Study on Fiber-Fabric Hierarchical Reinforcement for High-Toughness Magnesium Phosphate Cement Composites

Abstract

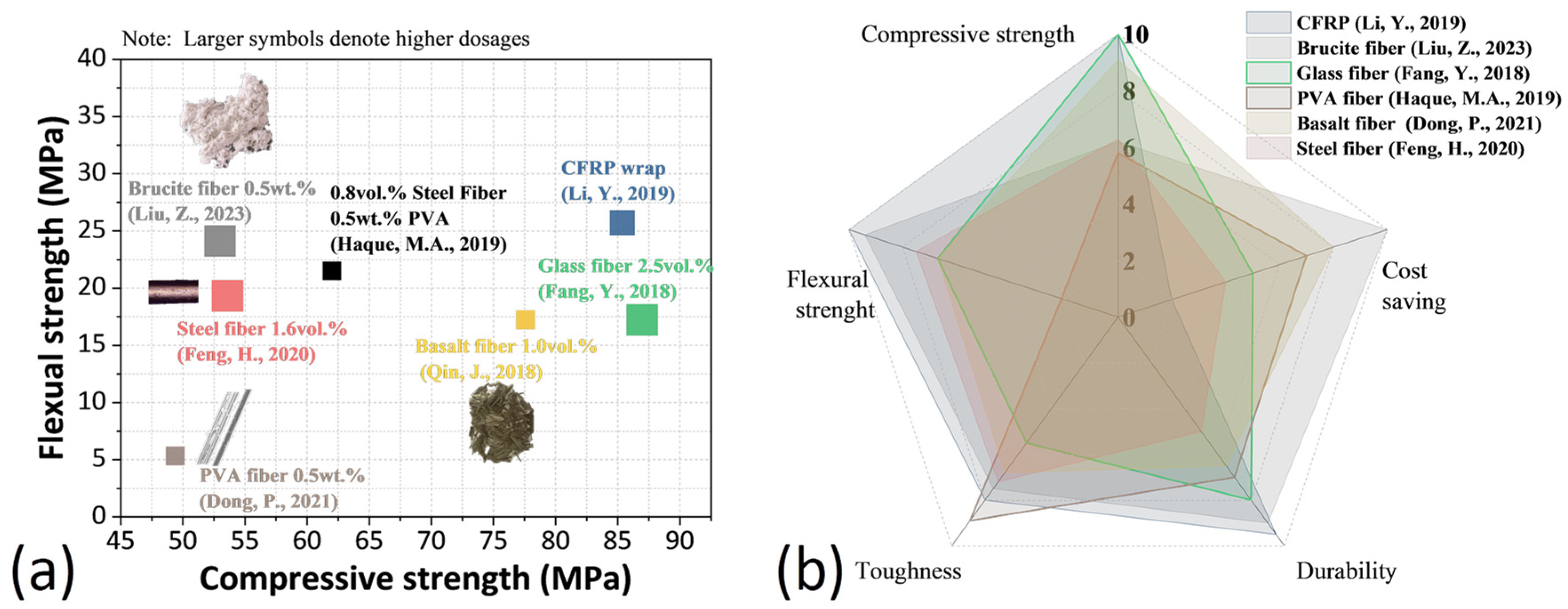

1. Introduction

2. Materials and Methods

2.1. Materials

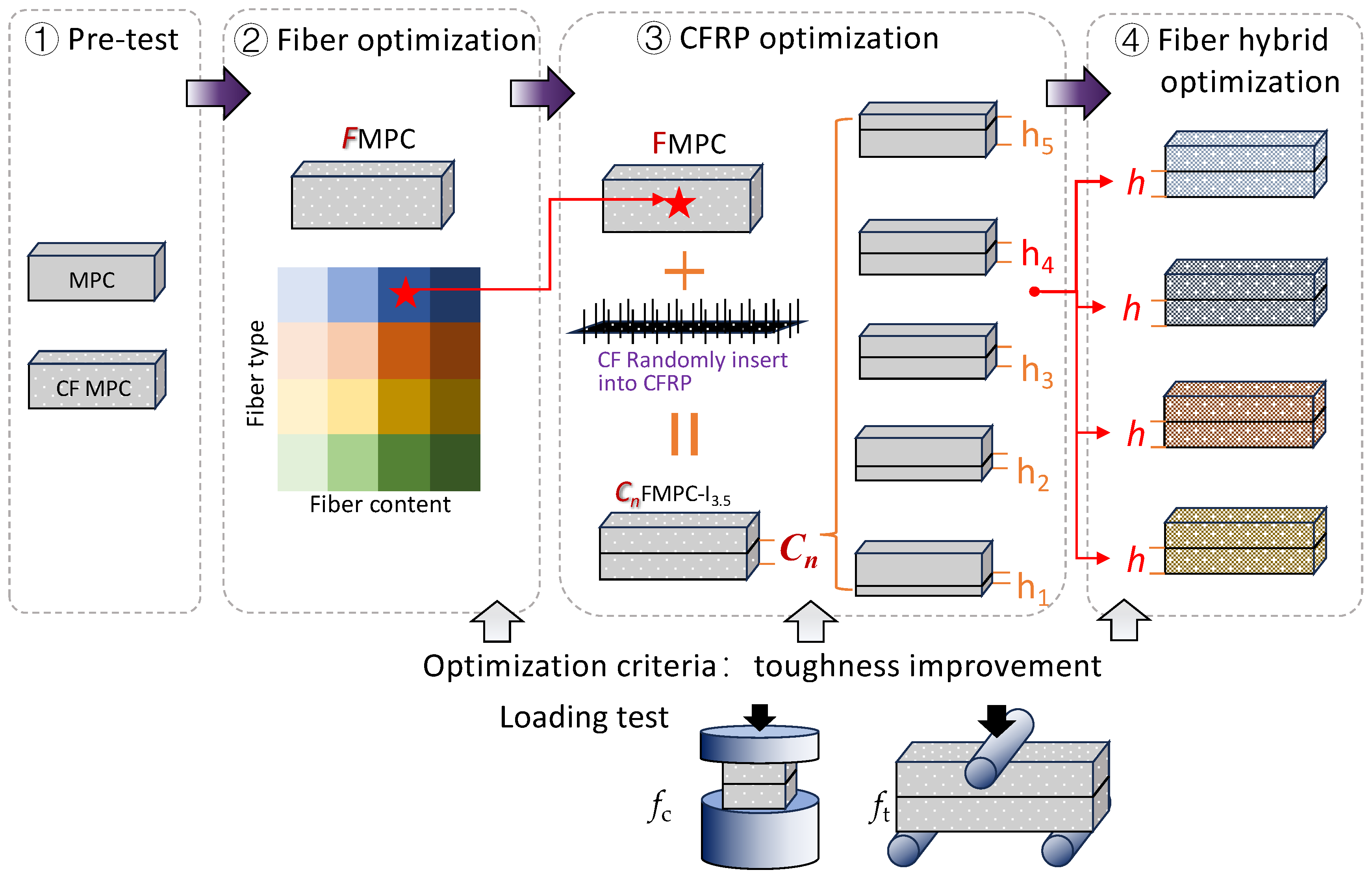

2.2. Experimental Design and Sample Preparation

| MPC: | Magnesium phosphate cement. |

| F: | Fibers. |

| Cn: | CFRP fabric placed at n mm (9, 13, 16, and 19; CFRP placed in Table 2). |

| Tm: | Fiber type designation (I, II, III, and V1-V5, Fiber type in Table 2). |

| m: | Fiber content in weight percentage (m = 1.5, 2.5, 3.5, and 5, Fiber column in Table 2). |

