1. Introduction

Polymer composites have become increasingly valuable in advanced engineering applications due to their tunable mechanical, thermal, and chemical properties. By combining multiple polymers and fillers, it is possible to leverage the unique attributes of each component. However, a fundamental challenge still remains: most polymer systems are immiscible, leading to phase-separated domains with weak interfacial adhesion. These weak interfaces often limit the mechanical performance of the resulting materials, highlighting the importance of processing techniques that can optimize interfacial properties and enhance overall composite performance [

1,

2]. To overcome the challenge of immiscibility, various compatibilization strategies are employed to strengthen the interface and refine the blend morphology. Compatibilizers have the ability to interact with both polymer phases to stabilize the interface. Relatedly, reactive compatibilization relies on chemical reactions during processing to form copolymers at the interface [

3]. Such approaches have been shown to refine and stabilize the morphology, improve phase adhesion, and enhance the overall performance of polymer blends [

1].

The coextrusion of liquid crystalline polymers (LCPs) with nylon presents an area for developing high-performance composite materials, while leveraging the unique properties of both materials. Studies have demonstrated that incorporating LCPs into nylon matrices can significantly improve the tensile strength and modulus. For instance, a composite fiber containing 40% weight LCP showed a 982.1% increase in the tensile modulus and a 123.3% increase in tensile strength compared to pure PA6,6 fibers [

1]. This enhancement is attributed to the in situ formation of LCP fibrils during processing, which align along the flow direction, reinforcing the matrix [

4,

5]. The rheological behavior of LCP/PA blends also plays a crucial role in determining the final properties of the composite. LCPs exhibit low melt viscosity and high shear sensitivity, facilitating their alignment during processing and promoting fibril formation. This alignment is further enhanced during coextrusion, where the shear and elongational flows orient the LCP domains, leading to improved mechanical performance [

6]. However, the immiscibility between LCPs and nylon can lead to phase separation and weak interfacial adhesion, potentially compromising the composite’s integrity. To address this, compatibilization strategies, such as the addition of adhesion-promoting polymers or reactive compatibilizers, have been employed to enhance interfacial bonding [

7]. Furthermore, the processing conditions during coextrusion, including the temperature, shear rate, and draw ratio, significantly influence the morphology and properties of the resulting fibers. Optimizing these parameters is essential to achieve the desired alignment and dispersion of LCP fibrils within the PA matrix [

8]. Advanced coextrusion techniques, such as multilayer coextrusion, have also been explored to fabricate composites with tailored architectures, offering more precise control over layer thickness and composition [

9,

10].

Agassant and Demay provide a comprehensive review of the polymer coextrusion processes, with a focus on the modeling of multilayer flows and the critical challenges associated with interfacial stability. The authors developed one-dimensional (1D) bilayer coextrusion models for both Newtonian and shear-thinning fluids, demonstrating that stationary interface positions and velocity profiles are established after a short distance, justifying the use of 1D stationary models for certain conditions. A significant portion of the review addresses interfacial instabilities that can arise during coextrusion. The authors note that such instabilities may be observed depending on the rheological properties of the coextruded polymers and their flow rate ratios. These instabilities can be amplified along the die land, leading to defects in the final product. Convective stability analysis and direct numerical computations are employed to distinguish flow situations that amplify or dampen these instabilities [

11].

Jape and Deshpande conducted a comprehensive study on the morphology, crystallization, and melting behavior of melt mixed blends of nylon 6,6 (PA6,6) and a thermotropic liquid crystalline polymer (LCP), specifically Vectra A950. The research aimed to understand how varying concentrations of LCP influence the thermal and morphological properties of the PA6,6 matrix. The study revealed that the PA6,6 and LCP blends are immiscible across all compositions, leading to distinct phase separation. Despite the immiscibility, the inclusion of LCP, particularly at lower concentrations, was found to accelerate the crystallization rate of the PA 6,6 matrix. This enhancement is attributed to the nucleating effect of the LCP, which facilitates the formation of smaller crystallites in the growth direction. Thermal analysis conducted indicated a decrease in the equilibrium melting temperature of the blends compared to pure PA6,6. The addition of LCP within the matrix also influenced the melting behavior [

12].

