Investigation of the Flexural and Charpy Impact Properties of Polymer Composites Reinforced with Tururi (Manicaria saccifera) Fibrous Fabric

Abstract

1. Introduction

2. Materials and Methods

2.1. Composites Preparation

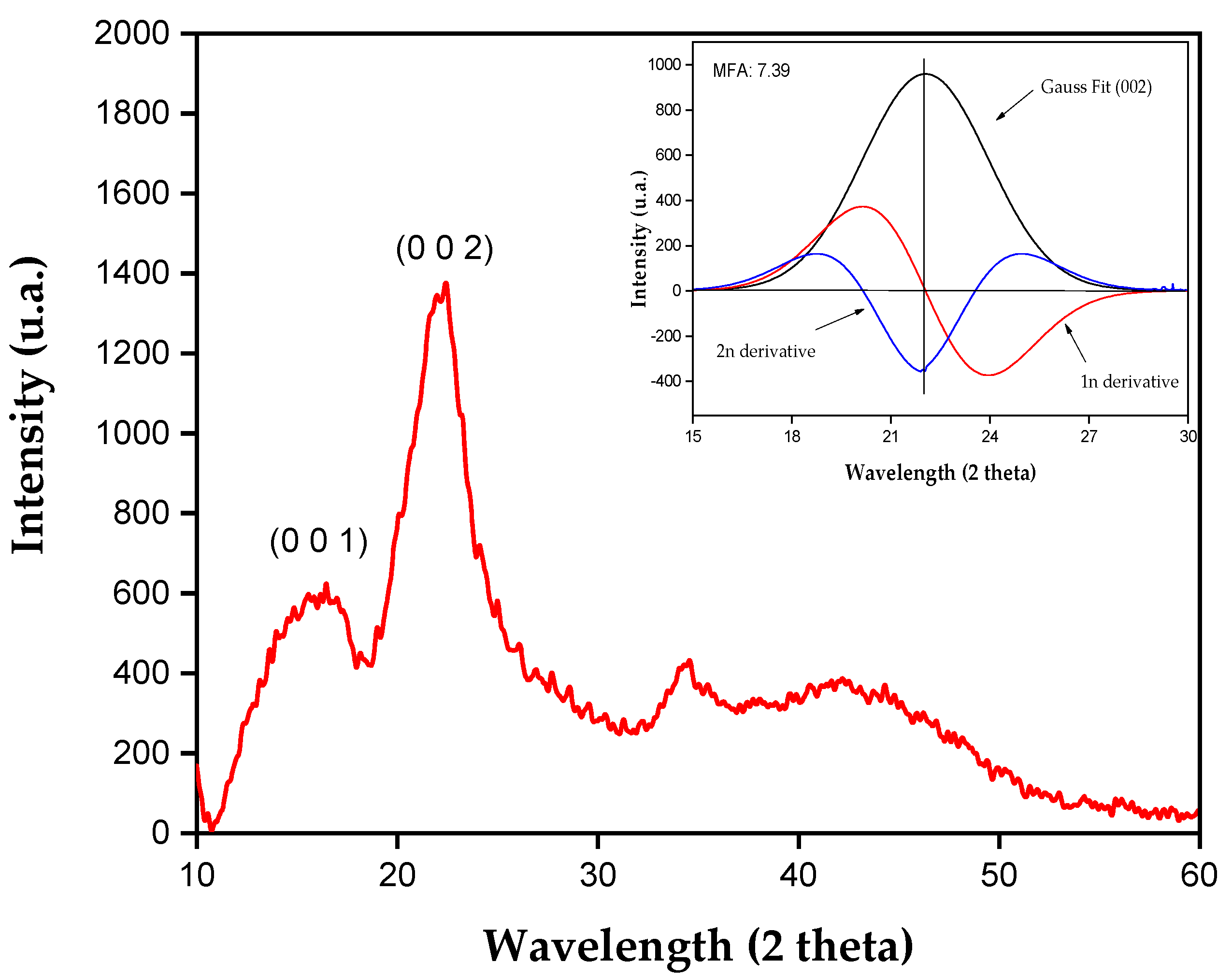

2.2. X-Ray Diffraction (XRD)

Microfibril Angle (MFA)

