Temperature Dependence of Tensile Properties and Deformation Behavior in Highly Strong Heat-Elongated Polypropylene

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. SAXS Measurement

2.2.2. Tensile Tests at Different Temperatures

2.2.3. DMA Measurement

2.2.4. DSC Measurement

3. Results and Discussion

3.1. Strengthening by Heat Elongation

3.2. Dynamic Mechanical Behavior

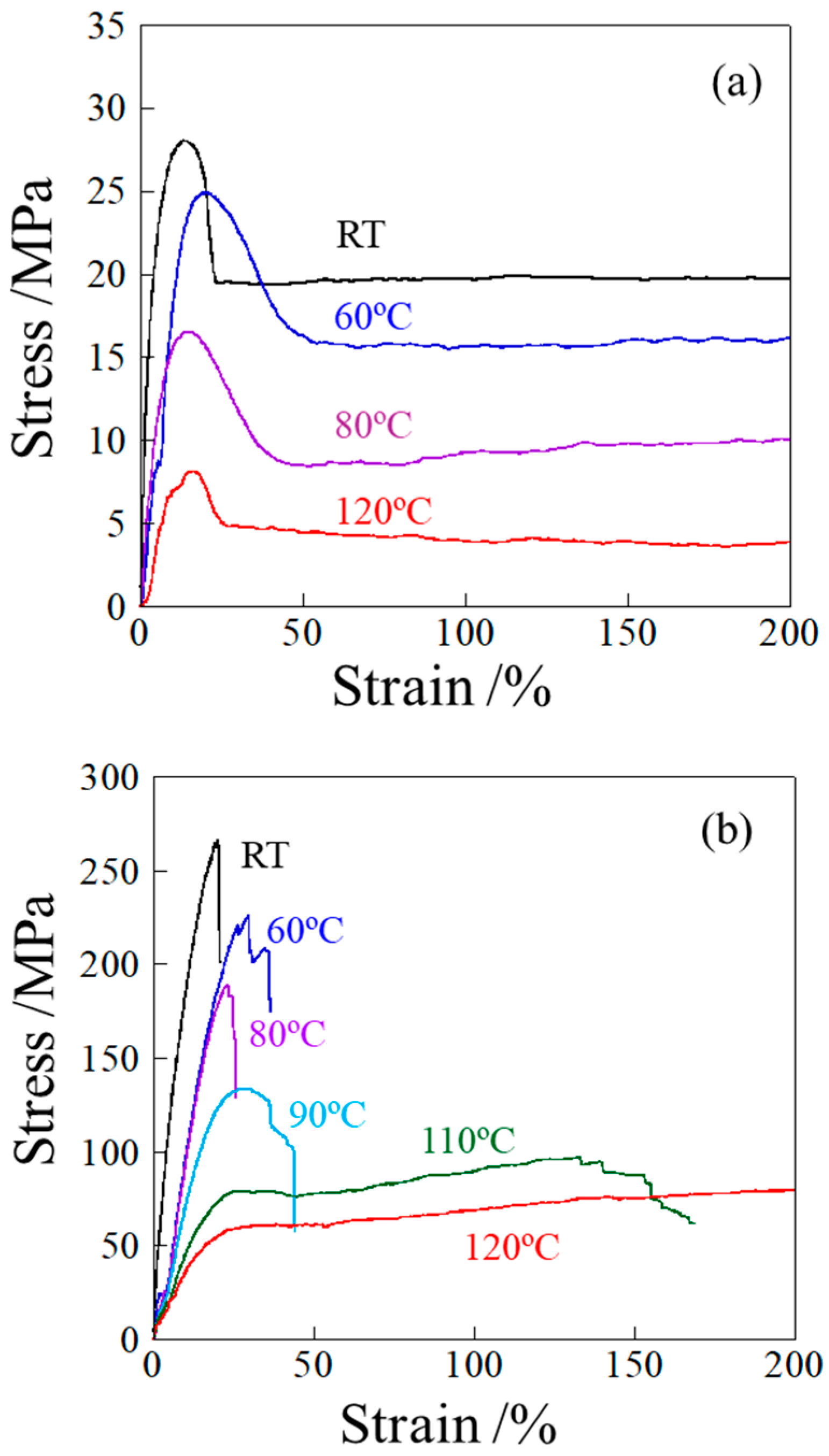

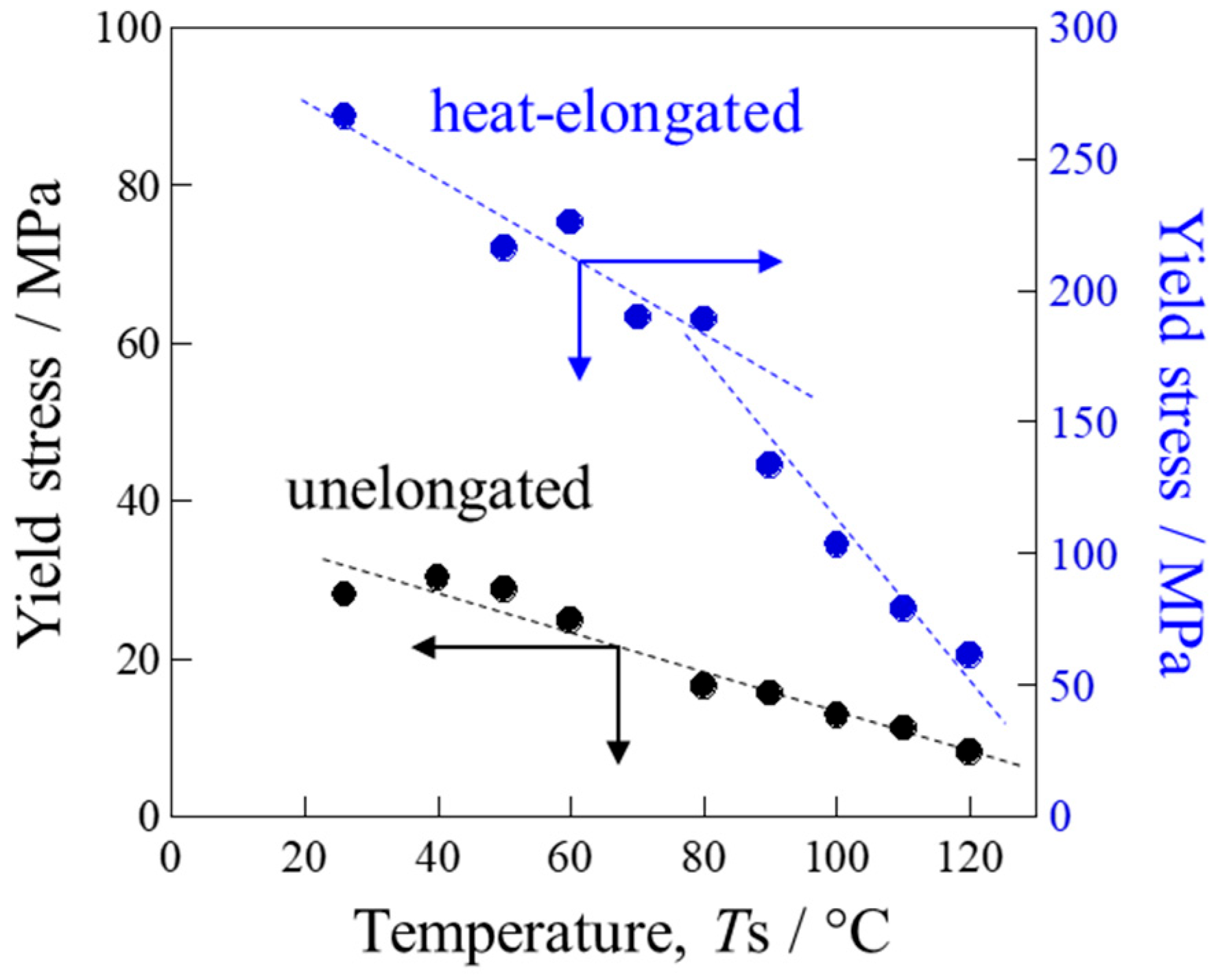

3.3. Stress–Strain Behavior at Different Temperatures

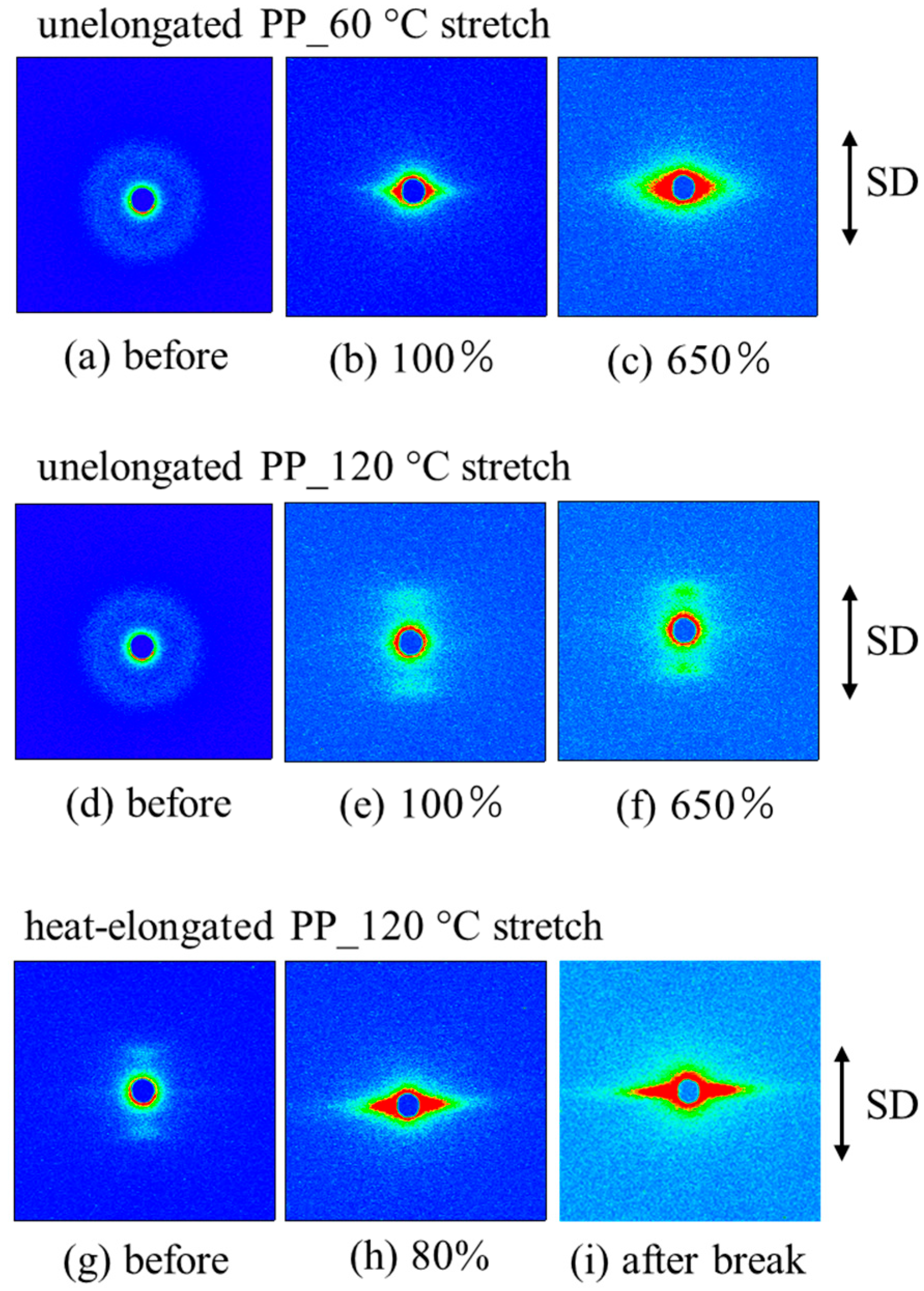

