Bonding Performance at the Interface of Glass Fiber-Reinforced Polymer Anchors and Polymer Concrete

Abstract

1. Introduction

2. Experimental Investigation

2.1. Test Materials

- (1)

- Raw Materials for Resin Concrete (UPC)

- (2)

- Preparation and Mechanical Properties of UPC Specimens

- (3)

- Mechanical Properties of GFRP Bolts

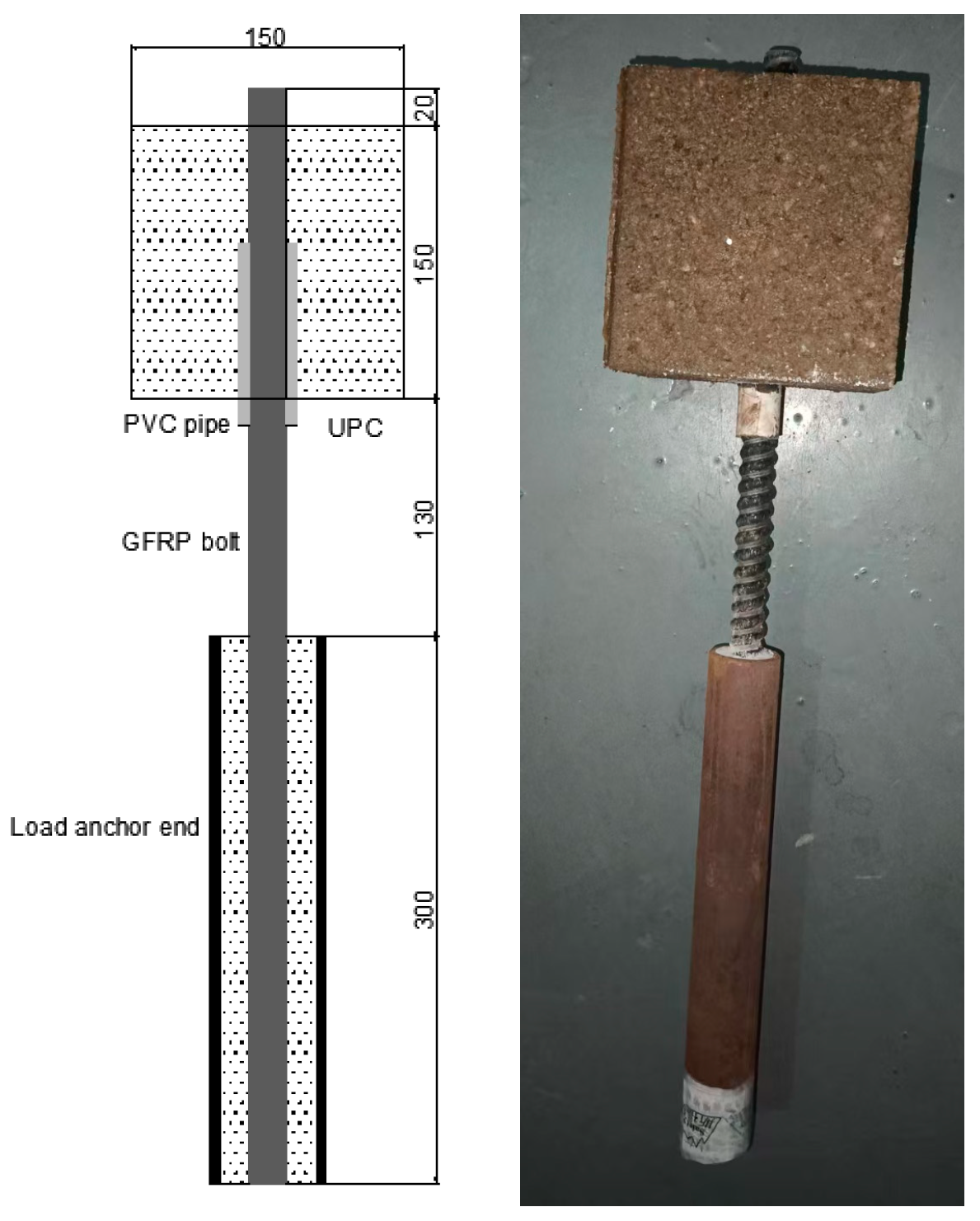

2.2. Specimen Preparation

- (1)

