Selective Elastane Removal Using DMSO–DBN Under Moderate Temperatures: From Pure Filaments to Cotton/Polyester Blends

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Elastane Degradation

2.3. Attenuated Total Reflectance-Fourier Transform Infrared Spectroscopy (ATR-FTIR)

2.4. Thermogravimetric Analysis and Differential Thermogravimetric Analysis (TGA/DTG)

2.5. Scanning Electron Microscopy (SEM)

2.6. Mechanical Properties

3. Results and Discussion

3.1. Elastane Solubilisation Assays

3.2. ATR-FTIR Analysis

3.3. Thermal Analysis

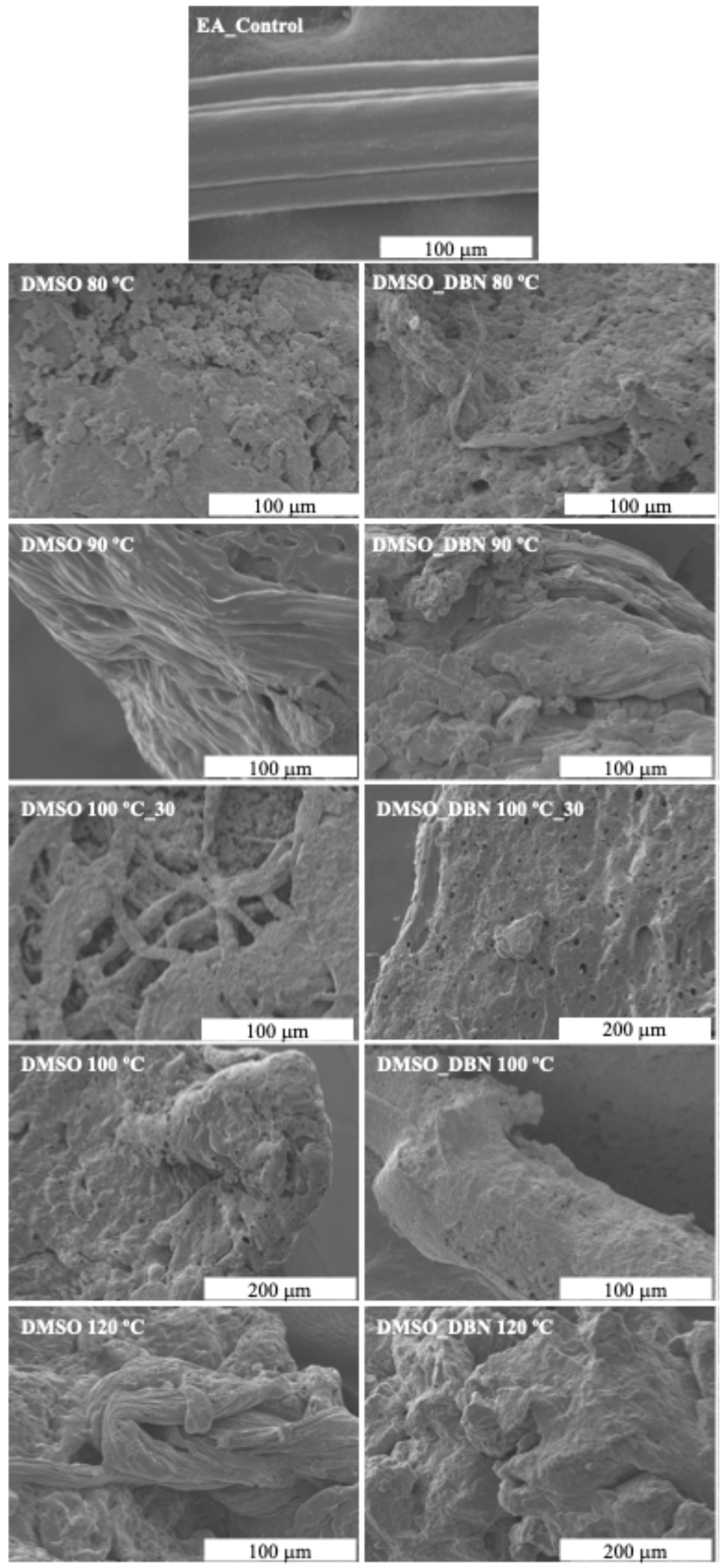

3.4. SEM Analysis

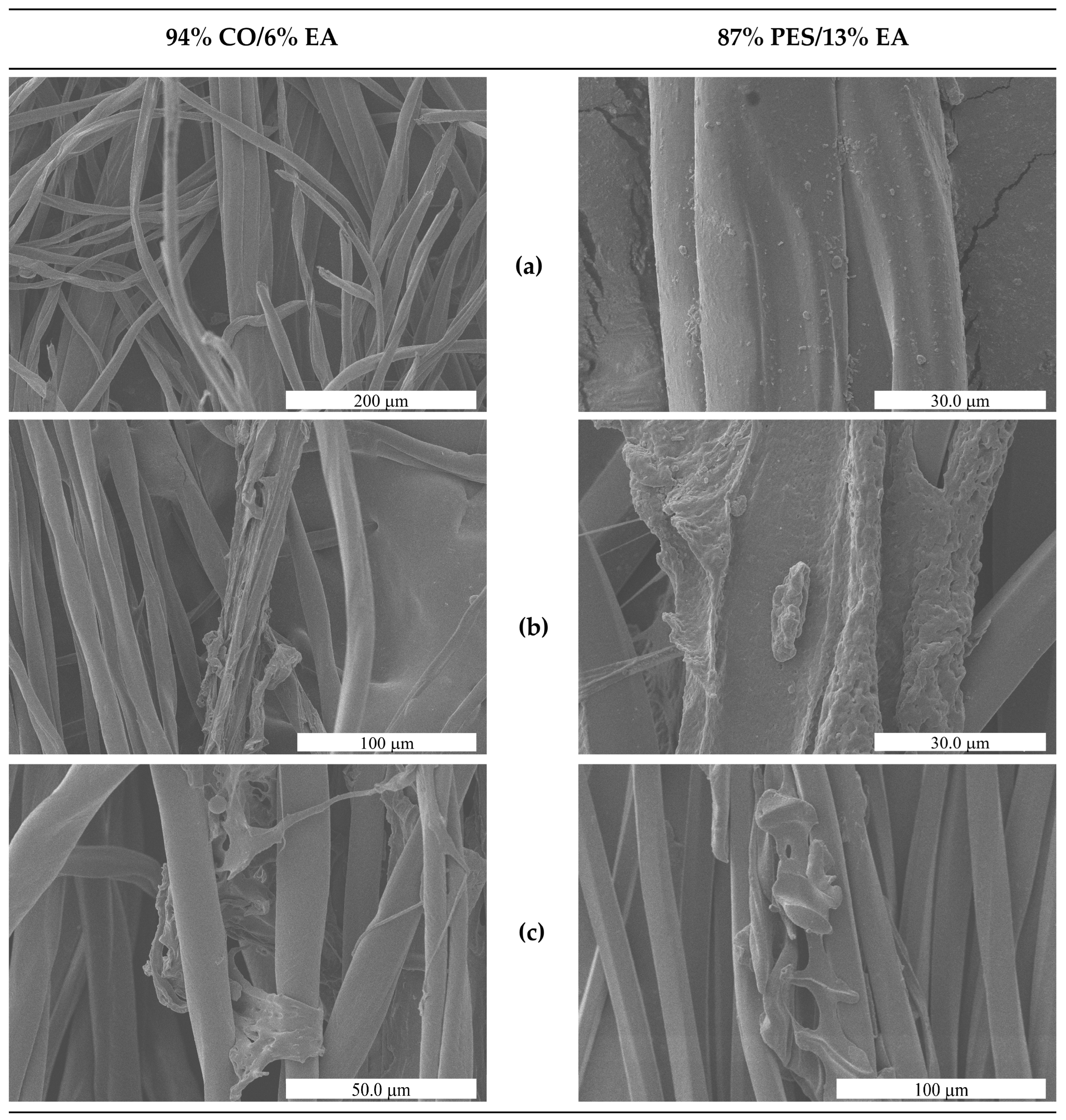

3.5. Case Study: Elastane Degradation from Cotton/Elastane and Polyester/Elastane Textile Blends

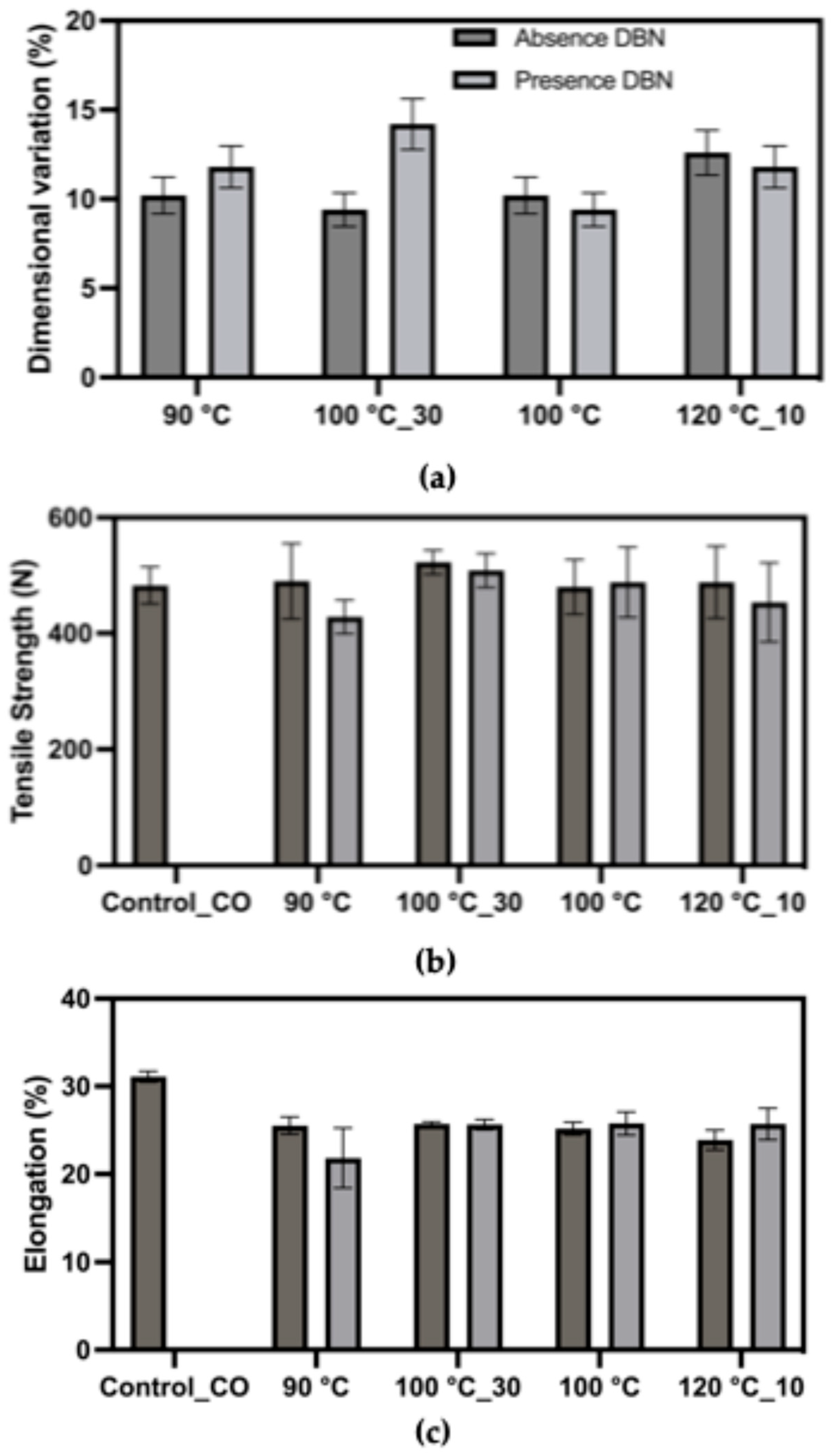

