Flexural Response Comparison of Nylon-Based 3D-Printed Glass Fiber Composites and Epoxy-Based Conventional Glass Fiber Composites in Cementitious and Polymer Concretes

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Conventional GFRP Composite

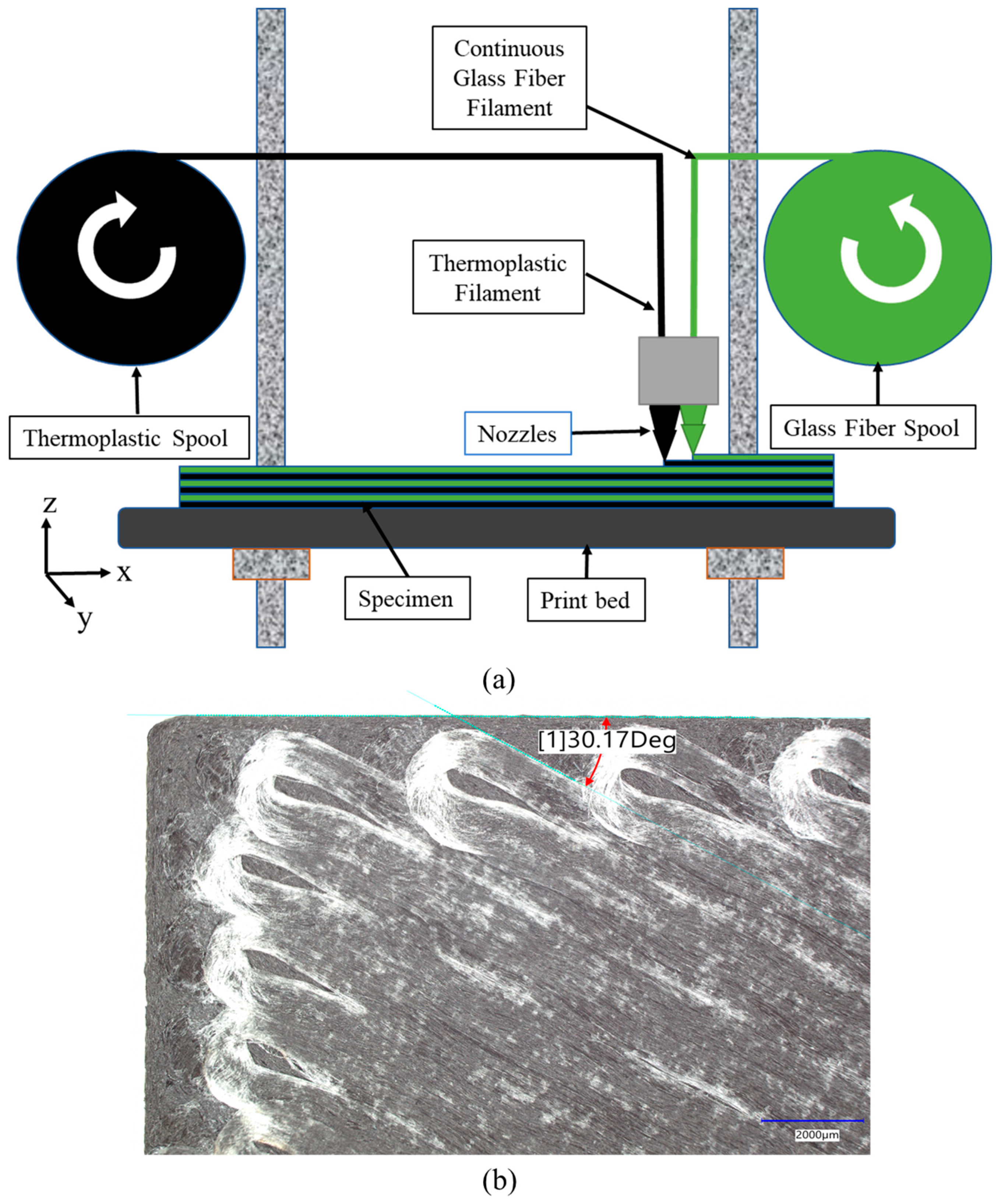

