Tuning the Compatibilizer Content and Healing Temperature in Thermally Mendable Polyamide 6/Cyclic Olefin Copolymer Blends

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Characterization

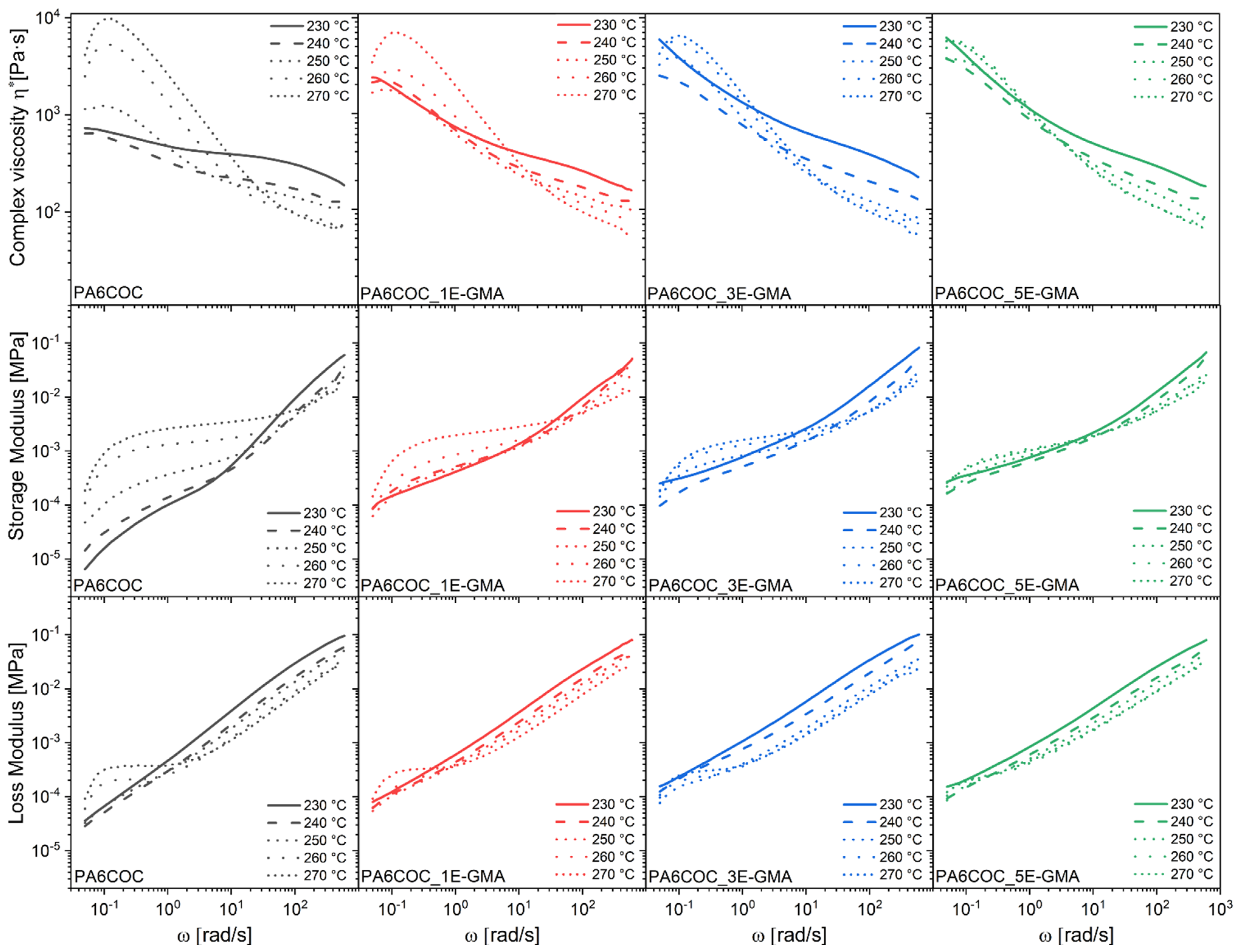

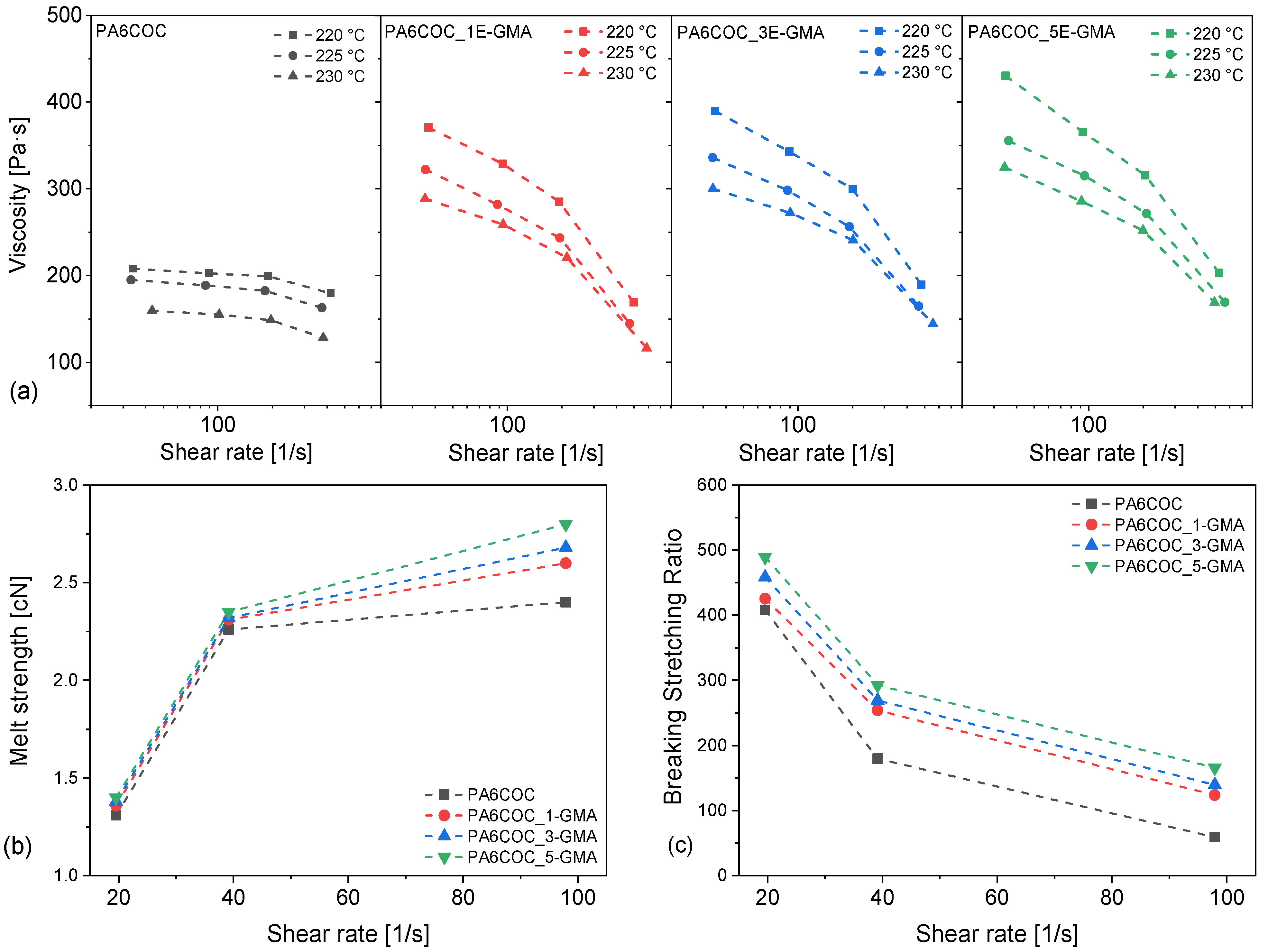

2.3.1. Rheological Properties

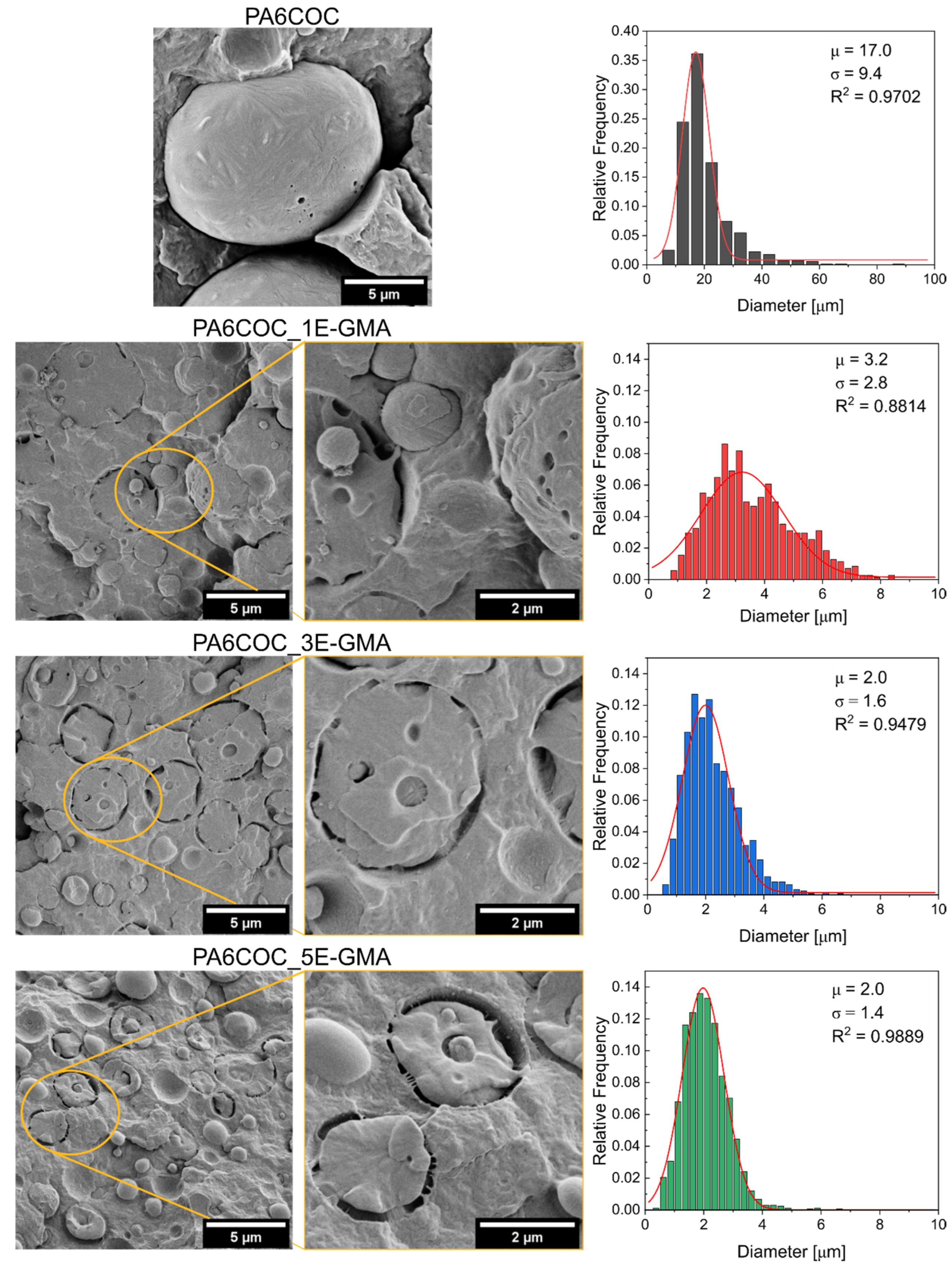

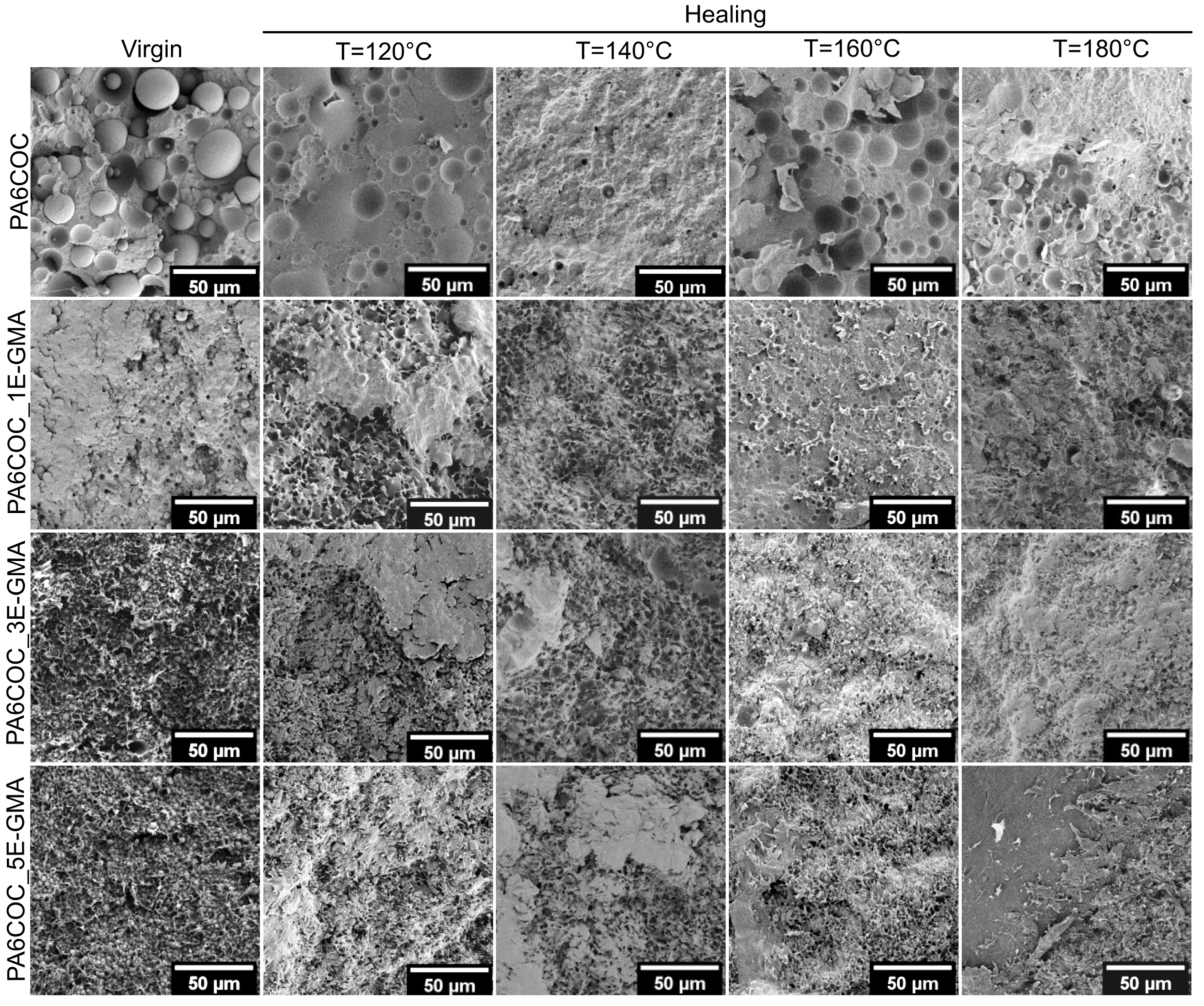

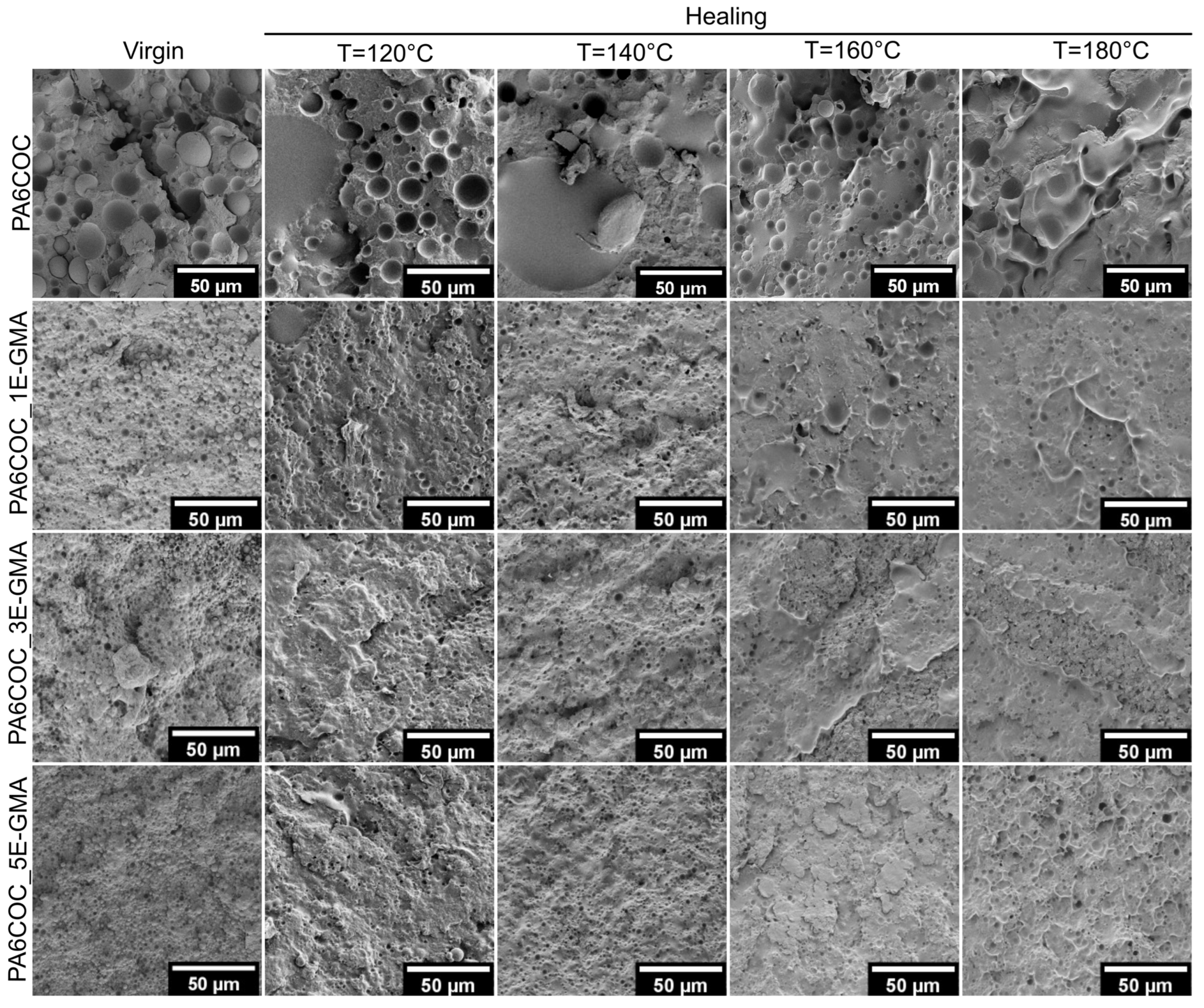

2.3.2. Microstructural and Chemical Properties

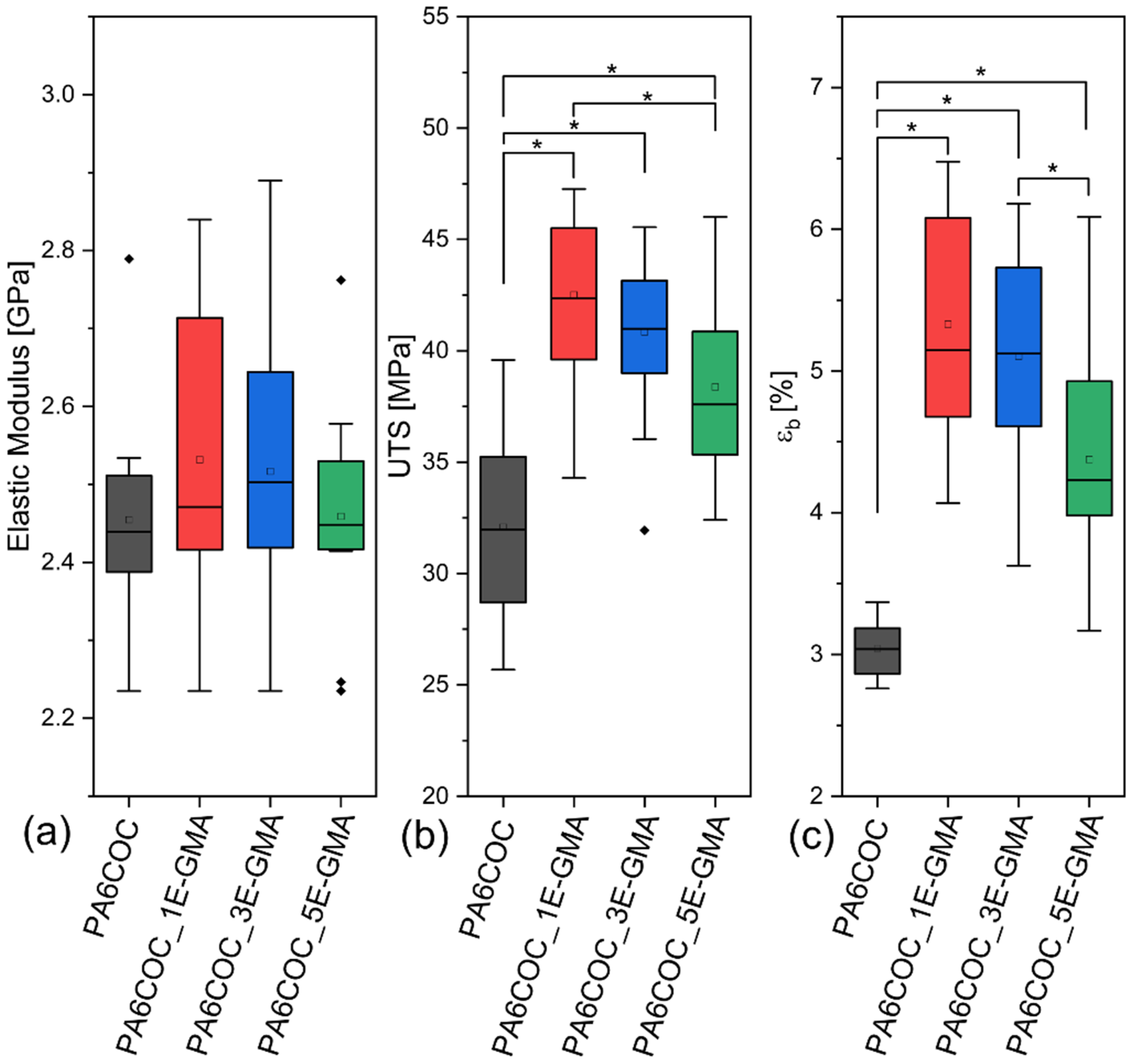

2.3.3. Mechanical Properties

2.3.4. Evaluation of the Healing Efficiency

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chung, D.D.L. A review of multifunctional polymer-matrix structural composites. Compos. Part B Eng. 2019, 160, 644–660. [Google Scholar] [CrossRef]

