Bond Properties of Steel Bar in Polyoxymethylene-Fiber-Reinforced Coral Aggregate Concrete

Abstract

1. Introduction

2. Experiment Design

2.1. Material

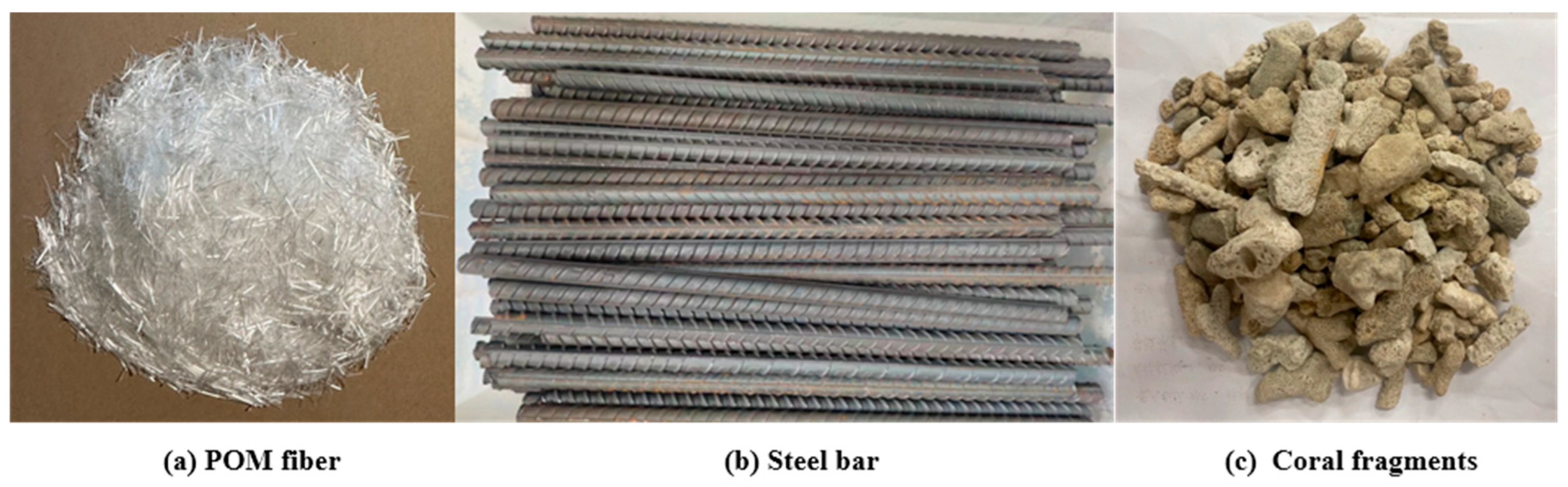

2.1.1. POM Fiber

2.1.2. Steel Bar

2.1.3. Concrete Raw Materials and Mix Proportion

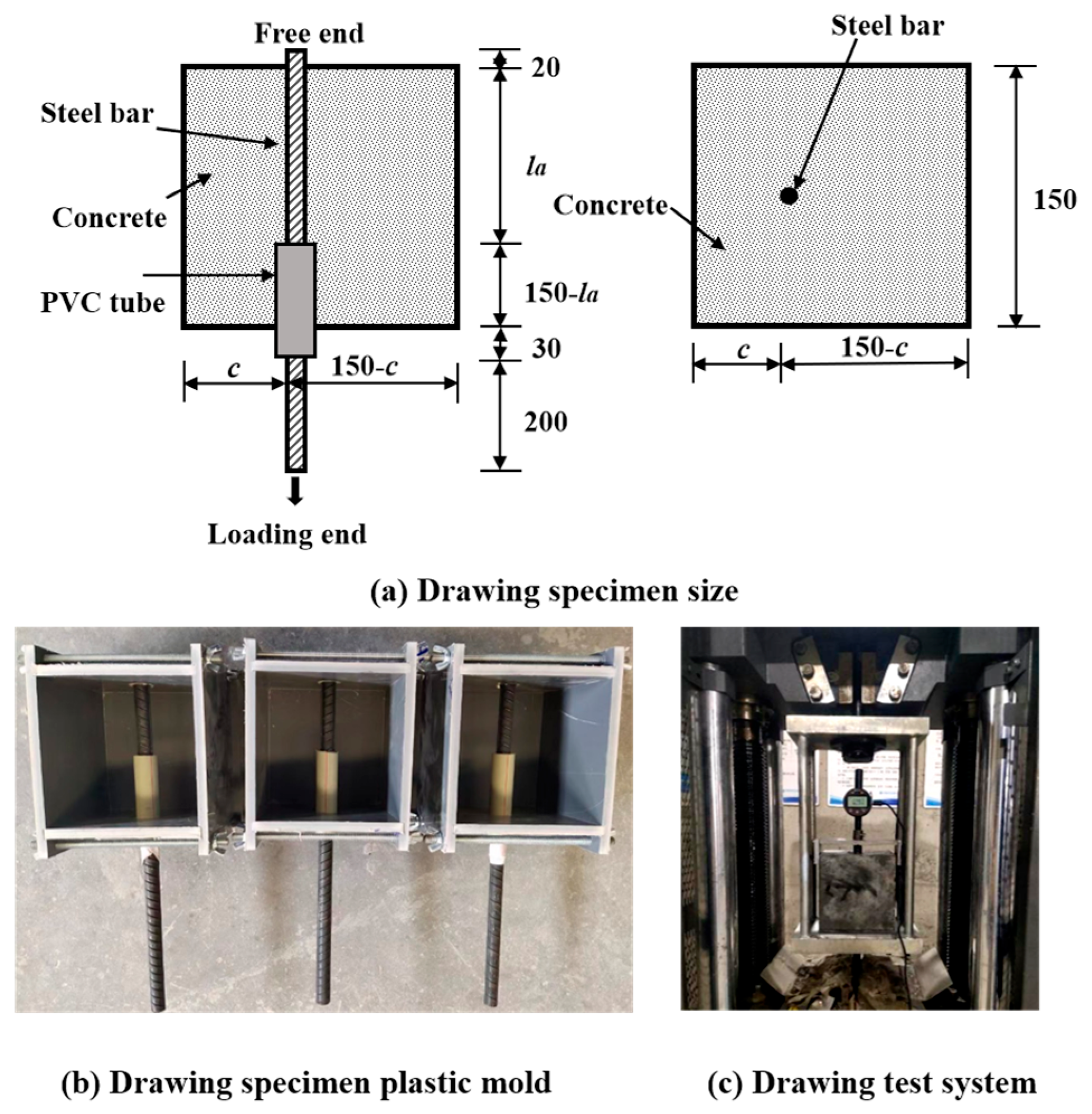

2.2. Drawing Specimen Design

2.3. Loading Device and Loading System

3. Results and Discussion

3.1. Failure Mode and Mechanism Analysis

3.2. Bond–Slip Curve and Model

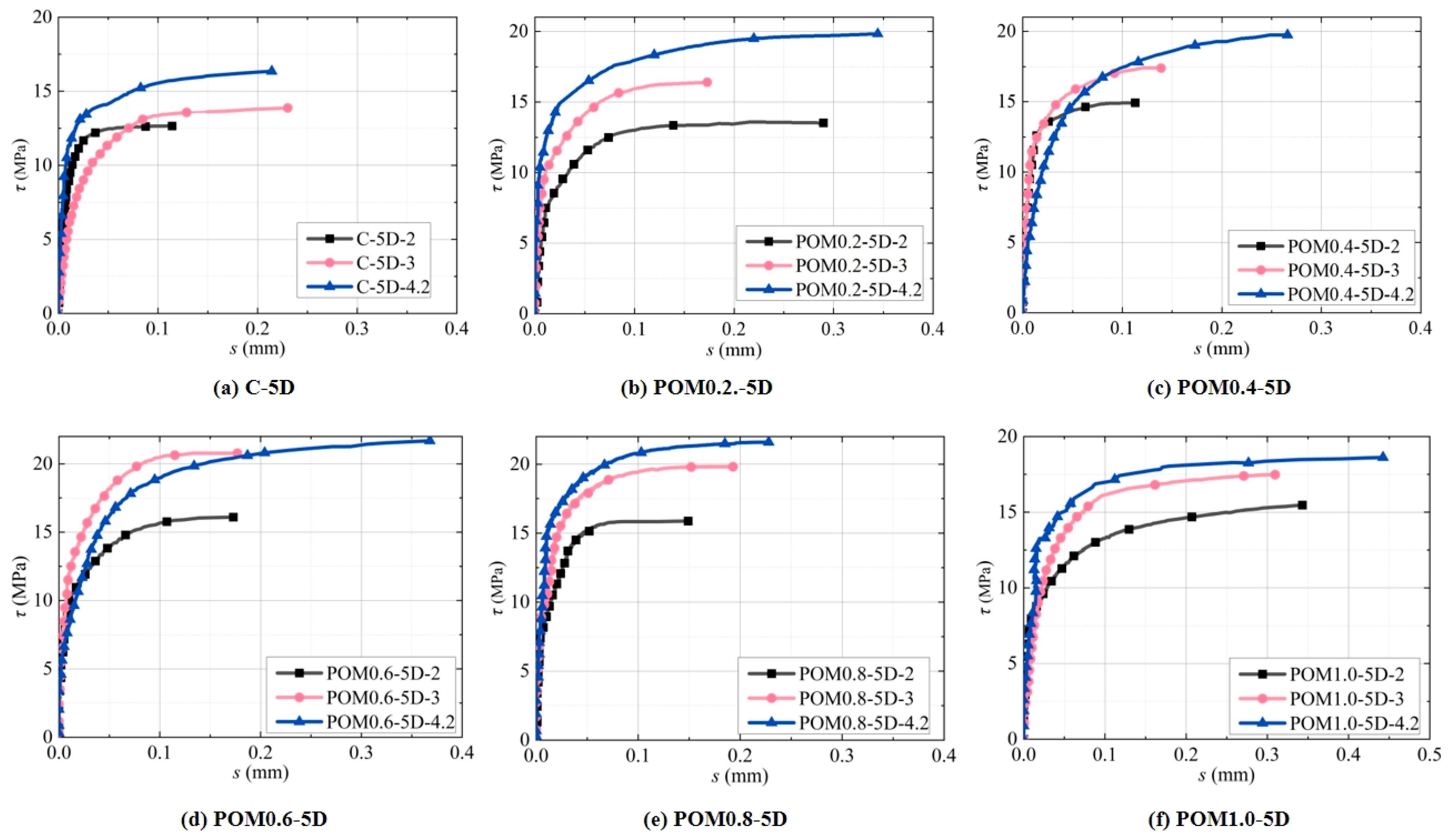

3.2.1. Bond–Slip Curve

- (1)

- Microslip stage: At the beginning of the loading stage, the load (F) and slip (s) of the testing machine exhibited a largely linear relationship, the loading force was small, and the free end exhibited almost no displacement. Meanwhile, the chemical adhesive force between the deformed reinforcement bar and the CAC made up most of the bonding force [59]. The surface of the specimen exhibited no visible distortion or fissures, and the curve was linear.

- (2)

- Slip stage: The curve becomes nonlinear and roughly presents an exponential function form at a peak load ranging between 30% and 100%. With the continuous increase in loading force, the steel rib successively develops cracks from the loading end to the free end, and the bonding force of the specimen was mainly supplied by the mechanical bite force and friction force [60]. The compressive stress in the front rib area increased, resulting in local concrete compression and friction and extrusion between the steel rib and CAC. Moreover, plastic deformation and micro-cracks gradually appeared inside the specimen. By forming a broken zone in front of the reinforcement rib, the radial component of the reinforcement rib pressure on the surrounding concrete creates circumferential tensile stress in the concrete. At this stage, the slip increases rapidly, and the bond–slip curve rises nonlinearly until it reaches a peak point, namely the peak bond stress.

- (3)

- Parallel stage: When the peak bond stress was reached, the slip between the reinforcement and concrete increased, the force remained largely unchanged, and the slip continued to increase. When the circumferential tensile stress exceeded the CAC tensile strength, radial cracks formed inside the specimen and developed from the surface of the steel bar to that of the specimen along the radial direction. Simultaneously, numerous fine cracks emerged on the surface of the concrete specimen. As slip increased, the adhesive force of the specimen was primarily from the friction force between the reinforcement and concrete and the mechanical bite force. Finally, the macroscopic crack developed rapidly, and splitting failure occurred.

