Enhancement of Poly(Lactic Acid) Fire Retardancy Through the Incorporation of Sludge Residue as a Synergistic Additive

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

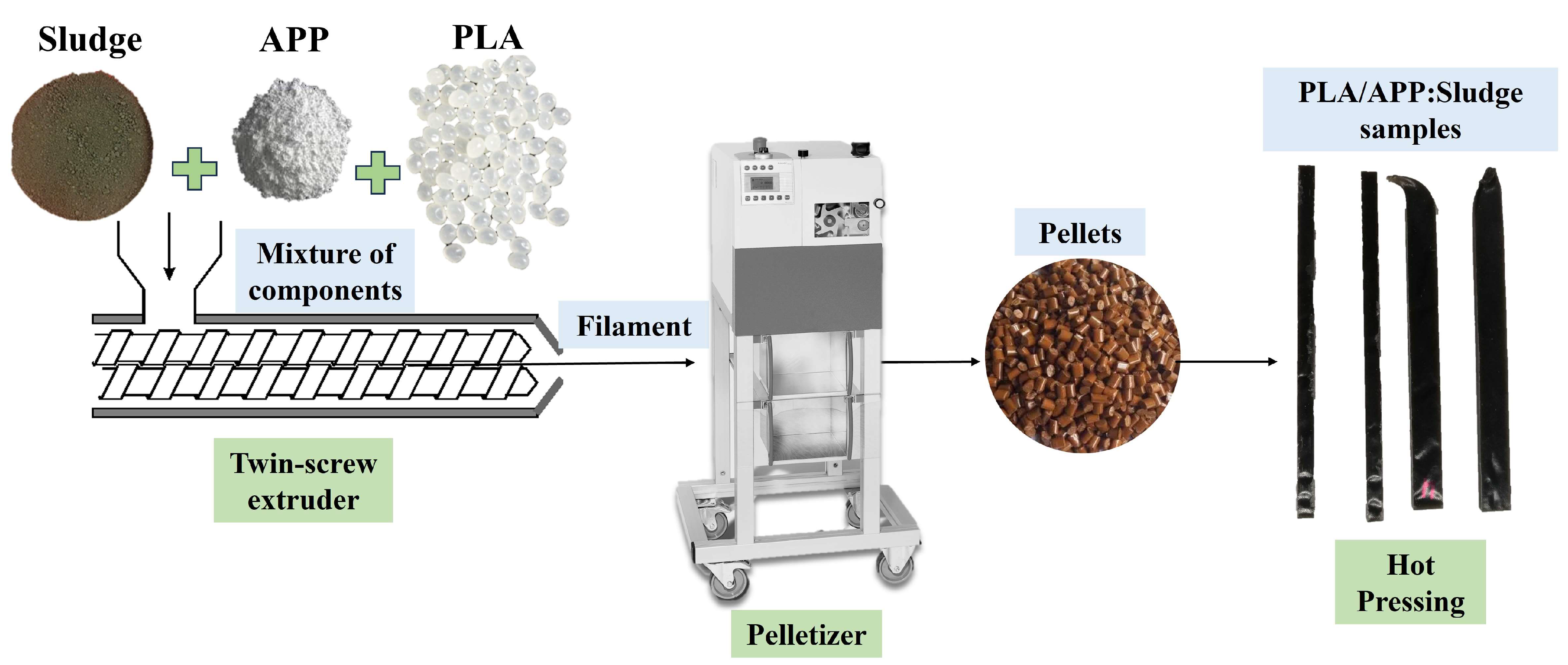

2.2. Sample Preparation

2.2.1. Sludge Treatment

2.2.2. Preparation of PLA Composites

2.3. Characterization

3. Results and Discussion

3.1. Characterization of the Treated Sludge

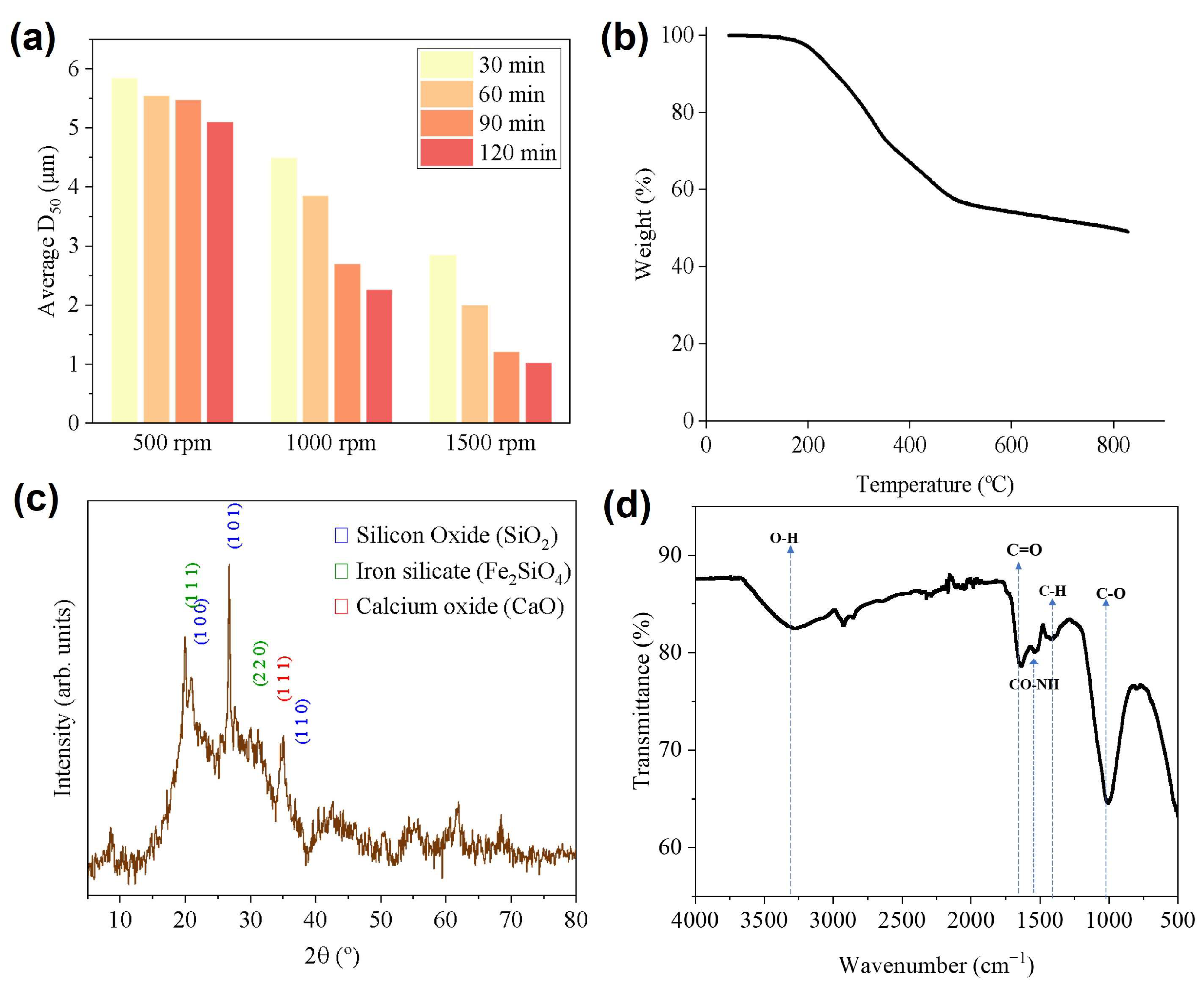

3.1.1. Particle Size Analysis

3.1.2. Thermogravimetric Analysis (TGA)

3.1.3. XRD

3.1.4. FTIR Analysis

3.1.5. SEM-EDX

3.2. PLA Composites

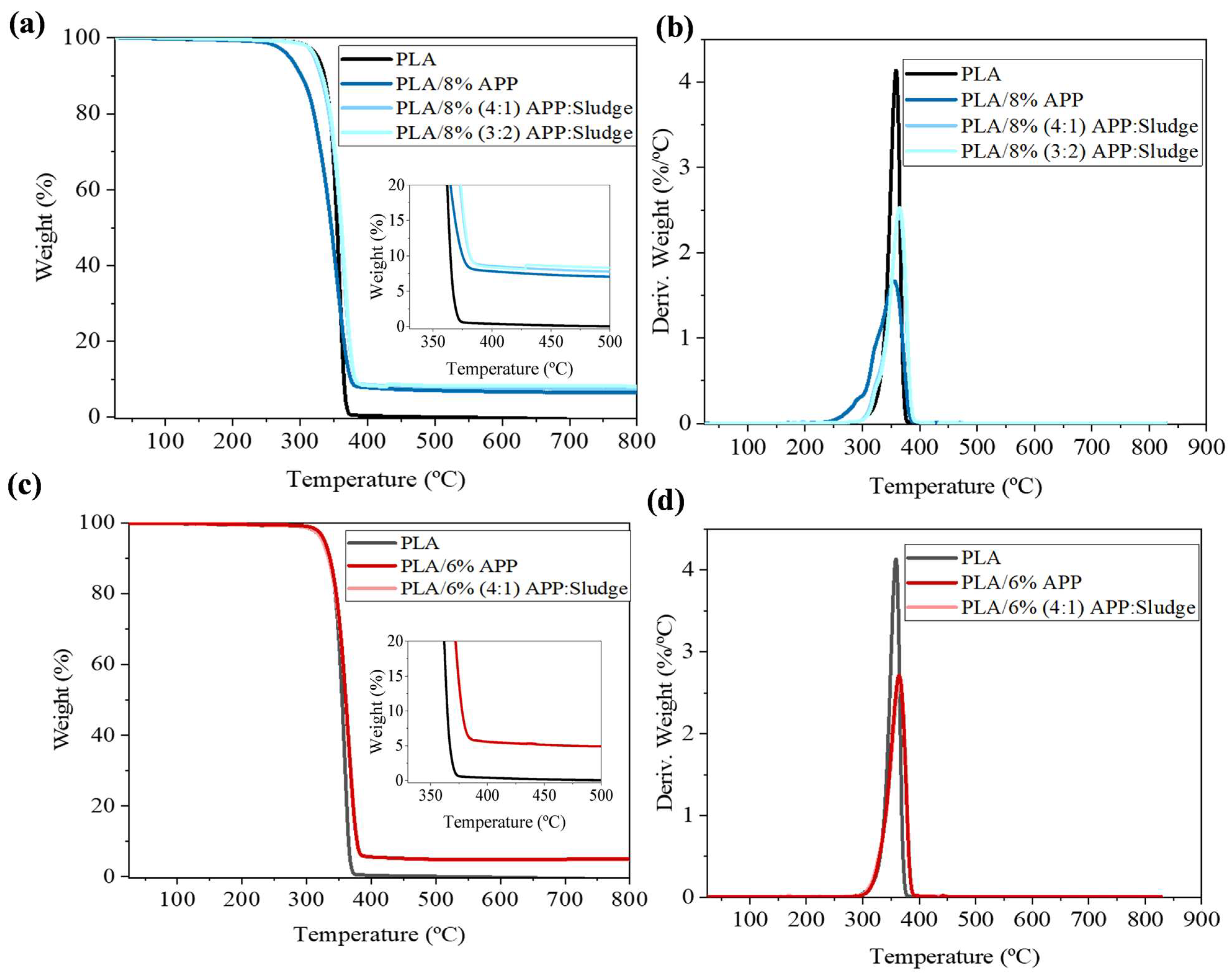

3.2.1. TGA

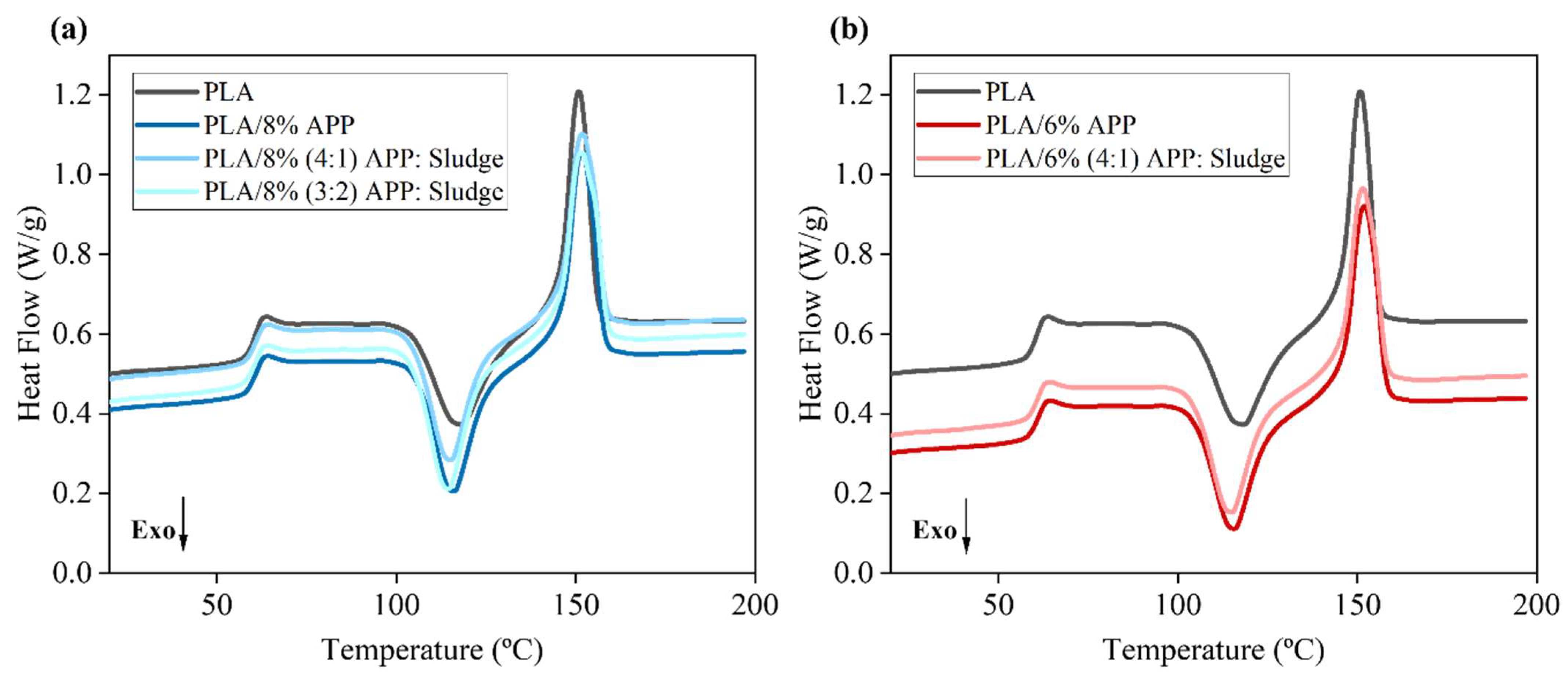

3.2.2. Differential Scanning Calorimetry (DSC)

3.2.3. Rheology Tests

3.2.4. SEM Cross-Section Analysis

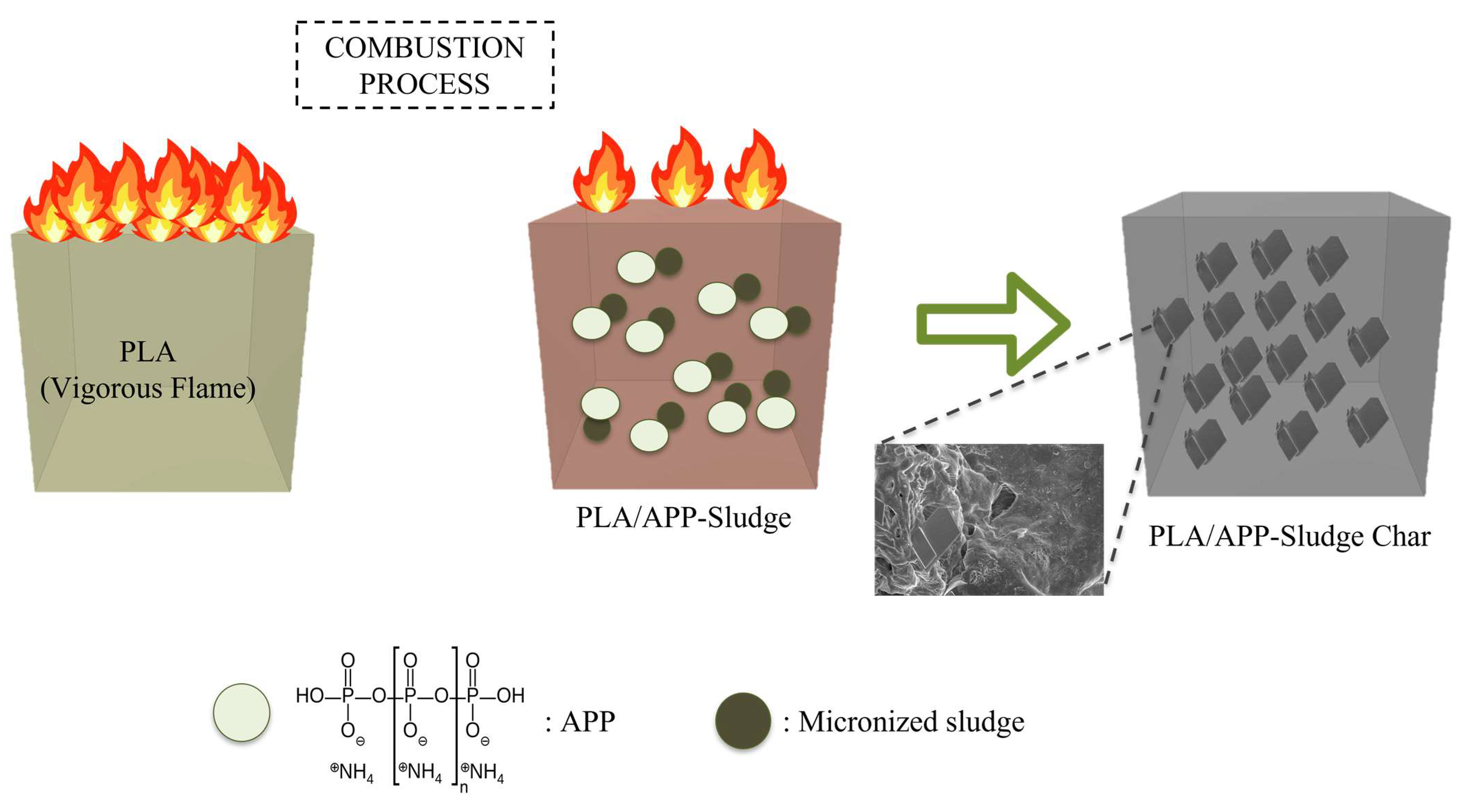

3.3. Fire Retardancy

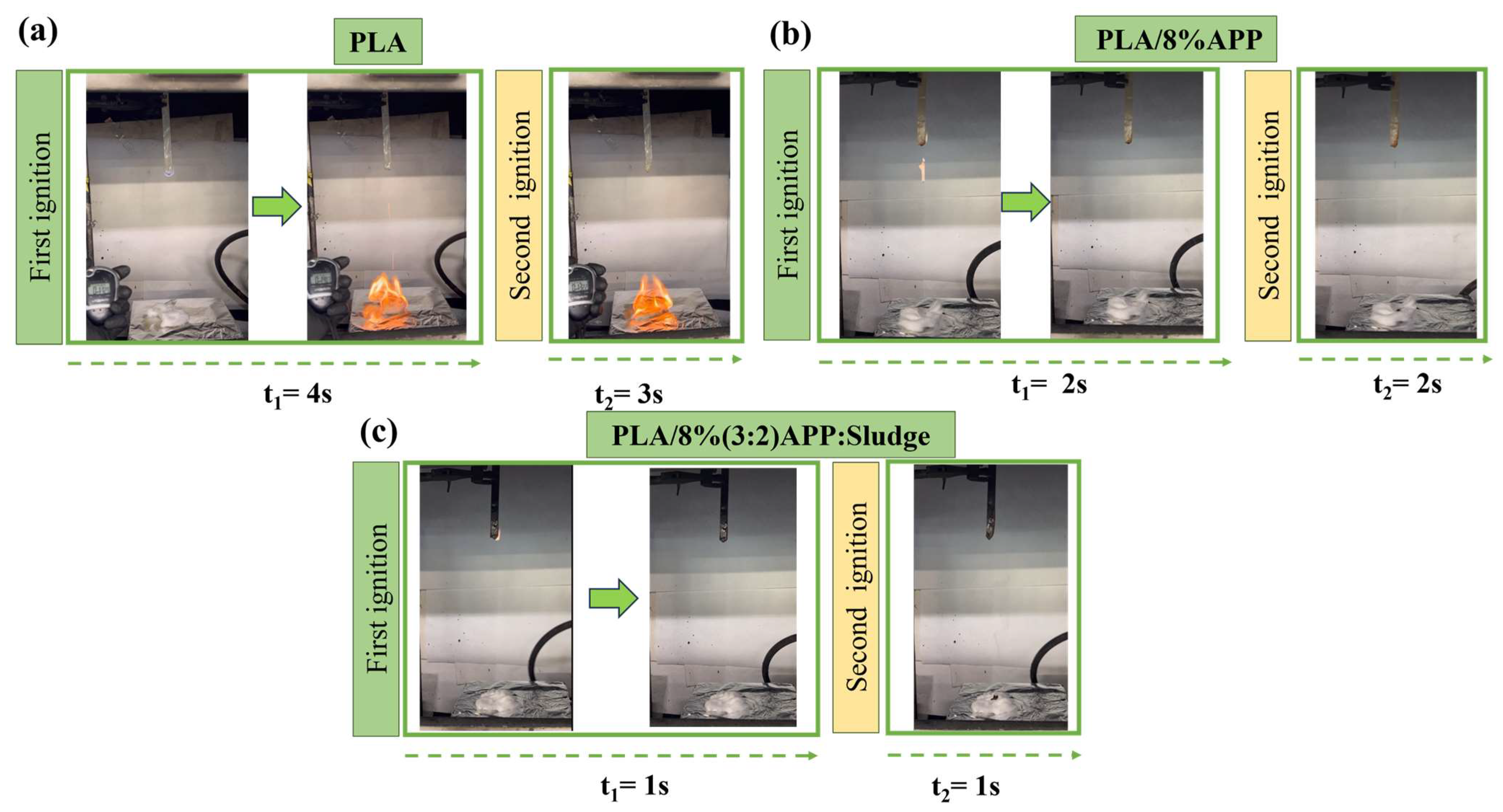

3.3.1. LOI and UL94 Tests

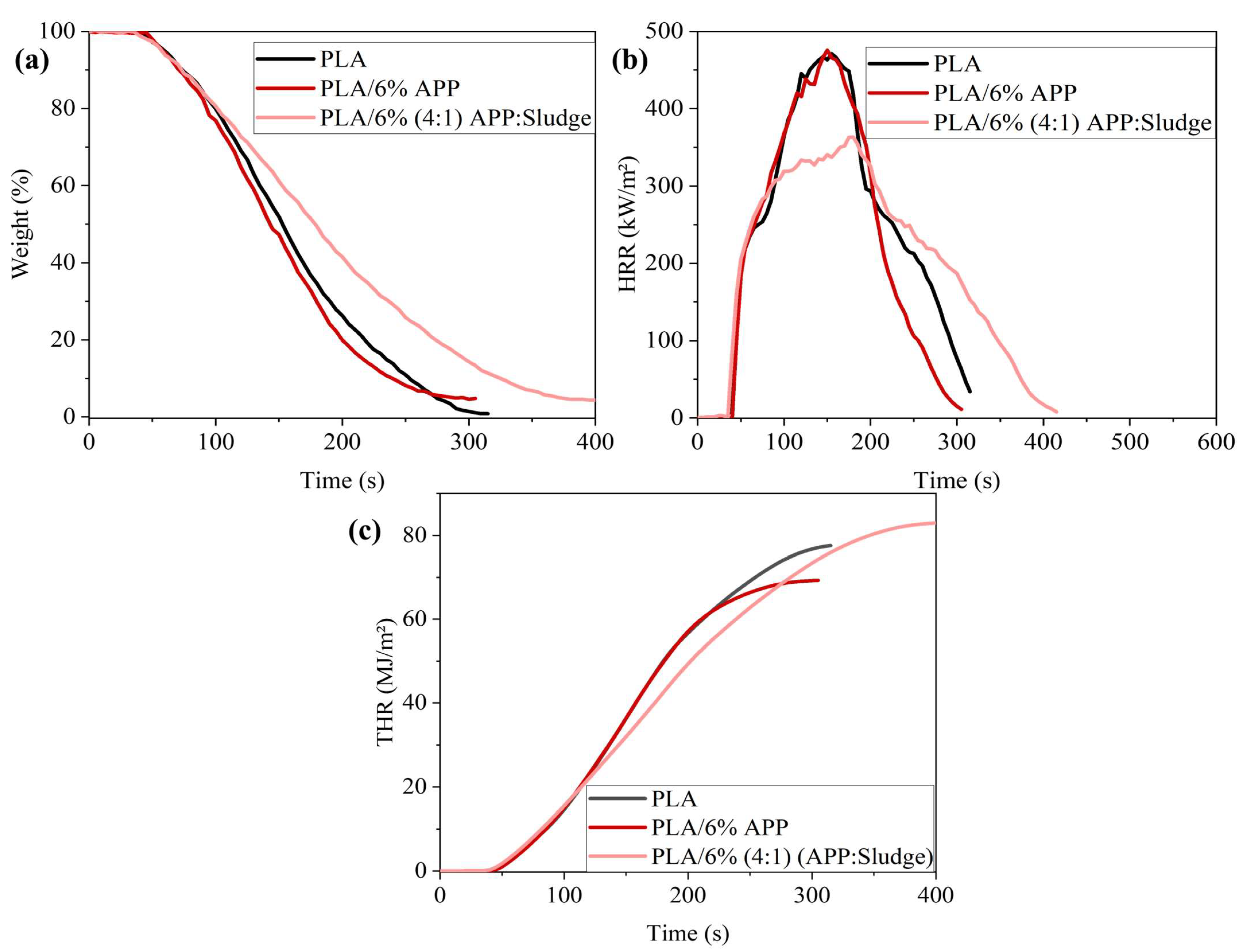

3.3.2. Cone Calorimeter Tests

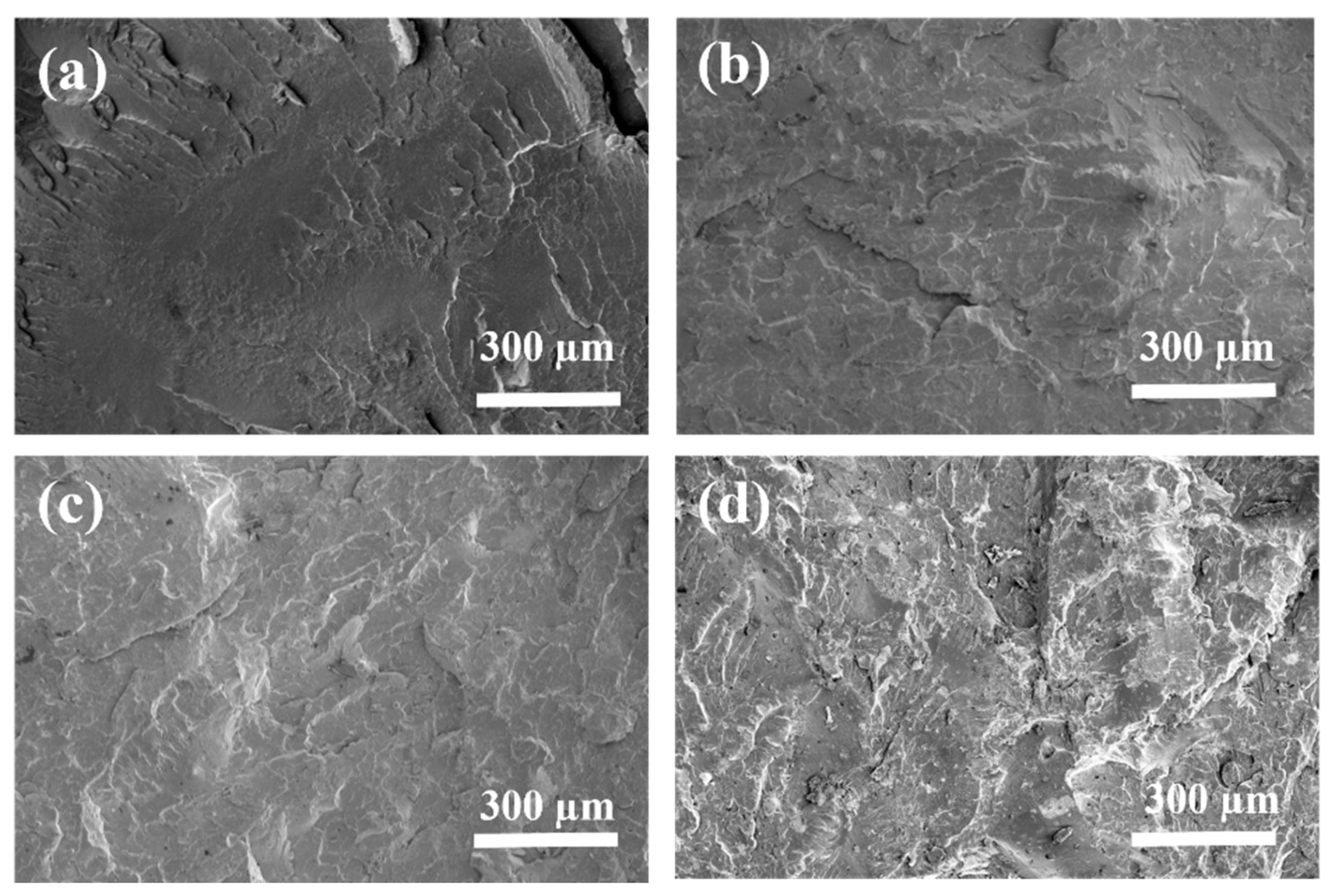

3.3.3. Char Analysis