- González, C.; Vilatela, J.J.; Molina-Aldareguía, J.M.; Lopes, C.S.; Llorca, J. Structural composites for multifunctional applications: Current challenges and future trends. Prog. Mater. Sci. 2017, 89, 194–251. [Google Scholar] [CrossRef]

- May, D.; Goergen, C.; Friedrich, K. Multifunctionality of polymer composites based on recycled carbon fibers: A review. Adv. Ind. Eng. Polym. Res. 2021, 4, 70–81. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Periasamy, K.; Kandare, E.; Das, R.; Darouie, M.; Khatibi, A.A. Interfacial Engineering Methods in Thermoplastic Composites: An Overview. Polymers 2023, 15, 415. [Google Scholar] [CrossRef] [PubMed]

- Barroeta Robles, J.; Dubé, M.; Hubert, P.; Yousefpour, A. Repair of thermoplastic composites: An overview. Adv. Manuf. Polym. Compos. Sci. 2022, 8, 68–96. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Verdejo, R.; López-Manchado, M.A.; Hernández Santana, M. Evolution of self-healing elastomers, from extrinsic to combined intrinsic mechanisms: A review. Mater. Horiz. 2020, 7, 2882–2902. [Google Scholar] [CrossRef]

- Malekkhouyan, R.; Neisiany, R.E.; Khorasani, S.N.; Das, O.; Berto, F.; Ramakrishna, S. The influence of size and healing content on the performance of extrinsic self-healing coatings. J. Appl. Polym. Sci. 2021, 138, 49964. [Google Scholar] [CrossRef]

- Agrawal, N.; Arora, B. Self-Healing Polymers and Composites: Extrinsic Routes. Mini-Rev. Org. Chem. 2022, 19, 496–512. [Google Scholar] [CrossRef]