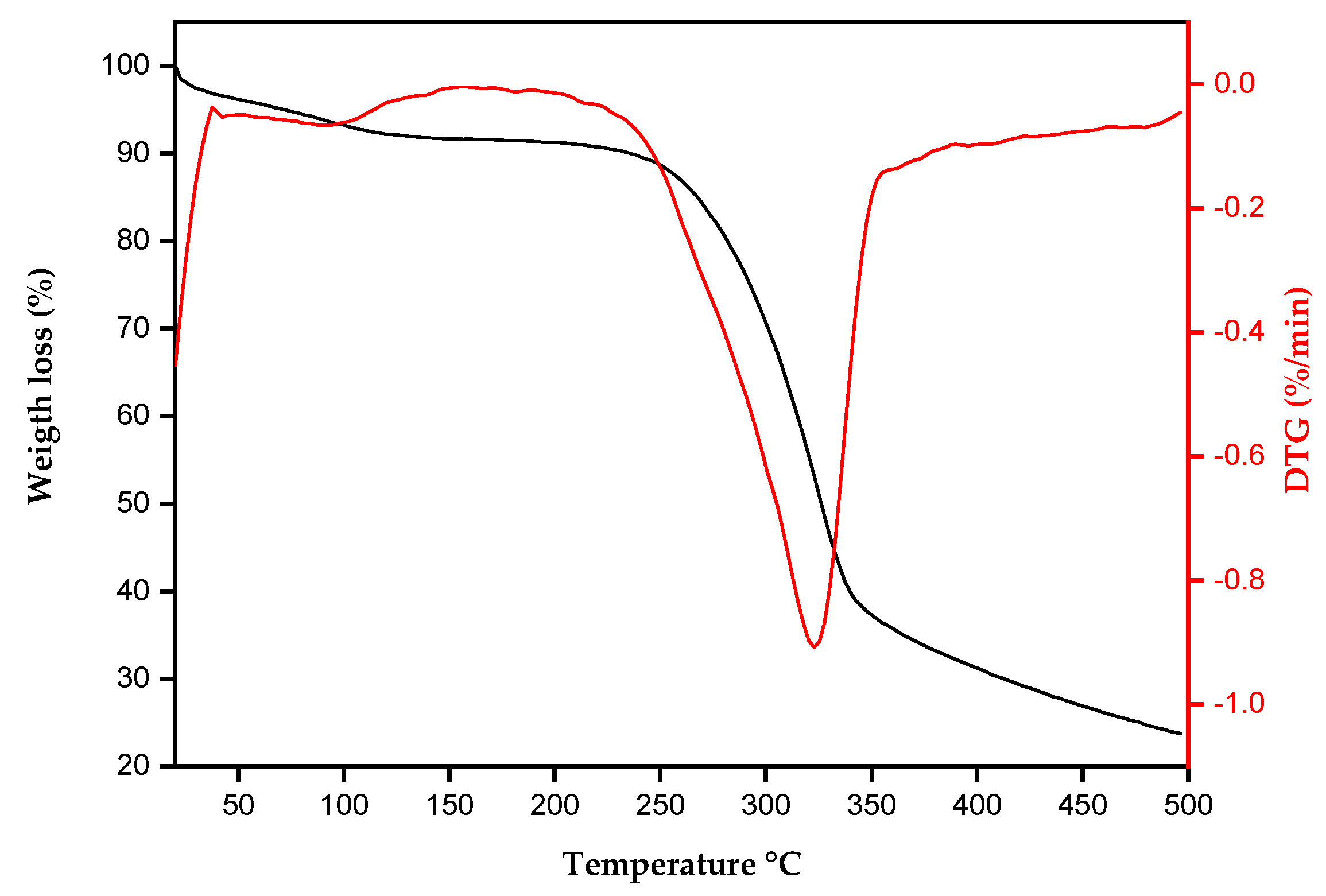

2.3. Thermogravimetric Analysis (TGA)

2.4. Fourier Transform Infrared Spectroscopy (FTIR)

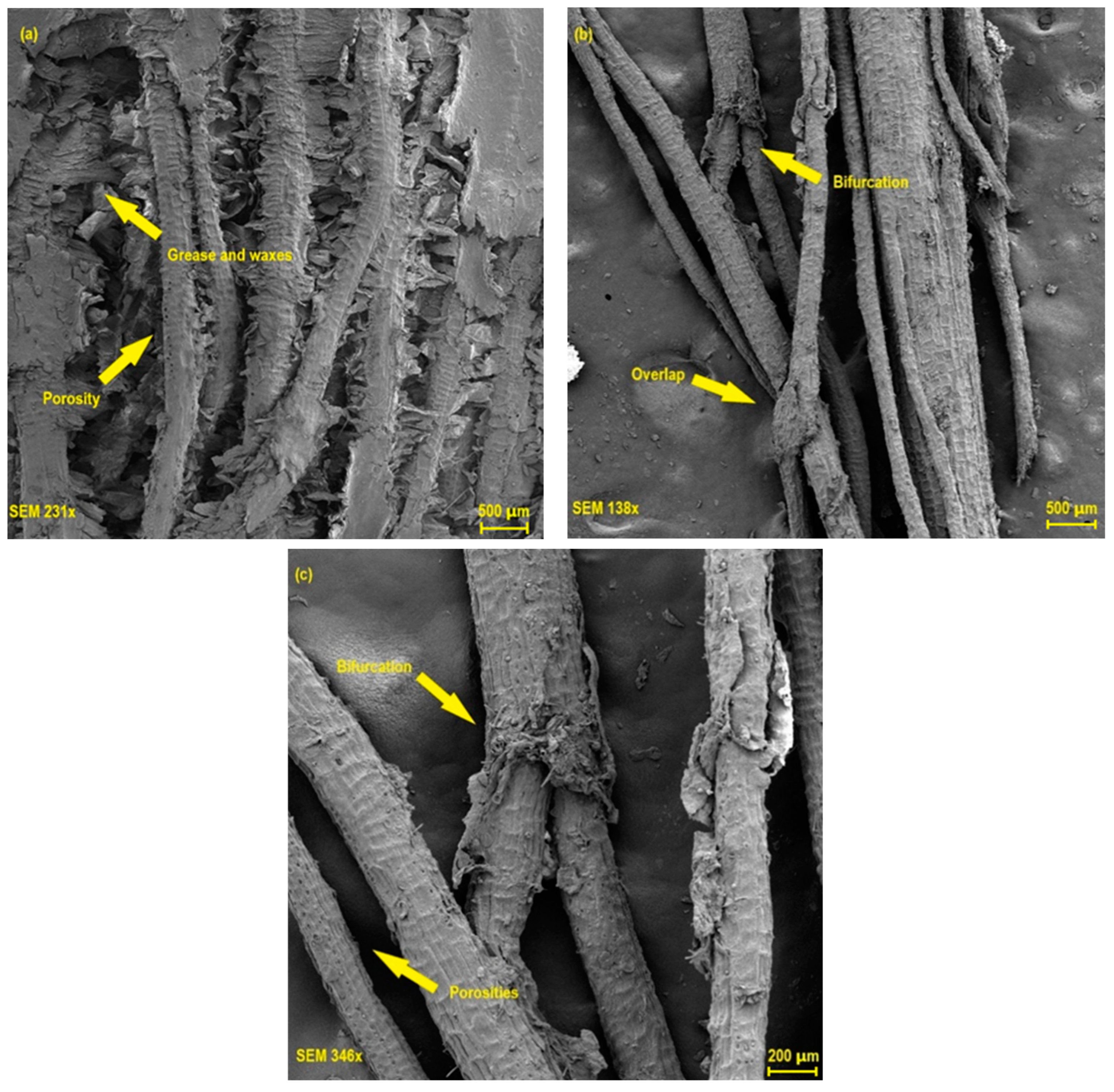

2.5. SEM Analysis

2.6. Mechanical Properties Tururi Fabric

2.7. DMA

2.8. Flexure Test

2.9. Charpy Impact Test

2.10. Statistical Analysis

3. Results

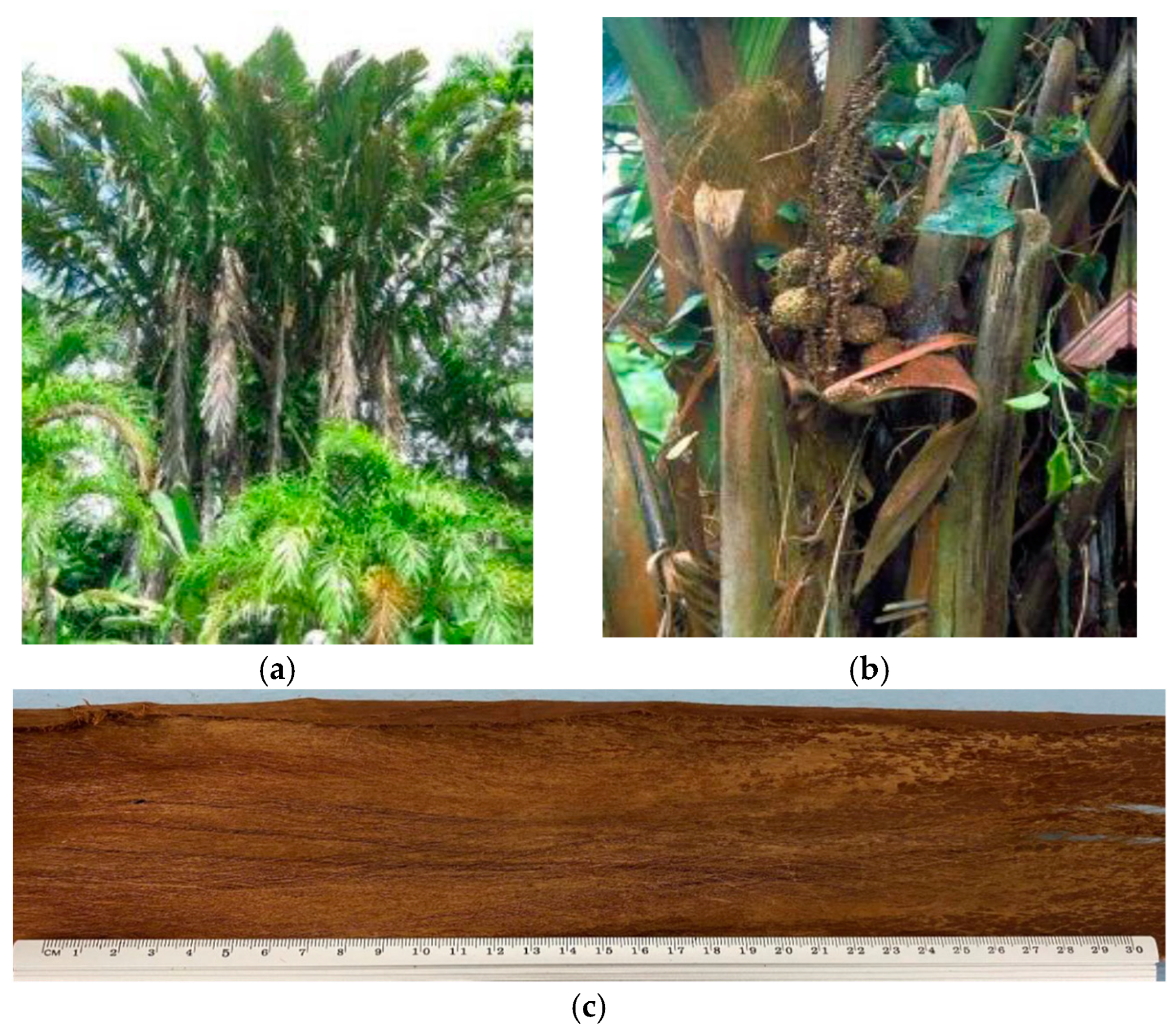

3.1. Characterization of Tururi Fabric

3.1.1. XRD Analysis

3.1.2. TGA

3.1.3. FTIR Analysis

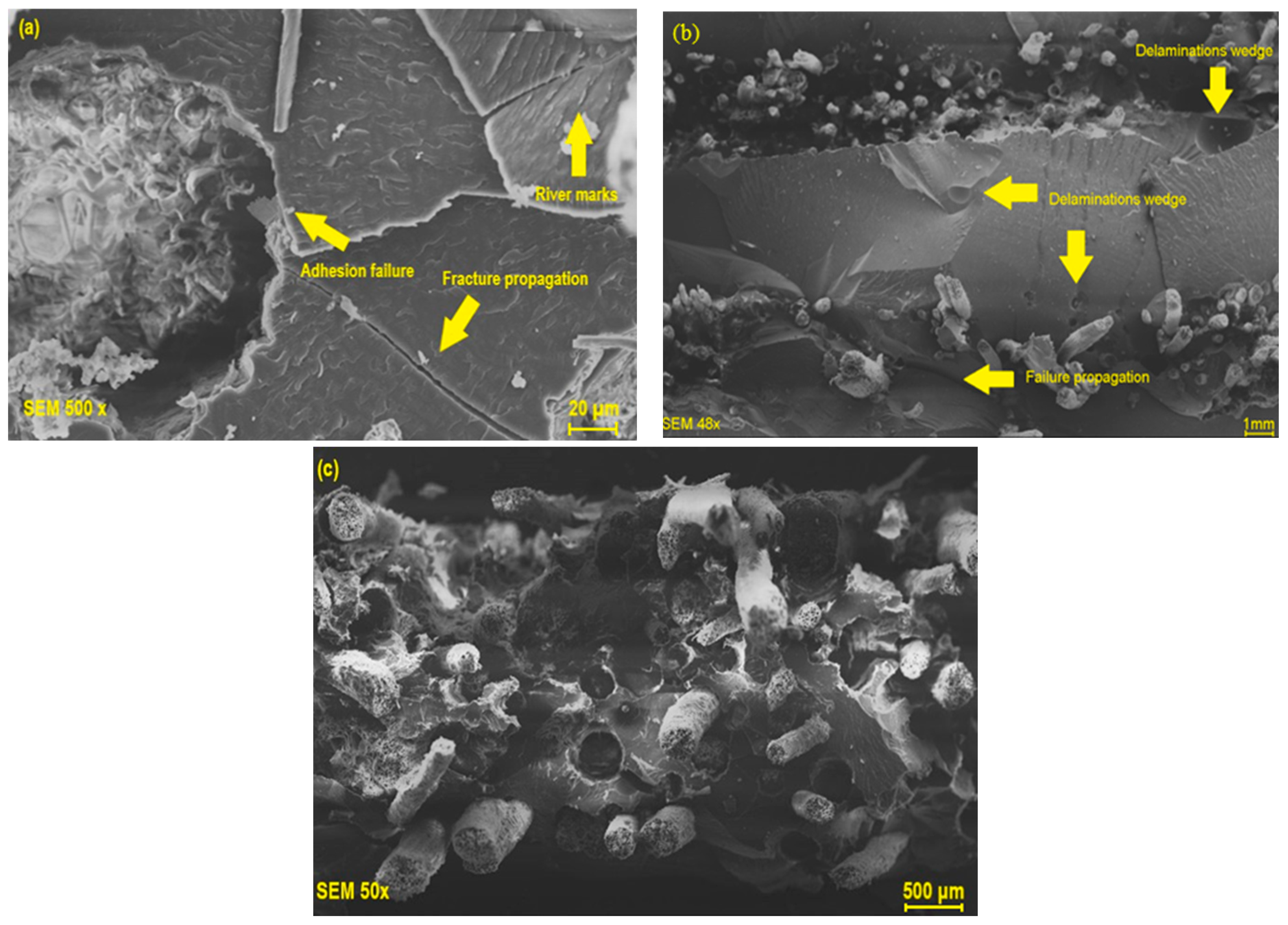

3.1.4. SEM Analysis of Tururi Fabric

3.1.5. Mechanical Properties Tururi Fabric

3.2. Characterization of Composite Materials

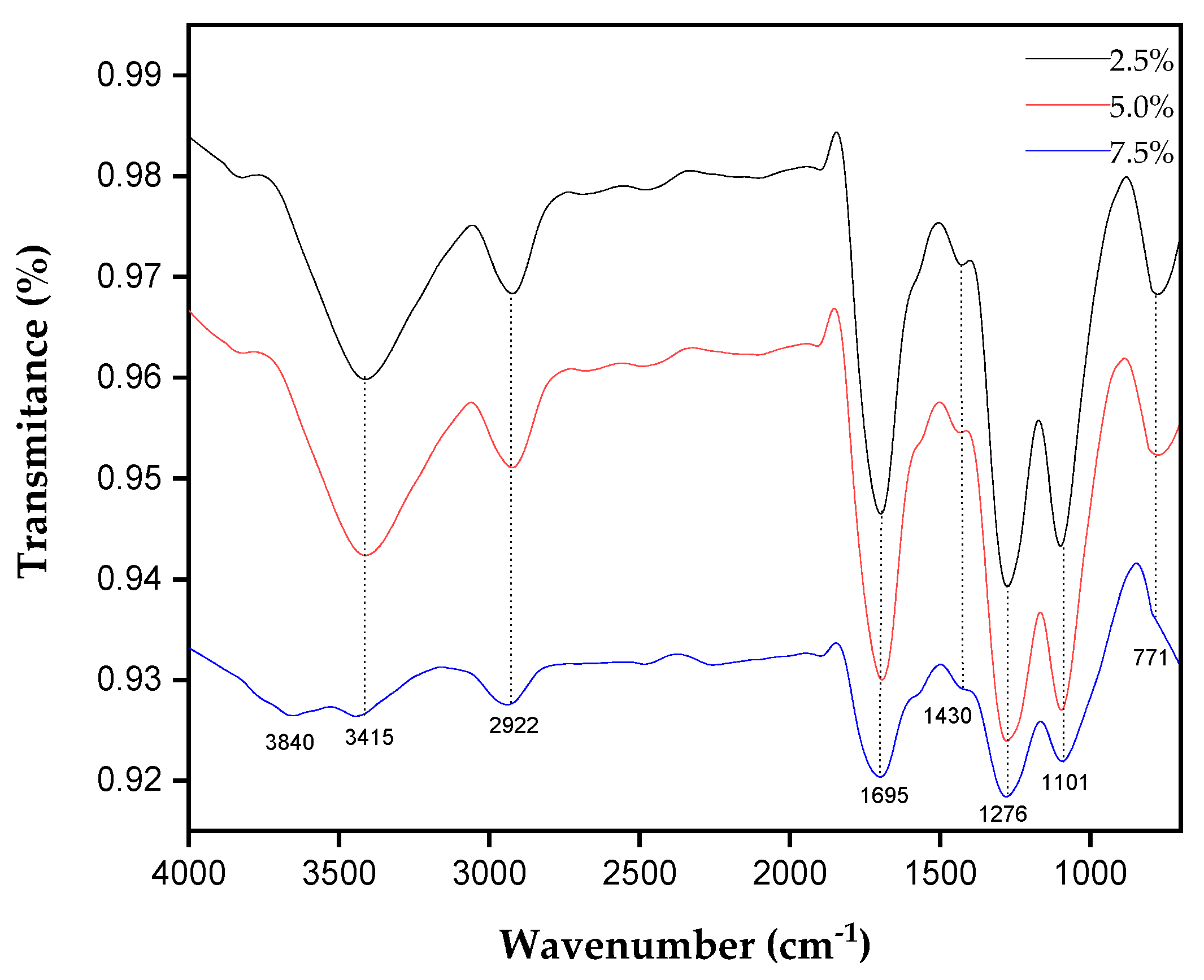

3.2.1. FTIR Composite Analysis

3.2.2. DMA of Composites

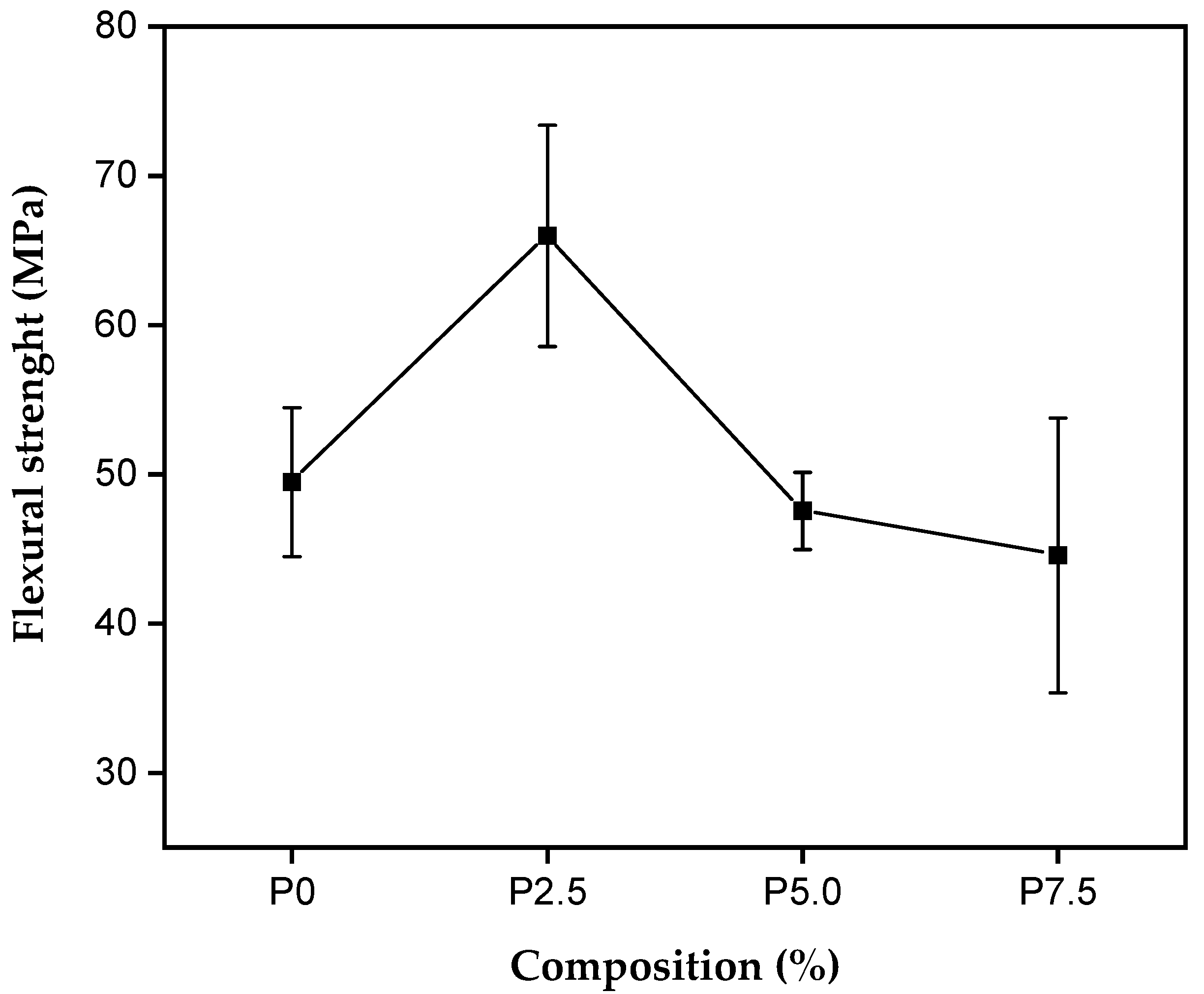

3.2.3. Flexure Test

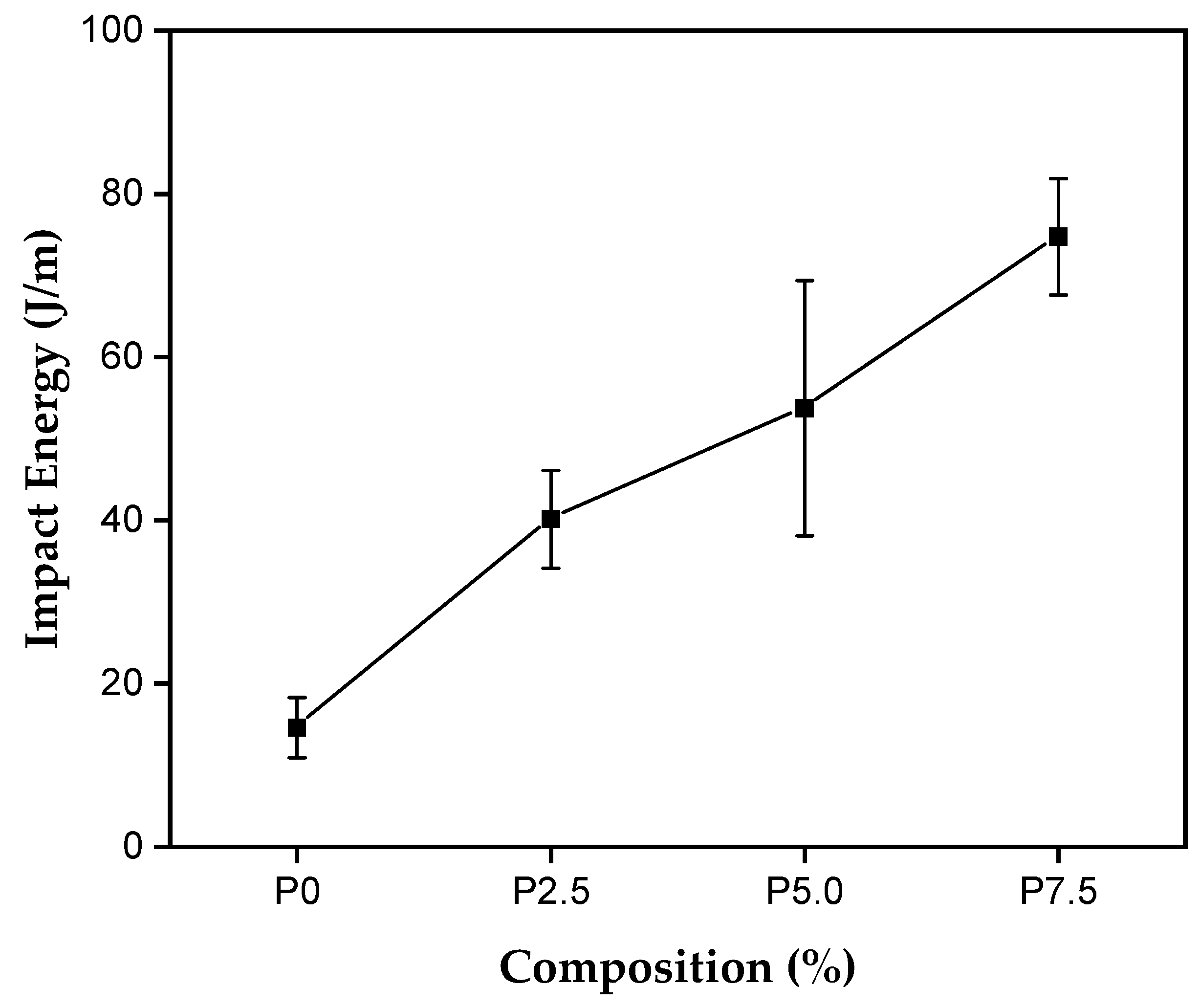

3.2.4. Charpy Impact Test