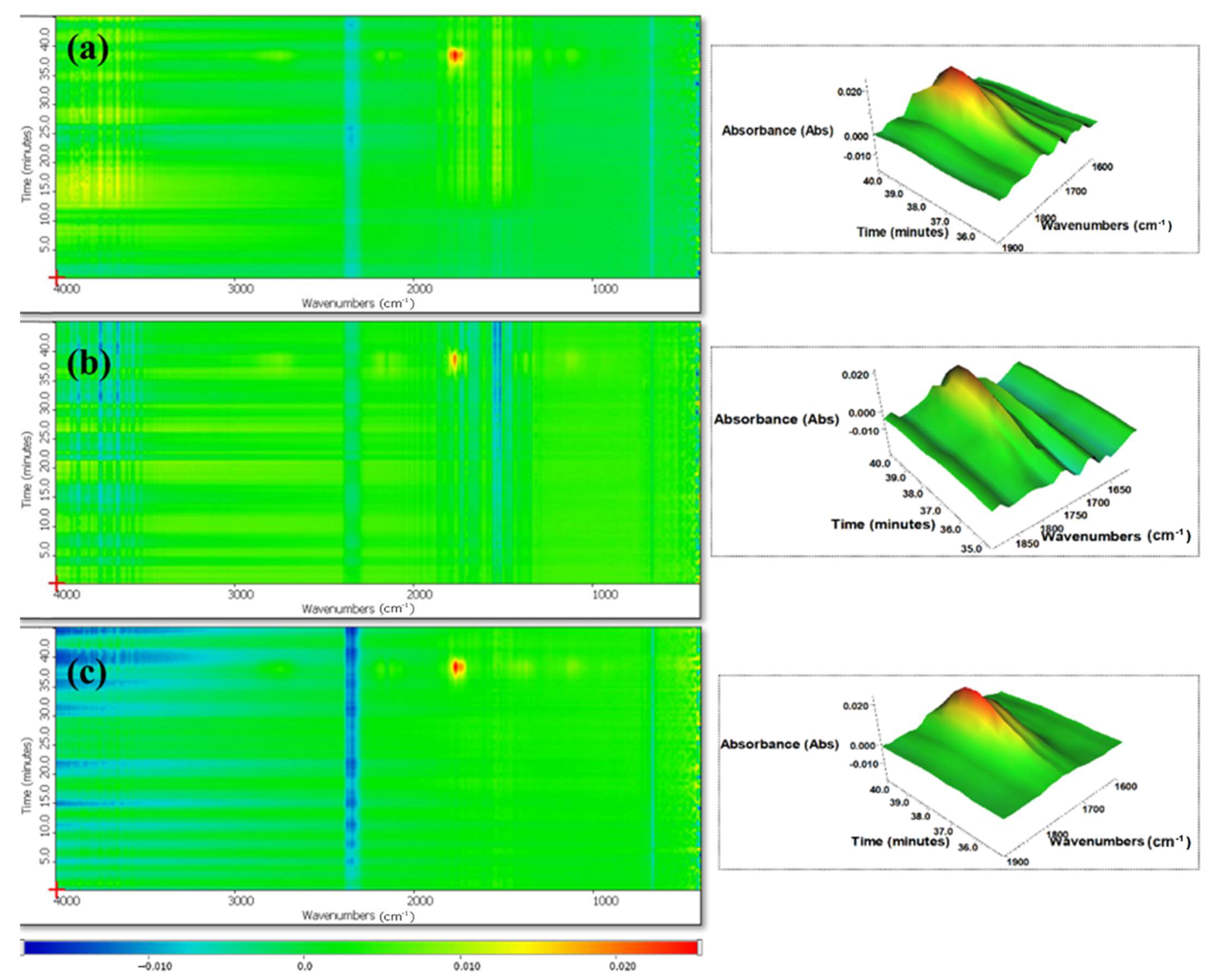

3.4. TGA-FTIR Analysis

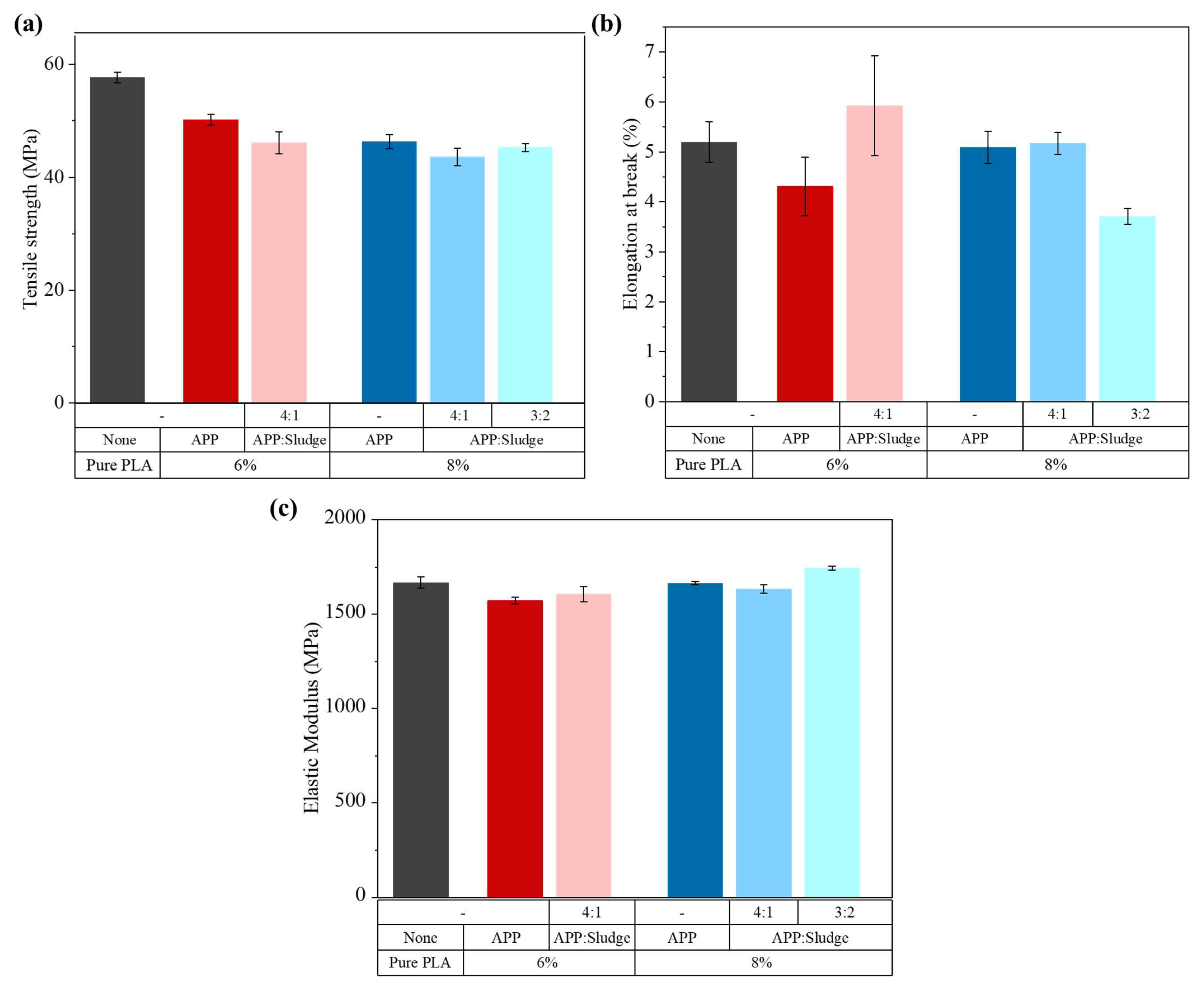

3.5. Mechanical Properties

3.6. Contact Angle Analysis

3.7. Printability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0. A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Kim, N.K.; Mao, N.; Lin, R.; Bhattacharyya, D.; van Loosdrecht, M.C.; Lin, Y. Flame retardant property of flax fabrics coated by extracellular polymeric substances recovered from both activated sludge and aerobic granular sludge. Water Res. 2020, 170, 115344. [Google Scholar] [CrossRef]

- Gao, N.; Kamran, K.; Quan, C.; Williams, P.T. Thermochemical conversion of sewage sludge: A critical review. Prog. Energy Combust. Sci. 2020, 79, 100843. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, X.; Jiang, J.; Han, J.; Li, W.; Li, X.; Leung, K.M.Y.; Snyder, S.A.; Alvarez, P.J. Which Micropollutants in Water Environments Deserve More Attention Globally? Environ. Sci. Technol. 2022, 56, 13–29. [Google Scholar] [CrossRef]

