Acoustic Emission Mechanisms During Polymer Processing and Chain Orientation: From Amorphous to Crystalline

Abstract

1. Introduction

2. AE Applied for Polymer and Polymer Composites

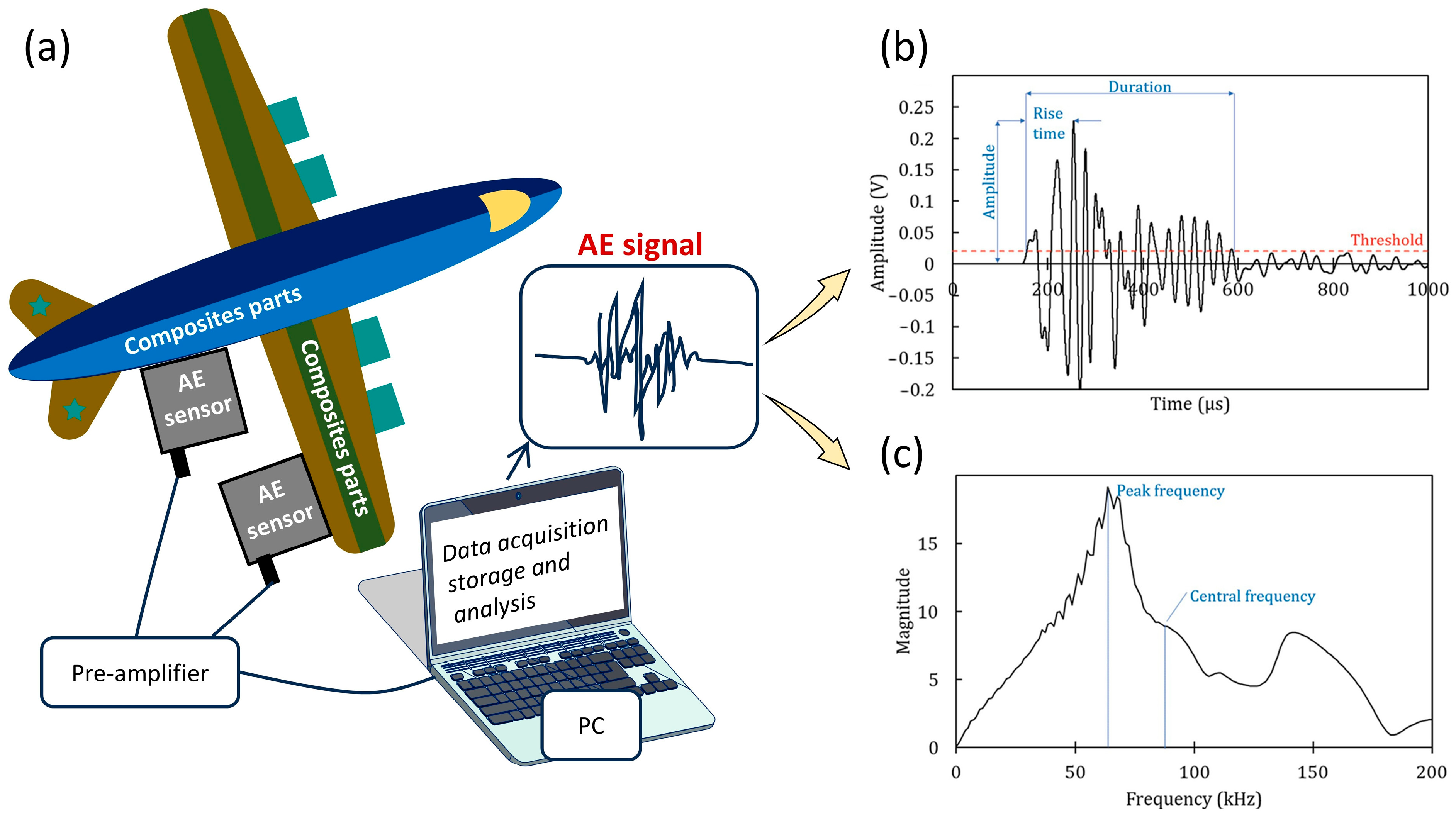

2.1. Basic AE Theories and Parameters

2.2. AE as NDT for Polymer and Polymer Composites

3. Polymer Crystallization and the In Situ Study

3.1. Crystalline Polymer Classifications and Applications

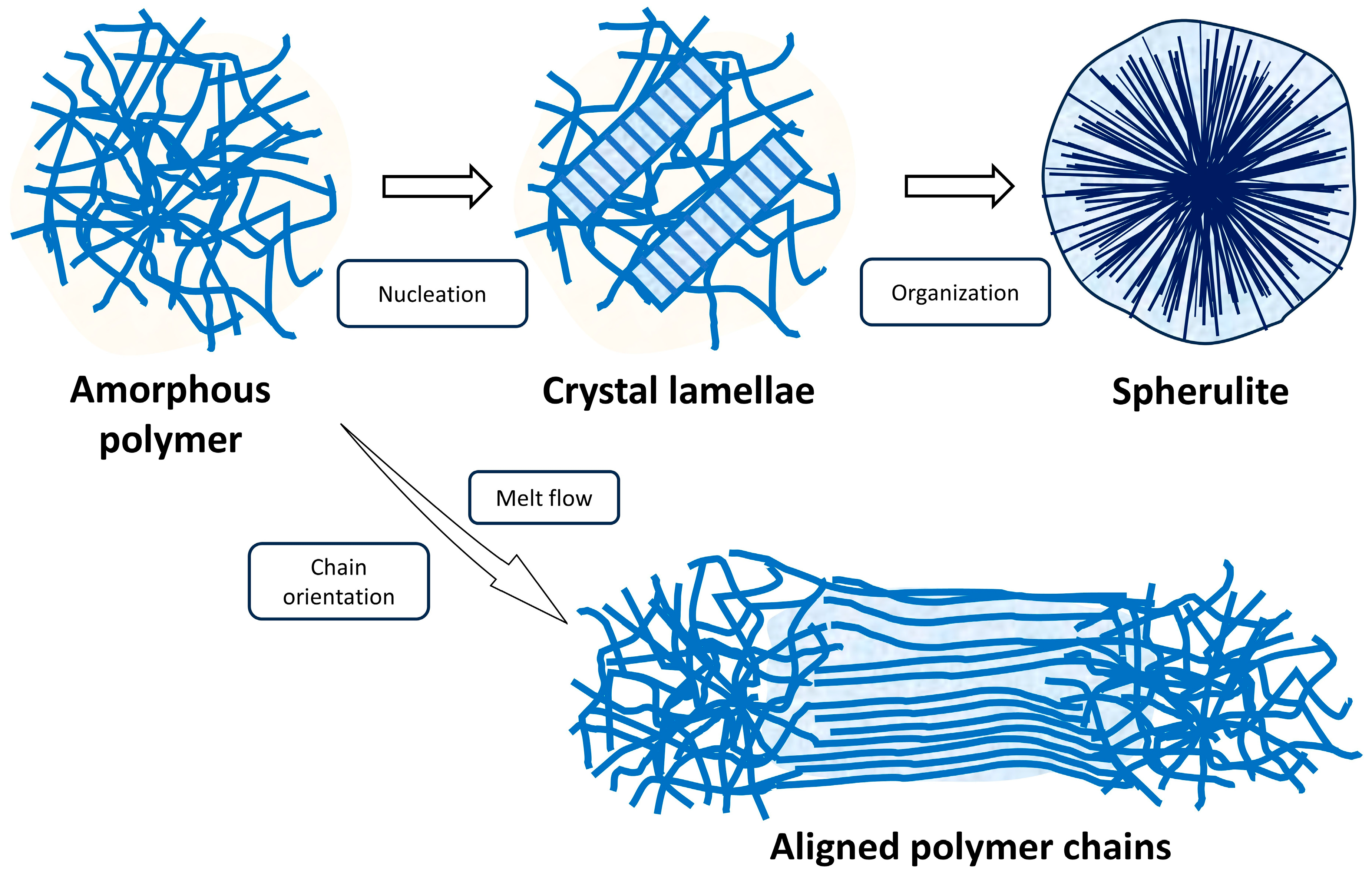

3.2. Crystallization Mechanisms

3.3. Defects or Imperfection Induced by Crystallization

3.4. In Situ Characterizations of Polymer Crystallization During Processing

4. Acoustic Emission Mechanisms of Polymers from Amorphous to Crystalline

4.1. AE Mechanisms During Crystallization

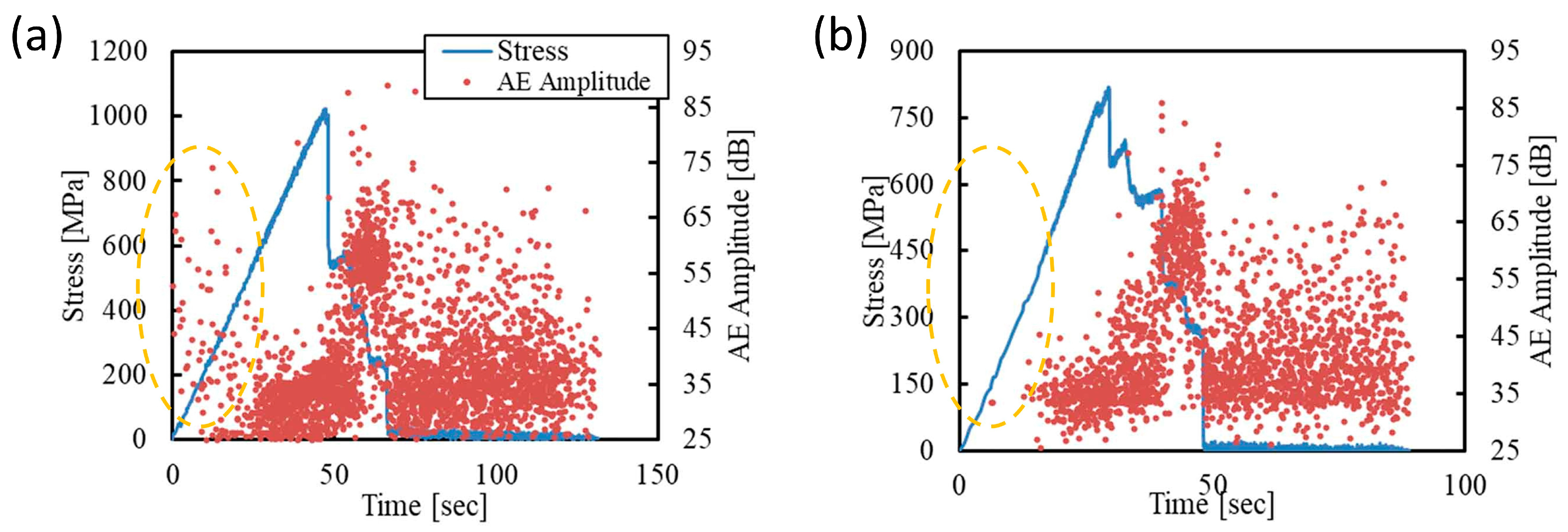

4.2. AE Mechanisms of Chain Orientation During Initial Plastic Deformation

5. Future Possibilities of AE for Early Defect Inspection of Crystalline Polymer Composites

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, S.; Zhang, B.; Niu, J.; Yang, C.; Sun, C.; Wang, L.; Li, D. High-strength carbon fiber-reinforced polyether-ether-ketone composites with longer fiber retention length manufactured via screw extrusion-based 3D printing. Addit. Manuf. 2024, 86, 104200. [Google Scholar] [CrossRef]