3.5.1. Cotton/Elastane Blend

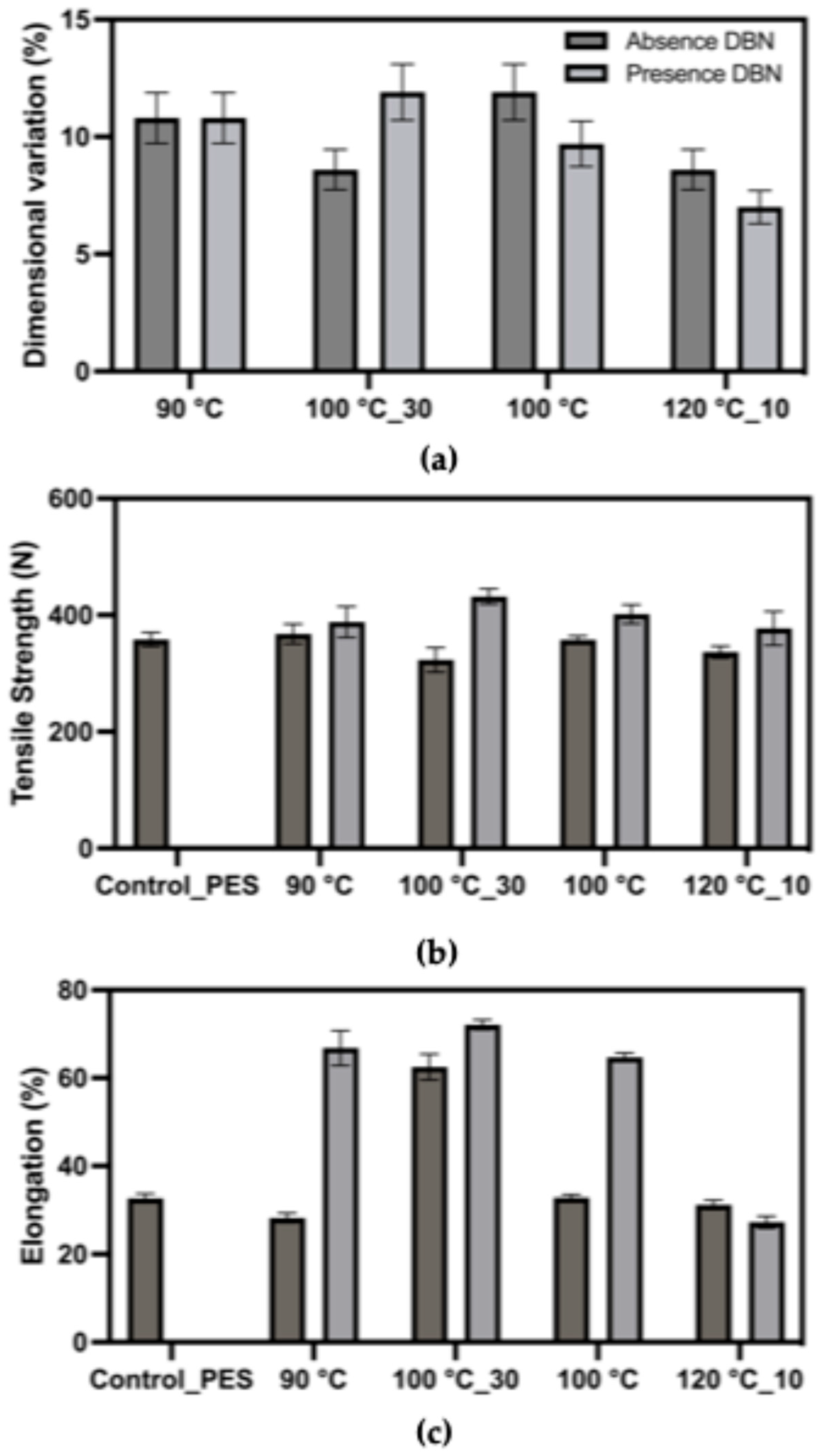

3.5.2. Polyester/Elastane Blend

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DMSO | Dimethyl sulfoxide |

| DBN | 1,5-diazabicyclo[4.3.0]non-5-ene |

| EA | Elastane |

| PES | Polyester |

| CO | Cotton |

| SEM | Scanning electron microscopy |

| DMF | Dimethylformamide |

| DMAc | Dimethylacetamide |

| PU | Polyurethane |

| ATR-FTIR | Attenuated total reflectance-Fourier transform infrared spectroscopy |

| TGA/DTG | Thermogravimetric analysis and differential thermogravimetric analysis |

References

- Materials Market Report, Textile Exchange. 2025. Available online: https://2d73cea0.delivery.rocketcdn.me/app/uploads/2025/09/Materials-Market-Report-2025.pdf (accessed on 1 October 2025).