2.2. 3D-Printed GFRP Composite

2.3. Concrete Mixing and Fabrication

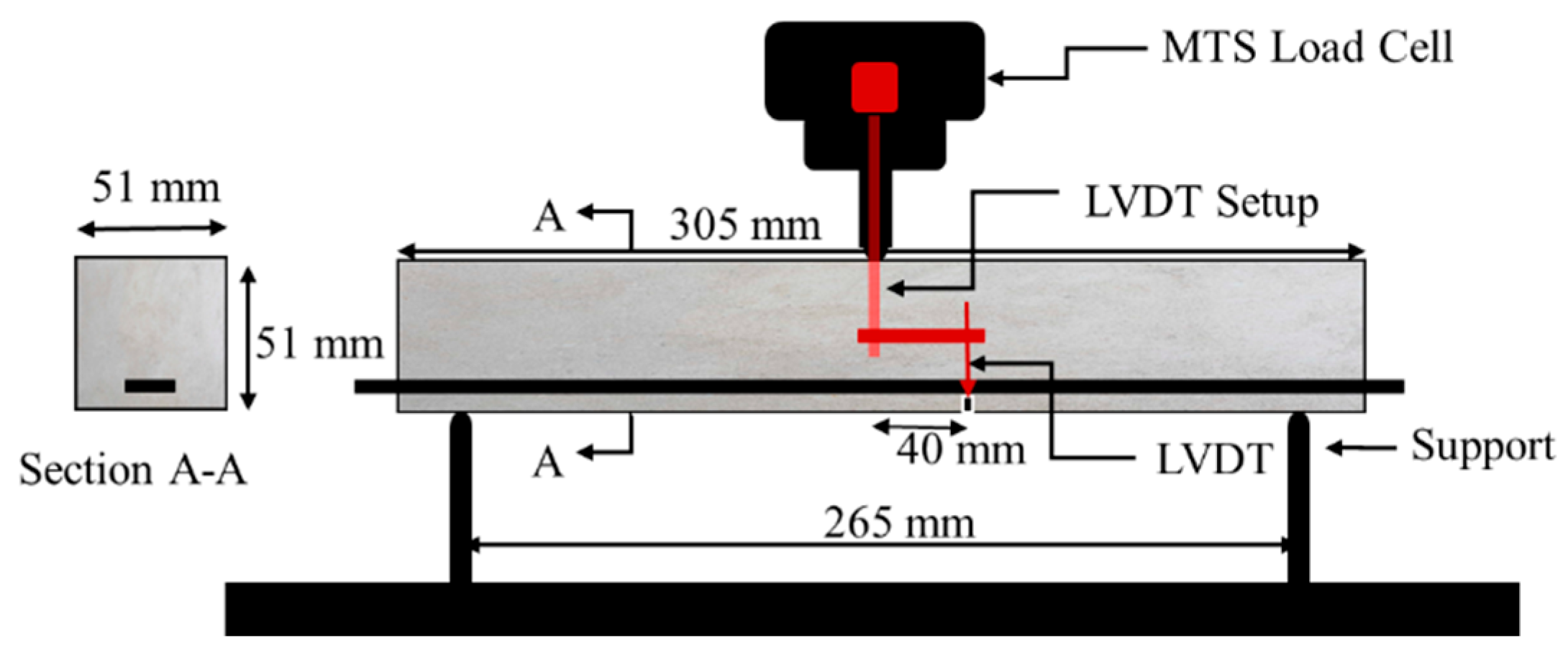

2.4. Flexural Test Setup

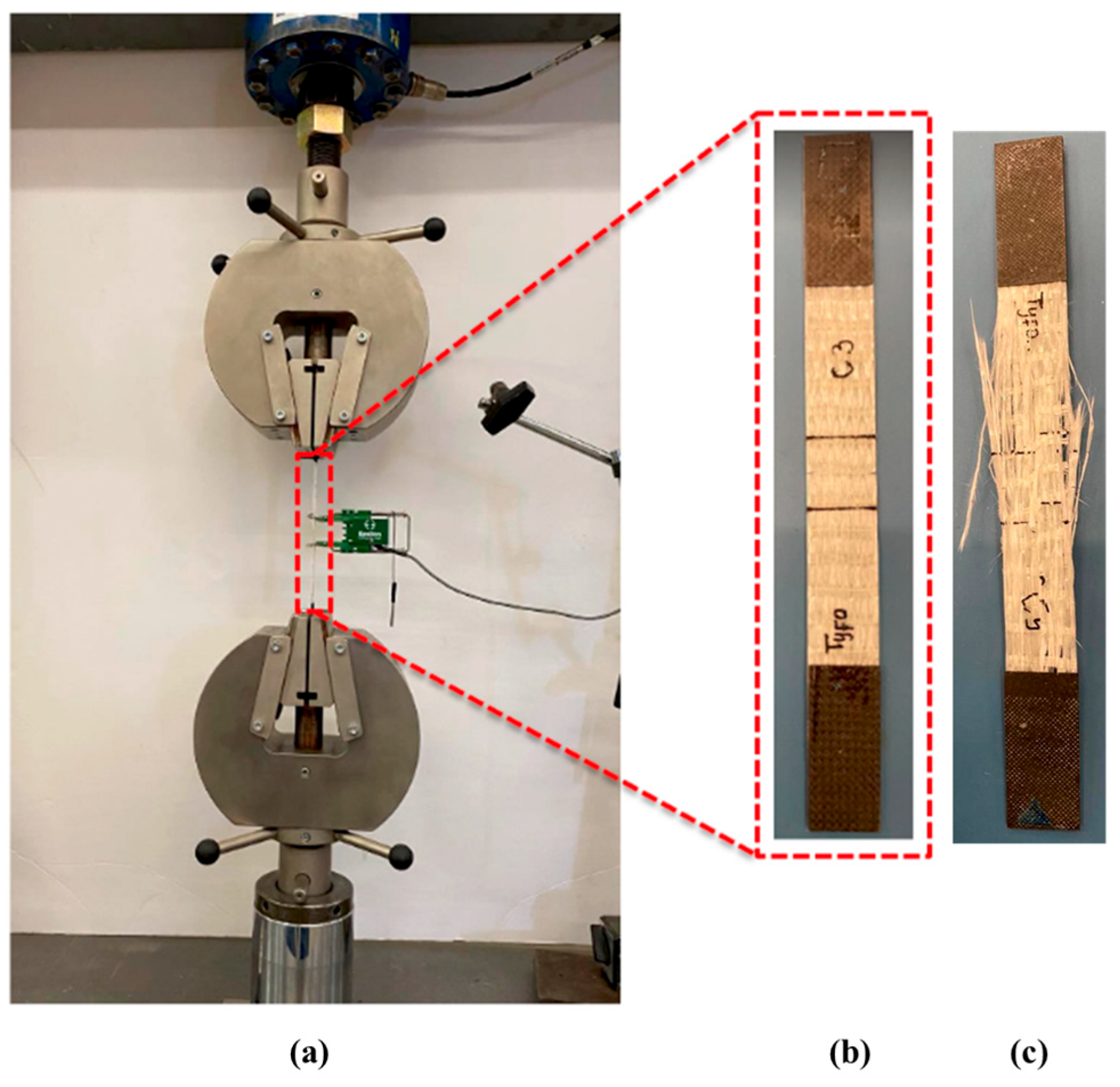

2.5. Tension Test Setup

2.6. Volume Fraction

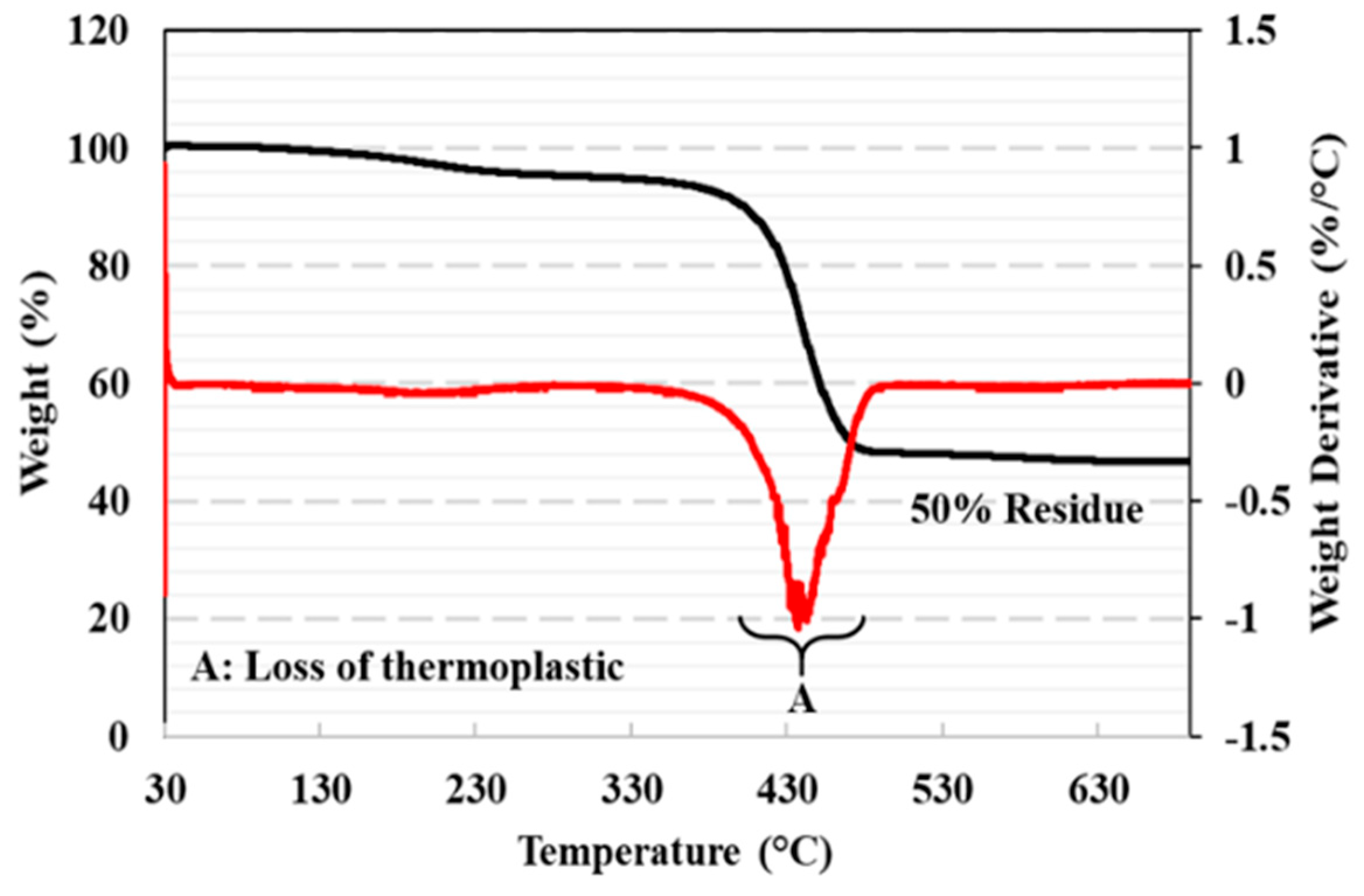

