Effect of Debinding Process on Aluminum Nitride Ceramics Fabrication via Digital Light Processing 3D Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

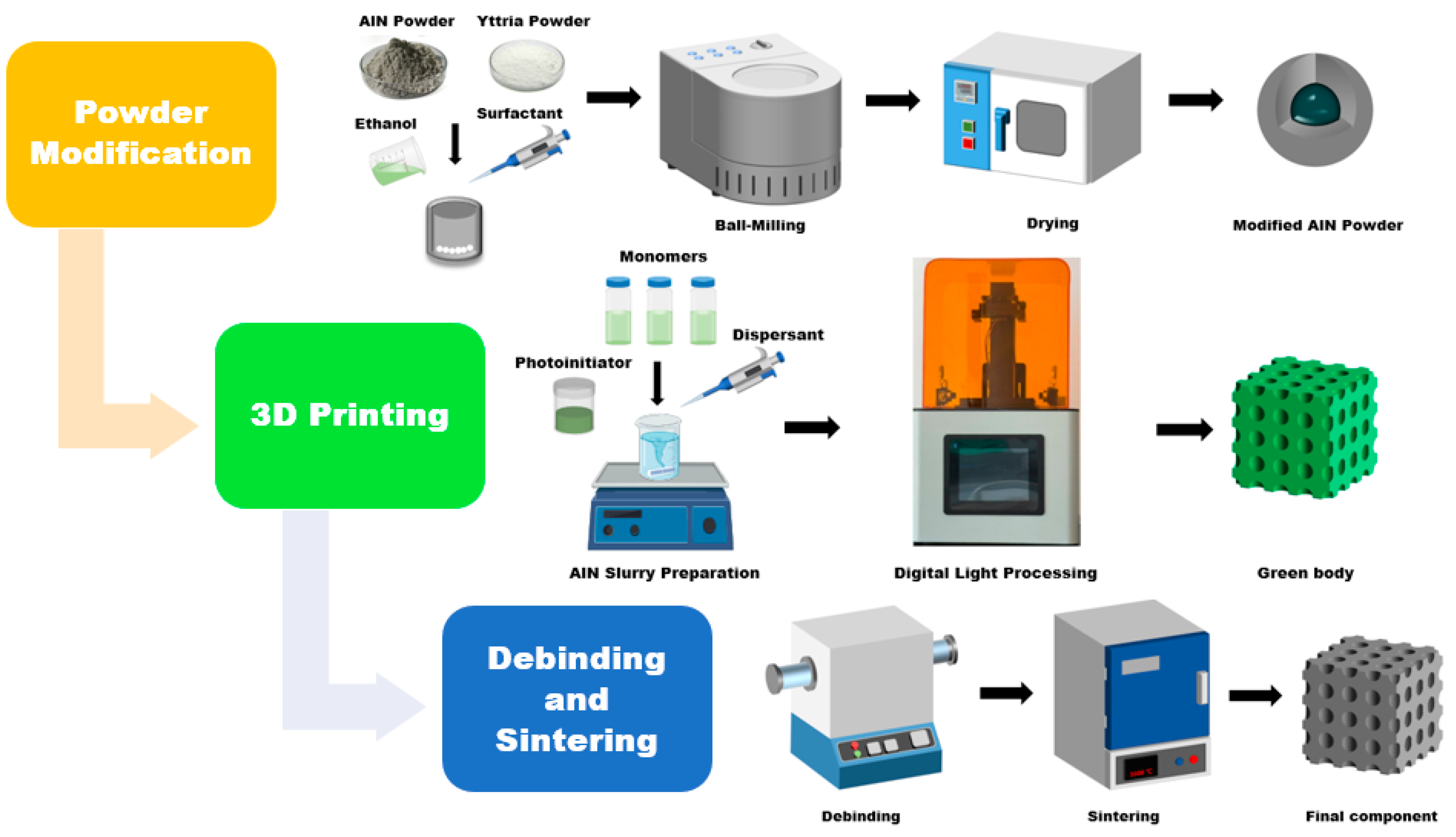

2.2. Powder Modification

