Research into the Influence of Volume Fraction on the Bending Properties of Selected Thermoplastic Cellular Structures from a Mechanical and Energy Absorption Perspective

Abstract

1. Introduction

2. State of the Art

3. Materials and Methods

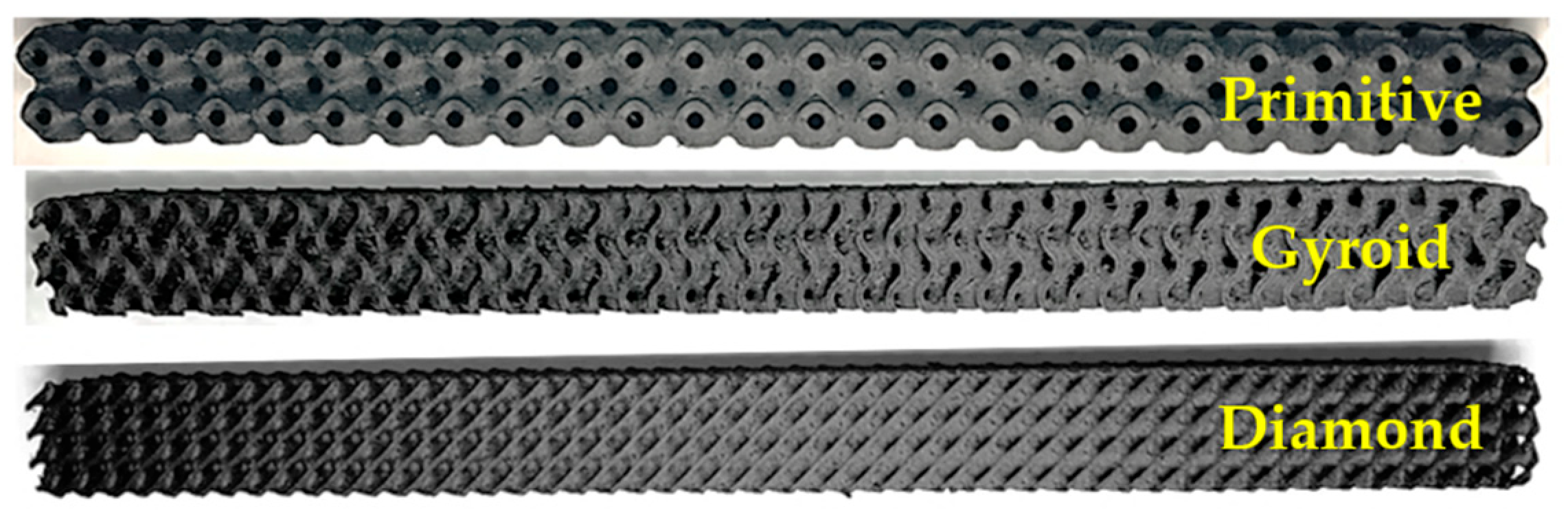

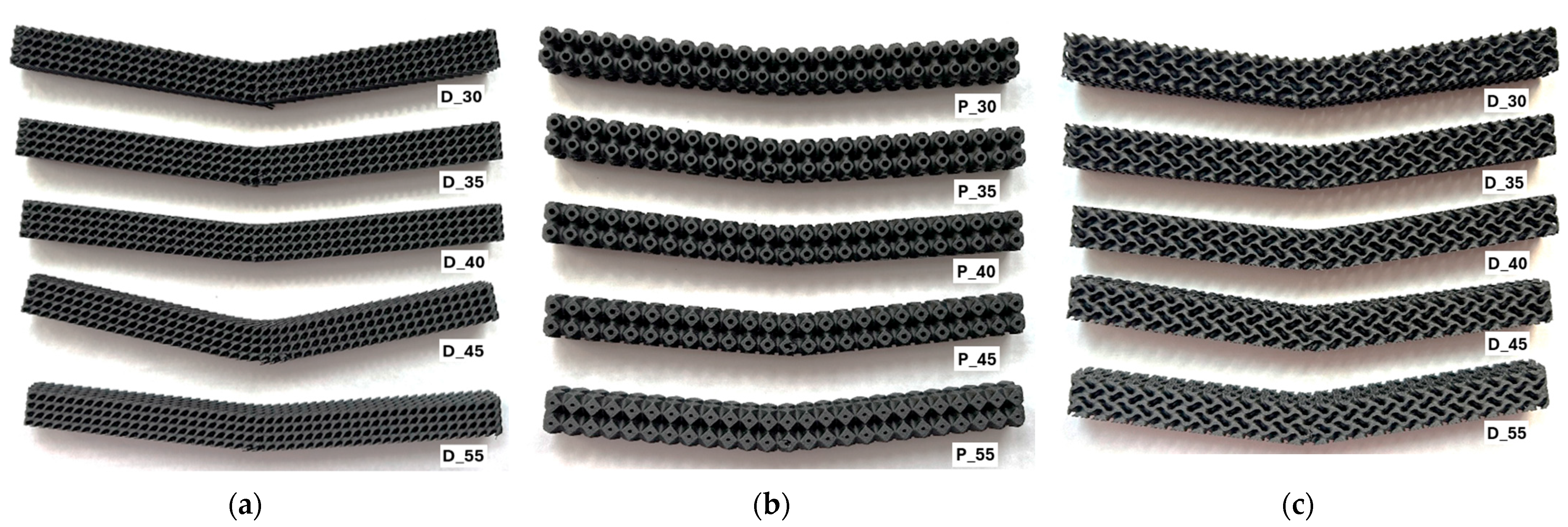

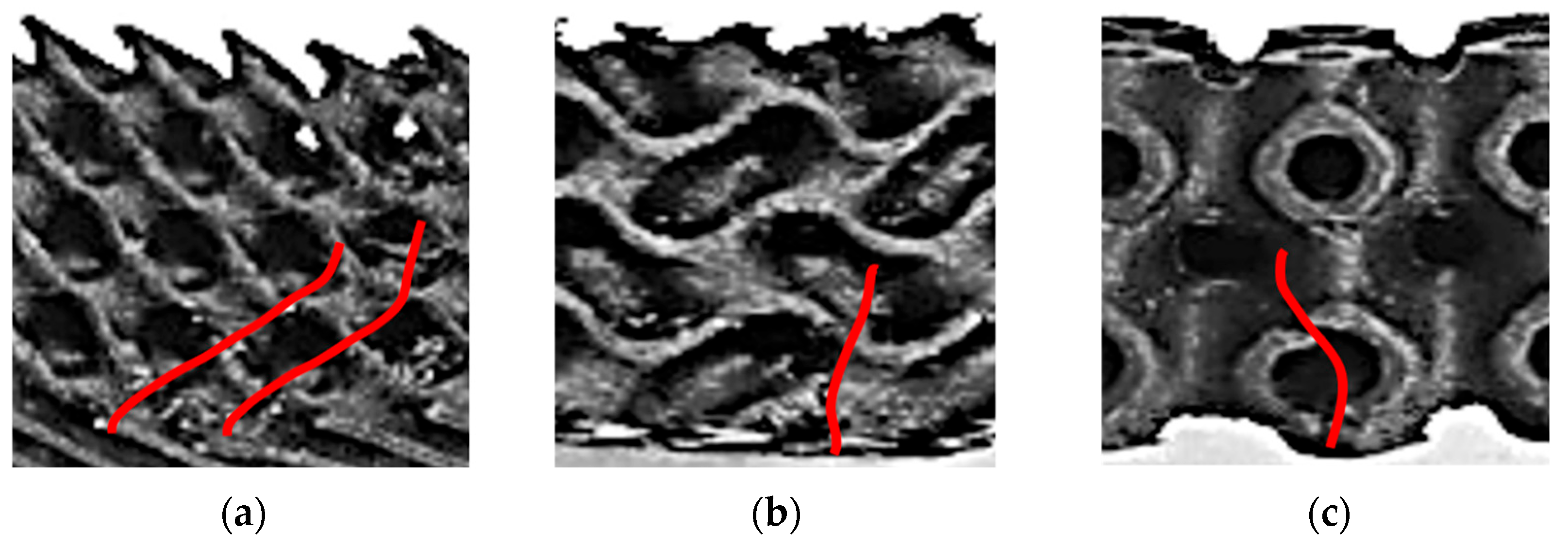