2.3. Mechanical Property Tests

2.4. Parameters of Flexural Properties

3. Results and Discussion

3.1. Effect of Fiber Types and Dosages

3.1.1. Mechanical Strengths

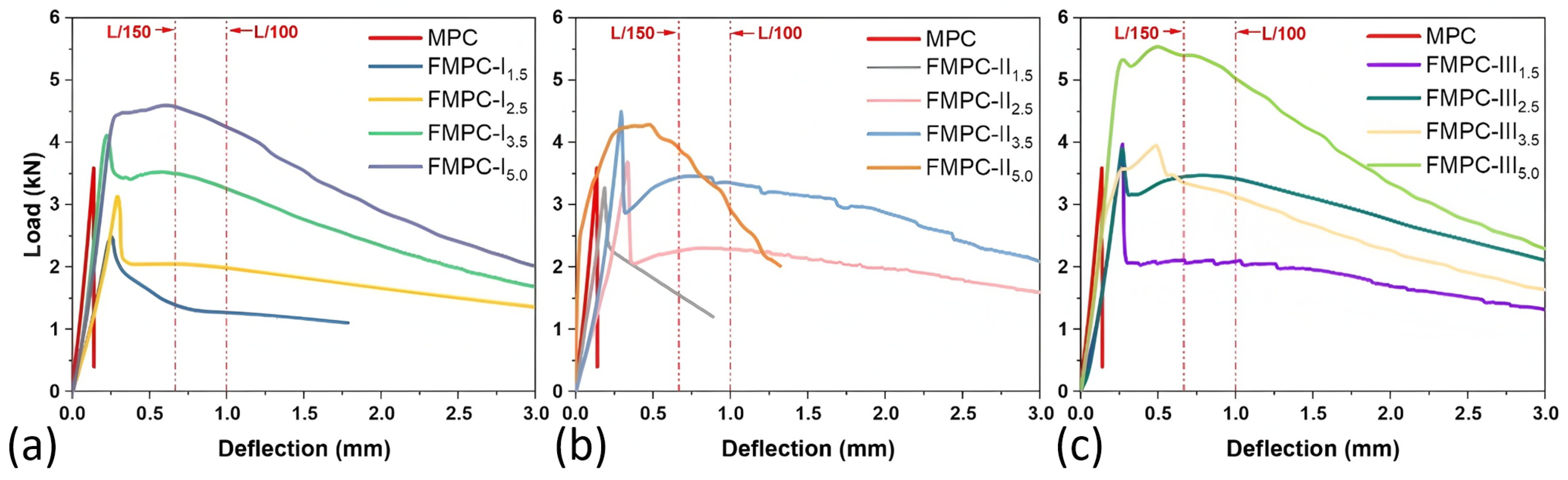

3.1.2. L-D Curves

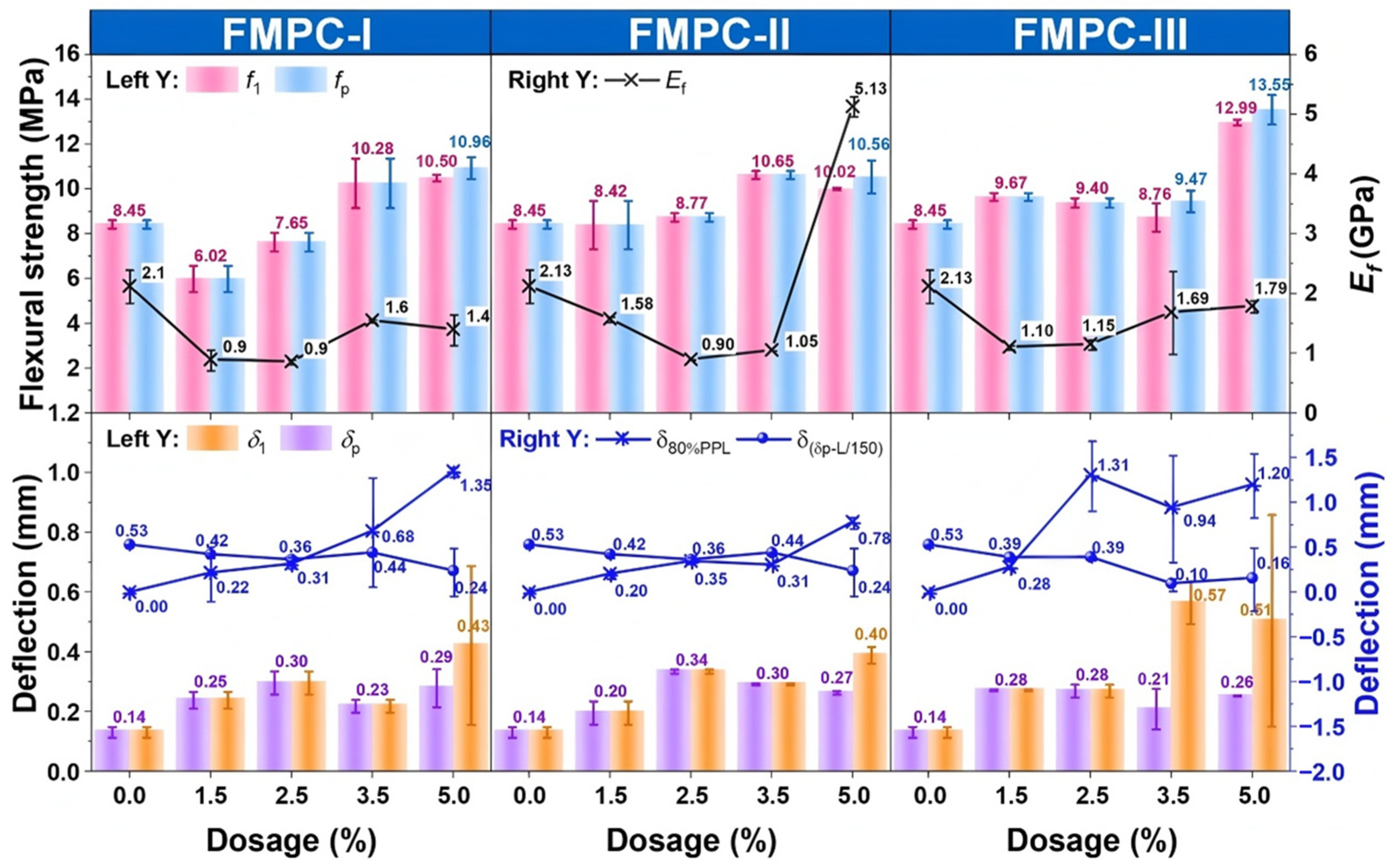

3.1.3. Flexural Strengths, Moduli, and Deflections

3.1.4. Other Flexural Parameters

3.1.5. Selection of FMPC for CFRP Fabric Addition

3.2. Effect of the Displacement of CFRP Fabric

3.2.1. Selection of FMPC for CFRP Fabric Addition

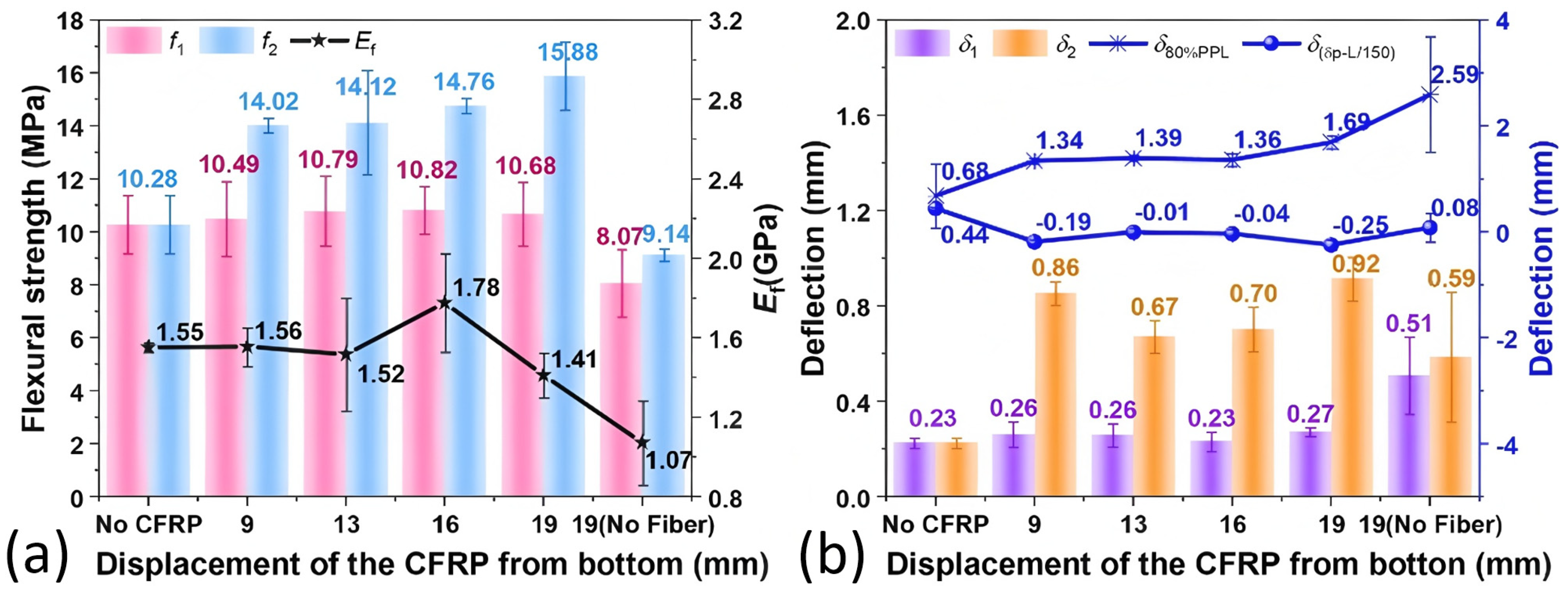

3.2.2. Flexural Strengths, Moduli, and Deflection

3.2.3. Other Flexural Parameters

3.2.4. Discussion