- Ren, L.; Guo, H.; Kang, L.; Niu, H.; Lv, R.; Bai, S.-L. Lightweight, electrical insulating, and high thermally conductive all-polymer composites with reinforced interfaces. Compos. Sci. Technol. 2023, 240, 110080. [Google Scholar] [CrossRef]

- Shu, J.; Zhou, Z.; Liang, H.; Yang, X. Polyimide as a biomedical material: Advantages and applications. Nanoscale Adv. 2024, 6, 4309–4324. [Google Scholar] [CrossRef]

- Han, S.; Li, Q.; Cui, Z.; Xiao, P.; Miao, Y.; Chen, L.; Li, Y. Non-destructive testing and structural health monitoring technologies for carbon fiber reinforced polymers: A review. Nondestr. Test. Eval. 2024, 39, 725–761. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Łukaszewicz, A.; Józwik, J.; Oksiuta, Z.; Shahar, F.S. Recent Trends in Non-Destructive Testing Approaches for Composite Materials: A Review of Successful Implementations. Materials 2025, 18, 3146. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Yu, Z.; Jin, H. Nondestructive testing and evaluation techniques of defects in fiber-reinforced polymer composites: A review. Front. Mater. 2022, 9, 986645. [Google Scholar] [CrossRef]

- Aramburu, A.B.; da Cruz, J.A.; Xavier da Silva, A.A.; Acosta, A.P.; Minillo, L.Q.; de Avila Delucis, R. Non-destructive testing techniques for pressure vessels manufactured with polymer composite materials: A systematic review. Measurement 2025, 246, 116729. [Google Scholar] [CrossRef]

- Chaki, S.; Krawczak, P. Non-Destructive Health Monitoring of Structural Polymer Composites: Trends and Perspectives in the Digital Era. Materials 2022, 15, 7838. [Google Scholar] [CrossRef]

- Ciecieląg, K.; Kęcik, K.; Skoczylas, A.; Matuszak, J.; Korzec, I.; Zaleski, R. Non-Destructive Detection of Real Defects in Polymer Composites by Ultrasonic Testing and Recurrence Analysis. Materials 2022, 15, 7335. [Google Scholar] [CrossRef]

- Katunin, A.; Dragan, K.; Nowak, T.; Chalimoniuk, M. Quality Control Approach for the Detection of Internal Lower Density Areas in Composite Disks in Industrial Conditions Based on a Combination of NDT Techniques. Sensors 2021, 21, 7174. [Google Scholar] [CrossRef]

- Yakovlev, E.V.; Zaytsev, K.I.; Dolganova, I.N.; Yurchenko, S.O. Non-Destructive Evaluation of Polymer Composite Materials at the Manufacturing Stage Using Terahertz Pulsed Spectroscopy. IEEE Trans. Terahertz Sci. Technol. 2015, 5, 810–816. [Google Scholar] [CrossRef]

