Effects of Process Parameters on the Mechanical Properties and Microstructure of Additively Manufactured Carbon Black Particles-Reinforced Thermoplastic Polyurethane Composite Samples

Abstract

1. Introduction

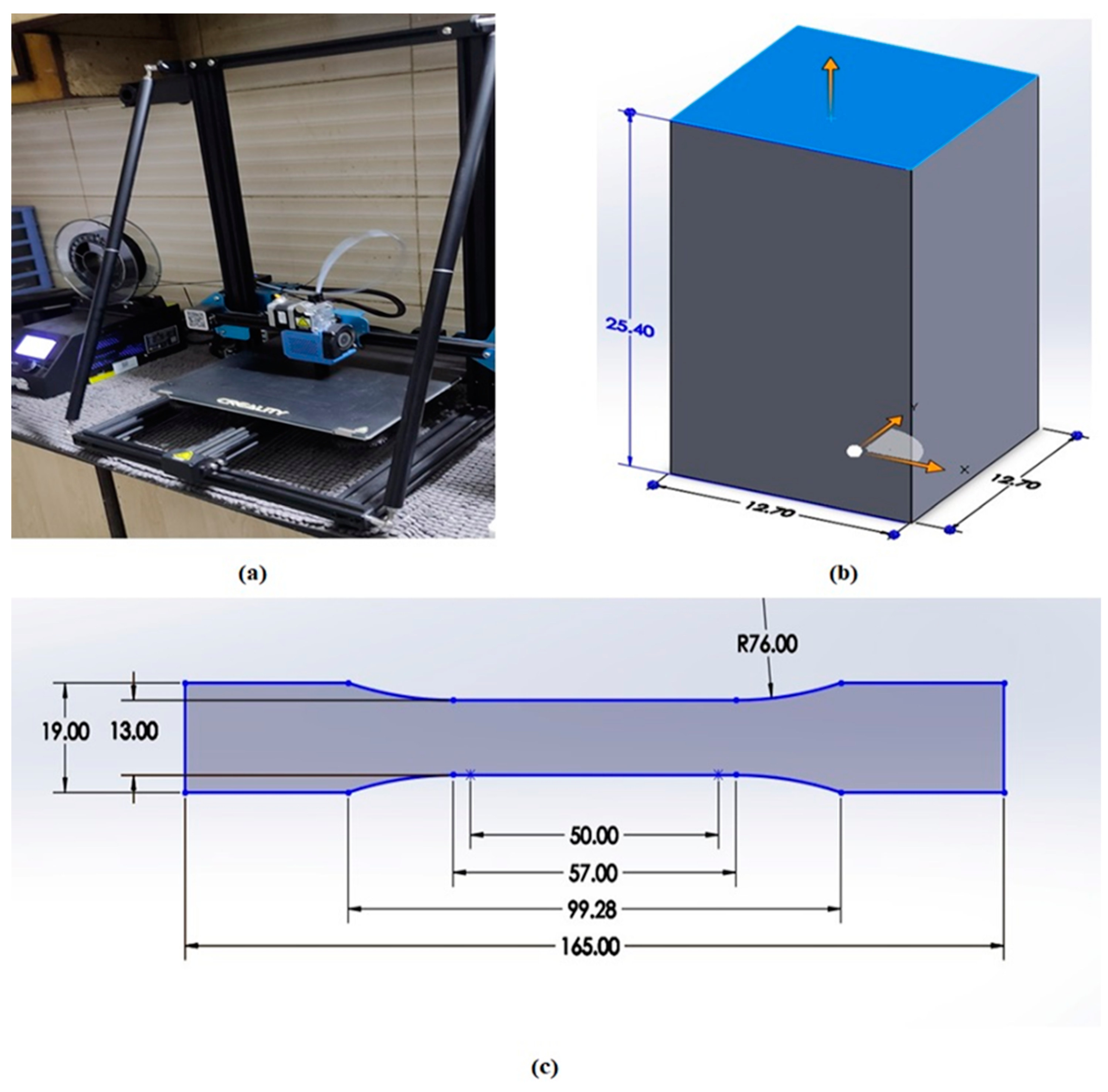

2. Materials and Methods

3. Results and Discussion

3.1. Mechanical Testing Results

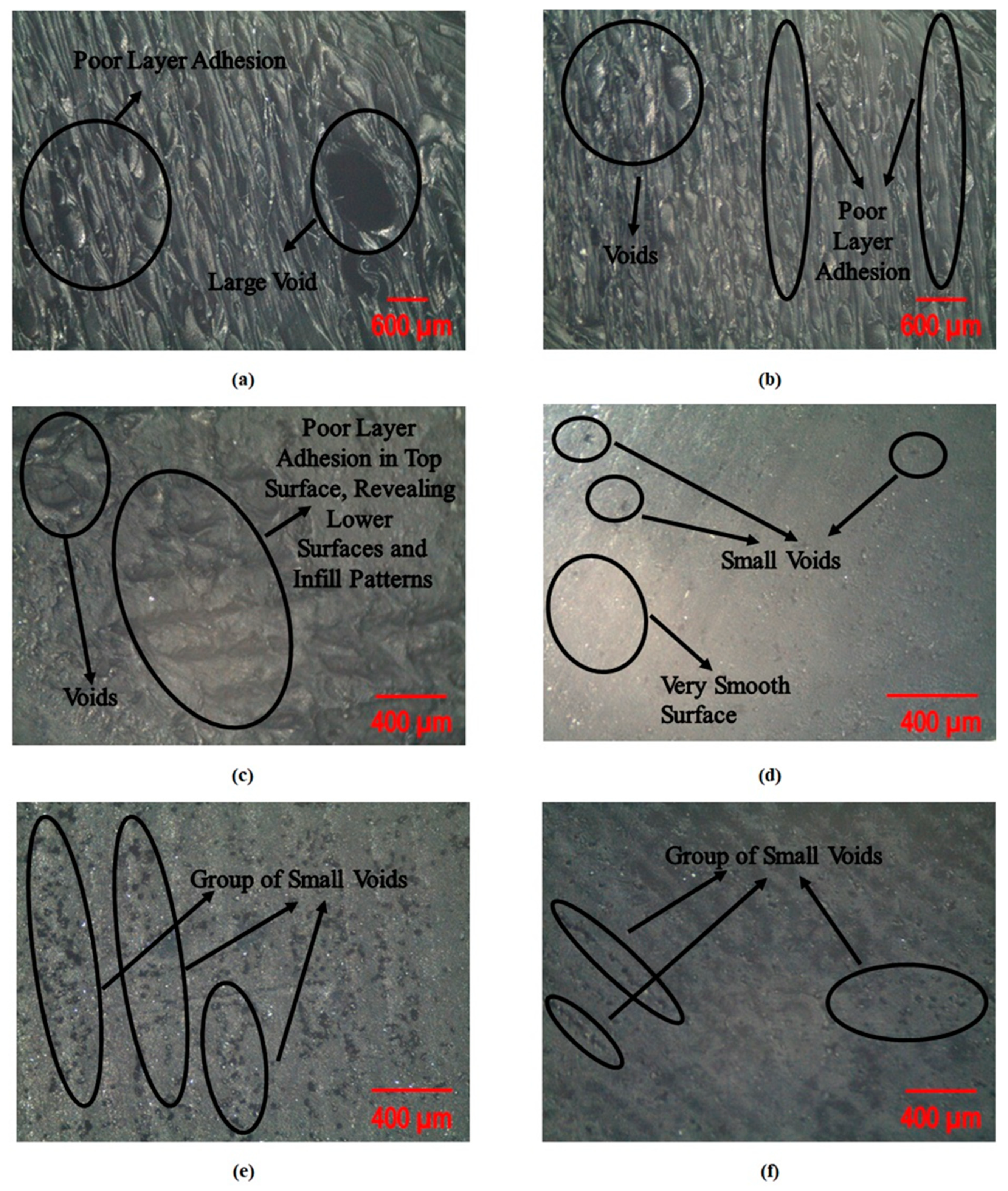

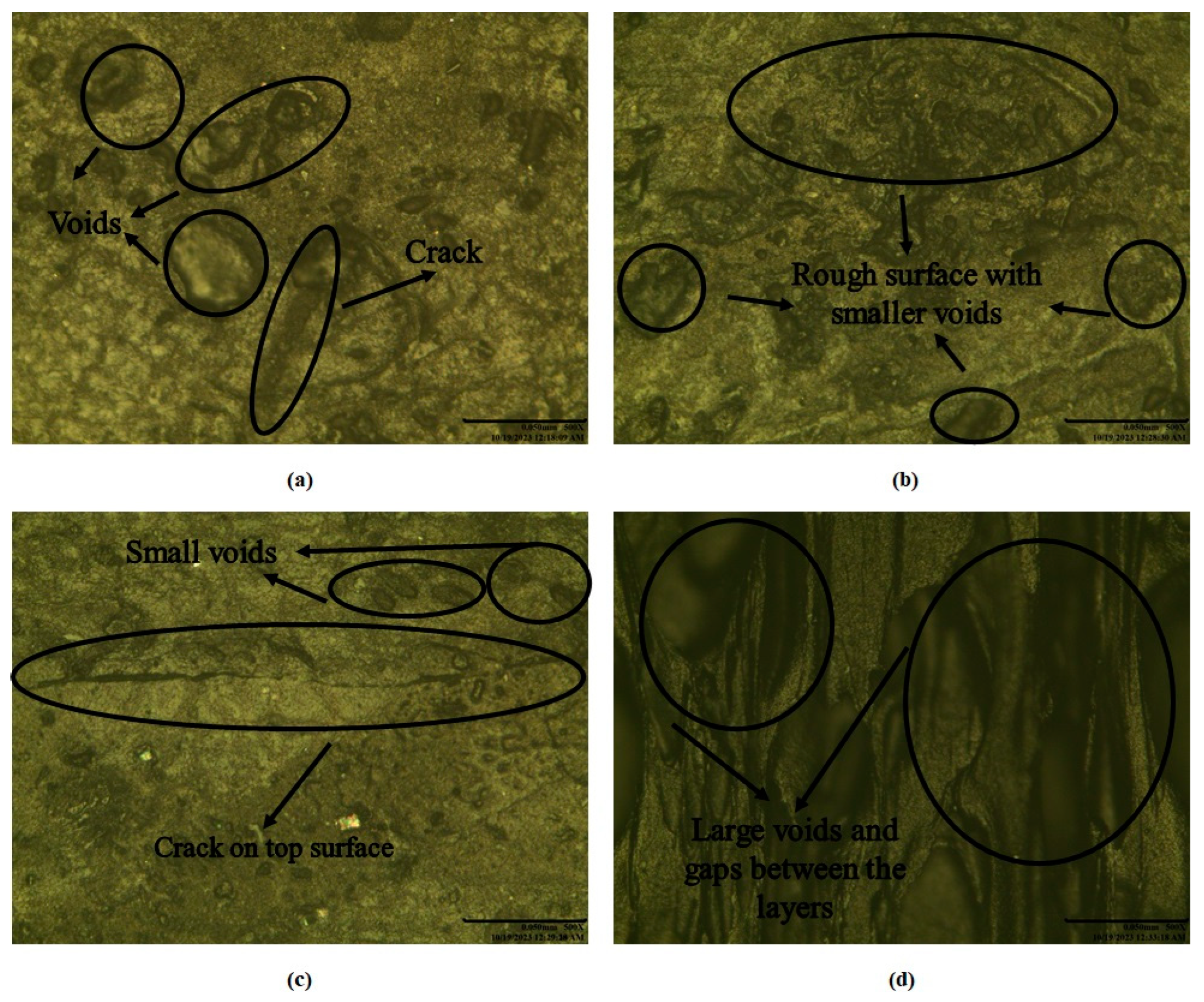

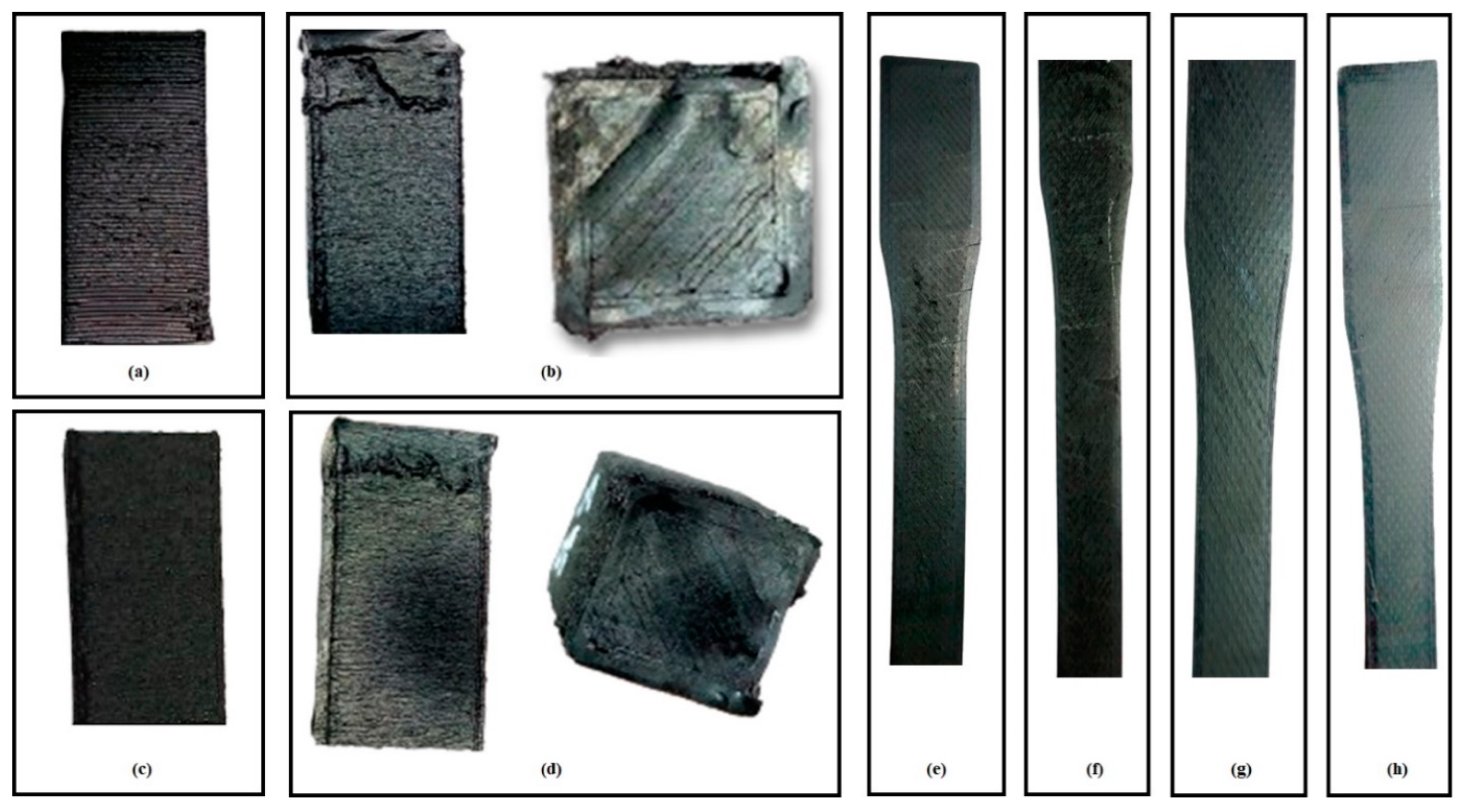

3.2. Microscopic and Visual Analysis

3.3. ANOVA Analysis

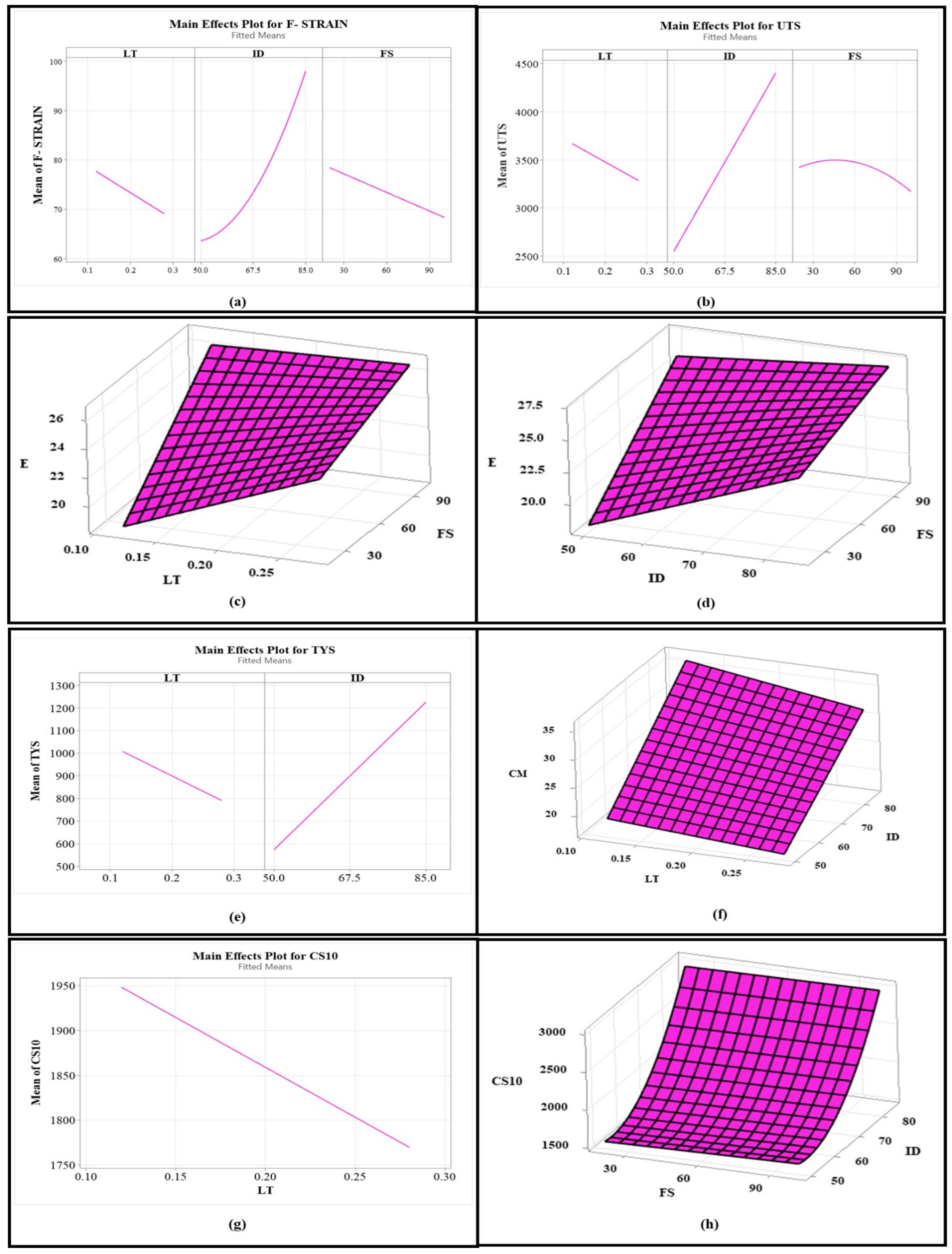

3.4. Effects of Process Parameters on Mechanical Properties