2.7. Thermogravimetric Analysis (TGA)

2.8. Microscopic Analysis

3. Results and Discussion

3.1. Concrete Properties

3.2. GFRP Composite Properties

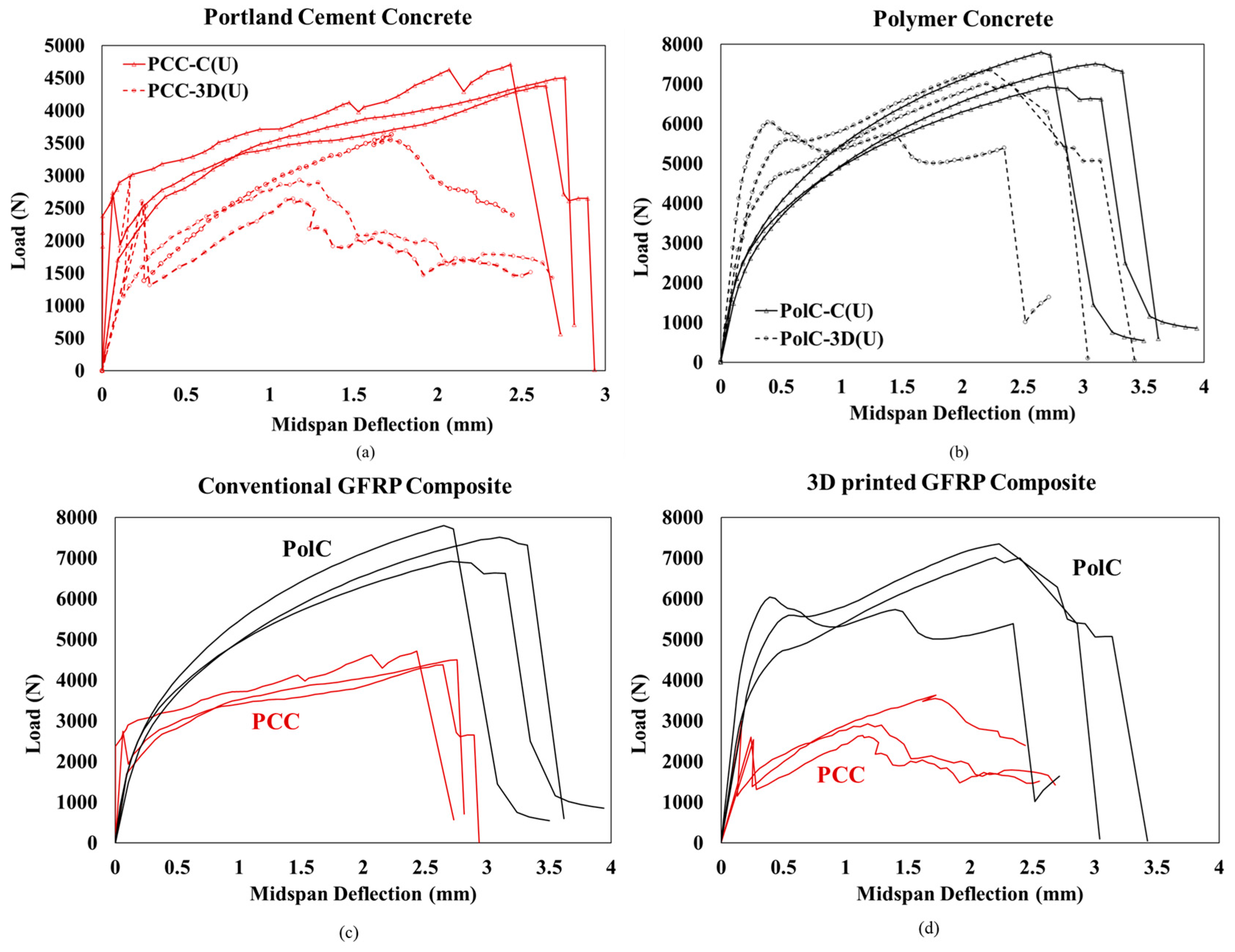

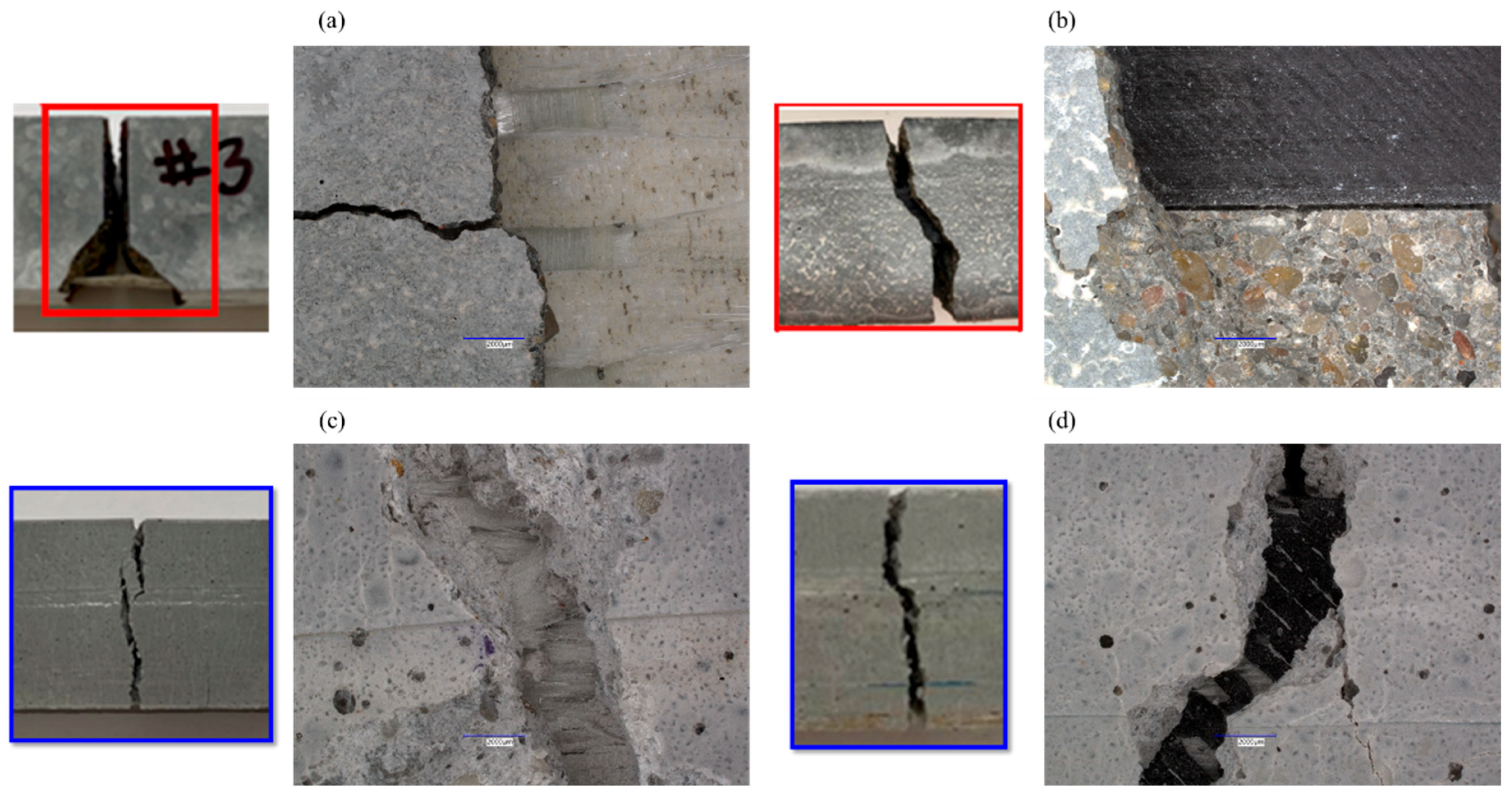

3.3. Load–Deflection of Concrete Specimens with Reinforcement

4. Conclusions

- Overall, the study showed that 3D-printed FRP composites can be a viable reinforcement material in terms of comparable mechanical strength and deflections to failure for cementitious and polymer concretes.

- Compared to concretes with no FRP reinforcement, the incorporation of a 3D-printed GFRP composite in cementitious concrete showed a 16.8% increase in load-carrying capacity, and in polymer concrete, incorporation showed a 90% increase in flexural capacity. This increase is much more evident in polymer concrete when compared to cementitious concrete.