- Mold Preparation and Rod Installation

- (2)

- Concrete Placement and Curing

- (3)

- Anchorage System Installation

2.3. Experimental Testing

- (1)

- Fixture Installation

- (2)

- Specimen Mounting

- (3)

- Loading Configuration

- (4)

- Displacement Measurement

- (5)

- Pre-Test Verification

- (1)

- Bolt Fracture

- (2)

- Concrete Splitting Failure

- (3)

- Bond Failure (Pull-out)

- (4)

- Excessive Slip (20 mm)

3. Bond–Slip Relationship Curve Model

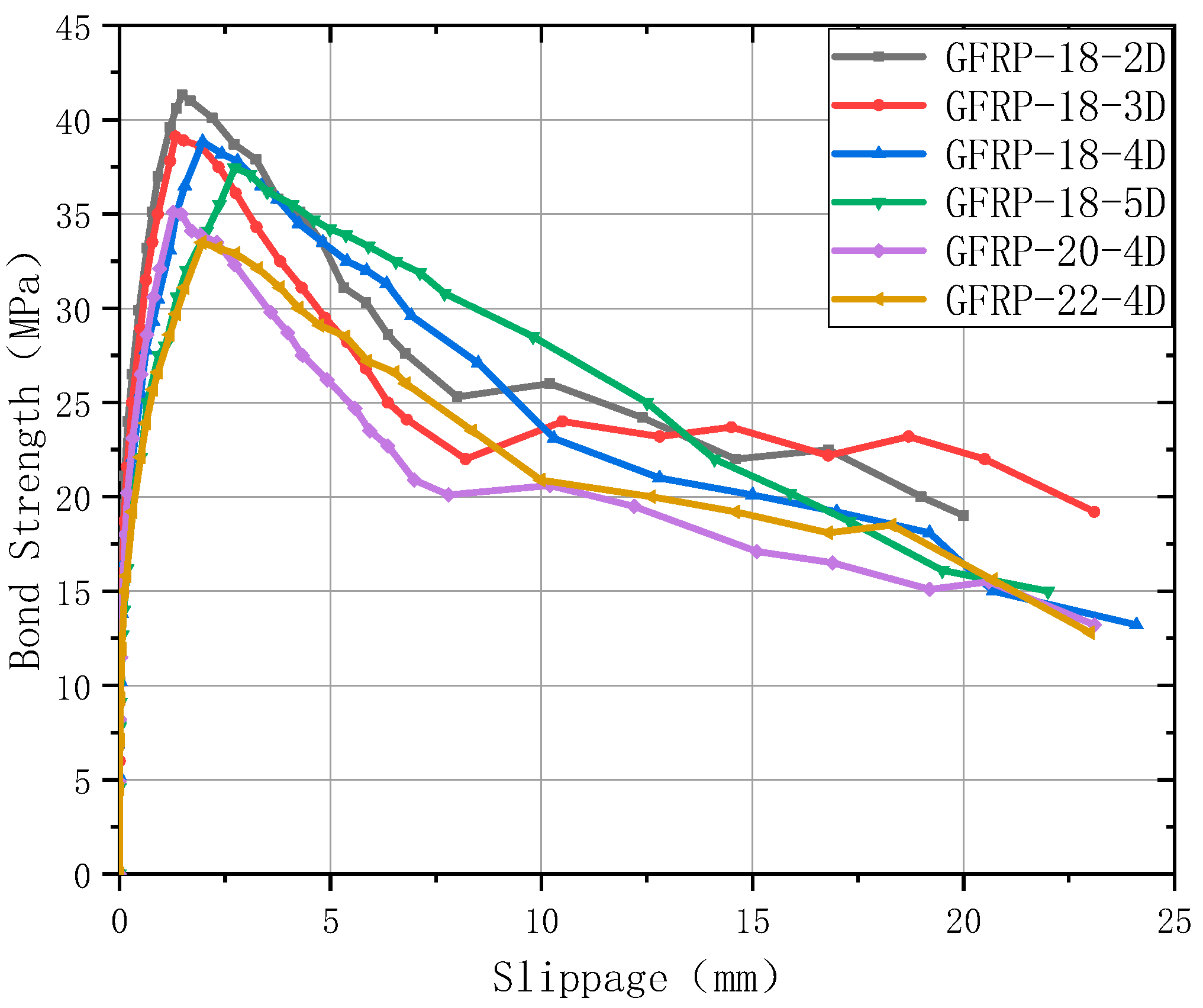

3.1. Experimental Results

- (1)

