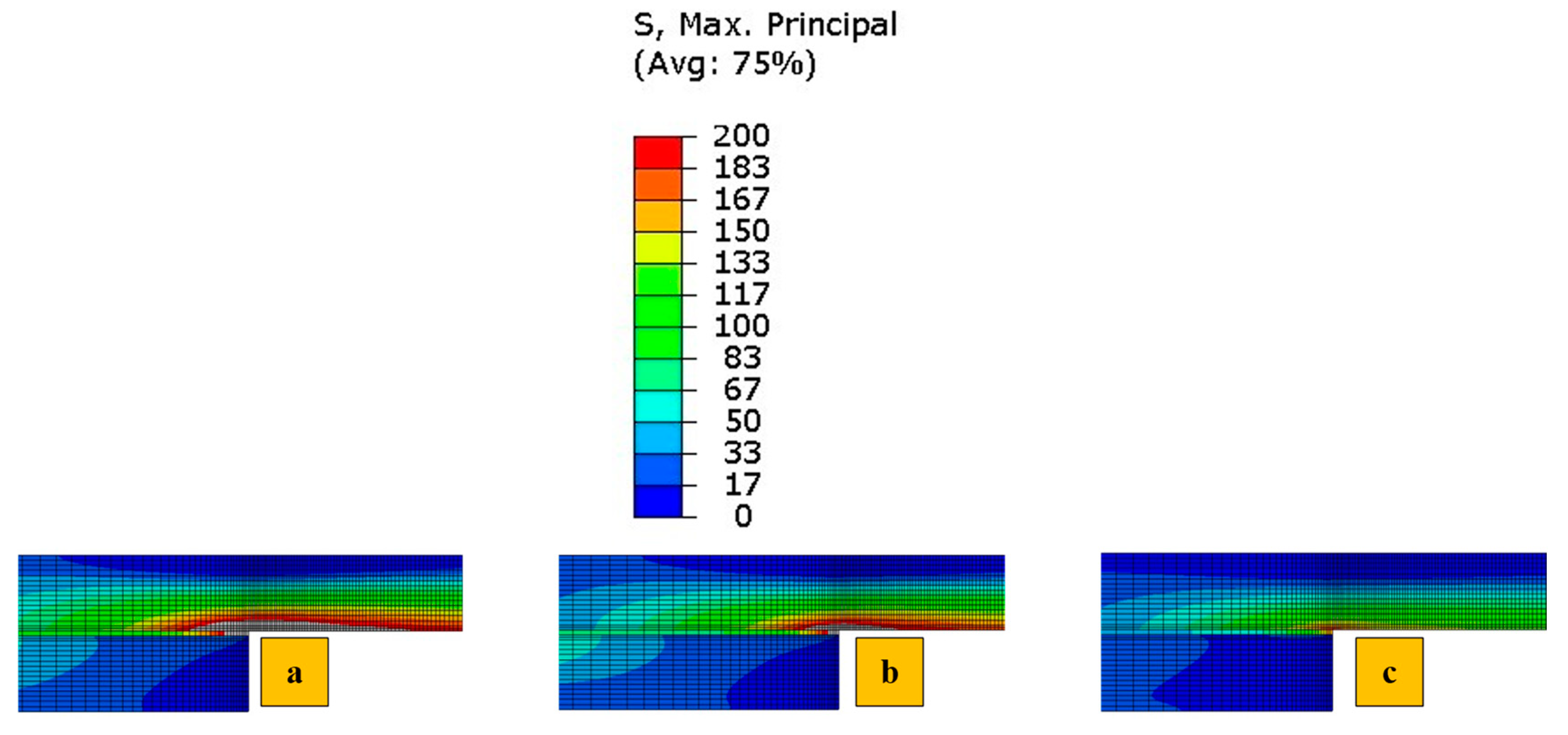

4.1. Numerical Stress Analysis

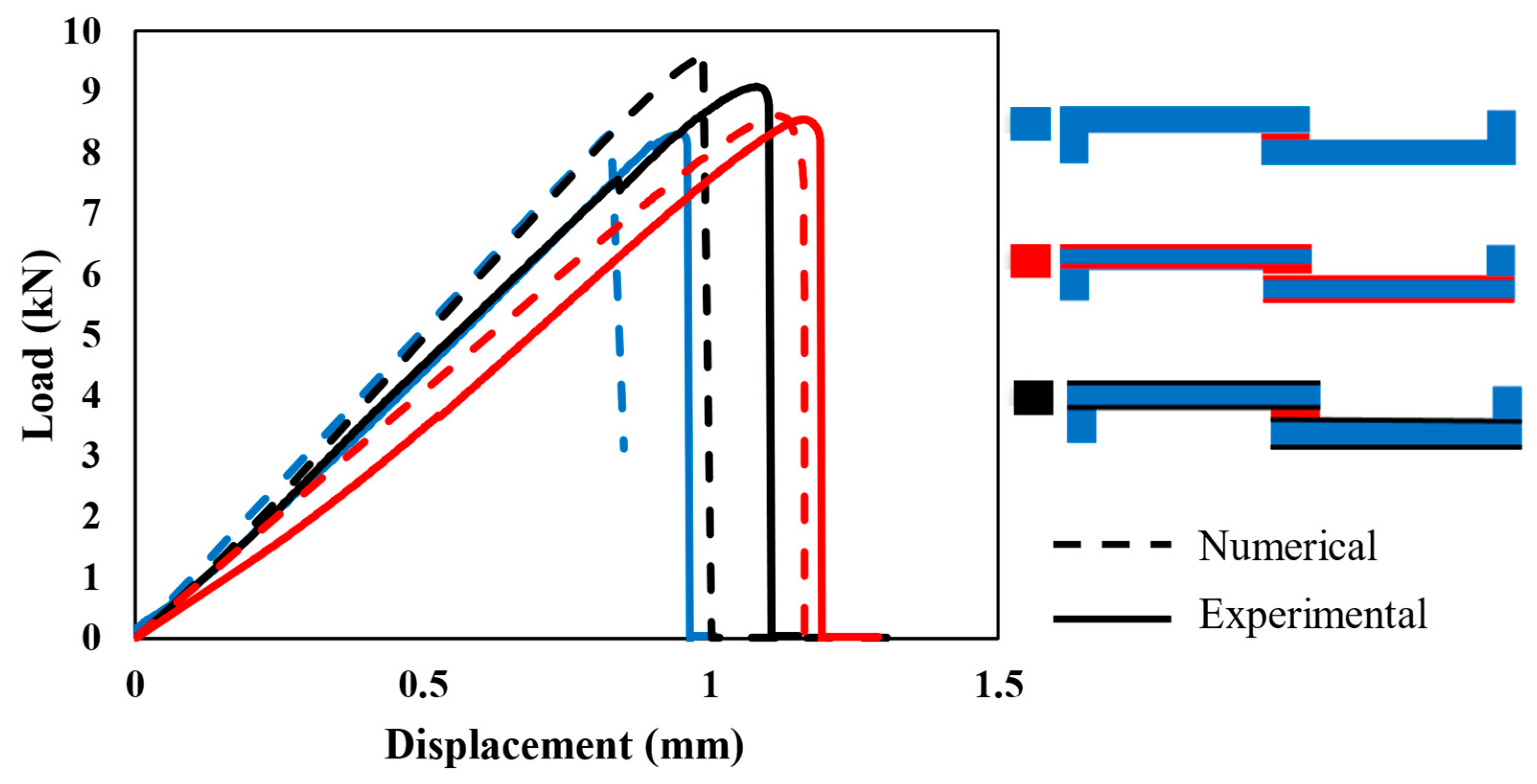

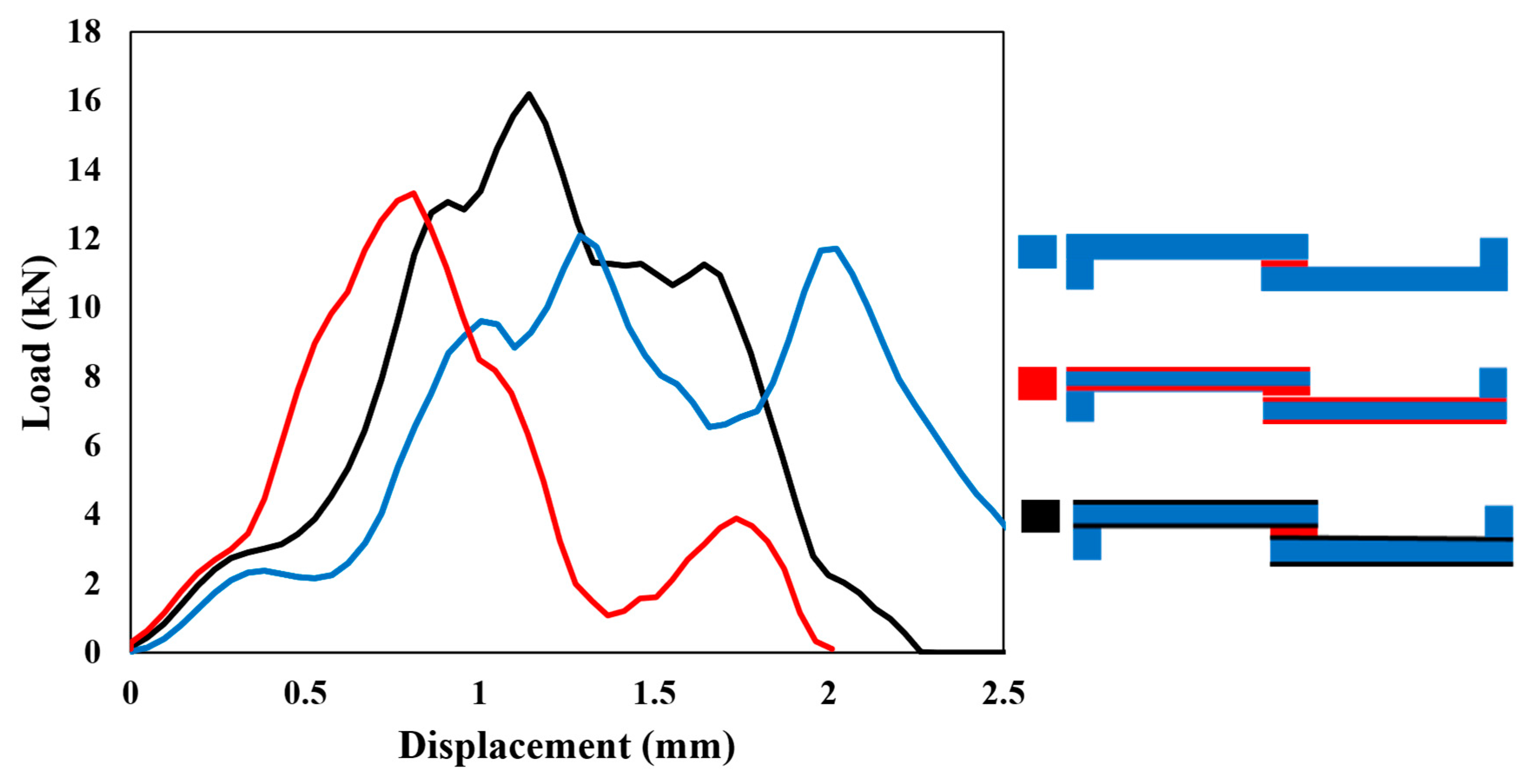

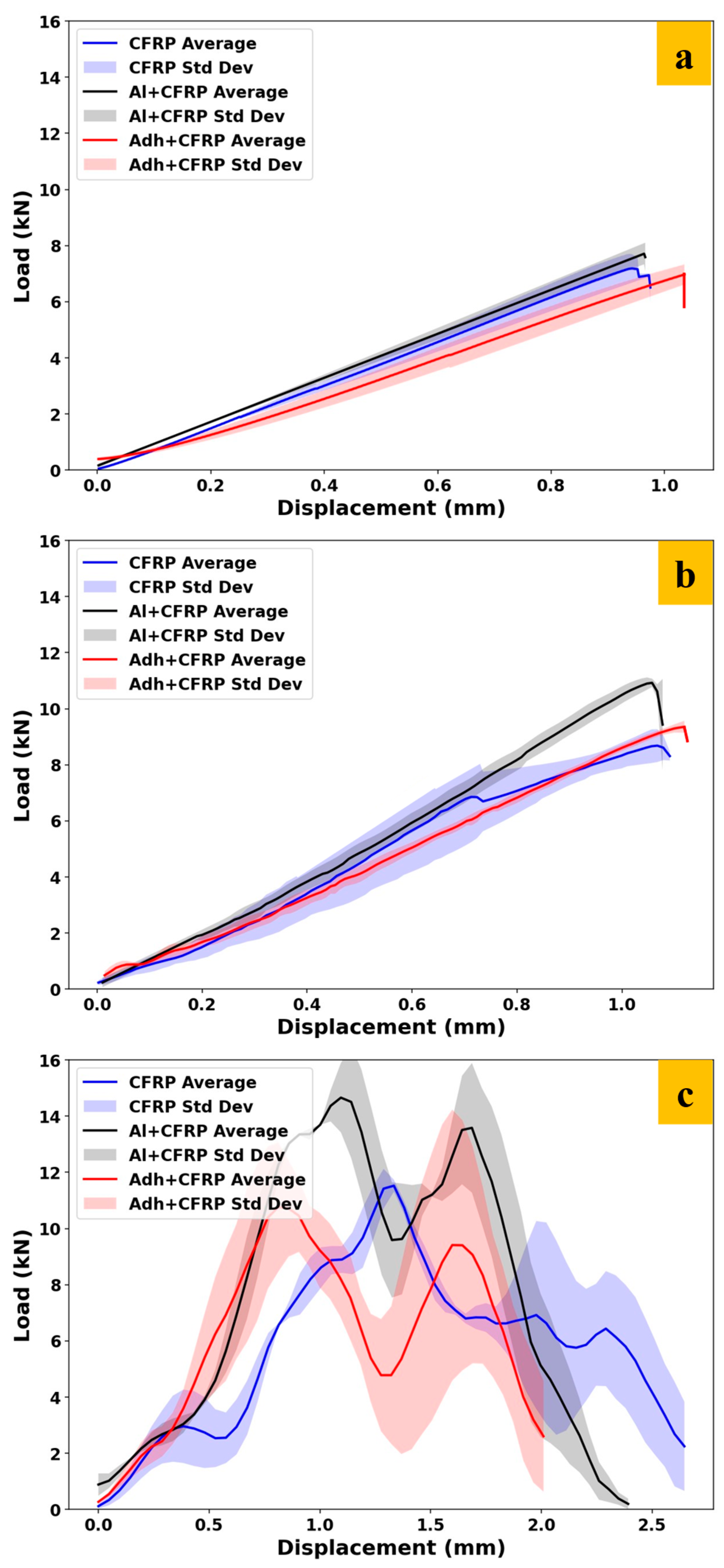

4.2. Comparison of Experimental and Numerical Results

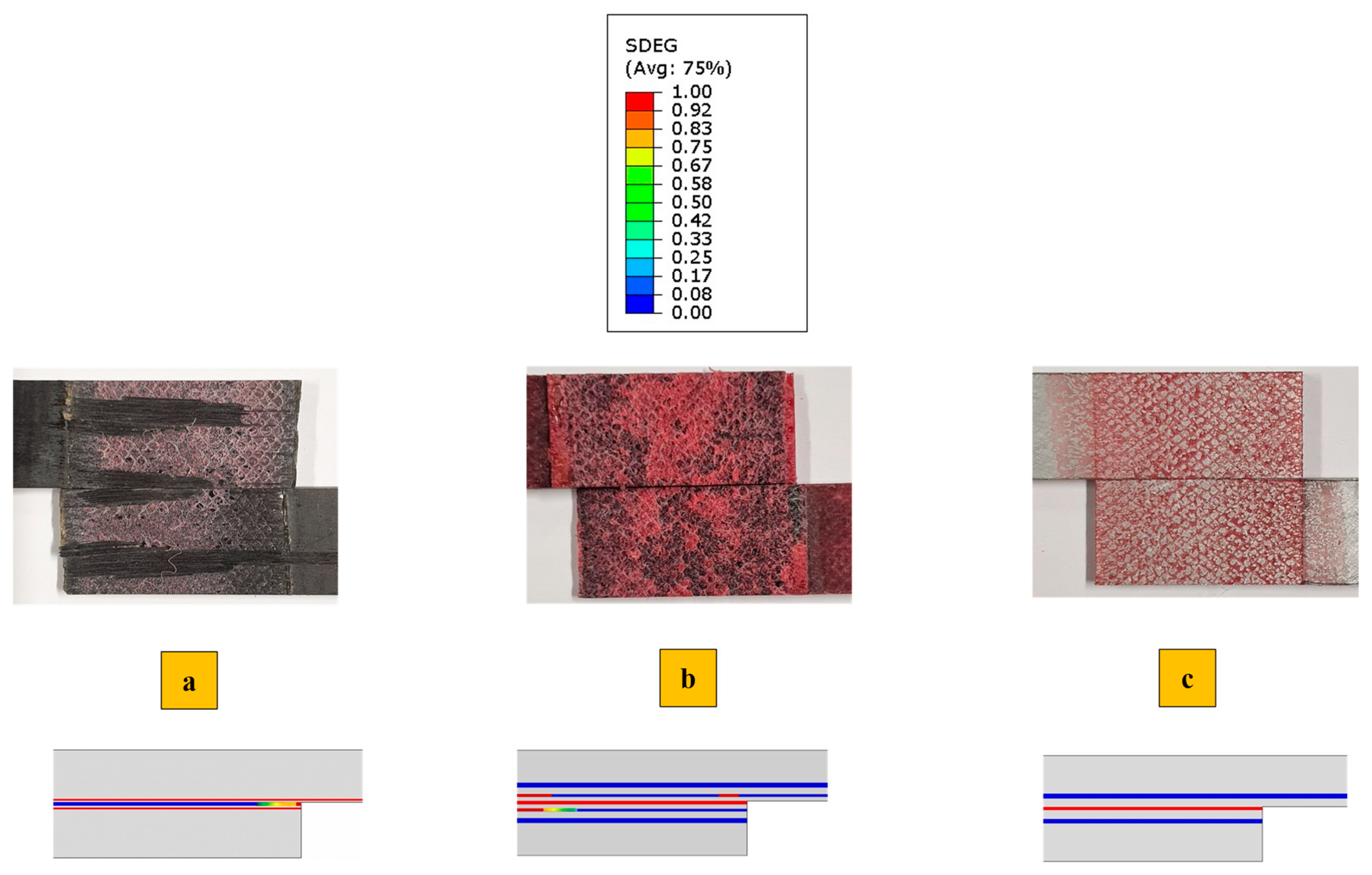

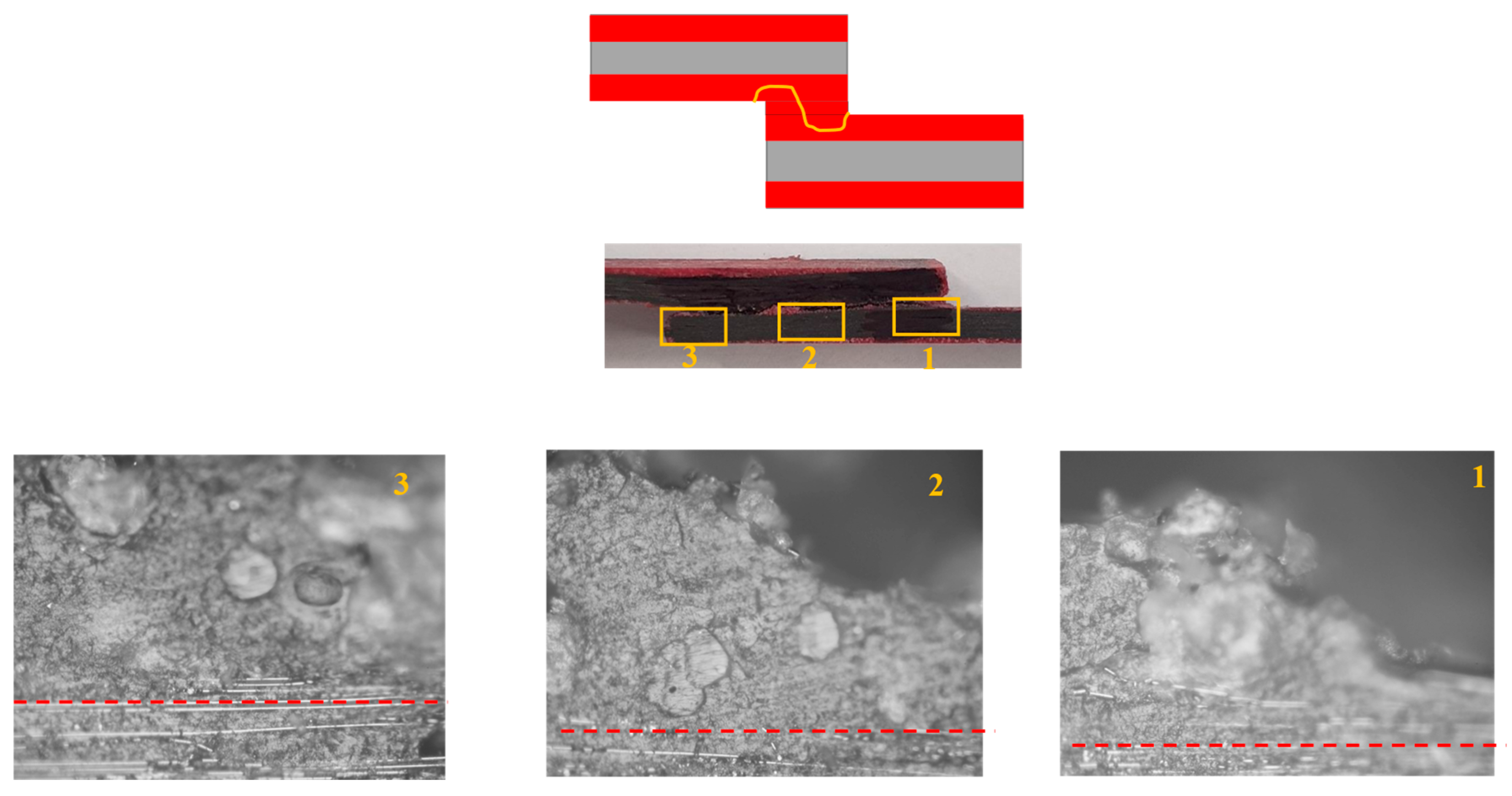

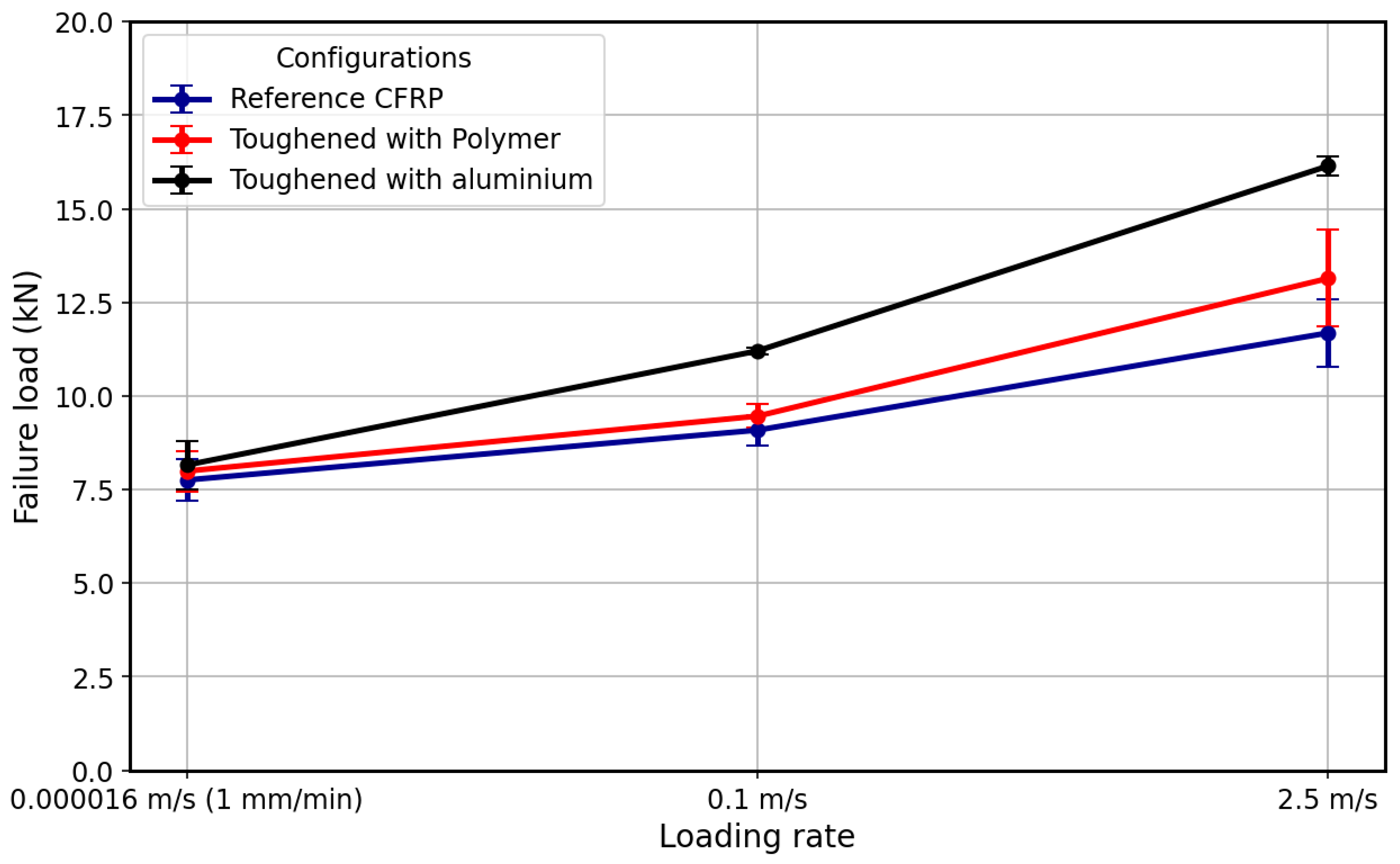

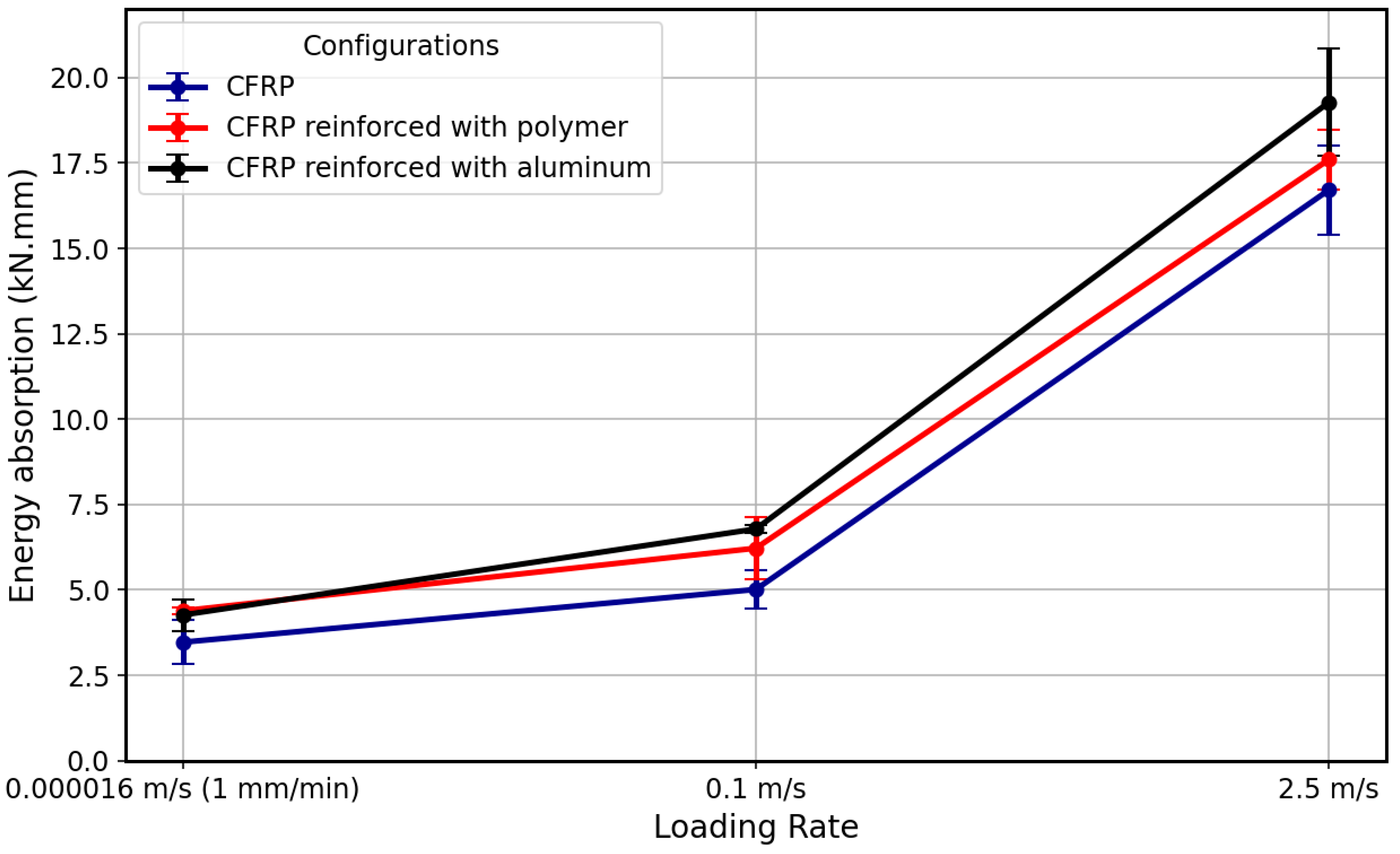

4.3. Performance Comparison of SLJ Configurations

5. Conclusions

- In the SLJs reinforced with aluminum, the metal layers can help slow down or prevent crack propagation that typically occurs in brittle composite layers under high-stress conditions. This combination of metal and composite materials allows the Al + CFRP to better withstand impact and high loading rates, as the ductile metal component absorbs energy, thereby reducing stress concentration in the composite layers. This combination not only increases the overall strength of the material but also makes it more resilient to damage under varying loading conditions, which is particularly valuable in applications requiring high-impact resistance, like aerospace or automotive structures.

- The composite SLJs reinforced with aluminum experience approximately 39% and 23% higher strength compared to reference CFRP under impact and high-rate loading, respectively.

- This enhancement was recorded at 13% and 5% for the composite SLJs reinforced with polymers.

- The energy absorption of the composite SLJs reinforced with aluminum is higher, especially as the loading rate increases, compared with the other configurations.