- Wang, J.; Tang, J.; Chen, D.; Xing, S.; Liu, X.; Hao, J. Intrinsic and extrinsic self-healing fiber-reinforced polymer composites: A review. Polym. Compos. 2023, 44, 6304–6323. [Google Scholar] [CrossRef]

- Ratwani, C.R.; Kamali, A.R.; Abdelkader, A.M. Self-healing by Diels-Alder cycloaddition in advanced functional polymers: A review. Prog. Mater. Sci. 2023, 131, 101001. [Google Scholar] [CrossRef]

- Khan, N.I.; Halder, S.; Gunjan, S.B.; Prasad, T. A review on Diels-Alder based self-healing polymer composites. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012007. [Google Scholar] [CrossRef]

- Ling, L.; Li, J.; Zhang, G.; Sun, R.; Wong, C.-P. Self-Healing and Shape Memory Linear Polyurethane Based on Disulfide Linkages with Excellent Mechanical Property. Macromol. Res. 2018, 26, 365–373. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Zhang, X. Strong, healable materials with bio-like ordered architectures and versatile functionality. SusMat 2024, 4, e248. [Google Scholar] [CrossRef]

- Hornat, C.C.; Urban, M.W. Shape memory effects in self-healing polymers. Prog. Polym. Sci. 2020, 102, 101208. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, S.; Liu, W.; Abbas, Y.; Wu, Z.; Eichen, Y.; Zhao, J. Thermally switchable polymers: From thermo-reversibly self-healing hybrid polymers to irreversibly crosslinked flame-retardant networks. Chem. Eng. J. 2021, 411, 128467. [Google Scholar] [CrossRef]