- Huber, A.; Dutta, S.; Schuster, A.; Kupke, M.; Drechsler, K. Automated NDT inspection based on high precision 3-D Thermo-Tomography model combined with engineering and manufacturing data. Procedia CIRP 2019, 85, 321–328. [Google Scholar] [CrossRef]

- Ashebir, D.A.; Hendlmeier, A.; Dunn, M.; Arablouei, R.; Lomov, S.V.; Di Pietro, A.; Nikzad, M. Detecting Multi-Scale Defects in Material Extrusion Additive Manufacturing of Fiber-Reinforced Thermoplastic Composites: A Review of Challenges and Advanced Non-Destructive Testing Techniques. Polymers 2024, 16, 2986. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Sause, M.G.R.; Packo, P.; Pullin, R.; Grigg, S.; Kek, T.; Lai, Y.-K. Acoustic Emission. In Structural Health Monitoring Damage Detection Systems for Aerospace; Sause, M.G.R., Jasiūnienė, E., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 175–217. [Google Scholar]

- Chen, G.; Luo, H.; Yang, H.; Zhang, T.; Li, S. Water effects on the deformation and fracture behaviors of the multi-scaled cellular fibrous bamboo. Acta Biomater. 2018, 65, 203–215. [Google Scholar] [CrossRef]

- Chen, G.; Luo, H. Effects of node with discontinuous hierarchical fibers on the tensile fracture behaviors of natural bamboo. Sustain. Mater. Technol. 2020, 26, e00228. [Google Scholar] [CrossRef]

- Ba, Z.; Luo, H.; Guan, J.; Luo, J.; Gao, J.; Wu, S.; Ritchie, R.O. Robust flexural performance and fracture behavior of TiO2 decorated densified bamboo as sustainable structural materials. Nat. Commun. 2023, 14, 1234. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Luo, H. Effects of moisture content and fibrous structure on the uniaxial compression behavior of natural bamboo. Constr. Build. Mater. 2023, 408, 133711. [Google Scholar] [CrossRef]

- Cui, J.; Luo, H.; Chen, G.; Wang, R.; Ba, Z.; Guo, Z. Fe3O4 nano particles filled densified bamboo with improved strength, fracture toughness, fire and water resistance. Constr. Build. Mater. 2024, 422, 135792. [Google Scholar] [CrossRef]

- Pawlak, A.; Galeski, A. Plastic Deformation of Crystalline Polymers: The Role of Cavitation and Crystal Plasticity. Macromolecules 2005, 38, 9688–9697. [Google Scholar] [CrossRef]

- Peterlin, A. Plastic deformation of crystalline polymers. Polym. Eng. Sci. 2004, 17, 183–193. [Google Scholar] [CrossRef]

- Ghadarah, N.; Ayre, D. A Review on Acoustic Emission Testing for Structural Health Monitoring of Polymer-Based Composites. Sensors 2023, 23, 6945. [Google Scholar] [CrossRef]

- Khan, M.T.I. Structural Health Monitoring by Acoustic Emission Technique. In Structural Health Monitoring from Sensing to Processing; IntechOpen: London, UK, 2018. [Google Scholar]

- Qian, R.; Wang, T. Some observations on the acoustic emission of polymers. Eur. Polym. J. 1983, 19, 947–948. [Google Scholar] [CrossRef]

- Braz, C.J.F.; da Silva, J.R.M.; Wellen, R.M.R.; Rabello, M.S. The investigation of the stress cracking behavior of PBT by acoustic emission. Polym. Adv. Technol. 2021, 32, 4787–4804. [Google Scholar] [CrossRef]

- Brunner, A.J. Identification of damage mechanisms in fiber-reinforced polymer-matrix composites with Acoustic Emission and the challenge of assessing structural integrity and service-life. Constr. Build. Mater. 2018, 173, 629–637. [Google Scholar] [CrossRef]

- Barile, C.; Pappalettera, G.; Kannan, V.P. An acoustic emission-based characterisation of intrinsically healing fibre-reinforced polymer composites. Compos. Commun. 2025, 59, 102563. [Google Scholar] [CrossRef]

- Chen, G.; Luo, H. Acoustic emission of the fracture behaviors of epoxy foam composites reinforced by bamboo fibers. Eur. J. Mech.—A/Solids 2023, 99, 104911. [Google Scholar] [CrossRef]

- Chen, G.; Luo, H.; Luo, S.; Lin, Z.; Ma, Y. Vertically oriented structure and its fracture behavior of the Indonesia white-pearl oyster. J. Mech. Behav. Biomed. Mater. 2017, 66, 211–223. [Google Scholar] [CrossRef]