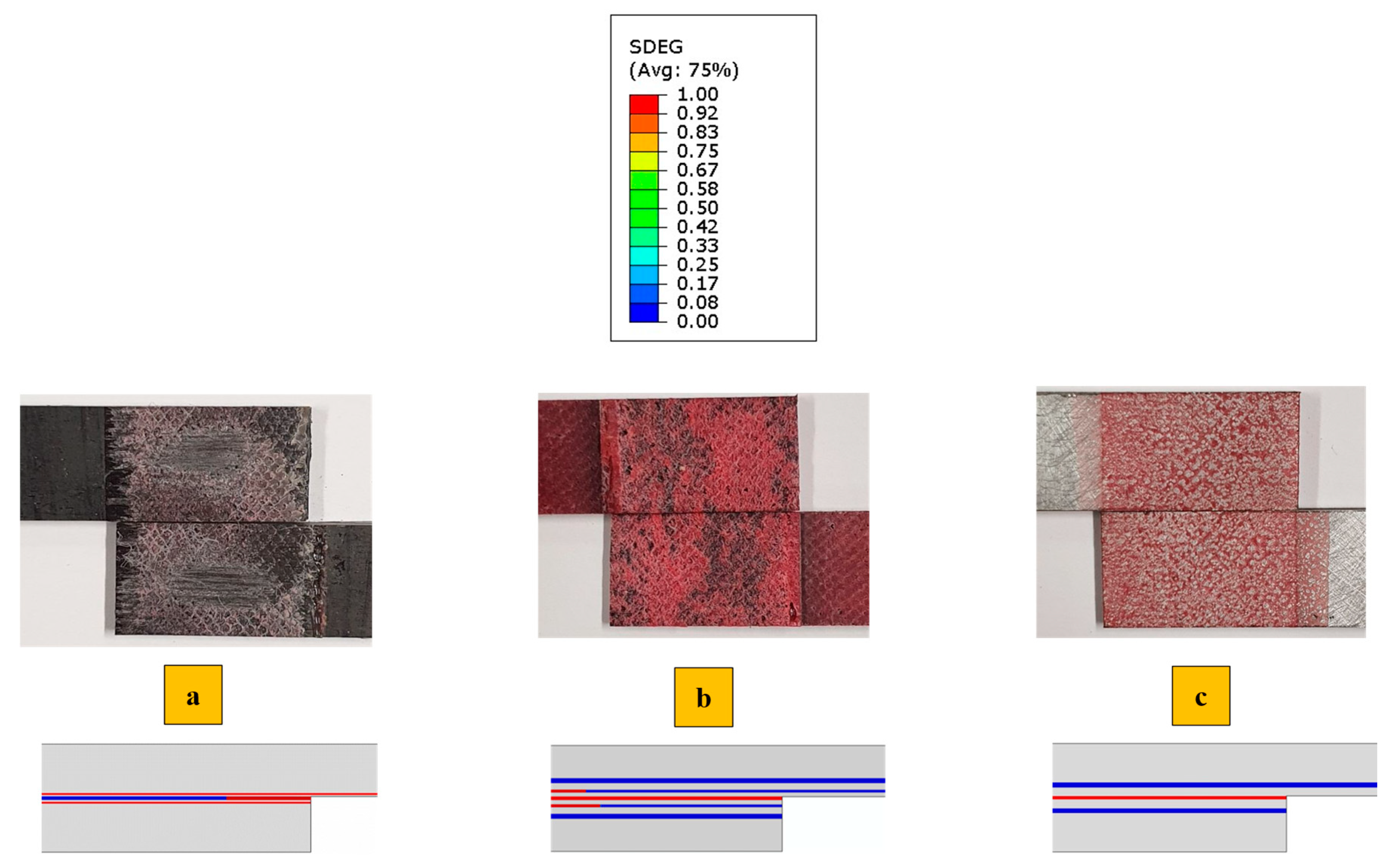

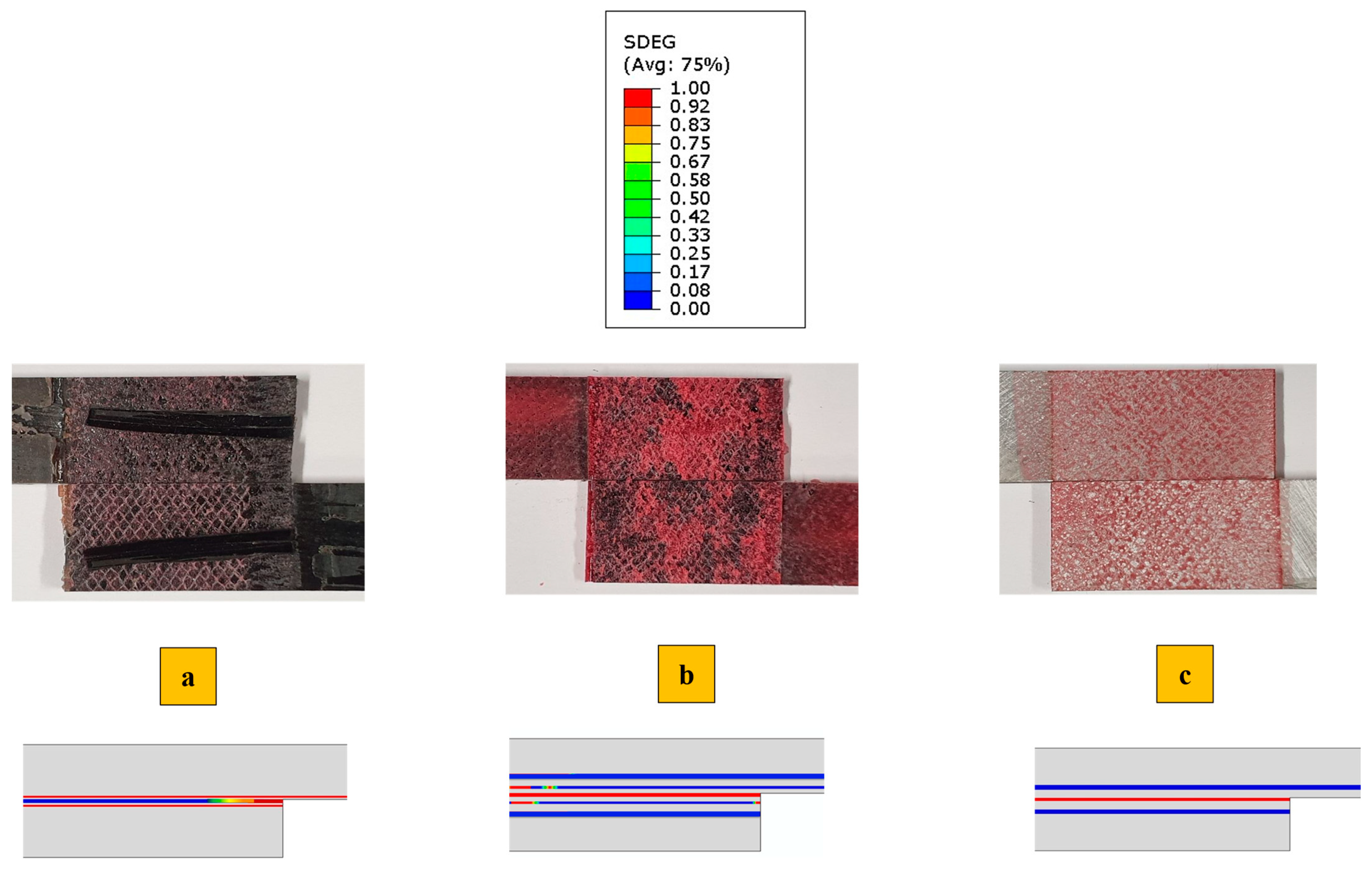

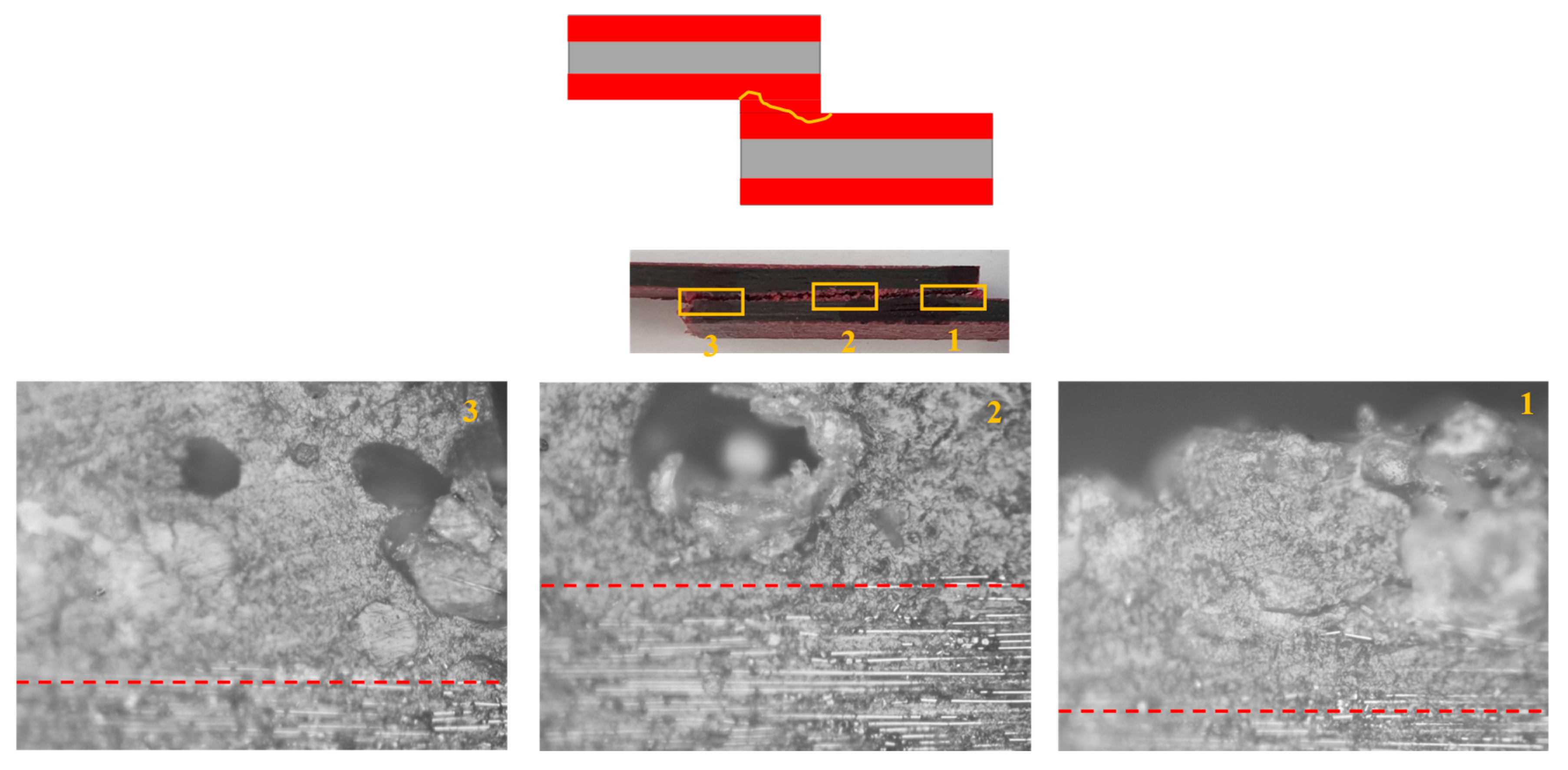

- While the aluminum-reinforced SLJs completely prevent delamination, the polymer-reinforced samples only shift the delamination from the CFRP within the polymer reinforcement.

- Both reinforcement methods reduce stress concentration at the overlap corners and result in a more uniform stress distribution and load transfer compared to the CFRP-only SLJs. Therefore, these two configurations have higher failure load and less delamination.

