Improvement in the Damping Behavior of Hierarchical Carbon Fiber-Reinforced Plastic for Park Golf Club Faces

Abstract

1. Introduction

2. Materials and Methods

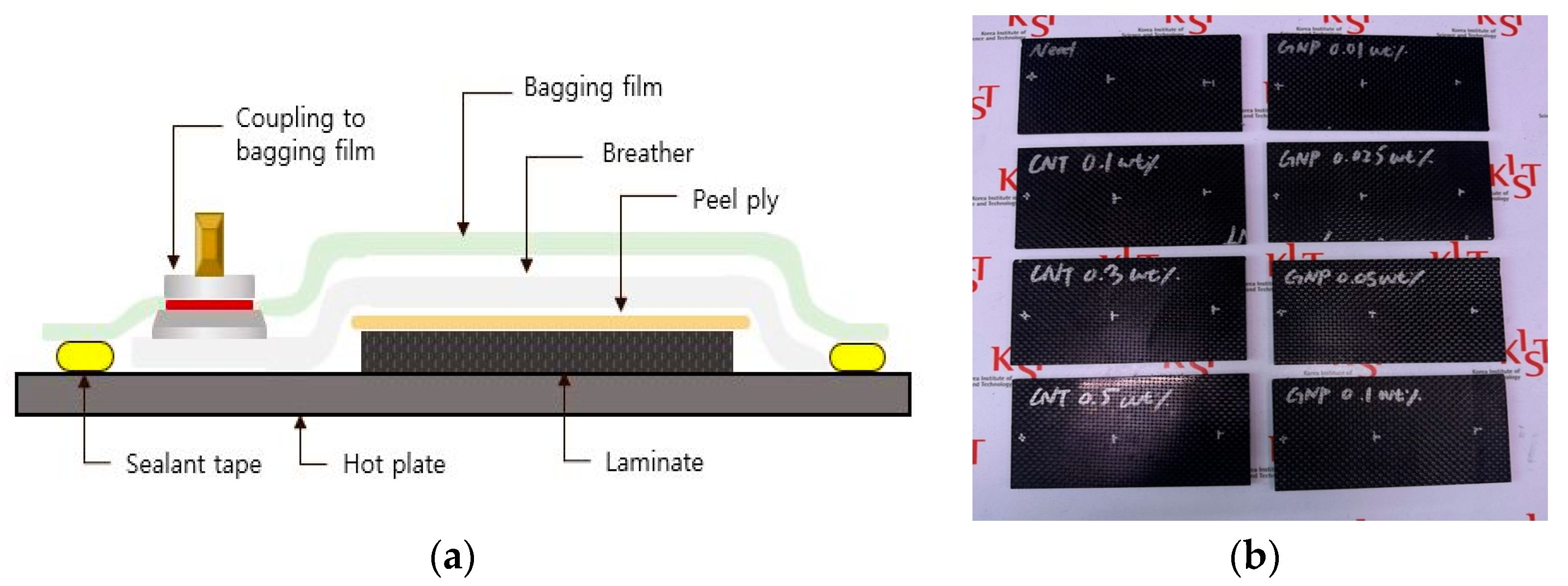