3.3. Effect of the Displacement of CFRP Fabric

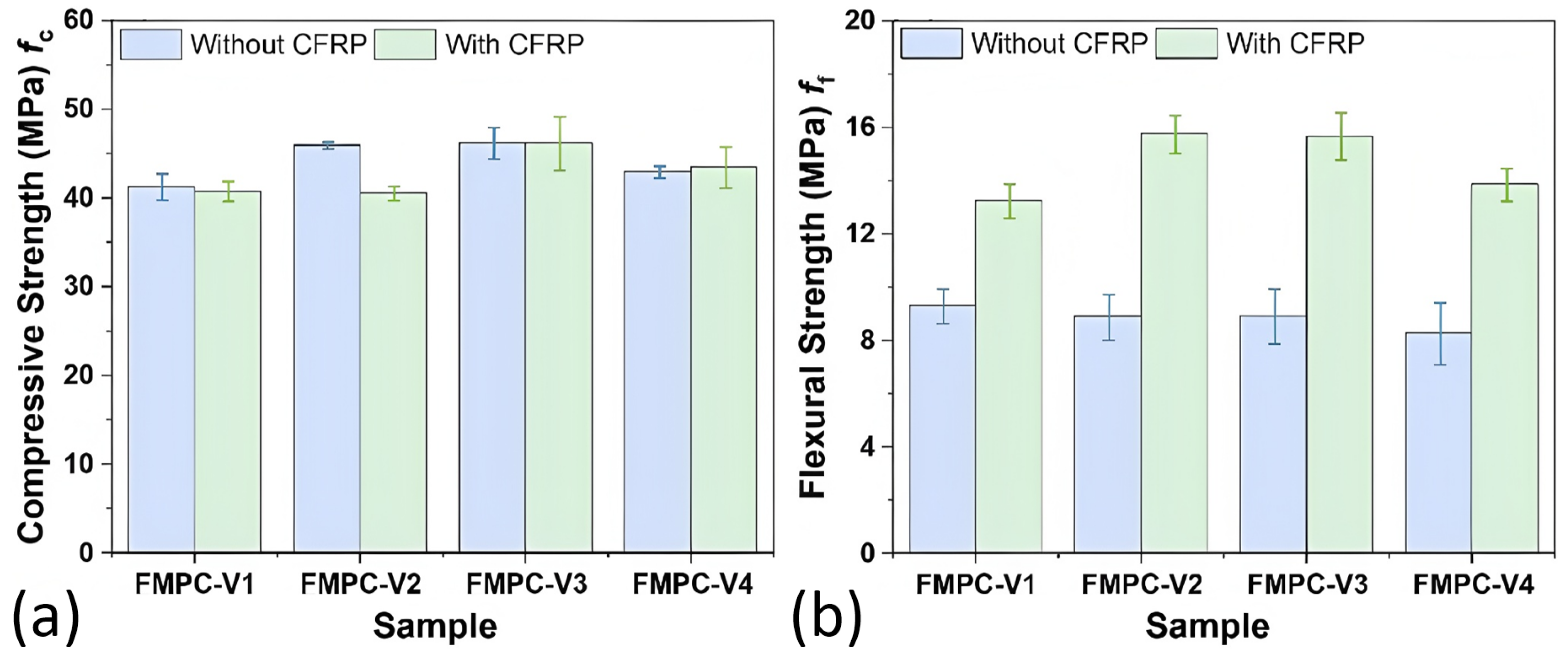

3.3.1. Mechanical Strengths and L-D Curves

3.3.2. Flexural Strengths, Moduli, and Deflections

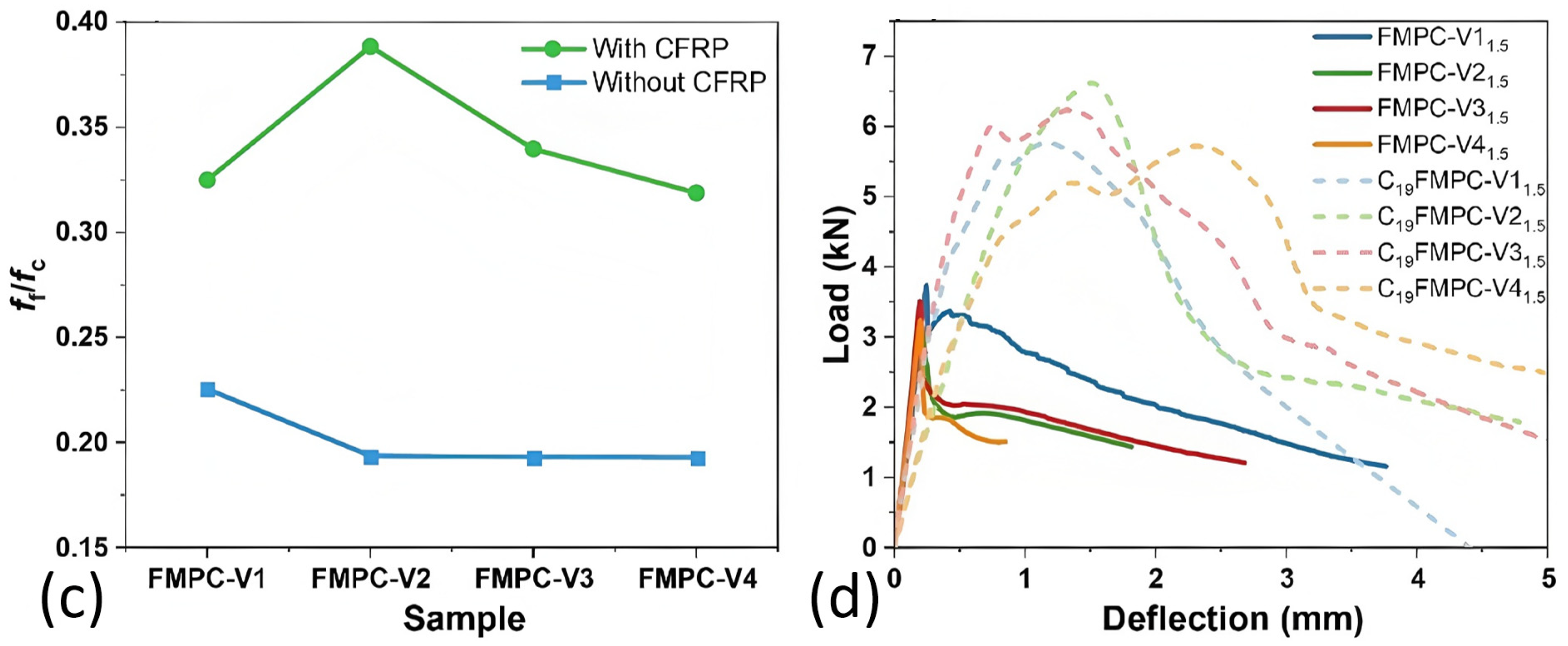

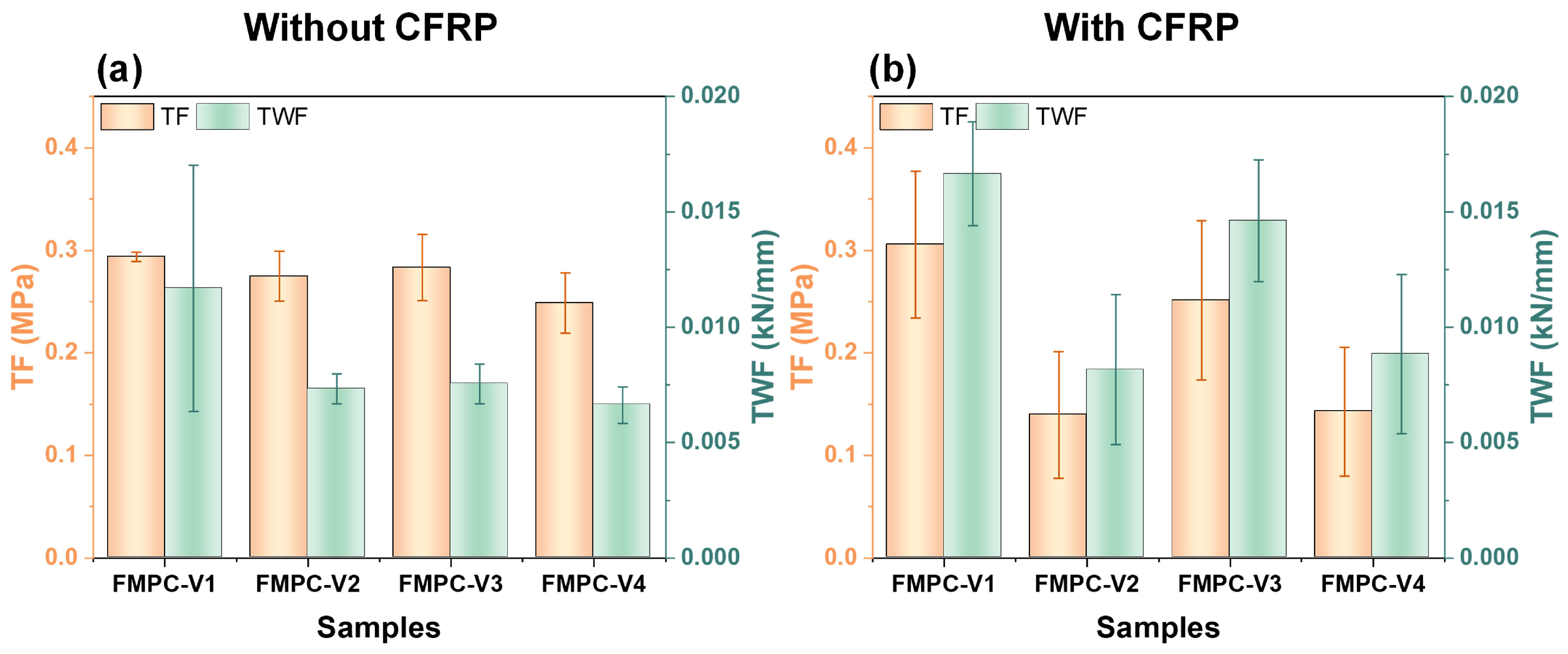

3.3.3. Other Flexural Parameters

3.3.4. Efficacy Evaluation

3.4. Further Discussion

4. Conclusions

- (1)

- The research establishes that fiber dosage exerts a more dominant influence on MPC properties than fiber type, with 3.5% fiber content providing the optimal balance between enhanced flexural performance (45% improvement) and minimal compressive strength reduction (<20%). Beyond this threshold, fiber agglomeration at 5.0% content introduces significant variability, highlighting the existence of critical fiber content limits for practical applications.

- (2)

- A fundamental finding is the identification of 19 mm as the optimal CFRP fabric displacement, which maximizes the synergistic interaction between fiber reinforcement and fabric confinement. This specific configuration achieves an exceptional ff/fc ratio of 0.389, demonstrating that strategic placement of internal CFRP fabric can overcome the traditional trade-off between compressive strength and flexural toughness in ceramic-based composites.

- (3)