- Bolaji, J.T.; Dolez, P.I. Mechanical Properties of Woven Fabrics Containing Elastane Fibers. Fibers 2024, 12, 30. [Google Scholar] [CrossRef]

- Villar, L.; Schlapp-Hackl, I.; Sánchez, P.B.; Hummel, M. High-Quality Cellulosic Fibers Engineered from Cotton–Elastane Textile Waste. Biomacromolecules 2024, 25, 1942–1949. [Google Scholar] [CrossRef] [PubMed]

- Rathinamoorthy, R.; Balasaraswathi, S.R.; Madhubashini, S.; Prakalya, A.; Rakshana, J.B.; Shathvika, S. Investigation on microfiber release from elastane blended fabrics and its environmental significance. Sci. Total Environ. 2023, 903, 166553. [Google Scholar] [CrossRef]

- Yin, Y.; Yao, D.; Wang, C.; Wang, Y. Removal of spandex from nylon/spandex blended fabrics by selective polymer degradation. Text. Res. J. 2014, 84, 16–27. [Google Scholar] [CrossRef]

- Vonbrül, L.; Cordin, M.; Manian, A.P.; Bechtold, T.; Pham, T. Solvent blends for selective elastane dissolution and recovery from mixed polyamide fabrics. Resour. Conserv. Recycl. 2024, 200, 107302. [Google Scholar] [CrossRef]

- Phan, K.; Ügdüler, S.; Harinck, L.; Denolf, R.; Roosen, M.; O’Rourke, G.; De Vos, D.; Van Speybroeck, V.; De Clerck, K.; De Meester, S. Analysing the potential of the selective dissolution of elastane from mixed fiber textile waste. Resour. Conserv. Recycl. 2023, 191, 106903. [Google Scholar] [CrossRef]

- Boschmeier, E.; Archodoulaki, V.-M.; Schwaighofer, A.; Lendl, B.; Ipsmiller, W.; Bartl, A. New separation process for elastane from polyester/elastane and polyamide/elastane textile waste. Resour. Conserv. Recycl. 2023, 198, 107215. [Google Scholar] [CrossRef]

- Wang, L.; Huang, S.; Wang, Y. Recycling of Waste Cotton Textile Containing Elastane Fibers through Dissolution and Regeneration. Membranes 2022, 12, 355. [Google Scholar] [CrossRef]

- Calvo-Flores, F.G.; Martin-Martinez, F.J. Biorefineries: Achievements and challenges for a bio-based economy. Front. Chem. 2022, 10, 973417. [Google Scholar] [CrossRef]

- Jönsson, C.; Wei, R.; Biundo, A.; Landberg, J.; Bour, L.S.; Pezzotti, F.; Toca, A.; Jacques, L.M.; Bornscheuer, U.T.; Syrén, P. Biocatalysis in the Recycling Landscape for Synthetic Polymers and Plastics towards Circular Textiles. ChemSusChem 2021, 14, 4028–4040. [Google Scholar] [CrossRef]

- ASTM D5035-11 Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method). Ad-vancing Standards Transforming Markets, USA. 2019. Available online: https://store.astm.org/d5035-11r19.html (accessed on 20 October 2025).

- Xinrong, S.; Nanfang, W.; Kunyang, S.; Sha, D.; Zhen, C. Synthesis and characterization of waterborne polyurethane containing UV absorption group for finishing of cotton fabrics. J. Ind. Eng. Chem. 2014, 20, 3228–3233. [Google Scholar] [CrossRef]

- Johansen, M.B.; Donslund, B.S.; Henriksen, M.L.; Kristensen, S.K.; Skrydstrup, T. Selective chemical disassembly of elastane fibres and polyurethane coatings in textiles. Green Chem. 2023, 25, 10622–10629. [Google Scholar] [CrossRef]

- Gupta, R.K.; Kahol, P. (Eds.) Polyurethane Chemistry: Renewable Polyols and Isocyanates; American Chemical Society: Washington, DC, USA, 2021. [Google Scholar]

- Yuan, Q.; Zhou, T.; Li, L.; Zhang, J.; Liu, X.; Ke, X.; Zhang, A. Hydrogen bond breaking of TPU upon heating: Understanding from the viewpoints of molecular movements and enthalpy. RSC Adv. 2015, 5, 31153–31165. [Google Scholar] [CrossRef]

- Pardini, O.R.; Amalvy, J.I. FTIR, 1H-NMR spectra, and thermal characterization of water-based polyurethane/acrylic hybrids. J. Appl. Polym. Sci. 2008, 107, 1207–1214. [Google Scholar] [CrossRef]

