Cellulose-Derived Battery Separators: A Minireview on Advances Towards Environmental Sustainability

Abstract

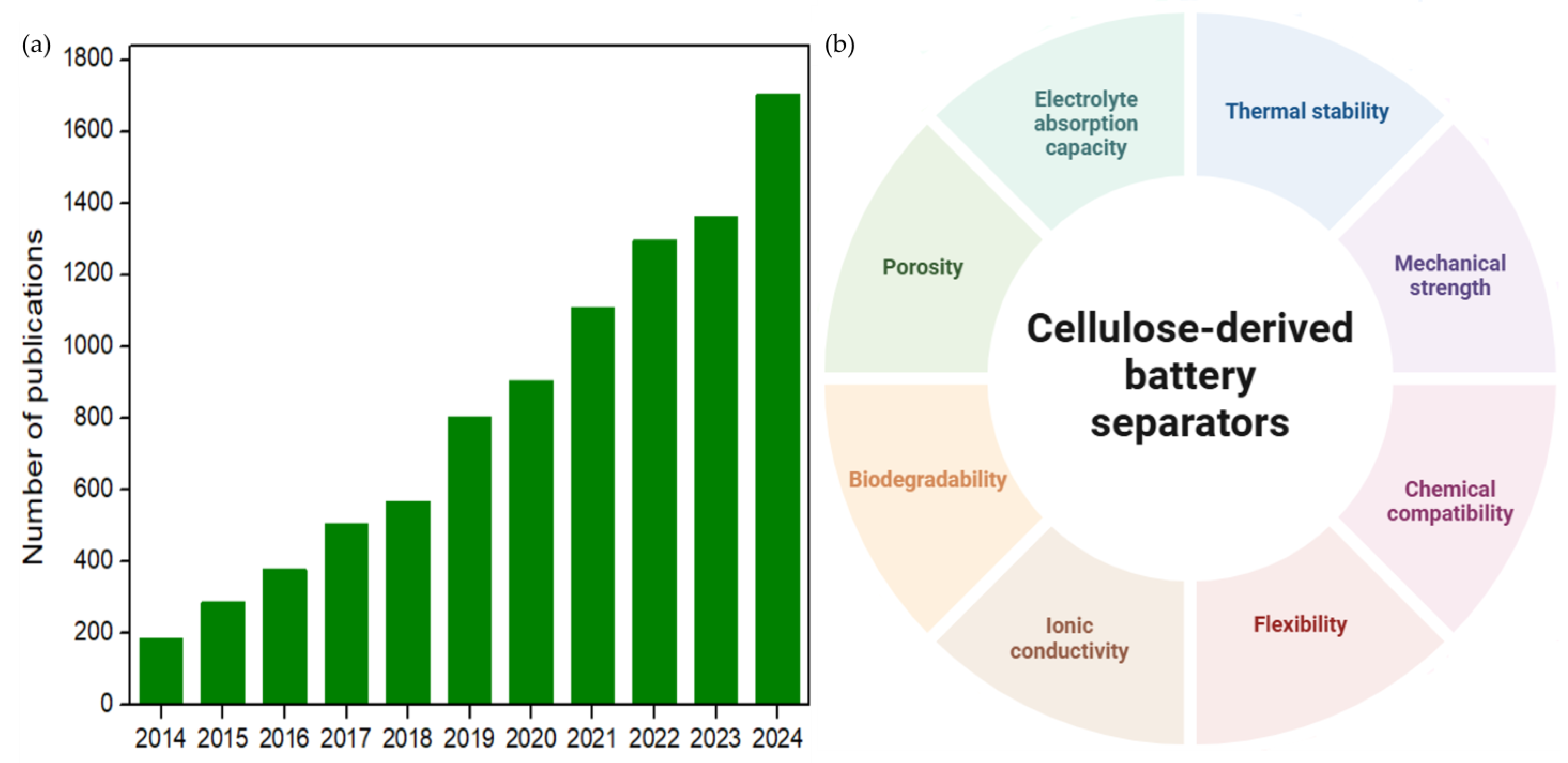

1. Introduction

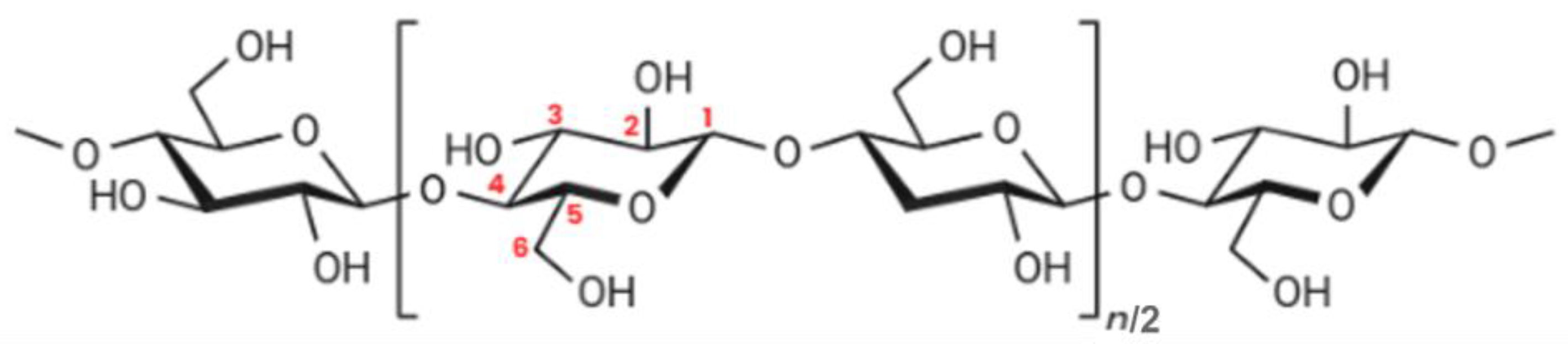

2. Cellulose and Its Derivatives

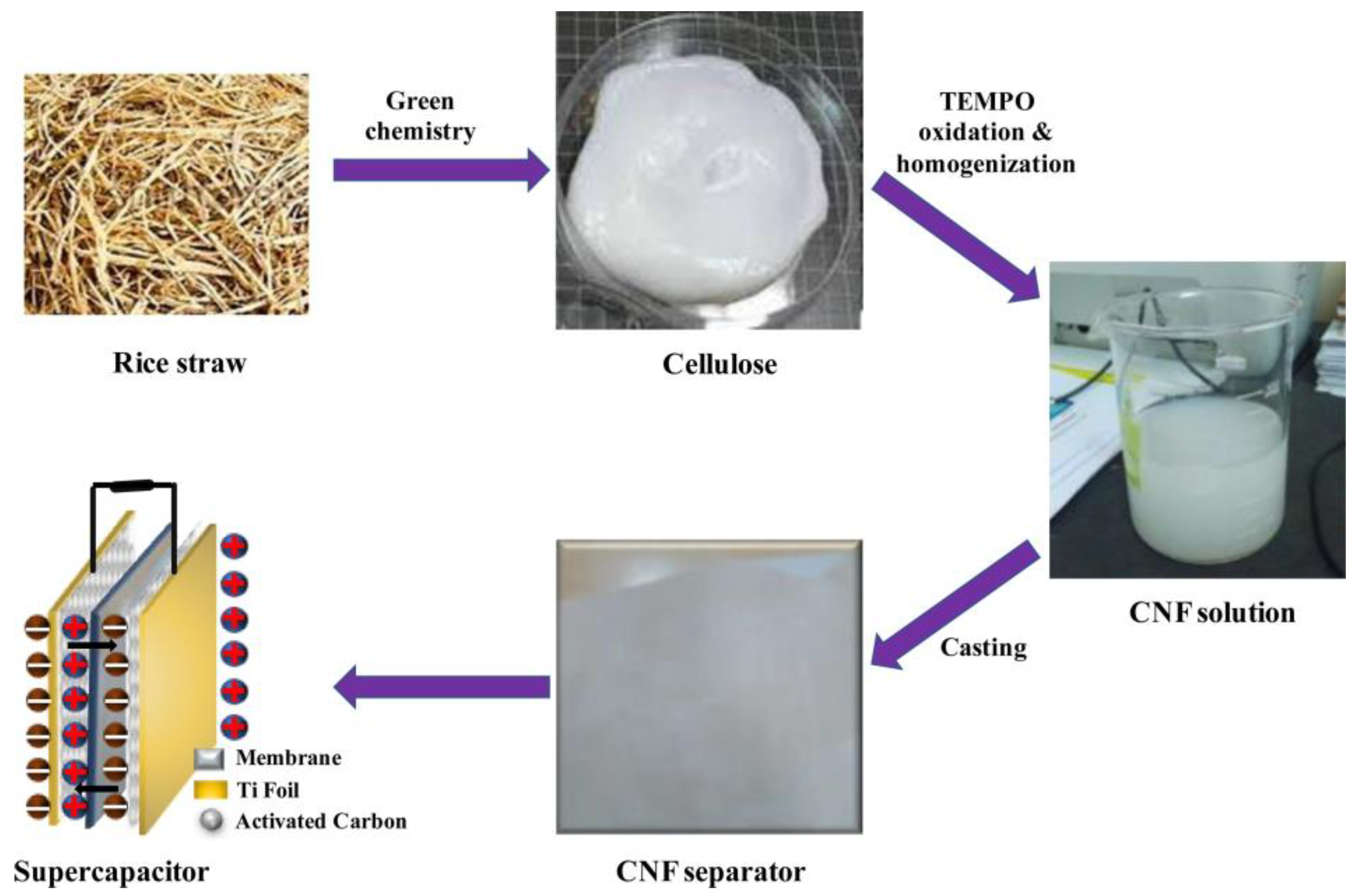

2.1. Cellulose Nanofibrils

2.2. Cellulose Nanocrystals

2.3. Bacterial Cellulose

2.4. Cellulose Acetate

2.5. Regenerated Cellulose

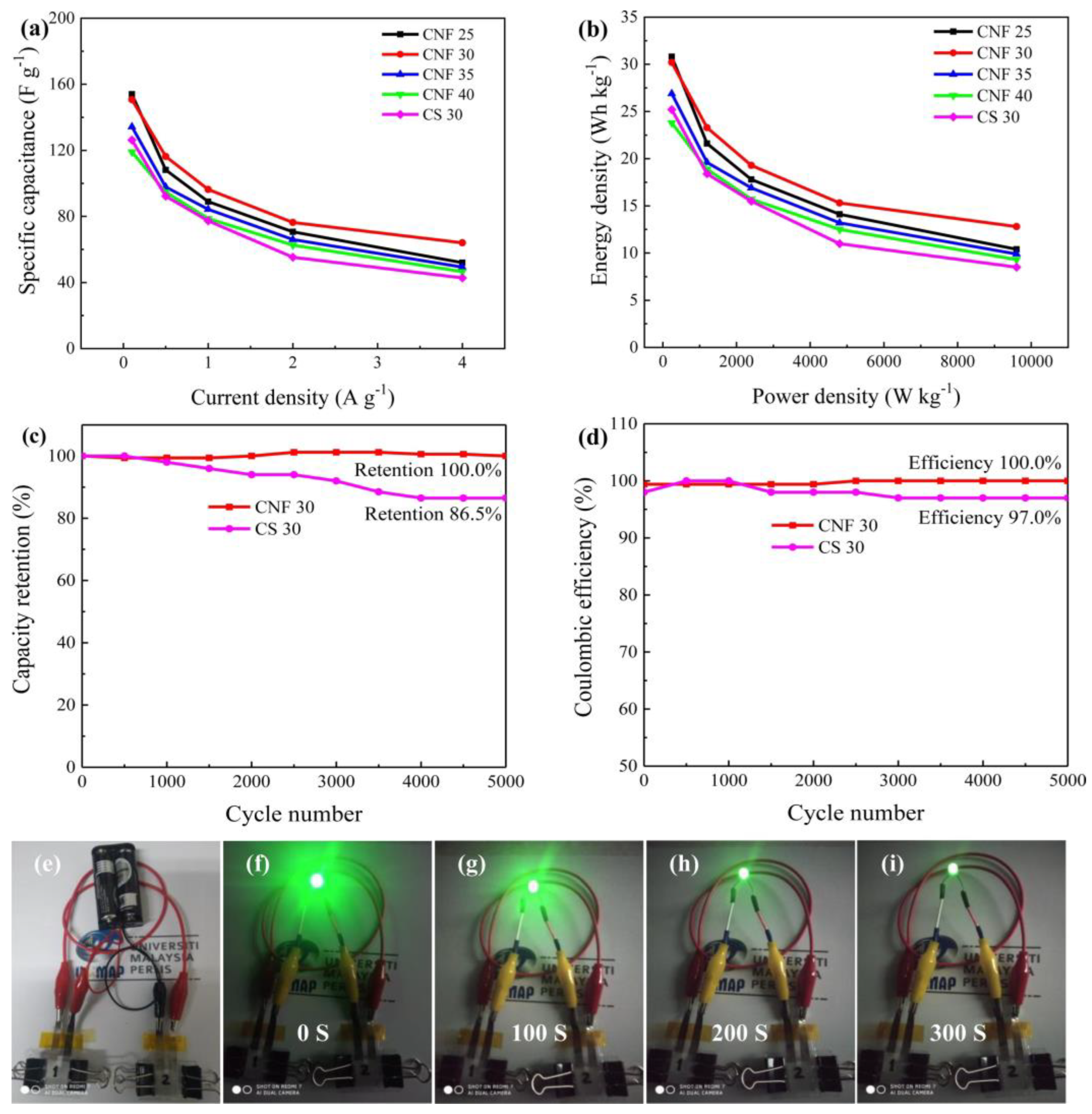

3. Performance of Cellulose-Derived Battery Separators

4. Environmental Impact and Sustainability of Cellulose-Derived Battery Separators

5. Conclusions

6. Challenges and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, W.; Si, Y.; Zhao, C.; Chen, T.; Li, C.; Zhang, C.; Wang, K. Biomass-derived carbono applications in the field of supercapacitores: Progress and prospects. Chem. Eng. J. 2024, 495, 153311. [Google Scholar] [CrossRef]

- Lingappan, N.; Lee, W.; Passerini, S.; Pecht, M. A comprehensive review of separator membranes in lithium-ion batteries. Renew. Sustain. Energy Rev. 2023, 187, 113726. [Google Scholar] [CrossRef]

- Babiker, D.M.D.; Usha, Z.R.; Wan, C.; Hassaan, M.M.E.; Chen, x.; Li, L. Recent progress of composite polyethylene separators for lithium/sodium batteries. J. Power Sources 2023, 564, 232853. [Google Scholar] [CrossRef]

- Bocchi, N.; Biaggio, S.R.; Filho, R.C.R. Prêmio Nobel de química 2019: Desenvolvimento das baterias íons lítio. Quím. Nova 2019, 41, 320–326. [Google Scholar]

- Joshi, S.A.; Pazhaniswamy, S.; Plank, C.; Danzer, M.A.; Hou, H.; Cheong, J.Y.; Breu, J.; Agarwal, S. High-Performance, Flame-Retardant, Binder-Free Li-Hectorite-Polybenzimidazole Fiber Separator for Li-Ion Batteries. Macromol. Mater. Eng. 2024, 309, 2300389. [Google Scholar] [CrossRef]