3.2.2. Bond–Slip Constitutive Model

3.3. Influencing Factors for Bonding Properties

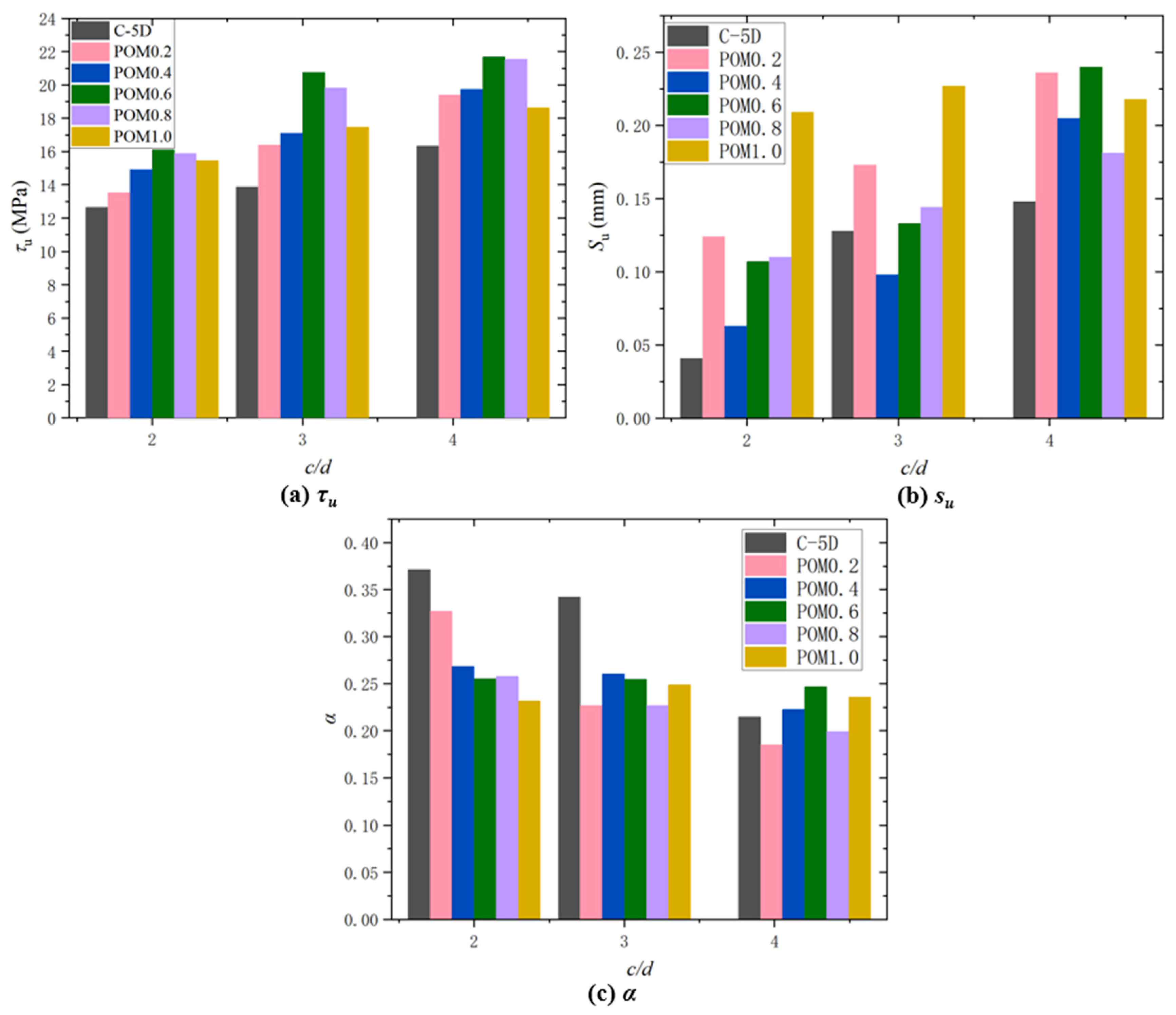

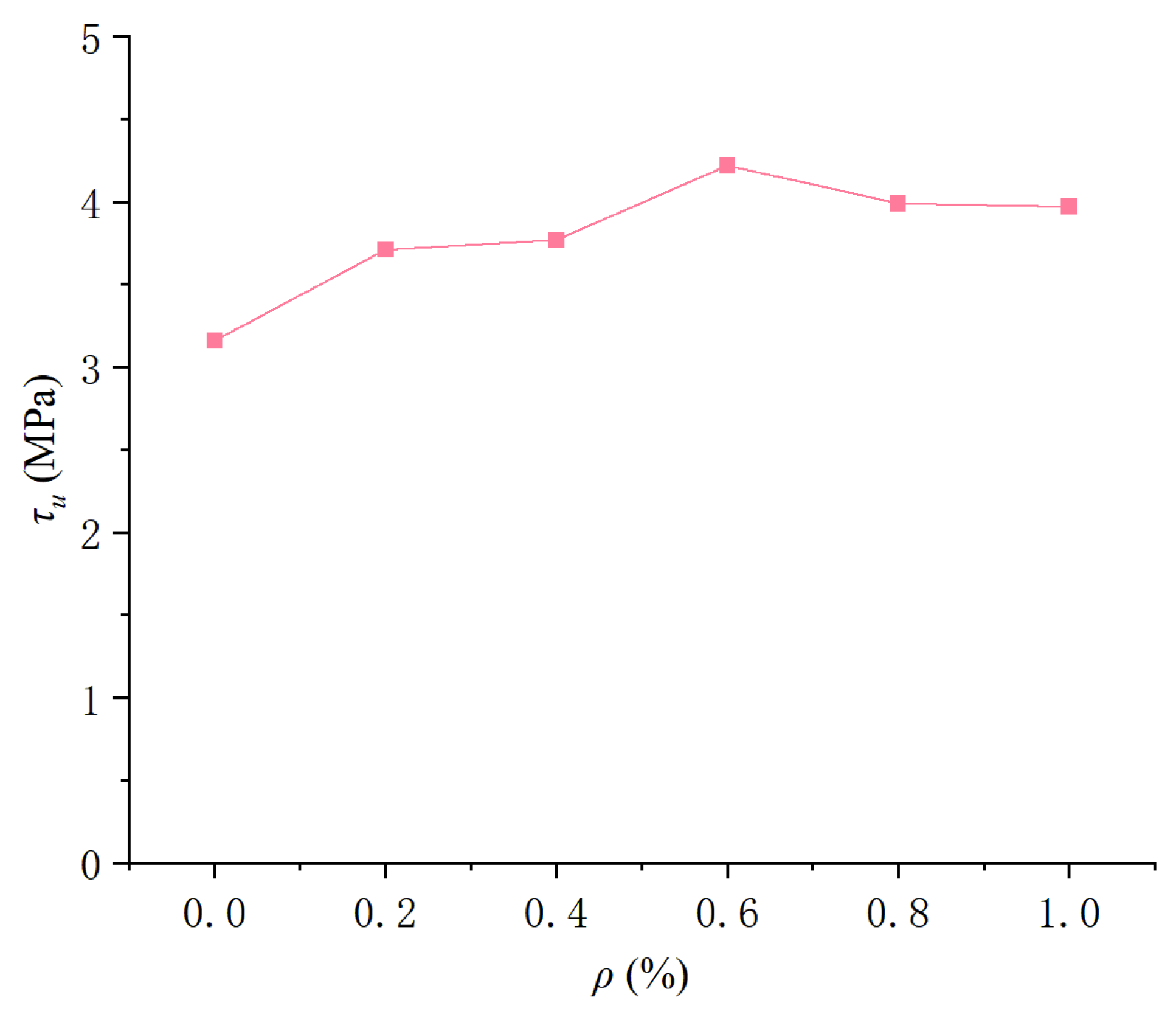

3.3.1. Influence of Different Fiber Contents

3.3.2. Impact of Different Protective Layer Thickness

3.3.3. Influence of Different Anchorage Lengths

3.3.4. Influence of Different Steel Bar Surface Morphologies

4. Proposed and Verified Bond–Slip Constitutive Model

4.1. Proposed Model

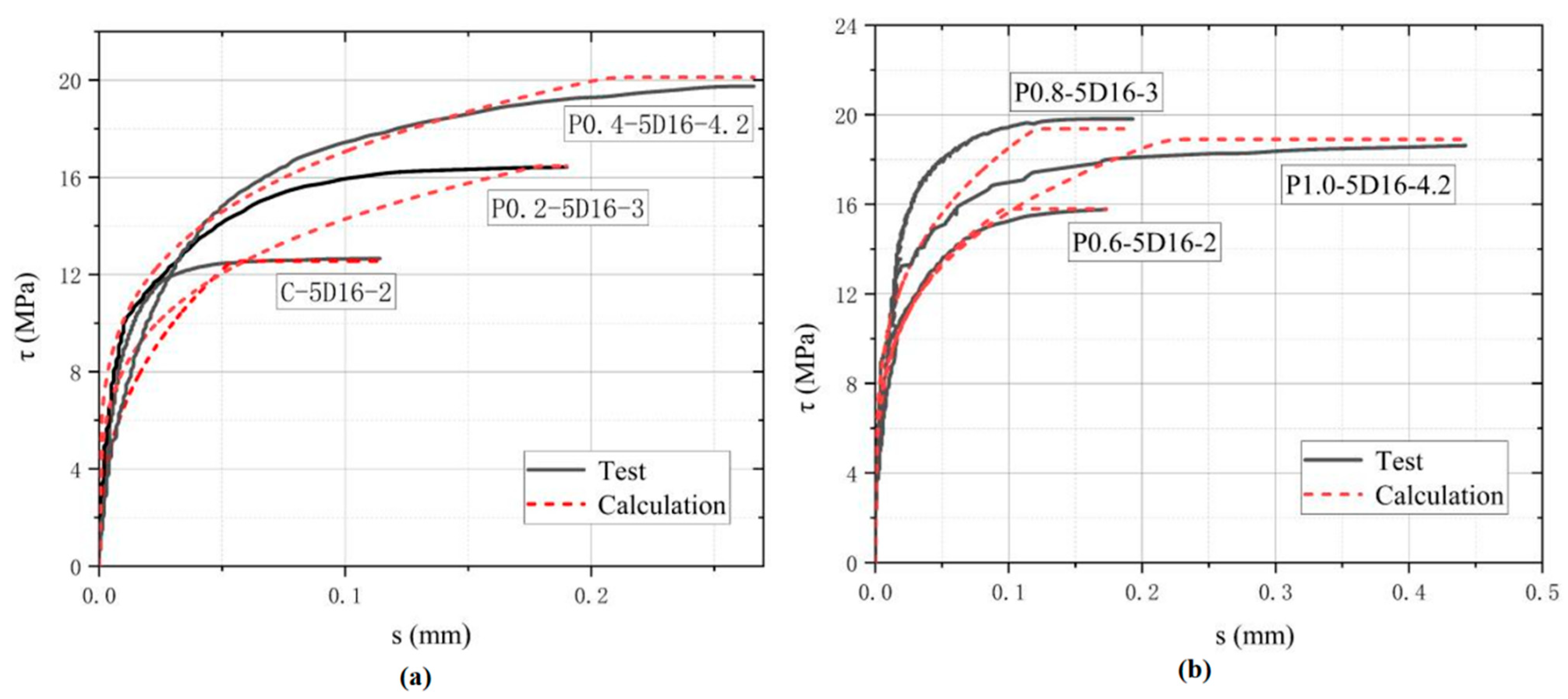

4.2. Model Verification

5. Basic Anchorage Length Design Recommendations

6. Conclusions

- (1)

- Split, pull-out with split, and pull-out failure are the bonding failure modes of deformed reinforcement bar and CAC. The thickness of the protective layer will affect the bonding failure mode. The thinner the protective barrier, the greater the likelihood of split failure. The bonding failure mode between the plain round steel bar and CAC is the pull-out failure mode. POM fiber has a small influence on the failure mode of the plain round reinforcement bar.

- (2)

- The bond–slip buckling of the deformed reinforcement bar and POM-fiber-reinforced CAC is divided into three stages: microslip, slip, and parallel stages. For different fiber contents, as c/d increases, the peak bond stress increases, the steepness of the curve is greater, and the characteristic value α of the rising portion of the curve is smaller; therefore, the larger c/d is, the faster the bond stress rises within the same range.

- (3)

- The peak bond stress τu of the deformed reinforcement bar and POM-fiber-reinforced CAC initially rises and then subsequently declines as the POM fiber content increases, and the increase in the peak stress is the most prominent when the POM fiber content is 0.6. Compared to CAC without fiber, an increase of 49.69% can be achieved with a POM fiber content of 0.6. The shape parameter α of the slip su and the rise section corresponding to the peak stress are concentrated in a certain interval, and the former has no strong correlation with the fiber content. However, with the change in c/d, su increases monotonically, and α decreases monotonically.

- (4)