- Cambi. Anaerobic Digestion for Sewage Sludge Management. Biosolids, Technology. 2022. Available online: https://www.cambi.com/blog/anaerobic-digestion/ (accessed on 11 April 2024).

- European Investment Bank—(EIB Projects Directorate—SECTOR PAPERS). Wastewater as a Resource. 2022. Available online: https://www.eib.org/files/publications/wastewater_as_a_resource_en.pdf (accessed on 4 October 2025).

- Eliche-Quesada, D.; Martínez-García, C.; Martínez-Cartas, M.L.M.; Cotes-Palomino, M.T.C.; Pérez-Villarejo, L.; Cruz-Pérez, N.; Corpas-Iglesias, F.A. The use of different forms of waste in the manufacture of ceramic bricks. Appl. Clay Sci. 2011, 52, 270–276. [Google Scholar] [CrossRef]

- Smol, M.; Kulczycka, J.; Henclik, A.; Gorazda, K.; Wzorek, Z. The possible use of sewage sludge ash (SSA) in the construction industry as a way towards a circular economy. J. Clean. Prod. 2015, 95, 45–54. [Google Scholar] [CrossRef]

- Adam, C.; Kley, G.; Simon, F.G. Thermal treatment of municipal sewage sludge aiming at marketable P-fertilisers. Mater. Trans. 2007, 48, 3056–3061. [Google Scholar] [CrossRef]