- Nitou, M.V.M.; Tang, M.; Niu, Y.; Pang, Y.; Wan, Z.; Mawuli, S.E.; Leoba, J.A.; Xiaodong, F.; Lv, W. Separator with active coating for fast and stable Li-ion batteries. J. Power Sources 2024, 602, 234406. [Google Scholar] [CrossRef]

- Xia, Y.; Li, X.; Zhuang, J.; Wang, W.; Abbas, S.C.; Fu, C.; Zhang, H.; Chen, T.; Yuan, Y.; Zhao, X.; et al. Exploitation of function groups in cellulose materials for lithium-ion batteries applications. Carbohydr. Polym. 2024, 325, 121570. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Sheng, J.; Zhu, H.; Yang, R. Nanoporous Regenerated Cellulose Separator for High-Performance Lithium Ion Batteries Prepared by Nonsolvent-Induced Phase Separation. ACS Sustain. Chem. Eng. 2021, 9, 14756–14765. [Google Scholar] [CrossRef]

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169–206. [Google Scholar] [CrossRef]

- Satchanska, G.; Davidova, S.; Petrov, P.D. Natural and Synthetic Polymers for Biomedical and Environmental Applications. Polymers 2024, 16, 1159. [Google Scholar] [CrossRef]

- Yi, T.; Zhao, H.; Mo, Q.; Pan, D.; Liu, Y.; Huang, L.; Xu, H.; Hu, B.; Song, H. From Cellulose to Cellulose Nanofibrils—A Comprehensive Review of the Preparation and Modification of Cellulose Nanofibrils. Materials 2020, 13, 5062. [Google Scholar] [CrossRef] [PubMed]

- Lizundia, E.; Costa, C.M.; Alves, R.; Lanceros-Méndez, S. Cellulose and its derivatives for lithium ion battery separators: A review on the processing methods and properties. Carbohydr. Polym. Technol. Appl. 2020, 1, 100001. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Z.; Feng, Y.; Cai, S.; Gao, H.; Wei, Z.; Zhao, Y. Cellulose-based separators for lithium batteries: Source, preparation and performance. Chem. Eng. J. 2023, 471, 144593. [Google Scholar] [CrossRef]

