1. Introduction

In modern plastics manufacturing, thin-walled injection molding has emerged as a dominant trend owing to its capacity to reduce product weight, optimize material efficiency, shorten production cycles, and enhance geometric accuracy [

1,

2]. This technology is pivotal in demanding sectors such as automotive, consumer electronics, biomedical devices, and precision engineering [

3,

4]. However, producing parts with wall thicknesses below 1 mm, intricate geometries, and stringent surface requirements presents significant challenges for the injection molding process, particularly in mold temperature control, thermal uniformity, and deformation mitigation [

5]. As wall thickness decreases, the reduced heat transfer area results in a steep through-thickness thermal gradient. This in turn leads to non-uniform shrinkage, geometric warpage, sink marks, and diminished dimensional stability [

6,

7]. To mitigate these issues, recent research has predominantly focused on two approaches: designing thin-walled mold inserts and integrating advanced cooling systems. Among these, the Cooling Layer concept has emerged as a particularly promising solution [

8].

The design of thin-walled mold inserts is pivotal for enhancing through-thickness heat transfer and reducing cooling time. As the insert thickness decreases, the thermal resistance of the conduction path is reduced, thereby promoting a more uniform temperature distribution and optimizing thermal efficiency [

9]. Experimental studies have demonstrated that reducing insert thickness from 12 mm to 4 mm can increase the through-thickness heat transfer rate by up to 35% and shorten the average cooling time by approximately 25–30% [

10]. However, thinner inserts also render the mold system more susceptible to temperature fluctuations. This can lead to non-uniform thermal distribution, higher residual stresses, and product warpage that is difficult to control without effective thermal management [

11]. This issue is exacerbated in products with intricate geometries and stringent requirements for dimensional accuracy or surface quality [

12].

To mitigate this thermal management challenge, several technologies have been developed. While resistance heating can accelerate heating, achieving uniform surface temperature is difficult [

13]. Induction heating provides faster heating rates but is more energy-intensive and offers limited compatibility with thin-walled inserts [

14]. Conformal cooling channels improve localized cooling, but their effectiveness diminishes with decreasing insert thickness [

15]. In contrast, the Cooling Layer system emerges as a superior solution. By positioning a specialized thermally conductive layer directly beneath the insert surface, this system simultaneously enhances through-thickness heat transfer, reduces the temperature differential (ΔT), and promotes a highly uniform surface temperature, ultimately leading to superior product quality [

16,

17].

The efficacy of the Cooling Layer has been well-documented in numerous experimental and simulation studies. Studies have reported that the Cooling Layer can reduce cooling time by 40–60% compared to conventional channels. Concurrently, it decreases the mold surface temperature differential (ΔT) from 18 °C to 6 °C, thereby stabilizing thermal conditions throughout the injection molding cycle [

18,

19]. This enhanced thermal control serves to minimize sink marks, improve surface quality, and reduce product warpage by up to 35% [

20]. Thermodynamic analyses further reveal that the Cooling Layer increases average through-thickness heat transfer efficiency by 25% and significantly improves temperature uniformity, particularly in mold regions with intricate geometries [

21]. Moreover, the Cooling Layer facilitates an approximate 30% reduction in overall residual stress, thereby mitigating nonlinear deformation and improving the dimensional accuracy of composite products [

22]. Select studies have also reported that by maintaining uniform cooling, the Cooling Layer can optimize glass fiber orientation in composites such as PA6 with 30 wt.% glass fiber (PA6/30 wt.% GF). This in turn reduces displacement behavior and enhances the mechanical homogeneity of molded parts [

23].

Numerous studies have employed methods such as the Taguchi design, Response Surface Methodology (RSM), and numerical simulations to optimize Cooling Layer configurations. These optimization efforts have demonstrated that adjusting the location, number, and dimensions of the layers can reduce the mold surface temperature differential (ΔT) by up to 70%, shorten the average cooling time by 45%, and decrease overall deformation by 30–40%, while simultaneously improving the dimensional accuracy of composite products [

24,

25].

Beyond technological solutions, the choice of engineering polymer is also critical to the quality of thin-walled parts. Among these materials, polyamide 6 (PA6) and its composite reinforced with 30 wt.% glass fiber (PA6/30 wt.% GF) are frequently utilized for their low density, high mechanical strength, and good thermal resistance [

26]. However, PA6 GF composites exhibit pronounced thermo-mechanical anisotropy, rendering them highly susceptible to thermal gradients, which often results in non-uniform shrinkage, complex warpage, and nonlinear displacement behavior [

27]. Experimental results have revealed that increasing the glass fiber content from 0% to 30% correlates with an approximate 30% increase in elastic modulus; however, the material’s sensitivity to thermal variations also increases, exacerbating product deformation [

28]. Notably, integrating Cooling Layers into the injection molding of PA6/30 wt.% GF composites has been shown to yield substantial benefits. These include the stabilization of fiber orientation, an approximate 25% reduction in residual stress, an overall warpage reduction of 35%, and a significant enhancement of surface quality [

29,

30].

Research on compliant mechanisms has garnered significant interest for applications in precision micro-positioning, displacement sensing, and metrology. Numerous studies have focused on design and optimization approaches to amplify displacement and enhance positioning accuracy. For instance, a study by [

31] presented a one-degree-of-freedom (1-DOF) compliant mechanism fabricated via additive manufacturing. Their results demonstrated that the bridge-type design improved displacement accuracy by up to 18% compared to conventional mechanisms. Building on this research, ref. [

32] proposed a two-degree-of-freedom (2-DOF) mechanism that synergized kinematic–static analysis with artificial neural network (ANN) modeling. This hybrid approach reduced deformation prediction errors to below 5% and enhanced micro-positioning capabilities. More recently, ref. [

33] designed an XYZ micropositioner with an integrated displacement sensor, achieving a positioning accuracy of ±2 µm. This level of precision, demonstrated in metrology and biological sample probing, highlights its potential for advanced measurement systems.

While advanced cooling solutions such as conformal cooling [

34,

35] and microchannel cooling [

16] have demonstrated efficacy in enhancing heat transfer, reducing cycle times, and mitigating warpage in injection molding, they exhibit significant limitations, particularly for thin-walled molds (less 1 mm thickness). Specifically, conformal cooling channels impose significant spatial requirements and can compromise the mechanical integrity of the mold insert. Meanwhile, while microchannels offer high heat exchange efficiency, they pose considerable fabrication challenges, are susceptible to clogging, and fail to ensure thermal stability under mass production conditions [

34]. Furthermore, the majority of existing research has predominantly focused on thermal efficiency or cooling cycle optimization. A significant research gap persists in the analysis of thermo-mechanical interactions needed to comprehensively evaluate the displacement behavior and non-linear deformation of composite materials during injection molding [

36].