- From the existing bond–slip curve calculation model, a 28 d bond–slip curve model for the deformed reinforcement bar and CAC was established considering POM fiber content and the ratio between concrete protective layer thickness and reinforcement diameter. This was then compared with the experimental results. The findings indicate that the model fits well with the experimental findings.

- (5)

- The basic anchorage length of HRB400 reinforcement and CAC was calculated according to design codes, and the recommended basic anchorage length of each POM fiber content was obtained for reference in engineering applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, N.; Wang, N.; Lin, W. Assessment of the impact of artificial island airport reclamation on marine ecosystem health: A case study of the Dalian offshore airport, China. Ocean Coast. Manag. 2022, 226, 106281. [Google Scholar] [CrossRef]

- Subraelu, P.; Ebraheem, A.A.; Sherif, M.; Sefelnasr, A.; Yagoub, M.M.; Rao, K.N. Land in Water: The Study of Land Reclamation and Artificial Islands Formation in the UAE Coastal Zone: A Remote Sensing and GIS Perspective. Land 2022, 11, 2024. [Google Scholar] [CrossRef]

- Chen, L.; Yang, M.; Chen, Z.; Xie, Z.; Huang, L.; Osman, A.I.; Farghali, M.; Sandanayake, M.; Liu, E.; Ahn, Y.H.; et al. Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Mater. Today Sustain. 2024, 27, 100930. [Google Scholar] [CrossRef]

- Fu, Q.; Xu, W.; Bu, M.; Su, L.; He, J.; Kou, H. A simplified dynamic constitutive model for BFRCAC under confining pressure considering the coupling effect of fibre reinforcement and mechanical damage. Compos. Struct. 2021, 268, 113944. [Google Scholar] [CrossRef]

- Ehlert, R. Coral Concrete at Bikini Atoll. Concr. Int. 1991, 13, 19–24. [Google Scholar]

- Wang, F.; Sun, Y.; Xue, X.; Wang, N.; Zhou, J.; Hua, J. Mechanical properties of modified coral aggregate seawater sea-sand concrete: Experimental study and constitutive model. Case Stud. Constr. Mater. 2023, 18, e02095. [Google Scholar] [CrossRef]

- Guo, R.; Ou, C.; Ma, L.; Long, Z.; Xu, F.; Yin, C. Experimental study on impact performance of seawater sea-sand concrete with recycled aggregates. Sustain. Mater. Technol. 2024, 41, e01060. [Google Scholar] [CrossRef]