- Barhoum, A.; Deshmukh, K.; García-Betancourt, M.; Alibakhshi, S.; Mousavi, S.M.; Meftahi, A.; Sabery, M.S.K.; Samyn, P. Nanocelluloses as sustainable membrane materials for separation and filtration technologies: Principles, opportunities, and challenges. Carbohydr. Polym. 2023, 317, 121057. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X.; Liang, Y. Preparation and characterization of a Lithium-ion battery separator from cellulose nanofibers. Helyon 2015, 1, e00032. [Google Scholar] [CrossRef]

- Delaporte, N.; Perea, A.; Paolella, A.; Dubé, J.; Vigeant, M.; Demers, H.; Clément, D.; Zhu, W.; Gariépy, V.; Zaghib, K. Alumina-flame retardant separators toward safe high voltage Li-Ion batteries. J. Power Sources 2021, 506, 230189. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, X.; Wu, X.; Lu, C. Flame Retardant, Heat Insulating Cellulose Aerogels from WasteCotton Fabrics by in Situ Formation of Magnesium Hydroxide Nanoparticles in Cellulose Gel Nanostructures. ACS Sustain. Chem. Eng. 2015, 3, 1853–1859. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, X.; Liang, J.; Chen, Q.; Huang, J. Environmentally friendly separators based on cellulose diacetate-based crosslinked networks for lithium-ion batteries. Polymer 2024, 290, 126564. [Google Scholar] [CrossRef]

- Norfarhana, A.S.; Ilyas, R.A.; Ngadi, N. A review of nanocellulose adsorptive membrane as multifunctional wastewater treatment. Carbohydr. Polym. 2022, 291, 119563. [Google Scholar] [CrossRef]

- Islam, M.A.; Ong, H.L.; Villagracia, A.R.; Halim, K.A.A.; Ganganboina, A.B.; Doong, R. Biomass–derived cellulose nanofibrils membrane from rice straw as sustainable separator for high performance supercapacitor. Ind. Crops Prod. 2021, 170, 113694. [Google Scholar] [CrossRef]