- Guerra, É.S.S.; Silva, B.L.; Melo, J.D.D.; Kalinka, G.; Barbosa, A.P.C. Microscale evaluation of epoxy matrix composites containing thermoplastic healing agent. Compos. Sci. Technol. 2023, 232, 109843. [Google Scholar] [CrossRef]

- Varley, R.J.; Craze, D.A.; Mouritz, A.P.; Wang, C.H. Thermoplastic Healing in Epoxy Networks: Exploring Performance and Mechanism of Alternative Healing Agents. Macromol. Mater. Eng. 2013, 298, 1232–1242. [Google Scholar] [CrossRef]

- Jones, A.R.; Watkins, C.A.; White, S.R.; Sottos, N.R. Self-healing thermoplastic-toughened epoxy. Polymer 2015, 74, 254–261. [Google Scholar] [CrossRef]

- Hayes, S.A.; Zhang, W.; Branthwaite, M.; Jones, F.R. Self-healing of damage in fibre-reinforced polymer-matrix composites. J. R. Soc. Interface 2007, 4, 381–387. [Google Scholar] [CrossRef]

- Yu, K.; Xin, A.; Feng, Z.; Lee, K.H.; Wang, Q. Mechanics of self-healing thermoplastic elastomers. J. Mech. Phys. Solids 2020, 137, 103831. [Google Scholar] [CrossRef]

- Fortelný, I.; Jůza, J. The Effects of Copolymer Compatibilizers on the Phase Structure Evolution in Polymer Blends—A Review. Materials 2021, 14, 7786. [Google Scholar] [CrossRef] [PubMed]

- Spontak, R.J.; Ryan, J.J. Chapter 3—Polymer blend compatibilization by the addition of block copolymers. In Compatibilization of Polymer Blends; Ajitha, A.R., Thomas, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 57–102. [Google Scholar]

- Nitiyah, K.K.; Musa, L.; Rasidi, M.S.M.; Rahim, S.Z.A.; Rahman, R.; Azmi, A.A.; Rennie, A. A review on graft compatibilizer for thermoplastic elastomer blend. J. Phys. Conf. Ser. 2021, 2080, 012003. [Google Scholar] [CrossRef]

- Aparna, S.; Purnima, D.; Adusumalli, R.B. Review on Various Compatibilizers and its Effect on Mechanical Properties of Compatibilized Nylon Blends. Polym. Plast. Technol. Eng. 2017, 56, 617–634. [Google Scholar] [CrossRef]

- Fredi, G.; Dorigato, A. Compatibilization of biopolymer blends: A review. Adv. Ind. Eng. Polym. Res. 2024, 7, 373–404. [Google Scholar] [CrossRef]

- Galloway, J.A.; Jeon, H.K.; Bell, J.R.; Macosko, C.W. Block copolymer compatibilization of cocontinuous polymer blends. Polymer 2005, 46, 183–191. [Google Scholar] [CrossRef]

- Tomić, N.Z.; Marinković, A.D. Chapter 4—Compatibilization of polymer blends by the addition of graft copolymers. In Compatibilization of Polymer Blends; Ajitha, A.R., Thomas, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 103–144. [Google Scholar]

- Hu, L.; Vuillaume, P.Y. Chapter 7—Reactive compatibilization of polymer blends by coupling agents and interchange catalysts. In Compatibilization of Polymer Blends; Ajitha, A.R., Thomas, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 205–248. [Google Scholar]

- Perin, D.; Odorizzi, G.; Dorigato, A.; Pegoretti, A. Development of Polyamide 6 (PA6)/Polycaprolactone (PCL) Thermoplastic Self-Healing Polymer Blends for Multifunctional Structural Composites. Appl. Sci. 2022, 12, 12357. [Google Scholar] [CrossRef]

- Perin, D.; Dorigato, A.; Pegoretti, A. Thermoplastic self-healing polymer blends for structural composites: Development of polyamide 6 and cyclic olefinic copolymer blends. J. Appl. Polym. Sci. 2023, 140, e53751. [Google Scholar] [CrossRef]

- Perin, D.; Dorigato, A.; Pegoretti, A. Compatibilization of Polyamide 6/Cyclic Olefinic Copolymer Blends for the Development of Multifunctional Thermoplastic Composites with Self-Healing Capability. Materials 2024, 17, 1880. [Google Scholar] [CrossRef]

- Sthle, L.; Wold, S. Analysis of variance (ANOVA). Chemom. Intell. Lab. Syst. 1989, 6, 259–272. [Google Scholar] [CrossRef]

- Kim, H.Y. Analysis of variance (ANOVA) comparing means of more than two groups. Restor. Dent. Endod. 2014, 39, 74–77. [Google Scholar] [CrossRef] [PubMed]

- Cohades, A.; Branfoot, C.; Rae, S.; Bond, I.; Michaud, V. Progress in Self-Healing Fiber-Reinforced Polymer Composites. Adv. Mater. Interfaces 2018, 5, 1800177. [Google Scholar] [CrossRef]

- Chiono, V.; Filippi, S.; Yordanov, H.; Minkova, L.; Magagnini, P. Reactive compatibilizer precursors for LDPE/PA6 blends. III: Ethylene–glycidylmethacrylate copolymer. Polymer 2003, 44, 2423–2432. [Google Scholar] [CrossRef]

- Radlmaier, V.; Heckel, C.; Winnacker, M.; Erber, A.; Koerber, H. Effects of thermal cycling on polyamides during processing. Thermochim. Acta 2017, 648, 44–51. [Google Scholar] [CrossRef]