3.1. The Samples Design and Production

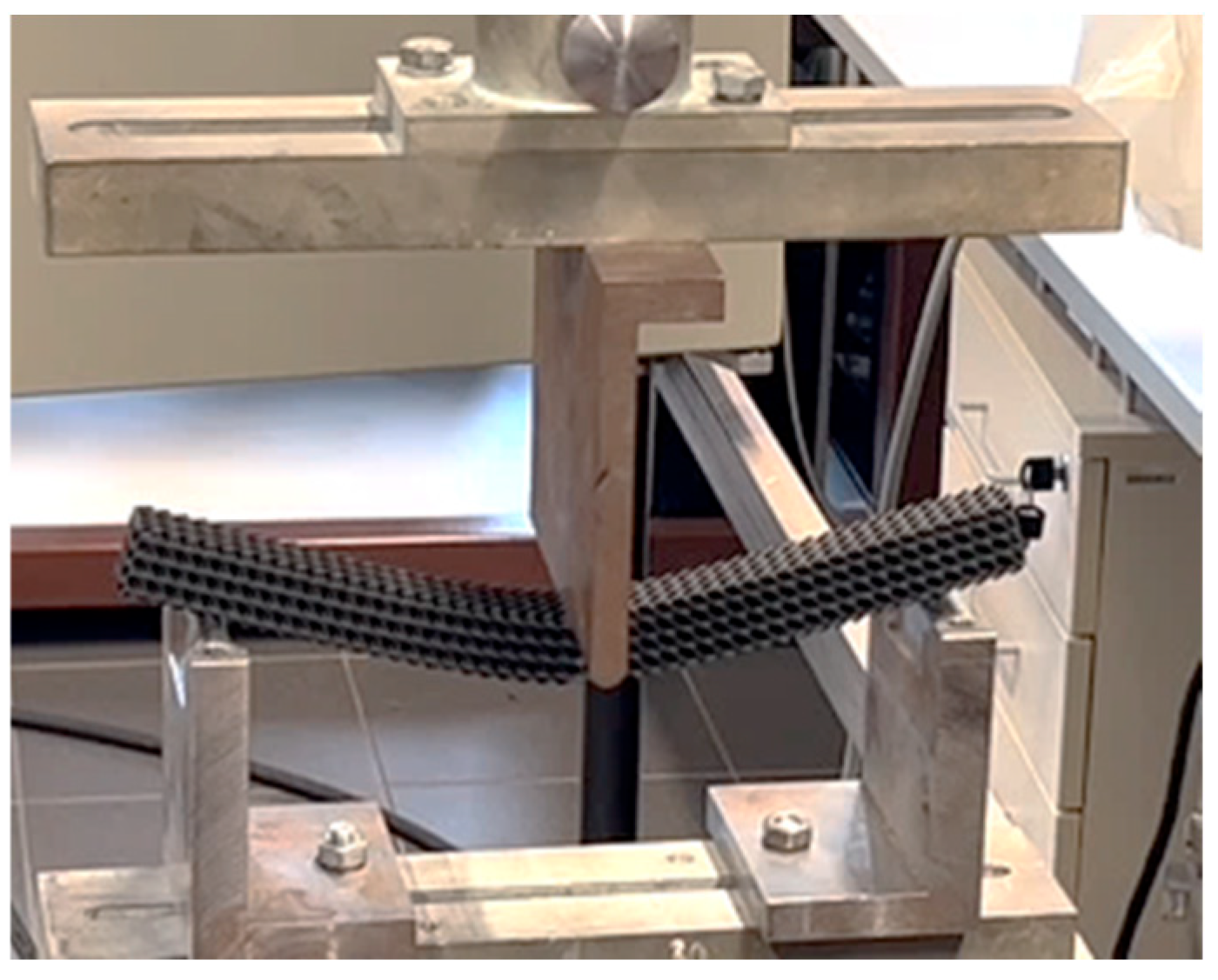

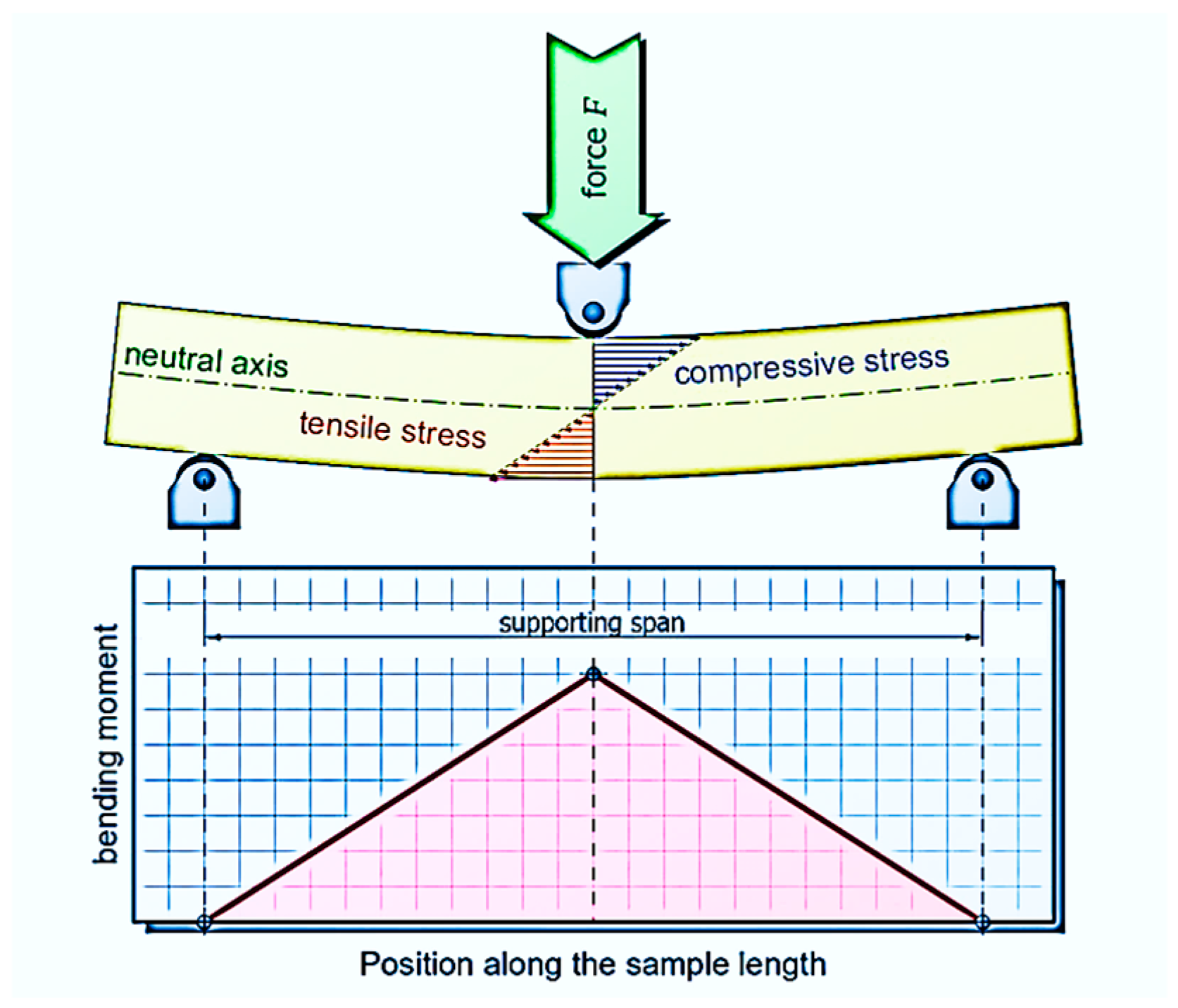

3.2. Testing and Evaluation Methodology

4. Results and Discussions

4.1. Experimental Results

4.2. Evaluation of Research Results from Mechanical and Energy Absorption Perspective

5. Conclusions

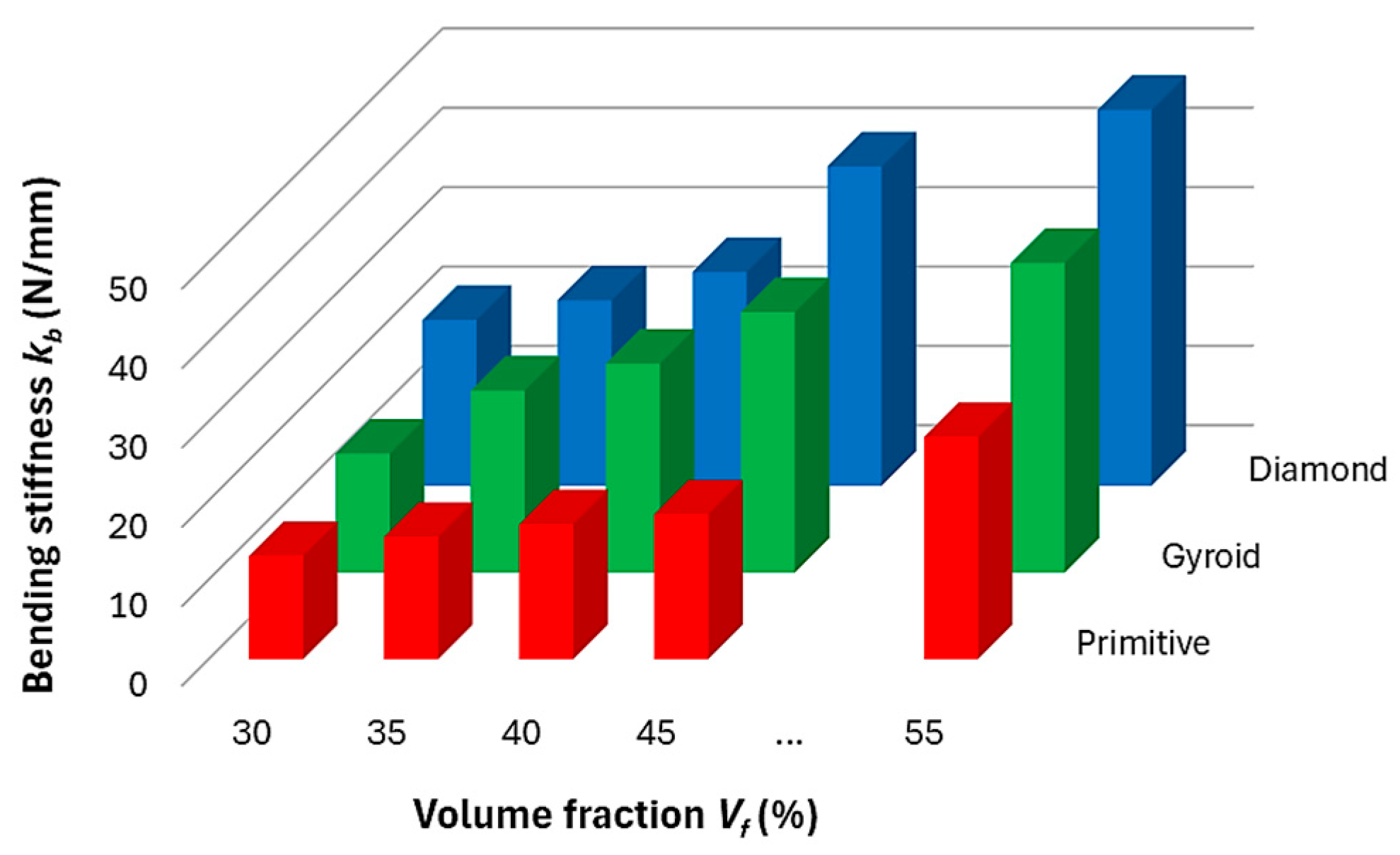

- The stiffness of the structure increased with increasing volume fraction, and the highest stiffness was shown by the Diamond structure with values from 20.9 to 47.3 N/mm, followed by Gyroid in the range of 15–39.3 N/mm, and finally by the Primitive structure with values of 13.2–28.4 N/mm in the investigated volume fraction range of 30–55%.