- European Chemicals Agency. Regulatory Strategy for Flame Retardants; European Chemicals Agency: Helsinki, Finland, 2023. [CrossRef]

- Kim, N.K.; Lin, R.; Bhattacharyya, D.; van Loosdrecht, M.C.M.; Lin, Y. Insight on how biopolymers recovered from aerobic granular wastewater sludge can reduce the flammability of synthetic polymers. Sci. Total Environ. 2022, 805, 150434. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Liu, J.; Yu, C.; Lou, G. Feasibility analysis of continuous extraction of biomaterials from flocculant sludge and potential applications in the fire protection field. J. Environ. Manag. 2024, 370, 122351. [Google Scholar] [CrossRef] [PubMed]

- Jiao, C.; Chen, X.; Zhang, J. Synergistic flame-retardant effects of aluminum oxide with layered double hydroxides in EVA/LDH composites. J. Thermoplast. Compos. Mater. 2010, 23, 501–512. [Google Scholar] [CrossRef]

- Yan, K.; Yuan, M.; Qi, S.; Sun, H.; Wang, K.; Shen, X.; Li, M. Effect of sludge-based suppression materials on the explosive flame characteristics of aluminium dust. Combust. Flame 2024, 260, 113241. [Google Scholar] [CrossRef]

- Kim, N.K.; Bhattacharyya, D.; van Loosdrecht, M.; Lin, Y. Enhancement of fire resistance and mechanical performance of polypropylene composites containing cellulose fibres and extracellular biopolymers from wastewater sludge. Polym. Test. 2023, 127, 108185. [Google Scholar] [CrossRef]

- Qiu, S.; Sun, J.; Li, H.; Gu, X.; Fei, B.; Zhang, S. A green way to simultaneously enhance the mechanical, flame retardant and anti-ultraviolet aging properties of polylactide composites by the incorporation of tannic acid derivatives. Polym. Degrad. Stab. 2022, 196, 109831. [Google Scholar] [CrossRef]

- Yang, X.-M.; Qiu, S.; Yusuf, A.; Sun, J.; Zhai, Z.; Zhao, J.; Yin, G.-Z. Recent advances in flame retardant and mechanical properties of polylactic acid: A review. Int. J. Biol. Macromol. 2023, 243, 125050. [Google Scholar] [CrossRef]

- Xue, Y.; Feng, J.; Ma, Z.; Liu, L.; Zhang, Y.; Dai, J.; Xu, Z.; Bourbigot, S.; Wang, H.; Song, P. Advances and challenges in eco-benign fire-retardant polylactide. Mater. Today Phys. 2021, 21, 100568. [Google Scholar] [CrossRef]