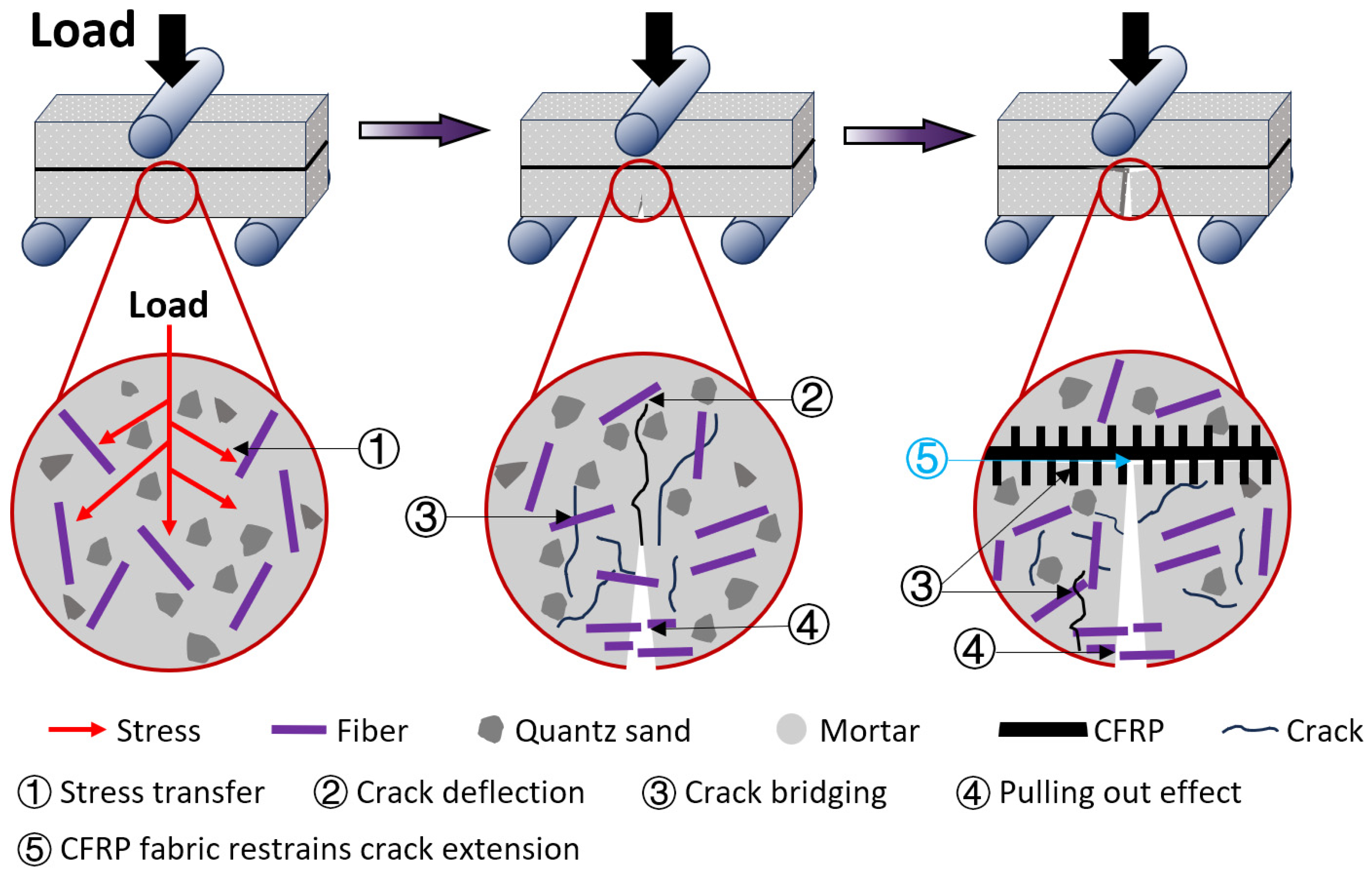

- The study further reveals that the cooperative reinforcement effect follows a hierarchical activation mechanism: microfibers initially bridge microcracks while CFRP fabric provides macro-scale crack restraint, with fiber–CFRP interfacial interactions enhancing stress redistribution. This multi-scale reinforcement strategy, validated across various fiber combinations, establishes a new paradigm for designing ductile MPC composites capable of transitioning from brittle to quasi-ductile fracture behavior.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wagh, A.S. Chemically Bonded Phosphate Ceramics. In Chemically Bonded Phosphate Ceramics; Elsevier: Amsterdam, The Netherlands, 2016; pp. 17–34. [Google Scholar] [CrossRef]

- Fang, B.; Hu, Z.; Shi, T.; Liu, Y.; Wang, X.; Yang, D.; Zhu, K.; Zhao, X.; Zhao, Z. Research progress on the properties and applications of magnesium phosphate cement. Ceram. Int. 2023, 49, 4001–4016. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, H.; Li, X.; Zhu, Z. Hydration behavior of magnesium potassium phosphate cement and stability analysis of its hydration products through thermodynamic modeling. Cem. Concr. Res. 2017, 98, 101–110. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B.; Yu, J. A comprehensive study of basalt fiber reinforced magnesium phosphate cement incorporating ultrafine fly ash. Compos. Part B Eng. 2019, 168, 204–217. [Google Scholar] [CrossRef]

- Haque, M.A.; Chen, B. Research progresses on magnesium phosphate cement: A review. Constr. Build. Mater. 2019, 211, 885–898. [Google Scholar] [CrossRef]

- Qiao, F.; Chau, C.K.; Li, Z. Property evaluation of magnesium phosphate cement mortar as patch repair material. Constr. Build. Mater. 2010, 24, 695–700. [Google Scholar] [CrossRef]

- Fang, Y.; Cui, P.; Ding, Z.; Zhu, J.-X. Properties of a magnesium phosphate cement-based fire-retardant coating containing glass fiber or glass fiber powder. Constr. Build. Mater. 2018, 162, 553–560. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Shi, T.; Li, J. Experimental study on mechanical properties and fracture toughness of magnesium phosphate cement. Constr. Build. Mater. 2015, 96, 346–352. [Google Scholar] [CrossRef]

- Feng, H.; Liang, J.; Guo, A.; Lv, L.; Sun, Z.; Sheikh, M.N.; Liu, F. Development and design of ultra-high ductile magnesium phosphate cement-based composite using fly ash and silica fume. Cem. Concr. Compos. 2023, 137, 104923. [Google Scholar] [CrossRef]

- Feng, H.; Li, Z.; Wang, W.; Liu, G.; Zhang, Z.; Gao, D. Deflection hardening behaviour of ductile fibre reinforced magnesium phosphate cement-based composite. Cem. Concr. Compos. 2021, 121, 104079. [Google Scholar] [CrossRef]

- Liu, Z.; Lai, Z.; Luo, X.; Xiao, R.; Chen, J.; Lu, Z. Properties of magnesium phosphate cement reinforced with natural brucite fiber. Constr. Build. Mater. 2023, 393, 132057. [Google Scholar] [CrossRef]

- Wang, L.; Yu, I.K.M.; Tsang, D.C.W.; Yu, K.; Li, S.; Poon, C.S.; Dai, J.-G. Upcycling wood waste into fibre-reinforced magnesium phosphate cement particleboards. Constr. Build. Mater. 2018, 159, 54–63. [Google Scholar] [CrossRef]

- Yue, L.; Bing, C. Factors that affect the properties of magnesium phosphate cement. Constr. Build. Mater. 2013, 47, 977–983. [Google Scholar] [CrossRef]

- Qin, J.; Qian, J.; Li, Z.; You, C.; Dai, X.; Yue, Y.; Fan, Y. Mechanical properties of basalt fiber reinforced magnesium phosphate cement composites. Constr. Build. Mater. 2018, 188, 946–955. [Google Scholar] [CrossRef]

- Tassew, S.; Lubell, A. Textile Reinforced Ceramic Composites for Structural Infill Slab Applications. In Proceedings of the IABSE Symposium: Large Structures and Infrastructures for Environmentally Constrained and Urbanised Areas, Venice, Italy, 22–24 September 2010; pp. 268–269. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, W.; Zhan, Z.; Wen, Q.; Zhang, H.; Xiong, X. Ablation and insulation properties of hybrid carbon-quartz fiber fabric reinforced magnesium phosphate cement composite. Constr. Build. Mater. 2025, 464, 140122. [Google Scholar] [CrossRef]

- Feng, H.; Sheikh, M.N.; Hadi, M.N.S.; Gao, D.; Zhao, J. Mechanical properties of micro-steel fibre reinforced magnesium potassium phosphate cement composite. Constr. Build. Mater. 2018, 185, 423–435. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Paulraj, S.; Balasundaram, N.; Kumar, K.; Devi, M. Experimental studies on strength and SCC characteristics of basalt fiber reinforced concrete. Int. J. Civ. Eng. Technol. 2017, 8, 704–711. [Google Scholar]

- High, C.; Seliem, H.M.; El-Safty, A.; Rizkalla, S.H. Use of basalt fibers for concrete structures. Constr. Build. Mater. 2015, 96, 37–46. [Google Scholar] [CrossRef]

- Dong, L.; Wang, X. Study on mechanical properties of E-glass fiber mat reinforced magnesium phosphate cement thin-slab. Structures 2025, 73, 108365. [Google Scholar] [CrossRef]

- Liu, F.; Wang, B.; Chen, Z.; Zhou, C. Interface bonding mechanism of BFPMPC and concrete: Insights from microscopic to molecular scale. J. Build. Eng. 2025, 107, 112678. [Google Scholar] [CrossRef]

- Zhan, Z.; Sun, W.; Zhang, S.; Wen, Q.; Zhang, H.; Xiong, X. Ablation and insulation behavior of magnesium phosphate cement composite in harsh environments. Corros. Sci. 2023, 221, 111326. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, B.; Oderji, S.Y. Experimental research on magnesium phosphate cement mortar reinforced by glass fiber. Constr. Build. Mater. 2018, 188, 729–736. [Google Scholar] [CrossRef]

- Dong, P.; Ahmad, M.R.; Chen, B.; Munir, M.J.; Kazmi, S.M.S. A study on magnesium phosphate cement mortars reinforced by polyvinyl alcohol fibers. Constr. Build. Mater. 2021, 302, 124154. [Google Scholar] [CrossRef]

- Haque, M.A.; Chen, B.; Ahmad, M.R.; Shah, S.F.A. Mechanical strength and flexural parameters analysis of micro-steel, polyvinyl and basalt fibre reinforced magnesium phosphate cement mortars. Constr. Build. Mater. 2020, 235, 117447. [Google Scholar] [CrossRef]