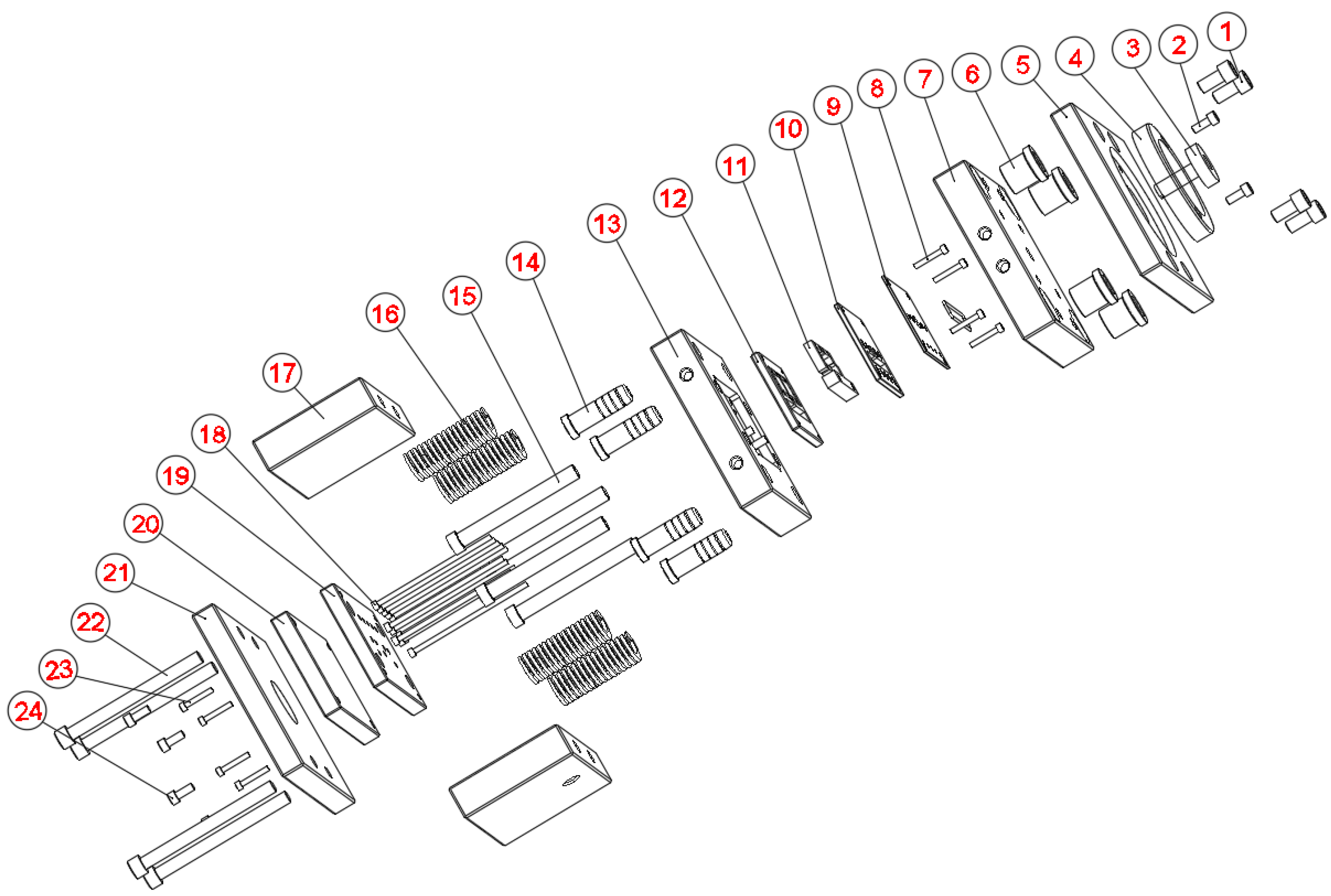

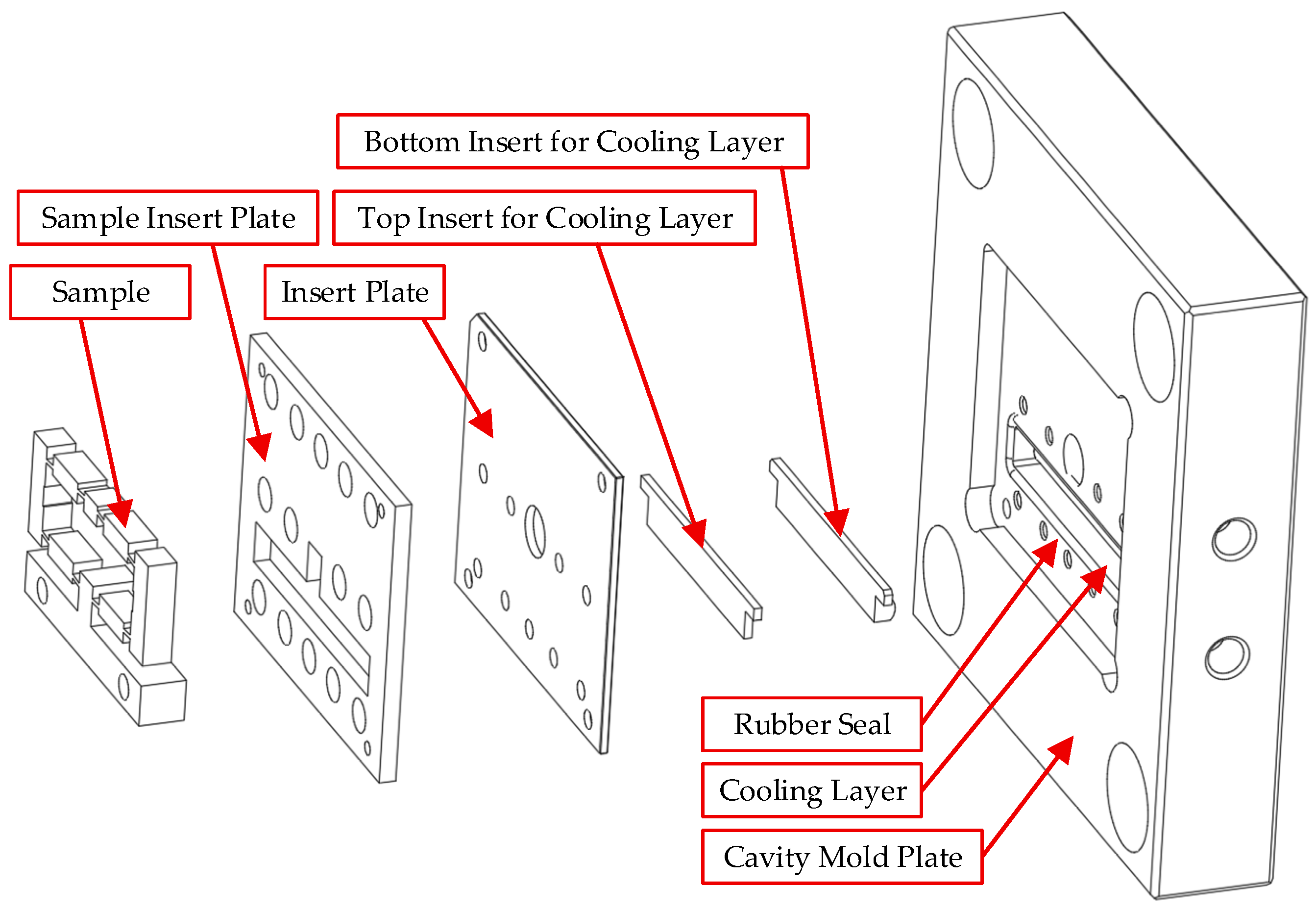

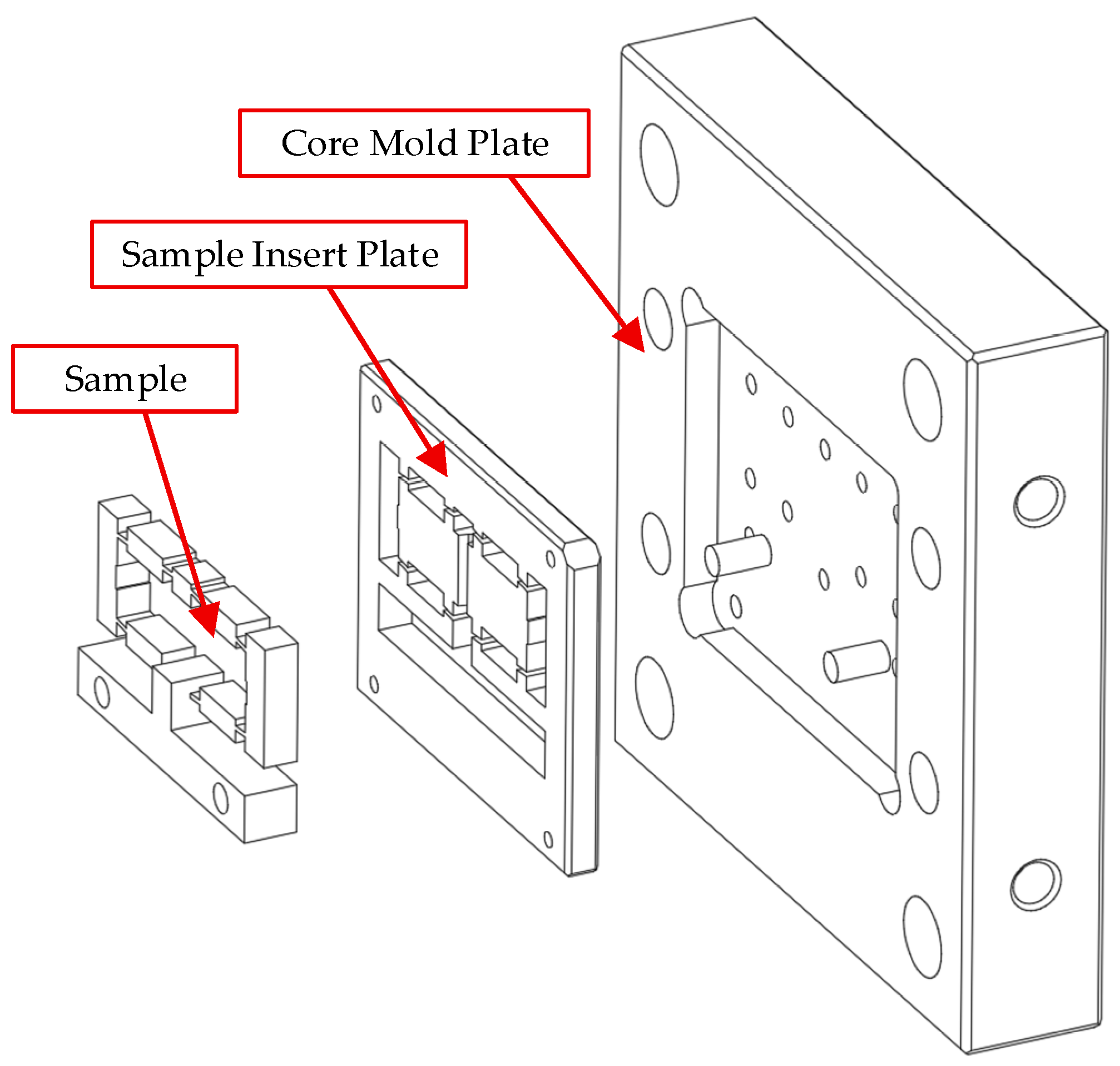

In contrast to the aforementioned methods, this study proposes a novel thin-walled mold design that integrates a Cooling Layer system directly beneath the insert. This design utilizes a specialized heat-conducting layer to shorten the through-thickness heat transfer path, reduce the surface temperature differential (ΔT), and enhance thermal uniformity throughout the injection cycle [

36,

37,

38]. A key innovation of this work is the pioneering integration of Taguchi-based parameter optimization with coupled thermo-mechanical simulations and experimental deformation measurements. This approach enables an in-depth analysis of the heat transfer–deformation mechanisms of PA6/PA6-GF materials under thin-wall injection molding conditions [

39]. This holistic approach not only addresses the limitations of conventional conformal and microchannel cooling but also establishes a new design framework. This framework is capable of enhancing heat transfer efficiency, reducing deformation, controlling residual stress, and significantly improving the quality of composite products in engineering applications that demand high geometrical precision [

40].

While previous studies have established that integrating thin-walled mold inserts with Cooling Layers yields significant advantages, these benefits have often been investigated in isolation. Such advantages include enhanced heat transfer efficiency, improved thermal uniformity, mitigated residual stress and warpage, and optimized fiber orientation. However, most existing works have focused on discrete aspects, such as thin-walled insert design [

9,

10], Cooling Layer optimization [

18,

24], or the warpage analysis of PA6 GF composites [

27,

29]. To date, a comprehensive study that simultaneously combines thin-walled insert design, Cooling Layer integration, and the displacement behavior analysis of PA6/GF composites via a coupled experimental and thermo-mechanical simulation approach is notably absent from the literature. This research gap provides the primary rationale for the present study. We aim to design, optimize, and experimentally validate an integrated Cooling Layer system within thin-walled inserts, while concurrently analyzing the displacement behavior and overall deformation of PA6/GF composite products. The ultimate goal is to propose an optimized mold design framework that simultaneously enhances heat transfer efficiency, minimizes warpage and shrinkage, and improves the overall quality of thin-walled composite products.