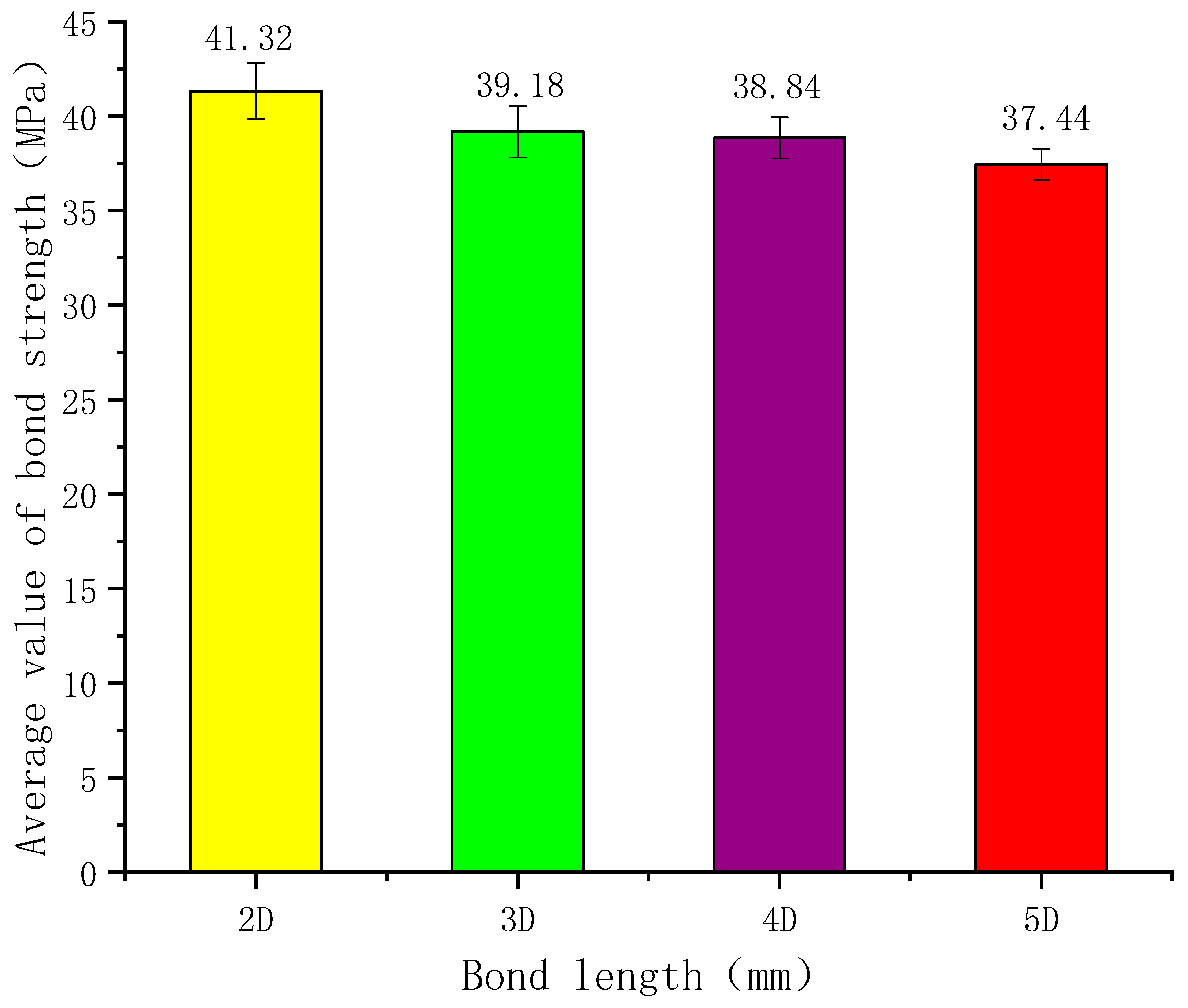

- Influence of Bond Length on Bond Strength

- (2)