- Péra, J.; Ambroise, J. Fiber-reinforced magnesia-phosphate cement composites for rapid repair. Cem. Concr. Compos. 1998, 20, 31–39. [Google Scholar] [CrossRef]

- Feng, H.; Li, L.; Zhang, P.; Gao, D.; Zhao, J.; Feng, L.; Sheikh, M.N. Microscopic characteristics of interface transition zone between magnesium phosphate cement and steel fiber. Constr. Build. Mater. 2020, 253, 119179. [Google Scholar] [CrossRef]

- Zhu, W.; Hu, X.; Zhang, J.; Li, T.; Chen, Z.; Shao, W. Experimental study on mechanical properties of a novel micro-steel fiber reinforced magnesium phosphate cement-based concrete. Front. Struct. Civ. Eng. 2021, 15, 1047–1057. [Google Scholar] [CrossRef]

- Feng, H.; Chen, G.; Gao, D.; Zhao, K.; Zhang, C. Mechanical Properties of Steel Fiber-Reinforced Magnesium Phosphate Cement Mortar. Adv. Civ. Eng. 2018, 2018, 3978318. [Google Scholar] [CrossRef]

- Tassew, S.T.; Lubell, A.S. Mechanical properties of glass fiber reinforced ceramic concrete. Constr. Build. Mater. 2014, 51, 215–224. [Google Scholar] [CrossRef]

- Hayashi, T. On the improvement of mechanical properties of composites by hybrid composition. In Proceedings of the 8th International Reinforced Plastics Conference, Brighton, UK, 10–12 October 1972; pp. 149–152. [Google Scholar]

- Li, Y.; Liu, X.; Wang, Z. Experimental Study on Reinforcement and Chloride Extraction of Concrete Column with MPC-CFRP Composite Anode. KSCE J. Civ. Eng. 2019, 23, 1766–1775. [Google Scholar] [CrossRef]

- Ding, Z.; Dai, J.-G.; Muner, S. Study on an Improved Phosphate Cement Binder for the Development of Fiber-Reinforced Inorganic Polymer Composites. Polymers 2014, 6, 2819–2831. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Wu, M.; Bai, W. Research of electrochemical chloride extraction and reinforcement of concrete column using MPC-bonded carbon fiber reinforced plastic sheet & mesh. Constr. Build. Mater. 2017, 153, 436–444. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). Chinese National Standard: Beijing, China, 2021.

- Bhutta, A.; Borges, P.H.R.; Zanotti, C.; Farooq, M.; Banthia, N. Flexural behavior of geopolymer composites reinforced with steel and polypropylene macro fibers. Cem. Concr. Compos. 2017, 80, 31–40. [Google Scholar] [CrossRef]

- Shi, J.; Liu, B.; Chu, S.H.; Zhang, Y.; Zhang, Z.; Han, K. Recycling air-cooled blast furnace slag in fiber reinforced alkali-activated mortar. Powder Technol. 2022, 407, 117686. [Google Scholar] [CrossRef]

- Moujoud, Z.; Sair, S.; Ousaleh, H.A.; Ayouch, I.; El Bouari, A.; Tanane, O. Geopolymer composites reinforced with natural Fibers: A review of recent advances in processing and properties. Constr. Build. Mater. 2023, 388, 131666. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Compressive and flexural strength of fiber-reinforced foamed concrete: Effect of fiber content, curing conditions and dry density. Constr. Build. Mater. 2019, 198, 479–493. [Google Scholar] [CrossRef]

- Wang, S.; Xue, Q.; Ma, W.; Zhao, K.; Wu, Z. Experimental study on mechanical properties of fiber-reinforced and geopolymer-stabilized clay soil. Constr. Build. Mater. 2021, 272, 121914. [Google Scholar] [CrossRef]

- Qin, J.; Zhang, Z.; Ma, H.; Dai, X.; Cheng, X.; Jia, X.; Qian, J. Improving mechanical properties of magnesium phosphate cement-based ultra-high performance concrete by ultrafine fly ash incorporation. Constr. Build. Mater. 2024, 448, 138198. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Q.; Long, X.; Pei, Y.; Skoczylas, F. Mechanical properties of magnesium phosphate cement composites reinforced with hybrid basalt and polyvinyl alcohol fibers. J. Build. Eng. 2025, 104, 112207. [Google Scholar] [CrossRef]

- Wang, X.; Hu, X.; Chong, L.; Yang, J.; Shi, C. Effects of the combination of NH4H2PO4 and KH2PO4 on the interfacial bond between magnesium phosphate cement and steel fiber. Constr. Build. Mater. 2023, 407, 133405. [Google Scholar] [CrossRef]

- Feng, H.; Lv, L.; Pang, Y.; Yuan, C.; Chu, L.; Zhao, X. Bond behavior between the nano-Al2O3-water-glass-modified magnesium-phosphate-cement mortar and steel fiber. Constr. Build. Mater. 2021, 306, 124814. [Google Scholar] [CrossRef]

- Liu, X.; Xiang, K.; Guo, Y.; Ye, Q.; Zhang, J.; Pei, X.; Wang, X. Experimental study on impact toughness of multi-combination hybrid fiber-reinforced magnesium phosphate cement-based materials. J. Build. Eng. 2023, 78, 107564. [Google Scholar] [CrossRef]

- Tang, Z.; Chen, D.; Wang, X.; Han, Z.; Tao, R.; Zhang, G.; Hou, D.; Wu, D.; Ding, Q. Impact of polyethylene fiber on the ductility and durability of magnesium phosphate cement. J. Build. Eng. 2023, 68, 106123. [Google Scholar] [CrossRef]

- Nie, S.; Guo, A.; Feng, H.; Yu, Z.; Hu, Q. Magnesium phosphate cement-based engineered cementitious composites with polyethylene fibers: Performance improvement and design method. J. Clean. Prod. 2024, 450, 141941. [Google Scholar] [CrossRef]

- Haque, M.A.; Chen, B.; Ahmad, M.R.; Shah, S.F.A. Evaluating the physical and strength properties of fibre reinforced magnesium phosphate cement mortar considering mass loss. Constr. Build. Mater. 2019, 217, 427–440. [Google Scholar] [CrossRef]

- Du, W.; Qian, C. Atomic-level insights into the mechanism by which synthetic organic fibers enhance the tensile strength of concrete. J. Build. Eng. 2023, 75, 106891. [Google Scholar] [CrossRef]

- Andersons, J.; Joffe, R.; Hojo, M.; Ochiai, S. Glass fibre strength distribution determined by common experimental methods. Compos. Sci. Technol. 2002, 62, 131–145. [Google Scholar] [CrossRef]

- Shi, F.; Pham, T.M.; Hao, H.; Hao, Y. Post-cracking behaviour of basalt and macro polypropylene hybrid fibre reinforced concrete with different compressive strengths. Constr. Build. Mater. 2020, 262, 120108. [Google Scholar] [CrossRef]

- Hamad, R.J.A.; Johari, M.A.M.; Haddad, R.H. Mechanical properties and bond characteristics of different fiber reinforced polymer rebars at elevated temperatures. Constr. Build. Mater. 2017, 142, 521–535. [Google Scholar] [CrossRef]

- Zeng, X.; Lan, X.; Zhu, H.; Long, G.; Xie, Y. Investigation on air-voids structure and compressive strength of concrete at low atmospheric pressure. Cem. Concr. Compos. 2021, 122, 104139. [Google Scholar] [CrossRef]

- Rovnaník, P.; Kusák, I.; Bayer, P.; Schmid, P.; Fiala, L. Comparison of electrical and self-sensing properties of Portland cement and alkali-activated slag mortars. Cem. Concr. Res. 2019, 118, 84–91. [Google Scholar] [CrossRef]

- Jin, H.; Yang, Z.; Cai, D.; Jia, D.; Zhou, Y. 3D printing of porous Si2N2O ceramics based on strengthened green bodies fabricated via strong colloidal gel. Mater. Des. 2020, 185, 108220. [Google Scholar] [CrossRef]