- Xue, Y.; Zuo, X.; Wang, L.; Zhou, Y.; Pan, Y.; Li, J.; Yin, Y.; Li, D.; Yang, R.; Rafailovich, M.H.; et al. Enhanced flame retardancy of poly(lactic acid) with ultra-low loading of ammonium polyphosphate. Compos. B Eng. 2020, 196, 108124. [Google Scholar] [CrossRef]

- Shao, Z.B.; Cui, J.; Li, X.L.; Díaz Palencia, J.L.; Wang, D.Y. Chemically inorganic modified ammonium polyphosphate as eco-friendly flame retardant and its high fire safety for epoxy resin. Compos. Commun. 2021, 28, 100959. [Google Scholar] [CrossRef]

- Wang, J.S.; Wang, D.Y.; Liu, Y.; Ge, X.G.; Wang, Y.Z. Polyamide-enhanced flame retardancy of ammonium polyphosphate on epoxy resin. J. Appl. Polym. Sci. 2008, 108, 2644–2653. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, C.; Zhang, H.; Zhang, Y.; Fang, Z.; Song, R.; Lin, Z.; Feng, J.; Song, P. Combination effects of a bio-based fire retardant and functionalized graphene oxide on a fire retardant and mechanical properties of polylactide. Mater. Today Chem. 2023, 30, 101565. [Google Scholar] [CrossRef]