3.5. Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hassan, M.; Misra, M.; Taylor, G.W.; Mohanty, A.K. A review of AI for optimization of 3D printing of sustainable polymers and composites. Compos. Part C Open Access 2024, 15, 100513. [Google Scholar] [CrossRef]

- Khan, W.A.; Hassan, M.; Ahmed, I.; Xiao, M.; Faraz, M.I.; Li, K.; Khan, I.; Muhammad, R.; Wu, H.; Hussain, G. Insights into Flexural and Impact Properties of Polymer Based Materials Printed Through Fused Filament Fabrication: Progress in the Last Decade. Int. J. Light. Mater. Manuf. 2024, 7, 925–957. [Google Scholar] [CrossRef]

- Tariq, A.; Arif, Z.U.; Khalid, M.Y.; Hossain, M.; Rasool, P.I.; Umer, R.; Ramakrishna, S. Recent Advances in the Additive Manufacturing of Stimuli-Responsive Soft Polymers. Adv. Eng. Mater. 2023, 25, 2301074. [Google Scholar] [CrossRef]

- Khan, I.; Yaseen, M.; Ahmad, M.M.; Abas, M.; Shah, M.I.; Hussain, H.; Hira, F. Integrating resistance-based sensing into fused filament fabricated mechanical metamaterial structure. Prog. Addit. Manuf. 2025, 10, 465–474. [Google Scholar] [CrossRef]

- Marudhappan, R.; Chandrasekhar, U. Additive Manufacturing in India Aerospace Manufacturing and MRO Industry: Challenges and Opportunities. J. Inst. Eng. Ser. C 2022, 103, 1013–1030. [Google Scholar] [CrossRef]