- Kasprzyk, P.; Głowińska, E.; Parcheta-Szwindowska, P.; Rohde, K.; Datta, J. Green TPUs from Prepolymer Mixtures Designed by Controlling the Chemical Structure of Flexible Segments. Int. J. Mol. Sci. 2021, 22, 7438. [Google Scholar] [CrossRef] [PubMed]

- Boschmeier, E.; Archodoulaki, V.-M.; Schwaighofer, A.; Lendl, B.; Bartl, A. A novel quantification tool for elastane in textiles using thermal treatment. Polym. Test. 2023, 118, 107920. [Google Scholar] [CrossRef]

- Gostev, A.; Shundrina, I.; Pastukhov, V.; Shutov, A.; Chernonosova, V.; Karpenko, A.; Laktionov, P. In Vivo Stability of Polyurethane-Based Electrospun Vascular Grafts in Terms of Chemistry and Mechanics. Polymers 2020, 12, 845. [Google Scholar] [CrossRef]

- Oenema, J.; Liu, H.; Coensel, N.D.; Eschenbacher, A.; Van De Vijver, R.; Weng, J.; Li, L.; Wang, C.; Van Geem, K.M. Review on the pyrolysis products and thermal decomposition mechanisms of polyurethanes. J. Anal. Appl. Pyrolysis 2022, 168, 105723. [Google Scholar] [CrossRef]

- Kemona, A.; Piotrowska, M. Polyurethane Recycling and Disposal: Methods and Prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef]

- Alobad, Z.K.; Albozahid, M.; Naji, H.Z.; Alraheem, H.S.; Saiani, A. Influence of hard segments content on thermal, morphological and mechanical properties of homo and co-polyurethanes: A comparative study. Arch. Mater. Sci. Eng. 2021, 1, 5–16. [Google Scholar] [CrossRef]

- Yang, Y.; Song, L.; Peng, C.; Liu, E.; Xie, H. Activating cellulose via its reversible reaction with CO2 in the presence of 1,8-diazabicyclo[5.4.0]undec-7-ene for the efficient synthesis of cellulose acetate. Green Chem. 2015, 17, 2758–2763. [Google Scholar] [CrossRef]

- Wu, H.; Wang, B.; Li, T.; Wu, Y.; Yang, R.; Gao, H.; Nie, Y. Efficient recycle of waste poly-cotton and preparation of cellulose and polyester fibers using the system of ionic liquid and dimethyl sulfoxide. J. Mol. Liq. 2023, 388, 122757. [Google Scholar] [CrossRef]

- Wolfs, J.; Meier, M.A.R. A more sustainable synthesis approach for cellulose acetate using the DBU/CO2 switchable solvent system. Green Chem. 2021, 23, 4410–4420. [Google Scholar] [CrossRef]

| Method | Conditions | Reagents |

|---|---|---|

| Exhaustion | 80, 90 and 100 °C, 1 h 100 °C 30 min 120 °C, 10 min | DMSO with presence or absence of DBN (0.1% v/v) Bath ratio 100:1 |

| Sample | I1703/1732 Oxidation of Soft Segments | I1102/1221 Hydrolysis of Urethane Bonds |

