Study of Adhesion–Cohesive Interactions of Modified Bitumen Compositions

Abstract

1. Introduction

- Investigation of the adhesive properties of the binary “bitumen-AG-4I”, “bitumen-AS-2” compositions, and the triple composition “bitumen-AS-2-AG-4I” according to the mass of the detached binder from the surface of two types of crushed stone;

- Study of the effect of the concentration of modifiers on the change in the specific surface energy of “bitumen–air” and the wetting angle of mineral fillers;

- Physicochemical determination of the adhesive and cohesive strength of binary and triple bitumen compositions from the concentration of additives;

- Modeling of the effect of concentrations of AG-4I and AS-2 on the thermodynamic work of adhesion and the adhesive efficiency of triple bitumen compositions.

2. Materials and Methods

2.1. Materials

- –

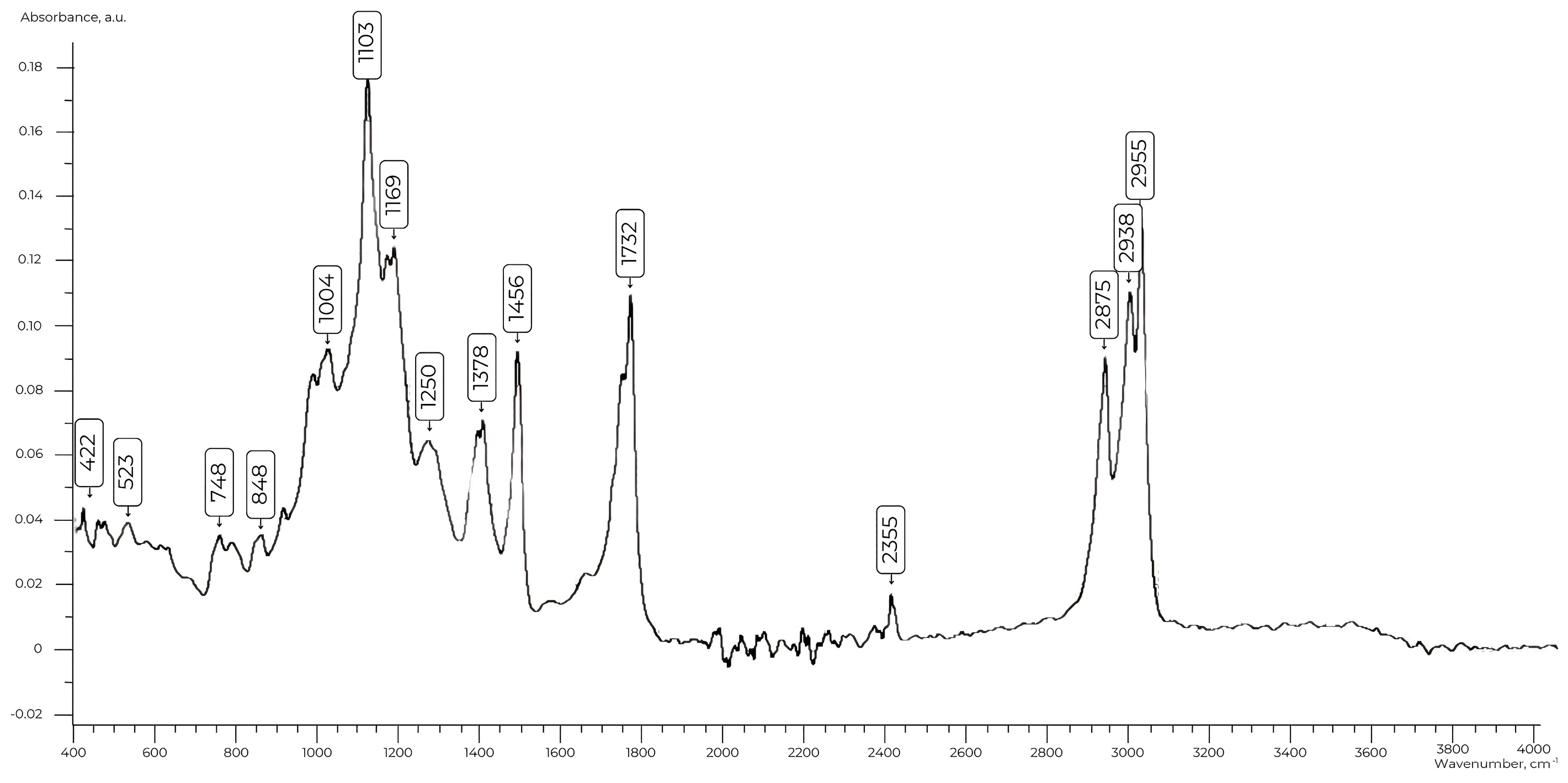

- AS-2 [25]—a product of the interaction between bottom residues of petrochemical production KON-92 and urea, representing a mixture of amines with the general formula (molecular weight of 237 a.m.u).