- Chen, G.; Luo, H.; Zhang, Z.; Fan, X. Flexural deformation and fracture behaviors of the sandwich turtle rib bones with hierarchical woven fibers. Colloid Interface Sci. Commun. 2020, 34, 100230. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Kannan, V.P. Application of different acoustic emission descriptors in damage assessment of fiber reinforced plastics: A comprehensive review. Eng. Fract. Mech. 2020, 235, 107083. [Google Scholar] [CrossRef]

- Hamam, Z.; Godin, N.; Fusco, C.; Doitrand, A.; Monnier, T. Acoustic Emission Signal Due to Fiber Break and Fiber Matrix Debonding in Model Composite: A Computational Study. Appl. Sci. 2021, 11, 8406. [Google Scholar] [CrossRef]

- Guo, F.; Li, W.; Jiang, P.; Chen, F.; Liu, Y. Deep Learning Approach for Damage Classification Based on Acoustic Emission Data in Composite Materials. Materials 2022, 15, 4270. [Google Scholar] [CrossRef]

- Chen, G.; Luo, H.; Wu, S.; Guan, J.; Luo, J.; Zhao, T. Flexural deformation and fracture behaviors of bamboo with gradient hierarchical fibrous structure and water content. Compos. Sci. Technol. 2018, 157, 126–133. [Google Scholar] [CrossRef]

- Kalteremidou, K.-A.; Aggelis, D.G.; Van Hemelrijck, D.; Pyl, L. Acoustic emission for identification of the dominant stress component in polymer composites at early loads. In Proceedings of the 35th European and 10th International Conference on Acoustic Emission Testing: EWGAE 35 & ICAE 10: Conference Proceedings, Ljubljana, Slovenia, 13–16 September 2022; Volume 28. [Google Scholar] [CrossRef]

- Cuadra, J.; Vanniamparambil, P.A.; Hazeli, K.; Bartoli, I.; Kontsos, A. Damage quantification in polymer composites using a hybrid NDT approach. Compos. Sci. Technol. 2013, 83, 11–21. [Google Scholar] [CrossRef]

- Tsangouri, E.; Muruzabal, A.T.; Rahier, H.; Aggelis, D.G. Acoustic Emission application to detect nanoscale fracture on polymers with self-healing ability. In Proceedings of the 12th European Conference on Non-Destructive Testing, Gothenburg, Sweden, 11–15 June 2018; pp. 1–8. [Google Scholar]

- Mileva, D.; Tranchida, D.; Gahleitner, M. Designing polymer crystallinity: An industrial perspective. Polym. Cryst. 2018, 1, e10009. [Google Scholar] [CrossRef]

- Galeski, A. Strength and toughness of crystalline polymer systems. Prog. Polym. Sci. 2003, 28, 1643–1699. [Google Scholar] [CrossRef]

- Tiwari, S.; Bag, D.S.; Mishra, P.; Lal, G.; Dwivedi, M. High-performance PPS/PEEK blend and its composites with milled carbon fiber: Study on their mechanical, thermal and dielectric properties. Polym. Compos. 2024, 45, 11845–11859. [Google Scholar] [CrossRef]

- Jiang, S.; Zhou, Z.; Zhang, J.; Yi, N.; Wang, J.; Zhao, J.; Fan, L.; Wu, Y.; Gan, F. Fabrication of high-performance polyimide films by tailoring coordination bond and chain rigidity. Eur. Polym. J. 2024, 214, 113161. [Google Scholar] [CrossRef]

- Chen, G.; Mohanty, A.K.; Misra, M. Progress in research and applications of Polyphenylene Sulfide blends and composites with carbons. Compos. Part B Eng. 2021, 209, 108553. [Google Scholar] [CrossRef]

- Schaller, R.; Peijs, T.; Tervoort, T.A. High-performance liquid-crystalline polymer films for monolithic “composites”. Compos. Part A Appl. Sci. Manuf. 2016, 81, 296–304. [Google Scholar] [CrossRef]

- Volpe, V.; Lanzillo, S.; Affinita, G.; Villacci, B.; Macchiarolo, I.; Pantani, R. Lightweight High-Performance Polymer Composite for Automotive Applications. Polymers 2019, 11, 326. [Google Scholar] [CrossRef]

- Kwon, D.; Park, S.-K.; Yoo, Y. Flow enhanced high-filled polyamide composites without the strength-flowability trade-off. Polym. Bull. 2024, 81, 14823–14836. [Google Scholar] [CrossRef]

- Dallal, S.; Eslami, B.; Tiari, S. Recent Advances in PEEK for Biomedical Applications: A Comprehensive Review of Material Properties, Processing, and Additive Manufacturing. Polymers 2025, 17, 1968. [Google Scholar] [CrossRef] [PubMed]

- Mamunya, Y.; Matzui, L.; Vovchenko, L.; Maruzhenko, O.; Oliynyk, V.; Pusz, S.; Kumanek, B.; Szeluga, U. Influence of conductive nano- and microfiller distribution on electrical conductivity and EMI shielding properties of polymer/carbon composites. Compos. Sci. Technol. 2019, 170, 51–59. [Google Scholar] [CrossRef]