2.3. Preparation of AlN Ceramic Slurry

2.4. Fabrication

2.5. Characterization

3. Results and Discussion

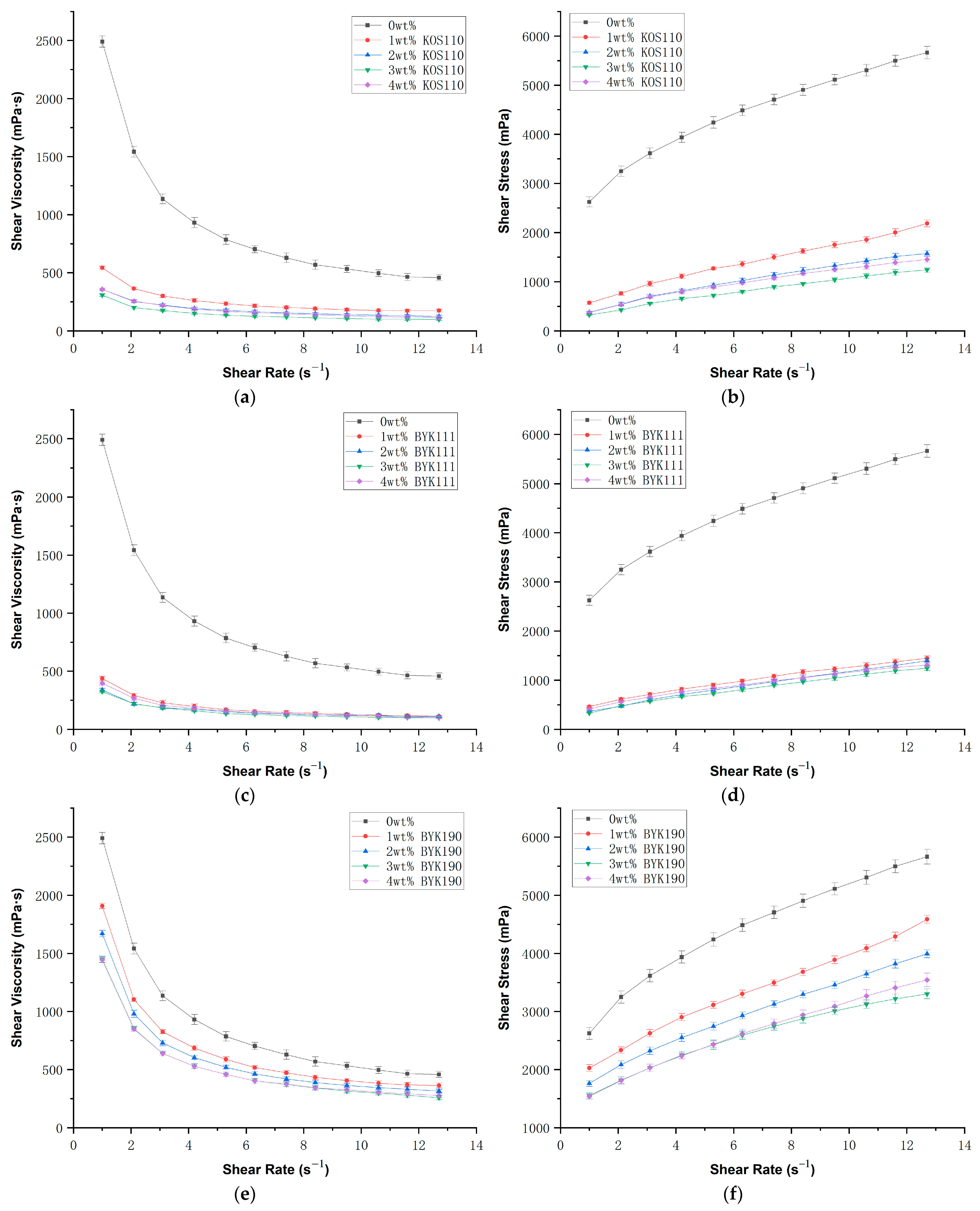

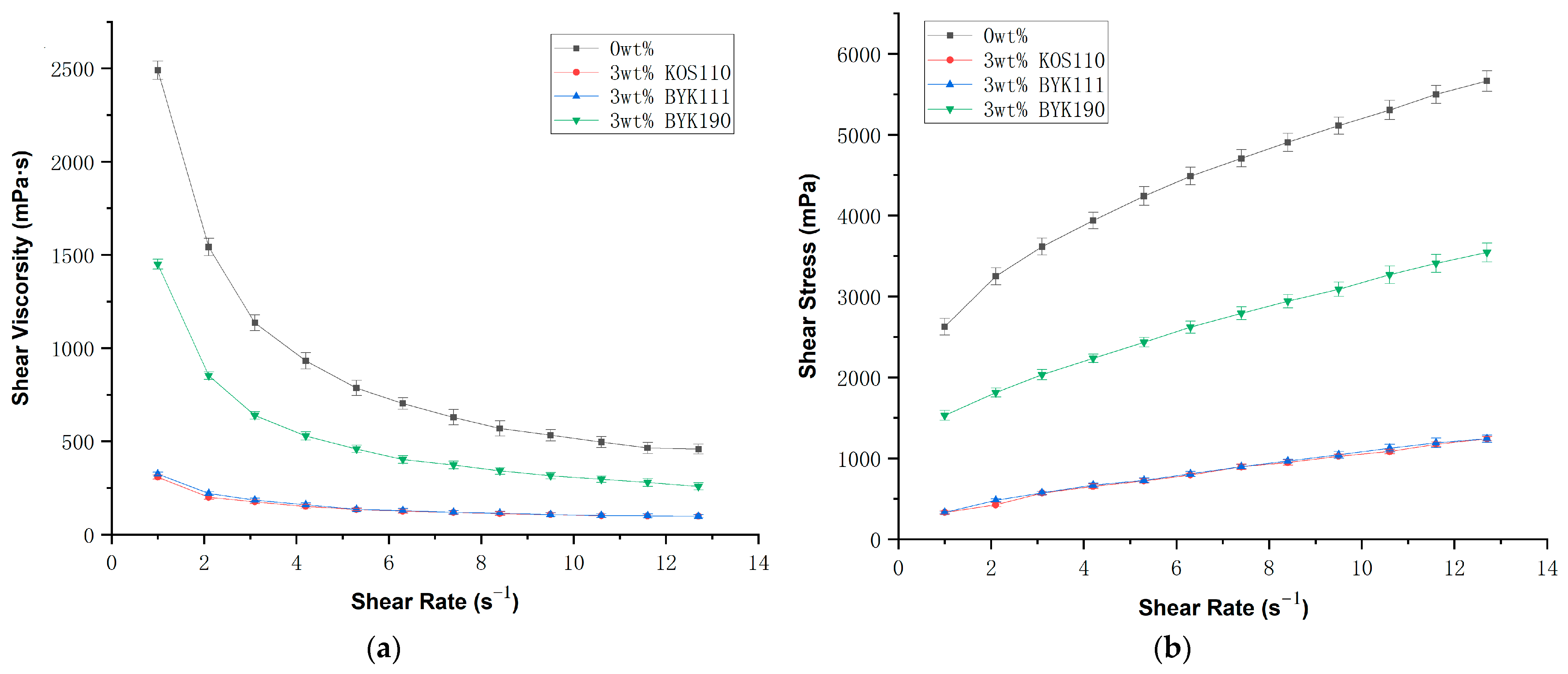