- Kim, A.; Dash, J.K.; Patel, R. Recent Development in Novel Lithium-Sulfur Nanofiber Separators: A Review of the Latest Fabrication and Performance Optimizations. Membranes 2023, 13, 183. [Google Scholar] [CrossRef] [PubMed]

- Ding, Z.; Yang, X.; Tang, Y. Nanocellulose-based electrodes and separator toward sustainable and flexible all-solid-state supercapacitor. Int. J. Biol. Macromol. 2023, 228, 467–477. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.P.; Calvar, I.L.; Catchmark, J.M.; Liu, J.R.; Demirci, A.; Cheng, K.C. Biosynthesis, production and applications of bacterial cellulose. Cellulose 2013, 20, 2191–2219. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, D.; Lee, Y.H.; Chen, W.; Lee, S.Y. Nanocellulose for energy storage systems: Beyond the limits of synthetic materials. Adv. Mater. 2019, 31, 1804826. [Google Scholar] [CrossRef]

- Gregory, D.A.; Tripathi, L.; Fricker, A.; Asare, E.; Roy, L. Bacterial cellulose: A smart biomaterial with diverse applications. J. Mater. Res. 2021, 145, 100623. [Google Scholar] [CrossRef]

- Wang, J.; Tavakoli, J.; Tang, Y. Bacterial cellulose production, properties and applications with different culture methods—A review. Carbohydr. Polym. 2019, 219, 63–76. [Google Scholar] [CrossRef]

- Yan, J.; Yu, D.G. Smoothening electrospinning and obtaining high-quality cellulose acetate nanofibers using a modified coaxial process. J. Mater. Sci. 2012, 47, 7138–7147. [Google Scholar] [CrossRef]

- Yang, C.; Chen, C.; Pan, Y.; Li, S.; Wang, F.; Li, J.; Li, N.; Li, X.; Zhang, Y.; Li, D. Flexible highly specific capacitance aerogel electrodes based on cellulose nanofibers, carbon nanotubes and polyaniline. Electrochim. Acta 2015, 182, 264–271. [Google Scholar] [CrossRef]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L. Wood-derived materials for green electronics, biological devices, and energy applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Zhang, L. New solvents and functional materials prepared from cellulose solutions in alkali/urea aqueous system. Food Res. Int. 2013, 52, 387–400. [Google Scholar] [CrossRef]

- Sheng, J.; Chen, T.; Wang, R.; Zhang, Z.; Hua, F.; Yang, R. Ultra-light cellulose nanofibril membrane for lithium-ion batteries. J. Memb. Sci. 2020, 595, 117550. [Google Scholar] [CrossRef]

- Kumar, S.N.; Johnsi, M.; Shalini, V.J.A.; Kavitha, N.P.; Balasubramanian, N. Cellulose nanofibril separator from Coffea arabica waste for supercapacitor applications. Ind. Crops Prod. 2024, 214, 118459. [Google Scholar] [CrossRef]

- Sheng, J.; Wang, R.; Yang, R. Physicochemical Properties of Cellulose Separators for Lithium Ion Battery: Comparison with Celgard2325. Materials 2019, 12, 2. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, C.; Li, C.; Liang, Z.; Hu, X.; Liu, H.; Zhang, Z.; Cui, M.; Chen, G.; Wan, J.; et al. Highly Thermally Stable, Highly Electrolyte-Wettable Hydroxyapatite/Cellulose Nanofiber Hybrid Separators for Lithium-Ion Batteries. ACS Appl. Energy Mater. 2023, 6, 3862–3871. [Google Scholar] [CrossRef]

- Gonçalves, R.; Lizundia, E.; Silva, M.M.; Costa, C.M.; Lanceros-Méndez, S. Mesoporous Cellulose Nanocrystal Membranes as Battery Separators for Environmentally Safer Lithium-Ion Batteries. ACS Appl. Energy Mater. 2019, 2, 3749–3761. [Google Scholar] [CrossRef]