- Influence of Anchorage Diameter on Bond Strength

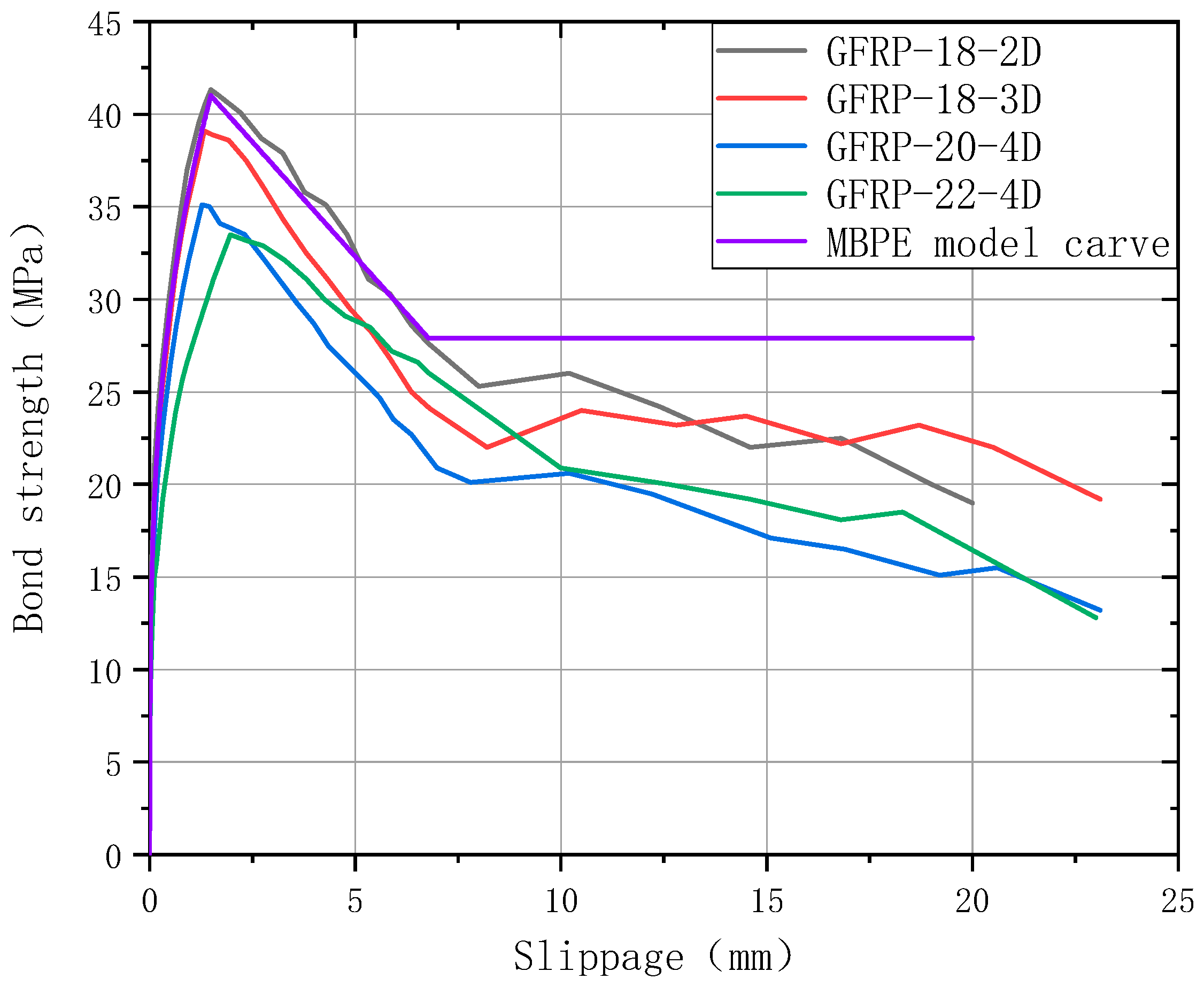

3.2. Bond–Slip Constitutive Model Proposed in This Study

3.3. Comparison Between Theoretical and Experimental Values

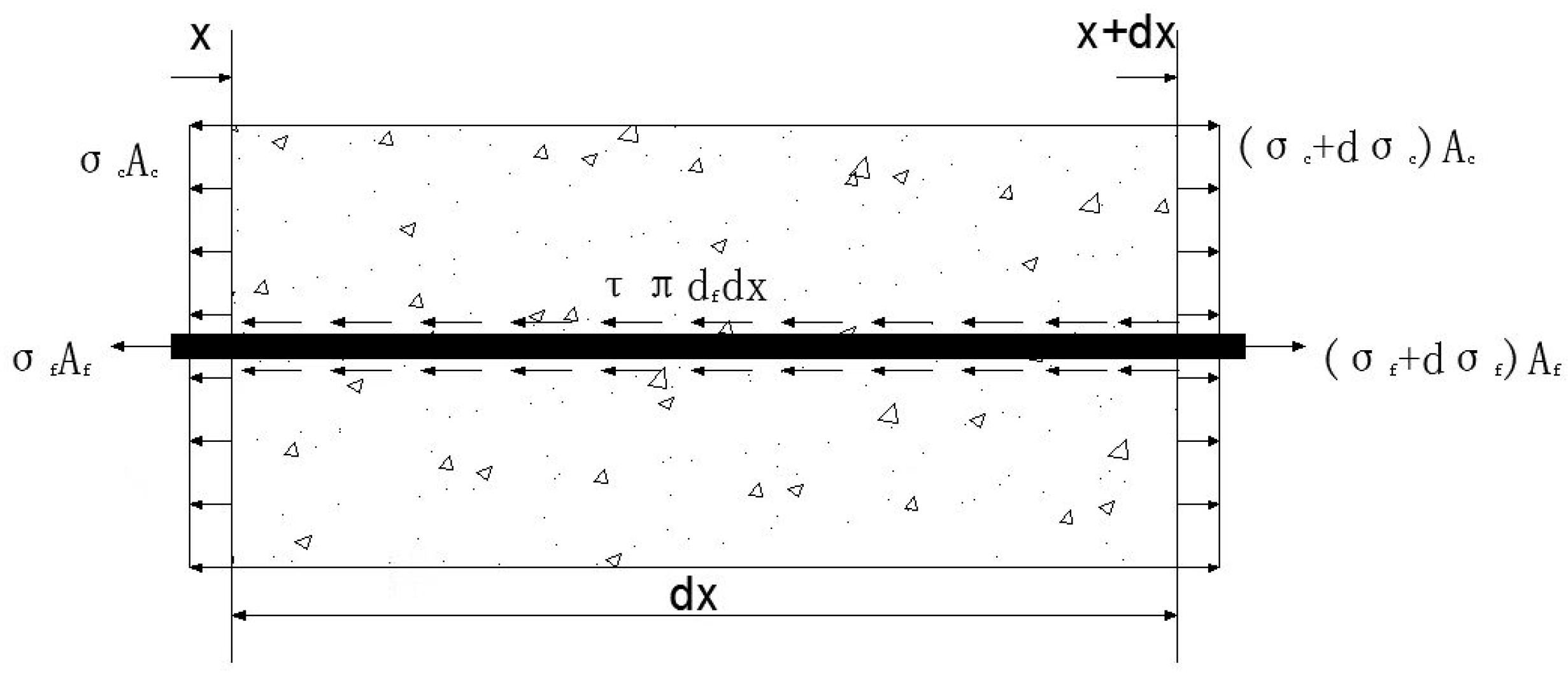

- ①

- Equilibrium Equation:

- ②

- Constitutive equation in the elastic stage:

- ③

- Deformation compatibility equation:

- ①

- Rising branch:

- ②

- The descending branch:

4. Conclusions

- (1)

- This study proposes the use of resin concrete to replace resin anchorage agents in coal mines. The results demonstrate that resin concrete provides enhanced mechanical interlock and higher anchorage strength.

- (2)

- The effect of bond length on anchorage strength was investigated; it was found that bond strength decreases with increasing bond length. Taking 18 mm diameter anchors as an example, when the bond lengths were 2D, 3D, 4D, and 5D, the average bond strengths were 41.32 MPa, 39.18 MPa, 38.84 MPa, and 37.44 MPa, respectively. Compared to the preceding shorter bond length, the strengths decreased by 5.18%, 6.00%, and 9.39%, respectively.