- –

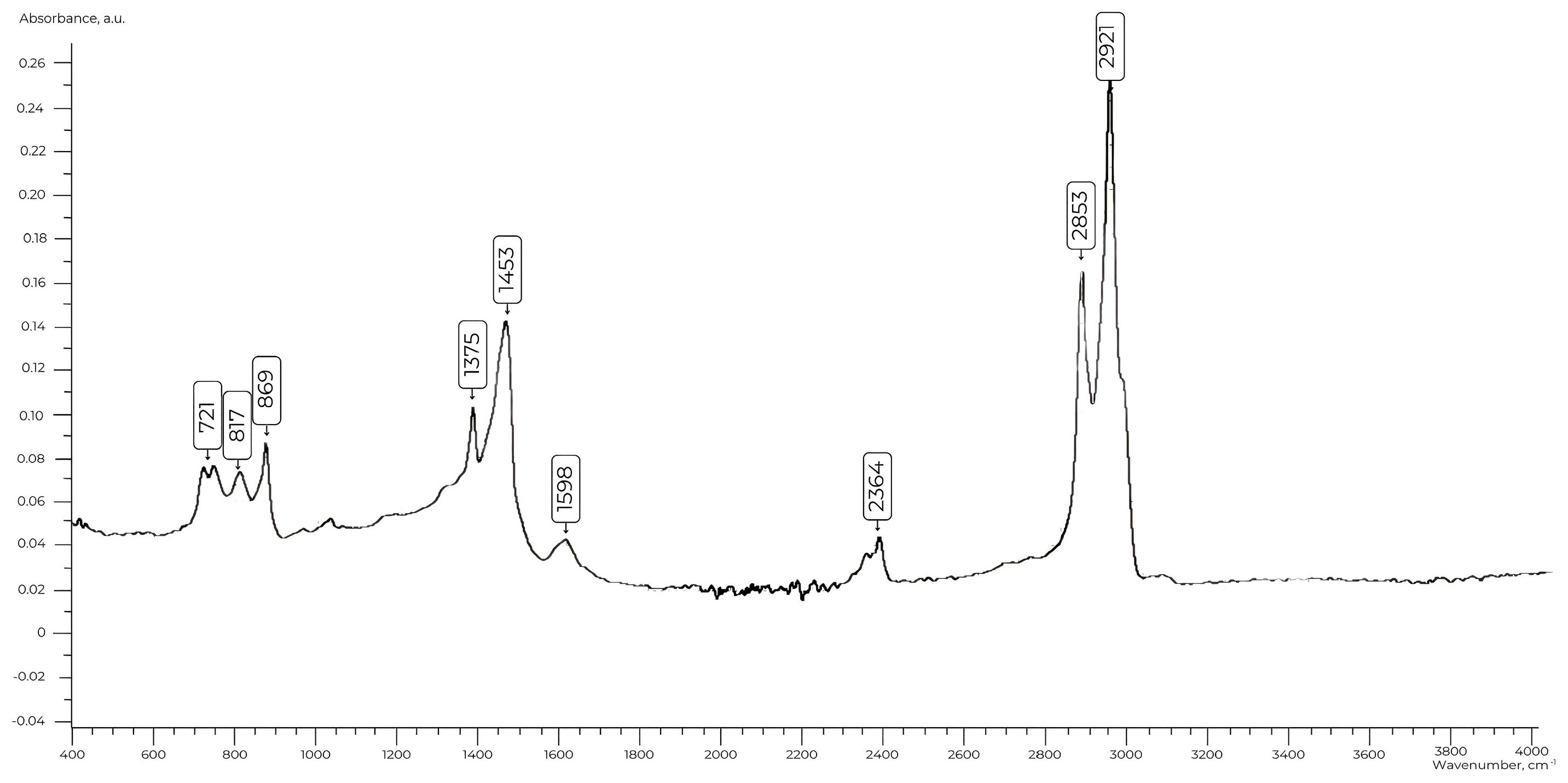

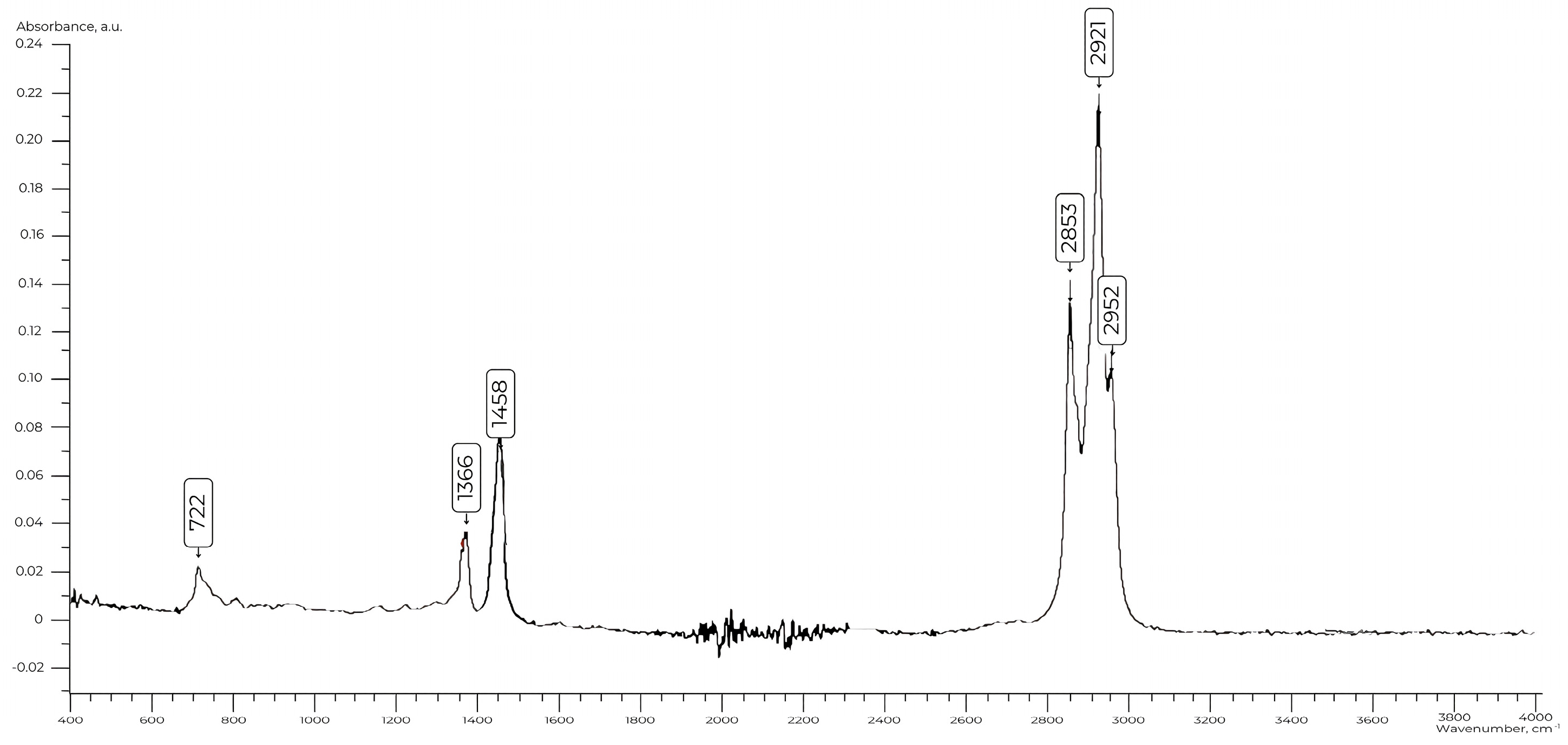

- AG-4I—waste sealing liquid, consisting of high-molecular polyisobutylene (PIB) and petroleum oils (molecular weight—5400 a.m.u), produced by “Germetika Research and Production Company”, Moscow, Russia. In the IR spectra of waste sealing liquid (Figure 3), absorption bands corresponding to deformation vibrations of C-H bonds in the region of 722 cm−1 are observed.

- –

- Crushed stone sourced from the “KazRosResurs” deposit in Kazakhstan, with its chemical composition detailed in Table 1 (hereinafter referred to as KS).

- –

- Crushed stone from the “Korneevka” deposit in Kazakhstan, with its chemical composition provided in Table 2 (hereinafter referred to as KA).