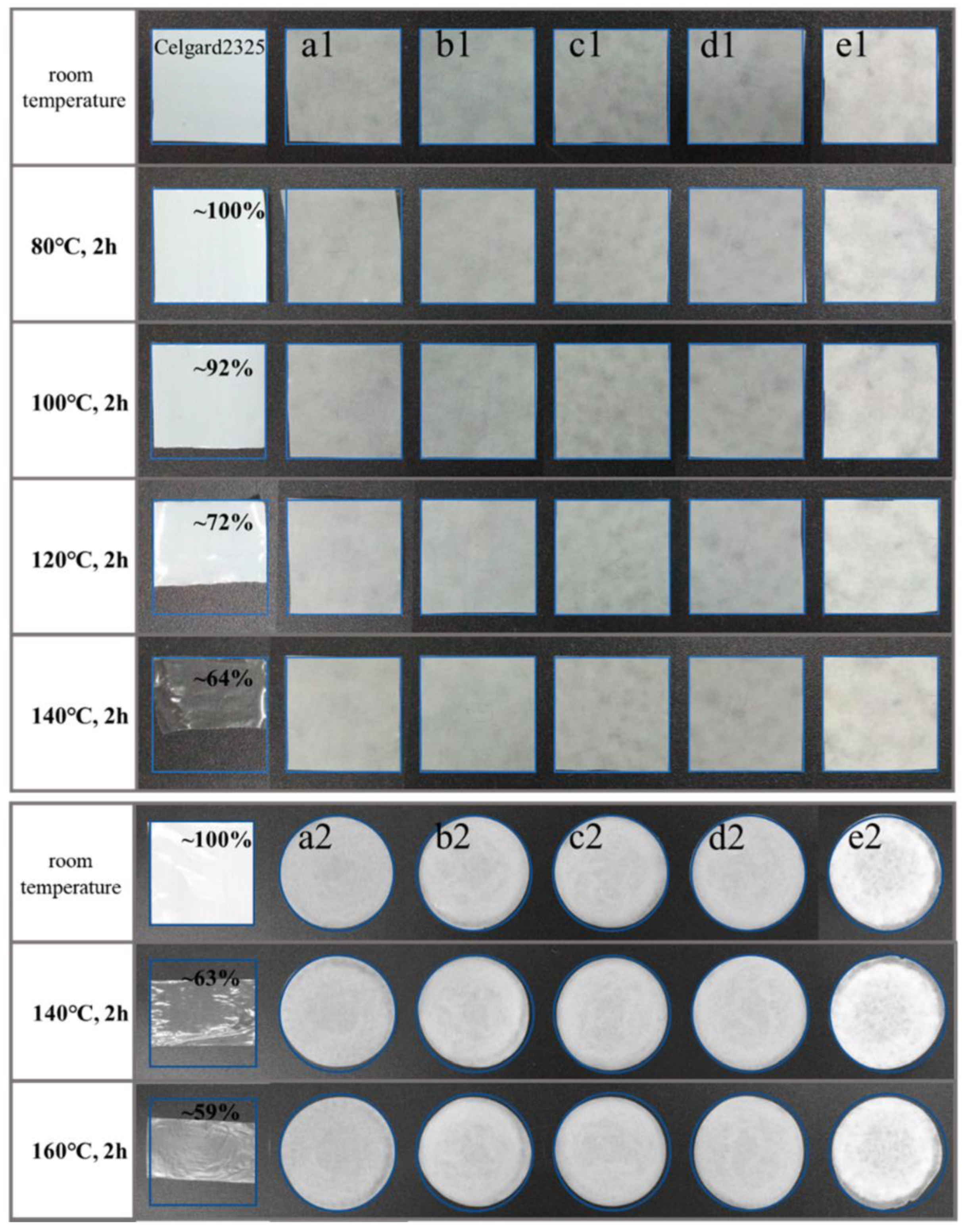

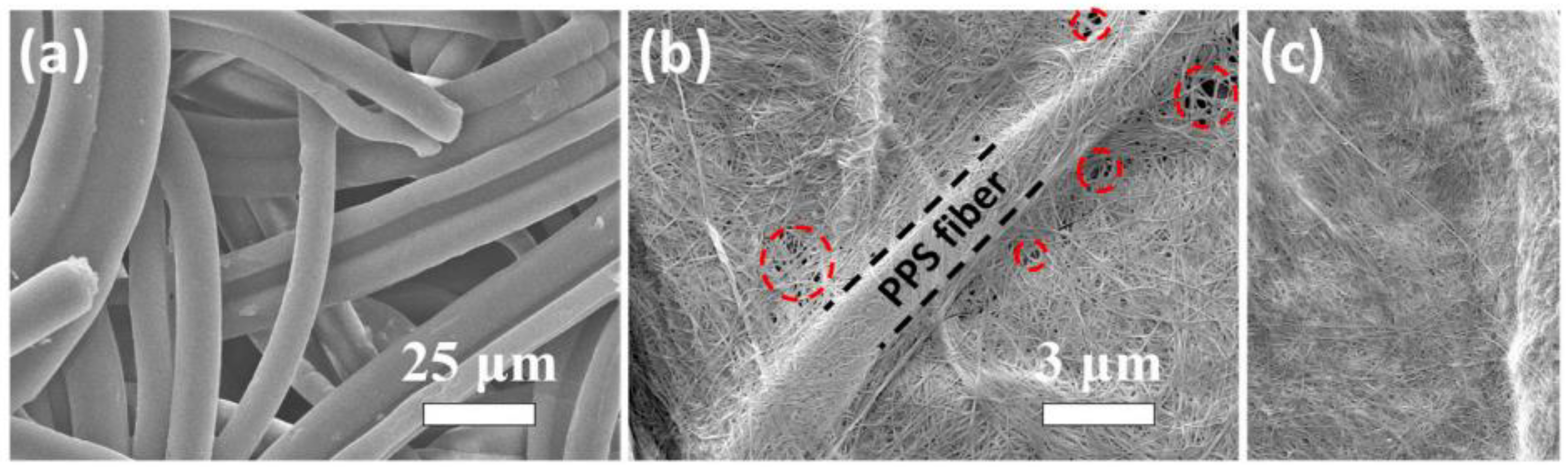

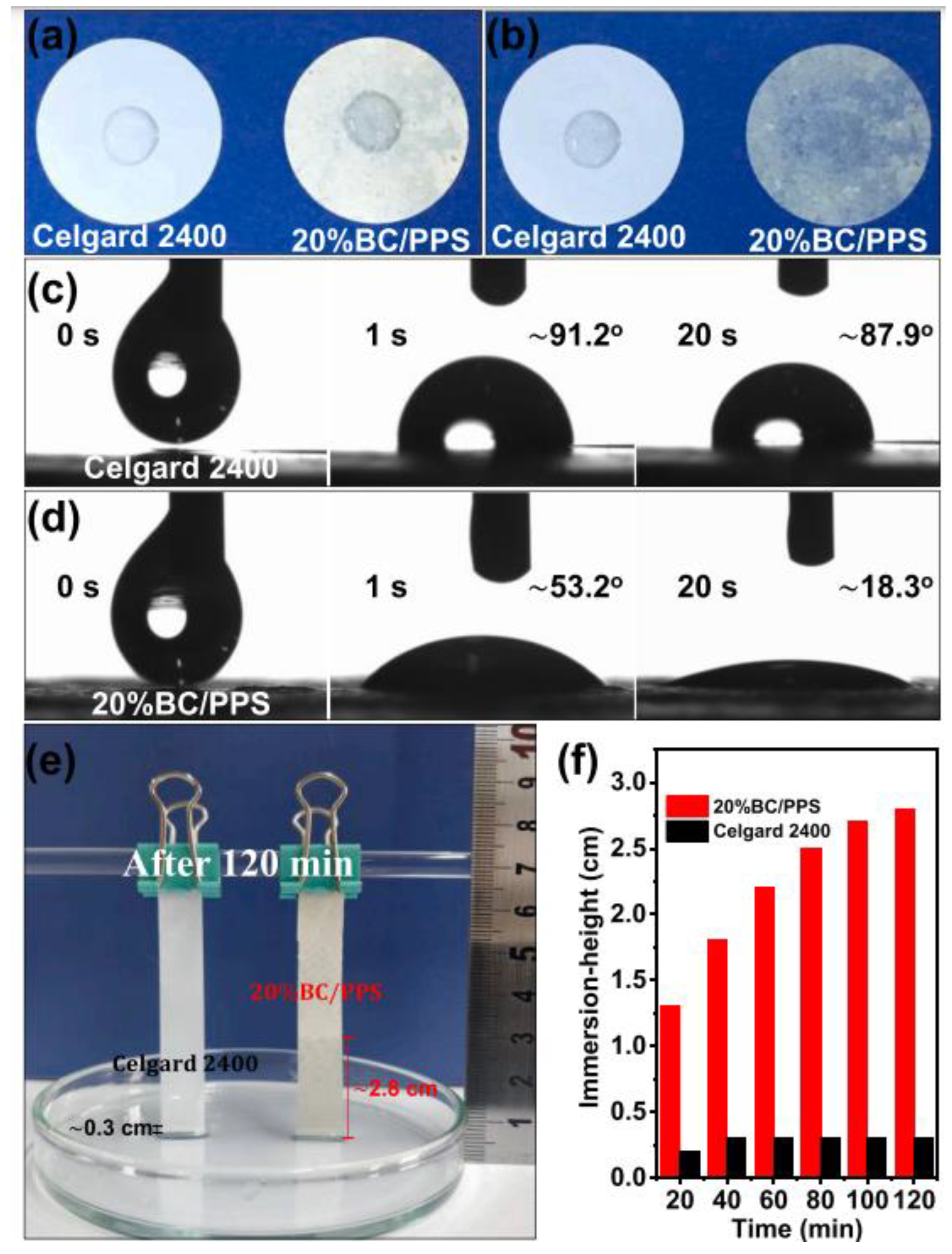

- Zhu, C.; Zhang, J.; Qiu, S.; Jia, Y.; Wang, L.; Wang, H. Tailoring the pore size of polyphenylene sulfide nonwoven with bacterial cellulose (BC) for heat-resistant and high-wettability separator in lithium-ion battery. Compos. Commun. 2021, 24, 100659. [Google Scholar] [CrossRef]

- Huang, C.; Ji, H.; Yang, Y.; Guo, B.; Luo, L.; Meng, Z.; Fan, L.; Xu, J. TEMPO-oxidized bacterial cellulose nanofiber membranes as high-performance separators for lithium-ion batteries. Carbohydr. Polym. 2020, 230, 115570. [Google Scholar] [CrossRef]

- Chen, W.; Wang, X.; Liang, J.; Chen, Y.; Ma, W.; Zhang, S. A High Performance Polyacrylonitrile Composite Separator with Cellulose Acetate and Nano-Hydroxyapatite for Lithium-Ion Batteries. Membranes 2022, 12, 124. [Google Scholar] [CrossRef]

- Chen, Y.; Qu, L.; Ma, X.; Dong, L.; Jin, Z.; Xia, G.; Du, P.; Xiong, J. Electrospun cellulose polymer nanofiber membrane with flame resistance properties for lithium-ion batteries. Carbohydr. Polym. 2020, 234, 115907. [Google Scholar] [CrossRef]

- Guo, T.; Song, J.; Jin, Y.; Sun, Z.; Li, L. Thermally stable and green cellulose-based composites strengthened by styrene-co-acrylate latex for lithium-ion battery separators. Carbohydr. Polym. 2019, 206, 801–810. [Google Scholar] [CrossRef]

- Zhou, Y. Lifecycle battery carbon footprint analysis for battery sustainability with energy digitalization and artificial intelligence. Appl. Energy 2024, 371, 123665. [Google Scholar] [CrossRef]

- Li, P.; Xia, X.; Guo, J. A review of the life cycle carbon footprint of electric vehicle batteries. Sep. Purif. Technol. 2022, 296, 121389. [Google Scholar] [CrossRef]

- de Pedro, M.B.; Ponce, C.H.; de Meatza, I.; Frax, L.M.; Peidro, C.S.; Boyano, I.; Díaz, M.Y. Environmental and economic assessment of a higher energy density and safer operation lithium-ion cell for stationary applications. Sustain. Mater. Technol. 2023, 37, e00704. [Google Scholar] [CrossRef]

- Dai, J.; Shi, C.; Li, C.; Shen, X.; Peng, L.; Wu, D.; Sun, D.; Zhang, P.; Zhao, J. A rational design of separator with substantially enhanced thermal features for lithium-ion batteries by the polydopamine–ceramic composite modification of polyolefin membranes. Energy Environ. Sci. 2016, 9, 3252–3261. [Google Scholar] [CrossRef]