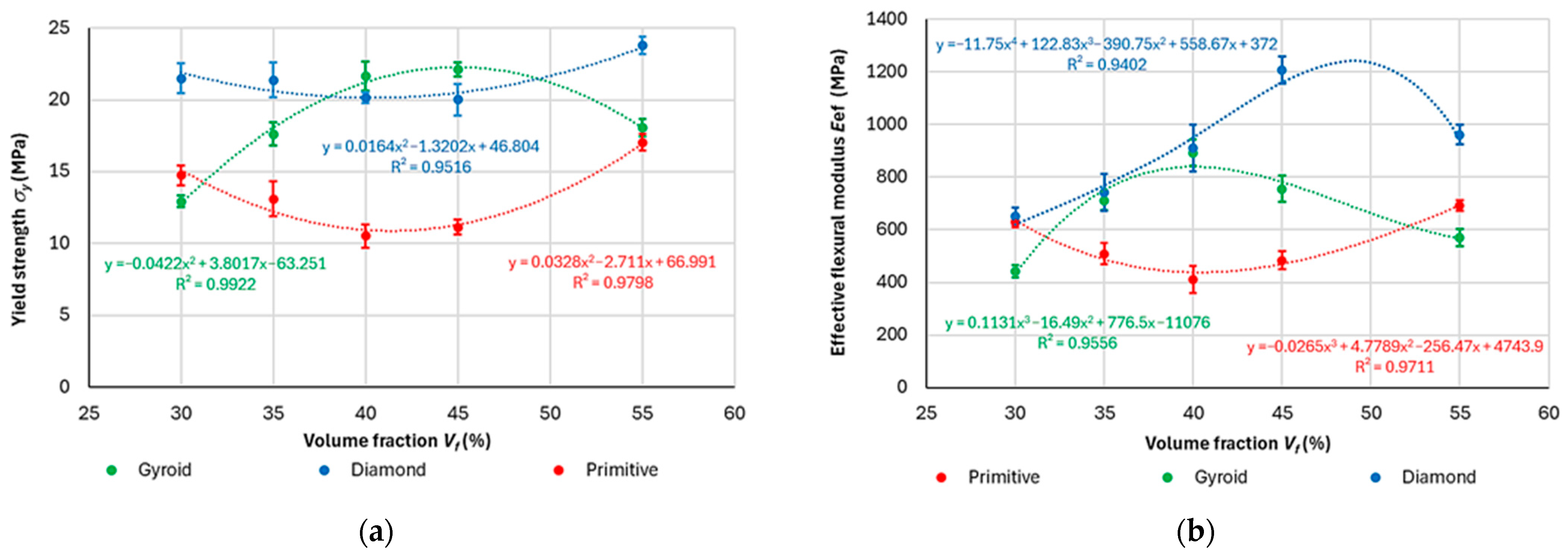

- When assessing the behavior of the sample in the elastic region, the results of yield strength and effective elastic modulus showed that within the investigated volume fraction range of 30–55%, there is an area in which the individual structures show the best/worst properties, which may mean that this specific combination of material, structure, technological conditions, cell size, and volume fraction is the most suitable (or least suitable). The dependencies of the above variables on Vf can be described by polynomial functions with relatively good reliability, but the resulting equations and coefficients will need to be verified in the future by testing with a larger number of samples.

- Thicker and stiffer cell walls of these structures have shown increased resistance to plastic flow and are more susceptible to elastic buckling or local deformations, which allow for a more efficient distribution of the loaded energy without permanent damage to the material. This leads to a higher value of absorbed energy, but at the cost of reduced ductility, since plastic deformation—and therefore the ability of the material to change its shape without immediate failure—is significantly limited.