3.2.5. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Balla, V.K.; Kate, K.H.; Satyavolu, J. Additive Manufacturing of Natural Fiber Reinforced Polymer Composites: Processing and Prospects. Compos. Part B 2019, 174, 106956. [Google Scholar] [CrossRef]

- Hossain, M.D.S.; Mobarak, M.B.; Rony, F.K.; Sultana, S.; Mahmud, M.; Ahmed, S. Fabrication and Characterization of Banana Fiber Reinforced Unsaturated Polyester Resin Based Composites. Nano Hybrids Compos. 2020, 29, 84–92. [Google Scholar] [CrossRef]

- Mekonnen, B.Y.; Mano, Y.J. Tensile and Flexural Analysis of a Hybrid Bamboo/Jute Fiber-Reinforced Composite with Polyester Matrix as a Sustainable Green Material for Wind Turbine Blades. Int. J. Eng. 2020, 33, 314–319. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Khalina, A.; Nurazzi, N.M.; Lee, S.H.; Lee, C.H. Uma Revisão Abrangente em Tecido Sustentável Avançado Compósitos de polímeros de fibra natural. Polímeros 2021, 13, 471. [Google Scholar] [CrossRef]

- Cavalcanti, D.K.K.; Banea, M.D.; Neto, J.S.S. Comparative Analysis of the Mechanical and Thermal Properties of Polyester and Epoxy Natural Fiber-Reinforced Hybrid Composites. J. Compos. Mater. 2021, 55, 1683–1692. [Google Scholar] [CrossRef]

- Dipen, K.R.; Durgesh, D.P.; Ravinder, K. Recent Progress of Reinforcement Materials: A Comprehensive Overview of Composite Materials. J. Mater. Res. Technol. 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- Das Subrata, C.; Debasree, P.; Sotirios, A.I.; Siddiquee, M.A.B.; Papatzani, S.; Koralli, P.; Islam, J.M.M.; Khan, M.A.; Shauddin, S.M.; Khan, R.A.; et al. Effect of Stacking Sequence on the Performance of Hybrid Natural/Synthetic Fiber Reinforced Polymer Composite Laminates. Compos. Struct. 2021, 276, 114525. [Google Scholar] [CrossRef]

