Chitosan-Grafted Graphene Oxide-Reinforced Bio-Based Waterborne Epoxy Nanocomposites for Antibacterial and Corrosion Resistance in Tropical Marine Environments: A Mini-Review

Abstract

1. Introduction

2. Review of Waterborne Bio-Based Epoxies

2.1. Raw Material Types and Synthesis Methods of Bio-Based Epoxy Resins

2.2. Advantages and Challenges of Waterborne Epoxy Systems

3. Introduction and Functional Modification of Nano-Fillers in Epoxy Composites

3.1. Fundamentals and Limitations of Graphene Oxide

3.2. Functionalization Strategies and Mechanisms of Chitosan-Grafted GO

- Improved Dispersion

- Antibacterial Functionality

- Enhanced Interfacial Adhesion

3.3. Comparison and Synergy with Other Nano-Fillers

4. Comparative and Critical Analysis of the Antibacterial and Corrosion-Resistant Mechanisms of Chitosan, Graphene Oxide, and Chitosan-Grafted Graphene Oxide

4.1. The Antibacterial and Corrosion-Resistant Mechanisms of Chitosan

4.1.1. Electrostatic Adsorption and Membrane Disruption

4.1.2. Induction of Oxidative Stress

4.1.3. Concentration-Dependent Efficacy

4.1.4. Corrosion Resistance Mechanism

4.2. The Antibacterial and Corrosion-Resistant Mechanisms of Graphene Oxide

4.3. The Synergistic Enhancement Mechanism of Chitosan-Grafted Graphene Oxide

- Enhanced Electrostatic Adsorption

- Carrier Effect

- Multi-Mechanistic Action

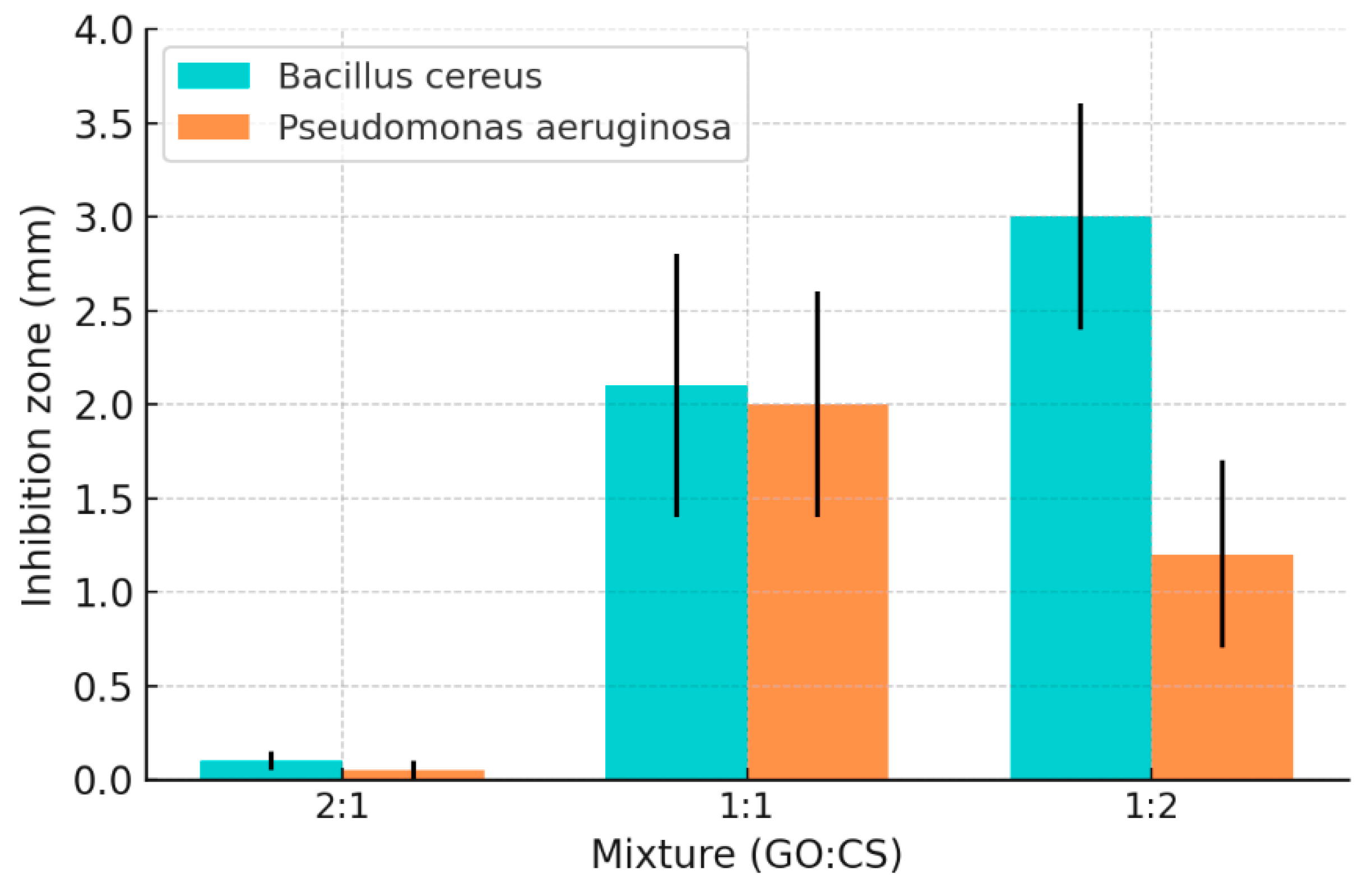

- Optimized Composition

4.4. Performance Comparison and Case Analysis

4.5. Critical Analysis of Current Research

- pH Sensitivity

- GO Stability and Performance Degradation

- Ecotoxicological Uncertainty

- Future Directions

5. Corrosion Resistance Enhancement by Chi-GO: Mechanisms, Evaluation and Challenges

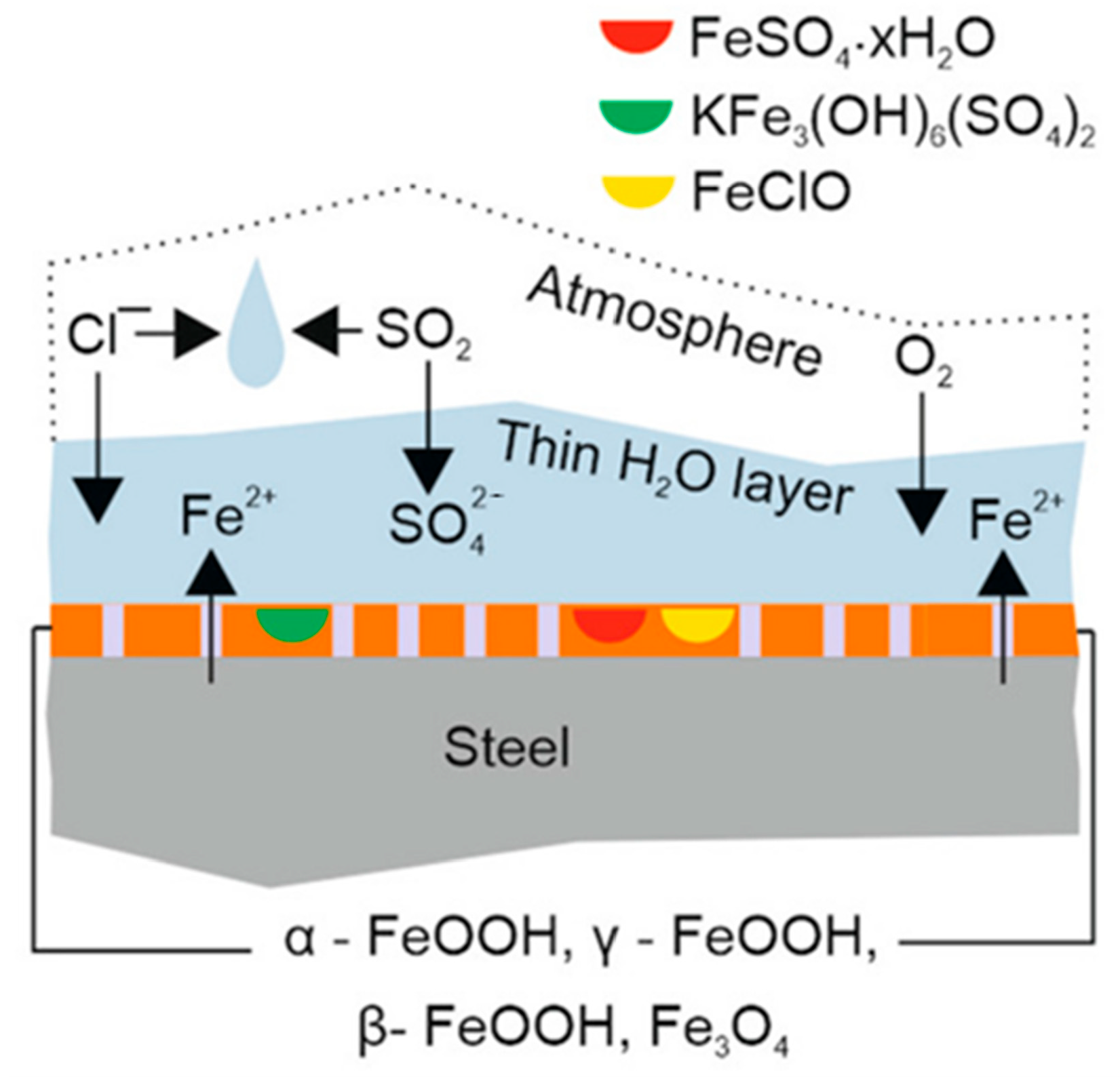

5.1. Corrosion Challenges in Tropical Marine Environments

5.2. Chi-GO Electrochemical Testing Technology and Application Cases

- Electrochemical Impedance Spectroscopy (EIS)

- Scanning Vibrating Electrode Technique (SVET)