- Yu, J.; Qian, J.; Tang, J.; Ji, Z.; Fan, Y. Effect of ettringite seed crystals on the properties of calcium sulphoaluminate cement. Constr. Build. Mater. 2019, 207, 249–257. [Google Scholar] [CrossRef]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

- Zainal, S.M.I.S.; Hejazi, F.; Mafaileh, A.M.A. Strengthening of Reinforced Concrete slabs using macro and micro synthetic fibers. Structures 2023, 51, 1579–1590. [Google Scholar] [CrossRef]

- Yang, J.; Yu, J.; Zhang, Z.; Zou, Y.; Chen, R.; Zhou, J.; Li, B. Flexural behavior of 15-year-old full-scale hollow slab beams strengthened with fiber-reinforced composites. Case Stud. Constr. Mater. 2023, 19, e02545. [Google Scholar] [CrossRef]

- Ashraf, S.; Rucka, M. Microcrack monitoring and fracture evolution of polyolefin and steel fibre concrete beams using integrated acoustic emission and digital image correlation techniques. Constr. Build. Mater. 2023, 395, 132306. [Google Scholar] [CrossRef]

- Feng, H.; Zheng, Y.; Yu, Z.; Guo, A.; Yang, Z. Flexural performance of concrete reinforced with ultra-high ductility magnesium phosphate cement-based composites and CFRP. Constr. Build. Mater. 2024, 432, 136631. [Google Scholar] [CrossRef]

- Abdulrazzaq, A.M.; Hassan, M.S.; Abdulhameed, H.A. Ultimate capacity and failure mode analysis of heat-damaged concrete cylinders wrapped with CFRP fabric. Eng. Fail. Anal. 2025, 177, 109705. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Q.; Deng, Y.; Lin, J. Reinforcement effects of multi-scale hybrid fiber on flexural and fracture behaviors of ultra-low-weight foamed cement-based composites. Cem. Concr. Compos. 2020, 108, 103509. [Google Scholar] [CrossRef]

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Gao, C.; Li, Y.; Xu, J.; Huang, J.; Xu, D.; Hu, Z.; Han, F.; Liu, J. A Review on Multi-Scale Toughening and Regulating Methods for Modern Concrete: From Toughening Theory to Practical Engineering Application. Research 2024, 7, 0518. [Google Scholar] [CrossRef]

- Yang, K.; Tang, Z.; Li, W.; Long, Z.; He, J.; Ma, G.; Li, Y.; Xiang, Y.; Xie, Y.; Long, G. A comprehensive review on the toughening technologies of cement-based materials: From multiscale materials to advanced processes. Constr. Build. Mater. 2024, 456, 139274. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B. Effect of silica fume and basalt fiber on the mechanical properties and microstructure of magnesium phosphate cement (MPC) mortar. Constr. Build. Mater. 2018, 190, 466–478. [Google Scholar] [CrossRef]

- Feng, H.; Li, L.; Wang, W.; Cheng, Z.; Gao, D. Mechanical properties of high ductility hybrid fibres reinforced magnesium phosphate cement-based composites. Compos. Struct. 2022, 284, 115219. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, L.; Zheng, W.; Huang, X.; Zhang, J.; Zhang, W. Properties and interfacial performances with magnesium phosphate cement of coir fiber treated by an efficient water bath method: Effect of immersion temperatures and times. Constr. Build. Mater. 2024, 429, 136443. [Google Scholar] [CrossRef]

- Zhang, Z.; Chang, Z.; Qian, J.; Hua, Y.; Wang, A.; Luo, Z. Preparation and properties of sisal fiber reinforced magnesium phosphate cement. Compos. Part B Eng. 2025, 307, 112859. [Google Scholar] [CrossRef]

- Zhang, X.; Gong, Y.; Liu, Q.; Sheng, Y.; Liang, L. Axial compressive performance of CFRP-confined concrete columns with magnesium phosphate cement-based adhesives, Case Studies in Construction. Materials 2025, 22, e04603. [Google Scholar] [CrossRef]

| Name Abbreviation | Type | Length | Diameter | Color |

|---|---|---|---|---|

| CF | Cracked fiber | 15 mm | 18–48 μm | White |

| GF | Glass fiber | 6 mm | 13–15 μm | White |

| GFP | Glass fiber powder | - | 150 μm | White |

| PMF | Polypropylene mesh fiber | 19 mm | - | White |

| WSF | Waveform steel fiber | 30 mm | 0.2–0.6 mm | Silver |

| CPSF | Copper-plated steel fiber | 10, 15 mm | 0.18–0.25 mm | Brass |

| WW | Wave wire | 11 mm | 0.5–0.7 mm | Silver |

| SW | Straight wire | 11 mm | 0.5–0.7 mm | Silver |

| Sample | MPP (g) | DBM (g) | BR (g) | QS (g) | W (g) | Fiber * (wt.%) | Fiber Type | CFRP Place ** |

|---|---|---|---|---|---|---|---|---|

| MPC | 459.5 | 540.5 | 54.1 | 500 | 250 | 0 | - | - |

| FMPC | 459.5 | 540.5 | 54.1 | 500 | 250 | 1.5 2.5 3.5 5.0 | I-GF/CF = 1/1 II-GF/GFP/CF = 0.4/1.4/1 III-PMF/GF/CF = 0.4/1.4/1 | - |

| CnFMPC-I3.5 | 459.5 | 540.5 | 54.1 | 500 | 250 | 3.5 | I-GF/CF = 1/1 | 9 13 16 19 |

| C19MPC | 459.5 | 540.5 | 54.1 | 500 | 250 | 0 | - | 19 |

| FMPC-V1.5 | 459.5 | 540.5 | 54.1 | 500 | 250 | 1.5 | V1-CF/WSF/CPS10 = 1/1/1 V2-CF/WSF/CPS15 = 1/1/1 V3-CF/WSF/WW = 1/1/1 V4-CF/WSF/SW = 1/1/1 | - |

| C19FMPC-V1.5 | 459.5 | 540.5 | 54.1 | 500 | 250 | 1.5 | V1-CF/WSF/CPS10 = 1/1/1 V2-CF/WSF/CPS15 = 1/1/1 V3-CF/WSF/WW = 1/1/1 V4-CF/WSF/SW = 1/1/1 | 19 |

| Symbol | Parameter | Definition/Equation | |

|---|---|---|---|

| P1 | First peak load | Load causes the first cracking in the samples | |

| Pp | Peak load | The highest load on the L-D curve | |

| δ1 | Deflection at P1 | Deflection at the P1 on the L-D curve | |

| δp | Deflection at Pp | Deflection at the Pp on the L-D curve | |

| f1 | First peak strength | Strength calculated by (2), where P = P1 | |

| fp | Peak strength | Strength calculated by (2), where P = Pp | |

| 80%PPL | 80% of peak load | Load equals 80% × Pp | |

| δ80%PPL | Deflection at 80% Pp in post-peak | 80%PPL deflection on the descending curve after Pp | |

| δδp-L/150 | Difference between δp and L/150 | δδp-L/150 = (L/150)-δp (L = 100 mm here) | (5) |

| PL/150 | Load at L/150 deflection | Residual load at the deflection of L/150 | |

| fL/150 | Strength at L/150 deflection | Strength calculated by (2), where P = PL/150 | |

| TD150 | Toughness index at L/150 | The area under the L-D curve from 0 to L/150 | |

| PL/100 | Load at L/100 deflection | Residual load at the deflection of L/100 | |

| fL/100 | Strength at L/100 deflection | Strength calculated by (2), where P = PL/100 | |

| TD100 | Toughness index at L/100 | The area under the L-D curve from 0 to L/100 | |

| RDT,150 | Equivalent flexural strength ratio (EFSR, implying flexural ductility) | (6) | |

| TF | Toughness factor | (7) | |

| PEA | EA from 0 to δ1 | The area under the L-D curve from 0 to δ1 | |

| PoEA | EA from δ1 to δp | The area under the L-D curve from δ1 to δp | |

| TEA | Total EA | TD150 for softening deflection L-D curves TD100 for hardening deflection L-D curves | |

