Study on the Space Charge Characteristics of Polypropylene Insulation Material Under a Polarity Reversal Electric Field

Abstract

1. Introduction

2. Sample Preparation and Testing Methods

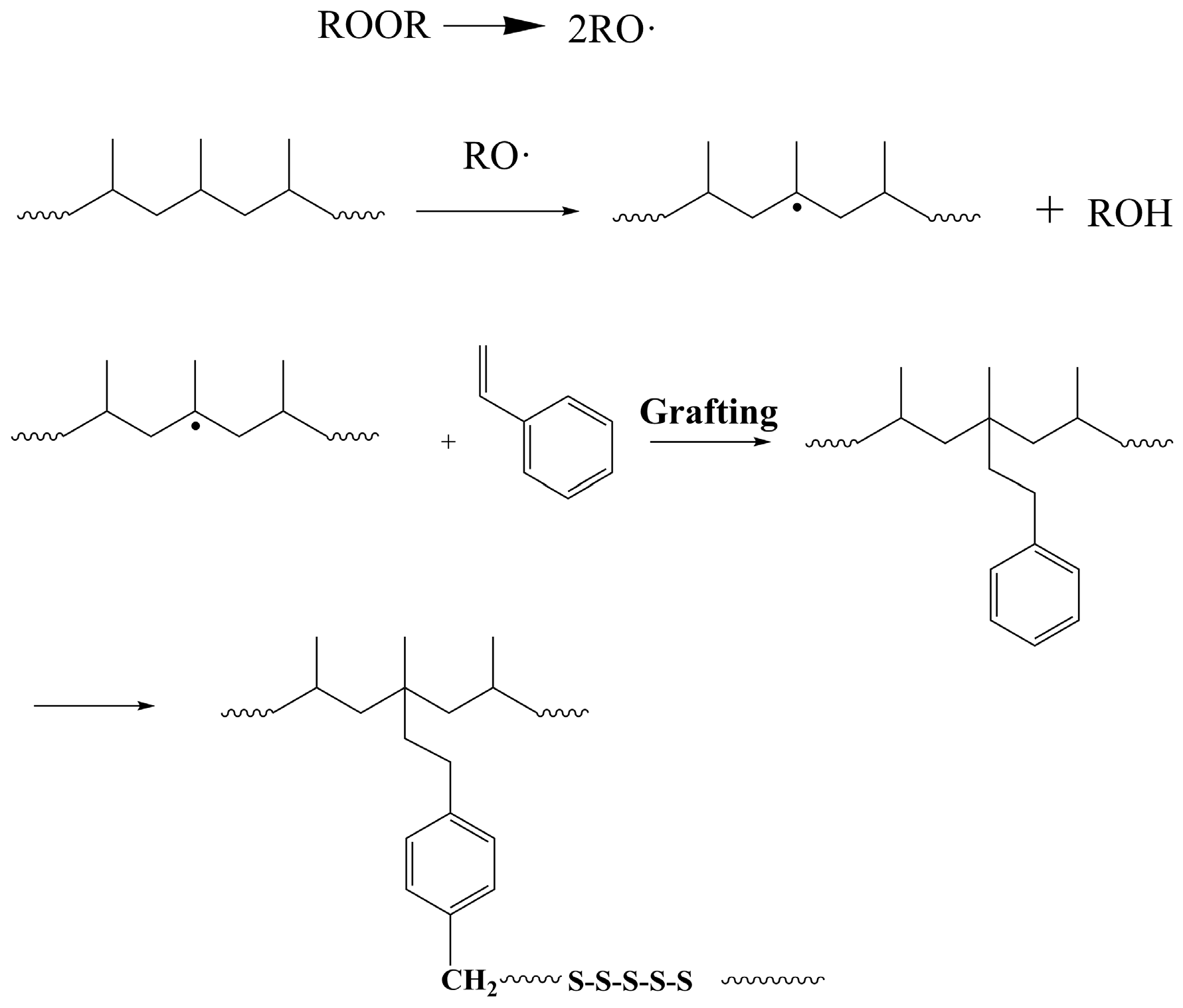

2.1. Preparation of Grafted PP Samples

2.2. Testing Methods

3. Results

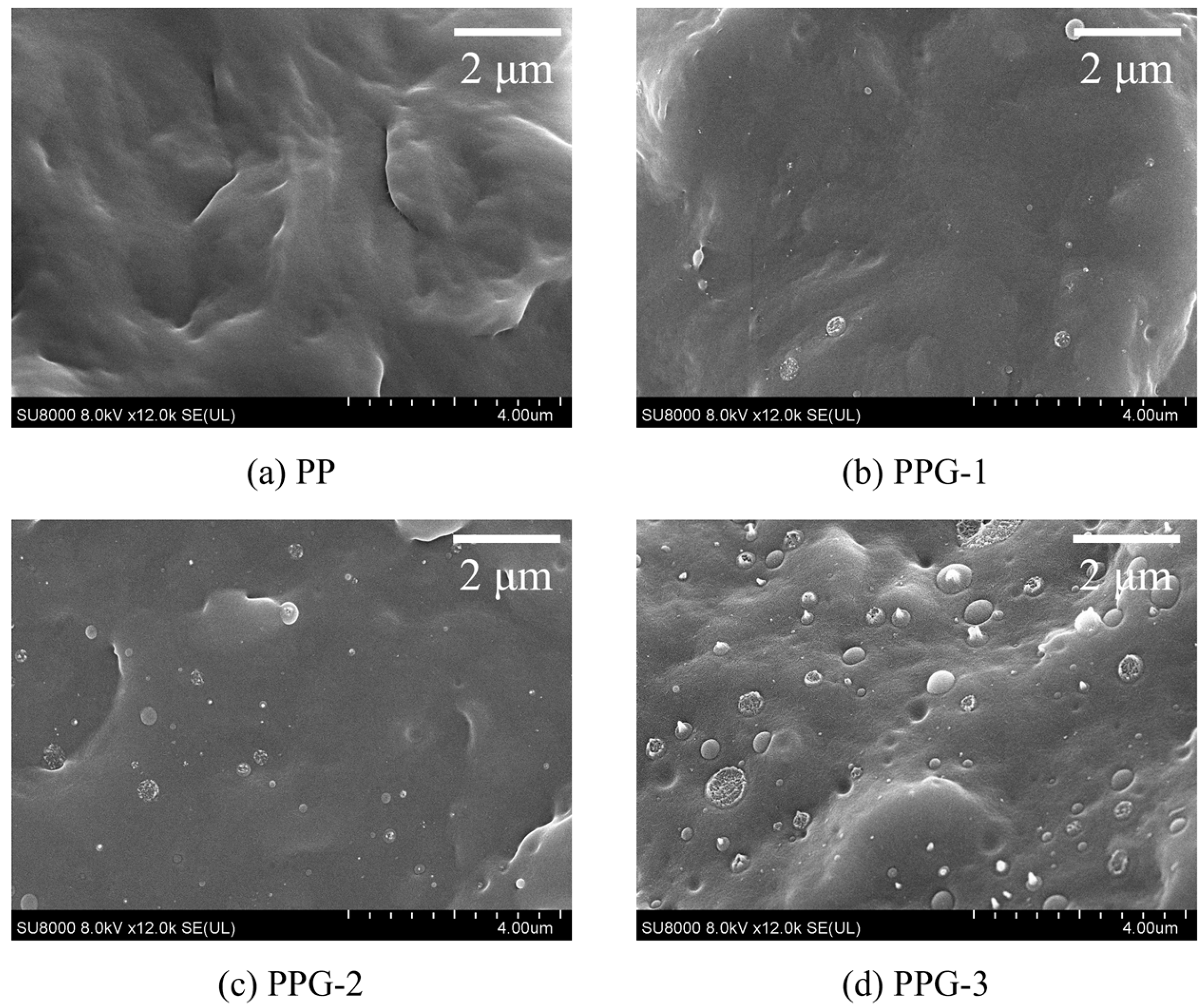

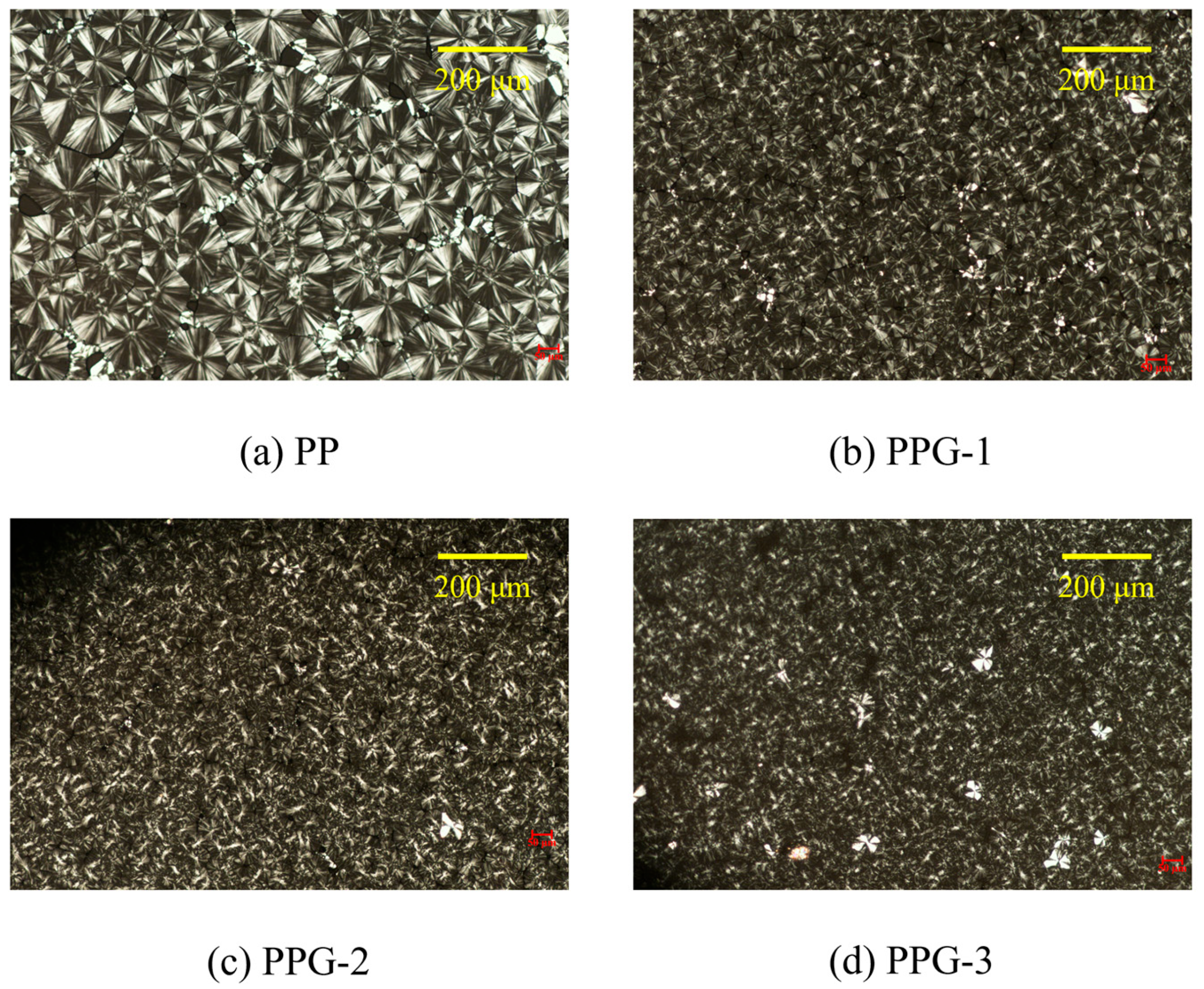

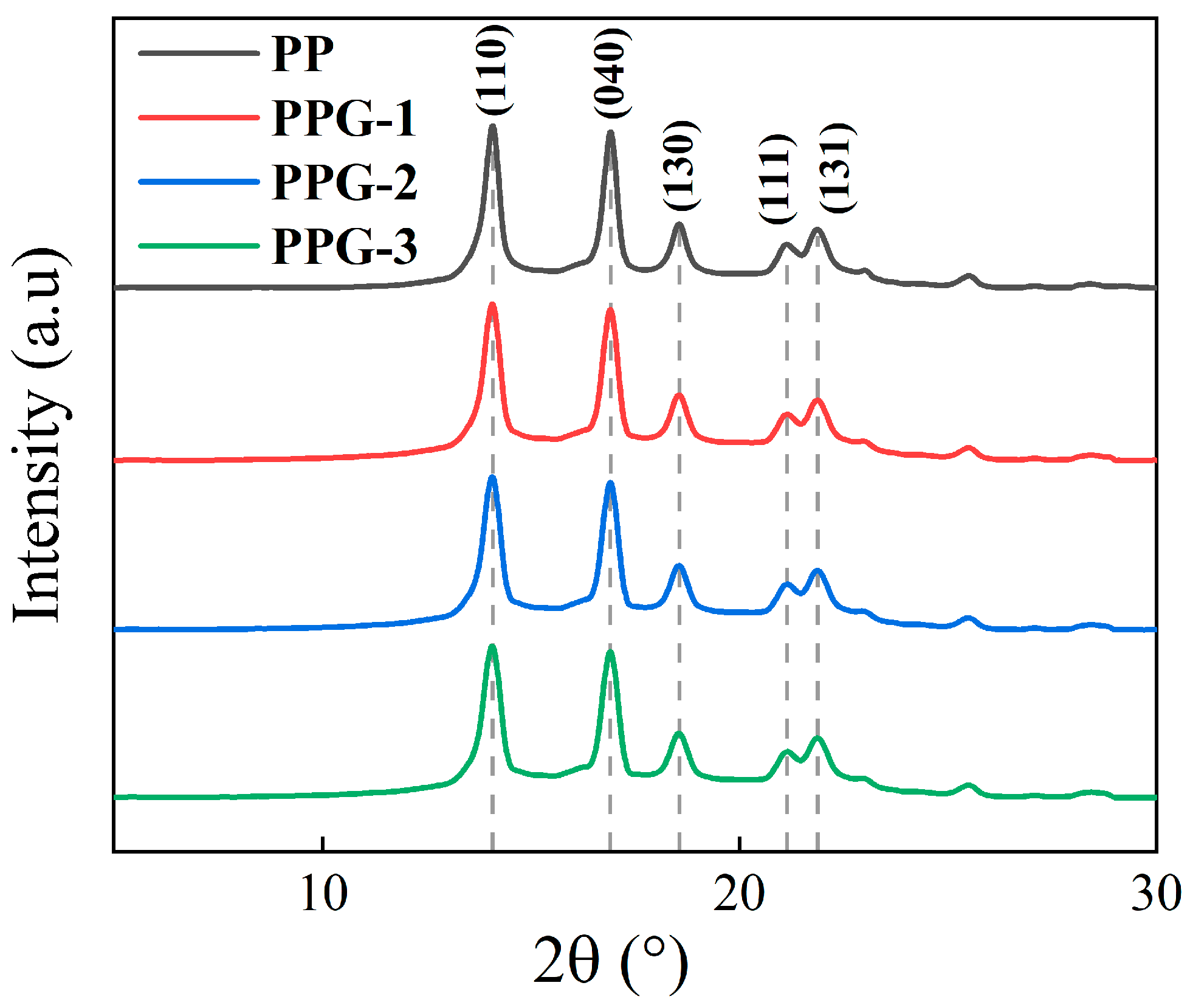

3.1. The Microstructure of St-Grafted PP

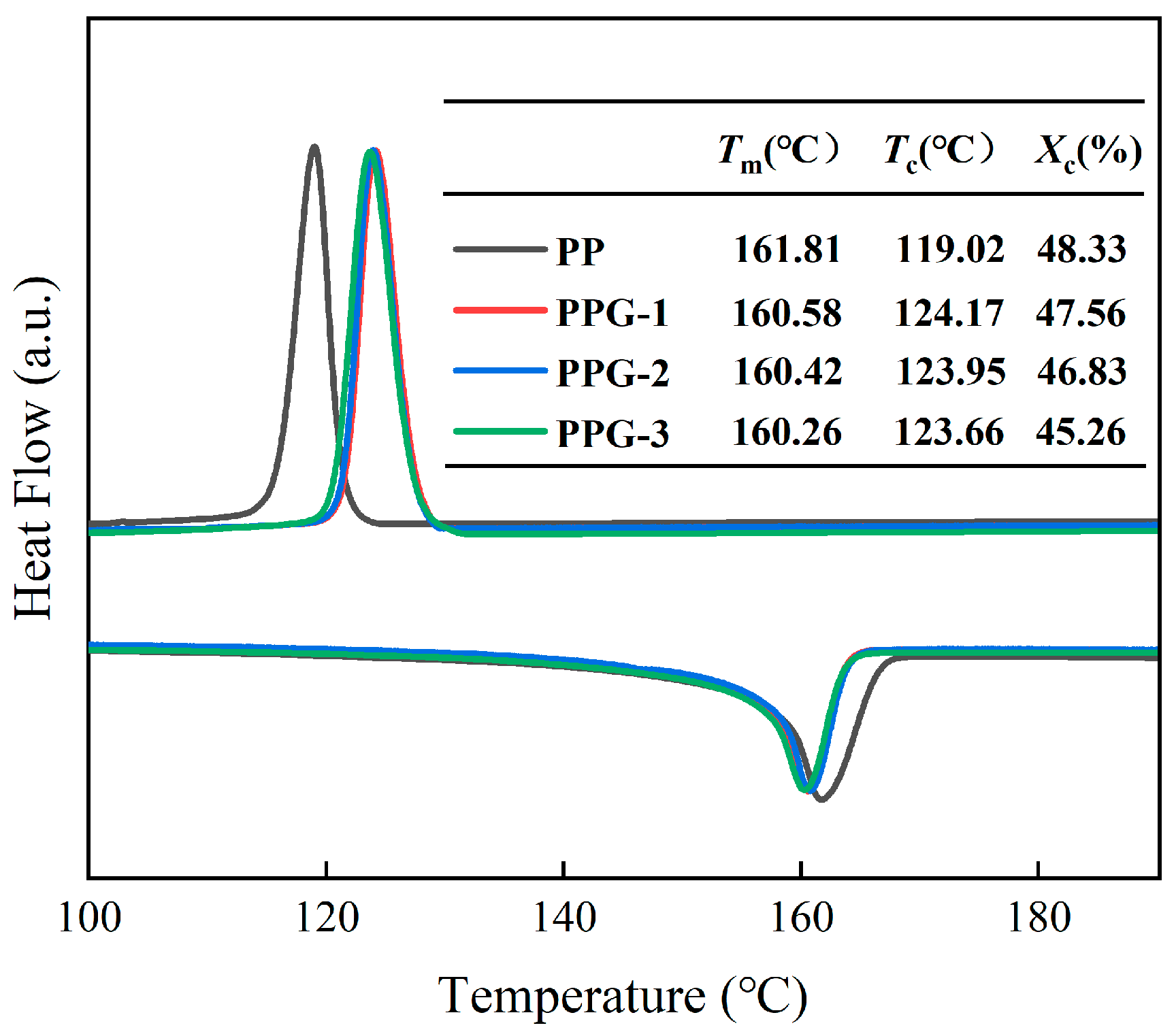

3.2. Thermal Properties of St-Grafted PP

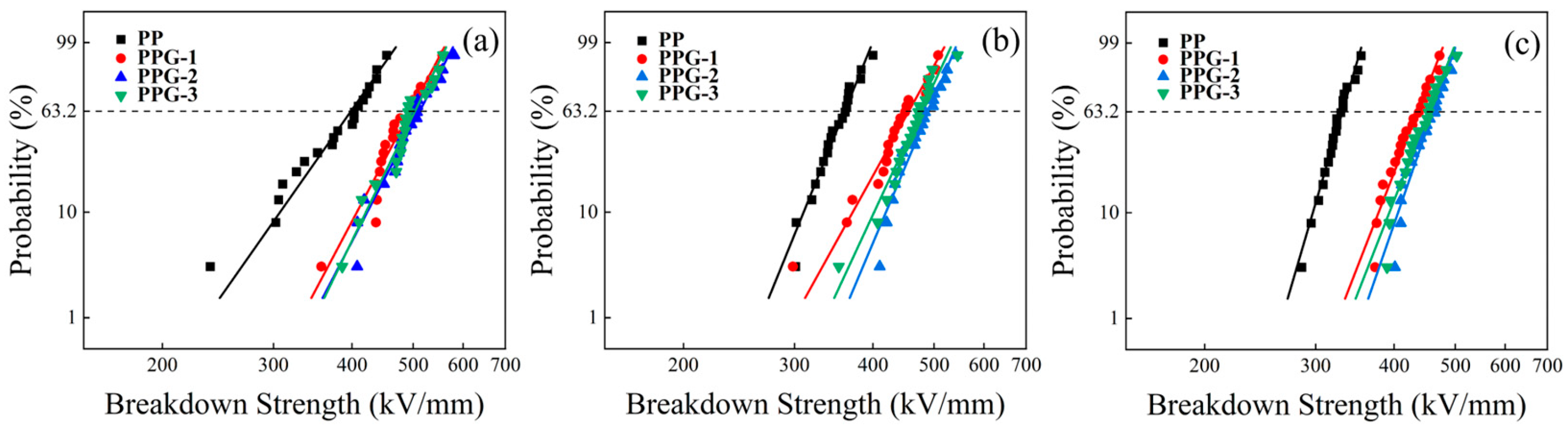

3.3. DC Breakdown Strength

3.4. Conductivity

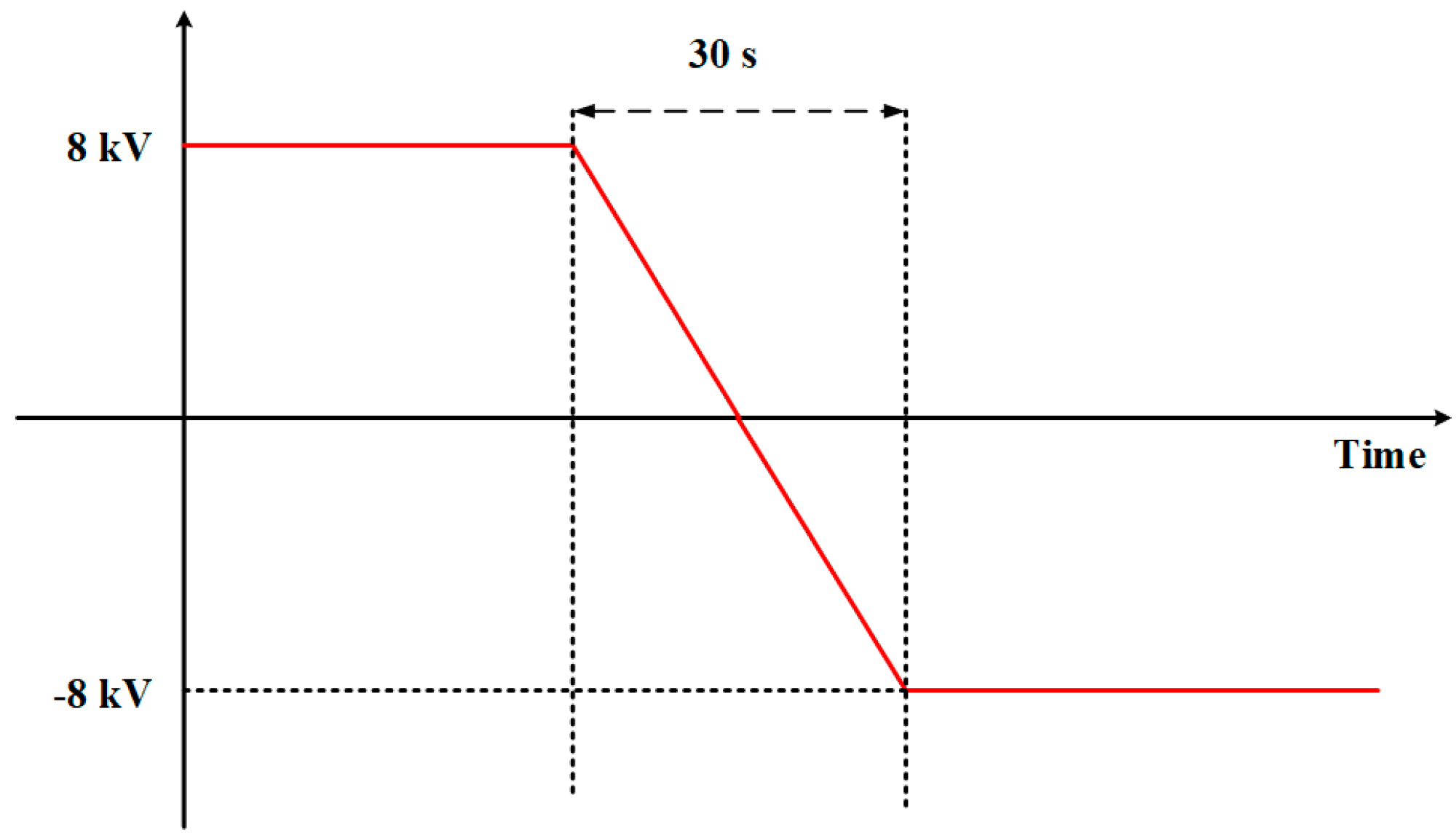

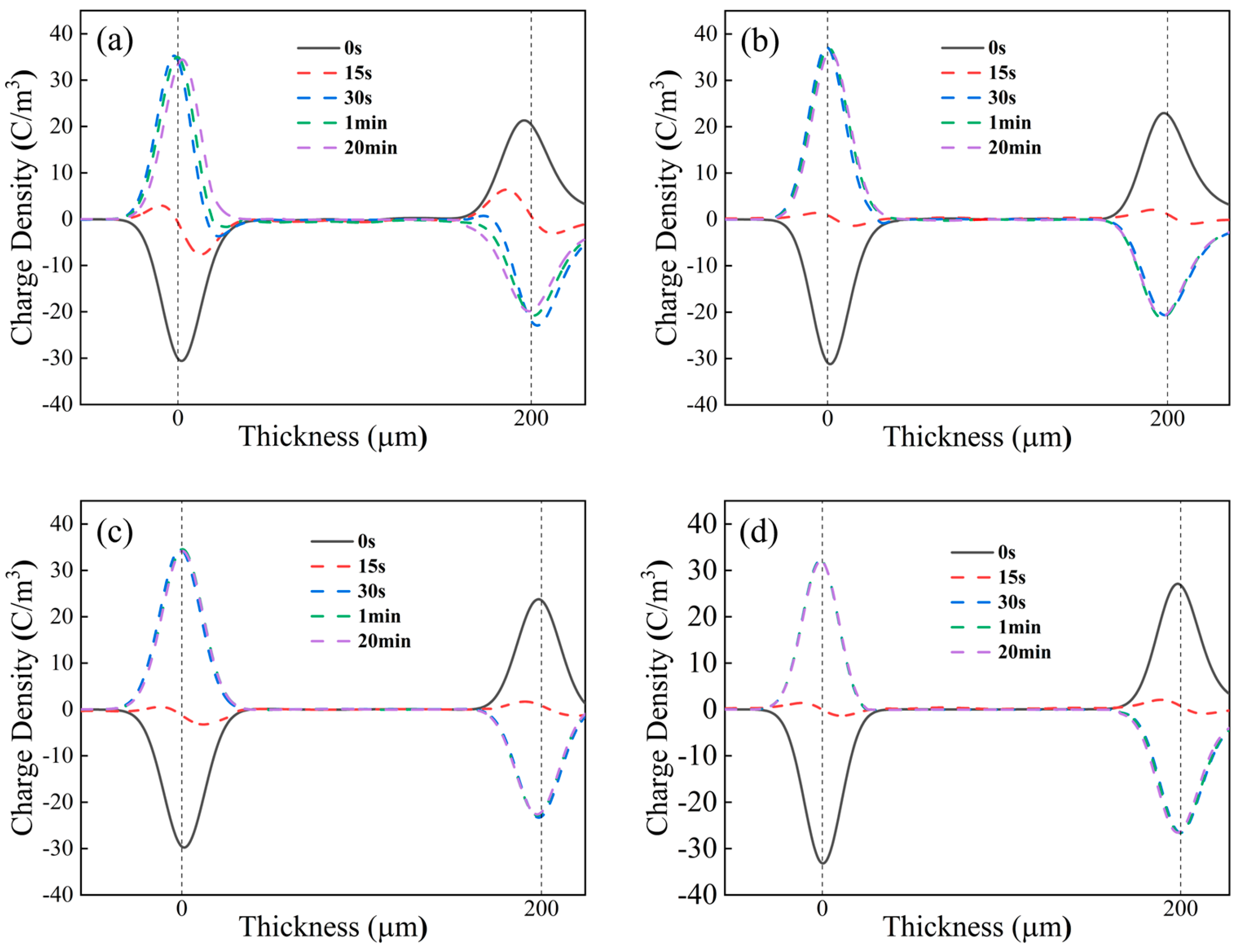

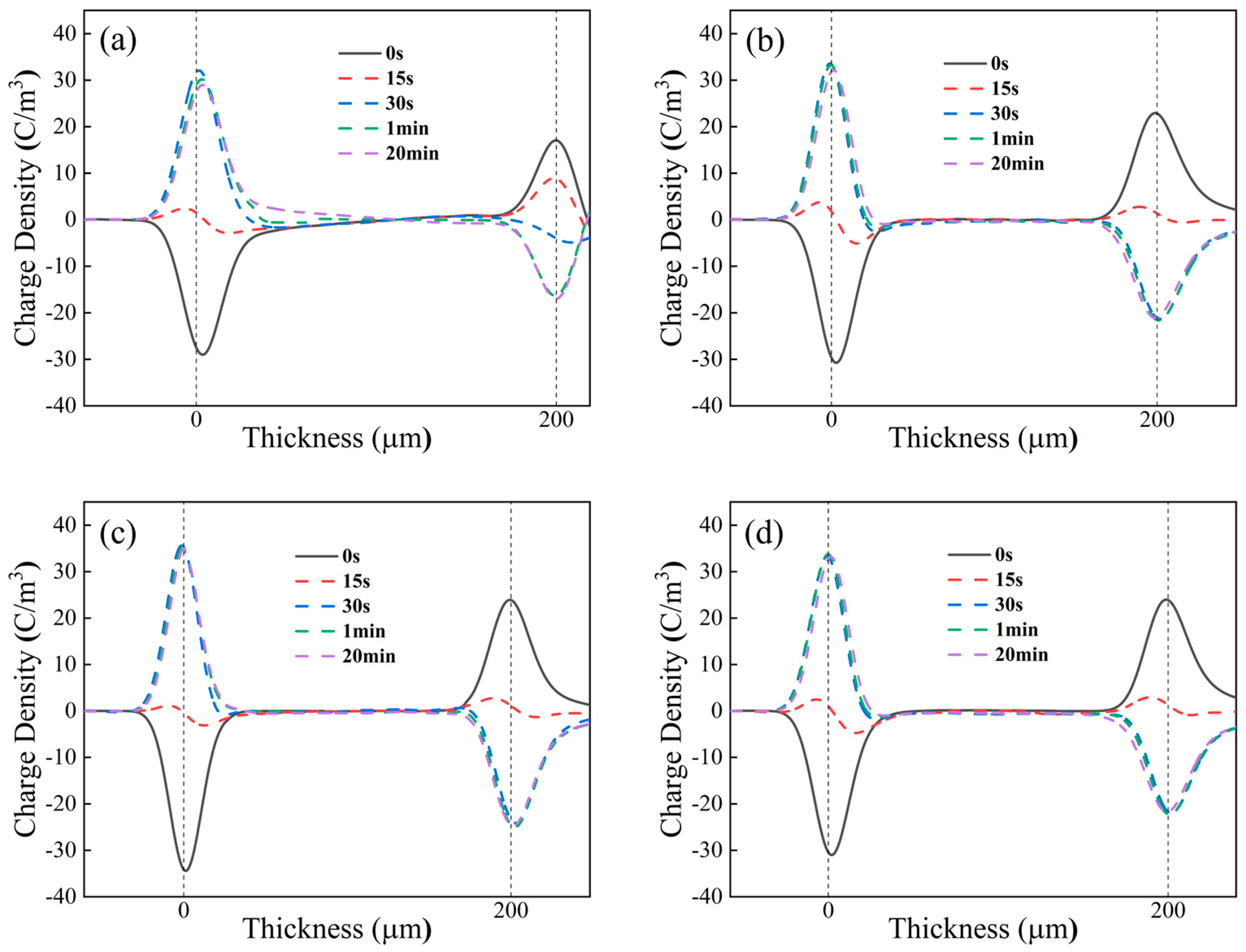