- Tafel Polarization

5.3. Summary of the Mechanism of Nanofillers in Enhancing Corrosion Resistance

5.3.1. Physical Barrier Effect

5.3.2. Chemical Interactions and Interface Enhancements

5.3.3. Interface Regulation

5.3.4. Self-Healing Function

5.4. Engineering Challenges and Research Gaps

6. Environmental Sustainability and Industrial Application Prospects

6.1. Environmental Friendliness and Sustainability Analysis

6.2. Current Situation and Challenges in Industrial Applications

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, T.; Zhang, D.; Ma, L.; Huang, Y.; Hao, X.; Terryn, H.; Mol, A.; Li, X. Smart protective coatings with self-sensing and active corrosion protection dual functionality from pH-sensitive calcium carbonate microcontainers. Corros. Sci. 2022, 200, 110254. [Google Scholar] [CrossRef]

- Wang, L.; Li, S.; Vijayan, P.P.; El-Gawady, Y.M.H.; Al-Maadeed, M.A.S.A. Halloysite Nanotube as Multifunctional Component in Epoxy Protective Coating. Ind. Eng. Chem. Res. 2016, 55, 11186–11192. [Google Scholar] [CrossRef]

- Fu, J. Self-healing anti-corrosion coatings based on micron-nano containers with different structural morphologies. Prog. Org. Coat. 2023, 175, 107381. [Google Scholar] [CrossRef]

- Wu, H.; Zhu, Z.; Gao, N.; Ma, L.; Li, J.; Liu, F. The biomimetic design provides efficient self-healing of ultrahigh-tough and damage-warning bio-based elastomer for protective clothing of metals. Nano Res. 2023, 16, 10587–10596. [Google Scholar] [CrossRef]

- Liang, R.; Zhang, H.; Wang, Y.; Ye, J.; Guo, L.; He, L.; Li, X.; Qiu, T.; Tuo, X. Dual dynamic network system constructed by waterborne polyurethane for improved and recoverable performances. Chem. Eng. J. 2022, 442, 136204. [Google Scholar] [CrossRef]

- Sun, F.; Liu, L.; Xu, J.; Fu, J. Smart healable polyurethanes: Sustainable problem solvers based on constitutional dynamic chemistry. Mater. Chem. Front. 2023, 7, 3494–3523. [Google Scholar] [CrossRef]

- Qiang, Y.; Ran, B.; Li, M.; Xu, Q.; Peng, J. GO-functionalized MXene towards superior anti-corrosion coating. J. Colloid Interface Sci. 2023, 642, 595–603. [Google Scholar] [CrossRef]

- Chen, L.; Yu, Z.; Yin, D.; Cao, K. Preparation and anticorrosion properties of BTA@HNTs-GO nanocomposite smart coatings. Compos. Interfaces 2021, 28, 1–16. [Google Scholar] [CrossRef]

- Lu, X.; Gu, X. A review on lignin-based epoxy resins: Lignin effects on their synthesis and properties. Int. J. Biol. Macromol. 2023, 229, 778–790. [Google Scholar] [CrossRef]

- Bagheri, S.; Nejad, M. Fully biobased composite made with epoxidized-lignin, reinforced with bamboo fibers. Polym. Compos. 2023, 44, 3926–3938. [Google Scholar] [CrossRef]

- Over, L.C.; Grau, E.; Grelier, S.; Meier, M.A.R.; Cramail, H. Synthesis and Characterization of Epoxy Thermosetting Polymers from Glycidylated Organosolv Lignin and Bisphenol A. Macromol. Chem. Phys. 2017, 218, 1600411. [Google Scholar] [CrossRef]

- Tao, Y.Q.; Fang, L.X.; Dai, M.L.; Wang, C.Y.; Sun, J.; Fang, Q. Sustainable alternative to bisphenol A epoxy resin: High-performance recyclable epoxy vitrimers derived from protocatechuic acid. Polym. Chem. 2020, 11, 4500–4506. [Google Scholar] [CrossRef]

- Gioia, C.; Colonna, M.; Tagami, A.; Medina, L.; Sevastyanova, O.; Berglund, L.A.; Lawoko, M. Lignin-Based Epoxy Resins: Unravelling the Relationship between Structure and Material Properties. Biomacromolecules 2020, 21, 1920–1928. [Google Scholar] [CrossRef]

- Varghese, T.P.; Nair, C.P.R.; Gopalakrishnan, J. Green Epoxidized Niepa Seed Oil for Toughening Epoxy Resin: An Insight Into Viscoelastic, Mechanical, Thermal and Adhesive Properties. Polym. Eng. Sci. 2025; Early Access. [Google Scholar] [CrossRef]

- Liu, G.; Jin, C.; Huo, S.; Kong, Z.; Chu, F. Preparation and properties of novel bio-based epoxy resin thermosets from lignin oligomers and cardanol. Int. J. Biol. Macromol. 2021, 193, 1400–1408. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Chandrashekhara, K.; Flanigan, V.; Kapila, S. Curing and mechanical characterization of a soy-based epoxy resin system. J. Appl. Polym. Sci. 2004, 91, 3513–3518. [Google Scholar] [CrossRef]

- van de Velde, N.; Javornik, S.; Sever, T.; Stular, D.; Sobak, M.; Stirn, Z.; Likozar, B.; Jerman, I. Bio-Based Epoxy Adhesives with Lignin-Based Aromatic Monophenols Replacing Bisphenol A. Polymers 2021, 13, 3879. [Google Scholar] [CrossRef]

- Norsworthy, R. Fusion bonded epoxy—A field proven fail-safe coating system. In Proceedings of the CORROSION 2006, San Diego, CA, USA, 12–16 March 2006. [Google Scholar]