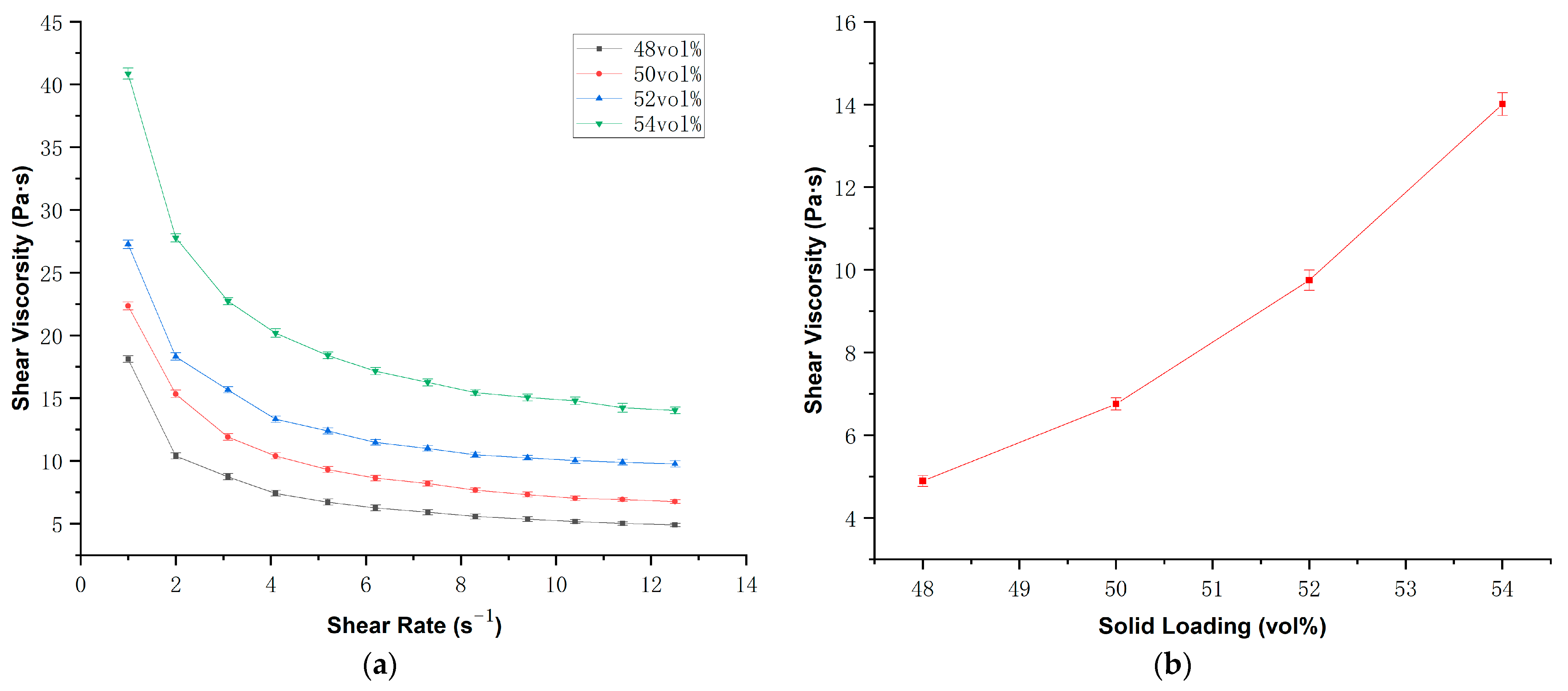

3.1. Rheological Properties of Photopolymer Resin

3.2. Photocuring Performance of AlN Ceramic Slurry

3.3. Debinding

3.4. Properties of AlN Ceramics

4. Conclusions

- Dispersant impact: this study clarified the crucial function of dispersants in regulating rheological properties, with the formulation containing 3 wt% BYK111 exhibiting the lowest viscosity across all evaluated compositions.