- Dudziak, M.; Bhatia, R.; Dey, R.; Falkenhagen, J.; Ullrich, M.S.; Thomsen, C.; Schartel, B. Wastewater phosphorus enriched algae as a sustainable flame retardant in polylactide. Polym. Degrad. Stab. 2024, 227, 110885. [Google Scholar] [CrossRef]

- da Rosa, T.S.; Trianoski, R.; Michaud, F.; Yamashita, F.; Iwakiri, S. Sludge fiber waste and kraft lignin powder as fillers in polylactic acid biocomposites: Physical, mechanical, and thermal properties. Polymers 2021, 13, 672. [Google Scholar] [CrossRef]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. Comprehensive characterization of polymeric composites reinforced with silica microparticles using leftover materials of fused filament fabrication 3D printing. Polymers 2021, 13, 2423. [Google Scholar] [CrossRef] [PubMed]

- ASTM D2863-19; Standard Test Method for Measuring the Minimum Oxygen Concentration to Support Candle-Like Combustion of Plastics (Oxygen Index). ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D3801-20; Standard Test Method for Measuring the Comparative Burning Characteristics of Solid Plastics in a Vertical Position (Vertical Burning Test). ASTM International: West Conshohocken, PA, USA, 2020.

- ISO 5660-1:2015; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss—Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Organization for Standardization: Geneva, Switzerland, 2015.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- Bocz, K.; Krain, T.; Marosi, G. Effect of Particle Size of Additives on the Flammability and Mechanical Properties of Intumescent Flame Retarded Polypropylene Compounds. Int. J. Polym. Sci. 2015, 2015, 493710. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Tariq, R.; Hameed, Z.; Ali, I.; Taqvi, S.A.; Naqvi, M.; Niazi, M.; Noor, T.; Farooq, W. Pyrolysis of high-ash sewage sludge: Thermo-kinetic study using TGA and artificial neural networks. Fuel 2018, 233, 529–538. [Google Scholar] [CrossRef]

- Hernandez, A.B.; Ferrasse, J.H.; Akkache, S.; Roche, N. Thermochemical Conversion of Sewage Sludge by TGA-FTIR Analysis: Influence of Mineral Matter Added. Dry. Technol. 2015, 33, 1318–1326. [Google Scholar] [CrossRef]

- Magdziarz, A.; Werle, S. Analysis of the combustion and pyrolysis of dried sewage sludge by TGA and MS. Waste Manag. 2014, 34, 174–179. [Google Scholar] [CrossRef]

- Chen, Z.; Hu, M.; Cui, B.; Liu, S.; Guo, D.; Xiao, B. The effect of bioleaching on sewage sludge pyrolysis. Waste Manag. 2016, 48, 383–388. [Google Scholar] [CrossRef]

- Zhang, B.; Xiong, S.; Xiao, B.; Yu, D.; Jia, X. Mechanism of wet sewage sludge pyrolysis in a tubular furnace. Int. J. Hydrogen Energy 2011, 36, 355–363. [Google Scholar] [CrossRef]

- Zhai, Y.; Peng, W.; Zeng, G.; Fu, Z.; Lan, Y.; Chen, H.; Wang, C.; Fan, X. Pyrolysis characteristics and kinetics of sewage sludge for different sizes and heating rates. J. Therm. Anal. Calorim. 2012, 107, 1015–1022. [Google Scholar] [CrossRef]

- Ranjbar, F.; Karrabi, M.; Danesh, S.; Gheibi, M. Improvement of wastewater sludge dewatering using ferric chloride, aluminum sulfate, and calcium oxide (experimental investigation and descriptive statistical analysis). Water Environ. Res. 2021, 93, 1138–1149. [Google Scholar] [CrossRef]

- Strande, L.; Ronteltap, M.; Brdjanovic, D. Strande Linda RM and BD. In Faecal Sludge Management; IWA Publishing: London, UK, 2014; Volume 13, ISBN 9781780404738. [Google Scholar] [CrossRef]

- Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Sonnier, R.; Dumazert, L. Influence of Ammonium Polyphosphate/Lignin Ratio on Thermal and Fire Behavior of Biobased Thermoplastic: The Case of Polyamide 11. Materials 2019, 12, 1146. [Google Scholar] [CrossRef]

- Fu, S.; Song, P.; Liu, X. Thermal and flame retardancy properties of thermoplastics/natural fiber biocomposites. In Advanced High Strength Natural Fibre Composites in Construction; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 479–508. [Google Scholar] [CrossRef]

- Kim, D.-K.; Lee, S.H.; Hong, S.-K.; Ahn, M.S.; Han, S.W.; Lee, D.H.; Yu, S. Influence of phosphorus-based flame retardants on polypropylene insulation for high-voltage power cable applications. Funct. Compos. Struct. 2022, 4, 045002. [Google Scholar] [CrossRef]

- Moldovan, A.; Sarosi, I.; Cuc, S.; Prodan, D.; Taut, A.C.; Petean, I.; Bombos, D.; Doukeh, R.; Nemes, O.; Man, S.C. Development and characterization of PLA food packaging composite. J. Therm. Anal. Calorim. 2024, 150, 2469–2481. [Google Scholar] [CrossRef]

- Grząbka-Zasadzińska, A.; Klapiszewski, Ł.; Bula, K.; Jesionowski, T.; Borysiak, S. Supermolecular structure and nucleation ability of polylactide-based composites with silica/lignin hybrid fillers. J. Therm. Anal. Calorim. 2016, 126, 263–275. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, G.; Siligardi, C.; Ori, G.; Lazzeri, A. Comparison of precipitated calcium carbonate/polylactic acid and halloysite/polylactic acid nanocomposites. J. Nanomater. 2015, 2015, 905210. [Google Scholar] [CrossRef]

- Petchwattana, N.; Naknaen, P.; Narupai, B. Combination effects of reinforcing filler and impact modifier on the crystallization and toughening performances of poly(Lactic acid). Express Polym. Lett. 2020, 14, 848–859. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Fang, Z.; Hull, T.R.; Kelarakis, A.; Stec, A.A. Mechanism of enhancement of intumescent fire retardancy by metal acetates in polypropylene. Polym. Degrad. Stab. 2017, 136, 139–145. [Google Scholar] [CrossRef]

- Farshbaf Taghinezhad, S.; Mansourieh, M.; Abbasi, A.; Major, I.; Pezzoli, R. Improved compatibilized TPS/PLA blends: Effects of singular and binary compatibilization systems. Carbohydr. Polym. Technol. Appl. 2025, 10, 100819. [Google Scholar] [CrossRef]

- Velghe, I.; Buffel, B.; Cardinaels, R.; Vandeginste, V.; Thielemans, W.; Desplentere, F. Quantification of PLA degradation in the melt phase using a parallel plate rheometer. Polym. Test. 2024, 137, 108506. [Google Scholar] [CrossRef]

- Baudez, J.C.; Slatter, P.; Eshtiaghi, N. The impact of temperature on the rheological behaviour of anaerobic digested sludge. Chem. Eng. J. 2013, 215–216, 182–187. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Carnevale Miino, M.; Bellazzi, S.; Caccamo, F.M.; Durante, A.; Abbà, A. Review of rheological behaviour of sewage sludge and its importance in the management of wastewater treatment plants. Water Pract. Technol. 2022, 17, 483–491. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Zhang, Z. Occurrence, effects, and biodegradation of plastic additives in sludge anaerobic digestion: A review. Environ. Pollut. 2021, 287, 117568. [Google Scholar] [CrossRef]