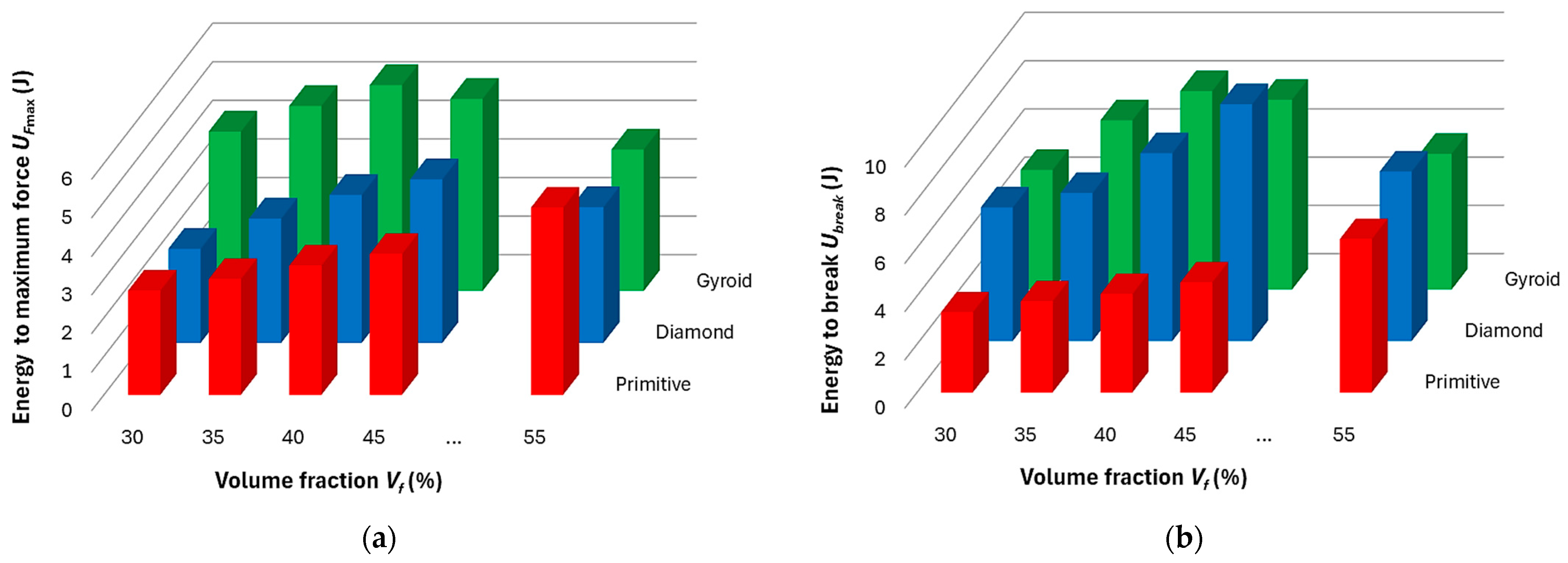

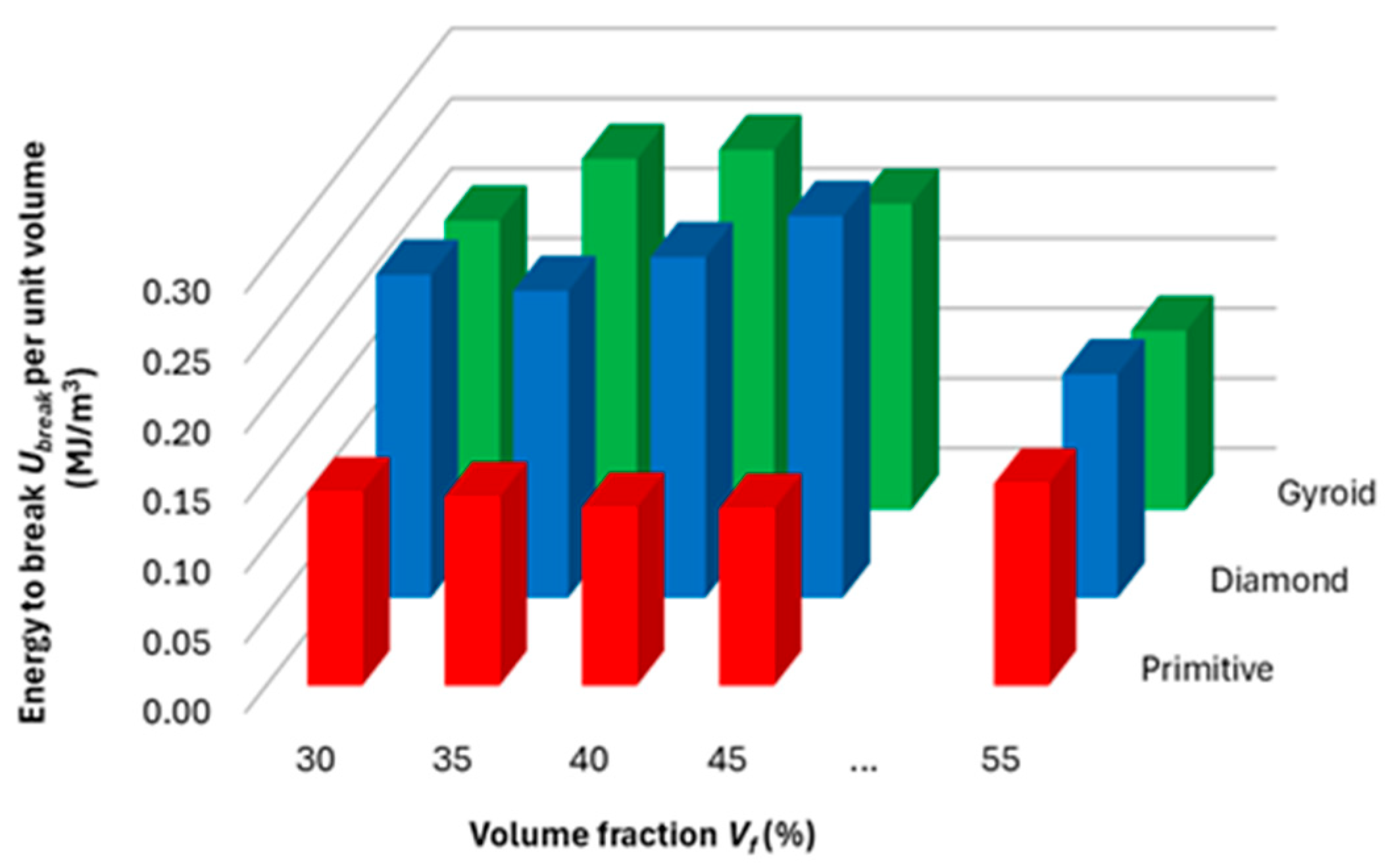

- Until reaching maximum force, the Gyroid structure is best able to absorb energy, and in terms of the total energy that the samples were able to absorb until failure, the Gyroid and Diamond structures were comparable; however, the highest values of absorbed energy were achieved by the Gyroid structure at 40% volume fraction, and the Diamond structure at Vf = 45%.

- The inverse relationship between energy absorption and ductility reflects deeper connections between microstructural geometry, deformation mechanisms, and energy dissipation.