- Wang, C.; Wu, K.; Cui, J.; Fang, X.; Li, J.; Zheng, N. Robust Room-Temperature Sodium-Sulfur Batteries Enabled by a Sandwich- Structured MXene@C/Polyolefin/MXene@C Dual-functional Separator. Small 2022, 18, 2106983. [Google Scholar] [CrossRef]

- Wang, E.; Chiu, C.; Chou, P. Safety assessment of polyolefin and nonwoven separators used in lithium-ion batteries. J. Power Sources 2020, 461, 228148. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, W.; Meng, G.; Zhang, J. Function-directed design of battery separators based on microporous polyolefin membranes. J. Mater. Chem. A 2022, 10, 14137–14170. [Google Scholar] [CrossRef]

- Wu, X.; Zhou, C.; Dong, C.; Shen, C.; Shuai, B.; Li, C.; Li, Y.; Na, Q.; Xu, X.; Mai, L. Polydopamine-assisted in-situ formation of dense MOF layer on polyolefin separator for synergistic enhancement of lithium-sulfur battery. Nano Res. 2022, 15, 8048–8055. [Google Scholar] [CrossRef]

- Zhang, Z.; Fang, Z.; Xiang, Y.; Liu, D.; Xie, Z.; Qu, D.; Sun, M.; Tang, H.; Li, J. Cellulose-based material in lithium-sulfur batteries: A review. Carbohydr. Polym. 2021, 255, 117469. [Google Scholar] [CrossRef]

- Sheng, J.; Tong, S.; He, Z.; Yang, R. Recent developments of cellulose materials for lithium-ion battery separators. Cellulose 2017, 24, 4103–4122. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Z.; Kong, Q.; Zhang, C.; Pang, S.; Yue, L.; Wang, X.; Yao, J.; Cui, G. Renewable and superior thermal-resistant cellulose-based composite nonwoven as lithium-ion battery separator. ACS Appl. Mater. Interfaces 2013, 5, 128–134. [Google Scholar]

- Jabbour, L.; Bongiovanni, R.; Chaussy, D.; Gerbaldi, C.; Beneventi, D. Cellulose-based Li-ion batteries: A review. Cellulose 2013, 20, 1523–1545. [Google Scholar] [CrossRef]

- Atila, D.; Keskin, D.; Tezcaner, A. Cellulose acetate based 3-dimensional electrospun scaffolds for skin tissue engineering applications. Carbohydr. Polym. 2015, 133, 251–261. [Google Scholar] [CrossRef]

- Grzybek, P.; Dudek, G.; Brugge, B. Cellulose-based films and membranes: A comprehensive review on preparation and applications. Chem. Eng. J. 2024, 495, 153500. [Google Scholar] [CrossRef]