3.4. Deformation Behavior

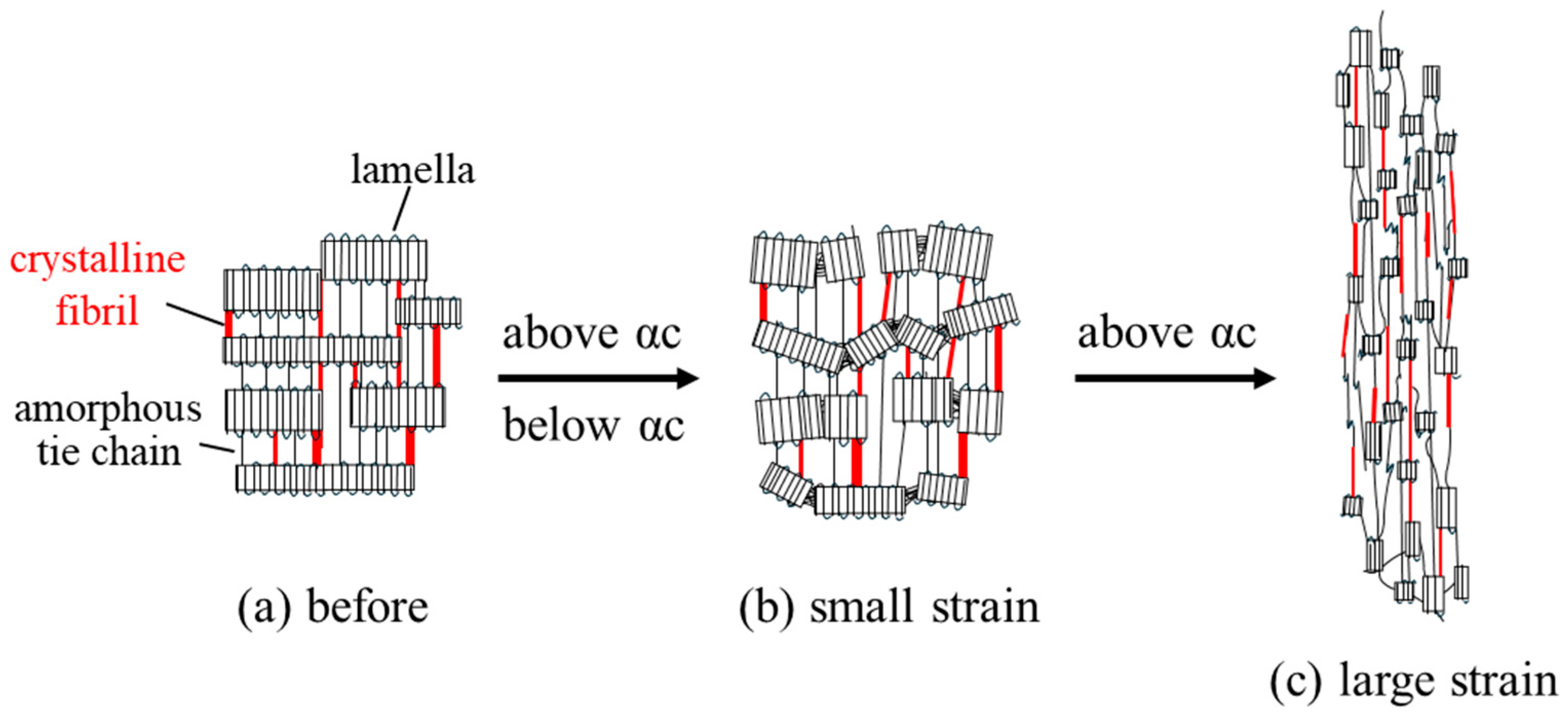

3.5. Deformation Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Acik, G.; Altinkok, C.; Acik, B. Biodegradable and antibacterial chlorinated polypropylene/chitosan based composite films for biomedical applications. Polym. Bull. 2022, 79, 9997–10011. [Google Scholar] [CrossRef]

- Maurya, A.K.; Manik, G. Advances towards development of industrially relevant short natural fiber reinforced and hybridized polypropylene composites for various industrial applications: A review. J. Polym. Res. 2023, 30, 47. [Google Scholar] [CrossRef]

- Hossain, M.T.; Shahid, M.A.; Mahmud, N.; Habib, A.; Rana, M.M.; Khan, S.A.; Hossain, M.D. Research and application of polypropylene: A review. Discov. Nano 2024, 19, 2. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Bárány, T. Polypropylene Handbook; Springer Nature: Cham, Switzerland, 2019. [Google Scholar]

- Wang, Y.; Nejati, F.; Edalatpanah, S.A.; Goudarzi Karim, R. Experimental study to compare the strength of concrete with different amounts of polypropylene fibers at high temperatures. Sci. Rep. 2024, 14, 8566. [Google Scholar] [CrossRef]

- Yao, X.; Han, Y.; Shen, L.; Zhu, D. Experimental study on the effect of polypropylene fiber on compressive strength and fracture properties of high-strength concrete after elevated temperatures. J. Build. Eng. 2024, 86, 108860. [Google Scholar] [CrossRef]

- Ma, Q.; Sahu, S.K.; Badgayan, N.D.; Rejab, M.R.M. Experimental and numerical investigations on tensile properties of carbon fibre-reinforced plastic and self-reinforced polypropylene composites. J. Mech. Behav. Mater. 2024, 33, 20240021. [Google Scholar] [CrossRef]