Building upon the identified research gap, this work aims not only to confirm the benefits of thin-walled inserts and the Cooling Layer system but also to formulate and test verifiable scientific hypotheses. The objective is to elucidate the thermo-mechanical interaction mechanisms during composite injection molding. Specifically, it is hypothesized that reducing the insert thickness in conjunction with increasing the thickness and thermal conductivity of the Cooling Layer will significantly mitigate the through-thickness thermal gradient (ΔT). This, in turn, is expected to improve mold surface temperature distribution, reduce residual stress, and consequently decrease the non-linear deformation and overall displacement of PA6/GF composite products [

37,

40,

41]. Furthermore, optimizing the Cooling Layer configuration is anticipated to increase through-thickness heat transfer efficiency by over 25% compared to traditional cooling systems and reduce the surface ΔT from 18 °C to below 6 °C. These improvements are projected to enhance the surface quality and geometrical accuracy of the final product [

13,

36,

37].

4. Conclusions

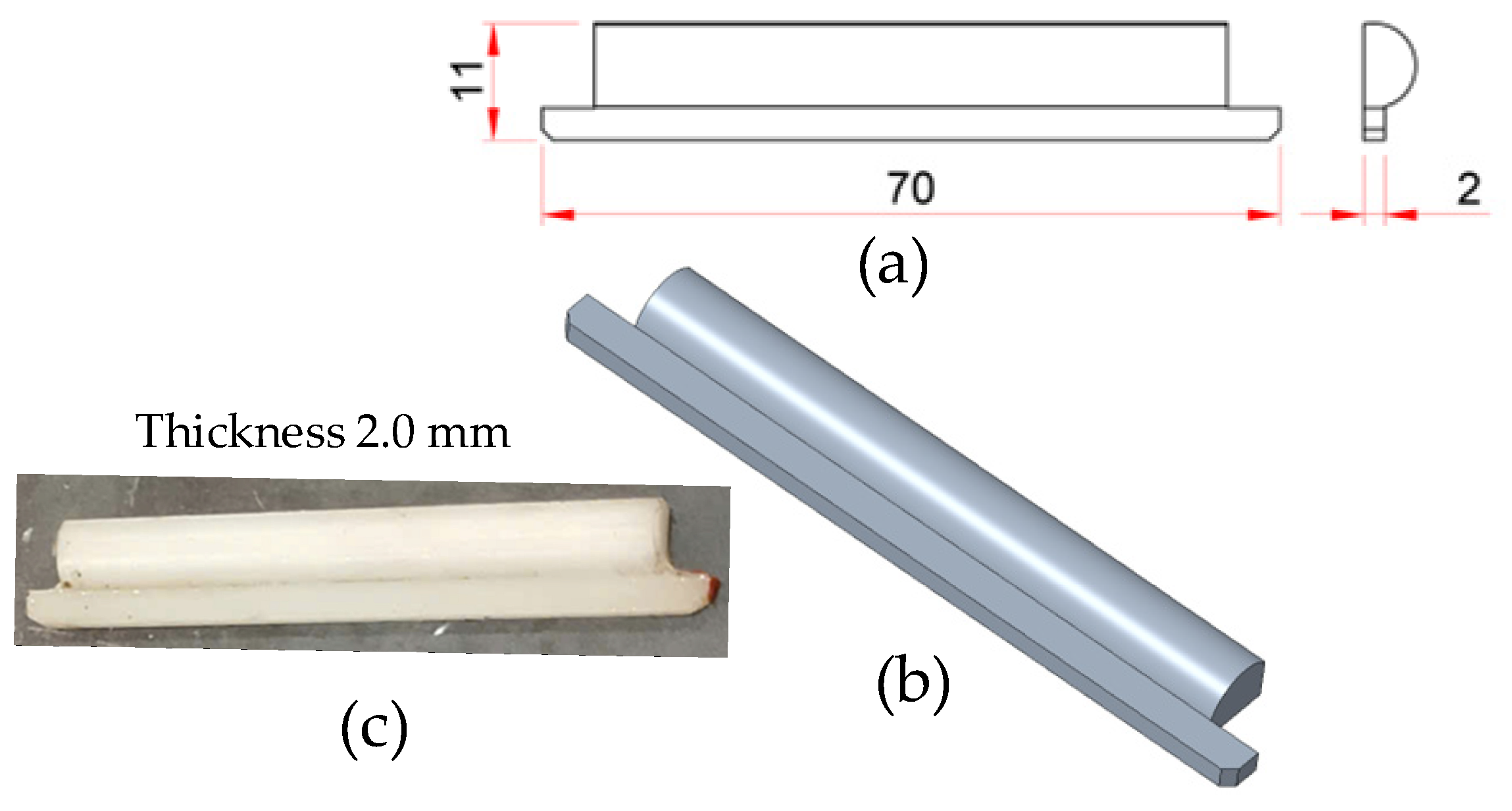

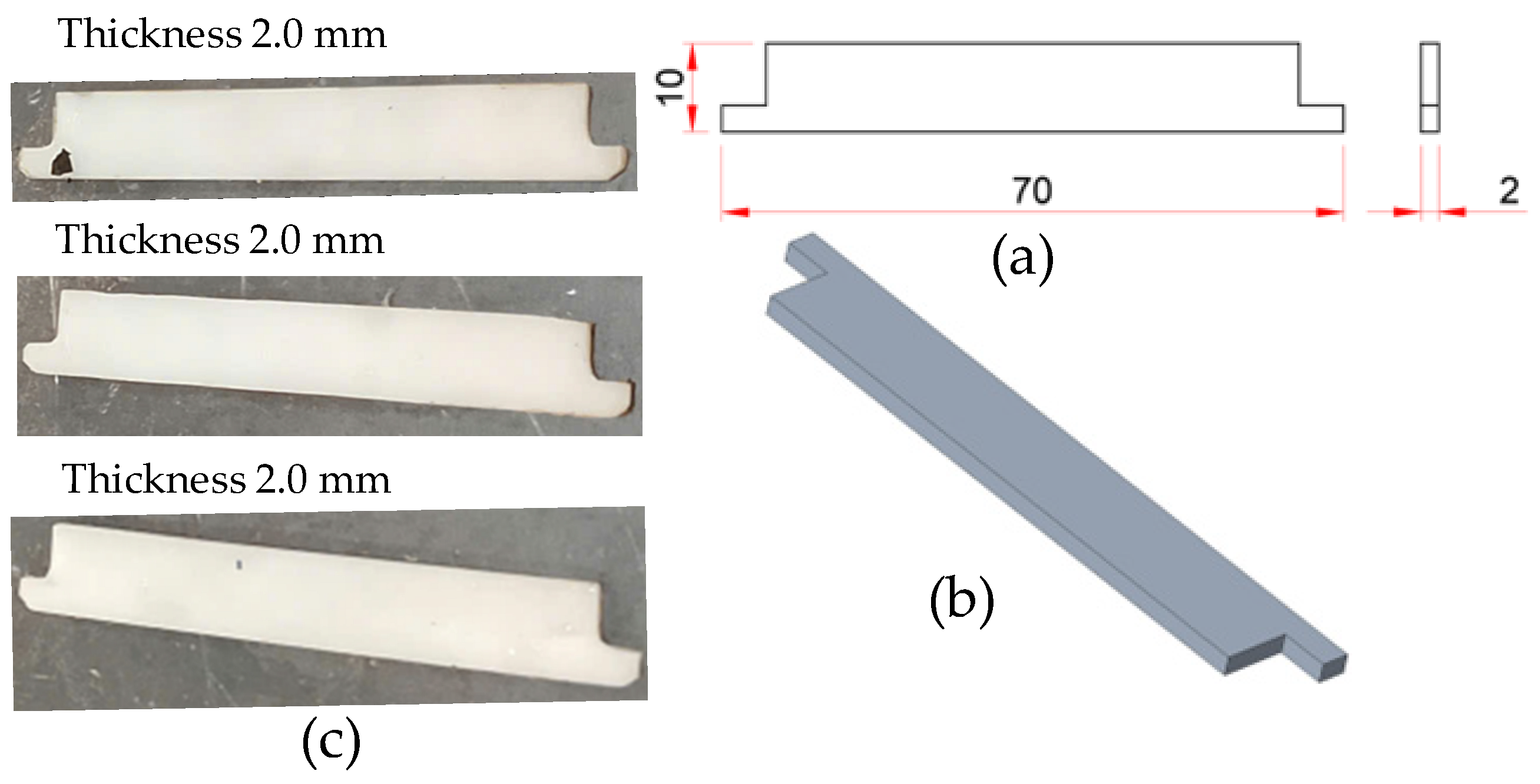

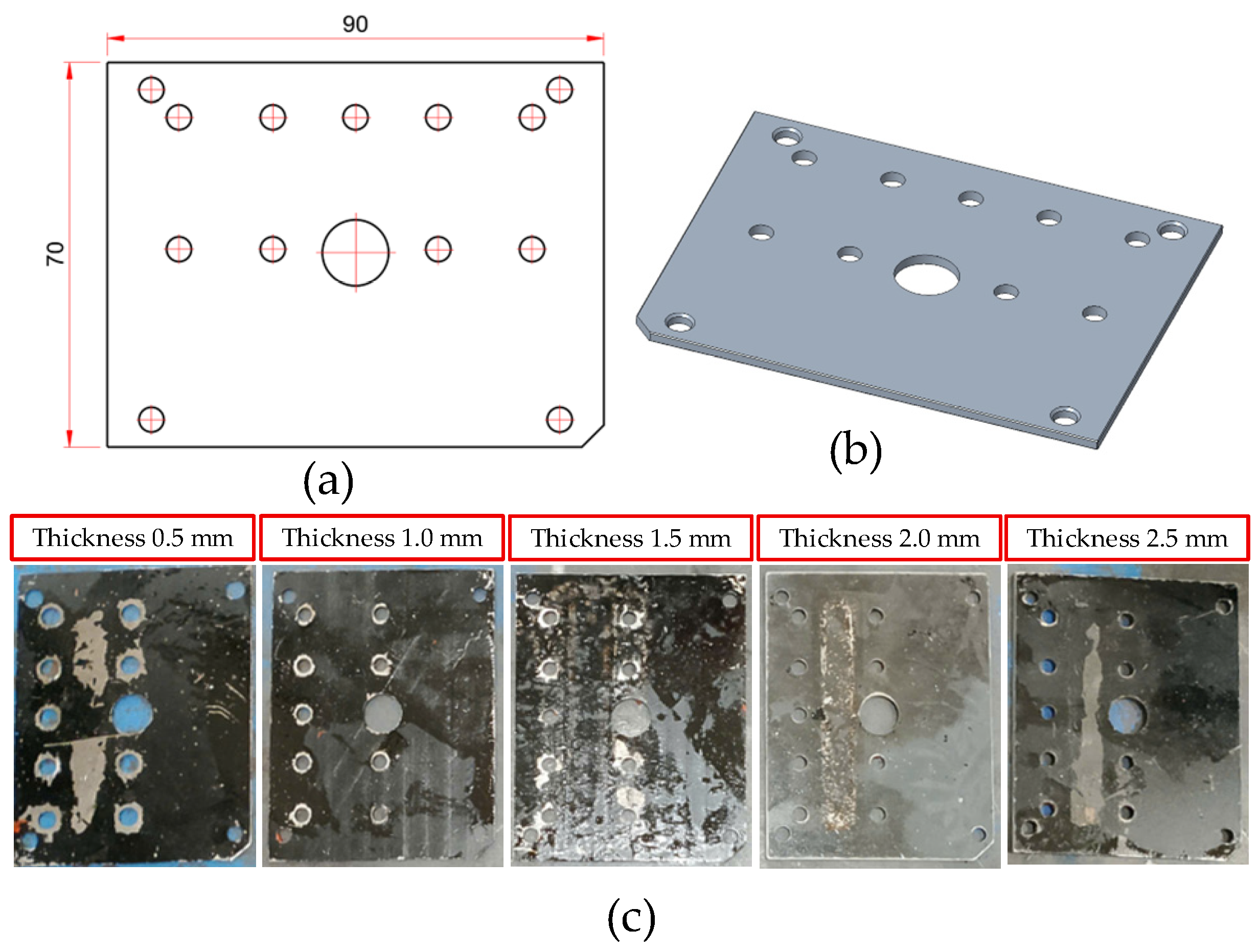

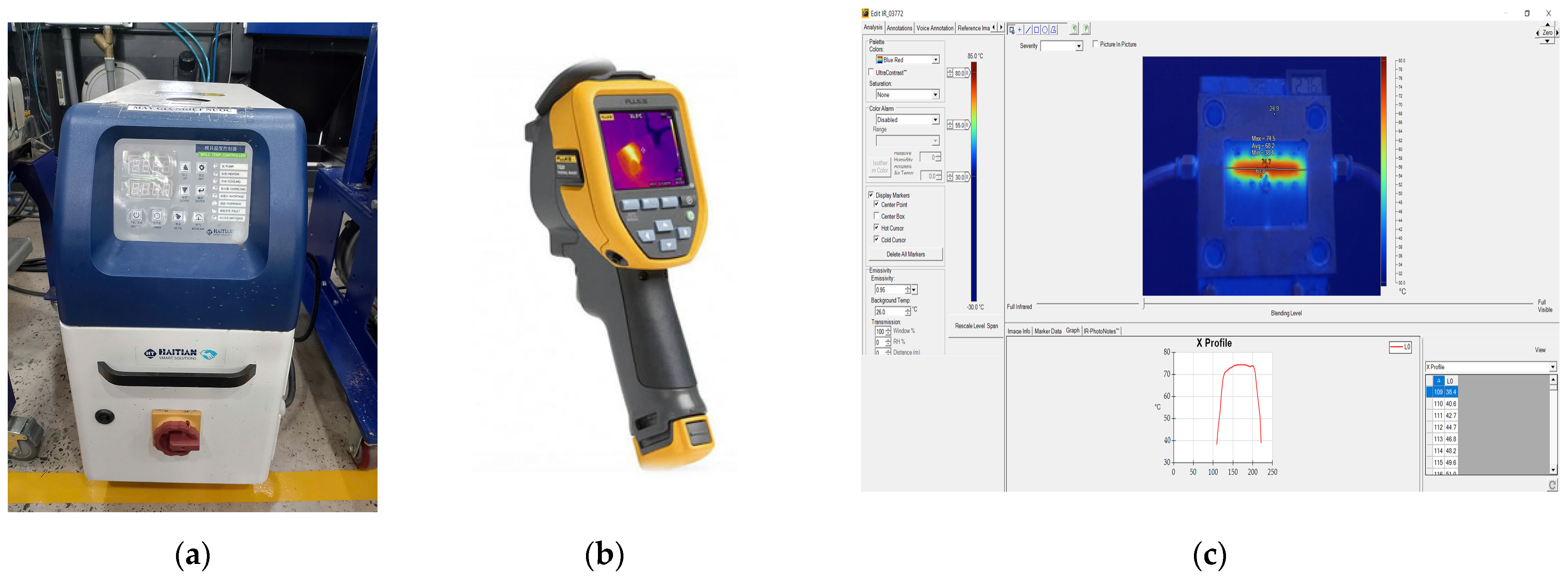

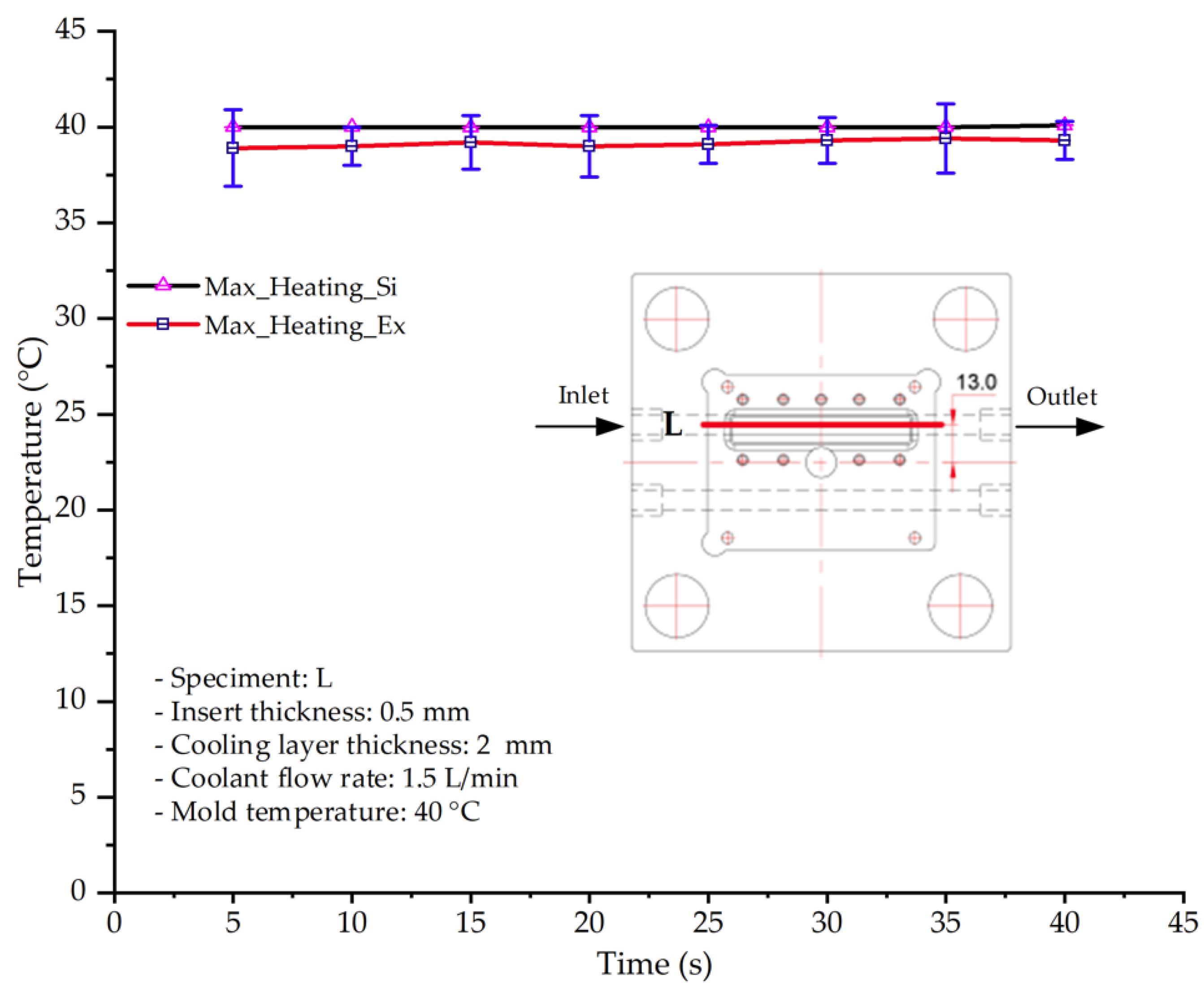