2.2. Method of Preparation of Modified Bituminous Compositions

2.3. Methodology for Determining the Adhesion Efficiency of Modifiers Based on the Mass of Exfoliated Bitumen

2.4. Methodology for Determining of the Surface Tension of Bituminous Compositions

2.5. Methodology for Measuring of the Contact Angle

2.6. Method of ProbabilisticDeterministic Planning

- –

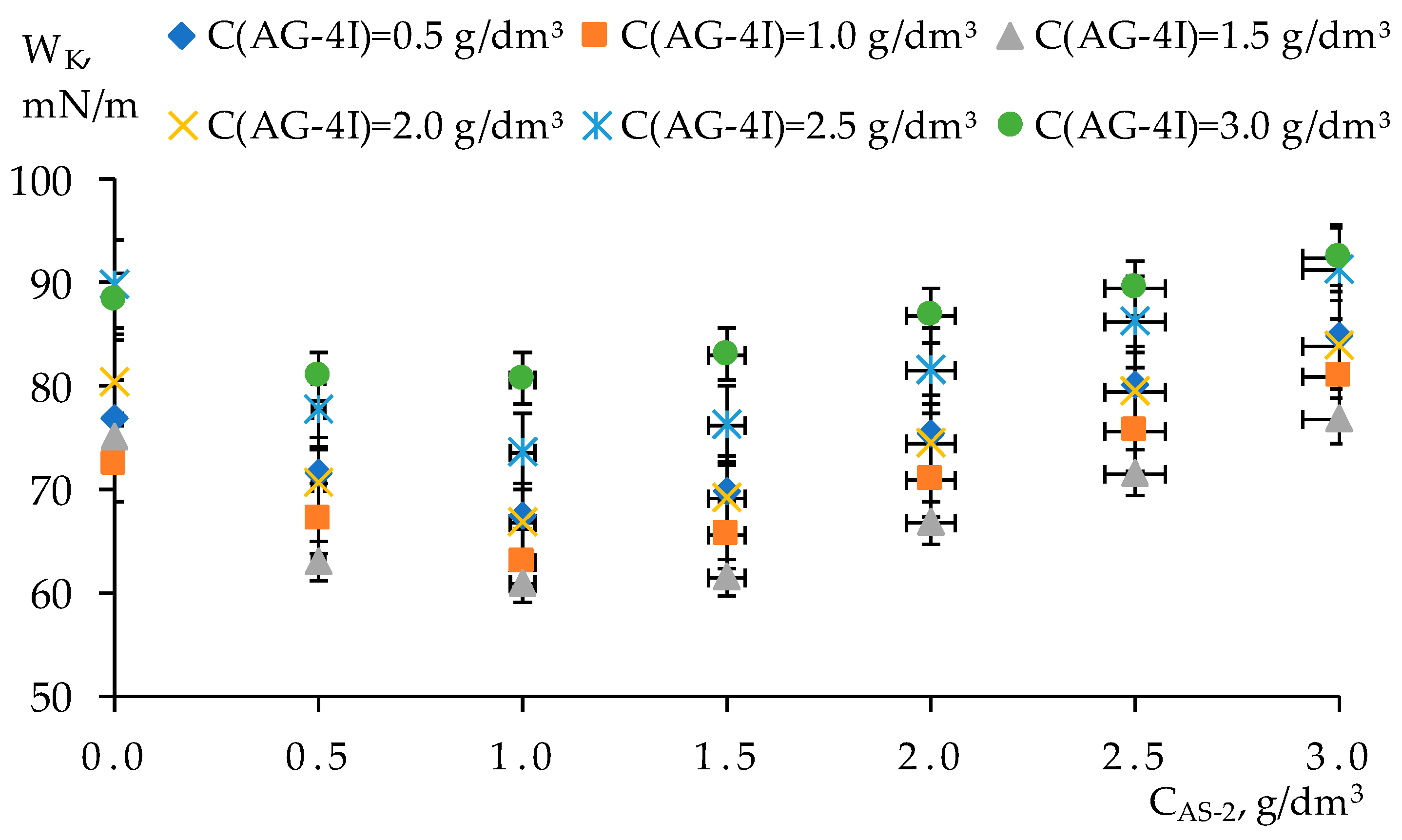

- Concentration of polymer AG-4I (CAG-4I, g/dm3) taking the following values: 0.5, 1.0, 1.5, 2.0, 2.5, or 3.0;

- –

- Concentration of surfactant AS-2 (CAS-2, g/dm3) taking the following values: 0.5, 1.0, 1.5, 2.0, 2.5, or 3.0.

3. Results and Discussion

3.1. Adhesion Properties of Binary Systems “BitumenAdditive” in Relation to the Surface of Mineral Filler

3.2. Adhesion Properties of Triple Systems “Bitumen-AG-4I-AS-2” in Relation to the Surface of Mineral Filler

3.3. Study of Adhesive and Cohesive Strength of Binary “BitumenAdditive”from the Concentration of Additives by the Thermodynamic Method

3.4. Study of Adhesive and Cohesive Strength of Triple Systems “Bitumen–AG-4I–AS-2” from the Concentration of Additives by the Thermodynamic Method