- Wang, Z.; Du, Q.; Hong, W.; Yu, G.; Wang, H.; Feng, Y.; Chen, X.; Li, H.; Guo, S.; Li, C. Achieving High-Performance Polypropylene-Based Synthetic Paper with High-Modulus Organic Oligomer and Biaxial Stretching Force Field. Polymers 2025, 17, 2951. [Google Scholar] [CrossRef]

- Lin, L.; Argon, A. Structure and plastic deformation of polyethylene. J. Mater. Sci. 1994, 29, 294–323. [Google Scholar] [CrossRef]

- Bartczak, Z.; Galeski, A. Plasticity of Semicrystalline Polymers. Macromol. Symp. 2010, 294, 67–90. [Google Scholar] [CrossRef]

- Sharaf, M.A.; Kloczkowski, A. Evolution of the Deformation- and Flow-Induced Crystallization and Characterization of the Microstructure of a Single Spherulite, Lamella, and Chain of Isotactic Polypropylene. Macromol. Chem. Phys. 2023, 225, 2300203. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, J.; Pan, P. Strain-induced multiscale structural evolutions of crystallized polymers: From fundamental studies to recent progresses. Prog. Polym. Sci. 2023, 140, 101676. [Google Scholar] [CrossRef]

- Lin, H.; Guo, J.; Huang, X.; Jiang, S.; Xu, M. Structural Characteristics of Fibrillar Crystals in Uniaxially Stretched Isotactic Polypropylene Dominated by Temperature and Strain. Macromol. Mater. Eng. 2024, 309, 2300448. [Google Scholar] [CrossRef]

- Bowden, P.B.; Young, R.D. Review Deformation mechanisms in crystalline polymers. J. Mater. Sci. 1974, 9, 2034–2051. [Google Scholar] [CrossRef]

- Nitta, K.-H.; Nomura, H. Stress–strain behavior of cold-drawn isotactic polypropylene subjected to various drawn histories. Polymer 2014, 55, 6614–6622. [Google Scholar] [CrossRef]

- Kida, T.; Oku, T.; Hiejima, Y.; Nitta, K.-h. Deformation mechanism of high-density polyethylene probed by in situ Raman spectroscopy. Polymer 2015, 58, 88–95. [Google Scholar] [CrossRef]

- Bao, R.; Ding, Z.; Zhong, G.; Yang, W.; Xie, B.; Yang, M. Deformation-induced morphology evolution during uniaxial stretching of isotactic polypropylene: Effect of temperature. Colloid Polym. Sci. 2011, 290, 261–274. [Google Scholar] [CrossRef]

- Dai, X.; Xing, Z.; Yang, W.; Zhang, C.; Li, F.; Chen, X.; Li, C.; Zhou, J.; Li, L.; Li, Z. The Effect of Annealing on the Structure and Electric Performance of Polypropylene Films. Int. J. Polym. Sci. 2022, 2022, 5970484. [Google Scholar] [CrossRef]

- Tabatabaei, S.H.; Carreau, P.J.; Ajji, A. Structure and properties of MDO stretched polypropylene. Polymer 2009, 50, 3981–3989. [Google Scholar] [CrossRef]

- van Erp, T.B.; Cavallo, D.; Peters, G.W.M.; Govaert, L.E. Rate-, temperature-, and structure-dependent yield kinetics of isotactic polypropylene. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 1438–1451. [Google Scholar] [CrossRef]

- Caelers, H.J.M.; Govaert, L.E.; Peters, G.W.M. The prediction of mechanical performance of isotactic polypropylene on the basis of processing conditions. Polymer 2016, 83, 116–128. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, S.; Wu, T.; Fu, Q. Yielding behavior of isotactic polypropylene at elevated temperature understood at the spherulite level. Polymer 2023, 281, 126150. [Google Scholar] [CrossRef]

- Guo, H.; Zhu, J.; Li, C.; Zhao, C.; Cui, K.; Li, L. Strain Rate Dependence of Amorphous Phase Instability in Semicrystalline Polymers: Insights from the Scale of Lamellar Stacks. Macromolecules 2024, 57, 4081–4094. [Google Scholar] [CrossRef]

- Pawlak, A.; Galeski, A. Cavitation and morphological changes in polypropylene deformed at elevated temperatures. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 1271–1280. [Google Scholar] [CrossRef]