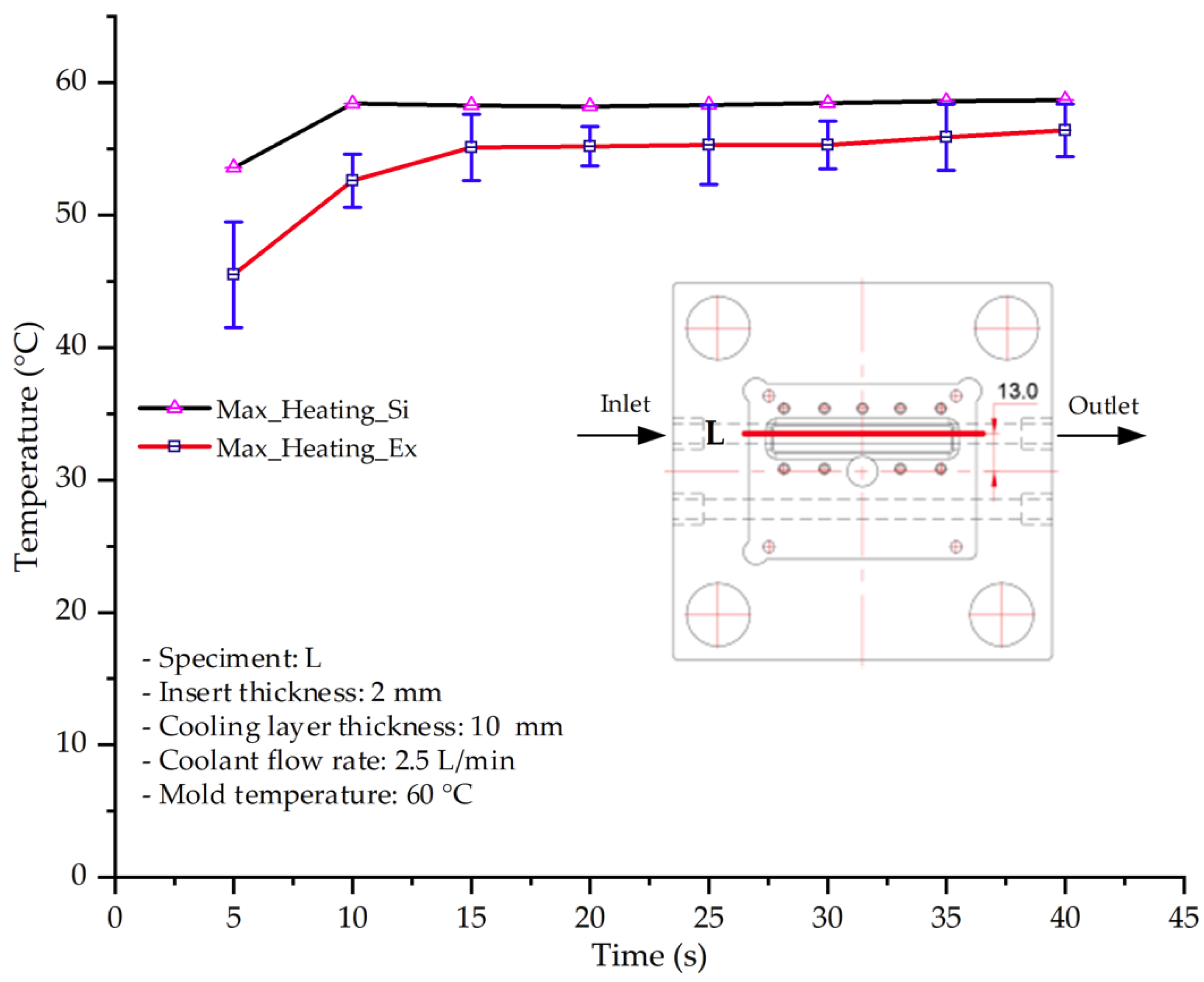

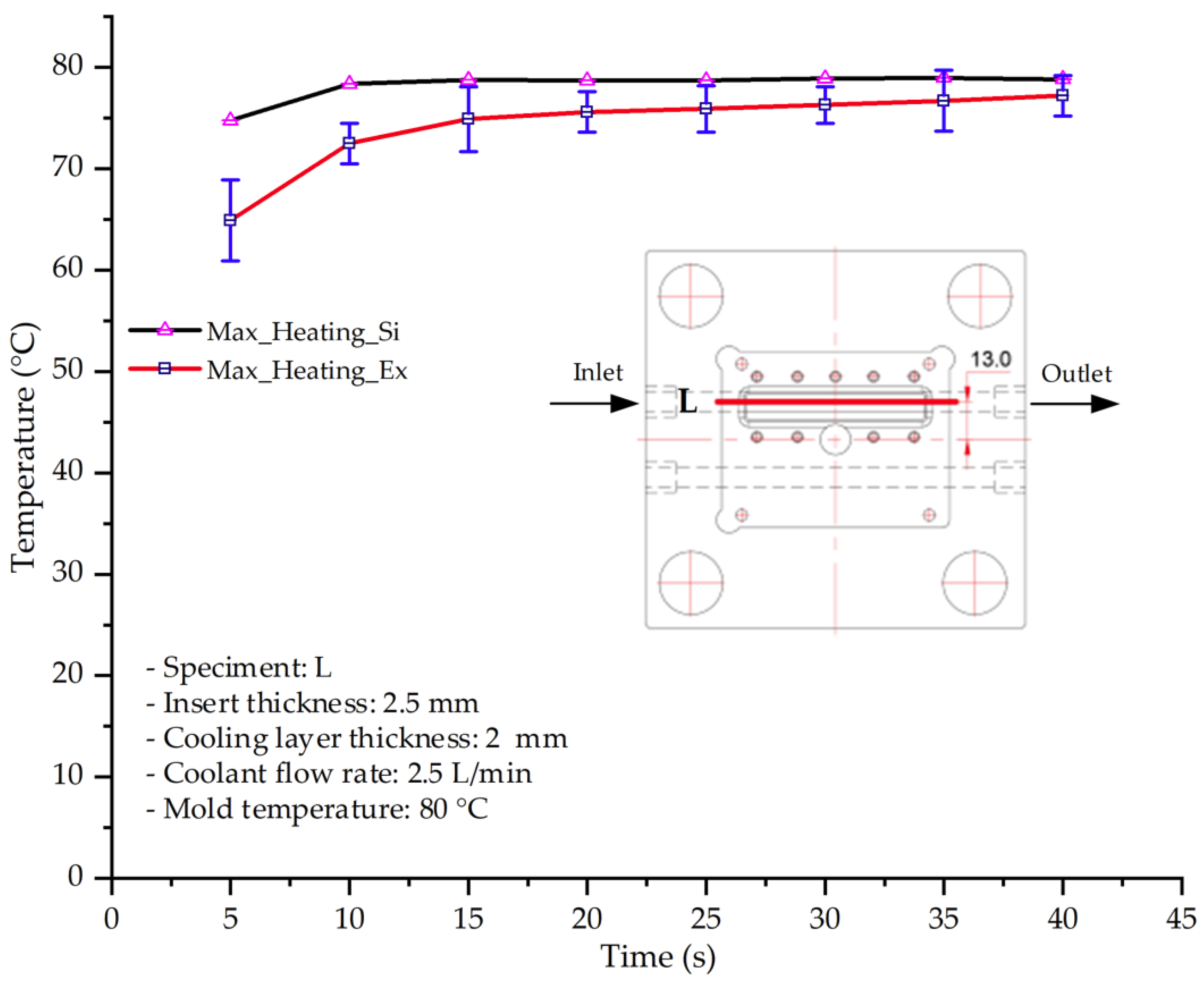

This study systematically investigated the effects of cooling layer integration and thin-walled mold design on the thermal and mechanical performance of PA6 and PA6/GF composites during thin-walled injection molding. By applying the Taguchi method with an L25 (54) orthogonal array, the number of experimental trials was significantly reduced while maintaining statistical robustness. This facilitated the identification of the most influential parameters—insert thickness, cooling layer thickness, coolant flow rate, and coolant temperature—on mold temperature distribution and composite displacement behavior.