- Li, H.; Huneault, M.A. Effect of chain extension on the properties of PLA/TPS blends. J. Appl. Polym. Sci. 2011, 122, 134–141. [Google Scholar] [CrossRef]

- Carrasco, F.; Cailloux, J.; Sánchez-Jiménez, P.E.; Maspoch, M.L. Improvement of the thermal stability of branched poly(lactic acid) obtained by reactive extrusion. Polym. Degrad. Stab. 2014, 104, 40–49. [Google Scholar] [CrossRef]

- Shin, B.Y.; Kim, J.H. Rheological and mechanical properties of polyamide 6 modified by electron-beam initiated mediation process. Radiat. Phys. Chem. 2015, 112, 88–96. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Ceraulo, M.; Mistretta, M.C.; Morreale, M. Rheological Behaviour, Mechanical Properties and Processability of Biodegradable Polymer Systems for Film Blowing. J. Polym. Environ. 2018, 26, 749–755. [Google Scholar] [CrossRef]

- Scaffaro, R.; La Mantia, F.P.; Canfora, L.; Polacco, G.; Filippi, S.; Magagnini, P. Reactive compatibilization of PA6/LDPE blends with an ethylene–acrylic acid copolymer and a low molar mass bis-oxazoline. Polymer 2003, 44, 6951–6957. [Google Scholar] [CrossRef]

- Filippi, S.; Chiono, V.; Polacco, G.; Paci, M.; Minkova, L.I.; Magagnini, P. Reactive compatibilizer precursors for LDPE/PA6 blends, 1: Ethylene/acrylic acid copolymers. Macromol. Chem. Phys. 2002, 203, 1512–1525. [Google Scholar] [CrossRef]

- Liang, J.-Z. Melt strength and drawability of HDPE, LDPE and HDPE/LDPE blends. Polym. Test. 2019, 73, 433–438. [Google Scholar] [CrossRef]

- Artykbaeva, E.; Ucpinar Durmaz, B.; Aksoy, P.; Aytac, A. Investigation of the properties of PA6/PA610 blends and glass fiber reinforced PA6/PA610 composites. Polym. Compos. 2022, 43, 7514–7525. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Zhang, H.D.; Yang, Y.L.; Vinckier, I.; Laun, H.M. Rheology and Morphology of Phase-Separating Polymer Blends. Macromolecules 2001, 34, 1416–1429. [Google Scholar] [CrossRef]

- Wei, Q.; Chionna, D.; Pracella, M. Reactive Compatibilization of PA6/LDPE Blends with Glycidyl Methacrylate Functionalized Polyolefins. Macromol. Chem. Phys. 2005, 206, 777–786. [Google Scholar] [CrossRef]

- Kossentini-Kallel, T.; Houichi, H. Reactive blending of PE-GMA/PA6 effect of composition and processing conditions. Polym. Adv. Technol. 2015, 26, 539–545. [Google Scholar] [CrossRef]

- Kotaka, T.; Watanabe, H. Entanglement in polymer blends: A manifestation of polymer effects. Die Makromol. Chem. 1985, 14, 179–199. [Google Scholar] [CrossRef]

- Minkova, L.; Yordanov, H.; Filippi, S.; Grizzuti, N. Interfacial tension of compatibilized blends of LDPE and PA6: The breaking thread method. Polymer 2003, 44, 7925–7932. [Google Scholar] [CrossRef]

- Chiou, K.-C.; Chang, F.-C.; Mai, Y.-W. Fracture Toughness Characterizations of Compatibilized Polyamide-6 (PA6)/Poly(phenylene ether) (PPE) Blends. J. Polym. Res. 2001, 8, 17–26. [Google Scholar] [CrossRef]

- Bahrami, R.; Löbling, T.I.; Schmalz, H.; Müller, A.H.E.; Altstädt, V. Micromechanics of “raspberry” morphology in PPE/SAN polymer blends compatibilized with linear ABC triblock terpolymers. Polymer 2015, 80, 52–63. [Google Scholar] [CrossRef]