- Lee, S.Y.; Yun, Y.M.; Le, T.H.M. Enhancing Railway Track Stabilization with Epoxy Resin and Crumb Rubber Powder-Modified Cement Asphalt Mortar. Polymers 2023, 15, 4462. [Google Scholar] [CrossRef]

- Fischer, J.; Ritter, H. Oligomeric epoxide-amine adducts based on 2-amino-N-isopropylacetamide and α-amino-ε-caprolactam: Solubility in presence of cyclodextrin and curing properties. Beilstein J. Org. Chem. 2013, 9, 2803–2811. [Google Scholar] [CrossRef] [PubMed]

- Klemencic, K.; Krajnc, A.; Puskaric, A.; Hus, M.; Marinic, D.; Likozar, B.; Logar, N.Z.; Mazaj, M. Amine-Functionalized Triazolate-Based Metal-Organic Frameworks for Enhanced Diluted CO2 Capture Performance. Angew. Chem.-Int. Ed. 2025, 64, e202424747. [Google Scholar] [CrossRef]

- Zhang, P.X.; Wang, Q.; Zhang, Y.X.; Lin, M.; Zhou, X.; David, A.; Ustyuzhanin, A.; Chen, M.S.; Katsnelson, M.I.; Trubyanov, M.; et al. Strain-induced crumpling of graphene oxide lamellas to achieve fast and selective transport of H2 and CO2. Nat. Nanotechnol. 2025; Early Access. [Google Scholar] [CrossRef]

- Chen, W.; Li, R.A.; Cao, Y.F.; Ye, C.J.; Liu, Z.L.; Xiao, H.N. Silanization-Modified Lignin Nanoparticles for Paper Coating with Enhanced Liquid and Vapor Barriers, Frication Resistance, and Self-Cleaning Properties. Polymers 2025, 17, 2066. [Google Scholar] [CrossRef]

- Garg, A.; Basu, S.; Mahajan, R.L.; Mehta, R. Effect of rGO synthesized from different precursors on the enhancement in mechanical properties of GFRPs. Sci. Rep. 2025, 15, 29108. [Google Scholar] [CrossRef]

- Lv, C.; Liu, J.; Guo, G.L.; Zhang, Y.M. The Mechanical Properties of Plant Fiber-Reinforced Geopolymers: A Review. Polymers 2022, 14, 4134. [Google Scholar] [CrossRef]

- Saboori, K.; Nassira, M.; Safari, M.; Namdar, N.; Montaseri, Z.; Osanloo, M. Antibacterial activity of a conventional hydrogel and a nanoparticle based hydrogel containing Satureja khuzestanica essential oil. Sci. Rep. 2025, 15, 21267. [Google Scholar] [CrossRef]

- Bergoglio, M.; Reisinger, D.; Schlögl, S.; Griesser, T.; Sangermano, M. Sustainable Bio-Based UV-Cured Epoxy Vitrimer from Castor Oil. Polymers 2023, 15, 1024. [Google Scholar] [CrossRef]

- Puasa, N.A.; Zulkharnain, A.; Verasoundarapandian, G.; Wong, C.Y.; Zahri, K.N.M.; Merican, F.; Shaharuddin, N.A.; Gomez-Fuentes, C.; Ahmad, S.A. Effects of Diesel, Heavy Metals and Plastics Pollution on Penguins in Antarctica: A Review. Animals 2021, 11, 2505. [Google Scholar] [CrossRef]

- Yeo, J.D. Food-Derived Extracellular Vesicles as Multi-Bioactive Complex and Their Versatile Health Effects. Antioxidants 2023, 12, 1862. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, S.I.; Ansari, M.N.M. Mechanical properties of graphene oxide (GO)/epoxy composites. HBRC J. 2015, 11, 151–156. [Google Scholar] [CrossRef]

- Outroumanis, N.; Manikas, A.C.; Pappas, P.N.; Anagnostopoulos, G.; Galiotis, C. Interfacial properties and mechanical performance of hybrid graphene/carbon fibre composites. Mater. Today Commun. 2024, 41, 110458. [Google Scholar] [CrossRef]

- Choudhury, D.N.; Pareta, A.S.; Rajesh, A.K.; Panda, S.K. Enhanced mechanical and interfacial performances of carbon fiber reinforced composites with low percentage of amine functionalized graphene. Polym. Compos. 2024, 45, 13772–13790. [Google Scholar] [CrossRef]

- Cui, G.; Bi, Z.; Zhang, R.; Liu, J.; Yu, X.; Li, Z. A comprehensive review on graphene-based anti-corrosive coatings. Chem. Eng. J. 2019, 373, 104–121. [Google Scholar] [CrossRef]

- Tang, H.; Liu, D.M.; Zhao, Y.; Yang, X.N.; Lu, J.; Cui, F.Y. Molecular Dynamics Study of the Aggregation Process of Graphene Oxide in Water. J. Phys. Chem. C 2015, 119, 26712–26718. [Google Scholar] [CrossRef]

- Yadav, N.; Dubey, A.; Shukla, S.; Saini, C.P.; Gupta, G.; Priyadarshini, R.; Lochab, B. Graphene Oxide-Coated Surface: Inhibition of Bacterial Biofilm Formation due to Specific Surface-Interface Interactions. ACS Omega 2017, 2, 3070–3082. [Google Scholar] [CrossRef] [PubMed]