- The CZM model performs well for all configurations under both quasi-static and high-rate loading. However, as the loading rate increases, the model’s accuracy decreases due to the need for more precise rate-dependent material properties.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wong, L.; Chowdhury, N.; Wang, J.; Chiu, W.K.; Kodikara, J. Fatigue Damage Monitoring of a Composite Step Lap Joint Using Distributed Optical Fibre Sensors. Materials 2016, 9, 374. [Google Scholar] [CrossRef] [PubMed]

- Malekinejadbahabadi, H.; Farrokhabadi, A.; Rahimi, G.; Nazerigivi, A. Effect of core shape on debonding failure of composite sandwich panels with foam-filled corrugated core. Steel Compos. Struct. 2022, 45, 467–482. [Google Scholar]

- Malekinejad, H.; Carbas, R.J.C.; Akhavan-Safar, A.; Marques, E.A.S.; Sousa, F.C.; da Silva, L.F.M. Enhancing Fatigue Life and Strength of Adhesively Bonded Composite Joints: A Comprehensive Review. Materials 2023, 16, 6468. [Google Scholar] [CrossRef] [PubMed]

- Kusukawa, K. Effects of laminate stacking sequence on the strength properties of aluminum alloy–carbon fiber-reinforced plastic dissimilar single-lap adhesive joints. J. Adv. Join. Process. 2024, 10, 100239. [Google Scholar] [CrossRef]

- Han, S.; Yuan, F.; Wang, T.; Li, Z.; Li, Y. Investigation of Residual Strength in CFRP Double-Adhesive Single Lap Bonded Joints after Low-velocity Impact. J. Adhes. 2024, 100, 1–33. [Google Scholar] [CrossRef]

- Wu, S.; Delp, A.; Freund, J.; Walther, F.; Haubrich, J.; Löbbecke, M.; Tröster, T. Correlation between interlaminar shear strength of CFRP and joint strength of aluminium-CFRP hybrid joints. J. Adhes. 2025, 101, 1–26. [Google Scholar] [CrossRef]

- da Silva, R.D.A.L.F.M.; Öchsner, A. Handbook of Adhesion Technology, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Budzik, M.K.; Wolfahrt, M.; Reis, P.; Kozłowski, M.; Sena-Cruz, J.; Papadakis, L.; Saleh, M.N.; Machalicka, K.V.; de Freitas, S.T.; Vassilopoulos, A.P. Testing mechanical performance of adhesively bonded composite joints in engineering applications: An overview. J. Adhes. 2022, 98, 2133–2209. [Google Scholar] [CrossRef]

- Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. The influence of epoxy adhesive toughness on the strength of hybrid laminate adhesive joints. Appl. Adhes. Sci. 2021, 9, 1. [Google Scholar] [CrossRef]

- Machado, J.J.M.; Gamarra, P.M.-R.; Marques, E.A.S.; da Silva, L.F.M. Numerical study of the behaviour of composite mixed adhesive joints under impact strength for the automotive industry. Compos. Struct. 2018, 185, 373–380. [Google Scholar] [CrossRef]

- Kang, M.H.; Choi, J.H.; Kweon, J.H. Fatigue life evaluation and crack detection of the adhesive joint with carbon nanotubes. Compos. Struct. 2014, 108, 417–422. [Google Scholar] [CrossRef]

- Malekinejad, H.; Ramezani, F.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Study of CFRP Laminate Gradually Modified throughout the Thickness Using Thin Ply under Transvers Tensile Loading. Materials 2024, 17, 2388. [Google Scholar] [CrossRef]

- Malekinejad, H.; Carbas, R.J.C.; Akhavan-Safar, A.; Marques, E.A.S.; Ferreira, M.; da Silva, L.F.M. Bio-Inspired Helicoidal Composite Structure Featuring Graded Variable Ply Pitch under Transverse Tensile Loading. J. Compos. Sci. 2024, 8, 228. [Google Scholar] [CrossRef]

- Pires, V.D.C.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Delamination prevention of composite joints with asymmetric carbon-fiber reinforced plastic adherends. J. Compos. Mater. 2024, 58, 1015–1029. [Google Scholar] [CrossRef]

- Meneghetti, G.; Quaresimin, M.; Ricotta, M. Damage mechanisms in composite bonded joints under fatigue loading. Compos. B Eng. 2012, 43, 210–220. [Google Scholar] [CrossRef]

- Santos, D.G.D.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Reinforcement of CFRP joints with fibre metal laminates and additional adhesive layers. Compos. B Eng. 2019, 165, 386–396. [Google Scholar] [CrossRef]

- Mohammadi, I.; Haghighi-Yazdi, M.; Safarabadi, M.; Yousefi, A. Crashworthiness analysis of a composite guardrail under impact loading. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 237, 1651–1664. [Google Scholar] [CrossRef]

- Asundi, A.; Choi, A.Y.N. Fiber metal laminates: An advanced material for future aircraft. J. Mater. Process. Technol. 1997, 63, 384–394. [Google Scholar] [CrossRef]

- Medjahed, A.B.; Youcef, L.; Toufik, S.; Abdelkhalek, H.; Abdeldjalil, Z.; Mehdi, D. On the bending behavior of hybrid fiber–metal laminates (HFMLs) based on aluminum and glass/Kevlar fibers reinforced epoxy. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 239, 207–220. [Google Scholar] [CrossRef]

- Xie, M.; Zhan, L.; Ma, B.; Hui, S. Classification of fiber metal laminates (FMLs), adhesion theories and methods for improving interfacial adhesion: A review. Thin-Walled Struct. 2024, 198, 111744. [Google Scholar] [CrossRef]

- Deng, S.; Djukic, L.; Paton, R.; Ye, L. Thermoplastic–epoxy interactions and their potential applications in joining composite structures—A review. Compos. Part A Appl. Sci. Manuf. 2015, 68, 121–132. [Google Scholar] [CrossRef]

- Sasso, M.; Mancini, E.; Dhaliwal, G.S.; Newaz, G.M.; Amodio, D. Investigation of the mechanical behavior of CARALL FML at high strain rate. Compos. Struct. 2019, 222, 110922. [Google Scholar] [CrossRef]

- Li, X.; Zhang, X.; Zhang, H.; Yang, J.; Nia, A.B.; Chai, G.B. Mechanical behaviors of Ti/CFRP/Ti laminates with different surface treatments of titanium sheets. Compos. Struct. 2017, 163, 21–31. [Google Scholar] [CrossRef]

- Buchan, S.; Rae, W.D. Chemical Nature of the Rubber-To-Brass Bond. Rubber Chem. Technol. 1946, 19, 968–986. [Google Scholar] [CrossRef]

- Mehr, M.E.; Aghamohammadi, H.; Abbandanak, S.N.H.; Aghamirzadeh, G.R.; Eslami-Farsani, R.; Siadati, S.M.H. Effects of applying a combination of surface treatments on the mechanical behavior of basalt fiber metal laminates. Int. J. Adhes. Adhes. 2019, 92, 133–141. [Google Scholar] [CrossRef]

- Fatima, I.; Ejaz, H.; Nigar, M.; Hussain, R.; Khurram, A.A. Correlation between toughness and metal volume fraction in carbon-glass fiber laminates tested under tensile loading. Compos. Interfaces 2023, 30, 1085–1098. [Google Scholar] [CrossRef]

- Allen, K.W. A Review of Contemporary Views of Theories of Adhesion. J. Adhes. 1987, 21, 261–277. [Google Scholar] [CrossRef]

- Mertens, T.; Kollek, H. On the stability and composition of oxide layers on pre-treated titanium. Int. J. Adhes. Adhes. 2010, 30, 466–477. [Google Scholar] [CrossRef]

- Lin, Y.; Li, H.; Wang, Q.; Gong, Z.; Tao, J. Effect of plasma surface treatment of aluminum alloy sheet on the properties of Al/Gf/PP laminates. Appl. Surf. Sci. 2020, 507, 145062. [Google Scholar] [CrossRef]

- Zhao, C.; Dai, X.; Liu, X.; Cui, X. Effect of synergistic action of anodising and graphene on the mechanical properties of fibre-reinforced metal laminates. J. Adhes. Sci. Technol. 2024, 38, 4137–4158. [Google Scholar] [CrossRef]

- Mui, T.S.M.; Silva, L.L.G.; Prysiazhnyi, V.; Kostov, K.G. Surface modification of aluminium alloys by atmospheric pressure plasma treatments for enhancement of their adhesion properties. Surf. Coat. Technol. 2017, 312, 32–36. [Google Scholar] [CrossRef]