- Ali, S.; Deiab, I.; Pervaiz, S. State-of-the-art review on fused deposition modeling (FDM) for 3D printing of polymer blends and composites: Innovations, challenges, and applications. Int. J. Adv. Manuf. Technol. 2024, 135, 5085–5113. [Google Scholar] [CrossRef]

- Fenollosa, F.; Gomà, J.R.; Buj-Corral, I.; Otero, A.T.; Minguella-Canela, J.; Uceda, R.; Valls, A.; Ayats, M. Foreseeing new multi-material FFF-Additive Manufacturing concepts meeting mimicking requirements with living tissues. Procedia Manuf. 2019, 41, 1063–1070. [Google Scholar] [CrossRef]

- Khan, A.S.; Ali, A.; Hussain, G.; Ilyas, M. An experimental study on interfacial fracture toughness of 3-D printed ABS/CF-PLA composite under mode I, II, and mixed-mode loading. J. Thermoplast. Compos. Mater. 2021, 34, 1599–1622. [Google Scholar] [CrossRef]

- Ali, S.; Mehra, V.; Eltaggaz, A.; Deiab, I.; Pervaiz, S. Optimization and prediction of additively manufactured PLA-PHA biodegradable polymer blend using TOPSIS and GA-ANN. Manuf. Lett. 2024, 41, 795–802. [Google Scholar] [CrossRef]

- Ali, S.; Nouzil, I.; Mehra, V.; Eltaggaz, A.; Deiab, I.; Pervaiz, S. Integrated optimization scheme for 3D printing of PLA-APHA biodegradable blends. Prog. Addit. Manuf. 2025, 10, 875–886. [Google Scholar] [CrossRef]

- Dey, A.; Eagle, I.N.R.; Yodo, N. A review on filament materials for fused filament fabrication. J. Manuf. Mater. Process. 2021, 5, 69. [Google Scholar] [CrossRef]