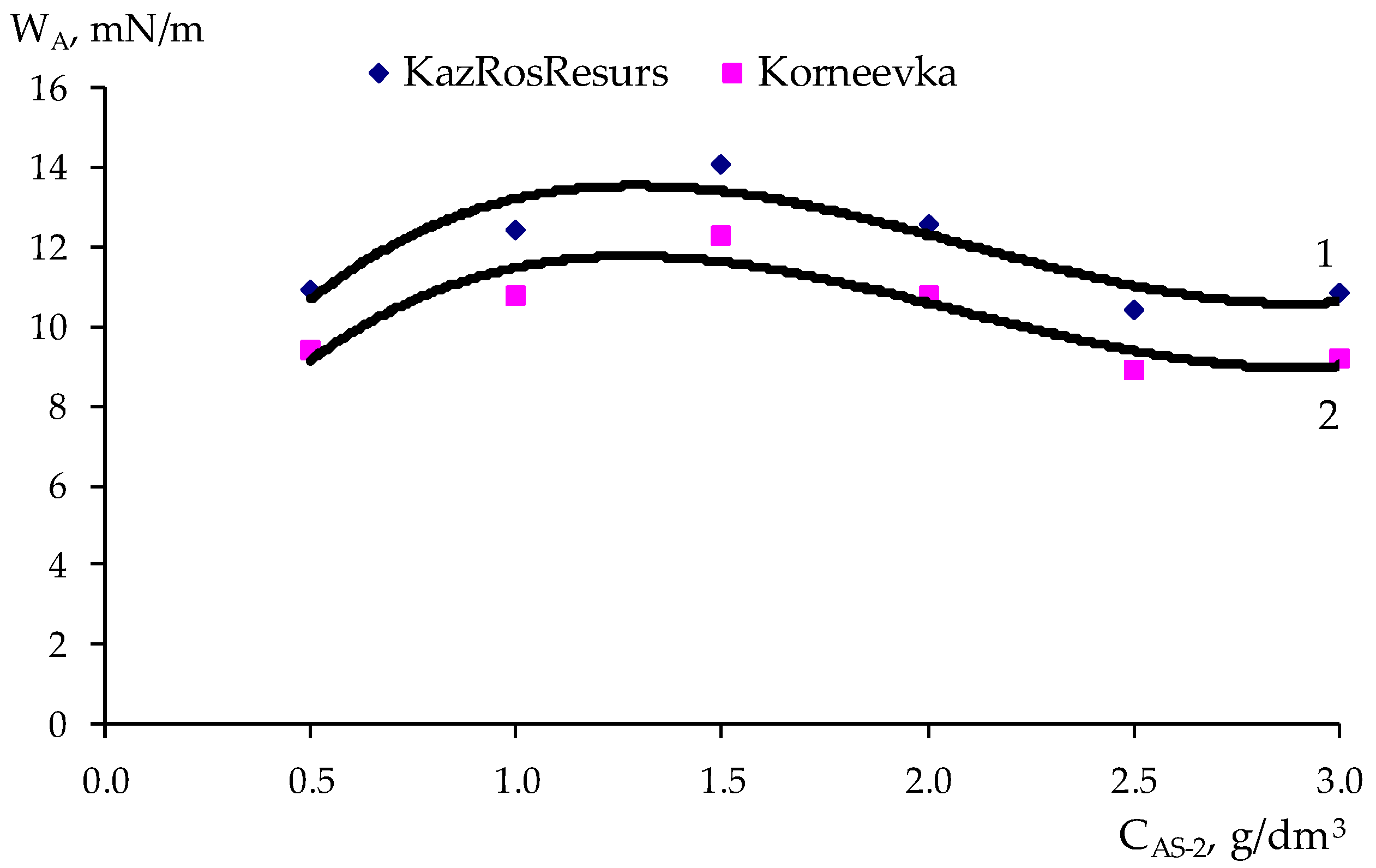

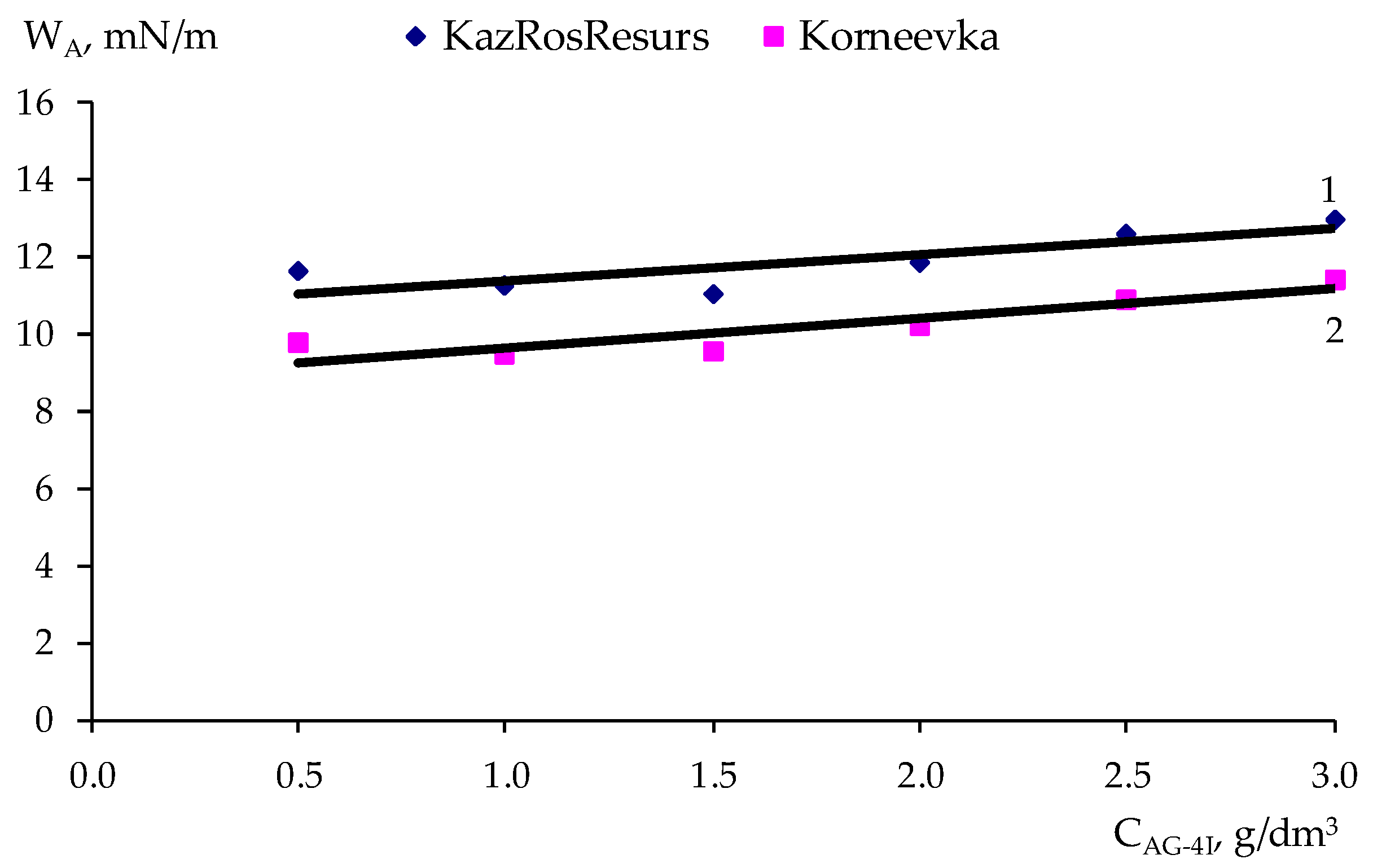

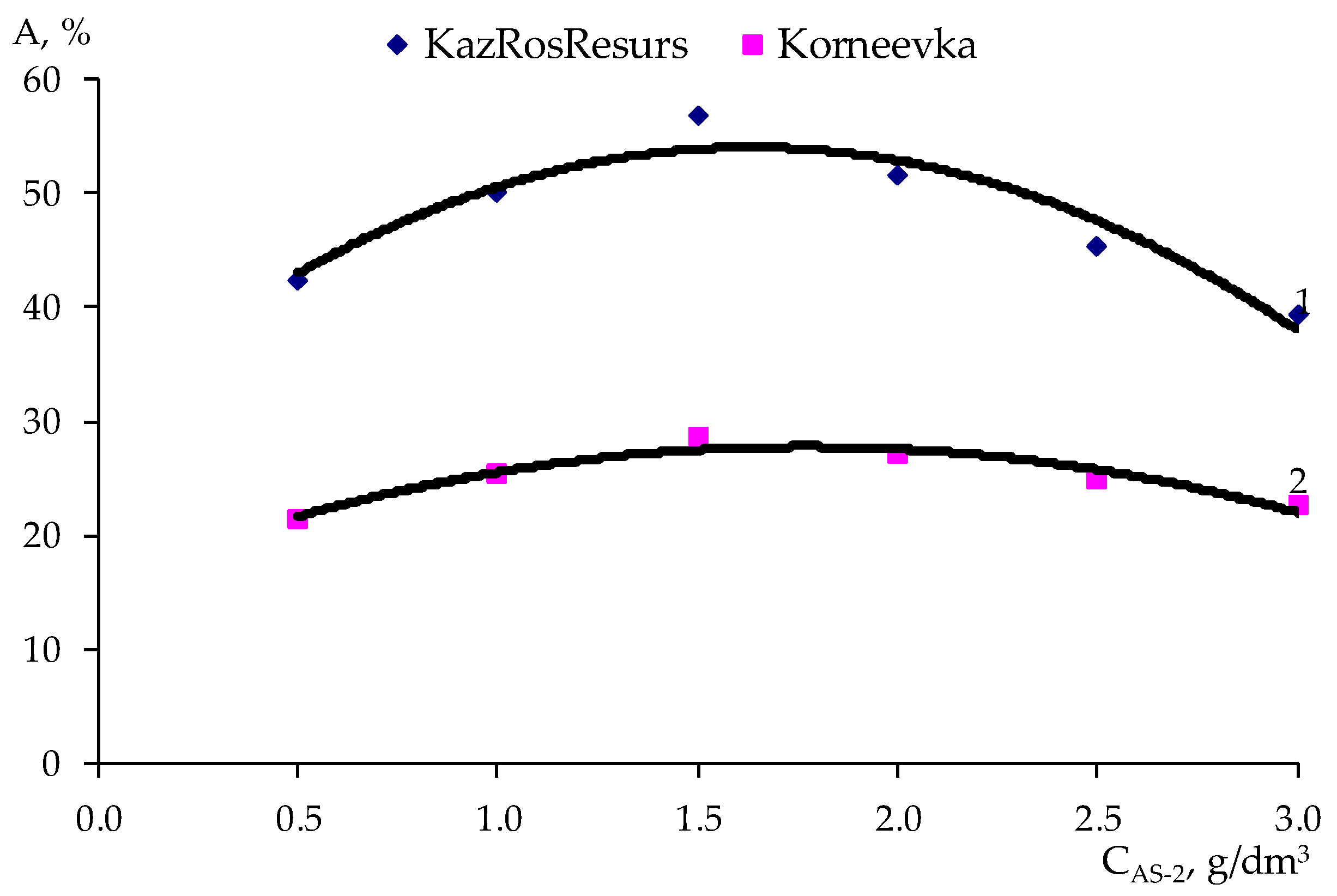

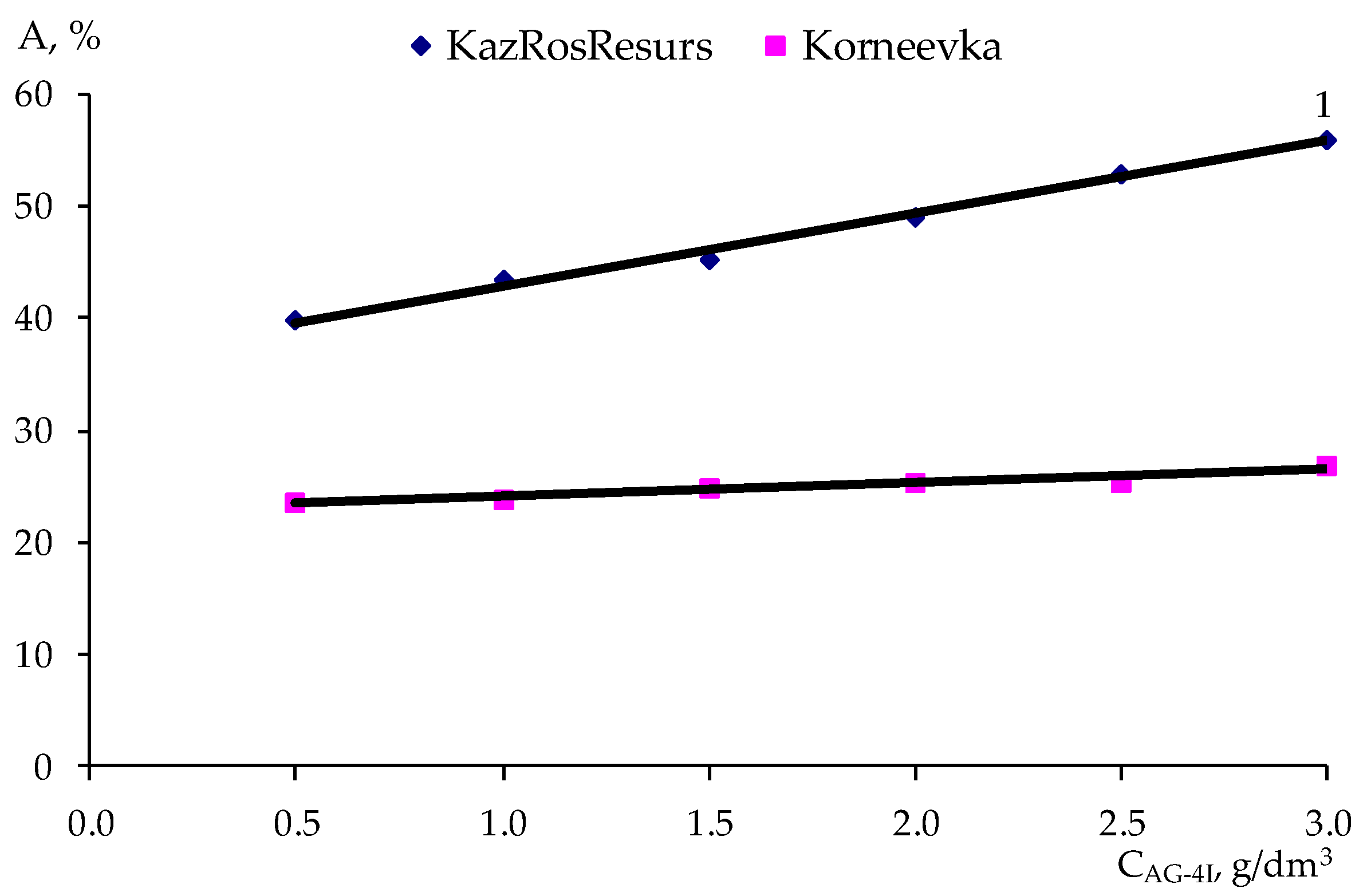

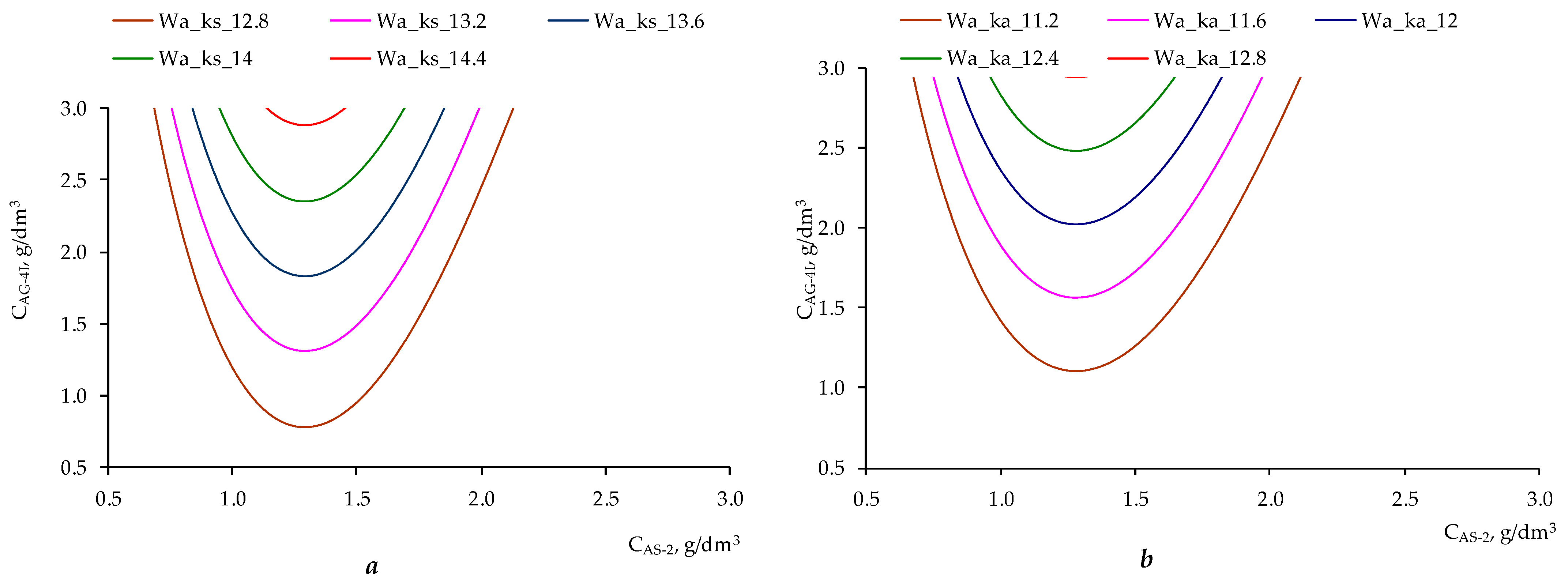

3.5. Modeling the Effect of Concentrations of AG-4I and AS-2 on the Thermodynamic Work of Adhesion and the Adhesive Efficiency of Triple Bitumen Compositions

4. Conclusions

- Adhesion–cohesion processes in modified bitumen systems are limited by the wetting effect of mineral fillers and the intensity of intermolecular forces in the condensed phase of the binder.

- In the binary composition “bitumen–AG-4I”, the minimum cohesive work (WK = 72.48 mN/m), the highest adhesive efficiency (AKS = 44.23%; AKA = 39.45%), and the maximum thermodynamic work of adhesion (WA(KS) = 14.04 mN/m; WA(KA) = 11.30 mN/m) on the surface of two types of mineral fillers werefixed at the same concentration (CAG-4I = 1.5 g/dm3) as the smallest contact angle (θKS = 126.45°; θKA = 131.94°).

- In the binary composition “bitumen–AS-2”, the minimum cohesive work (WK = 72.48 mN/m), the highest adhesive efficiency (AKS = 40.17%; AKA = 35.61%), and the maximum thermodynamic work of adhesion (WA(KS) = 12.68 mN/m; WA(KA) = 10.87 mN/m) on the surface of both types of mineral fillers were also revealed at the maximum wetting effect (θKS = 130.66°; θKA = 134.38°) but in the region of lower additive concentrations (CAS-2 = 1.0 g/dm3).