- Solid loading impact: a slurry with enhanced rheological properties was prepared by adding 3 wt% BYK111, achieving a high solid loading of 52 vol%.

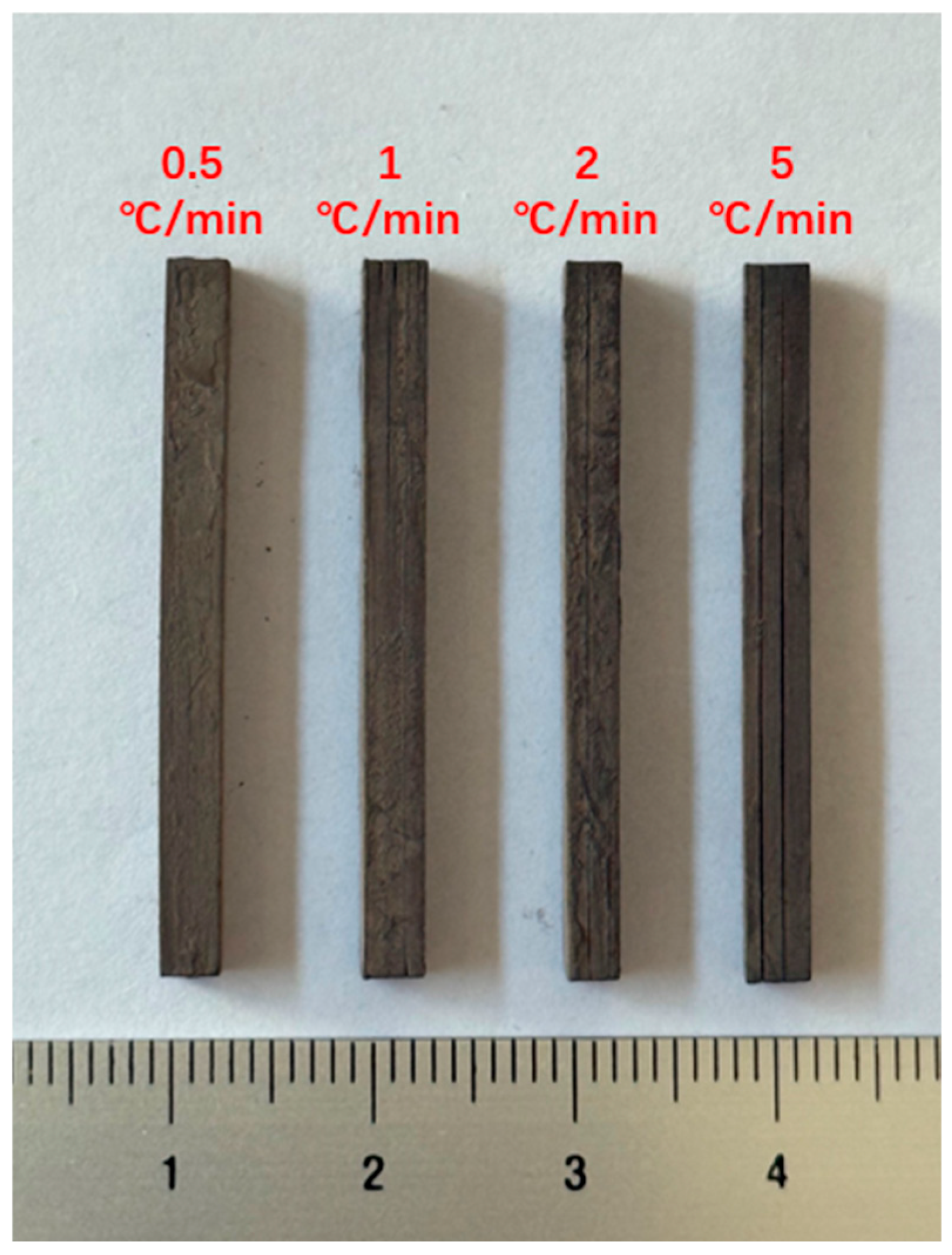

- Debinding process impact: this study demonstrates that employing a slower heating rate during debinding facilitates the removal of gases from the green body, thereby mitigating crack formation. Using green bodies printed with the optimized slurry and subjected to a debinding process at a heating rate of 0.5 °C/min, followed by sintering, dense aluminum nitride ceramic components were successfully obtained, achieving a bending strength of 212.6 MPa, and Vickers hardness of 1010.5 HV.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Du, X.; Qin, M.; Sun, Y.; Yuan, Z.; Yang, B. Structure and thermal conductivity of powder injection molded AlN ceramic. Adv. Powder Technol. 2010, 21, 431–434. [Google Scholar] [CrossRef]

- Kume, S.; Yasuoka, M.; Lee, S.; Kan, A.; Ogawa, H. Dielectric and thermal properties of AlN ceramics. J. Eur. Ceram. Soc. 2007, 27, 2967–2971. [Google Scholar] [CrossRef]

- Sheng, P.; Nie, G.; Li, Y.; Lin, L.; Wu, H. Research Progress in Shaping Technology of AlN Ceramics with High Thermal Conductivity. J. Ceram. 2020, 41, 771–782. [Google Scholar]

- Qin, M.; Lu, H.; Wu, H.; He, Q.; Liu, C. Powder injection molding of complex-shaped aluminium nitride ceramic with high thermal conductivity. J. Eur. Ceram. Soc. 2019, 39, 952–956. [Google Scholar] [CrossRef]

- Lee, H.M.; Kim, D.K. High-strength AlN ceramics by low-temperature sintering with CaZrO3–Y2O3 co-additives. J. Eur. Ceram. Soc. 2014, 34, 3627–3633. [Google Scholar] [CrossRef]