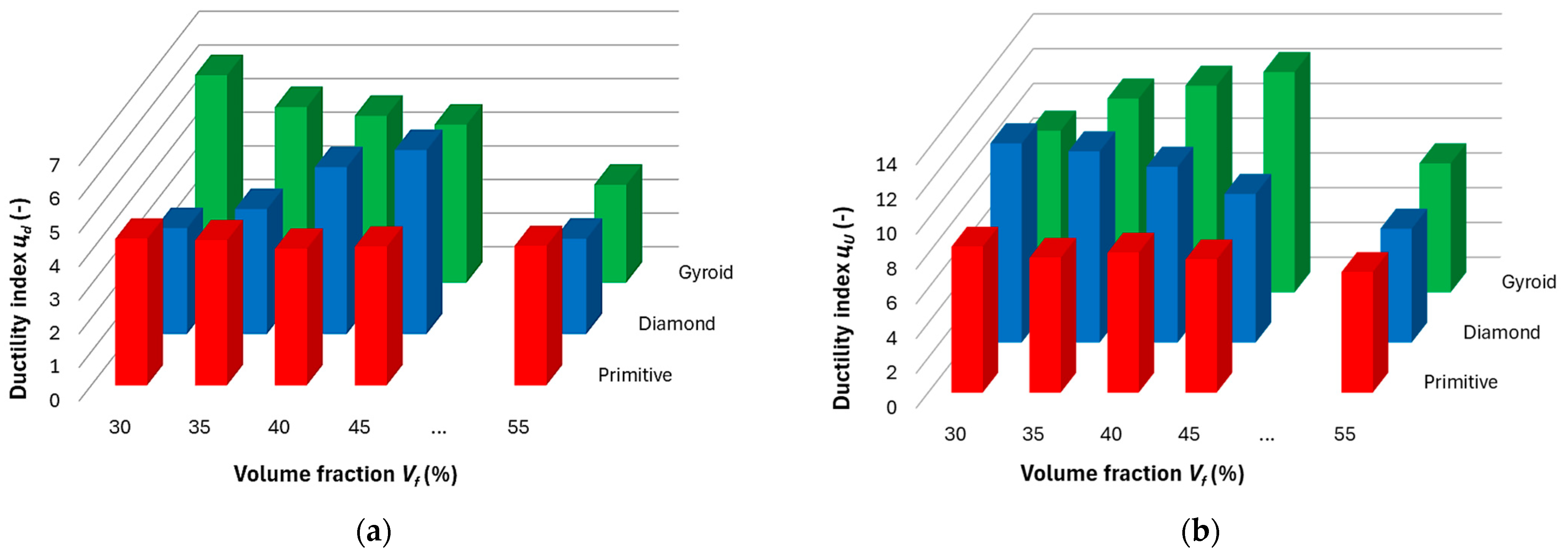

- In terms of ductility, the structures show different behavior. In the area up to the maximum load, the ductility index μd based on deflection shows for the Gyroid structure a decreasing character with increasing volume fraction, and, conversely, for the Diamond structure it increases, while at Vf = 55% a significant decrease was already recorded at the Diamond structure.In the area of the behavior of the samples up to failure, the ductility index derived on the basis of energy has the opposite trend; for the Gyroid it increases with volume fraction and for the Diamond it decreases.The Primitive structure shows stable values with the smallest influence of volume fraction in both ductility indices.

- Based on the research, it can be stated that both Gyroid and Diamond structures appear to be suitable static energy dissipators and the choice of structure will depend on the application and the area in which energy absorption is required (i.e., whether it is a stress area up to maximum load or to total failure). The damping properties during oscillation or impact will be verified and compared in the authors’ research in the near future.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arshad, A.; Kovaļčuks, V. Computational Investigations for the Feasibility of Passive Flow Control Devices for Enhanced Aerodynamics of Small-Scale UAVs. Aerospace 2024, 11, 473. [Google Scholar] [CrossRef]

- Hreha, P.; Hloch, S.; Monka, P.; Monkova, K.; Knapčikova, L.; Hlavaček, P.; Zeleňák, M.; Samardžić, I.; Kozak, D. Investigation of sandwich material surface created by abrasive water jet (AWJ) via vibration emission. Metalurgija 2014, 53, 29–32. [Google Scholar]

- Kadkhodapour, J.; Montazerian, H.; Darabi, A.; Anaraki, A.; Ahmadi, S.; Zadpoor, A.; Schmauder, S. Failure mechanisms of additively manufactured porous biomaterials. J. Mech. Behav. Biomed. Mater. 2015, 50, 180–191. [Google Scholar] [CrossRef]

- Plessis, A.D.; Razavi, S.M.J.; Benedetti, M.; Murchio, S.; Leary, M.; Watson, M.; Bhate, D.; Berto, F. Properties and applications of additively manufactured metallic cellular materials: A review. Prog. Mater. Sci. 2022, 125, 100918. [Google Scholar] [CrossRef]

- Monkova, K.; Monka, P.P.; Koroľ, M.; Torok, J.; Beňo, P. The Effect of a Face Wall on a Cellular Structure During Bending. In Smart Cities: Importance of Management and Innovations for Sustainable Development. Mobility IoT 2023. EAI/Springer Innovations in Communication and Computing; Springer: Cham, Switzerland, 2024. [Google Scholar]

- Kinik, D.; Gánovská, B.; Hloch, S.; Monka, P.; Monková, K.; Hutyrová, Z. On-line monitoring of technological process of material abrasive water jet cutting. Tech. Vjesn.-Tech. Gaz. 2015, 22, 351–357. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. Effects of fiber on the fracture behavior of 3D-printed fiber reinforced nylon. Procedia Struct. Integr. 2022, 35, 59–65. [Google Scholar] [CrossRef]

- Grbović, A.; Kastratović, G.; Božić, Ž.; Božić, I.; Obradović, A.; Sedmak, A.; Sedmak, S. Experimental and numerical evaluation of fracture characteristics of composite material used in the aircraft engine cover manufacturing. Eng. Fail. Anal. 2022, 137, 106286. [Google Scholar] [CrossRef]

- Bernard, A.R.; Yalcin, M.M.; ElSayed, M.S. Crashworthiness investigations for 3D printed multi-layer multi-topology carbon fiber nylon lattice materials. J. Reinf. Plast. Compos. 2024, 44, 634–649. [Google Scholar] [CrossRef]

- Sahu, S.K.; Badgayan, N.D.; Samanta, S.; Sreekanth, P.S.R. Evaluation of Cell Parameter Variation on Energy Absorption Characteristic of Thermoplastic Honeycomb Sandwich Structure. Arab. J. Sci. Eng. 2021, 46, 12487–12507. [Google Scholar] [CrossRef]

- Yalçın, M.M. Flexural Behavior of 3D-Printed Carbon Fiber-Reinforced Nylon Lattice Beams. Polymers 2024, 16, 2991. [Google Scholar] [CrossRef]

- Calignano, F.; Lorusso, M.; Roppolo, I.; Minetola, P. Investigation of the Mechanical Properties of a Carbon Fibre-Reinforced Nylon Filament for 3D Printing. Machines 2020, 8, 52. [Google Scholar] [CrossRef]

- Islam, N.; Baxevanakis, K.P.; Silberschmidt, V.V. Mechanical characterisation of AM nylon-matrix carbon-fibre-reinforced composite in tension. Mater. Today Proc. 2022, 70, 50–54. [Google Scholar] [CrossRef]

- Monkova, K.; Monka, P.P.; Burgerova, J.; Szabo, G. Investigating the Flexural Properties of 3D-Printed Nylon CF12 with Respect to the Correlation Between Loading and Layering Directions. Polymers 2025, 17, 788. [Google Scholar] [CrossRef]

- Alfouneh, M.; Hoang, V.N.; Luo, Z.; Luo, Q. Topology optimization for multi-layer multi-material composite structures. Eng. Optim. 2022, 55, 773–790. [Google Scholar] [CrossRef]

- Xie, K.; Li, M.; Shen, J. Dynamic Behavior and Energy Absorption of Typical Porous Materials under Impacts. Materials 2024, 17, 5035. [Google Scholar] [CrossRef]

- Taylor, S.V.; Moustafa, A.R.; Cordero, Z.C. Architectured Chain Lattices with Tailorable Energy Absorption in Tension. arXiv 2020, arXiv:2008.07402. [Google Scholar] [CrossRef]

- Zhao, X.; Li, X.; Su, Y. Origami-inspired viscoelastic lattice structures for energy absorption. Adv. Mater. 2023, 35, 2304–10238. [Google Scholar]

- Lee, C.S.; Park, Y.J. Mechanical behavior of octet-truss lattices with variable strut geometries. Mater. Des. 2023, 234, 111944. [Google Scholar] [CrossRef]