- Tan, X.; Liu, T.H.; Zhou, W.; Yuan, Q.; Ying, J.; Yan, Q.; Lv, L.; Chen, L.; Wang, X.; Du, S.; et al. Enhanced Electromagnetic Shielding and Thermal Conductive Properties of Polyolefin Composites with a Ti(3)C(2)T(x) MXene/Graphene Framework Connected by a Hydrogen-Bonded Interface. ACS Nano 2022, 16, 9254–9266. [Google Scholar] [CrossRef]

- Cheng, S.Z.D.; Jin, S. Crystallization and melting of metastable crystalline polymers. In Handbook of Thermal Analysis and Calorimetry; Applications to Polymers and Plastics; Elsevier: Amsterdam, The Netherlands, 2002; pp. 167–195. [Google Scholar]

- Lotz, B. What can polymer crystal structure tell about polymer crystallization processes? Eur. Phys. J. E 2000, 3, 185–194. [Google Scholar] [CrossRef]

- Arshad, M.A. A novel kinetic approach to crystallization mechanisms in polymers. Polym. Eng. Sci. 2021, 61, 1502–1517. [Google Scholar] [CrossRef]

- Nitta, K.-h. On the Orientation-Induced Crystallization of Polymers. Polymers 2016, 8, 229. [Google Scholar] [CrossRef]

- Zhong, G.-J.; Yang, S.-G.; Lei, J.; Li, Z.-M. Flow-Induced Polymer Crystallization under Pressure and Its Engineering Application in “Structuring” Polymer Processing. Macromolecules 2024, 57, 789–809. [Google Scholar] [CrossRef]

- Saalwächter, K.; Thurn-Albrecht, T.; Paul, W. Recent Progress in Understanding Polymer Crystallization. Macromol. Chem. Phys. 2023, 224, 2200424. [Google Scholar] [CrossRef]

- Yamamoto, T. Computer modeling of polymer crystallization—Toward computer-assisted materials’ design. Polymer 2009, 50, 1975–1985. [Google Scholar] [CrossRef]

- Desio, G.P.; Rebenfeld, L. Crystallization of fiber-reinforced poly(phenylene sulfide) composites. I. Experimental studies of crystallization rates and morphology. J. Appl. Polym. Sci. 2003, 44, 1989–2001. [Google Scholar] [CrossRef]

- Li, N.; Chen, J.-Y.; Wu, T.; Meng, X.; Zhou, Q.; Ye, H.-M. Polymer extended-chain crystals: Preparation, formation mechanisms and performances. Polymer 2025, 333, 128656. [Google Scholar] [CrossRef]

- North, M.J.; Jenkins, M.J. The mechanisms of the secondary crystallisation process in polymers: A narrative review. Polymer 2025, 321, 128122. [Google Scholar] [CrossRef]

- Jariyavidyanont, K.; Zhang, R.; Yu, Q.; Janke, A.; Thurn-Albrecht, T.; Schick, C.; Androsch, R. Formation of imperfect crystals in poly(ε-caprolactone) at high melt-supercooling. Mater. Lett. 2022, 324, 132704. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Zhai, G.; Chen, Y.; Christiansen, J.d.C.; Yu, D.; Jiang, S. Cold crystallization of polytrimethylene terephthalate and copolymers. Polymer 2024, 300, 126967. [Google Scholar] [CrossRef]

- Qian, J.; Qiang, Z. Synthesis of butadiene-derived polyolefin graft copolymers and their crystallization behaviors. Polym. Chem. 2025, 16, 2530–2542. [Google Scholar] [CrossRef]

- Yang, S.-G.; Lei, J.; Zhong, G.-J.; Xu, J.-Z.; Li, Z.-M. Role of lamellar thickening in thick lamellae formation in isotactic polypropylene when crystallizing under flow and pressure. Polymer 2019, 179, 121641. [Google Scholar] [CrossRef]

- Tashiro, K. Molecular theory of mechanical properties of crystalline polymers. Prog. Polym. Sci. 1993, 18, 377–435. [Google Scholar] [CrossRef]

- Ru, J.-F.; Yang, S.-G.; Lei, J.; Li, Z.-M. Thicker Lamellae and Higher Crystallinity of Poly(lactic acid) via Applying Shear Flow and Pressure and Adding Poly(ethylene Glycol). J. Phys. Chem. B. 2017, 121, 5842–5852. [Google Scholar] [CrossRef]

- He, B.; Zhang, X.; Zhang, Q.; Fu, Q. Real-time ultrasonic monitoring of the injection-molding process. J. Appl. Polym. Sci. 2007, 107, 94–101. [Google Scholar] [CrossRef]