2.1. Material and Specimen Preparation

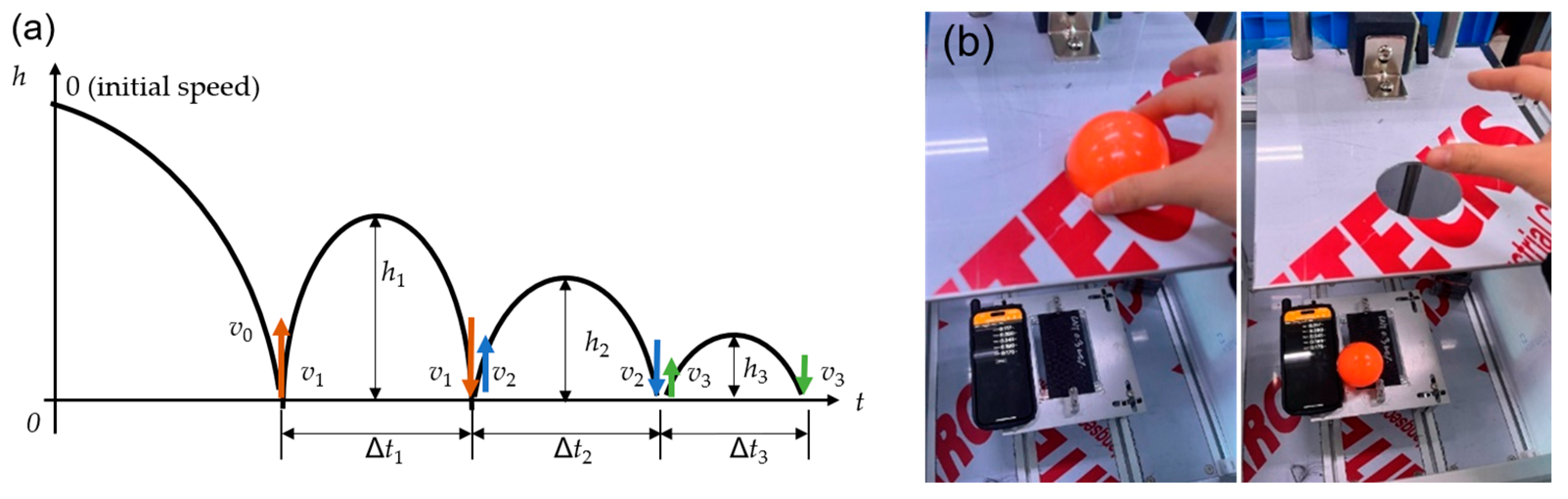

2.2. Measurement of Coefficient of Restitution (COR)

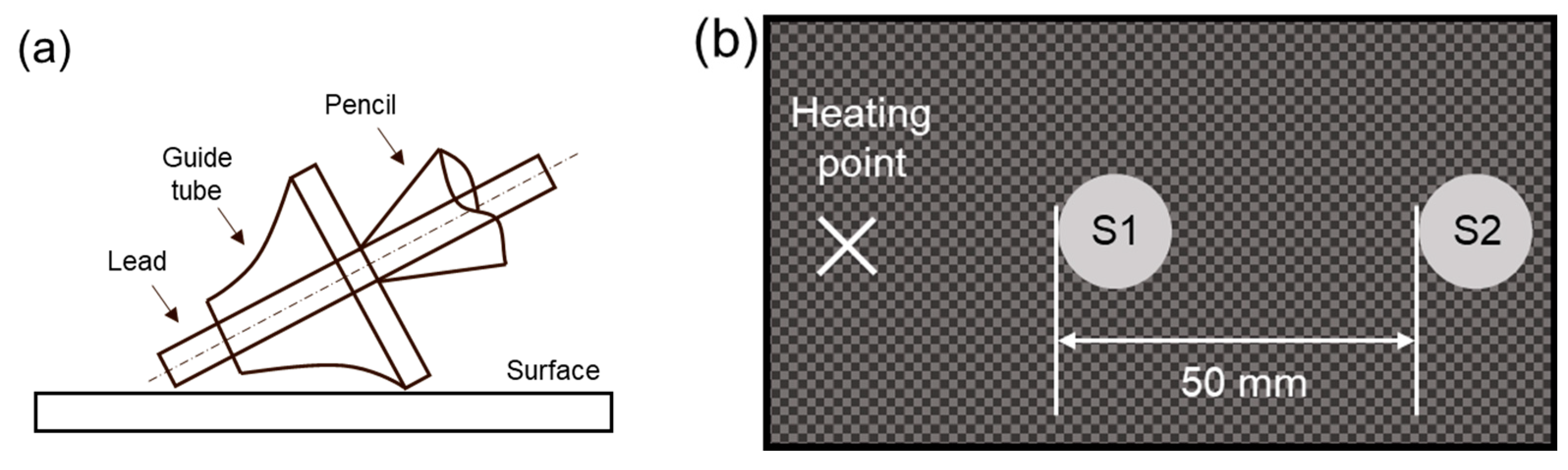

2.3. Vibration Damping