- Zhou, S.; Li, Y. Mechanical properties of FFF-printed hybrid lattice structures: A comparison of design strategies. J. Manuf. Process. 2023, 75, 358–368. [Google Scholar] [CrossRef]

- Wang, W.; Lee, D. Energy absorption and mechanical performance of flexible TPU lattice structures. Polym. Eng. Sci. 2020, 60, 1405–1417. [Google Scholar] [CrossRef]

- Zia, A.A.; Tian, X.; Liu, T.; Zhou, J.; Ghouri, M.A.; Yun, J.; Li, W.; Zhang, M.; Li, D.; Malakhov, A.V. Mechanical and energy absorption behaviors of 3D printed continuous carbon/Kevlar hybrid thread reinforced PLA composites. Compos. Struct. 2023, 303, 116386. [Google Scholar] [CrossRef]

- Farshbaf, S.; Dialami, N.; Cervera, M. Large deformation and collapse analysis of re-entrant auxetic and hexagonal honeycomb lattice structures subjected to tension and compression. Mech. Mater. 2025, 210, 105457. [Google Scholar] [CrossRef]

- Li, D.; Liao, W.; Dai, N.; Xie, Y.M. Comparison of Mechanical Properties and Energy Absorption of Sheet-Based and Strut-Based Gyroid Cellular Structures with Graded Densities. Materials 2019, 12, 2183. [Google Scholar] [CrossRef]

- Kahraman, M.F.; İriç, S.; Genel, K. Comparative failure behavior of metal honeycomb structures under bending: A finite element-based study. Eng. Fail. Anal. 2024, 157, 107963. [Google Scholar] [CrossRef]

- Sun, Q.; Sun, J.; Guo, K.; Wang, L. Compressive mechanical properties and energy absorption characteristics of SLM fabricated Ti6Al4V triply periodic minimal surface cellular structures. Mech. Mater. 2022, 166, 104241. [Google Scholar] [CrossRef]

- Benedetti, M.; du Plessis, A.; Ritchie, R.O.; Dallago, M.; Razavi, S.M.J.; Berto, F. Architected cellular materials: A review on their mechanical properties towards fatigue-tolerant design and fabrication. Mater. Sci. Eng. R 2021, 144, 100606. [Google Scholar] [CrossRef]

- Simsek, U.; Akbulut, A.; Gayir, C.E.; Basaran, C.; Sendur, P. Modal characterization of additively manufactured TPMS structures: Comparison between different modeling methods. Int. J. Adv. Manuf. Technol. 2021, 115, 657–674. [Google Scholar] [CrossRef]

- FDM Nylon 12 Carbon Fiber Data Sheet; Stratasys Ltd. 2018. Available online: https://www.stratasys.com/siteassets/materials/materials-catalog/fdm-materials/nylon-12cf/mds_fdm_nylon-12cf_0921a.pdf?v=48e2e4 (accessed on 15 June 2025).

- Christodoulou, T.I.; Alexopoulou, V.E.; Markopoulos, A.P. An experimental investigation of the mechanical properties of fused filament fabricated nylon-carbon fiber composites. Cut. Tools Technol. Syst. 2024, 100, 148–167. [Google Scholar] [CrossRef]

- Korol, M. Research on the Adaptation of the Characteristics of Cellular Structures for the Distribution of Stress in the Components. Ph.D. Thesis, Faculty of Manufacturing Technologies with a seat in Presov, Technical University in Kosice, Kosice, Slovakia, 2024. [Google Scholar]

- Guo, K.; Ren, Y.; Han, G.; Xie, T.; Jiang, H. Hygrothermal aging and durability prediction of 3D-printed hybrid fiber composites with continuous carbon/Kevlar-fiber and short carbon-fiber. Eng. Fail. Anal. 2025, 167 Pt A, 108958. [Google Scholar] [CrossRef]

- Korol, M.; Török, J.; Monka, P.P.; Baron, P.; Mrugalska, B.; Monkova, K. Researching on the Effect of Input Parameters on the Quality and Manufacturability of 3D-Printed Cellular Samples from Nylon 12 CF in Synergy with Testing Their Behavior in Bending. Polymers 2024, 16, 1429. [Google Scholar] [CrossRef]

- ISO 178:2019; Plastics Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017. [CrossRef]

- Mitrovic, N.; Milosevic, M.; Momcilovic, N.; Petrovic, A.; Miskovic, Z.; Sedmak, A.; Popovic, P. Local Strain and Stress Analysis of Globe Valve Housing Subjected to External Axial Loading. In Key Engineering Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2014; Volume 586, pp. 214–217. [Google Scholar]

- Kumar, R.; Lal, A.; Sutaria, B.M. Numerical and experimental investigation for flexural response of Kevlar short fiber tissue/carbon fiber belts toughened honeycomb sandwich plate. Forces Mech. 2023, 12, 100222. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, J.; Chen, L.; Du, B.; Liu, H.; Chen, L.; Li, W.; Liu, Y. Deformation behaviours and energy absorption of auxetic lattice cylindrical structures under axial crushing load. Aerosp. Sci. Technol. 2020, 98, 105662. [Google Scholar] [CrossRef]

- Zhang, X.; Jin, H.; Yu, S.; Bi, X.; Zhou, S. Analysis of bending deflection of tunnel segment under load- and corrosion-induced cracks by improved XFEM. Eng. Fail. Anal. 2022, 140, 106576. [Google Scholar] [CrossRef]

- Ribeiro, V.; Correia, J.; Mourão, A.; Lesiuk, G.; Gonçalves, A.; De Jesus, A.; Berto, F. Fatigue crack growth modelling by means of the strain energy density-based Huffman model considering the residual stress effect. Eng. Fail. Anal. 2022, 140, 106543. [Google Scholar] [CrossRef]

- Montazeri, A.; Bahmanpour, E.; Safarabadi, M. Three-Point Bending Behavior of Foam-Filled Conventional and Auxetic 3D-Printed Honeycombs. Adv. Eng. Mater. 2023, 25, 2300273. [Google Scholar] [CrossRef]

- Monkova, K.; Monka, P.P.; Božić, Ž.; Rački, I. Comparison of the stiffnesses of three types of porous structures. Procedia Struct. Integr. 2025, 68, 588–591. [Google Scholar] [CrossRef]

- Djordjevic, B.; Sedmak, A.; Mastilovic, S.; Popovic, O.; Kirin, S. History of ductile-to-brittle transition problem of ferritic steels. Procedia Struct. Integr. 2022, 42, 88–95. [Google Scholar] [CrossRef]

- Subhani, M.; Globa, A.; Al-Ameri, R.; Moloney, J. Flexural strengthening of LVL beam using CFRP. Constr. Build. Mater. 2017, 150, 480–489. [Google Scholar] [CrossRef]