| TWF | Total work of fracture | (8) | |

| Ef | Modulus of elasticity | (9) | |

| Compressive Strength (CS) | Flexural Strength (FS) | FS to CS Ratios | ||||||

|---|---|---|---|---|---|---|---|---|

| fc (MPa) | COV (%) | R (%) | ff (MPa) | COV (%) | R (%) | ff/fc | R (%) | |

| MPC | 72.17 | 4.00 | 0.00 | 8.45 | 2.20 | 0.00 | 0.12 | 0.00 |

| FMPC-I1.5 | 56.40 | 5.63 | −21.85 | 6.02 | 9.80 | −28.75 | 0.11 | −8.83 |

| FMPC-I2.5 | 55.00 | 2.41 | −23.79 | 7.65 | 5.39 | −9.39 | 0.14 | 18.89 |

| FMPC-I3.5 | 60.53 | 0.25 | −16.12 | 10.28 | 10.79 | 21.66 | 0.17 | 45.04 |

| FMPC-I5.0 | 63.87 | 1.15 | −11.50 | 10.96 | 4.40 | 29.70 | 0.17 | 46.56 |

| FMPC-II1.5 | 53.17 | 2.08 | −26.33 | 8.01 | 12.89 | −5.16 | 0.15 | 28.73 |

| FMPC-II2.5 | 64.53 | 0.36 | −10.58 | 8.90 | 5.00 | 5.36 | 0.14 | 17.82 |

| FMPC-II3.5 | 66.77 | 1.10 | −7.48 | 10.77 | 5.00 | 27.55 | 0.16 | 37.87 |

| FMPC-II5.0 | 58.10 | 1.34 | −19.49 | 10.25 | 12.25 | 21.37 | 0.18 | 50.75 |

| FMPC-III1.5 | 54.20 | 1.51 | −24.90 | 9.67 | 1.78 | 14.48 | 0.18 | 52.43 |

| FMPC-III2.5 | 50.70 | 0.90 | −29.75 | 9.40 | 2.19 | 11.32 | 0.19 | 58.45 |

| FMPC-III3.5 | 64.30 | 1.02 | −10.90 | 9.47 | 5.11 | 12.10 | 0.15 | 25.81 |

| FMPC-III5.0 | 59.67 | 2.58 | −17.32 | 13.55 | 4.88 | 60.42 | 0.23 | 94.03 |

| CFRP Displacement (mm) | fc (MPa) | SD | ff (MPa) | SD | Ef (GPa) | SD |

|---|---|---|---|---|---|---|

| 9 | 55.90 | ±0.78 | 14.02 | ±0.27 | 1.56 | ±0.10 |

| 13 | 54.43 | ±3.87 | 14.10 | ±1.40 | 1.52 | ±0.28 |

| 16 | 57.87 | ±2.16 | 14.76 | ±0.29 | 1.78 | ±0.25 |

| 19 | 50.27 | ±0.59 | 15.88 | ±1.28 | 1.41 | ±0.11 |

| CFRP Displacement (mm) | Toughness Index (kN·mm) | TF (MPa) | SD | TWF (kN/mm) | SD | |||

|---|---|---|---|---|---|---|---|---|

| TD150 | SD | TEA | SD | |||||

| 9 | 2.68 | ±0.02 | 4.64 | ±0.03 | 6.28 | ±0.04 | 0.029 | ±1.96 × 10−4 |

| 13 | 2.75 | ±0.09 | 4.72 | ±0.37 | 6.45 | ±0.22 | 0.029 | ±2.30 × 10−3 |

| 16 | 2.96 | ±0.07 | 5.00 | ±0.06 | 6.94 | ±0.17 | 0.031 | ±3.45 × 10−4 |

| 19 | 2.80 | ±0.18 | 5.04 | ±0.36 | 6.56 | ±0.42 | 0.032 | ±2.23 × 10−3 |

| With CFRP | Without CFRP | With CFRP | Without CFRP | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| fc (MPa) | SD | ff (MPa) | SD | fc (MPa) | SD | ff (MPa) | SD | ff/fc | ||

| FMPC-V1 | 40.80 | ±1.49 | 13.85 | ±1.13 | 41.30 | ±1.14 | 8.77 | ±1.04 | 0.34 | 0.21 |

| FMPC-V2 | 40.57 | ±0.40 | 15.76 | ±0.72 | 45.97 | ±0.81 | 8.90 | ±0.86 | 0.39 | 0.19 |

| FMPC-V3 | 46.17 | ±1.76 | 15.68 | ±0.88 | 46.23 | ±3.03 | 8.93 | ±1.03 | 0.34 | 0.19 |

| FMPC-V4 | 43.50 | ±0.68 | 13.87 | ±0.61 | 42.97 | ±2.34 | 8.29 | ±1.16 | 0.32 | 0.19 |

| References | Fiber Characteristics | CFRP | fc (MPa) | ff (MPa) | ff/fc | |

|---|---|---|---|---|---|---|

| Type | Content | |||||

| This work | CF/WSF/CPS15 | 1.5 wt.% (1:1:1) | Embedded | 40.57 | 15.76 | 0.389 |

| Dong [25] | PVA | 0.5 wt.% | None | 57.8 | 10.3 | 0.178 |

| Ahmad [68] | BS | 0.5 vol.% | None | 49.4 | 5.3 | 0.107 |

| Feng [69] | PVA + MS | 1.6 vol.% + 0.6 vol.% | None | 53.5 | 10.6 | 0.198 |

| Qin [14] | BS | 1 vol.% | None | 77.6 (28 d) | N/R | N/R |

| Qin [14] | BS | 1.5 vol.% | None | N/R | 5.06 (7 d) | N/R |

| Liu [70] | BC | 10 wt.% | None | 44.5 | 9.3 | 0.208 |

| Liu [70] | BC | 20 wt.% | None | 41.6 | 9.5 | 0.228 |

| Zhang [71] | Sisal | 30% | None | 80 | N/R | N/R |

| Zhang [43] | BS | 1.2 vol.% | None | ca. 60 (3 h) | ca. 12.5 (3 h) | ca. 0.208 |

| Zhang [43] | BS | 1.2 vol.% | None | ca. 88 (3 h) | ca. 14 (3 h) | ca. 0.159 |

| Zhang [72] | N/R | N/R | Wrapped | +47.1% | N/R | N/R |

| Feng [62] | N/R | N/R | Wrapped | N/R | +370% | N/R |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, W.; Fang, Y.; Wang, C.; Cui, P.; Zhuang, K.; Zhang, W.; Dong, Z. Study on Fiber-Fabric Hierarchical Reinforcement for High-Toughness Magnesium Phosphate Cement Composites. Polymers 2025, 17, 2844. https://doi.org/10.3390/polym17212844

Feng W, Fang Y, Wang C, Cui P, Zhuang K, Zhang W, Dong Z. Study on Fiber-Fabric Hierarchical Reinforcement for High-Toughness Magnesium Phosphate Cement Composites. Polymers. 2025; 17(21):2844. https://doi.org/10.3390/polym17212844

Chicago/Turabian StyleFeng, Weipeng, Yuan Fang, Chengman Wang, Peng Cui, Kunde Zhuang, Wenyang Zhang, and Zhijun Dong. 2025. "Study on Fiber-Fabric Hierarchical Reinforcement for High-Toughness Magnesium Phosphate Cement Composites" Polymers 17, no. 21: 2844. https://doi.org/10.3390/polym17212844

APA StyleFeng, W., Fang, Y., Wang, C., Cui, P., Zhuang, K., Zhang, W., & Dong, Z. (2025). Study on Fiber-Fabric Hierarchical Reinforcement for High-Toughness Magnesium Phosphate Cement Composites. Polymers, 17(21), 2844. https://doi.org/10.3390/polym17212844