- Pawlak, A.; Galeski, A.; Rozanski, A. Cavitation during deformation of semicrystalline polymers. Prog. Polym. Sci. 2014, 39, 921–958. [Google Scholar] [CrossRef]

- Lu, Y.; Men, Y. Cavitation-Induced Stress Whitening in Semi-Crystalline Polymers. Macromol. Mater. Eng. 2018, 303, 1800203. [Google Scholar] [CrossRef]

- Zhang, Y.; Ben Jar, P.Y.; Xue, S.; Li, L. Quantification of strain-induced damage in semi-crystalline polymers: A review. J. Mater. Sci. 2018, 54, 62–82. [Google Scholar] [CrossRef]

- Bartczak, Z.; Vozniak, A. Deformation Instabilities and Cavitation in Plastic Deformation of Semicrystalline Polyethylene. Macromolecules 2024, 57, 6474–6491. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, Y.; Ma, P.; Wen, K.; Liao, Y.; Perez-Camargo, R.A.; Zhao, Y.; Dong, J.Y.; Dong, X.; Muller, A.J.; et al. Tracking Early Cavitation in iPP: Insights from SEM During Uniaxial Stretching. Macromol. Rapid Commun. 2025, 46, e2500186. [Google Scholar] [CrossRef]

- Jabbari-Farouji, S.; Rottler, J.; Lame, O.; Makke, A.; Perez, M.; Barrat, J.L. Plastic Deformation Mechanisms of Semicrystalline and Amorphous Polymers. ACS Macro Lett. 2015, 4, 147–150. [Google Scholar] [CrossRef]

- Hagita, K.; Yamamoto, T.; Saito, H.; Abe, E. Chain-Level Analysis of Reinforced Polyethylene through Stretch-Induced Crystallization. ACS Macro Lett. 2024, 13, 247–251. [Google Scholar] [CrossRef] [PubMed]

- Caelers, H.J.M.; Troisi, E.M.; Govaert, L.E.; Peters, G.W.M. Deformation-Induced Phase Transitions in iPP Polymorphs. Polymers 2017, 9, 547. [Google Scholar] [CrossRef] [PubMed]

- Alcock, B.; Cabrera, N.O.; Barkoula, N.M.; Reynolds, C.T.; Govaert, L.E.; Peijs, T. The effect of temperature and strain rate on the mechanical properties of highly oriented polypropylene tapes and all-polypropylene composites. Compos. Sci. Technol. 2007, 67, 2061–2070. [Google Scholar] [CrossRef]

- Lin, Y.; Tian, F.; Meng, L.; Chen, X.; Lv, F.; Zhang, Q.; Li, L. Microbuckling: A possible mechanism to trigger nonlinear instability of semicrystalline polymer. Polymer 2018, 154, 48–54. [Google Scholar] [CrossRef]

- Lin, Y.; Li, X.; Meng, L.; Chen, X.; Lv, F.; Zhang, Q.; Zhang, R.; Li, L. Structural Evolution of Hard-Elastic Isotactic Polypropylene Film during Uniaxial Tensile Deformation: The Effect of Temperature. Macromolecules 2018, 51, 2690–2705. [Google Scholar] [CrossRef]

- Lin, Y.; Li, X.; Chen, X.; An, M.; Zhang, Q.; Wang, D.; Chen, W.; Sun, L.; Yin, P.; Meng, L.; et al. Structural evolution of hard-elastic polyethylene cast film in temperature-strain space: An in-situ SAXS and WAXS study. Polymer 2019, 184, 121930. [Google Scholar] [CrossRef]

- Liu, X.; Zou, L.; Chang, B.; Shi, H.; Yang, Q.; Cheng, K.; Li, T.; Schneider, K.; Heinrich, G.; Liu, C.; et al. Strain dependent crystallization of isotactic polypropylene during solid-state stretching. Polym. Test. 2021, 104, 107404. [Google Scholar] [CrossRef]

- Caelers, H.J.M.; Parodi, E.; Cavallo, D.; Peters, G.W.M.; Govaert, L.E. Deformation and failure kinetics of iPP polymorphs. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 729–747. [Google Scholar] [CrossRef]

- Jones, H.; McClements, J.; Ray, D.; Hindle, C.S.; Kalloudis, M.; Koutsos, V. Thermomechanical Properties of Virgin and Recycled Polypropylene-High-Density Polyethylene Blends. Polymers 2023, 15, 4200. [Google Scholar] [CrossRef]