2.4. Mechanical Testing and User-Based Performance Evaluation

3. Results and Discussion

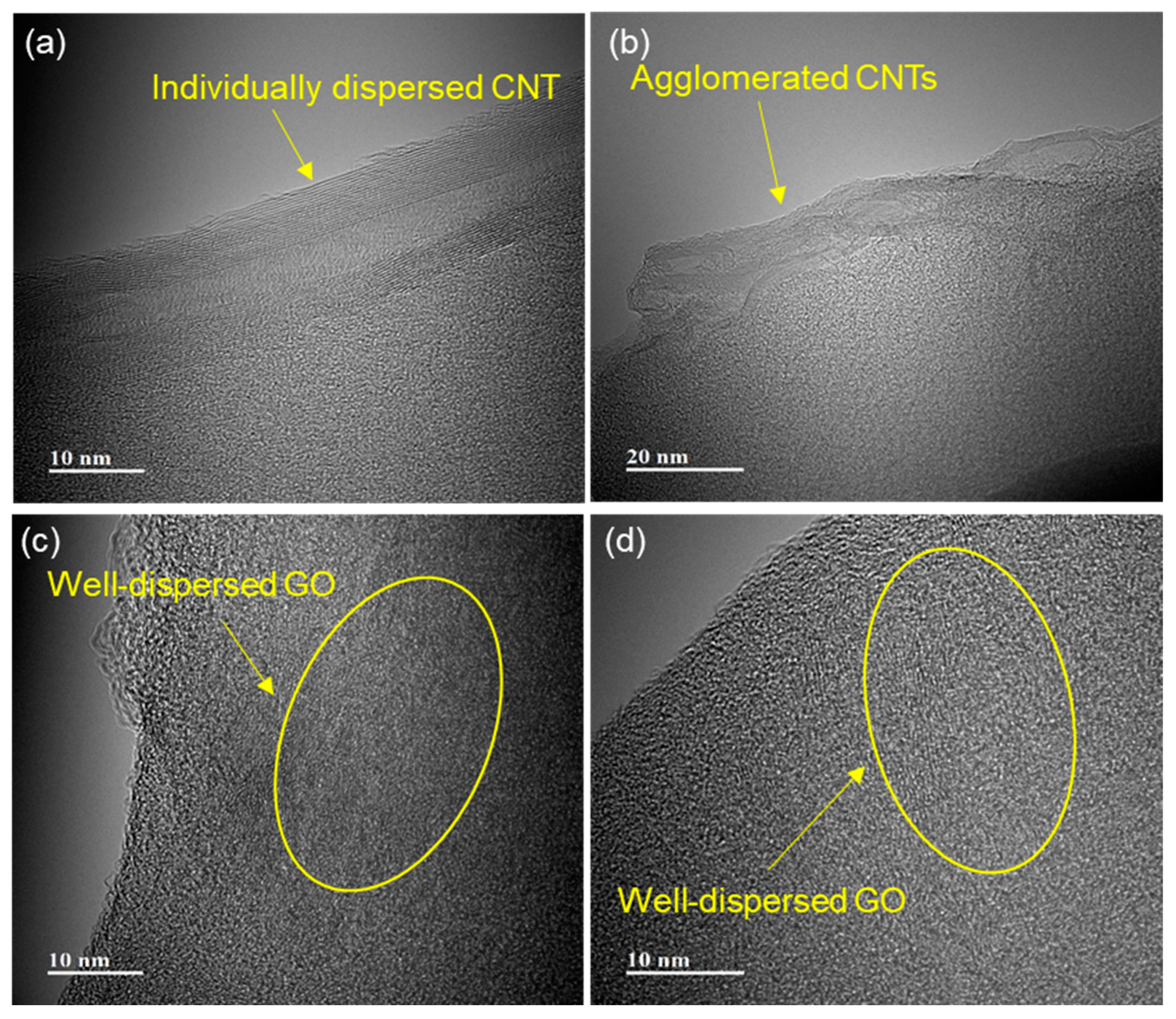

3.1. Morphological Analysis of Nanofiller Dispersion in CFRPs

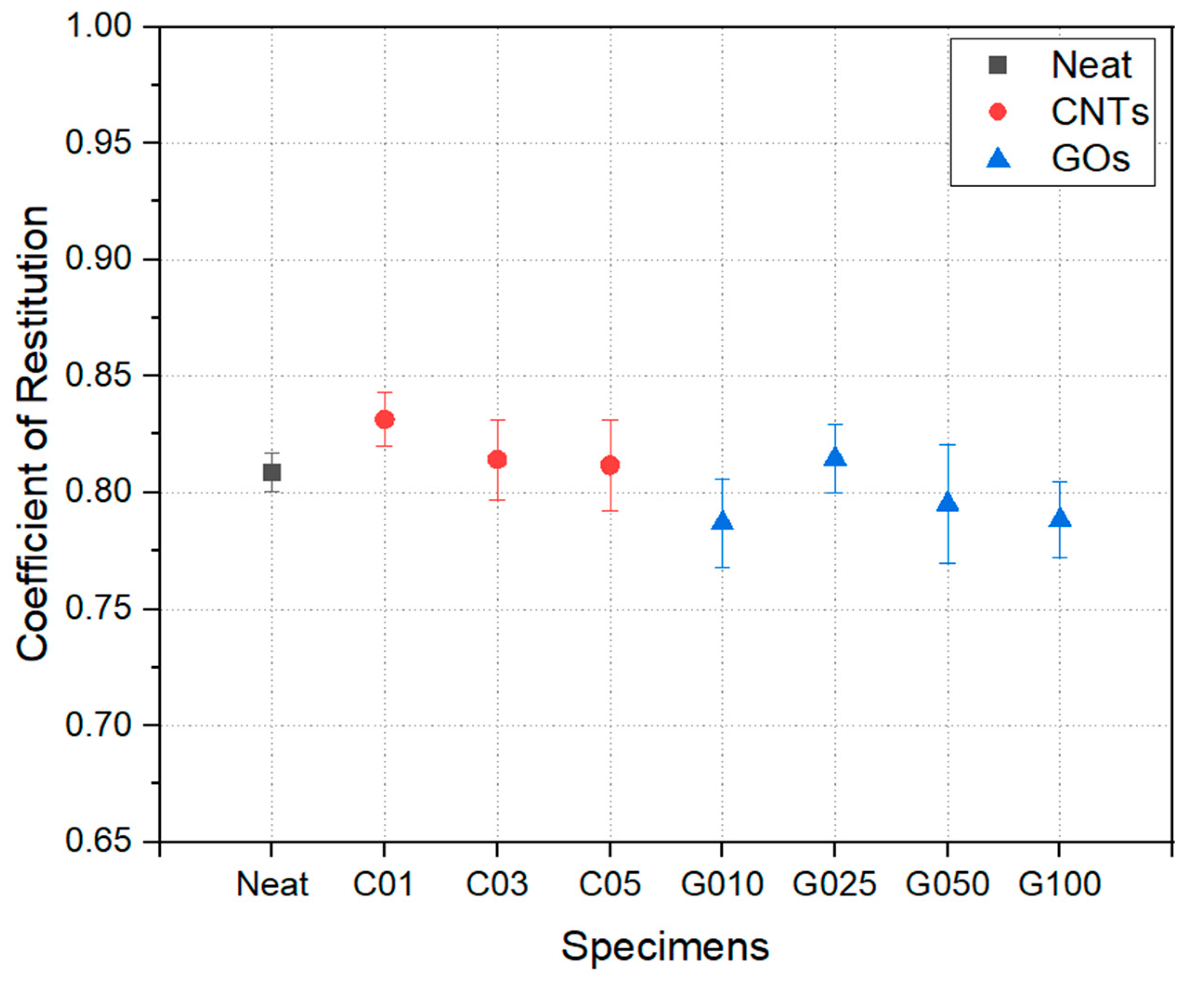