|---|---|---|

| EA_Control | 0.73 | 2.00 |

| EA_DMSO 80 °C | 0.75 | 2.00 |

| EA_DMSO_DBN 80 °C | 0.66 | 1.89 |

| EA_DMSO 90 °C | 0.66 | 1.97 |

| EA_DMSO_DBN 90 °C | 0.71 | 2.00 |

| EA_DMSO 100 °C_30 | 0.82 | 1.93 |

| EA_DMSO 100 °C | 0.76 | 1.97 |

| EA_DMSO 120 °C | 0.74 | 2.13 |

| Sediment | ||

| EA_DMSO_DBN 100 °C_30 | 0.98 | 1.90 |

| EA_DMSO_DBN 100 °C | 0.72 | 2.09 |

| EA_DMSO_DBN 120 °C | 0.86 | 1.94 |

| Samples | DP | T (°C) | WL (%) |

|---|---|---|---|

| EA_Control | 1 | 257 | 8.50 |

| 2 | 345 | 16.1 | |

| 3 | 418 | 73.0 | |

| EA_DMSO 80 °C | 1 | 300 | 19.7 |

| 2 | 349 | 14.3 | |

| 3 | 424 | 47.3 | |

| EA_DMSO + DBN 80 °C | 1 | 298 | 4.43 |

| 2 | 349 | 16.4 | |

| 3 | 422 | 75.6 | |

| EA_DMSO 90 °C | 1 | 78 | 2.86 |

| 2 | 296 | 7.63 | |

| 3 | 345 | 14.8 | |

| 4 | 419 | 71.4 | |

| EA_DMSO + DBN 90 °C | 1 | 297 | 5.29 |

| 2 | 343 | 17.5 | |

| 3 | 420 | 72.9 | |

| EA_DMSO 100 °C_30 | 1 | 304 | 9.05 |

| 2 | 332 | 15.7 | |

| 3 | 420 | 69.3 | |

| EA_DMSO 100 °C | 1 | 107 | 10.3 |

| 2 | 302 | 7.88 | |

| 3 | 348 | 13.8 | |

| 4 | 424 | 65.2 | |

| EA_DMSO 120 °C | 1 | 298 | 1.44 |

| 2 | 342 | 16.3 | |

| 3 | 420 | 71.1 | |

| Sediments | |||

| EA_DMSO_DBN 100 °C_30 | 1 | 134 | 1.26 |

| 2 | 317 | 12.2 | |

| 3 | 412 | 45.7 | |

| EA_DMSO_DBN 100 °C | 1 | 93 | 8.04 |

| 2 | 354 | 19.6 | |

| 3 | 420 | 63.4 | |

| EA_DMSO_DBN 120 °C | 1 | 274 | 3.06 |

| 2 | 332 | 19.5 | |

| 3 | 417 | 70.6 | |

| Sample | T5% (°C) | T10% (°C) | T20% (°C) | Tonset (°C) |

|---|---|---|---|---|

| EA_Control | 259.8 | 308.2 | 352.8 | 381 |

| EA_DMSO 80 °C | 289.7 | 321.3 | 359.9 | 382 |

| EA_DMSO_DBN 80 °C | 306.4 | 329.2 | 365.9 | 389 |

| EA_DMSO 90 °C | 272.6 | 307.2 | 349.9 | 384 |

| EA_DMSO_DBN 90 °C | 302.9 | 327.8 | 364.1 | 379 |

| EA_DMSO 100 °C_30 | 291.8 | 317.4 | 354.4 | 383 |

| EA_DMSO 100 °C | 89.0 | 139.1 | 328.2 | 395 |

| EA_DMSO 120 °C | 299.1 | 326.3 | 364.7 | 384 |

| Sediments | ||||

| EA_DMSO_DBN 100 °C_30 | 165.7 | 278.9 | 363.8 | 376 |

| EA_DMSO_DBN 100 °C | 74.1 | 180.6 | 338.7 | 385 |

| EA_DMSO_DBN 120 °C | 286.7 | 318.3 | 355.2 | 381 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azevedo, T.; Silva, A.C.; Chaves, D.M.; Fangueiro, R.; Ferreira, D.P. Selective Elastane Removal Using DMSO–DBN Under Moderate Temperatures: From Pure Filaments to Cotton/Polyester Blends. Polymers 2025, 17, 3247. https://doi.org/10.3390/polym17243247

Azevedo T, Silva AC, Chaves DM, Fangueiro R, Ferreira DP. Selective Elastane Removal Using DMSO–DBN Under Moderate Temperatures: From Pure Filaments to Cotton/Polyester Blends. Polymers. 2025; 17(24):3247. https://doi.org/10.3390/polym17243247

Chicago/Turabian StyleAzevedo, Tiago, Ana Catarina Silva, Diego M. Chaves, Raul Fangueiro, and Diana P. Ferreira. 2025. "Selective Elastane Removal Using DMSO–DBN Under Moderate Temperatures: From Pure Filaments to Cotton/Polyester Blends" Polymers 17, no. 24: 3247. https://doi.org/10.3390/polym17243247

APA StyleAzevedo, T., Silva, A. C., Chaves, D. M., Fangueiro, R., & Ferreira, D. P. (2025). Selective Elastane Removal Using DMSO–DBN Under Moderate Temperatures: From Pure Filaments to Cotton/Polyester Blends. Polymers, 17(24), 3247. https://doi.org/10.3390/polym17243247