- Figueroa, T.; Aguayo, C.; Fernández, K. Design and Characterization of Chitosan-Graphene Oxide Nanocomposites for the Delivery of Proanthocyanidins. Int. J. Nanomed. 2020, 15, 1229–1238. [Google Scholar] [CrossRef]

- Nath, J.; Chowdhury, A.; Dolui, S.K. Chitosan/graphene oxide-based multifunctional pH-responsive hydrogel with significant mechanical strength, self-healing property, and shape memory effect. Adv. Polym. Technol. 2018, 37, 3665–3679. [Google Scholar] [CrossRef]

- Ma, L.C.; Zhu, Y.Y.; Wu, G.S.; Li, X.R.; Tian, C.G.; Wang, Y.H.; Xu, L.Y.; Song, G.J. Hydroxyl-Terminated Triazine Derivatives Grafted Graphene Oxide for Epoxy Composites: Enhancement of Interfacial and Mechanical Properties. Polymers 2019, 11, 1866. [Google Scholar] [CrossRef]

- Naveas, N.; Pulido, R.; Torres-Costa, V.; Agullo-Rueda, F.; Santibanez, M.; Malano, F.; Recio-Sanchez, G.; Garrido-Miranda, K.A.; Manso-Silvan, M.; Hernandez-Montelongo, J. Antibacterial Films of Silver Nanoparticles Embedded into Carboxymethylcellulose/Chitosan Multilayers on Nanoporous Silicon: A Layer-by-Layer Assembly Approach Comparing Dip and Spin Coating. Int. J. Mol. Sci. 2023, 24, 10595. [Google Scholar] [CrossRef]

- Burgos-Díaz, C.; Opazo-Navarrete, M.; Palacios, J.L.; Barahona, T.; Mosi-Roa, Y.; Anguita-Barrales, F.; Bustamante, M. Synthesis of New Chitosan from an Endemic Chilean Crayfish Exoskeleton (Parastacus Pugnax): Physicochemical and Biological Properties. Polymers 2021, 13, 2304. [Google Scholar] [CrossRef]

- Liu, W.L.; Li, J.S. Sodium Lignosulfonate-Loaded Halloysite Nanotubes/Epoxy Composites for Corrosion Resistance Coating. ACS Omega 2023, 8, 18425–18434. [Google Scholar] [CrossRef]

- Stojanovic, I.; Cindric, I.; Turkalj, L.; Kurtela, M.; Rakela-Ristevski, D. Durability and Corrosion Properties of Waterborne Coating Systems on Mild Steel Dried under Atmospheric Conditions and by Infrared Radiation. Materials 2022, 15, 8001. [Google Scholar] [CrossRef] [PubMed]

- Ding, J.; Qiao, Z.; Zhang, Y.S.; Wei, D.R.; Chen, S.P.; Tang, J.J.; Chen, L.; Wei, D.; Sun, J.; Fan, H.S. NIR-responsive multi-healing HMPAM/dextran/AgNWs hydrogel sensor with recoverable mechanics and conductivity for human-machine interaction. Carbohydr. Polym. 2020, 247, 116686. [Google Scholar] [CrossRef]

- Li, Q.; Tang, R.; Wang, S.; Zou, Z.S. A coupled LES-LBM-IMB-DEM modeling for evaluating pressure drop of a heterogeneous alternating-layer packed bed. Chem. Eng. J. 2022, 433, 133529. [Google Scholar] [CrossRef]

- Bauer, K.N.; Tee, H.T.; Velencoso, M.M.; Wurm, F.R. Main-chain poly(phosphoester)s: History, syntheses, degradation, bio-and flame-retardant applications. Prog. Polym. Sci. 2017, 73, 61–122. [Google Scholar] [CrossRef]

- Van Vleet, M.J.; Weng, T.T.; Li, X.Y.; Schmidt, J.R. In Situ, Time-Resolved, and Mechanistic Studies of Metal-Organic Framework Nucleation and Growth. Chem. Rev. 2018, 118, 3681–3721. [Google Scholar] [CrossRef]

- Sealy, C. Hollow carbon balls hit tumors harder [News Item]. Mater. Today 2020, 38, 4–5. [Google Scholar] [CrossRef]

- Sreenilayam, S.P.; Ul Ahad, I.; Nicolosi, V.; Garzon, V.A.; Brabazon, D. Advanced materials of printed wearables for physiological parameter monitoring. Mater. Today 2020, 32, 147–177. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Zhao, T. Corrosion-Resisting Nanocarbon Nanocomposites for Aerospace Application: An Up-to-Date Account. Appl. Nano 2023, 4, 138–158. [Google Scholar] [CrossRef]

- Waseem, S.; Ehsan, U.H.; Ramzan, A.K.M.; Junaid, S.; Hassan, S. Synthesis of Nano Ceramic Epoxy Hybrid Composite Coating on Metallic Substrate for Corrosion Protection. Solid State Phenom. 2022, 6635, 49–59. [Google Scholar] [CrossRef]

- Sharif, M.; Tavakoli, S. Chitosan-modified graphene oxide filled photo-curable nanocomposite coating with advanced properties. Polym. Bull. 2024, 81, 11481–11498. [Google Scholar] [CrossRef]