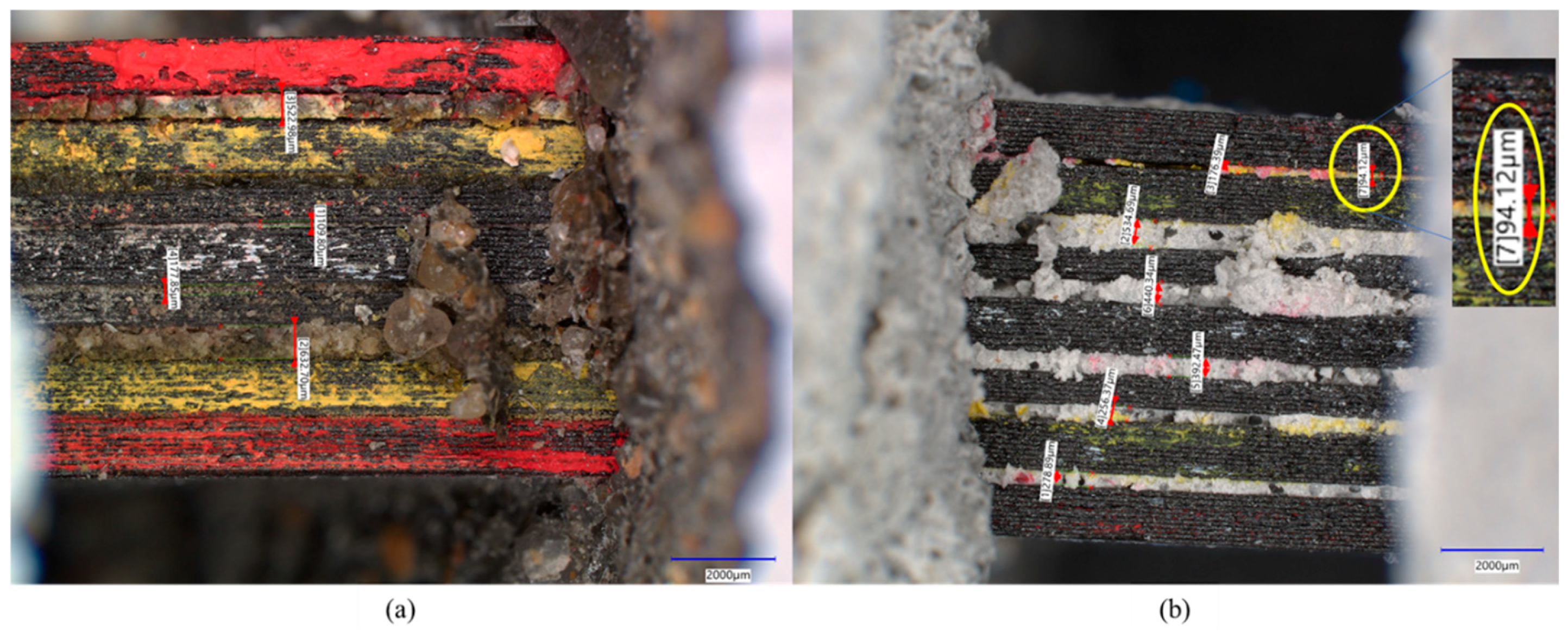

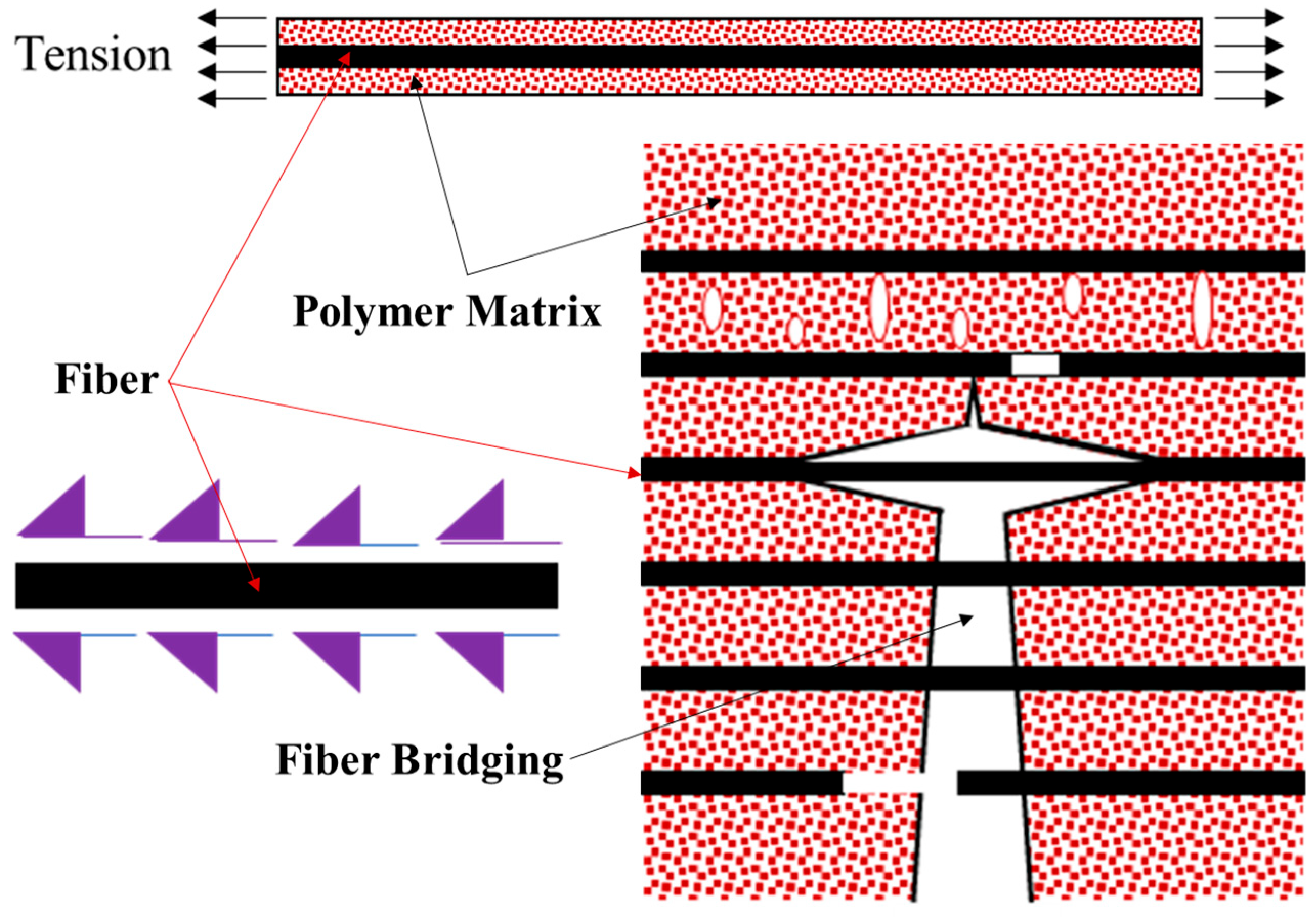

- In addition to demonstrating the viability of 3D-printed FRP composites as flexural reinforcement in concrete, this study also provides key insights into the capability of polymer concrete to penetrate layers of at least 90 microns in 3D-printed composites, providing fiber bridging capabilities and better engagement resulting in improved bond strength that is reflected in mechanical performance.