- Guo, L.; Yang, J.; Feng, Y.; Qiu, T. Non-aqueous gelcasting of AlN ceramics using a low-toxicity monomer (DMAA) as gelling agent. Ceram. Int. 2018, 44, 1621–1626. [Google Scholar]

- Huang, D.; Tian, Z.; Cui, W.; Gao, L.; Liu, Z. Effects of Y2O3 and yttrium aluminates as sintering additives on the thermal conductivity of AlN ceramic substrates. Ceram. Int. 2018, 44, 20556–20559. [Google Scholar] [CrossRef]

- Choi, H.S.; Im, H.N.; Kim, Y.M.; Chavan, A.; Song, S.J. Structural, thermal and mechanical properties of aluminum nitride ceramics with CeO2 as a sintering aid. Ceram. Int. 2016, 42, 11519–11524. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Prakash, K.S.; Nancharaih, T.; Rao, V.V.S. Additive Manufacturing Techniques in Manufacturing -An Overview. Mater. Today Proc. 2018, 5, 3873–3882. [Google Scholar] [CrossRef]

- Zhang, K.Q.; Xie, C.; Wang, G.; He, R.J.; Ding, G.J.; Wang, M. High Solid Loading, Low Viscosity Photosensitive Al2O3 Slurry for Stereolithography-Based Additive Manufacturing. Ceram. Int. 2019, 45, 203–208. [Google Scholar] [CrossRef]

- Lin, L.; Wu, H.; Ni, P.; Chen, Y.; Huang, Z. Additive manufacturing of complex-shaped and high-performance aluminum nitride-based components for thermal management. Addit. Manuf. 2022, 52, 102671. [Google Scholar] [CrossRef]

- Duan, W.; Li, S.; Wang, G.; Dou, R.; Wang, L. Thermal conductivities and mechanical properties of AlN ceramics fabricated by three dimensional printing. J. Eur. Ceram. Soc. 2020, 40, 3535–3540. [Google Scholar] [CrossRef]