- Huang, M.; Khor, E.; Lim, L.Y. Uptake and cytotoxicity of chitosan molecules and nanoparticles: Effects of molecular weight and degree of deacetylation. Pharm. Res. 2004, 21, 344–353. [Google Scholar] [CrossRef] [PubMed]

- Sahariah, P.; Gaware, V.S.; Lieder, R.; Jónsdóttir, S.; Hjálmarsdóttir, M.A.; Sigurjonsson, O.E.; Másson, M. The Effect of Substituent, Degree of Acetylation and Positioning of the Cationic Charge on the Antibacterial Activity of Quaternary Chitosan Derivatives. Mar. Drugs 2014, 12, 4635–4658. [Google Scholar] [CrossRef]

- Budhiraja, M.; Zafar, S.; Akhter, S.; Alrobaian, M.; Rashid, M.A.; Barkat, M.A.; Beg, S.; Ahmad, F.J. Mupirocin-Loaded Chitosan Microspheres Embedded in Piper betle Extract Containing Collagen Scaffold Accelerate Wound Healing Activity. AAPS PharmSciTech 2022, 23, 77. [Google Scholar] [CrossRef]

- Egorov, A.R.; Kirichuk, A.A.; Rubanik, V.V.; Rubanik, V.V., Jr.; Tskhovrebov, A.G.; Kritchenkov, A.S. Chitosan and Its Derivatives: Preparation and Antibacterial Properties. Materials 2023, 16, 6076. [Google Scholar] [CrossRef]

- Ke, C.L.; Deng, F.S.; Chuang, C.Y.; Lin, C.H. Antimicrobial Actions and Applications of Chitosan. Polymers 2021, 13, 904. [Google Scholar] [CrossRef]

- Rashki, S.; Asgarpour, K.; Tarrahimofrad, H.; Hashemipour, M.; Ebrahimi, M.S.; Fathizadeh, H.; Khorshidi, A.; Khan, H.; Marzhoseyni, Z.; Salavati-Niasari, M.; et al. Chitosan-based nanoparticles against bacterial infections. Carbohydr. Polym. 2021, 251, 117108. [Google Scholar] [CrossRef]

- Li, X.; Qu, Z.; Jing, S.; Li, X.; Zhao, C.; Man, S.; Wang, Y.; Gao, W. Dioscin-6′-O-acetate inhibits lung cancer cell proliferation via inducing cell cycle arrest and caspase-dependent apoptosis. Phytomedicine 2019, 53, 124–133. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, V.; Maiti, S.; Rajeshkumar, S.; Agarwal, S. Evaluation of compressive strength, color stability, and antimicrobial action of chitosan-modified temporary crowns. J. Adv. Pharm. Technol. Res. 2022, 13, S485–S490. [Google Scholar] [CrossRef]

- Ashry, N.M.; El Bahgy, H.E.K.; Mohamed, A.; Alsubhi, N.H.; Alrefaei, G.I.; Binothman, N.; Alharbi, M.; Selim, S.; Almuhayawi, M.S.; Alharbi, M.T.; et al. Evaluation of graphene oxide, chitosan and their complex as antibacterial agents and anticancer apoptotic effect on HeLa cell line. Front. Microbiol. 2022, 13, 922324. [Google Scholar] [CrossRef]

- Yin, N.; Du, R.P.; Zhao, F.K.; Han, Y.; Zhou, Z.J. Characterization of antibacterial bacterial cellulose composite membranes modified with chitosan or chitooligosaccharide. Carbohydr. Polym. 2020, 229, 115520. [Google Scholar] [CrossRef] [PubMed]

- ISO 12944-2:2018; Paints and Varnishes—Corrosion Protection of Steel Structures by Protective Paint Systems—Part 2: Classification of Environments. International Organization for Standardization: Geneva, Switzerland, 2018.

- ASTM B117-19; Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International: West Conshohocken, PA, USA, 2019.

- Seechurn, Y.; Surnam, B.Y.R.; Wharton, J.A. Marine atmospheric corrosion of carbon steel in the tropical microclimate of Port Louis. Mater. Corros.-Werkst. Korros. 2022, 73, 1474–1489. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Liu, T.; Sun, F.; Li, S.; Geng, Y.; Yao, B.; Xu, J.; Fu, J. Bio-inspired self-healing and anti-corrosion waterborne polyurethane coatings based on highly oriented graphene oxide. npj Mater. Degrad. 2023, 7, 96. [Google Scholar] [CrossRef]

- Zhang, F.Y.; Liu, W.Q.; Liang, L.Y.; Wang, S.; Shi, H.Y.; Xie, Y.K.; Yang, M.P.; Pi, K. The effect of functional graphene oxide nanoparticles on corrosion resistance of waterborne polyurethane. Colloids Surf. A-Physicochem. Eng. Asp. 2020, 591, 124565. [Google Scholar] [CrossRef]

- Duan, W.; Chen, Y.; Ma, J.; Wang, W.; Cheng, J.; Zhang, J. High-performance graphene reinforced epoxy nanocomposites using benzyl glycidyl ether as a dispersant and surface modifier. Compos. Part B-Eng. 2020, 189, 107878. [Google Scholar] [CrossRef]