- Favaro, M.M.; Marinelli, A.L.; Farah, M.; Bretas, R.E.S. Optical monitoring of polypropylene crystallization during injection molding. Polym. Eng. Sci. 2007, 48, 257–266. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, L.; Su, F.; Ji, Y.; Ali, S.; Zhao, H.; Meng, L.; Li, L. From Molecular Entanglement Network to Crystal-Cross-Linked Network and Crystal Scaffold during Film Blowing of Polyethylene: An in Situ Synchrotron Radiation Small- and Wide-Angle X-ray Scattering Study. Macromolecules 2018, 51, 4350–4362. [Google Scholar] [CrossRef]

- Shmueli, Y.; Jiang, J.; Zhou, Y.; Xue, Y.; Chang, C.-C.; Yuan, G.; Satija, S.K.; Lee, S.; Nam, C.-Y.; Kim, T.; et al. Simultaneous in Situ X-ray Scattering and Infrared Imaging of Polymer Extrusion in Additive Manufacturing. ACS Appl. Polym. Mater. 2019, 1, 1559–1567. [Google Scholar] [CrossRef] [PubMed]

- Hipp, A.K.; Walker, B.; Mazzotti, M.; Morbidelli, M. In-Situ Monitoring of Batch Crystallization by Ultrasound Spectroscopy. Ind. Eng. Chem. Res. 2000, 39, 783–789. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Li, Y.; Ozcan, A.; Jarrahi, M. High-throughput terahertz imaging: Progress and challenges. Light Sci. Appl. 2023, 12, 233. [Google Scholar] [CrossRef]

- Vorontsov, V.B.; Katalnikov, V.V. Analysis of acoustic emission effect accompanying metal crystallization. J. Phys. Conf. Ser. 2008, 98, 052005. [Google Scholar] [CrossRef]

- Fevotte, G.; Wang, X.; Ouabbas, Y. Acoustic Emission, a New Sensor for Monitoring Industrial Crystallization Processes. IFAC Proc. Vol. 2014, 47, 2727–2733. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Y. An investigation of the acoustic emission generated during crystallization process of salicylic acid. Powder Technol. 2017, 311, 350–355. [Google Scholar] [CrossRef]

- Galeski, A.; Piorkowska, E.; Koenczoel, L.; Baer, E. Acoustic emission during crystallization of polymers. J. Polym. Sci. Part B Polym. Phys. 2003, 28, 1171–1186. [Google Scholar] [CrossRef]

- Galeski, A.; Koenczoel, L.; Piorkowska, E.; Baer, E. Acoustic emission during polymer crystallization. Nature 1987, 325, 40–41. [Google Scholar] [CrossRef]

- Galeski, A.; Piorkowska, E. Negative Pressure Development During Crystallization of Polymers. In Liquids Under Negative Pressure; Springer: Dordrecht, The Netherlands, 2002; pp. 127–136. [Google Scholar]

- Shen, J.; Xu, D.; Yao, R.; Liu, R.; Li, D. Study of Acoustic Emission During Non-Isothermal Crystallization of Polypropylene. Chin. J. Polym. Sci. 1990, 8, 69–74. [Google Scholar]

- Betteridge, D.; Connors, P.A.; Lilley, T.; Shoko, N.R.; Cudby, M.E.A.; Wood, D.G.M. Analysis of acoustic emissions from polymers. Polymer 1983, 24, 1206–1212. [Google Scholar] [CrossRef]

- Betteridge, D.; Cridland, J.V.; Lilley, T.; Shoko, N.R.; Cudby, M.E.A.; Wood, D.G.M. Acoustic emission and e.s.r. studies of polymers under stress. Polymer 1982, 23, 178–184. [Google Scholar] [CrossRef]

- Shivaie Kojouri, A.; Aggelis, D.G.; Karami, J.; Sharma, A.; Van Paepegem, W.; Van Hemelrijck, D.; Kalteremidou, K.A. Investigation of the Sensitivity of Acoustic Emission to the Differentiation Between Mode I, II, and III Fracture in Bulk Polymer Materials. Polymers 2025, 17, 125. [Google Scholar] [CrossRef] [PubMed]

- Casiez, N.; Deschanel, S.; Monnier, T.; Lame, O. Acoustic emission from the initiation of plastic deformation of Polyethylenes during tensile tests. Polymer 2014, 55, 6561–6568. [Google Scholar] [CrossRef]

- Gedde, U.W.; Hedenqvist, M.S. Morphology of Semicrystalline Polymers. In Fundamental Polymer Science; Graduate Texts in Physics; Springer: Cham, Switzerland, 2019; pp. 251–326. [Google Scholar]

- Sakai, T.; Shamsudim, N.S.B.; Fukushima, R.; Kageyama, K. Effect of matrix crystallinity of carbon fiber reinforced polyamide 6 on static bending properties. Adv. Compos. Mater. 2020, 30, 71–84. [Google Scholar] [CrossRef]