- Yang, Z.; Li, R.; Zhu, H.; Zhang, B.; Dong, Z.; Zhan, X.; Zhang, G.; Zhang, H. Synthesis of eco-sustainable seawater sea-sand geopolymer mortars from ternary solid waste: Influence of microstructure evolution on mechanical performance. Sustain. Mater. Technol. 2024, 41, e01056. [Google Scholar] [CrossRef]

- Sun, L.; Wang, C.; Zhang, C.; Yang, Z.; Li, C.; Qiao, P. Experimental investigation on the bond performance of sea sand coral concrete with FRP bar reinforcement for marine environments. Adv. Struct. Eng. 2023, 26, 533–546. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Yi, J.; Qin, Q. Experimental study on stress-strain relationship of high strength coral concrete (HSCC). J. Build. Eng. 2024, 87, 109090. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Mei, H.; Ming, Y.; Guo, J.; Liu, Q.; Qian, K. Mechanical properties and failure criteria of carbon fiber-reinforced coral concrete under biaxial compression. Constr. Build. Mater. 2024, 446, 138029. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, H.; Ma, H.; Da, B.; Tan, Y. Rebar corrosion behavior of coral aggregate seawater concrete by electrochemical techniques. Anti-Corros. Methods Mater. 2020, 67, 59–72. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.; Ma, H.; Tan, Y.; Mi, R.; Dou, X. Experimental investigation of whole stress-strain curves of coral concrete. Constr. Build. Mater. 2016, 122, 81–89. [Google Scholar] [CrossRef]

- Ministry of Natural Resources of the People’s Republic of China. A Survey Report on the Coral Reef Ecosystem of Xianbin Jiao. 2024. Available online: https://www.mnr.gov.cn/sj/sjfw/hy/202408/t20240830_2856503.html (accessed on 1 October 2024).

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Lee, S.C.; Goh, W.I.; Yuen, C.W. Recycling of seashell waste in concrete: A review. Constr. Build. Mater. 2018, 162, 751–764. [Google Scholar] [CrossRef]

- Maglad, A.M.; Othuman Mydin, M.A.; Dip Datta, S.; Tayeh, B.A. Assessing the mechanical, durability, thermal and microstructural properties of sea shell ash based lightweight foamed concrete. Constr. Build. Mater. 2023, 402, 133018. [Google Scholar] [CrossRef]

- Carral, L.; Lamas-Galdo, M.I.; Buenhombre, J.L.M.; Barros, J.J.C.; Naya, S.; Tarrio-Saavedra, J. Application of residuals from purification of bivalve molluscs in galician to facilitate marine ecosystem resiliency through artificial reefs with shells—One generation. Sci. Total Environ. 2023, 856, 159095. [Google Scholar] [CrossRef] [PubMed]

- Kong, J.; Cong, G.; Ni, S.; Sun, J.; Guo, C.; Chen, M.; Quan, H. Recycling of waste oyster shell and recycled aggregate in the porous ecological concrete used for artificial reefs. Constr. Build. Mater. 2022, 323, 126447. [Google Scholar] [CrossRef]

- Chen, B.; Peng, L.; Zhong, H.; Zhao, Y.; Meng, T.; Zhang, B. Synergetic recycling of recycled concrete aggregate and waste mussel shell in concrete: Mechanical properties, durability and microstructure. Constr. Build. Mater. 2023, 371, 130825. [Google Scholar] [CrossRef]

- Sun, L.; Yang, Z.; Qin, R.; Wang, C. Mix design optimization of seawater sea sand coral aggregate concrete. Sci. China Technol. Sci. 2023, 66, 378–389. [Google Scholar] [CrossRef]

- Wang, F.; Hua, J.; Wang, N.; Yan, F.; Feng, D. Effect of Superfine Cement Modification on Properties of Coral Aggregate Concrete. Materials 2023, 16, 1103. [Google Scholar] [CrossRef]

- Wei, J.; Chen, Z.; Liu, J.; Liang, J.; Shi, C. Review on the characteristics and multi-factor model between pore structure with compressive strength of coral aggregate. Constr. Build. Mater. 2023, 370, 130326. [Google Scholar] [CrossRef]

- Arumugam, R.A.; Ramamurthy, K. Study of compressive strength characteristics of coral aggregate concrete. Mag. Concr. Res. 1996, 48, 141–148. [Google Scholar] [CrossRef]

- Zhou, L.; Guo, S.; Zhang, Z.; Shi, C.; Jin, Z.; Zhu, D. Mechanical behavior and durability of coral aggregate concrete and bonding performance with fiber-reinforced polymer (FRP) bars: A critical review. J. Clean. Prod. 2021, 289, 125652. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, J.; Yu, H.; Fang, Q.; Chen, L.; Yue, C. Experimental and mesoscopic investigation on the dynamic properties of coral aggregate concrete in compression. Sci. China Technol. Sci. 2021, 64, 1153–1166. [Google Scholar] [CrossRef]

- Yu, H.; Da, B.; Ma, H.; Dou, X.; Wu, Z. Service life prediction of coral aggregate concrete structure under island reef environment. Constr. Build. Mater. 2020, 246, 118390. [Google Scholar] [CrossRef]

- Liang, B.; Rao, L.; Zheng, Y. Statistics and analysis of the relationship between strength and age of coral concrete. Adv. Civ. Eng. 2022, 2022, 9234594. [Google Scholar] [CrossRef]

- Li, H.; Farzadnia, N.; Shi, C. The role of seawater in interaction of slag and silica fume with cement in low water-to-binder ratio pastes at the early age of hydration. Constr. Build. Mater. 2018, 185, 508–518. [Google Scholar] [CrossRef]

- Younis, A.; Ebead, U.; Suraneni, P.; Nanni, A. Fresh and hardened properties of seawater-mixed concrete. Constr. Build. Mater. 2018, 190, 276–286. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, S.; Li, X.; Pan, L.; Cao, Z.; Shuai, B.; Shen, C.; Zhao, Z. Impact splitting tensile properties and microstructural analysis of polypropylene fiber reinforced coral seawater concrete. Constr. Build. Mater. 2025, 471, 140747. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Chen, J. Bond durability between BFRP bars and seawater coral aggregate concrete under seawater corrosion environments. Constr. Build. Mater. 2023, 379, 131274. [Google Scholar] [CrossRef]

- Xiao, J.; Mei, J.; Yang, H.; Yang, Q.; Jiang, J. Bond behavior between stainless steel rebar and fiber reinforced coral concrete under lateral constraint. Eng. Struct. 2024, 317, 118697. [Google Scholar] [CrossRef]

- Niu, D.; Zhang, L.; Fu, Q.; Wen, B.; Luo, D. Critical conditions and life prediction of reinforcement corrosion in coral aggregate concrete. Constr. Build. Mater. 2020, 238, 117685. [Google Scholar] [CrossRef]

- Zhou, W.; Feng, P.; Lin, H.; Zhou, P. Bond behavior between GFRP bars and coral aggregate concrete. Compos. Struct. 2023, 306, 116567. [Google Scholar] [CrossRef]