- Droździel-Jurkiewicz, M.; Bieniaś, J. Evaluation of Surface Treatment for Enhancing Adhesion at the Metal–Composite Interface in Fibre Metal-Laminates. Materials 2022, 15, 6118. [Google Scholar] [CrossRef] [PubMed]

- van Rooijen, R.G.J.; Sinke, J.; van der Zwaag, S. Improving the adhesion of thin stainless steel sheets for fibre metal laminate (FML) applications. J. Adhes. Sci. Technol. 2005, 19, 1387–1396. [Google Scholar] [CrossRef]

- Surowska, B.; Ostapiuk, M.; Jakubczak, P.; Droździel, M. The Durability of an Organic–Inorganic Sol–Gel Interlayer in Al-GFRP-CFRP Laminates in a Saline Environment. Materials 2019, 12, 2362. [Google Scholar] [CrossRef] [PubMed]

- Morgado, M.A.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Reinforcement of CFRP single lap joints using metal laminates. Compos. Struct. 2019, 230, 111492. [Google Scholar] [CrossRef]

- Xu, P.; Zhou, Z.; Liu, T.; Mal, A. Determination of geometric role and damage assessment in hybrid fiber metal laminate (FML) joints based on acoustic emission. Compos. Struct. 2021, 270, 114068. [Google Scholar] [CrossRef]

- Mottaghian, F.; Taheri, F. Strength and failure mechanism of single-lap magnesium-basalt fiber metal laminate adhesively bonded joints: Experimental and numerical assessments. J. Compos. Mater. 2022, 56, 1941–1955. [Google Scholar] [CrossRef]

- Carbas, R.J.; Palmares, M.P.; da Silva, L.F. Experimental and FE study of hybrid laminates aluminium carbon-fibre joints with different lay-up configurations. Manuf. Rev. 2020, 7, 2. [Google Scholar] [CrossRef]

- Harris, J.A.; Adams, R.A. Strength prediction of bonded single lap joints by non-linear finite element methods. Int. J. Adhes. Adhes. 1984, 4, 65–78. [Google Scholar] [CrossRef]

- Atkins, R.W.; Adams, R.D.; Harris, J.A.; Kinloch, A.J. Stress Analysis and Failure Properties of Carbon-Fibre-Reinforced-Plastic/Steel Double-Lap Joints. J. Adhes. 2010, 20, 29–53. [Google Scholar] [CrossRef]

- Adams, R.D.; Harris, J.A. The influence of local geometry on the strength of adhesive joints. Int. J. Adhes. Adhes. 1987, 7, 69–80. [Google Scholar] [CrossRef]

- Mottaghian, F.; Taheri, F. Assessment of failure mechanism of double-strap 3D-FML adhesively bonded joints under tensile and compressive loadings using cohesive zone modelling approach. Compos. Struct. 2023, 318, 117078. [Google Scholar] [CrossRef]

- Xu, J.-Q.; Liu, Y.-H.; Wang, X.-G. Numerical methods for the determination of multiple stress singularities and related stress intensity coefficients. Eng. Fract. Mech. 1999, 63, 775–790. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; Banea, M.D.; Pinto, A.M.G.; da Silva, L.F.M.; de Jesus, A.M.P. Strength prediction of single- and double-lap joints by standard and extended finite element modelling. Int. J. Adhes. Adhes. 2011, 31, 363–372. [Google Scholar] [CrossRef]

- Xará, J.T.S.; Campilho, R.D.S.G. Strength estimation of hybrid single-L bonded joints by the eXtended Finite Element Method. Compos. Struct. 2018, 183, 397–406. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; de Moura, M.F.S.F.; Domingues, J.J.M.S. Modelling single and double-lap repairs on composite materials. Compos. Sci. Technol. 2005, 65, 1948–1958. [Google Scholar] [CrossRef]

- Karakaş, Ö.; Szusta, J. Monotonic and low cycle fatigue behaviour of 2024-T3 aluminium alloy between room temperature and 300 °C for designing VAWT components. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 95–109. [Google Scholar] [CrossRef]

- 3M Aerospace and Commercial Transportation Division. AC-130-2-Brochure. Available online: https://www.3m.com/3M/en_US/aerospace-us/?utm_medium=redirect&utm_source=vanity-url&utm_campaign=www.3m.com/aerospace (accessed on 16 August 2024).

- Flaig, F.; Fräger, T.; Kaufmann, M.; Vallée, T.; Fricke, H.; Müller, M. How to find the perfect application pattern for adhesively bonded joints? J. Adv. Join. Process. 2023, 8, 100147. [Google Scholar] [CrossRef]

- Perry, J.I.; Walley, S.M. Measuring the Effect of Strain Rate on Deformation and Damage in Fibre-Reinforced Composites: A Review. J. Dyn. Behav. Mater. 2022, 8, 178–213. [Google Scholar] [CrossRef]

| Properties |

Quasi-Static (1 mm/min) |

High-Rate (0.1 m/s) |

Impact (2.5 m/s) |

|---|---|---|---|

| Maximum tensile strength (MPa) * | 46.93 | 46.93 | 46.93 |

| Young’s modulus (MPa) * | 1520 | 1520 | 1520 |

| Maximum shear strength (MPa) | 46.86 | 46.68 | 42.3 |

| Shear modulus (MPa) * | 565 | 565 | 565 |

| Mode I fracture toughness (N/mm) | 4.05 | 4.12 | 5.72 |

| Mode II fracture toughness (N/mm) | 9.77 | 10.07 | 17.24 |

| Ex (MPa) | Ey (MPa) | Ez (MPa) | νxy | νyz | νxz | Gxy (MPa) | Gyz (MPa) | Gzx (MPa) |

|---|---|---|---|---|---|---|---|---|

| 109,000 | 8819 | 8819 | 0.342 | 0.342 | 0.38 | 4315 | 4315 | 3200 |

| Properties | Quasi-Static | High-Rate | Impact |

|---|---|---|---|

| Maximum tensile strength (MPa) * | 40 | 40 | 40 |

| Maximum shear strength (MPa) * | 35 | 35 | 35 |

| Mode I fracture toughness (N/mm) | 0.59 | 0.58 | 0.42 |

| Mode II fracture toughness (N/mm) | 1.2 | 1.19 | 0.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malekinejad, H.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Performance of Hybrid Reinforced Composite Substrates in Adhesively Bonded Joints Under Varied Loading Rates. Polymers 2025, 17, 469. https://doi.org/10.3390/polym17040469

Malekinejad H, Carbas RJC, Marques EAS, da Silva LFM. Performance of Hybrid Reinforced Composite Substrates in Adhesively Bonded Joints Under Varied Loading Rates. Polymers. 2025; 17(4):469. https://doi.org/10.3390/polym17040469

Chicago/Turabian StyleMalekinejad, Hossein, Ricardo J. C. Carbas, Eduardo A. S. Marques, and Lucas F. M. da Silva. 2025. "Performance of Hybrid Reinforced Composite Substrates in Adhesively Bonded Joints Under Varied Loading Rates" Polymers 17, no. 4: 469. https://doi.org/10.3390/polym17040469

APA StyleMalekinejad, H., Carbas, R. J. C., Marques, E. A. S., & da Silva, L. F. M. (2025). Performance of Hybrid Reinforced Composite Substrates in Adhesively Bonded Joints Under Varied Loading Rates. Polymers, 17(4), 469. https://doi.org/10.3390/polym17040469