- The experimental observations in this study create new pathways of 3D-printable reinforcement for different concrete applications. Moreover, 3D printing offers much more flexibility in achieving a combination of fiber orientations, which is highly challenging in conventional FRP fabrication techniques.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agarwal, K.; Kuchipudi, S.K.; Girard, B.; Houser, M. Mechanical properties of fiber reinforced polymer composites: A comparative study of conventional and additive manufacturing methods. J. Compos. Mater. 2018, 52, 3173–3181. [Google Scholar] [CrossRef]

- Bai, J. Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Bank, L.C. Composites for Construction: Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Chennareddy, R.; Tuwair, H.; Kandil, U.F.; ElGawady, M.; Taha, M.R. UV-resistant GFRP composite using carbon nanotubes. Constr. Build. Mater. 2019, 220, 679–689. [Google Scholar] [CrossRef]

- Lau, D. 8—Hybrid fiber-reinforced polymer (FRP) composites for structural applications. In Developments in Fiber-Reinforced Polymer (FRP) Composites for Civil Engineering; Uddin, N., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 205–225. [Google Scholar]

- Gunaslan, S.E.; Karasin, A.; Öncü, M.E. Properties of FRP Materials for Strengthening. Int. J. Innov. Sci. Eng. Technol. 2014, 1, 656–660. [Google Scholar]

- Sonnenschein, R.; Gajdosova, K.; Holly, I. FRP composites and their using in the construction of bridges. Procedia Eng. 2016, 161, 477–482. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Dickson, A.N.; Barry, J.N.; McDonnell, K.A.; Dowling, D.P. Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing. Addit. Manuf. 2017, 16, 146–152. [Google Scholar] [CrossRef]

- El-Hajjar, R.; Tan, H.; Pillai, K.M. 3—Advanced processing techniques for composite materials for structural applications. In Developments in Fiber-Reinforced Polymer (FRP) Composites for Civil Engineering; Uddin, N., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 54–77e. [Google Scholar]

- Gowayed, Y. 1—Types of fiber and fiber arrangement in fiber-reinforced polymer (FRP) composites. In Developments in Fiber-Reinforced Polymer (FRP) Composites for Civil Engineering; Uddin, N., Ed.; Woodhead Publishing: Cambridge, UK, 2013; pp. 3–17. [Google Scholar]

- Krishna, S.V.; Kumar, M.P. Properties Evaluation of Chopped, Bi-Directional and Uni-Directional Glass Fibre Reinforced Epoxy based Composites. Int. J. Innov. Res. Sci. Technol. 2016, 3, 372–376. [Google Scholar]

- Pervaiz, S.; Qureshi, T.A.; Kashwani, G.; Kannan, S. 3D Printing of Fiber-Reinforced Plastic Composites Using Fused Deposition Modeling: A Status Review. Materials 2021, 14, 4520. [Google Scholar] [CrossRef]

- Salmi, M. Additive manufacturing processes in medical applications. Materials 2021, 14, 191. [Google Scholar] [CrossRef]

- Tse, L.; Kapila, S.; Barton, K. Contoured 3D printing of fiber reinforced polymers. In 2016 International Solid Freeform Fabrication Symposium; University of Texas at Austin: Austin, TX, USA, 2016. [Google Scholar]

- Tighiouart, B.; Benmokrane, B.; Gao, D. Investigation of bond in concrete member with fibre reinforced polymer (FRP) bars. Constr. Build. Mater. 1998, 12, 453–462. [Google Scholar] [CrossRef]

- Shamass, R.; Cashell, K. Experimental investigation into the flexural behaviour of basalt FRP reinforced concrete members. Eng. Struct. 2020, 220, 110950. [Google Scholar] [CrossRef]

- Kara, I.F.; Ashour, A.F. Flexural performance of FRP reinforced concrete beams. Compos. Struct. 2012, 94, 1616–1625. [Google Scholar] [CrossRef]

- Theriault, M.; Benmokrane, B. Effects of FRP reinforcement ratio and concrete strength on flexural behavior of concrete beams. J. Compos. Constr. 1998, 2, 7–16. [Google Scholar] [CrossRef]

- Ke, L.; Li, Y.; Li, C.; Cheng, Z.; Ma, K.; Zeng, J. Bond behavior of CFRP-strengthened steel structures and its environmental influence factors: A critical review. Sustain. Struct. 2024, 4, 000038. [Google Scholar] [CrossRef]

- Vemuganti, S. Pseudo-Ductile 3D Printed Fiber Reinforced Polymer Composites; The University of New Mexico: Albuquerque, NM, USA, 2021. [Google Scholar]

- Vemuganti, S.; Soliman, E.; Reda Taha, M. 3D-printed pseudo ductile fiber-reinforced polymer (FRP) composite using discrete fiber orientations. Fibers 2020, 8, 53. [Google Scholar] [CrossRef]

- Vemuganti, S.; Soliman, E.; Taha, M.R. Exploiting fiber control for delayed failure in 3D printed fiber reinforced polymer composites. Compos. Part B Eng. 2023, 251, 110495. [Google Scholar] [CrossRef]

- Xian, G.; Zhou, P.; Li, C.; Dong, S.; Du, H.; Tian, J.; Guo, R.; Peng, Z.; Zhang, Z.; He, T. Mechanical properties evaluation of glass fiber reinforced thermoplastic composite plate under combined bending loading and water immersion. Constr. Build. Mater. 2024, 440, 137470. [Google Scholar] [CrossRef]

- Du, H.; Xian, G.; Tian, J.; Ma, Z.; Li, C.; Xin, M.; Zhang, Y. Effect of fiber surface treatment with silane coupling agents and carbon nanotubes on mechanical properties of carbon fiber reinforced polyamide 6 composites. Polym. Compos. 2024, in press. [CrossRef]

- Farina, I.; Fabbrocino, F.; Carpentieri, G.; Modano, M.; Amendola, A.; Goodall, R.; Feo, L.; Fraternali, F. On the reinforcement of cement mortars through 3D printed polymeric and metallic fibers. Compos. Part B Eng. 2016, 90, 76–85. [Google Scholar] [CrossRef]