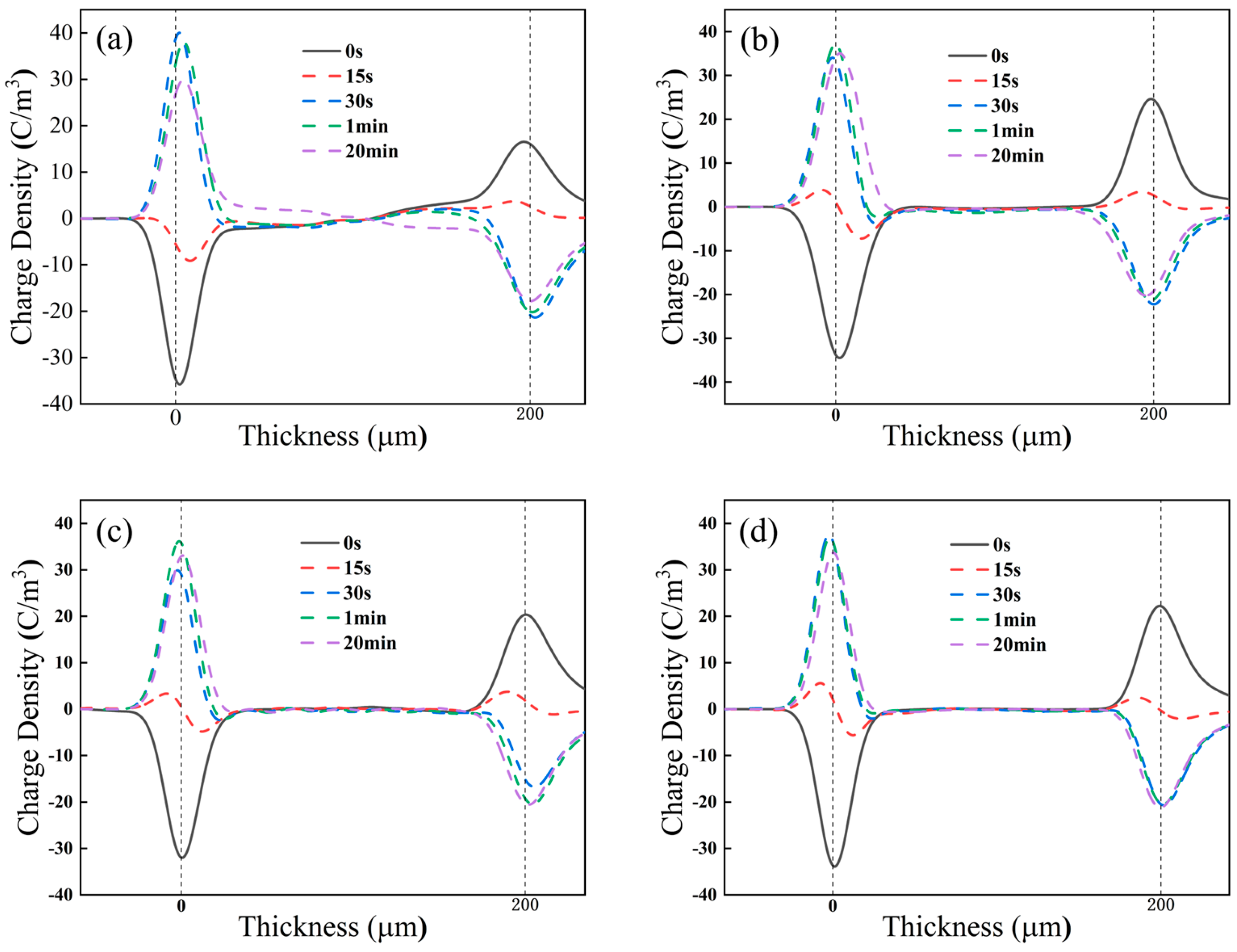

3.5. Space Charge Characteristics

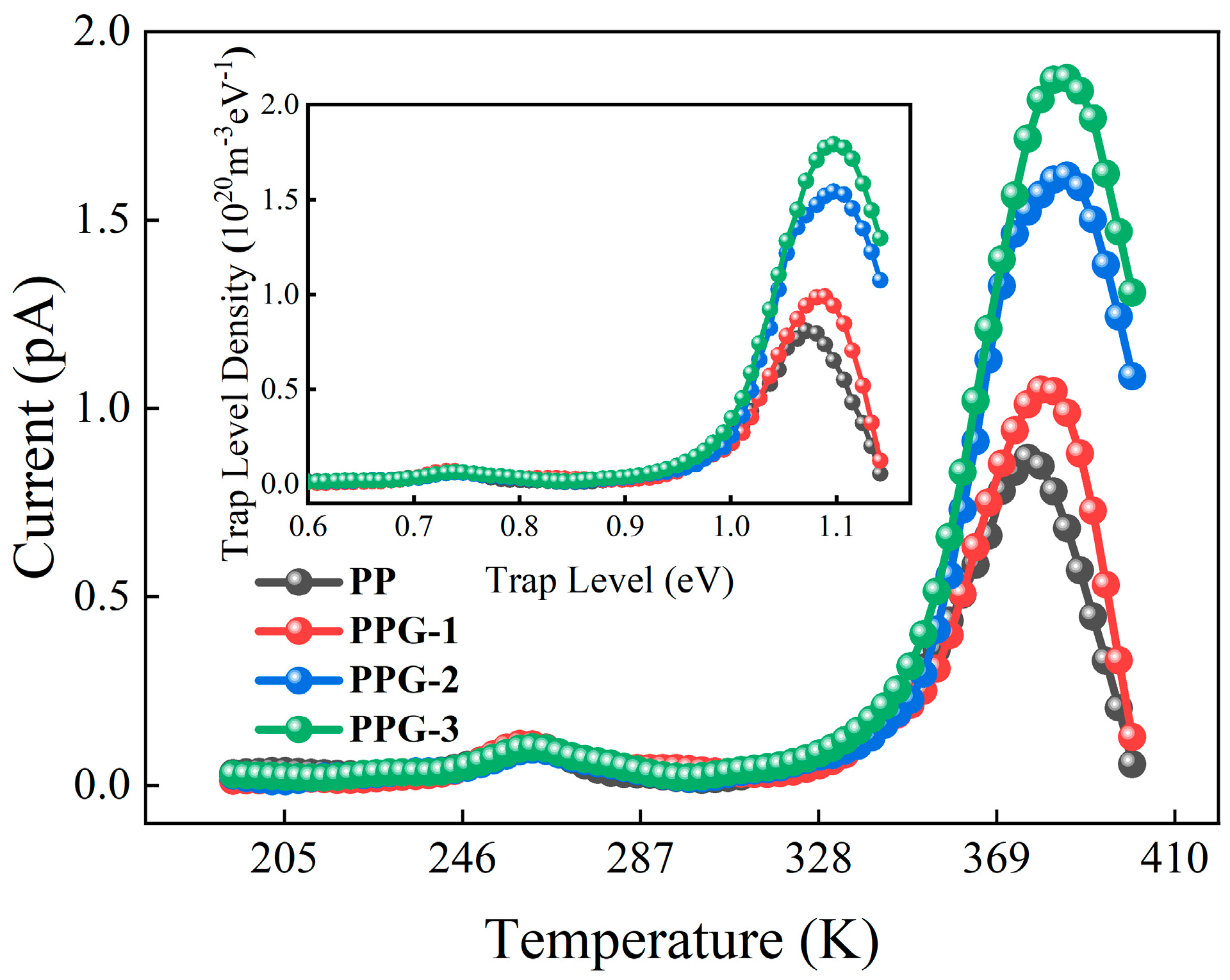

3.6. Trap Distribution

4. Discussion

5. Conclusions

- (1)

- Grafting St introduces grafted side chains into the sample and entangles them with each other, presenting a spherical structure in the fracture surface, with chain breakage observed inside some spherical structures. Grafting modification does not cause changes in the crystal form of PP, but it leads to an increase in crystallization temperature and a decrease in melting temperature and crystallinity.

- (2)

- Grafting modification can significantly improve the electrical properties of PP, with PPG-2 having the optimal DC breakdown strength at all temperatures, showing a maximum increase