3.2. Rebound Test (Coefficient of Restitution)

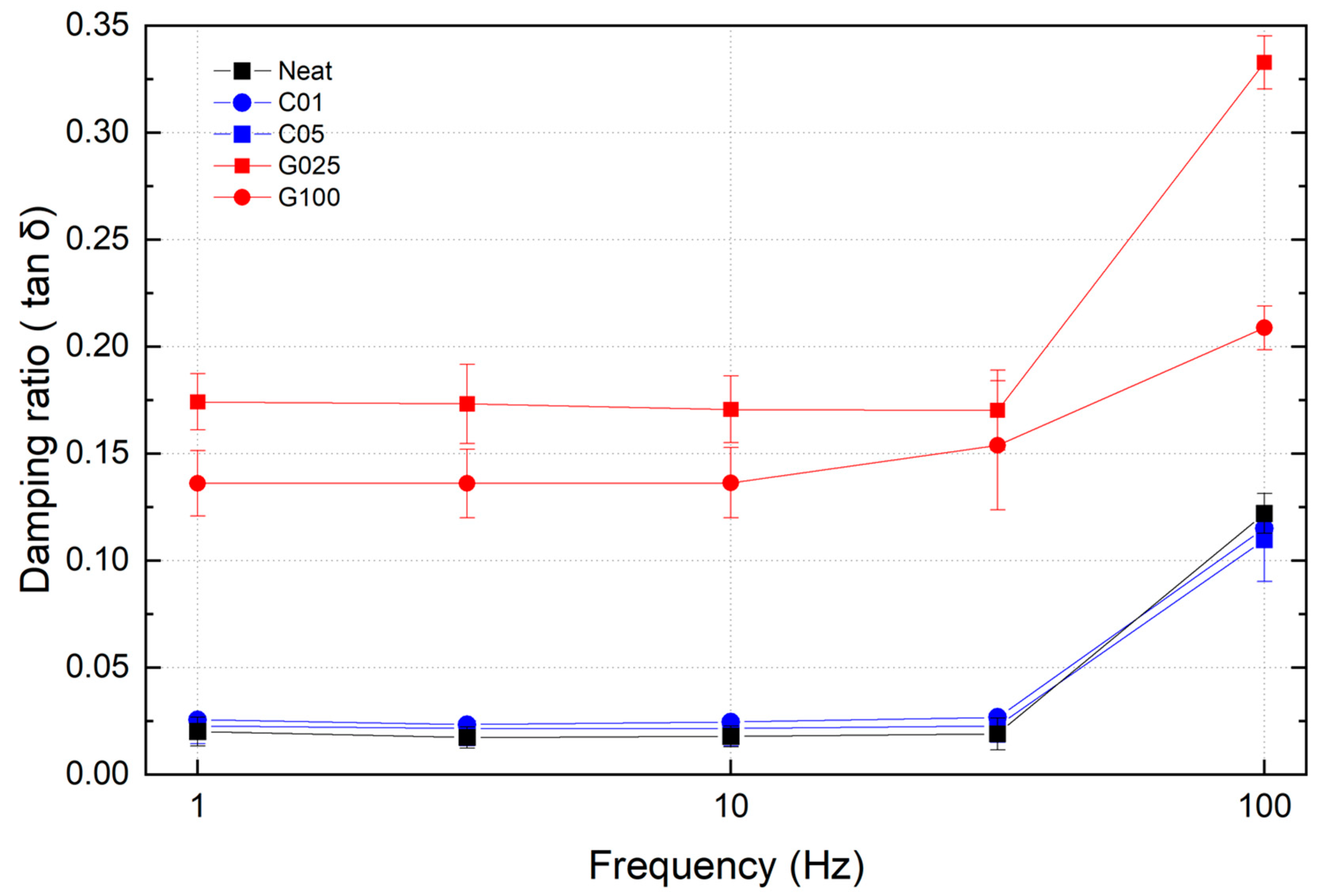

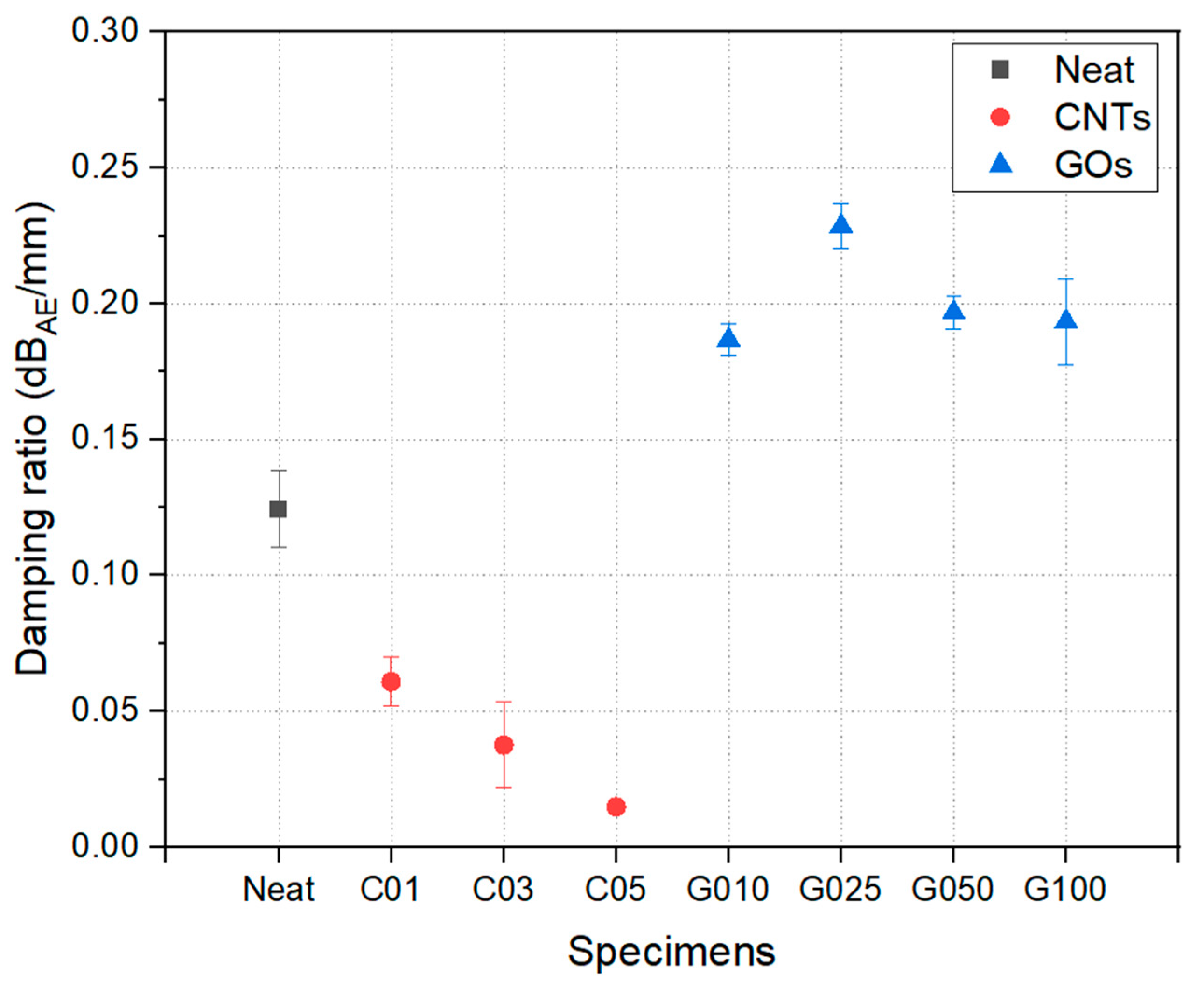

3.3. Enhanced Vibration Damping in CFRP: Effects of CNT and GO Nanofillers