- Mastalygina, E.E.; Aleksanyan, K.V. Recent Approaches to the Plasticization of Poly(lactic Acid) (PLA) (A Review). Polymers 2024, 16, 87. [Google Scholar] [CrossRef]

- Liu, H.; Huang, Z.; Chen, X.; Zhong, J.; Wang, Y.; He, X.; Liu, X. Preparation and properties of hydrotalcite inorganic filler/polylactic acid composites. J. Phys. Conf. Ser. 2021, 2009, 012009. [Google Scholar] [CrossRef]

- Liu, X.; Wang, T.; Chow, L.C.; Yang, M.; Mitchell, J.W. Effects of inorganic fillers on the thermal and mechanical properties of poly(lactic acid). Int. J. Polym. Sci. 2014, 2014, 827028. [Google Scholar] [CrossRef] [PubMed]

- Ran, G.; Liu, X.; Guo, J.; Sun, J.; Li, H.; Gu, X.; Zhang, S. Improving the flame retardancy and water resistance of polylactic acid by introducing polyborosiloxane microencapsulated ammonium polyphosphate. Compos. B Eng. 2019, 173, 106772. [Google Scholar] [CrossRef]

- Jing, J.; Zhang, Y.; Fang, Z.P.; Wang, D.Y. Core-shell flame retardant/graphene oxide hybrid: A self-assembly strategy towards reducing fire hazard and improving toughness of polylactic acid. Compos. Sci. Technol. 2018, 165, 161–167. [Google Scholar] [CrossRef]

- Liu, T.; Yao, Y.; Zhao, D.; Hu, F.; Yun, C.; Jiang, G.; Shen, Y.; Wang, T. Improving thermal insulation and fire resistance of ceramifiable EVA/ceramic hybrid composites via low temperature sintering and foaming strategy. Ceram. Int. 2024, 50, 6207–6219. [Google Scholar] [CrossRef]

- Fan, F.Q.; Xia ZBin Li, Q.Y.; Li, Z. Effects of inorganic fillers on the shear viscosity and fire retardant performance of waterborne intumescent coatings. Prog. Org. Coat. 2013, 76, 844–851. [Google Scholar] [CrossRef]

- Levchik, S. Phosphorus-based flame retardants. In Non-Halogenated Flame Retardant Handbook; Wiley: Hoboken, NJ, USA, 2021; pp. 23–99. [Google Scholar] [CrossRef]

- Tang, G.; Huang, X.; Ding, H.; Wang, X.; Jiang, S.; Zhou, K.; Wang, B.; Yang, W.; Hu, Y. Combustion properties and thermal degradation behaviors of biobased polylactide composites filled with calcium hypophosphite. RSC Adv. 2014, 4, 8985–8993. [Google Scholar] [CrossRef]

- Wang, F.; Liu, H.; Yan, L. Comparative study of fire resistance and char formation of intumescent fire-retardant coatings reinforced with three types of shell bio-fillers. Polymers 2021, 13, 4333. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.H. Influence of filler surface characteristics on morphological, physical, acoustic properties of polyurethane composite foams filled with inorganic fillers. Compos. Sci. Technol. 2017, 146, 147–154. [Google Scholar] [CrossRef]

| Sample | PLA (wt%) | APP (wt%) | Sludge (wt%) |

|---|---|---|---|

| PLA | 100 | 0 | 0 |

| PLA/8%APP | 92 | 8 | 0 |

| PLA/8% (3:2) APP:Sludge | 92 | 4.8 | 3.2 |

| PLA/8% (4:1) APP:Sludge | 92 | 6.4 | 1.6 |

| PLA/6%APP | 94 | 6.0 | 0 |

| PLA/6% (4:1) APP:Sludge | 94 | 4.8 | 1.2 |

| Sample | Tg (°C) | Tc (°C) | Tm (°C) | ΔHc − ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|

| PLA | 63.3 | 118.2 | 150.9 | 1.6 | 1.7 |

| PLA/8% APP | 63.5 | 116.1 | 151.8 | 0.9 | 1.0 |

| PLA/8% (3:2) APP:Sludge | 63.2 | 114.6 | 151.4 | 1.6 | 1.9 |

| PLA/8% (4:1) APP:Sludge | 63.4 | 115.1 | 152.0 | 1.9 | 2.2 |

| PLA/6% APP | 63.7 | 115.8 | 152.1 | 1.4 | 1.6 |

| PLA/6% (4:1) APP:Sludge | 63.5 | 115.0 | 151.4 | 2.4 | 2.7 |

| UL-94 (3.2 mm) | |||||

|---|---|---|---|---|---|

| Sample | (s) | Cotton Ignition (Yes/No) | Dripping (Yes/No) | Rating | LOI (%) |

| PLA | 5 | Y | Y (severe) | V-2 | 22.8 |

| PLA/8%APP | 4 | N | Y | V-0 | 31.4 |

| PLA/8% (4:1) APP:Sludge | 6 | N | Y | V-0 | 33.0 |

| PLA/8% (3:2) APP:Sludge | 2 | N | Y | V-0 | 33.0 |

| PLA/6%APP | 3 | N | Y | V-0 | 31.4 |

| PLA/6% (4:1) APP:Sludge | 5 | N | Y | V-0 | 33.0 |

| PLA/6% (3:2) APP:Sludge | 2 | Y | Y | V-2 | 32.0 |

| PLA/5%APP | 11 | Y | Y | V-2 | 30.4 |

| Sample | TTI (s) | pHRR (kW/m2) | THR (MJ/m2) | TSP (m2) | MARHE (kW/m2) | Char Residue @700 °C (wt%) |

|---|---|---|---|---|---|---|

| PLA | 37 ± 3 | 471 ± 7 | 77 ± 2 | 0.31 ± 0.1 | 284 ± 9 | 0.4 ± 0.2 |

| PLA/6%APP | 39 ± 4 | 476 ± 4 | 69 ± 1 | 2.31 ± 0.3 | 286 ± 6 | 2.0 ± 0.4 |

| PLA/6% (4:1) APP:Sludge | 34 ± 2 | 363 ± 6 | 83 ± 1 | 1.60 ± 0.5 | 251 ± 7 | 2.0 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de la Vega, J.; Vázquez-López, A.; Wang, D.-Y. Enhancement of Poly(Lactic Acid) Fire Retardancy Through the Incorporation of Sludge Residue as a Synergistic Additive. Polymers 2025, 17, 2717. https://doi.org/10.3390/polym17202717

de la Vega J, Vázquez-López A, Wang D-Y. Enhancement of Poly(Lactic Acid) Fire Retardancy Through the Incorporation of Sludge Residue as a Synergistic Additive. Polymers. 2025; 17(20):2717. https://doi.org/10.3390/polym17202717

Chicago/Turabian Stylede la Vega, Jimena, Antonio Vázquez-López, and De-Yi Wang. 2025. "Enhancement of Poly(Lactic Acid) Fire Retardancy Through the Incorporation of Sludge Residue as a Synergistic Additive" Polymers 17, no. 20: 2717. https://doi.org/10.3390/polym17202717

APA Stylede la Vega, J., Vázquez-López, A., & Wang, D.-Y. (2025). Enhancement of Poly(Lactic Acid) Fire Retardancy Through the Incorporation of Sludge Residue as a Synergistic Additive. Polymers, 17(20), 2717. https://doi.org/10.3390/polym17202717