- Mindermann, P.; Gil Pérez, M.; Knippers, J.; Gresser, G.T. Investigation of the Fabrication Suitability, Structural Performance, and Sustainability of Natural Fibers in Coreless Filament Winding. Materials 2022, 15, 3260. [Google Scholar] [CrossRef]

- Kumar, S.; Prasad, L.; Bijlwan, P.P.; Yadav, A. Thermogravimetric Analysis of Lignocellulosic Leaf-Based Fiber-Reinforced Thermosets Polymer Composites: An Overview. Biomass Convers. Biorefinery 2024, 14, 12673–12698. [Google Scholar] [CrossRef]

- Zhao, X.; Li, K.; Wang, Y.; Tekinalp, H.; Richard, A.; Webb, E.; Ozcan, S. Bio-Treatment of Poplar via Amino Acid for Interface Control in Biocomposites. Compos. Part B Eng. 2020, 199, 108276. [Google Scholar] [CrossRef]

- Zhao, X.; Copenhaver, K.; Wang, L.; Korey, M.; Gardner, D.J.; Li, K.; Lamm, M.E.; Kishore, V.; Bhagia, S.; Tajvidi, M.; et al. Recycling of Natural Fiber Composites: Challenges and Opportunities. Resour. Conserv. Recycl. 2022, 177, 105962. [Google Scholar] [CrossRef]

- Asrofi, M.; Sapuan, S.M.; Ilyas, R.A.; Ramesh, M. Characteristic of Composite Bioplastics from Tapioca Starch and Sugarcane Bagasse Fiber: Effect of Time Duration of Ultrasonication (Bath-Type). Mater. Today Proc. 2020, 46, 1626–1630. [Google Scholar] [CrossRef]

- Sabaruddin, F.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Abdan, K.; Mazlan, N.; Roseley, A.S.M.; Abdul Khalil, H.P.S. The Effects of Unbleached and Bleached Nanocellulose on the Thermal and Flammability of Polypropylene-Reinforced Kenaf Core Hybrid Polymer Bionanocomposites. Polymers 2020, 13, 116. [Google Scholar] [CrossRef]

- Gohal, H.; Kumar, V.; Jena, H. Study of Natural Fiber Composite Material and Its Hybridization Techniques. Mater. Today Proc. 2020, 26, 1368–1372. [Google Scholar] [CrossRef]

- Haris, N.I.N.; Hassan, M.Z.; Ilyas, R.A.; Suhot, M.A.; Sapuan, S.M.; Dolah, R.; Mohammad, R.L.; Asyraf, M.R.M. Dynamic Mechanical Properties of Natural Fiber Reinforced Hybrid Polymer Composites: A Review. J. Mater. Res. Technol. 2022, 19, 167–182. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Alhijazi, M.; Safaei, B.; Zeeshan, Q.; Asmael, M.; Eyvazian, A.; Qin, Z. Recent Developments in Luffa Natural Fiber Composites: Review. Sustainability 2020, 12, 7683. [Google Scholar] [CrossRef]

- Ribeiro, M.M.; Pinheiro, M.A.; Rodrigues, J.d.S.; Ramos, R.P.B.; Corrêa, A.d.C.; Monteiro, S.N.; da Silva, A.C.R.; Candido, V.S. Comparison of Young’s Modulus of Continuous and Aligned Lignocellulosic Jute and Mallow Fibers Reinforced Polyester Composites Determined Both Experimentally and from Theoretical Prediction Models. Polymers 2022, 14, 401. [Google Scholar] [CrossRef]

- Kumar, S.S. Effect of Natural Fiber Loading on Mechanical Properties and Thermal Characteristics of Hybrid Polyester Composites for Industrial and Construction Fields. Fibers Polym. 2020, 21, 1508–1514. [Google Scholar] [CrossRef]

- Sarikaya, E.; Çallioğlu, H.; Demirel, H. Production of Epoxy Composites Reinforced by Different Natural Fibers and Their Mechanical Properties. Compos. Part B Eng. 2019, 167, 461–466. [Google Scholar] [CrossRef]

- Bachchan, A.A.; Das, P.P.; Chaudhary, V. Effect of Moisture Absorption on the Properties of Natural Fiber Reinforced Polymer Composites: A Review. Mater. Today Proc. 2021, 49, 3403–3408. [Google Scholar] [CrossRef]

- Gazem de Carvalho, J.P.R.; Duarte Lopes, F.P.; Simonassi, N.T.; Neves, A.C.C.; Atem de Carvalho, E.; Monteiro, S.N.; Vieira, C.M.F. Methodological Analysis of Composites Green Polyurethane Resin Reinforced with Jute Fabric. Case Stud. Constr. Mater. 2022, 17, e01512. [Google Scholar] [CrossRef]

- Mishra, T.; Mandal, P.; Rout, A.K.; Sahoo, D. A State-of-the-Art Review on Potential Applications of Natural Fiber-Reinforced Polymer Composite Filled with Inorganic Nanoparticle. Compos. Part C Open Access 2022, 9, 100298. [Google Scholar] [CrossRef]

- Akhil, U.V.; Radhika, N.; Saleh, B.; Krishna, S.A.; Nobre, N.; Rajeshkumar, L. Uma Revisão Abrangente Sobre Compósitos Poliméricos Reforçados A comprehensive review on plant-based natural fiber reinforced polymer composites: Fabrication, properties, and applications. Polím. Compós. 2023, 44, 2598–2633. [Google Scholar] [CrossRef]

- Liu, S.; Dong, C.; Yuan, C.; Bai, X.; Tian, Y.; Zhang, G. A new polyimide matrix composite to improve friction-induced chatter performance through reducing fluctuation in friction force. Compos. Part B Eng. 2021, 217, 108887. [Google Scholar] [CrossRef]

- Monteiro, A.S.; Dantas, D.; Yojo, T. Preparation of Amazonian Palm Tree Fiber (Manicaria saccifera Gaertn.) for Composite Materials. U.Porto J. Eng. 2021, 7, 31–36. [Google Scholar] [CrossRef]

- Oliveira, J.R.; Kotzebue, L.R.V.; Freitas, D.B.; Mattos, A.L.A.; da Costa Júnior, A.E.; Mazzetto, S.E.; Lomonaco, D. Towards Novel High-Performance Bio-Composites: Polybenzoxazine-Based Matrix Reinforced with Manicaria saccifera Fabrics. Compos. Part B Eng. 2020, 194, 108060. [Google Scholar] [CrossRef]

- Ng, L.F.; Yahya, M.Y.; Muthukumar, C. Mechanical Characterization and Water Absorption Behaviors of Pineapple Leaf/Glass Fiber-Reinforced Polypropylene Hybrid Composites. Polym. Compos. 2022, 43, 203–214. [Google Scholar] [CrossRef]

- Ng, L.F.; Yahya, M.Y.; Muthukumar, C.; Parameswaranpillai, J.; Ma, Q.; Muhammad Asyraf, M.R.; Abdul Majid, R. Mechanical Characterization, Water Absorption, and Thickness Swelling of Lightweight Pineapple Leaf/Ramie Fabric-Reinforced Polypropylene Hybrid Composites. Polymers 2024, 16, 1847. [Google Scholar] [CrossRef]

- Monteiro, A.S.; Leonardi, B.; Savastano, H., Jr.; Baruque-Ramos, J. Tururi Palm Fibrous Material (Manicaria saccifera Gaertn.) Characterization. Green Mater. 2015, 3, 120–131. [Google Scholar] [CrossRef]

- Porras, A.; Maranon, A.; Ashcroft, I.A. Characterization of a Novel Natural Cellulose Fabric from Manicaria saccifera Palm as Possible Reinforcement of Composite Materials. Compos. Part B Eng. 2015, 74, 66–73. [Google Scholar] [CrossRef]

- Midani, M.; Seyam, A.F.M.; Monteiro, A.S.; Baruque-Ramos, J. Effect of Structural Parameters on the Impact Properties of Multilayer Composites from Tururi Palm (Manicaria saccifera Gaertn.) Fibrous Material. J. Nat. Fibers 2018, 17, 284–297. [Google Scholar] [CrossRef]

- Botanical Garden Lancetilla. Manicaria Saccifera Gaertn. 2014. Available online: http://jblancetilla.org/manicaria_saccifera_gaertn.htm (accessed on 27 October 2024).