- Luo, X.; Cheng, H.; Wu, X. Nanomaterials Reinforced Polymer Filament for Fused Deposition Modeling: A State-of-the-Art Review. Polymers 2023, 15, 2980. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, H.; Hussain, G.; Gohar, S.; Ali, A.; Alkahtani, M. Impact toughness of hybrid carbon fiber-PLA/ABS laminar composite produced through fused filament fabrication. Polymers 2021, 13, 3057. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Zhuo, P.; Li, S.; Ashcroft, I.A.; Jones, A.I. Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: A review and outlook. Compos. Part B Eng. 2021, 224, 109143. [Google Scholar] [CrossRef]

- Khan, I.; Farooq, U.; Tariq, M.; Abas, M.; Ahmad, S.; Shakeel, M.; Riaz, A.A.; Hira, F. Investigation of effects of processing parameters on the impact strength and microstructure of thick tri-material based layered composite fabricated via extrusion based additive manufacturing. J. Eng. Res. 2024. [Google Scholar] [CrossRef]

- Pratama, J.; Cahyono, S.I.; Suyitno, S.; Muflikhun, M.A.; Salim, U.A.; Mahardika, M.; Arifvianto, B. A review on reinforcement methods for polymeric materials processed using fused filament fabrication (Fff). Polymers 2021, 13, 4022. [Google Scholar] [CrossRef]

- Yousaf, A.; Al Rashid, A.; Koç, M. 3D printing of alkali-activated geopolymers for sustainable and circular economy advancements. Circ. Econ. 2024, 3, 100101. [Google Scholar] [CrossRef]

- Yousaf, A.; Al Rashid, A.; Koç, M. Parameter tuning for sustainable 3D Printing(3DP) of clay structures. J. Eng. Res. 2024. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Tang, F.; Shen, C. PLA-Based Composite Panels Prepared via Multi-Material Fused Filament Fabrication and Associated Investigation of Process Parameters on Flexural Properties of the Fabricated Composite. Polymers 2024, 16, 109. [Google Scholar] [CrossRef]

- Ghabezi, P.; Sam-Daliri, O.; Flanagan, T.; Walls, M.; Harrison, N.M. Upcycling waste polypropylene with basalt fibre reinforcement enhancing additive manufacturing feedstock for advanced mechanical performance. Appl. Mater. Today 2024, 41, 102486. [Google Scholar] [CrossRef]

- Ghabezi, P.; Sam-Daliri, O.; Flanagan, T.; Walls, M.; Harrison, N.M. Circular economy innovation: A deep investigation on 3D printing of industrial waste polypropylene and carbon fibre composites. Resour. Conserv. Recycl. 2024, 206, 107667. [Google Scholar] [CrossRef]

- Hassan, M.; Mohanty, A.K.; Misra, M. 3D printing in upcycling plastic and biomass waste to sustainable polymer blends and composites: A review. Mater. Des. 2024, 237, 112558. [Google Scholar] [CrossRef]

- Kim, K.; Park, J.; Suh, J.H.; Kim, M.; Jeong, Y.; Park, I. 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments. Sens. Actuators A Phys. 2017, 263, 493–500. [Google Scholar] [CrossRef]

- Rasheed, A.; Hussain, M.; Ullah, S.; Ahmad, Z.; Kakakhail, H.; Riaz, A.A.; Khan, I.; Ahmad, S.; Akram, W.; Eldin, S.M.; et al. Experimental investigation and Taguchi optimization of FDM process parameters for the enhancement of tensile properties of Bi-layered printed PLA-ABS. Mater. Res. Express 2023, 10, 095307. [Google Scholar] [CrossRef]

- Hu, Q.; Duan, Y.; Zhang, H.; Liu, D.; Yan, B.; Peng, F. Manufacturing and 3D printing of continuous carbon fiber prepreg filament. J. Mater. Sci. 2018, 53, 1887–1898. [Google Scholar] [CrossRef]

- Johnson, L.; Samms, J. Thermoplastic polyurethane technologies for the textile industry. J. Ind. Text. 1997, 27, 48–62. [Google Scholar] [CrossRef]

- Przybytek, A.; Kucińska-Lipka, J.; Janik, H. Thermoplastic elastomer filaments and their application in 3D printing. Elastomery 2016, 20, 32–39. [Google Scholar]

- Kim, N.P. 3D-Printed Conductive Carbon-Infused Thermoplastic Polyurethane. Polymers 2020, 12, 1224. [Google Scholar] [CrossRef]

- Pejak Simunec, D.; Sola, A. Emerging Research in Conductive Materials for Fused Filament Fabrication: A Critical Review. Adv. Eng. Mater. 2022, 24, 2101476. [Google Scholar] [CrossRef]