- Naaman, A.E.; Jeong, S.M. Structural Ductility of Concrete Beams Prestressed with FRP Tendons. In Non-Metallic (FRP) Reinforcement for Concrete Structures, Proceedings of the 2nd International RILEM Symposium (FRPRXS-2), Ghent, Belgium, 23–25 August 1995; RILEM: Bagneus, France, 1995; pp. 379–386. [Google Scholar]

- Burnett, C.; Graninger, G.; Eren, Z.; Fazlan, B.G.; Kazanci, Z. Tensile performance of carbon fibre-reinforced 3D-printed polymers: Effect of printing parameters. Eng. Fail. Anal. 2025, 152, 107436. [Google Scholar] [CrossRef]

- Marşavina, L.; Valean, C.; Marghitas, M.; Linul, E.; Razavi, N.; Berto, F.; Brighenti, R. Effect of the manufacturing parameters on the tensile and fracture properties of FDM 3D-printed PLA specimens. Eng. Fract. Mech. 2022, 274, 108766. [Google Scholar] [CrossRef]

- Monkova, K.; Monka, P.P.; Žaludek, M.; Beňo, P.; Hricová, R.; Šmeringaiová, A. Experimental Study of the Bending Behaviour of the Neovius Porous Structure Made Additively from Aluminium Alloy. Aerospace 2023, 10, 361. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties; Cambridge University Press: Cambridge, UK, 1997; ISBN 9781139878326. [Google Scholar] [CrossRef]

- Bazios, P.; Tserpes, K.; Pantelakis, S. Modelling and Experimental Validation of the Porosity Effect on the Behaviour of Nano-Crystalline Materials. Metals 2020, 10, 821. [Google Scholar] [CrossRef]

- Mohabeddine, A. Comparison between brittle and ductile adhesives in CFRP/steel joints. Procedia Struct. Integr. 2022, 37, 1043–1048. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, Y.; Xi, J.; Jiang, J.; Wang, Y.; Chen, A.; Nikbin, K. Energy dissipation-based LCF model for additive manufactured alloys with dispersed fatigue properties. Eng. Fail. Anal. 2024, 159, 108139. [Google Scholar] [CrossRef]

- Feng, J.; Zhu, G.; Niu, X.; Lv, R.; Wang, Z.; Guo, B. Energy absorption of CFRP tubes filled with bio-inspired graded lattices under bending load. Eng. Struct. 2025, 336, 120309. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, D.; Liu, Z.; Xu, P.; Lu, F.; Fei, Q. Bending response and energy absorption of sandwich beams with combined reinforced auxetic honeycomb core. Mech. Adv. Mater. Struct. 2024, 32, 4993–5005. [Google Scholar] [CrossRef]

- Zhou, Q.; Xu, Z.; Cui, Y.; Wang, K.; Wang, B.; Wang, B. Evaluations of three-point bending and energy absorption performances of novel auxetic honeycomb circular tubes under different impact loading. Constr. Build. Mater. 2025, 475, 141132. [Google Scholar] [CrossRef]

- Cetin, E.; Baykasoğlu, C. Energy absorption of thin-walled tubes enhanced by lattice structures. Int. J. Mech. Sci. 2019, 157–158, 471–484. [Google Scholar] [CrossRef]

- Lin, S.; Peng, C.; Deng, F.; Yin, D.; Ye, B. Influence of structural geometry on tensile properties and fracture toughness in 3D printed novel structures. Eng. Fail. Anal. 2024, 161, 108277. [Google Scholar] [CrossRef]

- Luo, J.; Luo, Q.; Zhang, G.; Sun, G. On strain rate and temperature dependent mechanical properties and constitutive models for additively manufactured polylactic acid (PLA) materials. Thin-Walled Struct. 2022, 179, 109624. [Google Scholar] [CrossRef]

- Najafi, M.; Ahmadi, H.; Liaghat, G. Experimental investigation on energy absorption of auxetic structures. Mater. Today Proc. 2021, 34, 350–355. [Google Scholar] [CrossRef]

| Property | Unit | Value |

|---|---|---|

| Density | g/cm3 | 1.19 |

| Melting point | °C | 180–190 |

| Tensile modulus of elasticity * | GPa | 3–9.46 |

| Ultimate tensile strength * | MPa | 32.7–83.5 |

| Elongation at break | % | 1.2–2.4 |

| Toughness | J/m2 | 50 |

| Vf | Structure Type | |||

|---|---|---|---|---|

| Diamond | Primitive | Gyroid | ||

| Maximal Force Fmax (N) | 30% | 163 ± 6.67 | 141 ± 5.33 | 110 ± 4.67 |

| 35% | 190 ± 2.67 | 151 ± 4.67 | 227 ± 2.33 | |

| 40% | 213 ± 2.00 | 158 ± 5.33 | 242 ± 4.67 | |

| 45% | 279 ± 4.67 | 179 ± 4.00 | 252 ± 6.67 | |

| 55% | 317 ± 6.67 | 314 ± 6.33 | 283 ± 0.50 | |

| Structure Type | Volume Fraction Vf (%) | ||||

|---|---|---|---|---|---|

| 30 | 35 | 40 | 45 | 55 | |

| Gyroid | 0.1737 | 0.2107 | 0.2161 | 0.1837 | 0.1075 |

| Diamond | 0.1940 | 0.1843 | 0.2046 | 0.2292 | 0.1343 |

| Primitive | 0.1162 | 0.1134 | 0.1071 | 0.1064 | 0.1215 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monkova, K.; Monka, P.P.; Godec, D.; Torokova, M. Research into the Influence of Volume Fraction on the Bending Properties of Selected Thermoplastic Cellular Structures from a Mechanical and Energy Absorption Perspective. Polymers 2025, 17, 2795. https://doi.org/10.3390/polym17202795

Monkova K, Monka PP, Godec D, Torokova M. Research into the Influence of Volume Fraction on the Bending Properties of Selected Thermoplastic Cellular Structures from a Mechanical and Energy Absorption Perspective. Polymers. 2025; 17(20):2795. https://doi.org/10.3390/polym17202795

Chicago/Turabian StyleMonkova, Katarina, Peter Pavol Monka, Damir Godec, and Monika Torokova. 2025. "Research into the Influence of Volume Fraction on the Bending Properties of Selected Thermoplastic Cellular Structures from a Mechanical and Energy Absorption Perspective" Polymers 17, no. 20: 2795. https://doi.org/10.3390/polym17202795

APA StyleMonkova, K., Monka, P. P., Godec, D., & Torokova, M. (2025). Research into the Influence of Volume Fraction on the Bending Properties of Selected Thermoplastic Cellular Structures from a Mechanical and Energy Absorption Perspective. Polymers, 17(20), 2795. https://doi.org/10.3390/polym17202795