- Razaqpur, A.; Wang, Y.; Liao, X.; Liao, Y.; Wang, R. Progress of photothermal membrane distillation for decentralized desalination: A review. Water Res. 2021, 201, 117299. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiao, J.; Deng, Z.; Yang, H.; Jiang, J.; Wei, T. Mechanical properties and damage constitutive model of basalt fibre-reinforced coral concrete under compression-shear loading. J. Build. Eng. 2024, 98, 111217. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, F.; Zhan, X.; Zhu, H.; Zhang, B.; Chen, Z.; Zhang, H. Mechanical properties and mesoscopic damage characteristics of basalt fibre-reinforced seawater sea-sand slag-based geopolymer concrete. J. Build. Eng. 2024, 84, 108688. [Google Scholar] [CrossRef]

- Chen, L.; Chen, Z.; Xie, Z.; Wei, L.; Hua, J.; Huang, L.; Yap, P.-S. Recent developments on natural fiber concrete: A review of properties, sustainability, applications, barriers, and opportunities. Dev. Built Environ. 2023, 16, 100255. [Google Scholar] [CrossRef]

- Zhou, C.; Cao, J.; Zhang, Z.; Zhu, Y. Effect of fiber reinforcement on bond behavior between coral aggregate concrete and GFRP bar. Constr. Build. Mater. 2023, 403, 133201. [Google Scholar] [CrossRef]

- Khalil, N.; Assaad, J.J. Bond properties between smooth carbon fibre-reinforced polymer bars and ultra-high performance concrete modified with polymeric latexes and fibres. Eur. J. Environ. Civ. Eng. 2022, 26, 6211–6228. [Google Scholar] [CrossRef]

- Tsiotsias, K.; Pantazopoulou, S.J. Bond behavior of high-performance fiber reinforced concrete (HPFRC) under direct tension pullout. Eng. Struct. 2021, 243, 112701. [Google Scholar] [CrossRef]

- Yang, S.; Yu, M.; Dong, K.; Yang, Y. Properties of alkali-resistant glass fiber reinforced coral aggregate concrete. Materials 2020, 13, 3450. [Google Scholar] [CrossRef]

- Dai, J.; Yin, S.; Wang, F.; Ge, M. Analysis of microstructure and compressive properties of full coral concrete under fiber reinforcement. J. Build. Eng. 2024, 93, 109826. [Google Scholar] [CrossRef]

- Deng, Z.; Zhou, Y.; Jiang, J.; Huang, X.; Liu, B. Mechanical properties and uniaxial constitutive model of fiber-reinforced coral aggregate concrete. Struct. Concr. 2023, 24, 4259–4275. [Google Scholar] [CrossRef]

- Mohebi, Z.H.; Bahnamiri, A.B.; Dehestani, M. Effect of polypropylene fibers on bond performance of reinforcing bars in high strength concrete. Constr. Build. Mater. 2019, 215, 401–409. [Google Scholar] [CrossRef]

- Yaqin, C.; Haq, S.U.; Iqbal, S.; Khan, I.; Room, S.; Khan, S.A. Performance evaluation of indented macro synthetic polypropylene fibers in high strength self-compacting concrete (SCC). Sci. Rep. 2024, 14, 20844. [Google Scholar] [CrossRef]

- Mohamed, O.; Zuaiter, H. Fresh properties, strength, and durability of fiber-reinforced geopolymer and conventional concrete: A review. Polymers 2024, 16, 141. [Google Scholar] [CrossRef] [PubMed]

- Mashayekhi, A.; Hassanli, R.; Zhuge, Y.; Ma, X.; Chow, C.W.K. Synergistic effects of fiber hybridization on the mechanical performance of seawater sea-sand concrete. Constr. Build. Mater. 2024, 416, 135087. [Google Scholar] [CrossRef]

- Gong, J.; Ma, Y.; Fu, J.; Hu, J.; Ouyang, X.; Zhang, Z.; Wang, H. Utilization of fibers in ultra-high performance concrete: A review. Compos. Part B Eng. 2022, 241, 109995. [Google Scholar] [CrossRef]

- Islam, T.; Safiuddin, M.; Roman, R.A.; Chakma, B.; Al Maroof, A. Mechanical properties of PVC fiber-reinforced concrete—Effects of fiber content and length. Buildings 2023, 13, 2666. [Google Scholar] [CrossRef]

- Labaran, Y.H.; Atmaca, N.; Tan, M.; Atmaca, K. High-strength fiber-reinforced concrete: Assessing the impact of polyvinyl alcohol, glass, and polypropylene fibers on structural integrity and cost efficiency. Discov. Civ. Eng. 2024, 1, 37. [Google Scholar] [CrossRef]

- Shafei, B.; Kazemian, M.; Dopko, M.; Najimi, M. State-of-the-art review of capabilities and limitations of polymer and glass fibers used for fiber-reinforced concrete. Materials 2021, 14, 409. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Dong, Q.; Chen, X.; Li, J.; Wang, X.; Shi, B. An experimental and numerical study on the hybrid effect of basalt fiber and polypropylene fiber on the impact toughness of fiber reinforced concrete. Constr. Build. Mater. 2024, 411, 134270. [Google Scholar] [CrossRef]

- Espinach, F.X.; Granda, L.A.; Tarrés, Q.; Duran, J.; Fullana-i-Palmer, P.; Mutjé, P. Mechanical and micromechanical tensile strength of eucalyptus bleached fibers reinforced polyoxymethylene composites. Compos. Part B Eng. 2017, 116, 333–339. [Google Scholar] [CrossRef]

- Hua, J.; Yang, Z.; Xue, X.; Huang, L.; Wang, N.; Chen, Z. Bond properties of bimetallic steel bar in seawater sea-sand concrete at different ages. Constr. Build. Mater. 2022, 323, 126539. [Google Scholar] [CrossRef]

- GB/T17431.1-2010; Lightweight Aggregates and Its Test Methods—Part 1: Lightweight Aggregates. China Standard Press: Beijing, China, 2010.

- GB50152-92; Standard Methods for Testing of Concrete Structures. China Architecture and Building Press: Beijing, China, 1992.

- GB/T50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture and Building Press: Beijing, China, 2019.