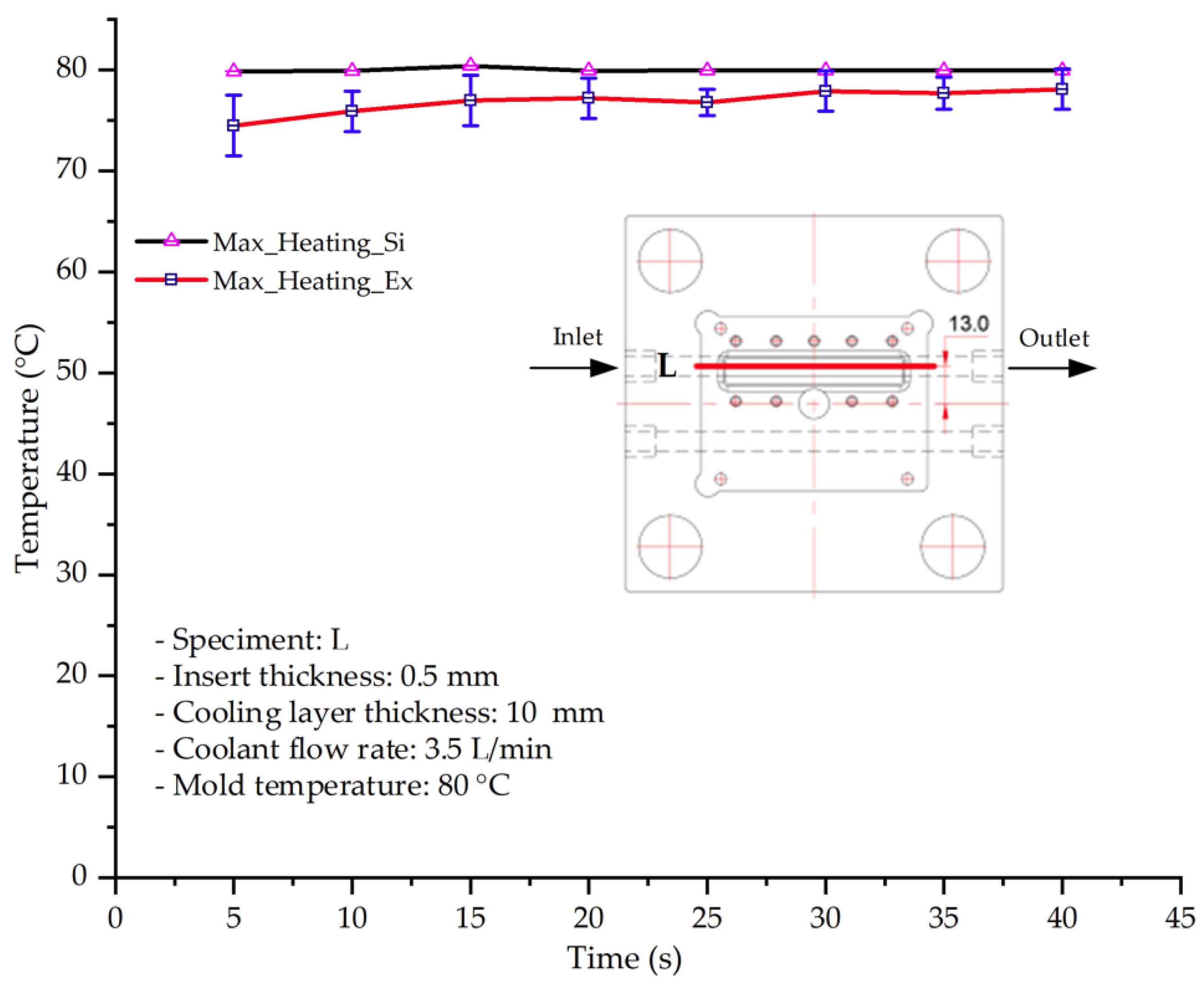

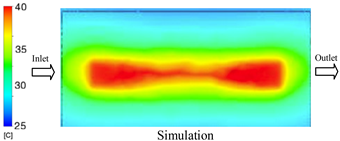

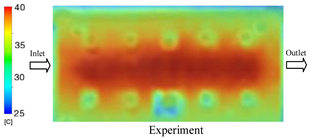

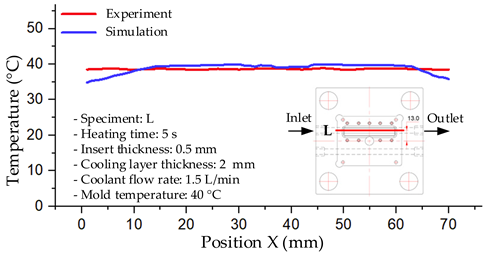

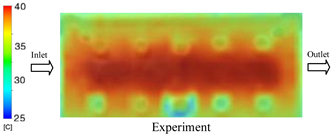

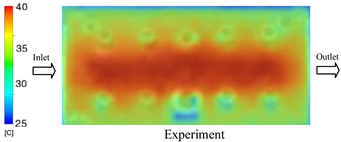

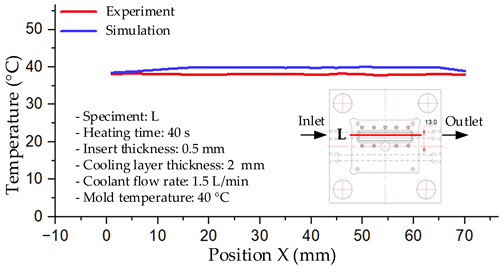

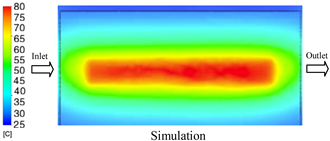

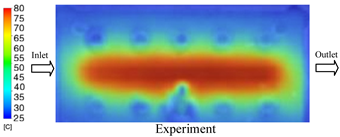

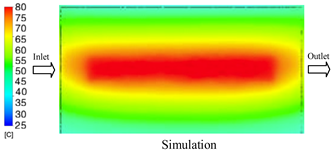

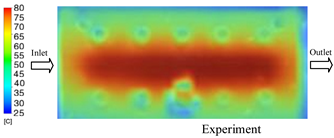

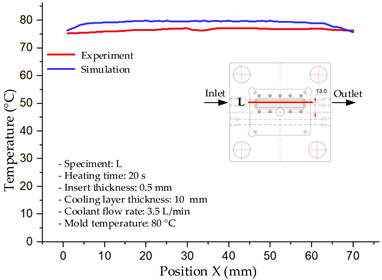

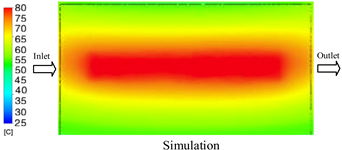

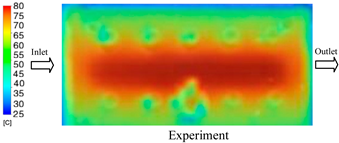

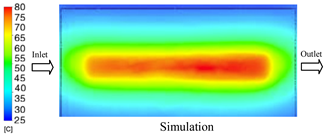

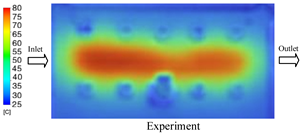

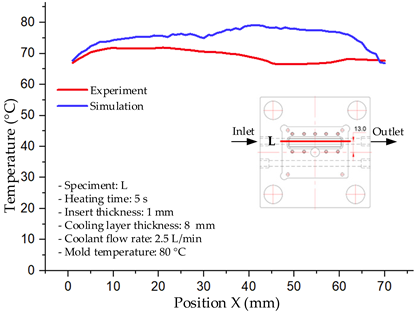

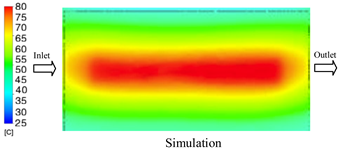

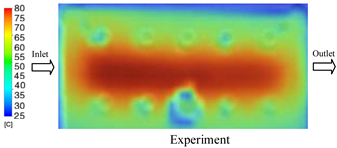

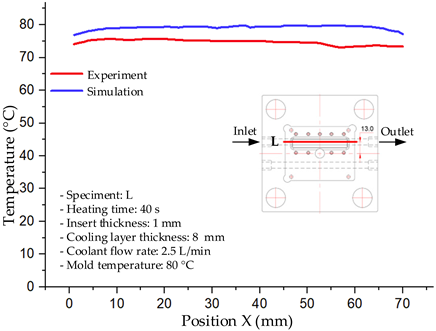

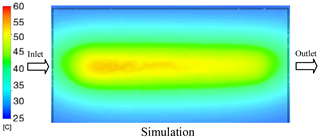

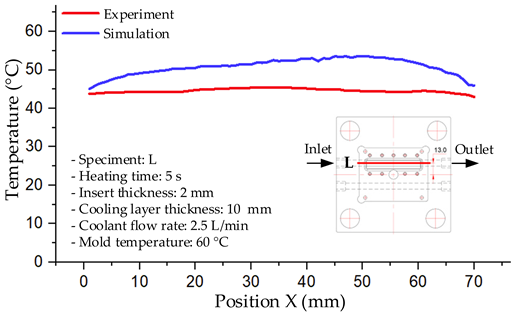

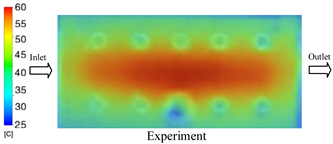

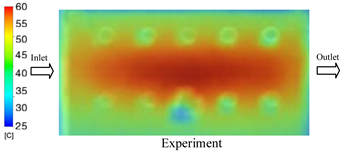

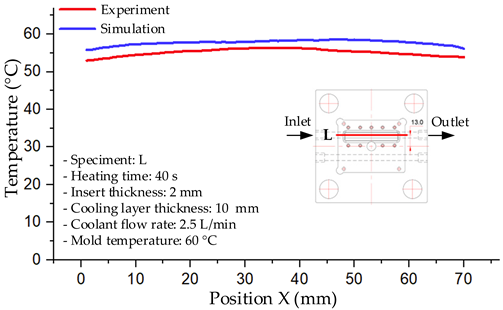

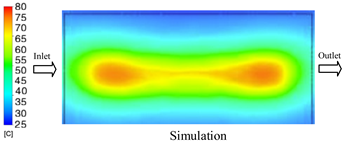

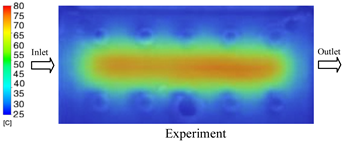

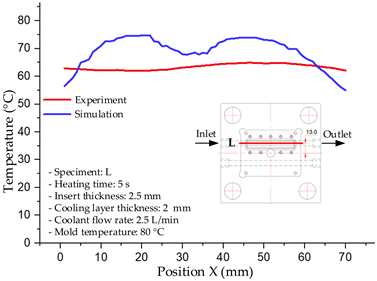

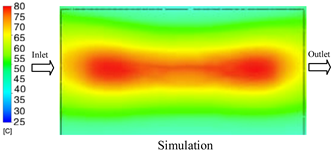

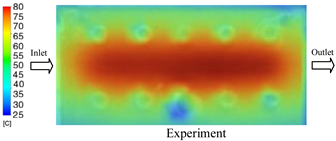

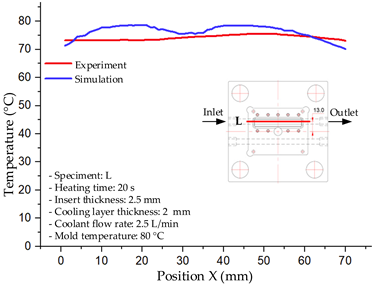

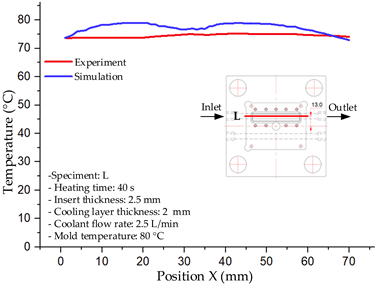

The results demonstrate that a thin insert (0.5 mm) combined with a 10 mm cooling layer and a high coolant flow rate (3.5 L/min) at 80 °C (Case 5) represents the optimal configuration. This setup not only elevates the mold surface temperature to improve melt flow and reduce weld-line defects, but also ensures a uniform temperature distribution with a maximum steady-state deviation of only 3.6 °C. Moreover, the deviation between simulation and experiment remained within 2.4–7.2%, affirming the predictive fidelity of the proposed model.