- (3)

- The influence of anchor diameter on anchorage strength was also investigated. Due to the shear lag effect, the average bond strength decreases as the GFRP anchor diameter increases. Using a bond length of 5D (where D is the anchor diameter) as a reference, for anchor diameters of 18 mm, 20 mm, 22 mm, and 24 mm, the corresponding average bond strengths were 37.44 MPa, 33.97 MPa, 32.18 MPa, and 31.50 MPa. These values represent decreases of 9.27%, 14.05%, and 15.87% compared to the preceding smaller diameter.

- (4)

- Building on existing studies and tests, a simpler bond–slip model for GFRP anchors in resin concrete is developed. Since engineers mainly care about the rising part of the curve in real applications, our model focuses only on three key stages. It is easy to understand yet meets key requirements like infinite initial slope and smooth peak transition. By establishing and solving the differential equations, analytical expressions for the slip displacement, normal stress, and shear stress distribution along the anchorage length in the ascending branch are derived, providing a theoretical basis for engineering design.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, L.K. Current Status and Development of Geotechnical Anchoring Technology. China Civ. Eng. J. 2001, 34, 7–13. [Google Scholar]

- Zhang, B.; Benmokrane, B.; Chennouf, A.; Mukhopadhyaya, P.; El-Safty, A. Tensile behavior of FRP tendons for prestressed ground anchors. J. Compos. Constr. 2001, 5, 85–93. [Google Scholar] [CrossRef]

- Yong, Y.; Xin, J.; You, Y.F. Feasibility Study of GFRP Rock Bolts. J. Highw. Transp. Technol. 2004, 21, 13–15. [Google Scholar]

- Cheng, Y.M.; Au, S.K.; Albert, T.Y. Laboratory and field evaluation of several types of soil nails for different geological conditions. Can. Geotech. J. 2016, 53, 634–645. [Google Scholar] [CrossRef]

- Machello, C.; Rahmati, M. Machine learning-based prediction of bond performance of FRP composite bars in concrete for marine composite structure. Compos. Struct. 2025, 370, 119401. [Google Scholar] [CrossRef]

- Sharifianjazi, F.; Zeydi, P.; Bazli, M.; Esmaeilkhanian, A.; Rahmani, R.; Bazli, L.; Khaksar, S. Fibre-reinforced polymer reinforced concrete members under elevated temperatures: A review on structural performance. Polymers 2022, 14, 472. [Google Scholar] [CrossRef]

- Huang, Z.; Deng, W.; Li, R.; Chen, J.; Sui, L.; Zhou, Y.; Zhao, D.; Yang, L.; Ye, J. Multi-impact performance of prestressed CFRP-strengthened RC beams using H-typed end anchors. Mar. Struct. 2022, 85, 103264. [Google Scholar] [CrossRef]

- Li, N.; Tang, W.; Chen, X.; Wang, K.; Li, S. Compressive behavior degradation of FRPconfined RC columns exposed to a chlorine environment. Mar. Struct. 2022, 86, 103277. [Google Scholar] [CrossRef]

- Wei, J.; Liu, C.; Liu, J.; Yu, X.; Xu, S.; Su, Y. Investigations on geopolymer-based seawater sea-sand high performance concrete slabs reinforced with basalt FRP bars under direct contact explosions. Constr. Build. Mater. 2024, 411, 134538. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Shakiba, M.; Bazli, M.; Javaheri, A. Using four-point flexure test to investigate effects of temperature and bar size on the tensile properties of GFRP bars. Polym. Test. 2022, 112, 107627. [Google Scholar] [CrossRef]

- Abolfazli, M.; Bazli, M.; Rajabipour, A.; Heitzmann, M.; Pourasiabi, H.; Wang, H.; Arashpour, M. Residual compressive strength of filament wound hybrid glass/carbon fibre reinforced polymer tubes after exposure to elevated temperature. Compos. Struct. 2023, 316, 117050. [Google Scholar] [CrossRef]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Beravior and modeling of bond of FRP rebars to concrete. J. Compos. Constr. 1997, 1, 40–51. [Google Scholar] [CrossRef]

- Gao, D.; Zhu, H.; Xie, J. The constitutive models for bond slip relation between FRP bars and concrete. Ind. Constr. 2003, 33, 41–43. [Google Scholar]