- The addition of AS-2 into bitumen compositions with polyisobutylene solution increases adhesion efficiency and thermodynamic work of adhesion in relation to the filler surface. The adhesion efficiency and thermodynamic work of adhesion in the “bitumen-AG-4I-AS-2” system reached their maximum at CAG-4I = 3.0 g/dm3 and CAS-2 = 1.5 g/dm3. In these concentration ranges, the composition achieved the maximum increase in adhesion efficiency (AKS = 65.18%; AKA = 48.11%) and the greatest increase in thermodynamic work of adhesion (WA(KS) = 15.79 mN/m; WA(KA) = 14.13 mN/m).

- Based on the results of mathematical modeling, two-factor nomograms were developed, enabling the solution of practical problems, particularly the optimization of bitumen–mineral compositions with specified adhesive properties.

- A comparative analysis of the two methods for determining the adhesive–cohesive interactions of bitumen in the presence of additives has shown that the thermodynamic approach is fundamental to justify the obtained modification results.

- One of the directions of our further research is the development of a methodology for determining quantitative indicators of cohesive and adhesive fracture of contact surfaces of mineral filler with modified bitumen using computer-optical microscopy, including a method and algorithm for its implementation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Oliviero, R.C. Bitumen and bitumen modification: A review on latest advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Zhou, Y.; Yu, F.; Huang, M.; Guo, Y.; Wei, J.; You, Z.; Ju, H.; Peng, Z. The influence mechanism of bitumen components on its macroscopic and microscopic properties: Analysis based on polyphosphoric acid modification. Fuel 2024, 372, 132085. [Google Scholar] [CrossRef]

- Teltayev, B.; Rossi, C.; Izmailova, G.; Amirbayev, E.; Elshibayev, A. Evaluating the Effect of Asphalt Binder Modification on the Low-Temperature Cracking Resistance of Hot Mix Asphalt. Case Stud. Constr. Mater. 2019, 11, e00238. [Google Scholar] [CrossRef]

- Valentin, J.; Trejbal, J.; Nezerka, V.; Valentova, T.; Vackova, P.; Ticha, P. A comprehensive study on adhesion between modified bituminous binders and mineral aggregates. Constr. Build. Mater. 2021, 305, 124686. [Google Scholar] [CrossRef]

- Pstrowska, K.; Gunka, V.; Sidun, I.; Demchuk, Y.; Vytrykush, N.; Kulazynski, M.; Bratychak, M. Adhesion in bitumen/aggregate system: Adhesion mechanism and test methods. Coatings 2022, 12, 1934. [Google Scholar] [CrossRef]

- Shi, B.; Liu, Q.; Gao, Y.; Wu, J.; Chen, J. Analysis of the cohesion/adhesion proportion around bitumen-mineral failure interface under tensile loading. Constr. Build. Mater. 2023, 399, 132555. [Google Scholar] [CrossRef]

- Xiao, R.; Ding, Y.; Polaczyk, P.; Ma, Y.; Jiang, X.; Huang, B. Moisture damage mechanism and material selection of HMA with amine antistripping agent. Mater. Des. 2022, 220, 110797. [Google Scholar] [CrossRef]

- Ma, L.; Varveri, A.; Jing, R.; Erkens, S. Comprehensive review on the transport and reaction of oxygen and moisture towards coupled oxidative ageing and moisture damage of bitumen. Constr. Build. Mater. 2021, 283, 122632. [Google Scholar] [CrossRef]

- Hanizah, O.; Hasan, M.; Rosli, M.; Najib, M.; Raman, N. Effects of Alkylamines-Based and Polyalkylene Glycol-Based Bonding Enhancers on the Performance of Asphalt Binders. IOPConf. Ser. Earth Environ. Sci. 2021, 920, 012021. [Google Scholar] [CrossRef]

- Rossi, C.O.; Teltayev, B.; Angelico, R. Adhesion Promoters in Bituminous Road Materials: A Review. Appl. Sci. 2017, 7, 524. [Google Scholar] [CrossRef]

- Treybig, D.; Chang, D. Asphalt Compositions Containing Anti-Stripping Additives Prepared from Hydrocarbyl Substituted Nitrogen-Containing Aromatic Heterocyclic Compounds, Aldehydes or Ketones and Amines. USA Patent 4724003A, 9 February 1988. Available online: https://patents.google.com/patent/US4724003A/en (accessed on 9 January 2025).

- Han, M.; Li, J.; Muhammad, Y.; Yin, Y.; Yang, J.; Yang, S.; Duan, S. Studies on the secondary modification of SBS modified asphalt by the application of octadecyl amine grafted graphene nanoplatelets as modifier. Diam. Relat. Mater. 2018, 89, 140–150. [Google Scholar] [CrossRef]

- Yang, Q.; Lin, J.; Wang, X.; Wang, D.; Xie, N.; Shi, X. A review of polymer-modified asphalt binder: Modification mechanisms and mechanical properties. Clean. Mater. 2024, 12, 100255. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Hasan, H.; Alamri, M.; Al-Attar, A.; Hamad, A.; Abdulmawjoud, A.; Mezaal, M.; Elmagarhe, A. Assessing the effects of copolymer modifier addition on asphalt attributes: Towards achieving performance optimization. Constr. Build. Mater. 2024, 420, 135645. [Google Scholar] [CrossRef]

- Akkenzheyeva, A.; Haritonovs, V.; Bussurmanova, A.; Merijs-Meri, R.; Imanbayev, Y.; Riekstins, A.; Serikbayeva, A.; Sydykov, S.; Aimova, M.; Mustapayeva, G. Study of the Viscoelastic and Rheological Properties of Rubber-Bitumen Binders Obtained from Rubber Waste. Polymers 2024, 16, 114. [Google Scholar] [CrossRef] [PubMed]

- Akimov, A.E.; Yadykina, V.V.; Lebedev, M.S.; Denisov, V.P.; Inozemtcev, S.S.; Inozemtcev, A.S.; Korshunov, A.V.; Pilipenko, A.S. Development of an Energy-Efficient Method of Obtaining Polymer-Modified Bitumen with High Operational Characteristics via Polymer–Bitumen Concentrate Application. J. Compos. Sci. 2024, 8, 337. [Google Scholar] [CrossRef]

- Aldagari, S.; Hung, A.M.; Saba Shariati, S.K.; Kabir, F.; Ranka, M.; Bird, R.C.; Fini, E. Enhanced sustainability at the bitumen-aggregate interface using organosilane coating technology. Constr. Build. Mater. 2022, 359, 129500. [Google Scholar] [CrossRef]

- Wieser, M.; Schaur, A.; Unterberger, S.H. Polymer-Bitumen Interaction: A Correlation Study with Six Different Bitumens to Investigate the Influence of SARA Fractions on the Phase Stability, Swelling, and Thermo-Rheological Properties of SBS-PmB. Materials 2021, 14, 1273. [Google Scholar] [CrossRef] [PubMed]

- Raos, G.; Zappone, B. Polymer Adhesion: Seeking New Solutions for an Old Problem. Macromolecules 2021, 54, 10617–10644. [Google Scholar] [CrossRef]

- Tadmor, R.; Das, R.; Gulec, S.; Liu, J.; Nguessan, H.; Shah, M.; Wasnik, P.; Yadav, S. Solid-Liquid Work of Adhesion. Langmuir 2017, 33, 3594–3600. [Google Scholar] [CrossRef]

- Zhai, R.; Hao, P.; Li, X.; Liu, C.; He, Z. Investigating the effect of physic-chemical and thermodynamic impact on cohesive performance of asphalt. Petrol. Sci. Technol. 2020, 38, 535–541. [Google Scholar] [CrossRef]

- Hensel, R.; Thiemecke, J.; Booth, J.A. Preventing Catastrophic Failure of Microfibrillar Adhesives in Compliant Systems Based on Statistical Analysis of Adhesive Strength. ACS Appl. Mater. Interfaces 2021, 13, 19422–19429. [Google Scholar] [CrossRef] [PubMed]

- Panteleenko, F.I.; Karpets, M.N.; Belotserkovsky, M.A.; Sosnovsky, A.V. Determination of the adhesive and cohesive strength of metal coatings deposited by hypersonic metallization. Sci. Technol. 2021, 20, 459–464. Available online: https://cyberleninka.ru/article/n/opredelenie-adgezionnoy-i-kogezionnoy-prochnosti-metallicheskih-pokrytiy-nanesennyh-giperzvukovoy-metallizatsiey (accessed on 17 October 2024). [CrossRef]

- EN13614:2021; Bitumen and Bituminous Binders-Determination of Adhesivity of Bituminous Emulsions by Water Immersion Test. European Committee for Standardization: Brussels, Belgium, 2021.