of 35.86% compared with PP. PPG-3 has the highest critical electric field at all temperatures, with a maximum of 38.7 kV/mm at 30 °C.

- (3)

- Compared with PP, PPG samples effectively inhibit the injection of space charge. Before the voltage polarity reversal, a large amount of homocharge accumulates inside the PP, resulting in poor space charge performance after reversal. The PPG samples effectively improve the situation, and the suppression of space charge gradually increases with the rise in grafting content. PPG-3 has the strongest suppression of space charge under the polarity reversal electric field.

- (4)

- Further research was conducted on the trap characteristics of PPG samples, indicating that the grafted St monomers introduce a large number of deep traps. These deep traps inhibit carrier injection and migration, thereby improving the insulation properties of the material. The heterogeneous nucleation effect of the grafted side chains in the PPG samples increases the number of spherulites in the material, reduces the boundary size, hinders the migration of carriers, and reduces the accumulation of internal charges. Meanwhile, the entanglement of the grafted side chains inside the PPG samples enhances the structural stability of the material and reduces the formation of low-density regions, which improves the insulation properties of PP.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; He, J.; Hu, J.; Huang, X.; Jiang, P. Evaluation of polypropylene/polyolefin elastomer blends for potential recyclable HVDC cable insulation applications. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 673–681. [Google Scholar] [CrossRef]

- Chen, G.; Hao, M.; Xu, Z.; Vaughan, A.; Cao, J.; Wang, H. Review of high voltage direct current cables. CSEE J. Power Energy 2015, 1, 9–21. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, S.; Hu, J.; He, J. Polymeric insulation materials for HVDC cables: Development, challenges and future perspective. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1308–1318. [Google Scholar] [CrossRef]

- Meng, X.; Yu, H.; Lu, Z.; Jin, T. Catalytic pyrolysis of polypropylene for cable semiconductive buffer layers. Polymers 2024, 16, 1435. [Google Scholar] [CrossRef]

- Barber, K.; Alexander, G. Insulation of electrical cables over the past 50 Years. IEEE Electr. Insul. Mag. 2013, 29, 27–32. [Google Scholar] [CrossRef]