- Zhou, C.H.; Yang, B. Bond-slip behavior of the FRP bar-sea sand concrete interface and its effect on the finite element analysis of RC beam. Constr. Build. Mater. 2024, 436, 136917. [Google Scholar] [CrossRef]

- Zhao, Y.; Hu, x.; Shi, C.; Zhang, Z.; Zhu, D. A review on seawater sea-sand concrete: Mixture proportion, hydration, microstructure and properties. Constr. Build. Mater. 2021, 295, 123602. [Google Scholar]

- Chen, Z.; Mo, L.; Song, C.; Zhang, Y. Investigation on compression properties of seawater-sea sand concrete. Adv. Concr. Constr. 2021, 12, 93–103. [Google Scholar]

- He, X.; Zhou, J. Mechanical characteristics of sea-sand concrete in simulated marine environment. Constr. Build. Mater. 2021, 274, 122098. [Google Scholar] [CrossRef]

- Cui, Y.; Jiang, J.; Fu, T.; Liu, S. Feasibility of using waste brine/seawater and sea sand for the production of concrete: An experimental investigation from mechanical properties and durability perspectives. Sustainability 2022, 14, 142013340. [Google Scholar] [CrossRef]

- Dhondy, T.; Remennikov, A.; Sheikh, M.N. Properties and application of sea sand in sea sand-seawater concrete. J. Mater. Civ. Eng. 2020, 32, 0003475. [Google Scholar] [CrossRef]

- Chen, S.; Lyu, H.-b.; Wang, L. Constitutive model of bond-slip relation between FRP bar and coral concrete. J. Guilin Univ. Technol. 2019, 39, 107–113. [Google Scholar]

- Gao, Y. Research on Design, Performance and Dynamics of Unsaturated Polyester Resin Concrete. Ph.D. Thesis, Chang’an University, Changan, China, 2020. [Google Scholar]

- Chen, D. Research on Static and Dynamic Mechanical Properties of Unsaturated Polyester Polymer Concrete and Its Engineering Applications. Ph.D. Thesis, Guangdong University of Technology, Guangzhou, China, 2019. [Google Scholar]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Analytical modelling of bond between FRP reinforcing bars and concrete. In Non-Metallic (FRP) Reinforcement for Concrete Structures, Proceedings of the Second International RILEM Symposium (FRPRCS2), Ghent, Belgium, 23–25 August 1995; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Eligehausen, R.; Popov, E.P.; Bertero, V.V. Local Bond Stress-Slip Relationships of Deformed Bars under Generalized Excitations: Experimental Results and Analytical Model; Earthquake Engineering Research Center, University of California, Berkeley: Berkeley, CA, USA, 1983. [Google Scholar]

- Malvar, L.J. Bond Stress–Slip Characteristics of FRP Bars; Rep TR 2012-SHR; Naval Facilities Engineering Service Center: Port Hueneme, CA, USA, 1994. [Google Scholar]

- GB/T 50081-2019; Standard for Test Method of Mechanical and Physical Performanceon Concrete. National Standard of the People’s Republic of China. China Building Industry Press: Beijing, China, 2019.

- CSA S807-19; Specification for Fibre-Reinforced Polymers. National Standard of Canada: Toronto, ON, Canada, 2019.

- El-Nemr, A.; Ahmed, E.A.; Barris, C.; Joyklad, P.; Hussain, Q.; Benmokrane, B. Bond performance of fiber reinforced polymer bars in normal- and high-strength concrete. Constr. Build. Mater. 2023, 393, 131957. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Teng, J.G. Bond behavior of FRP bars in normal-strength concrete. J. Compos. Constr. 2005, 9, 3. [Google Scholar]

- Devaraj, R.; Olofinjana, A.; Gerber, C. On the Factors That Determine the Bond Behaviour of GFRP Bars to Concrete: An Experimental Investigation. Buildings 2023, 13, 2896. [Google Scholar] [CrossRef]

| Resin | 3–5 mm Quartz Sand | 20–40 Mesh Quartz Sand | 40–70 Mesh Quartz Sand | 70–120 Mesh Quartz Sand |