- Bolatbaev, K.N.; Dyuryagina, A.N.; Nurushov, A.K.; Korytina, O.G. Method for Obtaining an Inhibitor of Acid Corrosion of Metals. Patent of the Republic of Kazakhstan No. 10797. Available online: https://kzpatents.com/0-pp14466-sposob-polucheniya-ingibitora-kislotnojj-korrozii-metallov.html (accessed on 9 January 2025).

- Dyuryagina, A.; Byzova, Y.; Ostrovnoy, K.; Demyanenko, A.; Lutsenko, A.; Shirina, T. Increasing the Adhesion of Bitumen to the Surface of Mineral Fillers through Modification with a Recycled Polymer and Surfactant Obtained from Oil Refining Waste. Polymers 2024, 16, 714. [Google Scholar] [CrossRef]

- Zheng, X.; Feng, C.; Guo, X.Y. Low-temperature cohesive and adhesive strength testing of contact surface between bitumen and mineral aggregates by image analysis. Constr. Build. Mater. 2018, 183, 95–101. [Google Scholar] [CrossRef]

- Tyukanko, V.; Demyanenko, A.; Semenyuk, V.; Dyuryagina, A.; Alyoshin, D.; Brilkov, S.; Litvinov, S.; Byzova, Y. Optimization of polyethylene rotomolded tank design for storage of liquid mineral fertilizers by the Taguchi method. East.-Eur. J. Enterp. Technol. 2024, 3, 45–56. [Google Scholar] [CrossRef]

- Dyuryagina, A.; Byzova, Y.; Ostrovnoy, K.; Demyanenko, A.; Tyukanko, V.; Lutsenko, A. The Effect of the Microstructure and Viscosity of Modified Bitumen on the Strength of Asphalt Concrete. Polymers 2024, 16, 1370. [Google Scholar] [CrossRef] [PubMed]

| SiO2 % | TiO2 % | Al2O3 % | Fe2O3 % | CaO % | MgO % | S % | Mn ppm | K2O % | Na2O % |

|---|---|---|---|---|---|---|---|---|---|

| 75.37 | 0.98 | 12.04 | 2.67 | 0.78 | 0.31 | - | 774 | 5.27 | 2.58 |

| SiO2 % | TiO2 % | Al2O3 % | Fe2O3 % | CaO % | MgO % | Cl % | MnO ppm | K2O % | Na2O % |

|---|---|---|---|---|---|---|---|---|---|

| 76.50 | 0.90 | 11.70 | 2.37 | 0.38 | 0.31 | 0.14 | 257 | 5.29 | 2.40 |

| CAc-2, g/dm3 | σl-g, mN/m | WK, mN/m | “KazRosResurs” | “Korneevka” | ||

|---|---|---|---|---|---|---|

| θ, ° | WA, mN/m | θ, ° | WA, mN/m | |||

| 0 | 40.50 | 81.00 | 140.10 | 9.32 | 142.11 | 8.51 |

| 0.5 | 38.36 | 76.72 | 134.88 | 11.12 | 138.25 | 9.59 |

| 1.0 | 36.24 | 72.48 | 130.66 | 12.68 | 134.38 | 10.87 |

| 1.5 | 37.54 | 75.08 | 132.63 | 12.01 | 136.66 | 10.14 |

| 2.0 | 40.18 | 80.36 | 134.60 | 12.05 | 138.45 | 10.05 |

| 2.5 | 44.84 | 89.68 | 137.76 | 11.66 | 140.83 | 9.86 |

| 3.0 | 44.10 | 88.20 | 137.93 | 11.47 | 140.98 | 9.70 |

| CAG-4I, g/dm3 | σl-g, mN/m | WK, mN/m | “KazRosResurs” | “Korneevka” | ||

|---|---|---|---|---|---|---|

| θ, ° | WA, mN/m | θ, ° | WA, mN/m | |||

| 0 | 40.50 | 81.00 | 140.10 | 9.32 | 142.11 | 8.51 |

| 0.5 | 38.42 | 76.84 | 134.55 | 11.53 | 138.16 | 9.61 |

| 1.0 | 36.32 | 72.64 | 131.92 | 11.99 | 136.08 | 10.17 |

| 1.5 | 34.24 | 68.48 | 126.45 | 14.04 | 131.94 | 11.30 |

| 2.0 | 38.06 | 76.12 | 132.11 | 12.56 | 136.14 | 10.66 |

| 2.5 | 45.10 | 90.20 | 136.77 | 12.18 | 139.96 | 10.37 |

| 3.0 | 41.54 | 83.08 | 136.93 | 11.22 | 139.98 | 9.55 |

| CAG-4I, g/dm3 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CAS-2, g/dm3 | σex*, mN/m | σc, mN/m | σex*, mN/m | σc, mN/m | σex*, mN/m | σc, mN/m | σex*, mN/m | σc, mN/m | σex*, mN/m | σc, mN/m | σex*, mN/m | σc, mN/m |

| 0.5 | 35.72 | 36.28 | 33.58 | 34.18 | 31.54 | 32.10 | 35.38 | 35.92 | 38.82 | 42.96 | 40.48 | 39.40 |

| 1.0 | 33.68 | 34.16 | 31.52 | 32.06 | 30.46 | 29.98 | 33.36 | 33.80 | 36.82 | 40.84 | 40.38 | 37.28 |

| 1.5 | 34.94 | 35.46 | 32.80 | 33.36 | 30.72 | 31.28 | 34.56 | 35.10 | 38.08 | 42.14 | 41.56 | 38.58 |

| 2.0 | 37.65 | 38.10 | 35.42 | 36.00 | 33.38 | 33.92 | 37.28 | 37.74 | 40.74 | 44.78 | 43.38 | 41.22 |

| 2.5 | 39.98 | 42.76 | 37.80 | 40.66 | 35.82 | 38.58 | 39.72 | 42.20 | 43.14 | 49.44 | 44.74 | 45.88 |

| 3.0 | 42.42 | 42.02 | 40.46 | 39.92 | 38.36 | 37.84 | 42.02 | 41.66 | 45.60 | 48.70 | 46.28 | 45.14 |