- Levesque, J.; Chamberland, F.; Gosselin, B. 3D Printed Graphite Based Flexible Thermoplastic Polyurethane Electromyography Electrode. In Proceedings of the 21st IEEE Interregional NEWCAS Conference, NEWCAS 2023-Proceedings, Edinburgh, Scotland, 26–28 June 2023. [Google Scholar] [CrossRef]

- Miyama, K.; Hasegawa, S.; Kawaharazuka, K.; Yamaguchi, N.; Okada, K.; Inaba, M. Design of a Five-Fingered Hand with Full-Fingered Tactile Sensors Using Conductive Filaments and Its Application to Bending after Insertion Motion. In Proceedings of the IEEE-RAS International Conference on Humanoid Robots, Ginowan, Japan, 28–30 November 2022. [Google Scholar] [CrossRef]

- Affortunati, S.; Zagar, B. Tomographic Artificial Skin for Robotic Application. In Proceedings of the 2022 17th International Conference on Control, Automation, Robotics and Vision, ICARCV 2022, Singapore, 11–13 December 2022. [Google Scholar] [CrossRef]

- Riley, K.S.; Arrieta, A.F. Flexible Mechanical Sensors with Time-Dependent, Viscoelastic Responses. In Proceedings of the FLEPS 2023-IEEE International Conference on Flexible and Printable Sensors and Systems, Proceedings, Boston, MA, USA, 9–12 July 2023. [Google Scholar] [CrossRef]

- Aloqalaa, Z. Electrically Conductive Fused Deposition Modeling Filaments: Current Status and Medical Applications. Crystals 2022, 12, 1055. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, A.; Wegener, K. Materials perspective of polymers for additive manufacturing with selective laser sintering. J. Mater. Res. 2014, 29, 1824–1832. [Google Scholar] [CrossRef]

- Gonçalves, J.; Lima, P.; Krause, B.; Pötschke, P.; Lafont, U.; Gomes, J.R.; Abreu, C.S.; Paiva, M.C.; Covas, J.A. Electrically conductive polyetheretherketone nanocomposite filaments: From production to fused deposition modeling. Polymers 2018, 10, 925. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, S.; Zhang, K.; Wu, J.; Li, A.; Liu, J.; Yang, D. 3D printing of continuous carbon fibre reinforced polymer composites with optimised structural topology and fibre orientation. Compos. Struct. 2023, 313, 116914. [Google Scholar] [CrossRef]

- El Essawi, B.; Abdallah, S.; Ali, S.; Nassir Abdo Mohammed, A.; Susantyoko, R.A.; Pervaiz, S. Optimization of infill density, fiber angle, carbon fiber layer position in 3D printed continuous carbon-fiber reinforced nylon composite. Results Eng. 2024, 21, 101926. [Google Scholar] [CrossRef]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef]

- Conductive Filaflex TPU Filament Electrically Conductive. Available online: https://recreus.com/gb/filaments/3-21-filaflex-conductivo.html#/1-colour-black/2-diameter-175_mm/3-weight-500_gr (accessed on 1 January 2023).

- D638 Standard Test Method for Tensile Properties of Plastics. Available online: https://www.astm.org/d0638-22.html (accessed on 15 January 2025).

- D695 Standard Test Method for Compressive Properties of Rigid Plastics. Available online: https://www.astm.org/d0695-23.html?utm_source=chatgpt.com (accessed on 15 January 2025).

| Parameter | Short Form | Unit | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|---|