- Feng, P.; Meng, X.; Zhang, H. Mechanical behavior of FRP sheets reinforced 3D elements printed with cementitious materials. Compos. Struct. 2015, 134, 331–342. [Google Scholar] [CrossRef]

- San-José, J.T.; Vegas, I.; Meyer, F. Structural analysis of FRP reinforced polymer concrete material. Constr. Build. Mater. 2006, 20, 971–981. [Google Scholar] [CrossRef]

- Tavares, C.; Ribeiro, M.; Ferreira, A.; Guedes, R. Creep behaviour of FRP-reinforced polymer concrete. Compos. Struct. 2002, 57, 47–51. [Google Scholar] [CrossRef]

- Vemuganti, S.; Soliman, E.; Taha, M.M.R. Manipulating interfacial bond for controlling load transfer in 3D printed fiber reinforced polymer composites. J. Reinf. Plast. Compos. 2024, 07316844241238502. [Google Scholar] [CrossRef]

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C579-18; Standard Test Methods for Compressive Strength of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer Concretes. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C78/C78M-18; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C580-18; Standard Test Method for Flexural Strength and Modulus of Elasticity of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer Concretes. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D3171-22; Standard Test Methods for Constituent Content of Composite Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- Murcia, D.H.; Çomak, B.; Soliman, E.; Taha, M.M.R. Flexural behavior of a novel textile-reinforced polymer concrete. Polymers 2022, 14, 176. [Google Scholar] [CrossRef] [PubMed]

- Missau, J.; da Rocha, J.d.G.; Dotto, G.L.; Bertuol, D.A.; Ceron, L.P.; Tanabe, E.H. Purification of crude wax using a filter medium modified with a nanofiber coating. Chem. Eng. Res. Des. 2018, 136, 734–743. [Google Scholar] [CrossRef]

- Choi, S.-W.; Choi, J.; Lee, S.-C. Probabilistic analysis for strain-hardening behavior of high-performance fiber-reinforced concrete. Materials 2019, 12, 2399. [Google Scholar] [CrossRef]

| Conventional GFRP composite | ||

| Dry fiber in fabric | Epoxy matrix 1 | |

| Properties | Manufacturer value | Manufacturer value |

| Tensile strength (GPa) | 3.24 | 0.072 |

| Tensile modulus (GPa) | 72.4 | 3.18 |

| Ultimate elongation (%) | 4.5 | 5 |

| Density (g/cc) | 2.55 | 1.11 |

| 3D-printed GFRP composite | ||

| Fiberglass filament | Nylon 66 thermoplastic | |

| Properties | Manufacturer value | Manufacturer value |

| Density (g/cc) | 2.55 | 1.11 |

| Spool volume (cc) | 150 | 800 |

| Filament diameter (mm) | 0.35 | 1.75 |

| Melting temperature (°C) | 229 | 273 |

| Materials | Polymer Concrete | Portland Cement Concrete |

|---|---|---|

| Aggregate | 2002 | 2350.6 |

| Water | - | 352.7 |

| Superplasticizer | - | 9.1 |

| Polymer Resin | 251 | - |

| Portland Cement | - | 1175.3 |

| Properties | Conventional VAHT | 3D-Printed Unidirectional 1 | 3D-Printed Multidirectional 1 |

|---|---|---|---|

| Fiber volume fraction (%) | 42.5 ± 0.4 | 24.3 ± 0.1 | - |

| Tensile modulus (GPa) | 29.2 ± 0.8 | 16.60 ± 0.2 | 6.4 ± 0.5 |

| Tensile strength (MPa) | 526.4 ± 2.6 | 624 ± 6.5 | 146 ± 3.3 |

| Strain at first capacity drop (%) | - | - | 2.17 ± 0.11 |

| Strain at second capacity drop (%) | - | - | 2.6 ± 0.2 |

| Strain at third capacity drop (%) | - | - | 3.6 ± 0.2 |

| Strain at failure (%) | 1.8 ± 0.13 | 3.86 ± 0.12 | 3.68 ± 0.22 |

| Ductility index (%) | 0 | 0 | 53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haibe, A.A.; Vemuganti, S. Flexural Response Comparison of Nylon-Based 3D-Printed Glass Fiber Composites and Epoxy-Based Conventional Glass Fiber Composites in Cementitious and Polymer Concretes. Polymers 2025, 17, 218. https://doi.org/10.3390/polym17020218

Haibe AA, Vemuganti S. Flexural Response Comparison of Nylon-Based 3D-Printed Glass Fiber Composites and Epoxy-Based Conventional Glass Fiber Composites in Cementitious and Polymer Concretes. Polymers. 2025; 17(2):218. https://doi.org/10.3390/polym17020218

Chicago/Turabian StyleHaibe, Abdirahman Ahmed, and Shreya Vemuganti. 2025. "Flexural Response Comparison of Nylon-Based 3D-Printed Glass Fiber Composites and Epoxy-Based Conventional Glass Fiber Composites in Cementitious and Polymer Concretes" Polymers 17, no. 2: 218. https://doi.org/10.3390/polym17020218

APA StyleHaibe, A. A., & Vemuganti, S. (2025). Flexural Response Comparison of Nylon-Based 3D-Printed Glass Fiber Composites and Epoxy-Based Conventional Glass Fiber Composites in Cementitious and Polymer Concretes. Polymers, 17(2), 218. https://doi.org/10.3390/polym17020218