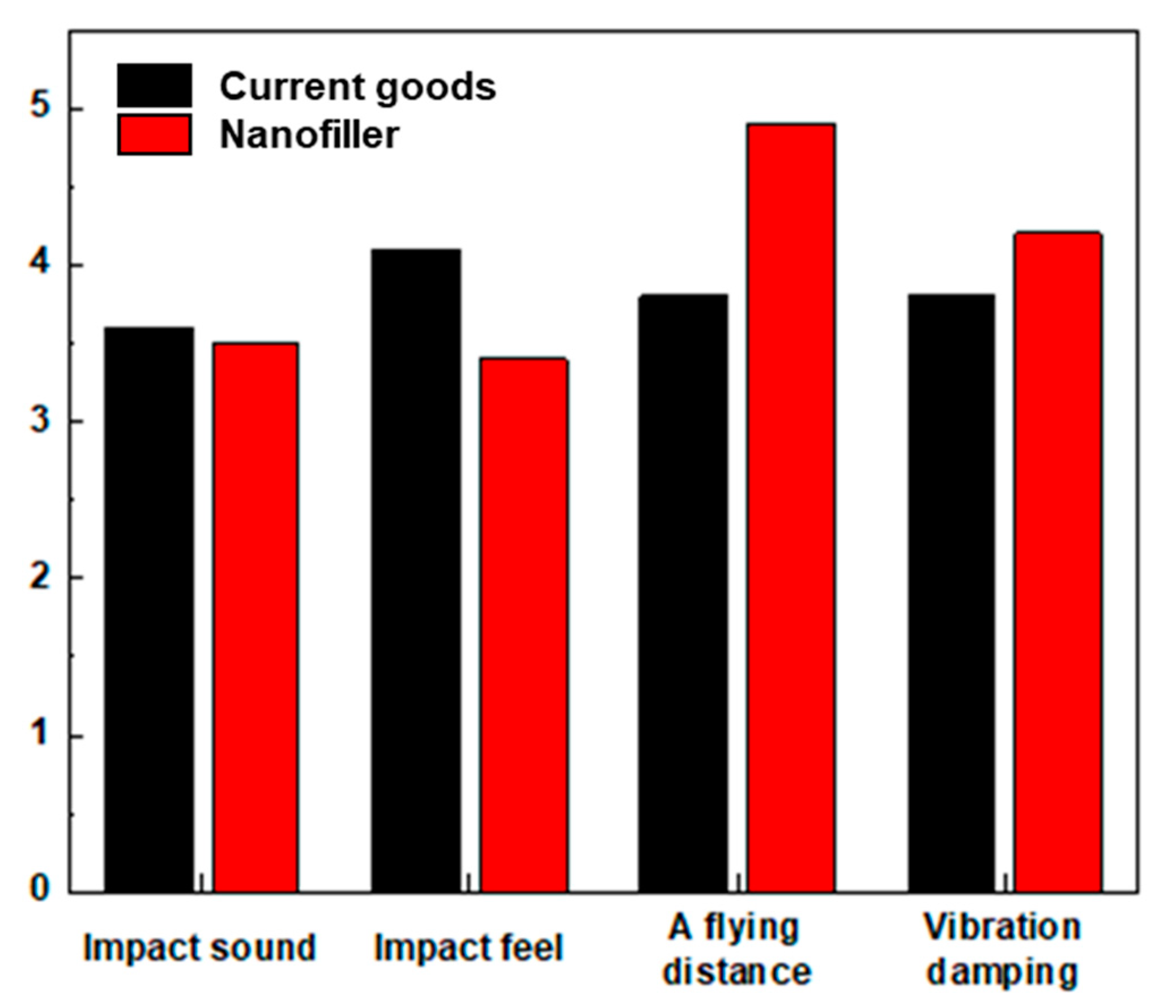

3.4. Mechanical Property and User-Based Performance Evaluation

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Association, N.P.G. Nippon Park Golf Association. Available online: https://www.parkgolf.or.jp/english/ (accessed on 22 November 2024).

- Kiel, J.K.K. Golfers Elbow. Available online: https://www.ncbi.nlm.nih.gov/books/NBK519000/ (accessed on 22 November 2024).