- Li, J.; Li, Z.; Chen, J.; Huang, Y.; Sun, K.; Niu, J. Assessment of the bond-slip behavior of rebar in fiber-reinforced self-compacting lightweight aggregate concrete via the acoustic emission technique. J. Build. Eng. 2024, 89, 109054. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Tan, J.; Li, X. Bond behaviours of deformed steel rebars in engineered cementitious composites (ECC) and concrete. Constr. Build. Mater. 2020, 252, 119082. [Google Scholar] [CrossRef]

- Song, X.; Wu, Y.; Gu, X.; Chen, C. Bond behaviour of reinforcing steel bars in early age concrete. Constr. Build. Mater. 2015, 94, 209–217. [Google Scholar] [CrossRef]

- Yang, Z. Study on Bonding Performance Between Bimetallic Steel Bar and Polyoxymethylene Fiber Seawater and Sea-Sand Concrete. Master’s Thesis, Chongqing University, Chongqing, China, 2022. [Google Scholar]

- Liu, K.; Song, R.; Li, J.; Guo, T.; Li, X.; Yang, J.; Yan, Z. Effect of steel fiber type and content on the dynamic tensile properties of ultra-high performance cementitious composites (UHPCC). Constr. Build. Mater. 2022, 342, 127908. [Google Scholar] [CrossRef]

- GB/T50010-2010; Code for Design of Concrete Structures. China Architecture and Building Press: Beijing, China, 2010.

| Fiber Type | Effects on Concrete Performance | Limitations/Drawbacks | Reference |

|---|---|---|---|

| Polyoxymethylene (POM) | Improves compressive, tensile, flexural strength, ductility and crack resistance, making the concrete less brittle and more durable under load | limit the durability of the concrete, and excessive fiber content can increase porosity or reduce strength | [43,44] |

| Polypropylene (PP) | Improves crack resistance, ductility, toughness, and bond strength; enhances durability | Poor dispersion, weak bond with cement matrix, reduced workability at high content | [45,46] |

| Polyvinyl Alcohol (PVA) | Increases tensile/flexural strength, ductility, and chemical bonding with matrix | High water absorption, workability loss, fiber clumping at high dosage | [47,48] |

| Polyethylene (PE) | Enhances tensile strength and ductility, good chemical resistance | Limited improvement in bond strength, may require surface treatment | [47,49] |

| Polyvinyl Chloride (PVC) | Increases compressive, flexural, and impact strength at optimal content; improves toughness | Workability decreases with higher content, performance drops above 1% fiber content | [50] |

| Glass Fiber | Improves tensile/flexural strength, bond strength, and durability | Susceptible to alkali attack, long-term durability concerns | [51,52] |

| Basalt Fiber | Increases compressive/flexural strength, impact resistance, and bond with matrix | Excessive content reduces ductility, higher cost | [53] |

| Density (kg/m3) | Tensile Strength (MPa) | Elongation (%) | Melting Point (°C) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| 1400 | 967 | 18 | 165 | 8 |

| Diameter (mm) | Form | Yield Strength (MPa) | Ultimate Strength (MPa) | Elongation After Fracture (%) | Elastic Modulus (MPa) |

|---|---|---|---|---|---|

| 16 | deformed | 416 | 622 | 28 | 2 × 105 |

| 16 | round | 314 | 435 | 29 | 2 × 105 |

| Specific Surface Area (m2/kg) | Standard Consistency (%) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | Loss on Ignition (%) | |||

|---|---|---|---|---|---|---|---|---|

| Initial Set | Final Set | 3 d | 28 d | 3 d | 28 d | |||

| 360 | 28.00 | 225 | 295 | 33.6 | 55.7 | 6.3 | 8.6 | 1.80 |

| Fineness (%) | Water Demand Ratio (%) | Loss on Ignition (%) | Chlorine Ion Content (%) | Sulfur Trioxide (%) | Rate of Water Content (%) |

|---|---|---|---|---|---|

| 12 | 95 | 5 | 0.02 | 5 | 0.1 |

| Specific Surface Area (m2/kg) | Liquidity Ratio (%) | Loss on Ignition (%) | Chlorine Ion Content (%) | Sulfur Trioxide (%) | Rate of Water Content (%) |

|---|---|---|---|---|---|

| 380 | 92 | 3 | 0.01 | 4 | 0.2 |

| Types | Cement (kg/m3) | Coarse Aggregate (kg/m3) | Sand (kg/m3) | Water (kg/m3) | Mineral Powder (kg/m3) | Fly Ash (kg/m3) | POM Fiber (kg/m3) | Water Reducer (%) | W/B | Slump (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| CAC | 330 | 620 | 1037 | 140 | 110 | 110 | 0 | 2 | 0.25 | 175 |

| CAC-POM0.2 | 330 | 620 | 1037 | 140 | 110 | 110 | 2.8 | 2 | 0.25 | 113 |

| CAC-POM0.4 | 330 | 620 | 1037 | 140 | 110 | 110 | 5.6 | 2 | 0.25 | 95 |

| CAC-POM0.6 | 330 | 620 | 1037 | 140 | 110 | 110 | 8.4 | 2 | 0.25 | 87 |

| CAC-POM0.8 | 330 | 620 | 1037 | 140 | 110 | 110 | 11.2 | 2 | 0.25 | 69 |

| CAC-POM1.0 | 330 | 620 | 1037 | 140 | 110 | 110 | 14 | 2 | 0.25 | 55 |

| Types | Cube Compressive Strength (MPa) | Axial Compressive Strength (MPa) | Splitting Tensile Strength (MPa) |

|---|---|---|---|

| CAC | 43.5 | 38.1 | 3.04 |

| POM0.2 | 44.7 | 40.4 | 3.20 |

| POM0.4 | 47.3 | 44.1 | 3.46 |

| POM0.6 | 49.8 | 44.1 | 3.55 |

| POM0.8 | 46.8 | 41.7 | 3.48 |

| POM1.0 | 45.9 | 40.5 | 3.22 |

| No. | Fiber Content (%) | d (mm) | la (mm) | c (mm) | Steel Bar Surface Morphology |

|---|---|---|---|---|---|

| C-5D-2 | - | 16 | 80 | 32 | D |

| C-5D-3 | - | 16 | 80 | 48 | D |

| C-5D-4.2 | - | 16 | 80 | 67 | D |

| POM0.2-5D-2 | 0.2 | 16 | 80 | 32 | D |

| POM0.2-5D-3 | 0.2 | 16 | 80 | 48 | D |

| POM0.2-5D-4.2 | 0.2 | 16 | 80 | 67 | D |

| POM0.4-5D-2 | 0.4 | 16 | 80 | 32 | D |

| POM0.4-5D-3 | 0.4 | 16 | 80 | 48 | D |

| POM0.4-5D-4.2 | 0.4 | 16 | 80 | 67 | D |

| POM0.6-5D-2 | 0.6 | 16 | 80 | 32 | D |

| POM0.6-5D-3 | 0.6 | 16 | 80 | 48 | D |

| POM0.6-5D-4.2 | 0.6 | 16 | 80 | 67 | D |

| POM0.8-5D-2 | 0.8 | 16 | 80 | 32 | D |

| POM0.8-5D-3 | 0.8 | 16 | 80 | 48 | D |

| POM0.8-5D-4.2 | 0.8 | 16 | 80 | 67 | D |

| POM1.0-5D-2 | 1.0 | 16 | 80 | 32 | D |

| POM1.0-5D-3 | 1.0 | 16 | 80 | 48 | D |

| POM1.0-5D-4.2 | 1.0 | 16 | 80 | 67 | D |

| C-5S-4.2 | - | 16 | 80 | 67 | S |

| POM0.6-5S-4.2 | 0.6 | 16 | 80 | 67 | S |

| POM0.2-5S-4.2 | 0.2 | 16 | 80 | 67 | S |

| POM0.4-5S-4.2 | 0.4 | 16 | 80 | 67 | S |

| POM0.8-5S-4.2 | 0.8 | 16 | 80 | 67 | S |

| POM1.0-5S-4.2 | 1.0 | 16 | 80 | 67 | S |

| POM0.6-2D-4.2 | 0.6 | 16 | 32 | 67 | D |

| POM0.6-3D-4.2 | 0.6 | 16 | 48 | 67 | D |

| POM0.6-6D-4.2 | 0.6 | 16 | 96 | 67 | D |

| No. | Average Value of Ultimate Load F (kN) | τu (MPa) | su (mm) | Failure Mode |