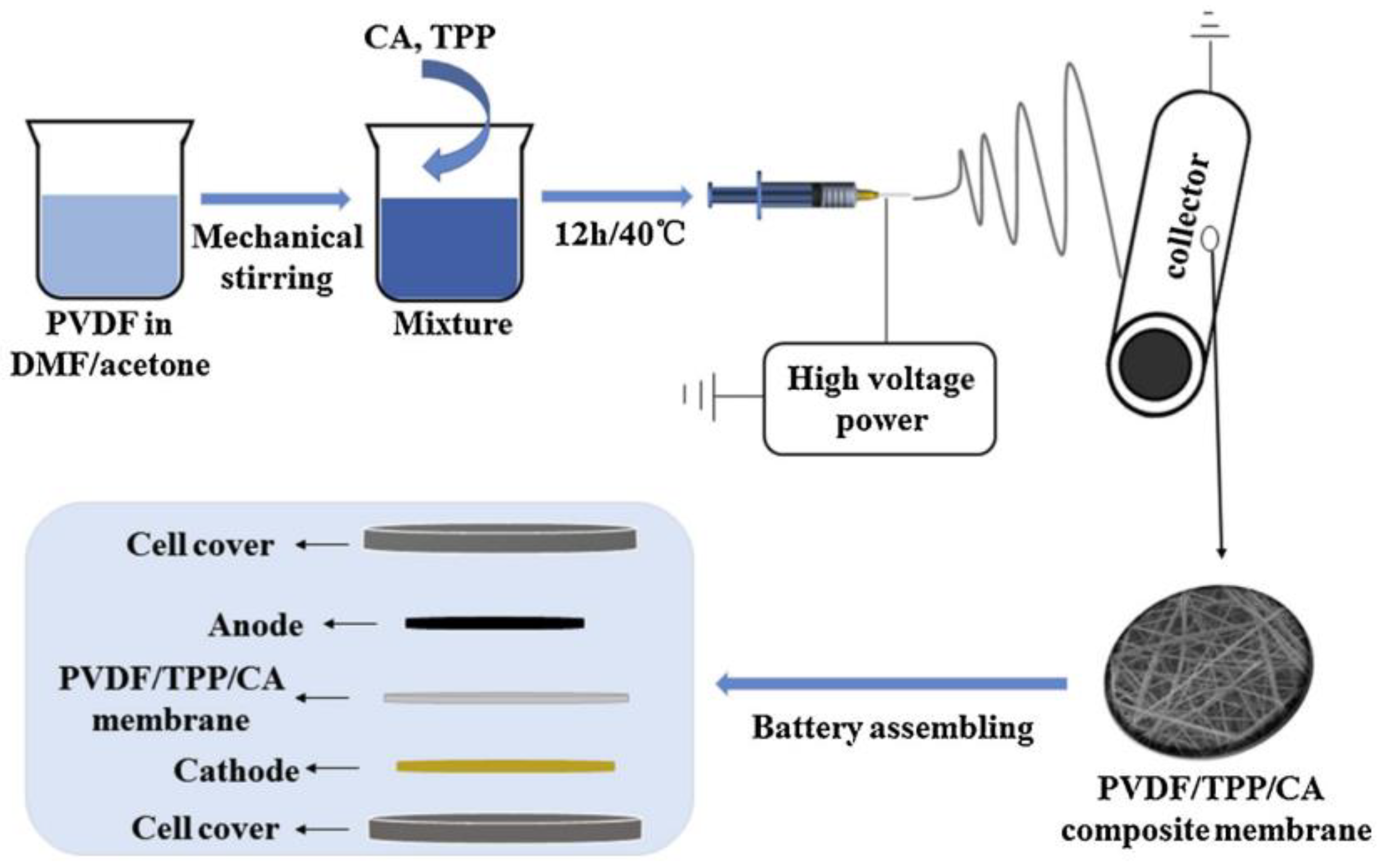

- Ratri, C.R.; Sabrina, Q.; Nugraha, A.F.; Astutiningsih, S.; Chalid, M. Green Chemistry of Cellulose Acetate Membrane Plasticized by Citric Acid and Succinonitrile for Lithium-Ion Battery Application. J. Renew. Mater. 2024, 12, 1863–1878. [Google Scholar] [CrossRef]

- Ren, J.; Guo, J.; Luo, X.; Dai, X.; Zhang, G.; Ping, P.; Kong, D. A sustainable green strategy: Flame-retardant cellulose-based separators for enhancing the safety and cycle stability of lithium-ion batteries. J. Power Sources 2025, 628, 235832. [Google Scholar] [CrossRef]

- Chen, M.; Xu, Y.; Dong, M.; Chen, K.; Zhang, Z.; Yang, L.; Chai, J.; Zheng, Y.; Li, Y.; Liu, Z.; et al. A safe composite cellulose membrane for quasi-solid-state lithium-ion batteries. Next Mater. 2024, 5, 100266. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, L.; Liu, C.; Feng, X.; Zhang, J.; Guan, L.; Mi, L.; Cui, S. Electrospun Flexible Cellulose Acetate-Based Separators for Sodium-Ion Batteries with Ultralong Cycle Stability and Excellent Wettability: The Role of Interface Chemical Groups. ACS Appl. Mater. Interfaces 2018, 10, 23883–23890. [Google Scholar] [CrossRef]

- Chen, W.; Shi, L.; Wang, Z.; Zhu, J.; Yang, H.; Mao, X.; Chi, M.; Sun, L.; Yuan, S. Porous cellulose diacetate-SiO2 composite coating on polyethylene separator for high-performance lithium-ion battery. Carbohydr. Polym. 2016, 147, 517–524. [Google Scholar] [CrossRef]

- Chen, J.; Liu, J.; Yuan, T.; Sun, R. Comparison of cellulose and chitin nanocrystals for reinforcing regenerated cellulose fibers. J. Appl. Polym. Sci. 2017, 134, 44880. [Google Scholar] [CrossRef]

- Hu, C.; Zhou, Y.; Zhang, T.; Jiang, T.; Meng, C.; Zeng, G. Morphological, Thermal, Mechanical, and Optical Properties of Hybrid Nanocellulose Film Containing Cellulose Nanofiber and Cellulose Nanocrystals. Fibers Polym. 2021, 22, 2187–2193. [Google Scholar] [CrossRef]