- Jee, Y.-S.; Lee, H.-J. Golf and Injury Incidence in Recreational Golfers: A Retrospective Study. J. Converg. Inf. Technol. 2013, 8, 522–528. [Google Scholar]

- Murray, A.; Daines, L.; Archibald, D.; Hawkes, R.; Schiphorst, C.; Kelly, P.; Grant, L.; Mutrie, N. The relationships between golf and health: A scoping review. Br. J. Sports Med. 2016, 51, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Thomas, Z.; Wilk, K. The Golfer’s Fore, Fore +, and Advanced Fore + Exercise Program: An Exercise Series and Injury Prevention Program for the Golfer. Int. J. Sports Phys. Ther. 2023, V18, 74973. [Google Scholar] [CrossRef]

- Duc, F.; Bourban, P.E.; Plummer, C.J.G.; Månson, J.A.E. Damping of thermoset and thermoplastic flax fibre composites. Compos. Part A Appl. Sci. Manuf. 2014, 64, 115–123. [Google Scholar] [CrossRef]

- Pereira, A.C.d.N.; Titotto, S. Bioinspired composites: Nature’s guidance for advanced materials future. Funct. Compos. Struct. 2023, 5, 012004. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Enhanced vibration damping and dynamic mechanical characteristics of composites with novel pseudo-thermoset matrix system. Compos. Struct. 2017, 179, 502–513. [Google Scholar] [CrossRef]

- Ma, Q.; Merzuki, M.N.M.; Rejab, M.R.M.; Sani, M.S.M.; Zhang, B. A review of the dynamic analysis and free vibration analysis on fiber metal laminates (FMLs). Funct. Compos. Struct. 2023, 5, 012003. [Google Scholar] [CrossRef]

- Shaid Sujon, M.A.; Islam, A.; Nadimpalli, V.K. Damping and sound absorption properties of polymer matrix composites: A review. Polym. Test. 2021, 104, 107388. [Google Scholar] [CrossRef]

- Kim, B.; Youn, B.; Song, Y.; Lee, D. Enhanced dispersion stability and interfacial damping of POSS-functionalized graphene oxide in PDMS nanocomposites. Funct. Compos. Struct. 2022, 4, 035009. [Google Scholar] [CrossRef]

- Pan, S.; Dai, Q.; Safaei, B.; Qin, Z.; Chu, F. Damping characteristics of carbon nanotube reinforced epoxy nanocomposite beams. Thin-Walled Struct. 2021, 166, 108127. [Google Scholar] [CrossRef]

- Pan, S.; Feng, J.; Safaei, B.; Qin, Z.; Chu, F.; Hui, D. A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets. Nanotechnol. Rev. 2022, 11, 1658–1669. [Google Scholar] [CrossRef]

- Gong, L.; Zhang, F.; Peng, X.; Scarpa, F.; Huang, Z.; Tao, G.; Liu, H.-Y.; Zhou, H.; Zhou, H. Improving the damping properties of carbon fiber reinforced polymer composites by interfacial sliding of oriented multilayer graphene oxide. Compos. Sci. Technol. 2022, 224, 109309. [Google Scholar] [CrossRef]

- Kim, J.J.; Brown, A.D.; Bakis, C.E.; Smith, E.C. Hybrid carbon nanotube—Carbon fiber composites for high damping. Compos. Sci. Technol. 2021, 207, 108712. [Google Scholar] [CrossRef]

- Feng, J.; Safaei, B.; Qin, Z.; Chu, F. Nature-inspired energy dissipation sandwich composites reinforced with high-friction graphene. Compos. Sci. Technol. 2023, 233, 109925. [Google Scholar] [CrossRef]

- Chandramohan, S.; Vaithiyanathan, M.; Chakraborty, B.C.; Dharmaraj, M.M. Synergistic effect of graphene and carbon black on the mechanical and vibration damping characteristics of styrene-butadiene rubber. Iran. Polym. J. 2024, 34, 17–27. [Google Scholar] [CrossRef]

- Nur Ainin, F.; Azaman, M.D.; Abdul Majid, M.S.; Ridzuan, M.J.M. Investigating the low-velocity impact behaviour of sandwich composite structures with 3D-printed hexagonal honeycomb core—A review. Funct. Compos. Struct. 2023, 5, 012001. [Google Scholar] [CrossRef]

- Mulla, M.H.; Norizan, M.N.; Abdullah, C.K.; Mohd Rawi, N.F.; Mohamad Kassim, M.H.; Abdullah, N.; Faiz Norrrahim, M.N.; Manzoore Elahi, M.S. Low velocity impact performance of natural fibre reinforced polymer composites: A review. Funct. Compos. Struct. 2023, 5, 035004. [Google Scholar] [CrossRef]

- Cucuzza, R.; Domaneschi, M.; Camata, G.; Marano, G.C.; Formisano, A.; Brigante, D. FRCM retrofitting techniques for masonry walls: A literature review and some laboratory tests. Procedia Struct. Integr. 2023, 44, 2190–2197. [Google Scholar] [CrossRef]

- Sharhan, Z.S.; Cucuzza, R.; Domaneschi, M.; Ghodousian, O.; Movahedi Rad, M. Reinforcement of RC Two-Way Slabs with CFRP Laminates: Plastic Limit Method for Carbon Emissions and Deformation Control. Buildings 2024, 14, 3873. [Google Scholar] [CrossRef]