- Xu, C.A.; Liang, W.; Ni, C.; Li, X.; Shi, X.; Chu, Z.; Hu, Y.; Yang, Z. Silicone and nano-diamond modified graphene oxide anticorrosive coating. Surf. Coat. Technol. 2024, 479, 130584. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Brito, F.S.; Franceschi, W.; Simonetti, E.A.N.; Cividanes, L.S.; Chipara, M.; Lozano, K. Functionalized graphene oxide as reinforcement in epoxy based nanocomposites. Surf. Interfaces 2018, 10, 100–109. [Google Scholar] [CrossRef]

- Kim, S.-H.; Rhee, K.Y.; Park, S.-J. Amine-terminated chain-grafted nanodiamond/epoxy nanocomposites as interfacial materials: Thermal conductivity and fracture resistance. Compos. Part B-Eng. 2020, 192, 107983. [Google Scholar] [CrossRef]

- Zou, Y.; Fang, L.; Chen, T.; Sun, M.; Lu, C.; Xu, Z. Near-Infrared Light and Solar Light Activated Self-Healing Epoxy Coating having Enhanced Properties Using MXene Flakes as Multifunctional Fillers. Polymers 2018, 10, 474. [Google Scholar] [CrossRef]

- Shao, H.L.; Chen, Z.H.; Chang, J.L.; Yin, X.S.; Chen, Y.; Liu, Y.; Zhang, K.G.; Yang, W.Z. Gum Arabic microgel-based biomimetic waterborne anticorrosive coatings with reinforced water and abrasive resistances. Carbohydr. Polym. 2024, 342, 122408. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, J.; Rupanty, N.S.; Noor, T.; Asif, T.R.; Islam, T.; Reukov, V. Functional coatings for textiles: Advancements in flame resistance, antimicrobial defense, and self-cleaning performance. RSC Adv. 2025, 15, 10984–11022. [Google Scholar] [CrossRef]

- Hart, A.; Ebiundu, K.; Peretomode, E.; Onyeaka, H.; Nwabor, O.F.; Obileke, K. Value-added materials recovered from waste bone biomass: Technologies and applications. RSC Adv. 2022, 12, 22302–22330. [Google Scholar] [CrossRef] [PubMed]

- Pan, T.; Lu, D.; Xin, H.; Li, B. Biophotonic probes for bio-detection and imaging. Light-Sci. Appl. 2021, 10, 124. [Google Scholar] [CrossRef] [PubMed]

- Abraham, E.; Kam, D.; Nevo, Y.; Slattegard, R.; Rivkin, A.; Lapidot, S.; Shoseyov, O. Highly Modified Cellulose Nanocrystals and Formation of EpoxyNanocrystalline Cellulose (CNC) Nanocomposites. ACS Appl. Mater. Interfaces 2016, 8, 28086–28095. [Google Scholar] [CrossRef] [PubMed]

- ASTM D5894-16; Standard Practice for Cyclic Salt Fog/UV Exposure of Painted Metal, (Alternating Exposures in a Fog/Dry Cabinet and a UV/Condensation Cabinet). ASTM International: West Conshohocken, PA, USA, 2016.

- ISO 20340:2009; Paints and Varnishes—Performance Requirements for Protective Paint Systems for Offshore and Related Structures. International Organization for Standardization: Geneva, Switzerland, 2009.

| Property | BPA-Based Epoxy | Lignin-Based Epoxy (Lignin Content of 66%) | Vegetable-Oil-Based Epoxy (Niepa Seed Oil/Epoxy (20/80)) |

|---|---|---|---|

| Tg (°C) | 93 [12] | 79 [13] | 53.9 [14] |

| Tensile Strength (MPa) | 47.5 ± 3.2 [12] | 66 [13] | 9.6 ± 0.4 [14] |

| Corrosion Resistance | High | Moderate | Low to Moderate |

| VOC Emissions | High | Low | Very Low |

| Benefits | Detailed Assessment | Limitations | Detailed Assessment |

|---|---|---|---|

| Low VOCs & Eco-friendly | Bio-based epoxy/Chi-GO system reduces petroleum use and VOC emissions, enhancing biodegradability and biocompatibility [20]. | Slow Curing & Humidity Sensitivity | Hydrophilicity of waterborne/bio-based systems delays curing under humid conditions; Chi-GO partially mitigates water uptake [21]. |

| Enhanced Barrier & Corrosion Protection | Chi-GO induces a tortuous diffusion path, with GO–chitosan synergy improving barrier and corrosion resistance in saline environments [22]. | Porous Microstructure & Water Uptake | Despite Chi-GO, water loss causes micro-porosity, and high humidity retains water, weakening initial barrier function [23]. |

| Improved Mechanical & Adhesion Properties | Chi-GO enhances tensile strength, modulus, and metal adhesion via interfacial interactions between chitosan amines and the epoxy matrix [24]. | Reduced Impact Resistance at High Bio-Content | When bio-content exceeds 30%, toughness decreases. Chi-GO helps recover stiffness but may reduce ductility if dispersion is poor [25]. |

| Antibacterial Activity | Chitosan exhibits intrinsic antibacterial activity, reducing microbial-induced corrosion in marine settings; graphene oxide enhances this via membrane disruption [26]. | Durability under UV/Thermal Exposure | Bio-based epoxies and chitosan degrade under UV and hydrolysis [27], limiting long-term performance in tropical climates without stabilizers. |