| Infill density | ID | % | 50 | 67.5 | 85 |

| Fan speed | FS | % | 20 | 60 | 100 |

| Layer thickness | LT | mm | 0.12 | 0.2 | 0.28 |

| EXP. # | LT | ID | FS | EXP. # | LT | ID | FS |

|---|---|---|---|---|---|---|---|

| 1 | 0.12 | 50 | 60 | 8 | 0.28 | 67.5 | 100 |

| 2 | 0.28 | 50 | 60 | 9 | 0.2 | 50 | 20 |

| 3 | 0.12 | 85 | 60 | 10 | 0.2 | 85 | 20 |

| 4 | 0.28 | 85 | 60 | 11 | 0.2 | 50 | 100 |

| 5 | 0.12 | 67.5 | 20 | 12 | 0.2 | 85 | 100 |

| 6 | 0.28 | 67.5 | 20 | 13 | 0.2 | 67.5 | 60 |

| 7 | 0.12 | 67.5 | 100 | - | |||

| EXP. # | TYS (KPa) | UTS (KPa) | E (MPa) | F-STRAIN (%) | CM (MPa) | CS10 (KPa) |

|---|---|---|---|---|---|---|

| 1 | 691.1 | 2634.2 | 19.2 | 67.9 | 19.41 | 1669 |

| 2 | 446.2 | 2337.5 | 22.9 | 58.7 | 17.11 | 1493 |

| 3 | 1437.9 | 4687.6 | 24.8 | 105.6 | 36.12 | 3058 |

| 4 | 1156.3 | 4259.4 | 26.7 | 86.7 | 31.38 | 2871 |

| 5 | 934.4 | 3616.8 | 18.7 | 75.3 | 27.87 | 1929 |

| 6 | 745.1 | 3274.7 | 23.7 | 73.5 | 23.99 | 1758 |

| 7 | 927.8 | 3367.8 | 26.1 | 73.9 | 27.58 | 1964 |

| 8 | 777.7 | 2898.0 | 26.4 | 69.4 | 24.85 | 1785 |

| 9 | 598.0 | 2529.7 | 18.9 | 70.9 | 18.47 | 1555 |

| 10 | 1163.7 | 4267.2 | 23.6 | 110.2 | 33.21 | 2951 |

| 11 | 637.0 | 2358.0 | 26.5 | 57.1 | 18.69 | 1609 |

| 12 | 1219.1 | 4062.3 | 26.7 | 89.3 | 33.03 | 2982 |

| 13 | 958.2 | 3468.7 | 24.5 | 74.9 | 26.09 | 1859 |

| Source | TYS | UTS | F-STRAIN | E | CM | CS10 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| Model | 121.22 | 0 | 276.51 | 0 | 26.08 | 0 | 0 | 32.16 | 1368.52 | 0 | 44,738.73 | 0 |

| LT | 24.13 | 0.001 | 44.13 | 0 | 5.37 | 0.049 | 22.72 | 0.002 | 201.02 | 0 | 3211.72 | 0 |

| ID | 218.32 | 0 | 1028.1 | 0 | 85.49 | 0 | 39.11 | 0 | 3891.69 | 0 | 193,620.1 | 0 |

| FS | - | - | 18.78 | 0.003 | 7.34 | 0.027 | 82.75 | 0 | - | - | 136.52 | 0 |

| FS*FS | - | - | 15.01 | 0.005 | - | - | - | - | - | - | - | - |

| LT*FS | - | - | - | - | - | - | 8.45 | 0.023 | - | - | - | - |

| LT*ID | - | - | - | - | - | - | - | - | 12.85 | 0.006 | - | - |

| ID*FS | - | - | - | - | - | - | 7.75 | 0.027 | - | - | 6.68 | 0.036 |

| ID*ID | - | - | - | - | 6.12 | 0.038 | - | - | - | - | 26,718.62 | 0 |

| Input Process Parameters | Predicted Output Responses | Composite Desirability | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LT | ID | FS | CM Fit | CS10 Fit | F-Strain Fit | UTS Fit | MoT Fit | YS Fit | E Fit | |

| 0.12 | 85 | 60 | 35.80 | 3054.62 | 102.25 | 4596.7 | 489.46 | 1333.24 | 24.1712 | 0.8881 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hira, F.; Asif, M.; Ullah, H.; Khan, I.; Hussain, G.; Amir, M.; Alkahtani, M. Effects of Process Parameters on the Mechanical Properties and Microstructure of Additively Manufactured Carbon Black Particles-Reinforced Thermoplastic Polyurethane Composite Samples. Polymers 2025, 17, 426. https://doi.org/10.3390/polym17030426

Hira F, Asif M, Ullah H, Khan I, Hussain G, Amir M, Alkahtani M. Effects of Process Parameters on the Mechanical Properties and Microstructure of Additively Manufactured Carbon Black Particles-Reinforced Thermoplastic Polyurethane Composite Samples. Polymers. 2025; 17(3):426. https://doi.org/10.3390/polym17030426

Chicago/Turabian StyleHira, Fatima, Muhammad Asif, Hammad Ullah, Imran Khan, Ghulam Hussain, Muhammad Amir, and Mohammed Alkahtani. 2025. "Effects of Process Parameters on the Mechanical Properties and Microstructure of Additively Manufactured Carbon Black Particles-Reinforced Thermoplastic Polyurethane Composite Samples" Polymers 17, no. 3: 426. https://doi.org/10.3390/polym17030426

APA StyleHira, F., Asif, M., Ullah, H., Khan, I., Hussain, G., Amir, M., & Alkahtani, M. (2025). Effects of Process Parameters on the Mechanical Properties and Microstructure of Additively Manufactured Carbon Black Particles-Reinforced Thermoplastic Polyurethane Composite Samples. Polymers, 17(3), 426. https://doi.org/10.3390/polym17030426