- Pollock, A.A. Material Brittleness and the Energetics of Acoustic Emission; Springer: New York, NY, USA, 2011; pp. 73–79. [Google Scholar]

- Barriga-Machado, B.; Hernández-Casamayor, Á.; Infante-García, D.; Giner, E. Damage mechanism identification in additive manufactured extruded polymer via acoustic emission technique, experimental testing and pattern recognition models. Eng. Fail. Anal. 2025, 181, 109928. [Google Scholar] [CrossRef]

- Prem, P.R.; Sanker, A.P.; Sebastian, S.; Kaliyavaradhan, S.K. A Review on Application of Acoustic Emission Testing During Additive Manufacturing. J. Nondestruct. Eval. 2023, 42, 96. [Google Scholar] [CrossRef]

- Chernov, A.V.; Savvas, I.K.; Alexandrov, A.A.; Kartashov, O.O.; Polyanichenko, D.S.; Butakova, M.A.; Soldatov, A.V. Integrated Video and Acoustic Emission Data Fusion for Intelligent Decision Making in Material Surface Inspection System. Sensors 2022, 22, 8554. [Google Scholar] [CrossRef]

- Dehghan Niri, E.; Farhidzadeh, A.; Salamone, S. Adaptive multisensor data fusion for acoustic emission source localization in noisy environment. Struct. Health Monit. 2012, 12, 59–77. [Google Scholar] [CrossRef]

- Li, M.; Yin, H.; Gu, F.; Duan, Y.; Zhuang, W.; Han, K.; Jin, X. Recent Advances and Applications of Nondestructive Testing in Agricultural Products: A Review. Processes 2025, 13, 2674. [Google Scholar] [CrossRef]

- Jin, H.; Han, K.; Xia, H.; Xu, B.; Jin, X. Detection of weeds in vegetables using image classification neural networks and image processing. Front. Phys. 2025, 13, 1496778. [Google Scholar] [CrossRef]

- Cheng, L.; Nokhbatolfoghahai, A.; Groves, R.M.; Veljkovic, M. Data level fusion of acoustic emission sensors using deep learning. J. Intell. Mater. Syst. Struct. 2024, 36, 77–96. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, Z.; Chen, Z.; Lu, H.; Yang, Z. A multi-level feature fusion artificial neural network for classification of acoustic emission signals. Ann. N. Y. Acad. Sci. 2025, 1544, 223–241. [Google Scholar] [CrossRef] [PubMed]

| AE Parameters | Definitions |

|---|---|

| Event | The signal captured either in the frequency domain or the time domain, resulting from the generation of elastic waves. It represents the complete AE waveform acquired during testing |

| Hit | An AE signal that exceeds the user-defined threshold on a single channel. Multiple hits may originate from multiple events or channels |

| Amplitude | The peak amplitude of an AE hit, expressed in decibels (dB) or volts |

| Rise time | The time interval from the initial threshold crossing to the point of maximum amplitude |

| Counts | The number of pulses within an AE hit that surpass the predefined threshold |

| Duration | The time from the first threshold crossing to the last |

| Energy | The integral of the signal envelope over the duration of the hit |

| Peak frequency | The frequency component with the highest magnitude in the AE signal spectrum |

| Central frequency | The centroid or center of gravity of the AE frequency spectrum |

| Method | Advantage | Disadvantage | Ref. |

|---|---|---|---|

| Ultrasound | Direct and efficient: sensitive to acoustic waves’ velocity and attenuation | Have to continuously emit ultrasonic waves, and timing is difficult to grasp | [65,69] |

| Optical method | Fast and imageable: depends on the light intensity and scattering pattern | Not suitable for low-crystalline polymers | [53,66] |

| THz spectroscopy | Quick imaging: capture changes of picosecond dynamics in media | Sensitive to temperature and moisture | [11,70] |

| X-ray imaging | High-throughput imaging and high resolution | Expensive; hard to catch the crystallization window; not through metal mold | [67,68] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, G.; Mekonnen, T. Acoustic Emission Mechanisms During Polymer Processing and Chain Orientation: From Amorphous to Crystalline. Polymers 2025, 17, 2948. https://doi.org/10.3390/polym17212948

Chen G, Mekonnen T. Acoustic Emission Mechanisms During Polymer Processing and Chain Orientation: From Amorphous to Crystalline. Polymers. 2025; 17(21):2948. https://doi.org/10.3390/polym17212948

Chicago/Turabian StyleChen, Guowei, and Tizazu Mekonnen. 2025. "Acoustic Emission Mechanisms During Polymer Processing and Chain Orientation: From Amorphous to Crystalline" Polymers 17, no. 21: 2948. https://doi.org/10.3390/polym17212948

APA StyleChen, G., & Mekonnen, T. (2025). Acoustic Emission Mechanisms During Polymer Processing and Chain Orientation: From Amorphous to Crystalline. Polymers, 17(21), 2948. https://doi.org/10.3390/polym17212948