| Applicability on Damp Surfaces | Waterborne systems show better damp-substrate tolerance; Chi-GO enhances wet adhesion via chitosan’s hydrophilicity [28]. | Storage & Freeze-Thaw Stability | Nano-reinforced systems may aggregate after repeated freeze-thaw cycles, impacting shelf life and necessitating optimized dispersion [29]. |

| Nano-Filler | Dispersion | Mechanical Enhancement | EIS (Ω·cm2) | Antibacterial Activity | Sustainability |

|---|---|---|---|---|---|

| GO | Moderate | Moderate | ~103–104 | Weak | Moderate |

| Chi-GO | Good | High | ~107 | Strong (>95% inhibition) | High (Bio-based) |

| CNT | Poor | High | ~108–109 | None | Low |

| CNC | Good | Moderate | ~105–106 | Moderate | High (Bio-based) |

| SiO2 | Good | High | ~109 | None | Moderate |

| Material | Antibacterial Advantage | Antibacterial Limitation | Corrosion Resistance Advantage | Corrosion Resistance Limitations |

|---|---|---|---|---|

| CS | Broad-spectrum antibacterial, biodegradable | pH sensitivity, poor mechanical properties | Film-forming property, metal chelation | High water affinity, easy dissolution |

| GO | Physical cutting potential (high concentration) | Easy to reunite, may promote bacterial growth | Extremely strong physical barrier, high specific surface area | No active antibacterial effect, difficult to disperse |

| Chi-GO | Synergistic antibacterial effects, enhanced pH adaptability | Barrier, Active Inhibition, Self-Repairing Multi-Functional Integration |

| Material | Inhibition Rate (%)—E. coli | Inhibition Rate (%)—S. aureus | MIC (μg/mL)—Pseudomonas | Marine Environment Stability |

|---|---|---|---|---|

| CS | 99.99 ± 0.01 | 99.99 ± 0.01 | 1000 | Poor (pH-dependent) |

| GO | 70 | 93 | >1000 | Moderate |

| Chi-GO (2:1) | >98 | >99 | 200 | High |

| Electrochemical Parameter | Pure WPU Coating | GO-WPU Coating | Chi-GO-WPU Composite Coating |

|---|---|---|---|

| Ecorr (V) | −0.224 | −0.101 | −0.2~−0.6 |

| Icorr (A/cm2) | 1.91 × 10−8 | 1.74 × 10−8 | 10−11~10−6 |

| Rp (Ω·cm2) | 2.30 × 106 | 2.54 × 106 | 104~107 |

| |Z|0.01 Hz (Ω·cm2) (20 days immersion in 3.5 wt.% NaCl solution) | 1.36 × 107 → 9.32 × 106 | 1.49 × 107 → 9.49 × 106 | ~108 |

| Mechanism Type | Mode of Action | Performance Manifestation | Key Influencing Factors |

|---|---|---|---|

| Physical Barrier | GO nanosheets form a tortuous maze barrier | Extends the Cl− penetration path by >10 times | GO dispersion, orientation, interlayer spacing |

| Chemical Interaction | Hydrogen bonding network and dynamic bonding | Enhances interfacial bonding strength, delays cracking | Functional group density, reactivity |

| Interface Regulation | Charge barrier and adhesion enhancement | Reduces cathodic delamination, improves binding strength | Degree of interfacial chemical reaction |

| Functional Self-Healing | NIR photothermal response and dynamic bond reorganization | Micro-crack repair efficiency >80% | Stimulus responsiveness, chain segment mobility |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Luo, Z.; Wang, Y.; Xu, C.; Li, Y. Chitosan-Grafted Graphene Oxide-Reinforced Bio-Based Waterborne Epoxy Nanocomposites for Antibacterial and Corrosion Resistance in Tropical Marine Environments: A Mini-Review. Polymers 2025, 17, 2964. https://doi.org/10.3390/polym17212964

Wu Y, Luo Z, Wang Y, Xu C, Li Y. Chitosan-Grafted Graphene Oxide-Reinforced Bio-Based Waterborne Epoxy Nanocomposites for Antibacterial and Corrosion Resistance in Tropical Marine Environments: A Mini-Review. Polymers. 2025; 17(21):2964. https://doi.org/10.3390/polym17212964

Chicago/Turabian StyleWu, Yunyang, Zhongyuan Luo, Yucheng Wang, Chengwei Xu, and Yuanzhe Li. 2025. "Chitosan-Grafted Graphene Oxide-Reinforced Bio-Based Waterborne Epoxy Nanocomposites for Antibacterial and Corrosion Resistance in Tropical Marine Environments: A Mini-Review" Polymers 17, no. 21: 2964. https://doi.org/10.3390/polym17212964

APA StyleWu, Y., Luo, Z., Wang, Y., Xu, C., & Li, Y. (2025). Chitosan-Grafted Graphene Oxide-Reinforced Bio-Based Waterborne Epoxy Nanocomposites for Antibacterial and Corrosion Resistance in Tropical Marine Environments: A Mini-Review. Polymers, 17(21), 2964. https://doi.org/10.3390/polym17212964