| Crushed Stone “KazRosResurs” | ||||||

| CAG-4I, g/dm3 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 |

| CAS-2, g/dm3 | θ, ° | θ, ° | θ, ° | θ, ° | θ, ° | θ, ° |

| 0 | 134.55 | 131.92 | 126.45 | 132.11 | 136.77 | 136.93 |

| 0.5 | 134.14 | 133.98 | 132.87 | 133.54 | 134.69 | 135.48 |

| 1.0 | 130.26 | 129.73 | 128.17 | 129.32 | 130.03 | 130.31 |

| 1.5 | 127.85 | 126.58 | 125.06 | 126.55 | 127.29 | 128.04 |

| 2.0 | 133.14 | 132.41 | 130.75 | 131.28 | 132.26 | 132.68 |

| 2.5 | 137.49 | 137.24 | 137.19 | 137.61 | 138.18 | 138.46 |

| 3.0 | 137.85 | 137.52 | 137.38 | 137.91 | 138.54 | 139.08 |

| Crushed stone “Korneevka” | ||||||

| CAG-4I, g/dm3 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 |

| CAS-2, g/dm3 | θ, ° | θ, ° | θ, ° | θ, ° | θ, ° | θ, ° |

| 0 | 138.16 | 136.08 | 131.94 | 136.14 | 139.96 | 139.98 |

| 0.5 | 137.98 | 137.42 | 136.34 | 137.59 | 137.92 | 138.24 |

| 1.0 | 134.27 | 133.98 | 132.19 | 132.78 | 133.31 | 133.94 |

| 1.5 | 132.98 | 131.55 | 128.97 | 129.58 | 130.39 | 130.98 |

| 2.0 | 136.83 | 136.37 | 134.79 | 135.5 | 135.69 | 136.26 |

| 2.5 | 141.24 | 141.02 | 140.29 | 140.98 | 141.32 | 141.67 |

| 3.0 | 141.78 | 141.53 | 140.12 | 141.23 | 141.74 | 141.98 |

| Concentrations of Additives | Grade of Crushed Stone | ||||

|---|---|---|---|---|---|

| “KazRosResurs” | “Korneevka” | ||||

| CAS-2, g/dm3 | CAG-4I, g/dm3 | WA_KS, mN/m | AKS, % | WA_KA, mN/m | AKA, % |

| 0.50 | 0.50 | 10.72 | 34.22 | 9.29 | 21.03 |

| 1.00 | 0.50 | 11.79 | 41.15 | 10.10 | 25.20 |

| 1.50 | 0.50 | 13.63 | 48.19 | 11.18 | 26.55 |

| 2.00 | 0.50 | 12.05 | 43.57 | 10.17 | 24.62 |

| 2.50 | 0.50 | 10.39 | 38.60 | 8.80 | 23.27 |

| 3.00 | 0.50 | 11.03 | 32.87 | 8.91 | 21.00 |

| 0.50 | 1.00 | 10.41 | 35.69 | 8.73 | 20.55 |

| 1.00 | 1.00 | 11.35 | 43.45 | 9.77 | 24.72 |

| 1.50 | 1.00 | 13.12 | 53.64 | 11.15 | 27.33 |

| 2.00 | 1.00 | 11.69 | 48.71 | 9.92 | 25.98 |

| 2.50 | 1.00 | 10.21 | 41.38 | 8.32 | 23.35 |

| 3.00 | 1.00 | 10.52 | 36.53 | 8.90 | 20.97 |

| 0.50 | 1.50 | 10.09 | 39.47 | 8.83 | 21.34 |

| 1.00 | 1.50 | 11.57 | 47.23 | 10.05 | 25.11 |

| 1.50 | 1.50 | 13.21 | 54.08 | 11.37 | 28.11 |

| 2.00 | 1.50 | 11.68 | 49.03 | 10.01 | 27.16 |

| 2.50 | 1.50 | 9.67 | 43.65 | 8.24 | 24.32 |

| 3.00 | 1.50 | 9.97 | 37.17 | 8.82 | 23.03 |

| 0.50 | 2.00 | 10.97 | 43.81 | 9.20 | 21.50 |

| 1.00 | 2.00 | 12.34 | 53.88 | 10.68 | 24.63 |

| 1.50 | 2.00 | 13.82 | 58.18 | 12.44 | 29.15 |

| 2.00 | 2.00 | 12.68 | 52.65 | 10.81 | 28.01 |

| 2.50 | 2.00 | 10.33 | 45.44 | 8.74 | 25.32 |

| 3.00 | 2.00 | 10.93 | 40.07 | 9.24 | 23.17 |

| 0.50 | 2.50 | 11.65 | 48.51 | 10.09 | 21.15 |

| 1.00 | 2.50 | 13.26 | 56.03 | 11.41 | 25.56 |

| 1.50 | 2.50 | 14.85 | 62.20 | 13.33 | 30.13 |

| 2.00 | 2.50 | 13.44 | 56.47 | 11.41 | 27.11 |

| 2.50 | 2.50 | 10.79 | 49.18 | 9.49 | 25.88 |

| 3.00 | 2.50 | 11.40 | 44.29 | 9.58 | 22.70 |

| 0.50 | 3.00 | 11.74 | 52.65 | 10.12 | 22.69 |

| 1.00 | 3.00 | 14.13 | 59.41 | 12.52 | 27.45 |

| 1.50 | 3.00 | 15.79 | 65.18 | 14.13 | 30.46 |

| 2.00 | 3.00 | 13.88 | 59.17 | 12.15 | 29.45 |

| 2.50 | 3.00 | 11.19 | 53.16 | 9.84 | 26.90 |

| 3.00 | 3.00 | 11.11 | 45.84 | 9.72 | 24.49 |

| CAS-2, g/dm3 | Grade of Crushed Stone | |||

|---|---|---|---|---|

| “KazRosResurs” | “Korneevka” | |||

| WA_KS, mN/m | AKS, % | WA_KA, mN/m | AKA, % | |

| 0.50 | 10.93 | 42.39 | 9.38 | 21.38 |

| 1.00 | 12.41 | 50.19 | 10.76 | 25.45 |

| 1.50 | 14.07 | 56.91 | 12.27 | 28.62 |

| 2.00 | 12.57 | 51.60 | 10.74 | 27.06 |

| 2.50 | 10.43 | 45.24 | 8.90 | 24.84 |

| 3.00 | 10.83 | 39.46 | 9.20 | 22.56 |

| CAG-4I, g/dm3 | Grade of Crushed Stone | |||

|---|---|---|---|---|

| “KazRosResurs” | “Korneevka” | |||

| WA_KS, mN/m | AKS, % | WA_KA, mN/m | AKA, % | |

| 0.50 | 11.60 | 39.77 | 9.74 | 23.61 |

| 1.00 | 11.22 | 43.24 | 9.46 | 23.82 |

| 1.50 | 11.03 | 45.11 | 9.55 | 24.85 |

| 2.00 | 11.84 | 49.01 | 10.18 | 25.30 |

| 2.50 | 12.56 | 52.78 | 10.88 | 25.42 |

| 3.00 | 12.97 | 55.90 | 11.41 | 26.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dyuryagina, A.; Degert, A.; Byzova, Y.; Ostrovnoy, K.; Demyanenko, A.; Lutsenko, A.; Shirina, T. Study of Adhesion–Cohesive Interactions of Modified Bitumen Compositions. Polymers 2025, 17, 199. https://doi.org/10.3390/polym17020199

Dyuryagina A, Degert A, Byzova Y, Ostrovnoy K, Demyanenko A, Lutsenko A, Shirina T. Study of Adhesion–Cohesive Interactions of Modified Bitumen Compositions. Polymers. 2025; 17(2):199. https://doi.org/10.3390/polym17020199

Chicago/Turabian StyleDyuryagina, Antonina, Alyona Degert, Yuliya Byzova, Kirill Ostrovnoy, Alexandr Demyanenko, Aida Lutsenko, and Tatyana Shirina. 2025. "Study of Adhesion–Cohesive Interactions of Modified Bitumen Compositions" Polymers 17, no. 2: 199. https://doi.org/10.3390/polym17020199

APA StyleDyuryagina, A., Degert, A., Byzova, Y., Ostrovnoy, K., Demyanenko, A., Lutsenko, A., & Shirina, T. (2025). Study of Adhesion–Cohesive Interactions of Modified Bitumen Compositions. Polymers, 17(2), 199. https://doi.org/10.3390/polym17020199