- ASTM. F1887–14; Standard Test Method for Measuring the Coefficient of Restitution (COR) of Baseballs and Softballs. ASTM: West Conshohocken, PA, USA, 2019. [CrossRef]

- Newton, I. Philosophiae Naturalis Principia Mathematica; Royal Society Publishing: London, UK, 1686. [Google Scholar]

- Tabor, D.; Taylor, G.I. A simple theory of static and dynamic hardness. Proc. R. Soc. London. Ser. A. Math. Phys. Sci. 1948, 192, 247–274. [Google Scholar] [CrossRef]

- Weir, G.; McGavin, P. The coefficient of restitution for the idealized impact of a spherical, nano-scale particle on a rigid plane. Proc. R. Soc. A Math. Phys. Eng. Sci. 2008, 464, 1295–1307. [Google Scholar] [CrossRef]

- ASTM. E976-15; Standard Guide for Determining the Reproducibility of Acoustic Emission Sensor Response. ASTM: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM. D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2017. [CrossRef]

- United States Golf Association. TPX3009, Protocol for Measuring the Coefficient of Restitution of a Clubhead Relative to a Baseline Plate. 2019, TPX3009. Available online: https://www.usga.org/content/dam/usga/pdf/2019/equipment-standards/TPX3009%20Protocol%20for%20Measuring%20the%20Coefficient%20of%20Restitution%20of%20a%20Clubhead%20Relative%20to%20a%20Baseline%20Plate.pdf (accessed on 18 January 2025).

- Hunt, K.H.; Crossley, F.R.E. Coefficient of Restitution Interpreted as Damping in Vibroimpact. J. Appl. Mech. 1975, 42, 440–445. [Google Scholar] [CrossRef]

- Liu, X.; Chen, W.; Shi, H. Improvement of Contact Force Calculation Model Considering Influence of Yield Strength on Coefficient of Restitution. Energies 2022, 15, 1041. [Google Scholar] [CrossRef]

- Jung, I.; Kim, J.; Kim, E.; Kim, C.D.; Kim, N.R.; Yang, C.-M.; Yu, W.-R.; Ahn, C.-H.; Jeon, S.-Y.; Cheon, J.; et al. Enhanced composite laminate fastening and delamination repair using hierarchical thermoplastic composite rivets. Compos. Part B Eng. 2024, 277, 111382. [Google Scholar] [CrossRef]

- Gardea, F.; Glaz, B.; Riddick, J.; Lagoudas, D.C.; Naraghi, M. Energy Dissipation Due to Interfacial Slip in Nanocomposites Reinforced with Aligned Carbon Nanotubes. ACS Appl. Mater. Interfaces 2015, 7, 9725–9735. [Google Scholar] [CrossRef]

| Sample Name | Filler Content. wt% | Sample Name | Filler Content. wt% |

|---|---|---|---|

| Neat | - | G010 | GO 0.01 |

| C01 | CNT 0.1 | G025 | GO 0.025 |

| C03 | CNT 0.3 | G050 | GO 0.05 |

| C05 | CNT 0.5 | G100 | GO 0.1 |

| Specimens (Unit) | Young’s Modulus (GPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Neat UD | 128.0 | 1090 | 0.905 |

| GO-added UD | 124.4 | 1173 | 0.913 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bae, S.; Shin, M.; Kim, E.; Lee, S.; Yu, W.-R.; Ahn, C.-H.; Na, W. Improvement in the Damping Behavior of Hierarchical Carbon Fiber-Reinforced Plastic for Park Golf Club Faces. Polymers 2025, 17, 264. https://doi.org/10.3390/polym17030264

Bae S, Shin M, Kim E, Lee S, Yu W-R, Ahn C-H, Na W. Improvement in the Damping Behavior of Hierarchical Carbon Fiber-Reinforced Plastic for Park Golf Club Faces. Polymers. 2025; 17(3):264. https://doi.org/10.3390/polym17030264

Chicago/Turabian StyleBae, Seoyeon, Minhyeok Shin, Eunjung Kim, Sungbi Lee, Woong-Ryeol Yu, Cheol-Hee Ahn, and Wonjin Na. 2025. "Improvement in the Damping Behavior of Hierarchical Carbon Fiber-Reinforced Plastic for Park Golf Club Faces" Polymers 17, no. 3: 264. https://doi.org/10.3390/polym17030264

APA StyleBae, S., Shin, M., Kim, E., Lee, S., Yu, W.-R., Ahn, C.-H., & Na, W. (2025). Improvement in the Damping Behavior of Hierarchical Carbon Fiber-Reinforced Plastic for Park Golf Club Faces. Polymers, 17(3), 264. https://doi.org/10.3390/polym17030264