- Xu, H.; Liu, R.; Bao, C.; Li, H.; Cao, Z.; Huang, N. Fabrication of aluminum nitride ceramics via digital light processing. Ceram. Int. 2025, 51, 25459–25472. [Google Scholar] [CrossRef]

- Lin, K.; Lin, L.; Qi, Y.; Lu, D.; Zhang, W.; Zong, X.; Wu, S. Additive manufacturing of high-performance aluminium nitride ceramics using high solid loading and low viscosity slurry. Virtual Phys. Prototyp. 2024, 19, e2383306. [Google Scholar] [CrossRef]

- Lin, L.; Wu, H.; Lin, K.; Li, Y.; Ni, P.; Lu, D.; Sheng, P.; Wu, S. Effect of yttrium nitrate coating on the vat photopolymerization forming process and sintering properties of aluminum nitride ceramics. Addit. Manuf. 2024, 84, 104115. [Google Scholar] [CrossRef]

- Wang, J.; Wu, H.; Qi, Y.; Zong, X.; Lin, K.; Lin, L.; Zhang, W.; Wu, S. High-performance aluminum nitride made by Vat photopolymerization through optimization of resin refractive index and plasticizer content. Ceram. Int. 2024, 50, 14896–14906. [Google Scholar] [CrossRef]

- Tang, Y.; Hu, S.; Xue, Z.; Zhou, G. Influence of solid loading on microstructure evolution and thermal conductivity of aluminum nitride ceramics fabricated by digital light processing 3D printing. J. Eur. Ceram. Soc. 2025, 45, 117028. [Google Scholar] [CrossRef]

- Qi, Y.; Wu, H.; Zhang, W.; Huang, P.; Chen, X.; Lin, K.; Wu, S. Vat photopolymerization of high-strength aluminum nitride ceramics through nitrate additives coating. J. Eur. Ceram. 2025, 45, 117228. [Google Scholar] [CrossRef]

- Xu, H.; Liu, R.; Bao, C.; Huang, N.; Li, P.; Li, H. Effect of ball-milling time on the properties of AlN ceramics fabricated via digital light processing. Mater. Today Commun. 2025, 45, 112429. [Google Scholar] [CrossRef]

- Hinczewski, C.; Sorbel, S.; Chartier, T. Ceramic suspensions suitable for stereolithography. J. Eur. Ceram. 1998, 18, 583–590. [Google Scholar] [CrossRef]

- Park, S.; Yang, D.; Lee, K. Two-photon stereolithography for realizing ultraprecise three-dimensional nano/microdevices. Laser Phot. Rev. 2009, 3, 1–11. [Google Scholar] [CrossRef]

- Gong, P.; Yan, X.; Xiong, W.; Hao, L.; Tang, D.; Li, Y. Design of a debinding process for polymetallic material green parts fabricated via metal paste injection 3D printing with dual nozzles. RSC Adv. 2020, 10, 18000–18007. [Google Scholar] [CrossRef]

- Alves, P.; Camargo, I.; Verza, J.; Luz, A. Impact of debinding atmosphere and sintering additives on the fabrication of alumina ceramics via vat photopolymerization. Ceram. Int. 2025, 51, 9063–9072. [Google Scholar] [CrossRef]

- Bezek, L.B.; Wilkerson, R.P.; Chad, J.L.; Quintana, T.E.; Patterson, B.M.; Adhikari, S.; Lee, K. Evolution of debinding and sintering of a silica-based ceramic using vat photopolymerization additive manufacturing. Addit. Manuf. 2025, 105, 104795. [Google Scholar] [CrossRef]

- Meng, Q.; Zhu, R.; Gong, Z.; Pu, J.; Zhang, K.; He, R.; Qu, Z.; Fang, D. 4D insight into the defect evolution of additively manufactured ceramics during debinding and sintering. Addit. Manuf. 2025, 109, 104873. [Google Scholar] [CrossRef]