- He, J.; Chen, G. Insulation materials for HVDC polymeric cables. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1307. [Google Scholar] [CrossRef]

- Zhou, Y.; Dang, B.; Wang, H.; Liu, J.; Li, Q.; Hu, J.; He, J. Polypropylene-based ternary nanocomposites for recyclable high-voltage direct-current cable insulation. Compos. Sci. Technol. 2018, 165, 168–174. [Google Scholar] [CrossRef]

- Zhan, Y.; Yang, X.; Yang, J.; Hou, S.; Fu, M. Improved electrical properties of organic modified thermoplastic insulation material for direct current cable application. Polymers 2023, 16, 46. [Google Scholar] [CrossRef]

- Li, Z.; Du, B. Polymeric insulation for high-voltage DC extruded cables: Challenges and development directions. IEEE Electr. Insul. Mag. 2018, 34, 30–43. [Google Scholar] [CrossRef]

- Liu, W.; Cheng, L.; Li, S. Review of electrical properties for polypropylene based nanocomposite. Compos. Commun. 2018, 10, 221–225. [Google Scholar] [CrossRef]

- Gao, Y.; Huang, X.; Min, D.; Li, S.; Jiang, P. Recyclable dielectric polymer nanocomposites with voltage stabilizer interface: Toward new generation of high voltage direct current cable insulation. ACS Sustain. Chem. Eng. 2019, 7, 513–525. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, J.; Dang, B.; He, J. Mechanism of highly improved electrical properties in polypropylene by chemical modification of grafting maleic anhydride. J. Phys. D Appl. Phys. 2016, 49, 415301. [Google Scholar] [CrossRef]