|---|---|---|---|---|

| C-5D-2 | 50.85 | 12.65 | 0.041 | S |

| C-5D-3 | 55.75 | 13.87 | 0.128 | S |

| C-5D-4.2 | 65.70 | 16.35 | 0.148 | S |

| POM0.2-5D-2 | 54.62 | 13.53 | 0.124 | S |

| POM0.2-5D-3 | 65.96 | 16.40 | 0.173 | PS |

| POM0.2-5D-4.2 | 78.03 | 19.41 | 0.236 | P |

| POM0.4-5D-2 | 59.99 | 14.92 | 0.063 | PS |

| POM0.4-5D-3 | 70.03 | 17.11 | 0.098 | PS |

| POM0.4-5D-4.2 | 80.62 | 19.75 | 0.205 | P |

| POM0.6-5D -2 | 64.94 | 16.10 | 0.107 | PS |

| POM0.6-5D-3 | 83.61 | 20.77 | 0.133 | PS |

| POM0.6-5D-4.2 | 87.19 | 21.68 | 0.240 | P |

| POM0.8-5D-2 | 64.14 | 15.88 | 0.110 | PS |

| POM0.8-5D-3 | 79.63 | 19.81 | 0.144 | PS |

| POM0.8-5D-4.2 | 86.77 | 21.54 | 0.181 | PS |

| POM1.0-5D-2 | 58.63 | 15.47 | 0.209 | PS |

| POM1.0-5D-3 | 77.55 | 17.48 | 0.227 | PS |

| POM1.0-5D-4.2 | 84.3 | 18.62 | 0.218 | PS |

| POM0.6-6D-4.2 | 93.26 | 19.34 | 1.119 | PS |

| POM0.6-3D-4.2 | 59.12 | 24.52 | 1.017 | PS |

| POM0.6-2D-4.2 | 26.4 | 16.42 | 0.892 | P |

| C-5S-4.2 | 12.70 | 3.16 | - | P |

| POM0.2-5S-4.2 | 14.93 | 3.71 | - | P |

| POM0.4-5S-4.2 | 15.16 | 3.77 | - | P |

| POM0.6-5S-4.2 | 16.98 | 4.22 | - | P |

| POM0.8-5S-4.2 | 16.02 | 3.99 | - | P |

| POM1.0-5S-4.2 | 15.96 | 3.97 | - | P |

| No. | τu (MPa) | su (mm) | α |

|---|---|---|---|

| C-5D-2 | 12.652 | 0.041 | 0.3712 |

| C-5D-3 | 13.874 | 0.128 | 0.3421 |

| C-5D-4.2 | 16.347 | 0.148 | 0.2147 |

| POM0.2-5D-2 | 13.526 | 0.124 | 0.3271 |

| POM0.2-5D-3 | 16.402 | 0.173 | 0.2266 |

| POM0.2-5D-4.2 | 19.411 | 0.236 | 0.1849 |

| POM0.4-5D-2 | 14.919 | 0.063 | 0.2686 |

| POM0.4-5D-3 | 17.108 | 0.098 | 0.2602 |

| POM0.4-5D-4.2 | 19.749 | 0.205 | 0.2225 |

| POM0.6-5D-2 | 16.099 | 0.107 | 0.2555 |

| POM0.6-5D-3 | 20.768 | 0.133 | 0.2547 |

| POM0.6-5D-4.2 | 21.681 | 0.240 | 0.2467 |

| POM0.8-5D-2 | 15.875 | 0.110 | 0.2577 |

| POM0.8-5D-3 | 19.812 | 0.144 | 0.2266 |

| POM0.8-5D-4.2 | 21.543 | 0.181 | 0.1992 |

| POM1.0-5D-2 | 15.467 | 0.209 | 0.2319 |

| POM1.0-5D-3 | 17.477 | 0.227 | 0.2486 |

| POM1.0-5D-4.2 | 18.619 | 0.218 | 0.2356 |

| Coefficient | c/d = 2 | c/d = 3 | c/d = 4.2 |

|---|---|---|---|

| p1 | −5.749 | −12.78 | −12.66 |

| p2 | 8.935 | 16.34 | 16.44 |

| p3 | 12.4 | 13.7 | 15.57 |

| Coefficient | CAC | POM0.2 | POM0.4 | POM0.6 | POM0.8 | POM1.0 |

|---|---|---|---|---|---|---|

| p4 | 0.0535 | 0.0560 | 0.071 | 0.0665 | 0.0355 | 0.0045 |

| p5 | −0.0548 | 0.0097 | −0.091 | −0.0395 | 0.0385 | 0.2045 |

| p6 | −0.07825 | −0.0711 | −0.0213 | −0.0044 | −0.02925 | 0.0018 |

| p7 | 0.5441 | 0.4595 | 0.3158 | 0.2655 | 0.3156 | 0.2332 |

| Types | fcu (MPa) | ft (MPa) | lab |

|---|---|---|---|

| CAC | 43.5 | 3.15 | 16.02 d |

| POM0.2 | 44.7 | 3.19 | 15.78 d |

| POM0.4 | 47.3 | 3.29 | 15.30 d |

| POM0.6 | 49.8 | 3.39 | 14.87 d |

| POM0.8 | 46.8 | 3.28 | 15.39 d |

| POM1.0 | 45.9 | 3.24 | 15.55 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Z.; Chen, L.; Huang, L.; Jin, J.; Hua, J.; Yap, P.-S.; Zhang, Y. Bond Properties of Steel Bar in Polyoxymethylene-Fiber-Reinforced Coral Aggregate Concrete. Polymers 2025, 17, 2954. https://doi.org/10.3390/polym17212954

Xie Z, Chen L, Huang L, Jin J, Hua J, Yap P-S, Zhang Y. Bond Properties of Steel Bar in Polyoxymethylene-Fiber-Reinforced Coral Aggregate Concrete. Polymers. 2025; 17(21):2954. https://doi.org/10.3390/polym17212954

Chicago/Turabian StyleXie, Zhuolin, Lin Chen, Lepeng Huang, Junlong Jin, Jianmin Hua, Pow-Seng Yap, and Yi Zhang. 2025. "Bond Properties of Steel Bar in Polyoxymethylene-Fiber-Reinforced Coral Aggregate Concrete" Polymers 17, no. 21: 2954. https://doi.org/10.3390/polym17212954

APA StyleXie, Z., Chen, L., Huang, L., Jin, J., Hua, J., Yap, P.-S., & Zhang, Y. (2025). Bond Properties of Steel Bar in Polyoxymethylene-Fiber-Reinforced Coral Aggregate Concrete. Polymers, 17(21), 2954. https://doi.org/10.3390/polym17212954