- Kaung, N.; Liu, Y.; Zhao, W.; Wu, J. Experiment Study of Photopolymer Resin Composition for AlN Ceramic 3D-Printing via Digital Light Processing. Polymers 2025, 17, 2344. [Google Scholar] [CrossRef]

- Sun, J.; Binner, J.; Bai, J. 3D Printing of Zirconia via Digital Light Processing: Optimization of Slurry and Debinding Process. J. Eur. Ceram. Soc. 2020, 40, 5837–5844. [Google Scholar] [CrossRef]

- Schwarzer-Fischer, E.; Zschippang, E.; Kunz, W.; Koplin, C.; Löw, Y.M.; Scheithauer, U.; Michaelis, A. CerAMfacturing of Silicon Nitride by Using Lithography-Based Ceramic Vat Photopolymerization (CerAM VPP). J. Eur. Ceram. Soc. 2023, 43, 321–331. [Google Scholar]

- Chartier, T.; Chaput, C.; Doreau, F.; Loiseau, M. Stereolithography of Structural Complex Ceramic Parts. J. Mater. Sci. 2002, 37, 3141–3147. [Google Scholar] [CrossRef]

- Huang, R.; Jiang, Q.; Wu, H.; Li, Y.; Liu, W.; Lu, X.; Wu, S. Fabrication of complex shaped ceramic parts with surface-oxidized Si3N4 powder via digital light processing based stereolithography method. Ceram. Int. 2019, 45, 5158–5162. [Google Scholar] [CrossRef]

- Gu, Q.; Wang, H.; Gao, W.; Yu, J.; Zhou, X. Preparation of large-size alumina ceramic parts by DLP 3D printing using high-solid-loading paste and optimizing the debinding process. Ceram. Int. 2023, 49, 28801–28812. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Hu, K.; Lu, Z.; Liang, J.; Li, J. Influence of debinding holding time on mechanical properties of 3D-printed alumina ceramic cores. Ceram. Int. 2021, 47, 4884–4894. [Google Scholar] [CrossRef]

- Kim, I.; Yoon, Y. Digital light processing 3D printing of porous ceramics: A systematic analysis from a debinding perspective. Addit. Manuf. 2024, 93, 104409. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, J.; Xiao, Z.; He, Y.; Liu, K.; He, B.; Xiang, B.; Zhai, J.; Kong, L. Effects of debinding condition on microstructure and densification of alumina ceramics shaped with photopolymerization-based additive manufacturing technology. Ceram. Int. 2022, 48, 14026–14038. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Liu, Y.; Zeng, Q.; Hu, K.; Lu, Z.; Liang, J. Effect of debinding temperature under an argon atmosphere on the microstructure and properties of 3D-printed alumina ceramics. Mater. Charact. 2020, 168, 110548. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuang, N.; Zhao, W.; Wu, J. Effect of Debinding Process on Aluminum Nitride Ceramics Fabrication via Digital Light Processing 3D Printing. Polymers 2025, 17, 2769. https://doi.org/10.3390/polym17202769

Kuang N, Zhao W, Wu J. Effect of Debinding Process on Aluminum Nitride Ceramics Fabrication via Digital Light Processing 3D Printing. Polymers. 2025; 17(20):2769. https://doi.org/10.3390/polym17202769

Chicago/Turabian StyleKuang, Ning, Wenjie Zhao, and Junfei Wu. 2025. "Effect of Debinding Process on Aluminum Nitride Ceramics Fabrication via Digital Light Processing 3D Printing" Polymers 17, no. 20: 2769. https://doi.org/10.3390/polym17202769

APA StyleKuang, N., Zhao, W., & Wu, J. (2025). Effect of Debinding Process on Aluminum Nitride Ceramics Fabrication via Digital Light Processing 3D Printing. Polymers, 17(20), 2769. https://doi.org/10.3390/polym17202769