- ASTM D790-17; Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2017.

- ASTM D6110-18; Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2010.

- Segal, L.A.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Cave, I.D. X-ray Microfibril Angle Measurement. For. Prod. J. 1966, 16, 37–42. [Google Scholar]

- Pinheiro, M.A.; Gomes, L.G.; da Silva, A.C.R.; Candido, V.S.; Reis, R.H.M.; Monteiro, S.N. Guaruman: A Natural Amazonian Fiber with Potential for Polymer Composite Reinforcement. Mater. Res. 2019, 22, e20190092. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Nunes, L.F.; Oliveira, M.S.; Veiga Júnior, V.F.; Garcia Filho, F.C.; Pinheiro, M.A.; Cândido, V.S.; Monteiro, S.N. Fibra Guaruman: Another possible reinforcement in composites. J. Mater. Res. Technol. 2020, 9, 6. [Google Scholar] [CrossRef]

- Marchi, B.Z.; Oliveira, M.S.; Bezerra, W.B.A.; de Sousa, T.G.; Candido, V.S.; da Silva, A.C.R.; Monteiro, S.N. Ubim Fiber (Geonoma baculífera): A Less Known Brazilian Amazon Natural Fiber for Engineering Applications. Sustainability 2022, 14, 421. [Google Scholar] [CrossRef]

- Pinheiro, M.A.; Ribeiro, M.M.; Rosa, D.L.S.; Nascimento, D.d.C.B.; da Silva, A.C.R.; dos Reis, M.A.L.; Monteiro, S.N.; Candido, V.S. Periquiteira (Cochlospermum orinocense): A Promising Amazon Fiber for Application in Composite Materials. Polymers 2023, 15, 2120. [Google Scholar] [CrossRef] [PubMed]

- Junio, R.F.P.; de Mendonça Neuba, L.; Souza, A.T.; Pereira, A.C.; Nascimento, L.F.C.; Monteiro, S.N. Thermochemical and Structural Characterization of Promising Carnauba Novel Leaf Fiber (Copernicia prunifera). J. Mater. Res. Technol. 2022, 18, 4714–4723. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties Characterization of Chemically Modified Hemp Hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef] [PubMed]

- Viscusi, G.; Barra, G.; Gorrasi, G. Modification of Hemp Fibers Through Alkaline Attack Assisted by Mechanical Milling: Effect of Processing Time on the Morphology of the System. Cellulose 2020, 27, 8653–8665. [Google Scholar] [CrossRef]

- da Silveira, P.H.P.M.; Santos, M.C.C.d.; Chaves, Y.S.; Ribeiro, M.P.; Marchi, B.Z.; Monteiro, S.N.; Gomes, A.V.; Tapanes, N.d.L.C.O.; Pereira, P.S.d.C.; Bastos, D.C. Characterization of Thermo-Mechanical and Chemical Properties of Polypropylene/Hemp Fiber Biocomposites: Impact of Maleic Anhydride Compatibilizer and Fiber Content. Polymers 2023, 15, 3271. [Google Scholar] [CrossRef]

- Hossain, S.; Jalil, M.A.; Islam, T.; Rahman, M.M. A Low-Density Cellulose Rich New Natural Fiber Extracted from the Bark of Jack Tree Branches and Its Characterizations. Heliyon 2022, 8, e11667. [Google Scholar] [CrossRef] [PubMed]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; da Luz, F.S.; Pinheiro, W.A.; Monteiro, S.N. Mechanical Properties of Composites with Graphene Oxide Functionalization of Either Epoxy Matrix or Curaua Fiber Reinforcement. J. Mater. Res. Technol. 2020, 9, 13390–13401. [Google Scholar] [CrossRef]

- Rekha, B.; NagarajaGanesh, B. X-ray Diffraction: An Efficient Method to Determine Microfibrillar Angle of Dry and Matured Cellulosic Fibers. J. Nat. Fibers 2022, 19, 3689–3696. [Google Scholar] [CrossRef]

- Demóstenes, L.C.C.; Nascimento, L.F.C.; Monteiro, S.N.; Costa, U.O.; da Costa Garcia Filho, F.; da Luz, F.S.; Oliveira, M.S.; Ramos, F.J.H.T.V.; Pereira, A.C.; Braga, F.O. Thermal and Structural Characterization of Buriti Fibers and Their Relevance in Fabric-Reinforced Composites. J. Mater. Res. Technol. 2020, 9, 115–120. [Google Scholar] [CrossRef]

- Subramanian, S.G.; Rajkumar, R.; Ramkumar, T. Characterization of Natural Cellulosic Fiber from Cereus hildmannianus. J. Nat. Fibers 2021, 18, 343–354. [Google Scholar] [CrossRef]

- Ding, L.; Han, X.; Li, H.; Han, J.; Cao, L.; Chen, Y.; Ling, Z.; He, S.; Jiang, S. Characterization of Novel Natural Fiber from Manau Rattan (Calamus manan) as a Potential Reinforcement for Polymer-Based Composites. J. Bioresour. Bioprod. 2022, 7(3), 190–200. [Google Scholar] [CrossRef]

- Khan, A.; Vijay, R.; Singaravelu, D.L.; Sanjay, M.R.; Siengchin, S.; Jawaid, M.; Asiri, A.M. Extraction and Characterization of Natural Fibers from Citrullus lanatus Climber. J. Nat. Fibers 2020, 19, 621–629. [Google Scholar] [CrossRef]

- Selvan, M.T.G.A.; Binoj, J.S.; Moses, J.T.E.J.; Sai, N.P.; Siengchin, S.; Sanjay, M.R.; Liu, Y. Extraction and Characterization of Natural Cellulosic Fiber from Fragrant Screw Pine Prop Roots as Potential Reinforcement for Polymer Composites. Polym. Compos. 2022, 43, 320–329. [Google Scholar] [CrossRef]

- Manimaran, P.; Senthamaraikannan, P.; Sanjay, M.R.; Marichelvam, M.K.; Jawaid, M. Study on Characterization of Furcraea foetida New Natural Fiber as Composite Reinforcement for Lightweight Applications. Carbohydr. Polym. 2018, 181, 650–658. [Google Scholar] [CrossRef] [PubMed]

- Dalmis, R.; Kilic, G.B.; Seki, Y.; Koktas, S.; Keskin, O.Y. Characterization of a Novel Natural Cellulosic Fiber Extracted from the Stem of Chrysanthemum morifolium. Cellulose 2020, 27, 8621–8634. [Google Scholar] [CrossRef]

- Khan, A.; Vijay, R.; Singaravelu, D.L.; Sanjay, M.R.; Siengchin, S.; Verpoort, F.; Alamry, K.A.; Asiri, A.M. Characterization of Natural Fibers from Cortaderia selloana Grass (Pampas) as Reinforcement Material for the Production of Composites. J. Nat. Fibers 2021, 18, 1893–1901. [Google Scholar] [CrossRef]

- Mannai, F.; Elhleli, H.; Dufresne, A.; Elaloui, E.; Moussaoui, Y. Opuntia (Cactaceae) Fibrous Network-Reinforced Composites: Thermal, Viscoelastic, Interfacial Adhesion, and Biodegradation Behavior. Fibers Polym. 2020, 21, 2353–2363. [Google Scholar] [CrossRef]

- Lai, T.S.M.; Jayamani, E.; Soon, K.H. Comparative Study on Thermogravimetric Analysis of Banana Fibers Treated with Chemicals. Mater. Today Proc. 2023, 78, 458–461. [Google Scholar] [CrossRef]

- Heckadka, S.S.; Ballambat, R.P.; Bhagavath, P.; Kini, M.V.; Sinha, R.K.; Sonali, M.K.; Sen, D. Thermogravimetric Analysis of Flax, Jute, and UHMWPE Fibers and Their Composites with Melamine and Phenol Formaldehyde Resins. Cogent Eng. 2023, 10, 2209990. [Google Scholar] [CrossRef]