- Islam, M.S.; Chen, L.; Sisler, J.; Tam, K.C. Cellulose nanocrystal (CNC)–inorganic hybrid systems: Synthesis, properties and applications. J. Mater. Chem. B 2018, 6, 864–883. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhu, W.; Tang, Q.; Huang, Z.; Yu, P.; Gui, X.; Lin, S.; Hu, J.; Tu, Y. Mini Review on Cellulose-Based Composite Separators for Lithium-Ion Batteries: Recent Progress and perspectives. Energy Fuels 2021, 35, 12938–12947. [Google Scholar] [CrossRef]

- Cai, M.; Yuan, D.; Zhang, X.; Pu, Y.; Liu, X.; He, H.; Zhang, L.; Ning, X. Lithium ion battery separator with improved performance via side-by-side bicomponent electrospinning of PVDF-HFP/PI followed by 3D thermal crosslinking. J. Power Sources 2020, 461, 228123. [Google Scholar] [CrossRef]

- Lv, D.; Chai, J.; Wang, P.; Zhu, L.; Liu, C.; Nie, S.; Li, B.; Cui, G. Pure cellulose lithium-ion battery separator with tunable pore size and improved working stability by cellulose nanofibrils. Carbohydr. Polym. 2021, 251, 116975. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, H.; Huang, H.; Wei, Z.; Zhao, Y. Water-soluble ammonium polyphosphate synchronously enables mechanically robust and flame-retardant cellulose composite separator for high safety lithium batteries. J. Power Sources 2023, 558, 232627. [Google Scholar] [CrossRef]

- Qian, J.; Chen, Q.; Hong, M.; Xie, W.; Jing, S.; Bao, Y.; Chen, G.; Pang, Z.; Hu, L.; Li, T. Toward stretchable batteries: 3D-printed deformable electrodes and separator enabled by nanocellulose. Mater. Today 2022, 54, 18–26. [Google Scholar] [CrossRef]

| Parameter | Objective |

|---|---|

| Pore size | <1.0 µm |

| Porosity | 40.0–60.0% |

| Thickness | 20.0–25.0 µm |

| Tensile strength | 98.06 (>1000 kg.cm−1) MPa |

| Thermal shrinkage | <5.0% at 90 °C for 60 min |

| High-temperature melt integrity | >150 °C |

| Ionic conductivity | 10−3–10−1 S.cm−1 |

| Type of Cellulose | Production Method | Advantages | Disadvantages |

|---|---|---|---|

| CNF | Mechanical defibrillation | Enhances mechanical strength, flexibility, thermal stability, ionic conductivity, and electrolyte retention | Tendency to aggregate, structural fragility |

| CNC | Acid hydrolysis and oxidation (e.g., TEMPO reagent) | Provides matrix reinforcement, better control of porosity, and improved ionic conductivity | High cost |

| BC | Synthesized by bacteria (e.g., Gluconacetobacter xylinus) | Excellent thermal stability, long cycle life, and potential for energy efficiency improvement with conductive additives | Slow production process, high cost |

| CA | Esterification of cellulose with acetic acid and anhydride | Flexibility, good electrical insulation, and can be modified to improve electrochemical properties | Limited chemical stability |

| RC | Chemical coagulation and regeneration processes | Flexibility, porosity, and enhances battery performance and lifespan | High hygroscopicity |

| Separator | Type of Cellulose | Methodology | Thickness (µm) | Porosity (%) | Ionic Conductivity (mS.cm−1) | Electrochemical Perfomance | Battery (Cathode/Anode) | Reference |

|---|---|---|---|---|---|---|---|---|

| CNF | Coffee waste | Casting | 25 | 55 | 3.00 | Specific capacitance retention of 47.1% | Zn/SS | [32] |

| CNF | Rice straw | Casting | 30 | 51 | 3.40 | 100% after 5000 cycles at 0.5C | Activated carbon | [20] |

| CNF | Bamboo pulp, hardwood pulp, softwood pulp, cotton pulp, and hemp pulp | Vacuum filtration | 20–30 | - | - | - | - | [33] |

| HAP/CNC | CNC | Vacuum filtration | 28 | 76 | 0.81 | 67.1% after 100 cycles at 2C | LiFePO4/Li | [34] |

| CNC | CNC | Casting | 150 | 75.3 | 2.7 | 91 mAhg−1 after 10 cycles at C/8 | LiFePO4/Li | [35] |

| BC/PPS | BC | Vacuum filtration | - | 62.7 | 1.55 | 91.3% after 100 cycles at 0.5C | LiFePO4/Li | [36] |

| TOBC | BC | Vacuum filtration | 29 | 88.3 | 13.45 | 94% after 100 cycles at 0.2C | LiFePO4/Li | [37] |

| PAN/CA/HAP | AC | Eletrospinning | 46 | 61 | 3.02 | 157.6 mAhg−1 after 50 cycles at 0.5C | LiFePO4/Li | [38] |

| PVDF/CA/TPP | AC | Eletrospinning | 58 | 90 | 4.4 | 86.9% after 100 cycles at 0.2C | LiFePO4/Li | [39] |

| RCS | Cotton pulp | Phase inversion | 19.74 | 61 | 1.25 | 72% after 100 cycles at 0.2C | LiFePO4/Li | [8] |

| CSA | Cotton pulp | Phase inversion | 109 | 58.43 | 1.34 | 78.7% after 80 cycles at 0.5C | LiFe0.2Mn0.8PO4/Li | [40] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turossi, T.C.; Júnior, H.L.O.; Monticeli, F.M.; Dias, O.T.; Zattera, A.J. Cellulose-Derived Battery Separators: A Minireview on Advances Towards Environmental Sustainability. Polymers 2025, 17, 456. https://doi.org/10.3390/polym17040456

Turossi TC, Júnior HLO, Monticeli FM, Dias OT, Zattera AJ. Cellulose-Derived Battery Separators: A Minireview on Advances Towards Environmental Sustainability. Polymers. 2025; 17(4):456. https://doi.org/10.3390/polym17040456

Chicago/Turabian StyleTurossi, Tayse Circe, Heitor Luiz Ornaghi Júnior, Francisco Maciel Monticeli, Otávio Titton Dias, and Ademir José Zattera. 2025. "Cellulose-Derived Battery Separators: A Minireview on Advances Towards Environmental Sustainability" Polymers 17, no. 4: 456. https://doi.org/10.3390/polym17040456

APA StyleTurossi, T. C., Júnior, H. L. O., Monticeli, F. M., Dias, O. T., & Zattera, A. J. (2025). Cellulose-Derived Battery Separators: A Minireview on Advances Towards Environmental Sustainability. Polymers, 17(4), 456. https://doi.org/10.3390/polym17040456