| Sample | PA6 Content [wt%] | COC Content [wt%] | E-GMA Content [wt%] |

|---|---|---|---|

| PA6COC | 70.0 | 30.0 | 0.0 |

| PA6COC_1E-GMA | 69.3 | 29.7 | 1.0 |

| PA6COC_3E-GMA | 67.9 | 29.1 | 3.0 |

| PA6COC_5E-GMA | 66.5 | 28.5 | 5.0 |

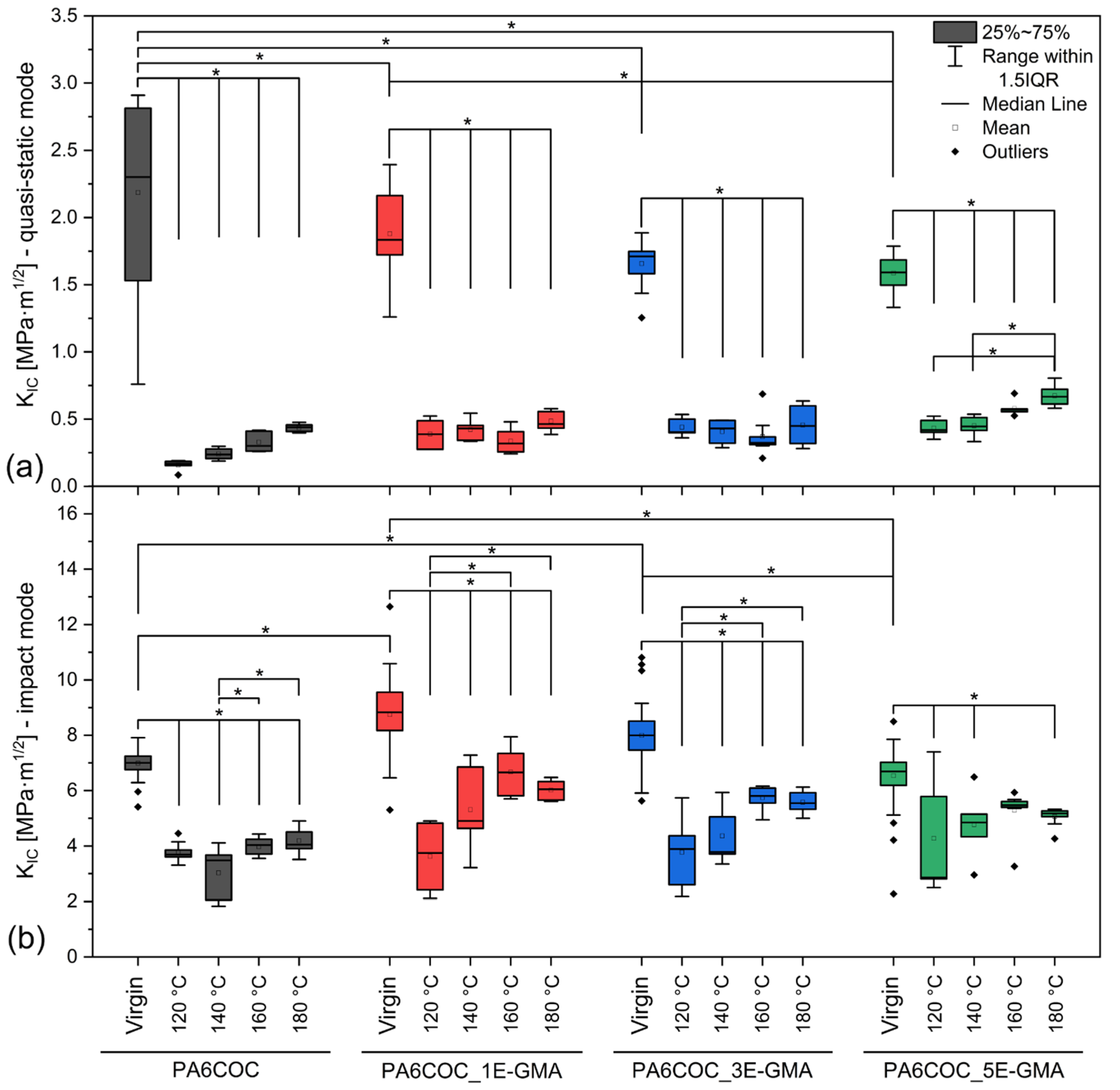

| Quasi-Static Mode | ||||

|---|---|---|---|---|

| Sample/T healing (°C) | 120 | 140 | 160 | 180 |

| PA6COC | 8 ± 3 | 10 ± 3 | 12 ± 3 | 17 ± 2 |

| PA6COC_1E-GMA | 17 ± 5 | 19 ± 3 | 20 ± 4 | 30 ± 7 |

| PA6COC_3E-GMA | 25 ± 4 | 24 ± 5 | 23 ± 7 | 29 ± 8 |

| PA6COC_5E-GMA | 27 ± 4 | 28 ± 4 | 38 ± 3 | 41 ± 4 |

| Impact mode | ||||

| Sample/T healing (°C) | 120 | 140 | 160 | 180 |

| PA6COC | 46 ± 7 | 45 ± 9 | 57 ± 5 | 58 ± 6 |

| PA6COC_1E-GMA | 48 ± 12 | 54 ± 9 | 75 ± 3 | 69 ± 3 |

| PA6COC_3E-GMA | 54 ± 17 | 50 ± 14 | 73 ± 5 | 70 ± 1 |

| PA6COC_5E-GMA | 67 ± 22 | 74 ± 16 | 82 ± 4 | 74 ± 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perin, D.; Botta, L.; Rigotti, D.; Dorigato, A.; Fredi, G.; Pegoretti, A. Tuning the Compatibilizer Content and Healing Temperature in Thermally Mendable Polyamide 6/Cyclic Olefin Copolymer Blends. Polymers 2025, 17, 280. https://doi.org/10.3390/polym17030280

Perin D, Botta L, Rigotti D, Dorigato A, Fredi G, Pegoretti A. Tuning the Compatibilizer Content and Healing Temperature in Thermally Mendable Polyamide 6/Cyclic Olefin Copolymer Blends. Polymers. 2025; 17(3):280. https://doi.org/10.3390/polym17030280

Chicago/Turabian StylePerin, Davide, Luigi Botta, Daniele Rigotti, Andrea Dorigato, Giulia Fredi, and Alessandro Pegoretti. 2025. "Tuning the Compatibilizer Content and Healing Temperature in Thermally Mendable Polyamide 6/Cyclic Olefin Copolymer Blends" Polymers 17, no. 3: 280. https://doi.org/10.3390/polym17030280

APA StylePerin, D., Botta, L., Rigotti, D., Dorigato, A., Fredi, G., & Pegoretti, A. (2025). Tuning the Compatibilizer Content and Healing Temperature in Thermally Mendable Polyamide 6/Cyclic Olefin Copolymer Blends. Polymers, 17(3), 280. https://doi.org/10.3390/polym17030280