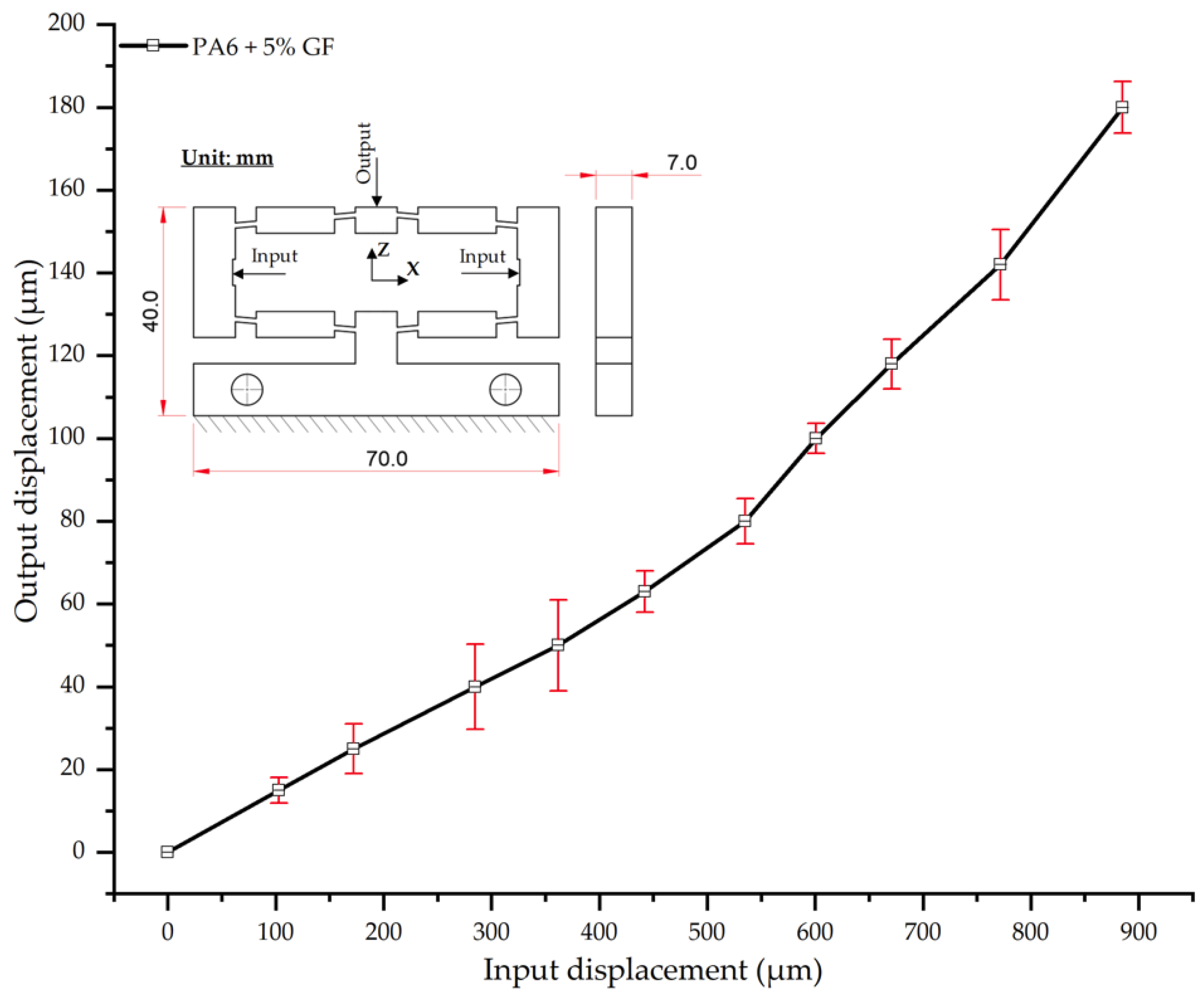

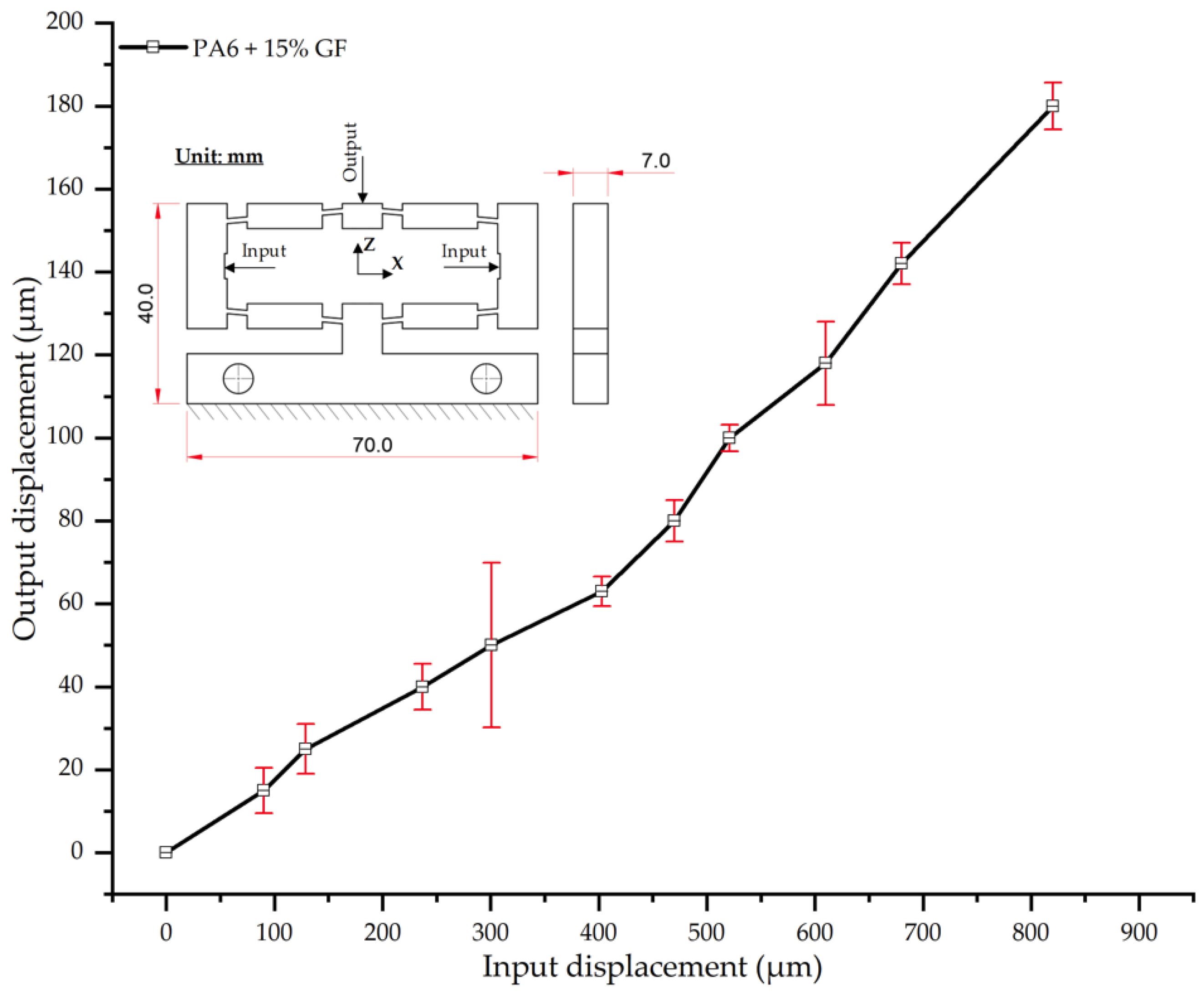

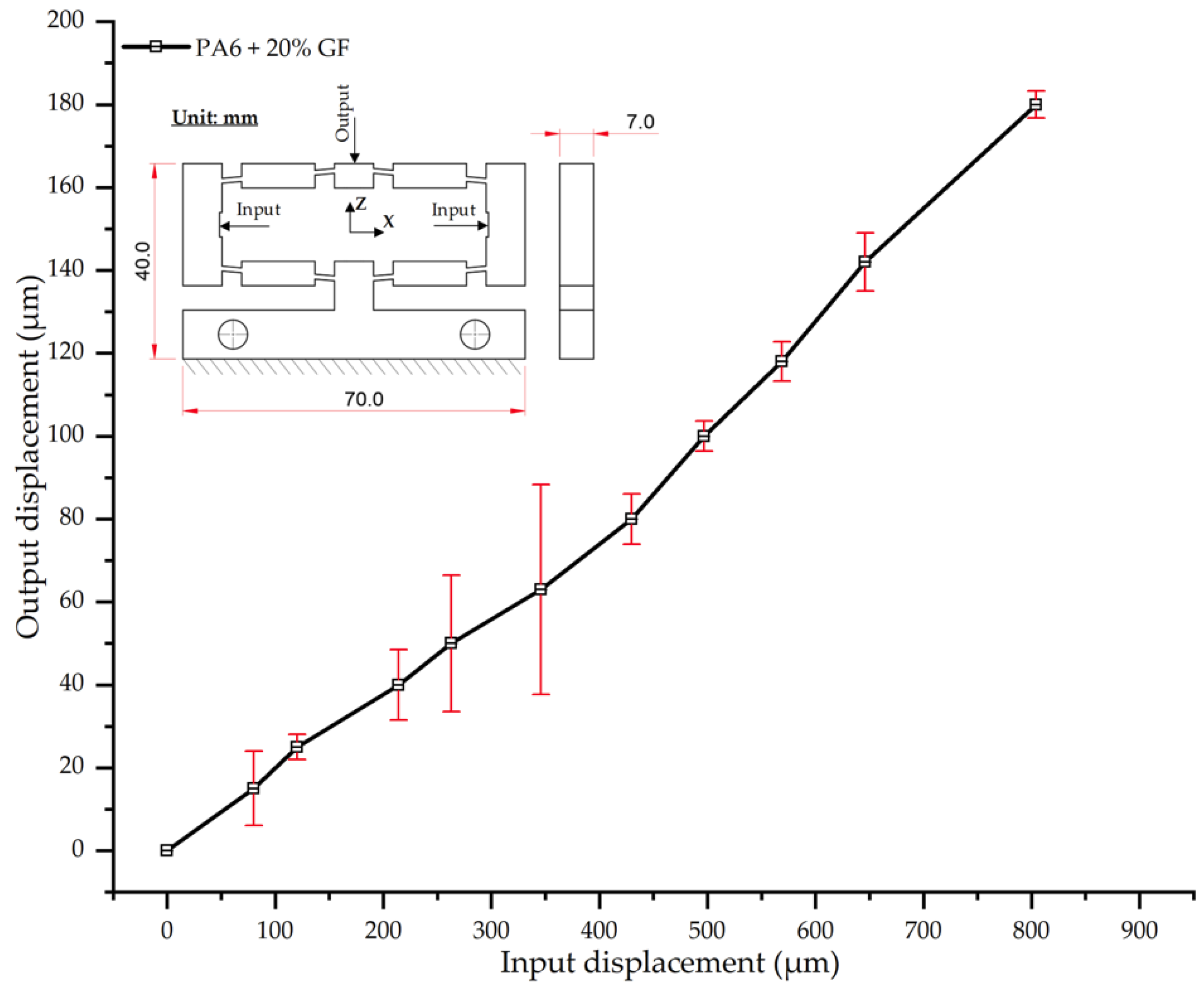

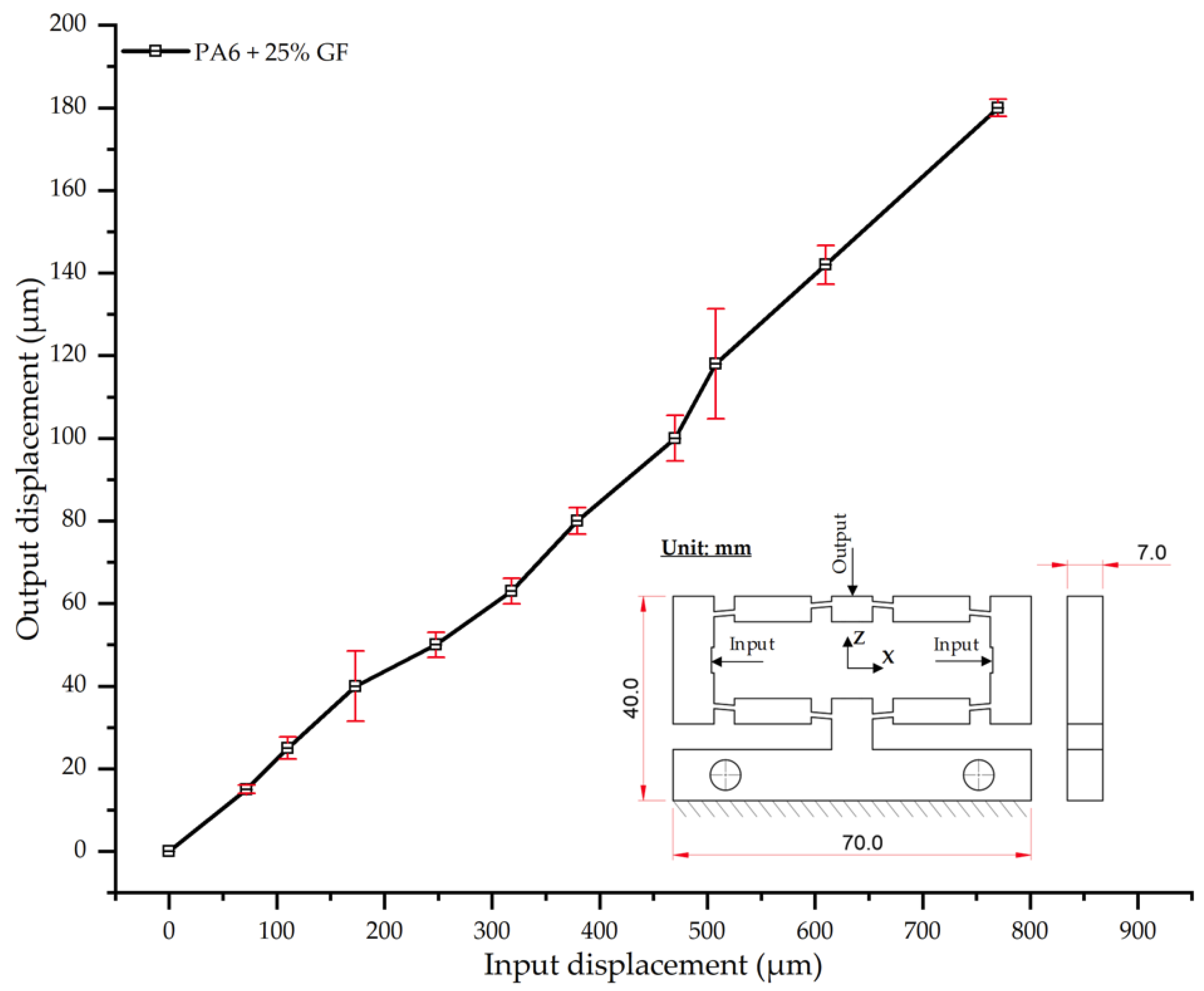

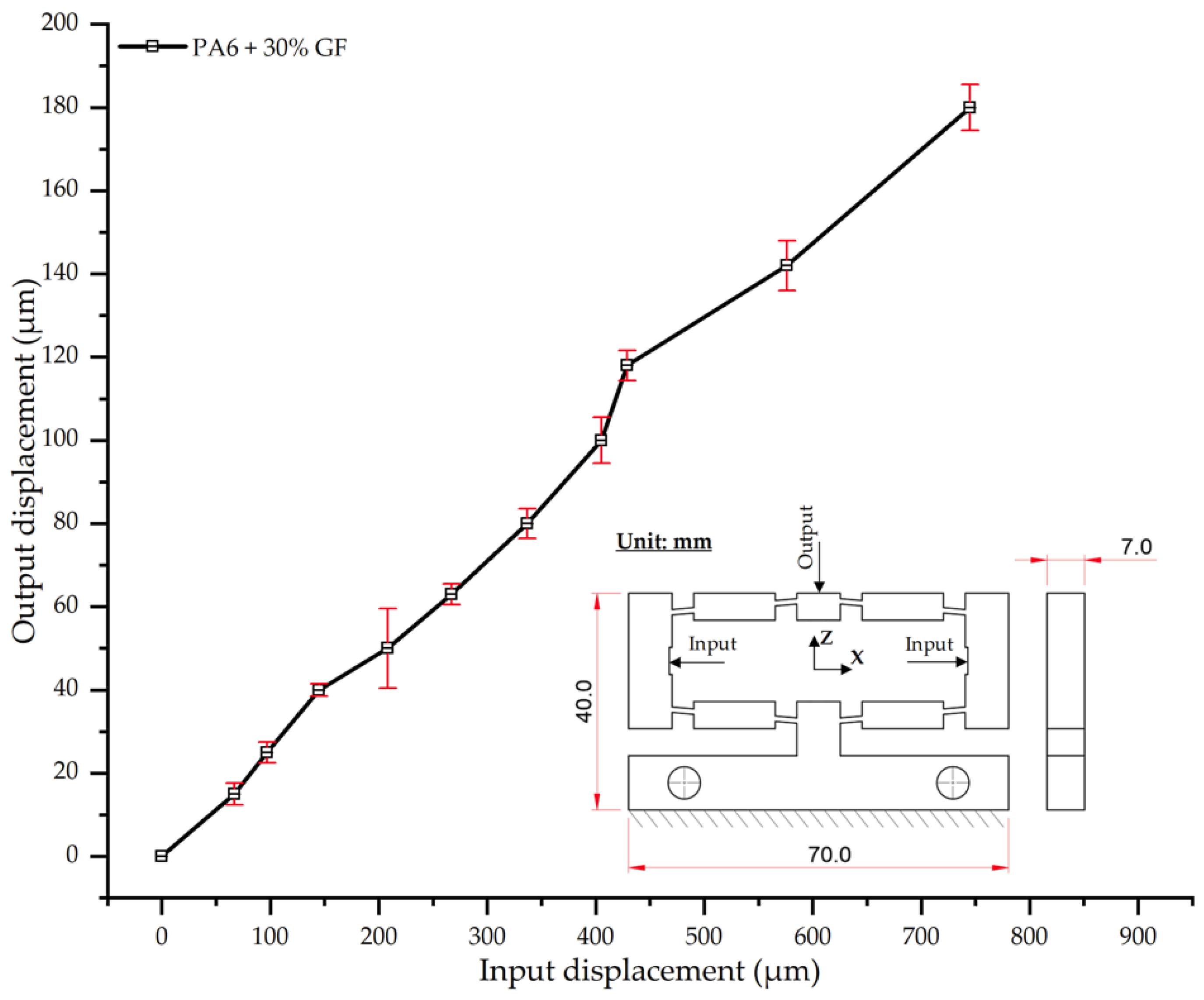

Thermo-mechanical analysis further revealed that the optimized cooling layer reduced residual stresses and warpage by up to 35% while simultaneously enhancing the dimensional stability of the composite samples. Increasing the glass fiber content from 0% to 30% progressively enhanced stiffness and reduced output displacement by nearly 19%, in agreement with established reinforcement mechanisms. However, a trade-off between stiffness and potential embrittlement was observed at high fiber ratios (>25%), highlighting the importance of balancing composite formulation with processing parameters.

The integration of a cooling layer with thin-walled inserts, optimized via a Taguchi-based design, provides a highly effective strategy for thermal management in thin-walled injection molding. This approach not only improves thermal uniformity and product quality but also yields practical insights into the processing of engineering composites like PA6/GF. These findings contribute to the development of advanced mold design strategies for next-generation injection molding applications where high precision, dimensional stability, and surface quality are paramount.

While this study demonstrates the efficacy of integrating a Cooling Layer system into a thin-walled insert for improving heat transfer, reducing ΔT, and controlling composite displacement, several limitations should be acknowledged. First, the number of experiments is constrained by the Taguchi design, which utilizes a small set of representative cases and thus does not cover the entire parameter space. Second, while the deviation between simulation and experiment is generally acceptable (2.4–7.2%), the results remain susceptible to practical factors such as ambient heat loss, material heterogeneity, and non-ideal thermal contact. Third, the current simulation model only considers steady-state heat transfer and does not yet incorporate detailed simulations of non-linear effects like turbulent flow or the residual stresses generated during rapid cooling.

Future work will aim to address these limitations. We plan to expand the experimental scope and perform a more rigorous statistical analysis via the Taguchi method, including ANOVA and Signal-to-Noise (S/N) ratio analysis. This will allow for a clearer quantification of each design factor’s influence on ΔT and displacement. Additionally, a fully coupled three-dimensional simulation model will be developed. This model will incorporate thermo-mechanical-flow interactions and the anisotropic behavior of the composite material. The ultimate goal is to enhance the model’s predictive capability and broaden the industrial applicability of the Cooling Layer system in high-precision, thin-walled injection molding.