- Jaruwan, M.; Klinkosum, P.; Chaichanasongkram, T.; Sarak, S.; Kaewtatip, K. Caracterização de uma nova fibra de celulose natural de Enhalus acoroides e sua potencial aplicação. Ind. Crops Prod. 2022, 186, 115285. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal Stability of Natural Fibers and Their Polymer Composites. Iran. Polym. J. 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Raja, A.K.A.; Geethan, K.A.V.; Kumar, S.S.; Kumar, P.S. Influência de atributos mecânicos, absorção de água, características de deflexão de calor e caracterização de compósitos híbridos epóxi reforçados com fibras naturais para uma aplicação de engenharia. Fibers Polym. 2021, 22, 3444–3455. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Shah, M.A.; Panchal, H.; Sharma, K.; Gopinath, R.; Sanjay, M.R.; Siengchin, S.; Rajesh Kumar, L.; Rampradheep, G.S. Characterization of New Cellulose Fiber Extracted from Second Generation Bitter Albizia Tree. Sci. Rep. 2024, 14, 1693. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Senthamaraikannan, P.; Pradeep, S.; Siengchin, S.; Jawaid, M.; Kathiresan, M. Effect of Various Chemical Treatments of Prosopis juliflora Fibers as Composite Reinforcement: Physicochemical, Thermal, Mechanical, and Morphological Properties. J. Nat. Fibers 2020, 17, 833–844. [Google Scholar] [CrossRef]

- Maheshwaran, M.V.; Hyness, N.R.J.; Senthamaraikannan, P.; Saravanakumar, S.S.; Sanjay, M.R. Characterization of Natural Cellulosic Fiber from Epipremnum aureum Stem. J. Nat. Fibers 2017, 15, 789–798. [Google Scholar] [CrossRef]

- Tamanna, T.A.; Belal, S.A.; Shibly, M.A.H.; Khan, A.N. Characterization of a New Natural Fiber Extracted from Corypha taliera Fruit. Sci. Rep. 2021, 11, 7622. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Arvindh Seshadri, S.; Devnani, G.L.; Sanjay, M.R.; Siengchin, S.; Prakash Maran, J.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites—A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Oliveira, A.K.F.; d’Almeida, J.R.M. Characterization of Ubuçu (Manicaria saccifera) Natural Fiber Mat. Polym. Renew. Resour. 2014, 5, 13–28. [Google Scholar] [CrossRef]

- Karthik, A.; James, D.J.; Vijayan, V.; Ahmad, Z.; Rajkumar, S.; Sharma, S.; Sharma, K.P.; Singh, R.; Li, C.; Eldin, S.M. Study on the Physicomechanical, Fracture-Strain, Interface-Adhesion, and Water-Absorption Properties of Twill Fabric Cotton-Bamboo/Epoxy Composites. J. Mater. Res. Technol. 2023, 24, 8429–8442. [Google Scholar] [CrossRef]

- Gao, I.; Fezzaa, K.; Chen, W. Multiscale dynamic experiments on fiber-reinforced composites with damage assessment using high-speed synchrotron X-ray phase-contrast imaging. NDT E Int. 2022, 129, 102636. [Google Scholar] [CrossRef]

- Vijay, R.; James Dhilip, J.D.; Gowtham, S.; Harikrishnan, S.; Chandru, B.; Amarnath, M.; Khan, A. Characterization of Natural Cellulose Fiber from the Barks of Vachellia farnesiana. J. Nat. Fibers 2020, 19, 1343–1352. [Google Scholar] [CrossRef]

- Alves Fidelis, M.E.; Pereira, T.V.C.; Gomes, O.D.F.M.; De Andrade, S.F.; Toledo Filho, R.D. The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Akter, N.; Das, S.C.; Fahad, M.M.; Islam, D.; Khan, M.A.; Shamsuddin, S.M. Tailoring the performance of cellulosic textiles by chemical treatment and ionizing radiation: Assessment of physical, mechanical, thermal, crystal and morphological properties. Next Mater. 2025, 7, 100372. [Google Scholar] [CrossRef]

- Triki, A.; Dittmer, J.; Hassen, M.B.; Arous, M.; Bulou, A.; Gargouri, M. Spectroscopy analyses of hybrid unsaturated polyester composite reinforced by Alfa, wool, and thermo-binder fibers. Polym. Sci. Ser. A 2016, 58, 255–264. [Google Scholar] [CrossRef]

- Ali, M.F.; Hossain, M.S.; Moin, T.S.; Ahmed, S.; Chowdhury, A.M.S. Utilization of waste chicken feather for the preparation of eco-friendly and sustainable composite. Clean. Eng. Technol. 2021, 4, 100190. [Google Scholar] [CrossRef]

- Alshahrani, H.; Arun Prakash, V.R. Mechanical, thermal, viscoelastic, and hydrophobicity behavior of complex grape stalk lignin and bamboo fiber reinforced polyester composite. Int. J. Biol. Macromol. 2022, 223, 851–859. [Google Scholar] [CrossRef]

- Prasad, L.; Singh, V.; Patel, R.V.; Yadav, A.; Kumar, V.; Winczek, J. Physical and Mechanical Properties of Rambans (Agave) Fiber Reinforced with Polyester. J. Nat. Fibers 2021, 19, 6104–6118. [Google Scholar] [CrossRef]

- Dhibar, B.; Singh, S.V.; Anwar, S.; Singh, A. Sugarcane Bagasse Reinforced Polyester Composites. Int. Res. J. Eng. Technol. (IRJET) 2018, 5, 4204–4211. [Google Scholar] [CrossRef]

- Ganesan, K.; Kailasanathan, C.; Rajini, N.; Ismail, S.O.; Ayrilmis, N.; Mohammad, F.; Al-Lohedan, H.A.; Tawfeek, A.M.; Issa, Z.A.; Aldhayan, D.M. Assessment on hybrid jute/coir fibers reinforced polyester composite with hybrid fillers under different environmental conditions. Constr. Build. Mater. 2021, 301, 124117. [Google Scholar] [CrossRef]

- Patel, U.; Ray, R.; Mohapatra, A.; Das, S.N.; Das, H.C. Effect of Different Chemical Treatments on Surface Morphology, Thermal, and Traction Strength of Bauhinia Vahlii (BV) Stem Fibers. J. Nat. Fibers 2020, 19, 280–291. [Google Scholar] [CrossRef]

- Neto, J.; Queiroz, H.; Aguiar, R.; Lima, R.; Cavalcanti, D.; Banea, M.D. A Review of Recent Advances in Hybrid Natural Fiber Reinforced Polymer Composites. J. Renew. Mater. 2022, 10, 561. [Google Scholar] [CrossRef]

- Meliande, N.M.; Silveira, P.H.P.M.d.; Monteiro, S.N.; Nascimento, L.F.C. Tensile Properties of Curaua–Aramid Hybrid Laminated Composites for Ballistic Helmet. Polymers 2022, 14, 2588. [Google Scholar] [CrossRef]

- Simonassi, N.T.; Pereira, A.C.; Monteiro, S.N.; Margem, F.M.; Rodríguez, R.J.S.; Deus, J.F.D.; Vieira, C.M.F.; Drelich, J. Reinforcement of Polyester with Renewable Ramie Fibers. Mater. Res. 2017, 20 (Suppl. S2), 51–59. [Google Scholar] [CrossRef]

- Vignesh, V.; Balaji, A.N.; Nagaprasad, N.; Sanjay, M.R.; Khan, A.; Asiri, A.M.; Ashraf, G.M.; Siengchin, S. Indian mallow fiber reinforced polyester composites: Mechanical and thermal properties. J. Mater. Res. Technol. 2021, 11, 274–284. [Google Scholar] [CrossRef]

- Hossain, M.T.; Hossain, M.S.; Uddin, M.B.; Khan, R.A.; Chowdhury, A.S. Preparation and characterization of sodium silicate–treated jute-cotton blended polymer–reinforced UPR-based composite: Effect of γ-radiation. Adv. Compos. Hybrid Mater. 2021, 4, 257–264. [Google Scholar] [CrossRef]

- Pereira, A.C.; Monteiro, S.N.; Assis, F.S. Charpy Toughness Behavior of Fique Fabric Reinforced Polyester Matrix Composites. In Characterization of Minerals, Metals, and Materials 2017; Ikhmayies, S., Li, B., Carpenter, J.S., Li, J., Hwang, J.-Y., Monteiro, S.N., Firrao, D., Zhang, M., Peng, Z., Escobedo-Diaz, J.P., et al., Eds.; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Pereira, A.C.; Assis, F.S.; Filho, F.C.G. Evaluation of the Projectile’s Loss of Energy in Polyester Composite Reinforced with Fique Fiber and Fabric. Mater. Res. 2019, 22 (Suppl. S1), e20190146. [Google Scholar] [CrossRef]