- Na, B.; Li, Z.; Lv, R.; Zou, S. Annealing-induced structural rearrangement and its toughening effect in injection-molded isotactic polypropylene. Polym. Eng. Sci. 2011, 52, 893–900. [Google Scholar] [CrossRef]

- Varma, P.; Lofgren, E.A.; Jabarin, S.A. Properties and kinetics of thermally crystallized oriented poly(ethylene terephthalate) (PET). II: Physical and optical properties. Polym. Eng. Sci. 1998, 38, 245–253. [Google Scholar] [CrossRef]

- Habumugisha, J.C.; Feng, S.; Iqbal, O.; Lin, Y.; An, M.; Meng, L.; Wang, D.; Chen, W.; Li, L. Stretch-induced structural evolution of pre-oriented isotactic polypropylene films: An in-situ synchrotron radiation SAXS/WAXS study. Polymer 2021, 214, 123234. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, J.; Yan, Q.; Zhang, Q.; Zhao, J.; Wu, T.; Wang, D.; Meng, L.; Chen, W.; Li, L. The formation of crystal cross-linked network in sequential biaxial stretching of poly(ethylene terephthalate): The essential role of MD pre-stretch. Polym. Test. 2021, 96, 107143. [Google Scholar] [CrossRef]

- He, W.; Kong, C.; Cai, Y.; Ye, L.; Chen, S.; Li, S.; Zhao, X. Thermal stability enhancement of oriented polyethylene by formation of epitaxial shish-kebab crystalline structure. Polym. Degrad. Stab. 2022, 195, 109771. [Google Scholar] [CrossRef]

- Zhang, Q.; Lan, L.; Zheng, Z.; Liu, P.; Wu, H.; Guo, S.; Lin, C.; He, G. Constructing highly oriented and condensed shish-kebab crystalline structure of HDPE/UHMWPE blends via intense stretching process: Achieving high mechanical properties and in-plane thermal conductivity. Polymer 2022, 241, 124532. [Google Scholar] [CrossRef]

- Somani, R.H.; Yang, L.; Zhu, L.; Hsiao, B.S. Flow-induced shish-kebab precursor structures in entangled polymer melts. Polymer 2005, 46, 8587–8623. [Google Scholar] [CrossRef]

- Cui, K.; Ma, Z.; Tian, N.; Su, F.; Liu, D.; Li, L. Multiscale and Multistep Ordering of Flow-Induced Nucleation of Polymers. Chem. Rev. 2018, 118, 1840–1886. [Google Scholar] [CrossRef]

- Liu, T.; Li, W.; Li, L.; Peng, X.; Kuang, T. Effect of dynamic oscillation shear flow intensity on the mechanical and morphological properties of high-density polyethylene: An integrated experimental and molecular dynamics simulation study. Polym. Test. 2019, 80, 106122. [Google Scholar] [CrossRef]

- Murayama, T.; Abe, E.; Saito, H. Strengthening of mille-feuille structured high-density polyethylene by heat elongation. Polymer 2021, 236, 124343. [Google Scholar] [CrossRef]

- Takano, M.; Takamatsu, K.; Saito, H. High-Strength Heat-Elongated Thermoplastic Polyurethane Elastomer Consisting of a Stacked Domain Structure. Polymers 2022, 14, 1470. [Google Scholar] [CrossRef]

- Zhu, E.; Wei, L.; Jin, Z.; Liu, Z.; Zhao, S. The effects of stretching on the mechanical properties of neat and nucleated isotactic polypropylene and its enhancement mechanism. Polymer 2025, 319, 128017. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, Z.; Zhang, S.; Cao, Y.; Chen, J. Structure Evolution and Deformation Behavior of Polyethylene Film during Biaxial Stretching. ACS Omega 2020, 5, 655–666. [Google Scholar] [CrossRef]

- Hagita, K.; Endo, M.; Egusa, D.; Saito, H.; Yamamoto, T.; Abe, E. Nano-structuring for strengthening semi-crystalline polymers. NPG Asia Mater. 2025, 17. [Google Scholar] [CrossRef]

- Sudeji, H.; Nakama, Y.; Komaba, K.; Taniguchi, M.; Saito, H. Highly strong and transparent heat-elongated crystallized cyclo olefin polymers. Polymer 2025, 343, 129420. [Google Scholar] [CrossRef]