- Zha, J.-W.; Wu, Y.-H.; Wang, S.-J.; Wu, D.-H.; Yan, H.-D.; Dang, Z.-M. Improvement of space charge suppression of polypropylene for potential application in HVDC cables. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2337–2343. [Google Scholar] [CrossRef]

- Liang, Y.; Liu, L.; Zhang, W.; Weng, L.; Hu, D.; Li, C. Preparation and electrical properties of 4-Acetoxystyrene grafted polypropylene for HVDC cable insulation. J. Mater. Sci.-Mater. Electron. 2020, 31, 3890–3898. [Google Scholar] [CrossRef]

- Liang, Y.; Weng, L.; Zhang, W. Preparation and electrical properties of 4-Allyloxy-2-Hydroxybenzophenone grafted polypropylene for HVDC cables. J. Electron. Mater. 2021, 50, 6228–6236. [Google Scholar] [CrossRef]

- Li, G.; An, T.; Liang, J.; Liu, W.; Joseph, T.; Lu, J.; Szechtman, M.; Andersen, B.R.; Lan, Y. Power reversal strategies for hybrid LCC/MMC HVDC systems. CSEE J. Power Energy 2020, 6, 203–212. [Google Scholar] [CrossRef]

- Wu, Z.-Y.; Jin, Y.-Z.; Shi, Z.-X.; Wang, Z.-Y.; Wang, W. Study on the relationship between electron transfer and electrical properties of XLPE/Modification SR under polarity reversal. Polymers 2024, 16, 2356. [Google Scholar] [CrossRef]

- Yuan, H.; Hu, S.; Zhou, Y.; Yuan, C.; Song, W.; Shao, Q.; Shi, H.; Li, J.; Hu, J.; Li, Q.; et al. Enhanced electrical properties of styrene-grafted polypropylene insulation for bulk power transmission HVDC cable. CSEE J. Power Energy 2024, 10, 361–370. [Google Scholar] [CrossRef]

- Yuan, H.; Zhou, Y.; Zhu, Y.; Hu, S.; Yuan, C.; Song, W.; Shao, Q.; Zhang, Q.; Hu, J.; Li, Q.; et al. Origins and effects of deep traps in functional group grafted polymeric dielectric materials. J. Phys. D Appl. Phys. 2020, 53, 475301. [Google Scholar] [CrossRef]

- Lezak, E.; Bartczak, Z. Plastic deformation of the γ phase isotactic polypropylene in plane−strain compression at elevated temperatures. Macromolecules 2007, 40, 4933–4941. [Google Scholar] [CrossRef]

- Liu, W.; Liu, H.; Cheng, L.; Li, S. Enhanced energy storage performance in polypropylene-acrylic acid grafted polypropylene-ZrO 2 ternary nanocomposites. J. Phys. D Appl. Phys. 2023, 56, 244001. [Google Scholar] [CrossRef]

- Xiao, M.; Zhang, M.; Du, B.; Ran, Z.; Liu, H.; Qin, Y. Breakdown strength improvement of polypropylene by introducing long-chain branched structures for film capacitors. J. Phys. D Appl. Phys. 2022, 55, 245501. [Google Scholar] [CrossRef]

- Lampert, M.A. Simplified theory of space-charge-limited currents in an insulator with traps. Phys. Rev. 1956, 103, 1648–1656. [Google Scholar] [CrossRef]

- Tian, F.; Bu, W.; Shi, L.; Yang, C.; Wang, Y.; Lei, Q. Theory of modified thermally stimulated current and direct determination of trap level distribution. J. Electrostat. 2011, 69, 7–10. [Google Scholar] [CrossRef]

- Wang, C.; Shen, Y.; Cao, X.; Zheng, X.; Ren, K. High energy density in all-organic polyimide-based composite film by doping of polyvinylidene fluoride-based relaxor ferroelectrics. Polymers 2024, 16, 1138. [Google Scholar] [CrossRef]

| Sample | α (kV/mm) | β | Increase in Breakdown Strength (%) |

|---|---|---|---|

| PP | 398 | 8.69 | / |

| PPG-1 | 495 | 11.50 | 24.37 |

| PPG-2 | 511 | 11.75 | 28.39 |

| PPG-3 | 503 | 12.55 | 26.38 |

| Sample | α (kV/mm) | β | Increase in Breakdown Strength (%) |

|---|---|---|---|

| PP | 361 | 14.98 | / |

| PPG-1 | 456 | 10.99 | 26.32 |

| PPG-2 | 490 | 14.42 | 35.73 |

| PPG-3 | 477 | 13.12 | 32.13 |

| Sample | α (kV/mm) | β | Increase in Breakdown Strength (%) |

|---|---|---|---|

| PP | 331 | 20.77 | / |

| PPG-1 | 436 | 15.68 | 31.72 |

| PPG-2 | 461 | 17.60 | 39.27 |

| PPG-3 | 453 | 15.55 | 35.86 |

| Critical Electric Field (kV/mm) | 30 °C | 60 °C | 90 °C |

|---|---|---|---|

| PP | 33.9 | 28.1 | 23.0 |

| PPG-1 | 36.1 | 32.8 | 30.2 |

| PPG-2 | 37.8 | 34.0 | 31.4 |

| PPG-3 | 38.7 | 36.3 | 34.1 |

| Sample | Trap Density (1020 m−3eV−1) | Trap Level (eV) |

|---|---|---|

| PP | 0.81 | 1.07 |

| PPG-1 | 0.99 | 1.09 |

| PPG-2 | 1.54 | 1.10 |

| PPG-3 | 1.79 | 1.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Bao, G.; Wang, W. Study on the Space Charge Characteristics of Polypropylene Insulation Material Under a Polarity Reversal Electric Field. Polymers 2025, 17, 430. https://doi.org/10.3390/polym17030430

Dong X, Bao G, Wang W. Study on the Space Charge Characteristics of Polypropylene Insulation Material Under a Polarity Reversal Electric Field. Polymers. 2025; 17(3):430. https://doi.org/10.3390/polym17030430

Chicago/Turabian StyleDong, Xinhua, Guodong Bao, and Wei Wang. 2025. "Study on the Space Charge Characteristics of Polypropylene Insulation Material Under a Polarity Reversal Electric Field" Polymers 17, no. 3: 430. https://doi.org/10.3390/polym17030430

APA StyleDong, X., Bao, G., & Wang, W. (2025). Study on the Space Charge Characteristics of Polypropylene Insulation Material Under a Polarity Reversal Electric Field. Polymers, 17(3), 430. https://doi.org/10.3390/polym17030430