- Candido, V.S.; Silva, A.C.R.; Simonassi, N.T.; da Luz, F.S.; Monteiro, S.N. Toughness of Polyester Matrix Composites Reinforced with Sugarcane Bagasse Fibers by Charpy Impact Tests. J. Mater. Res. Technol. 2017, 6, 334–338. [Google Scholar] [CrossRef]

- Kayaaslan, M.; Coskun, T.; Unlu, U.M.; Sahin, O.S. Effects of Thickness, Fiber Orientation and Fabric Textile on the Low-Velocity Impact Performances of Thermoset and Thermoplastic Composites. J. Thermoplast. Compos. Mater. 2023, 36, 4408–4429. [Google Scholar] [CrossRef]

- Chaves, Y.S.; Monteiro, S.N.; Nascimento, L.F.C.; Rio, T.G.-d. Mechanical and Ballistic Properties of Epoxy Composites Reinforced with Babassu Fibers (Attalea speciosa). Polymers 2024, 16, 913. [Google Scholar] [CrossRef]

- Sheng, C.; He, G.; Hu, Z.; Chou, C.; Shi, J.; Li, J.; Meng, Q.; Ning, X.; Wang, L.; Ning, F. Yarn on Yarn Abrasion Failure Mechanism of Ultrahigh Molecular Weight Polyethylene Fiber. J. Eng. Fibers Fabr. 2021, 16, 1925832385. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Vilaseca, F.; Méndez, J.A.; Espinach, F.X.; Aguado, R.J.; Delgado-Aguilar, M.; Mutjé, P. Response of Polypropylene Composites Reinforced with Natural Fibers: Impact Strength and Water-Uptake Behaviors. Polymers 2023, 15, 900. [Google Scholar] [CrossRef] [PubMed]

| Cellulose (%) | Hemicellulose (%) | Lignin (%) | Reference | |

|---|---|---|---|---|

| Tururi Fabric | 74.1 | 12.0 | 31.1 | [31] |

| Fiber | CI (%) | References |

|---|---|---|

| Tururi Fabric | 46.67 | Present Work |

| Carnauba | 86.90 | [42] |

| Hemp | 82.10 | [43,44,45] |

| Jack Tree Fiber | 86.00 | [46] |

| Curauá | 75.60 | [47] |

| Pineapple | 38.00 | [48] |

| Ubim | 83.00 | [40] |

| Periquiteira | 70.49 | [41] |

| Buriti | 63.00 | [49] |

| Cereus hildmannianus | 40.19 | [50] |

| Calamus manan | 48.28 | [51] |

| Citrullus lanatus | 33.33 | [52] |

| Sample | Flexural Strength (MPa) | Modulus Elastic (GPa) | Strain (mm/mm) |

|---|---|---|---|

| P0 | 49.47 ± 4.99 | 2.49 ± 0.28 | 0.065 ± 0.005 |

| P2.5 | 65.97 ± 7.41 | 3.64 ± 0.26 | 0.058 ± 0.008 |

| P5.0 | 47.55 ± 2.58 | 2.08 ± 0.13 | 0.080 ± 0.003 |

| P7.5 | 44.57 ± 9.20 | 3.95 ± 0.18 | 0.031 ± 0.011 |

| Sample | Charpy Impact Resistance (J/m) |

|---|---|

| P0 | 14.61 ± 3.69 |

| P2.5 | 40.13 ± 5.60 |

| P5.0 | 53.73 ± 15.63 |

| P7.5 | 74.72 ± 7.13 |

| Flexural Strengh (MPa) | ||||||

| Source | Sum squares | Degree of freedom | Mean of squares | F (calculated) | p-value | F-critical |

| Between the groups | 110,683.7 | 3 | 368.945 | 8.629 | 0.002 | 3.490 |

| Inside the groups | 513.064 | 12 | 42.755 | |||

| Total | 161,990.2 | 15 | ||||

| Elastic Modulus (GPa) | ||||||

| Source | Sum squares | Degree of freedom | Mean of squares | F (calculated) | p-value | F-critical |

| Between the groups | 9.652 | 3 | 3.217 | 28.951 | 8.88 × 10−6 | 3.490 |

| Inside the groups | 1.333 | 12 | 0.111 | |||

| Total | 10.986 | 15 | ||||

| Total Strain (mm/mm) | ||||||

| Source | Sum squares | Degree of freedom | Mean of squares | F (calculated) | p-value | F-critical |

| Between the groups | 0.005 | 3 | 0.001 | 17.288 | 1.181 × 10−4 | 3.490 |

| Inside the groups | 0.001 | 12 | 9.916 × 10−5 | |||

| Total | 0.006 | 15 | ||||

| Charpy Impact Resistance (J/m) | ||||||

| Source | Sum squares | Degree of freedom | Mean of squares | F (calculated) | p-value | F-critical |

| Between the groups | 7618.892 | 3 | 2539.631 | 22.099 | 3.54 × 10−5 | 3.490 |

| Inside the groups | 1379.001 | 12 | 114.916 | |||

| Total | 8997.893 | 15 | ||||

| Flexural Strength (m.s.d: 14.810) | ||||

| Sample | P0 | P2.5 | P5.0 | P7.5 |

| P0 | 0 | 16.018 * | 1.925 | 4.905 |

| P2.5 | 16.501 * | 0 | 18.427 * | 21.407 * |

| P5.0 | 1.925 | 18.427 * | 0 | 2.980 |

| P7.5 | 4.905 | 21.407 * | 2.980 | 0 |

| Elastic modulus (m.s.d: 0.755) | ||||

| Sample | P0 | P2.5 | P5.0 | P7.5 |

| P0 | 0 | 1.155 * | 0.405 | 1.462 * |

| P2.5 | 1.155 * | 0 | 1.56 * | 0.307 |

| P5.0 | 0.405 * | 1.56 * | 0 | 1.867 * |

| P7.5 | 1.462 * | 0.307 | 1.867 * | 0 |

| Total Strain (m.s.d: 0.022) | ||||

| Sample | P0 | P2.5 | P5.0 | P7.5 |

| P0 | 0 | 0.007 | 0.015 | 0.034 * |

| P2.5 | 0.088 * | 0 | 0.022 | 0.027 * |

| P5.0 | 0.015 * | 0.022 | 0 | 0.049 * |

| P7.5 | 0.034 * | 0.027 * | 0.049 * | 0 |

| Impact Energy (m.s.d: 24.280) | ||||

| Sample | P0 | P2.5 | P5.0 | P7.5 |

| P0 | 0 | 25.526 * | 39.125 * | 60.118 * |

| P2.5 | 25.526 * | 0 | 13.598 | 34.591 * |

| P5.0 | 39.125 | 13.598 | 0 | 20.993 |

| P7.5 | 60.118 * | 34.591 * | 20.993 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, A.G.A.; Nascimento, D.d.C.B.; Lopes, F.P.D.; Simonassi, N.T.; Monteiro, S.N.; Silva, A.C.R.d.; Candido, V.S. Investigation of the Flexural and Charpy Impact Properties of Polymer Composites Reinforced with Tururi (Manicaria saccifera) Fibrous Fabric. Polymers 2025, 17, 466. https://doi.org/10.3390/polym17040466

Santos AGA, Nascimento DdCB, Lopes FPD, Simonassi NT, Monteiro SN, Silva ACRd, Candido VS. Investigation of the Flexural and Charpy Impact Properties of Polymer Composites Reinforced with Tururi (Manicaria saccifera) Fibrous Fabric. Polymers. 2025; 17(4):466. https://doi.org/10.3390/polym17040466

Chicago/Turabian StyleSantos, Avener Gleidson Andrade, Damares da Cruz Barbosa Nascimento, Felipe Perissé Duarte Lopes, Noan Tonini Simonassi, Sérgio Neves Monteiro, Alisson Clay Rios da Silva, and Verônica Scarpini Candido. 2025. "Investigation of the Flexural and Charpy Impact Properties of Polymer Composites Reinforced with Tururi (Manicaria saccifera) Fibrous Fabric" Polymers 17, no. 4: 466. https://doi.org/10.3390/polym17040466

APA StyleSantos, A. G. A., Nascimento, D. d. C. B., Lopes, F. P. D., Simonassi, N. T., Monteiro, S. N., Silva, A. C. R. d., & Candido, V. S. (2025). Investigation of the Flexural and Charpy Impact Properties of Polymer Composites Reinforced with Tururi (Manicaria saccifera) Fibrous Fabric. Polymers, 17(4), 466. https://doi.org/10.3390/polym17040466