- An, H.; Guo, J.; Gao, J.; Zhong, Y.; Li, Y.; Wang, Z. Structural evolution of biaxially oriented polypropylene films upon asynchronous stretching. J. Polym. Sci. 2024, 62, 3947–3958. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, X.; Ma, Y.; Lu, X.; Jiang, Z. High-Performance Branched Polymer Elastomer Based on a Topological Network Structure and Dynamic Bonding. ACS Appl. Mater. Interfaces 2023, 15, 43048–43059. [Google Scholar] [CrossRef]

- Séguéla, R. Plasticity of semi-crystalline polymers: Crystal slip versus melting-recrystallization. e-Polymers 2007, 7, 032. [Google Scholar] [CrossRef]

- Grein, C.; Bernreitner, K.; Gahleitner, M. Potential and limits of dynamic mechanical analysis as a tool for fracture resistance evaluation of isotactic polypropylenes and their polyolefin blends. J. Appl. Polym. Sci. 2004, 93, 1854–1867. [Google Scholar] [CrossRef]

- Menard, K.P.; Menard, N.R. Dynamic Mechanical Analysis in the Analysis of Polymers and Rubbers. In Encyclopedia of Polymer Science and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2015; pp. 1–33. [Google Scholar]

- Lv, Y.; Huang, Y.; Kong, M.; Li, G. Improved thermal oxidation stability of polypropylene films in the presence of β-nucleating agent. Polym. Test. 2013, 32, 179–186. [Google Scholar] [CrossRef]

- Men, Y.; Strobl, G. Evidence for a mechanically active high temperature relaxation process in syndiotactic polypropylene. Polymer 2002, 43, 2761–2768. [Google Scholar] [CrossRef]

- Kida, T.; Yamaguchi, M. Role of Rigid–Amorphous chains on mechanical properties of polypropylene solid using DSC, WAXD, SAXS, and Raman spectroscopy. Polymer 2022, 249, 124834. [Google Scholar] [CrossRef]

- Roy, S.; Kyu, T.; Manley, R.S.J. Mechanical relaxations of oriented gelation-crystallized polyethylene films. Macromolecules 1988, 21, 1741–1746. [Google Scholar] [CrossRef]

- Kuriyagawa, M.; Nitta, K.-h. Structural explanation on natural draw ratio of metallocene-catalyzed high density polyethylene. Polymer 2011, 52, 3469–3477. [Google Scholar] [CrossRef]

- Bartczak, Z.; Kozanecki, M. Influence of molecular parameters on high-strain deformation of polyethylene in the plane-strain compression. Part I. Stress–strain behavior. Polymer 2005, 46, 8210–8221. [Google Scholar] [CrossRef]

- Khan, F.; Hossain, N.; Mim, J.J.; Rahman, S.M.M.; Iqbal, M.J.; Billah, M.; Chowdhury, M.A. Advances of composite materials in automobile applications—A review. J. Eng. Res. 2025, 13, 1001–1023. [Google Scholar] [CrossRef]

| ΔH (J/g) | Tm (°C) | Lamellar Thickness (nm) | Amorphous Thickness (nm) | Long Period (nm) | |

|---|---|---|---|---|---|

| unelongated PP | 108.5 | 162.2 | 9.1 | 5.2 | 14.3 |

| heat-elongated PP | 150.9 | 168.0 | 10.3 | 7.1 | 17.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onaka, K.; Saito, H. Temperature Dependence of Tensile Properties and Deformation Behavior in Highly Strong Heat-Elongated Polypropylene. Polymers 2025, 17, 3238. https://doi.org/10.3390/polym17243238

Onaka K, Saito H. Temperature Dependence of Tensile Properties and Deformation Behavior in Highly Strong Heat-Elongated Polypropylene. Polymers. 2025; 17(24):3238. https://doi.org/10.3390/polym17243238

Chicago/Turabian StyleOnaka, Karin, and Hiromu Saito. 2025. "Temperature Dependence of Tensile Properties and Deformation Behavior in Highly Strong Heat-Elongated Polypropylene" Polymers 17, no. 24: 3238. https://doi.org/10.3390/polym17243238

APA StyleOnaka, K., & Saito, H. (2025). Temperature Dependence of Tensile Properties and Deformation Behavior in Highly Strong Heat-Elongated Polypropylene. Polymers, 17(24), 3238. https://doi.org/10.3390/polym17243238