|---|---|---|---|---|

| 1 | 2.829 | 1.886 | 0.943 | 0.629 |

| Specimen Number | /kN | /kN | /MPa | /MPa | /mm | /mm | Failure Mode |

|---|---|---|---|---|---|---|---|

| GFRP-18-2D | 85.64 | 84.12 | 42.07 | 41.32 | 1.60 | 1.49 | Pull off |

| 80.66 | 39.62 | 1.52 | Pull off | ||||

| 86.05 | 42.27 | 1.36 | Pull off | ||||

| GFRP-18-3D | 120.74 | 119.64 | 39.54 | 39.18 | 1.42 | 1.33 | Pull off |

| 123.15 | 40.33 | 1.67 | Pull off | ||||

| 115.03 | 37.67 | 0.89 | Pull off | ||||

| GFRP-18-4D | 152.97 | 158.14 | 37.57 | 38.84 | 1.83 | 1.97 | Pull off |

| 161.31 | 39.62 | 2.11 | Pull off | ||||

| 160.13 | 39.33 | 1.98 | Pull off | ||||

| GFRP-18-5D | 180.67 | 180.84 | 36.51 | 37.44 | 4.21 | 2.73 | Rebar fracture |

| 179.40 | 37.68 | 3.43 | Rebar fracture | ||||

| 182.45 | 38.12 | 0.55 | Rebar fracture, UPC split | ||||

| GFRP-20-4D | 176.48 | 177.57 | 35.11 | 35.33 | 1.32 | 1.27 | Pull off |

| 174.87 | 34.79 | 1.36 | Pull off | ||||

| 181.36 | 36.08 | 1.12 | Pull off | ||||

| GFRP-20-5D | 224.69 | 212.29 | 35.76 | 33.79 | 1.26 | 1.77 | UPC split |

| 208.66 | 33.21 | 1.55 | Pull off | ||||

| 203.51 | 32.39 | 2.51 | Pull off | ||||

| GFRP-22-4D | 207.77 | 203.69 | 34.16 | 33.49 | 2.35 | 1.96 | Pull off |

| 198.22 | 32.59 | 1.65 | Pull off | ||||

| 205.09 | 33.72 | 1.87 | Pull off | ||||

| GFRP-22-5D | 252.33 | 244.65 | 33.19 | 32.18 | 1.65 | 1.48 | Pull off |

| 244.43 | 32.15 | 1.23 | Pull off | ||||

| 237.20 | 31.20 | 1.56 | Pull off | ||||

| GFRP-22-6D | 271.03 | 267.61 | 32.34 | 31.25 | 0.86 | 1.02 | Rebar fracture |

| 266.85 | 30.16 | 1.25 | Rebar fracture | ||||

| 264.95 | 31.26 | 0.95 | Rebar fracture | ||||

| GFRP-24-5D | 292.06 | 284.97 | 32.28 | 31.50 | 1.66 | Pull off | |

| 285.01 | 31.50 | 1.27 | 1.59 | Pull off | |||

| 277.86 | 30.71 | 1.83 | Pull off | ||||

| GFRP-24-6D | 328.54 | 325.91 | 30.26 | 31.01 | 0.75 | 1.13 | Rebar fracture |

| 322.10 | 31.77 | 1.12 | Rebar fracture | ||||

| 327.08 | 30.99 | 1.53 | Rebar fracture |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Li, W.; Ling, T.; Huang, B.; Zhou, M. Bonding Performance at the Interface of Glass Fiber-Reinforced Polymer Anchors and Polymer Concrete. Polymers 2025, 17, 2714. https://doi.org/10.3390/polym17192714

Liu K, Li W, Ling T, Huang B, Zhou M. Bonding Performance at the Interface of Glass Fiber-Reinforced Polymer Anchors and Polymer Concrete. Polymers. 2025; 17(19):2714. https://doi.org/10.3390/polym17192714

Chicago/Turabian StyleLiu, Kai, Wenchao Li, Tianlong Ling, Bo Huang, and Meihong Zhou. 2025. "Bonding Performance at the Interface of Glass Fiber-Reinforced Polymer Anchors and Polymer Concrete" Polymers 17, no. 19: 2714. https://doi.org/10.3390/polym17192714

APA StyleLiu, K., Li, W., Ling, T., Huang, B., & Zhou, M. (2025). Bonding Performance at the Interface of Glass Fiber-Reinforced Polymer Anchors and Polymer Concrete. Polymers, 17(19), 2714. https://doi.org/10.3390/polym17192714