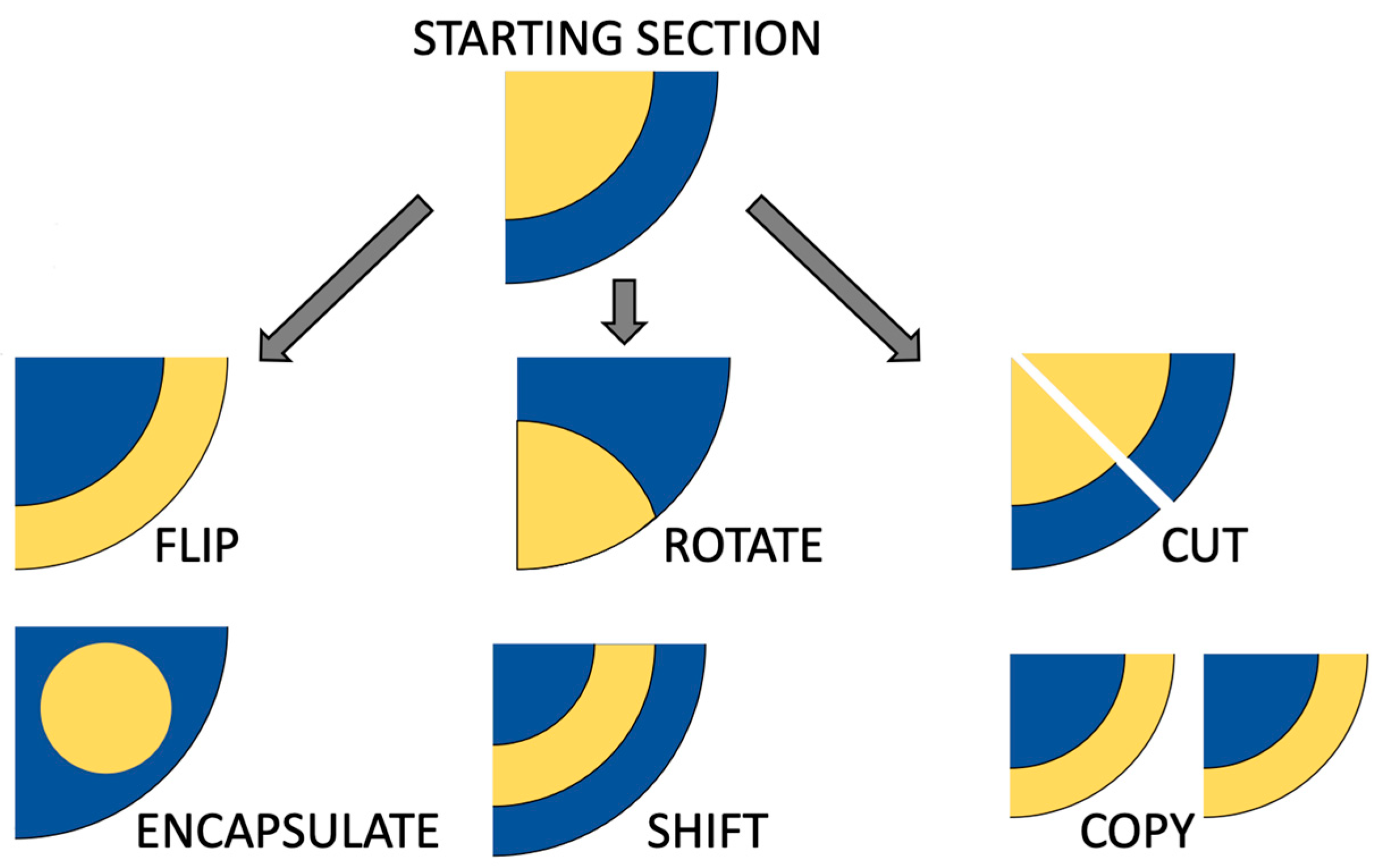

Layer-multiplying elements (LMEs) have emerged as a significant advancement in coextrusion technology, enabling the fabrication of multilayer polymer films with controlled architectures. By repeatedly splitting and stacking polymer streams, LMEs can produce films with hundreds to thousands of alternating layers, each potentially as thin as a few nanometers [

2]. The multilayer structure can lead to improved mechanical, barrier, and optical properties due to the increased interfacial area [

13]. Recent work in multilayer coextrusion has shown that such rheological contrasts can disrupt flow uniformity, but also that increasing the interfacial density can significantly enhance processing stability and strain hardening of the composite as a whole [

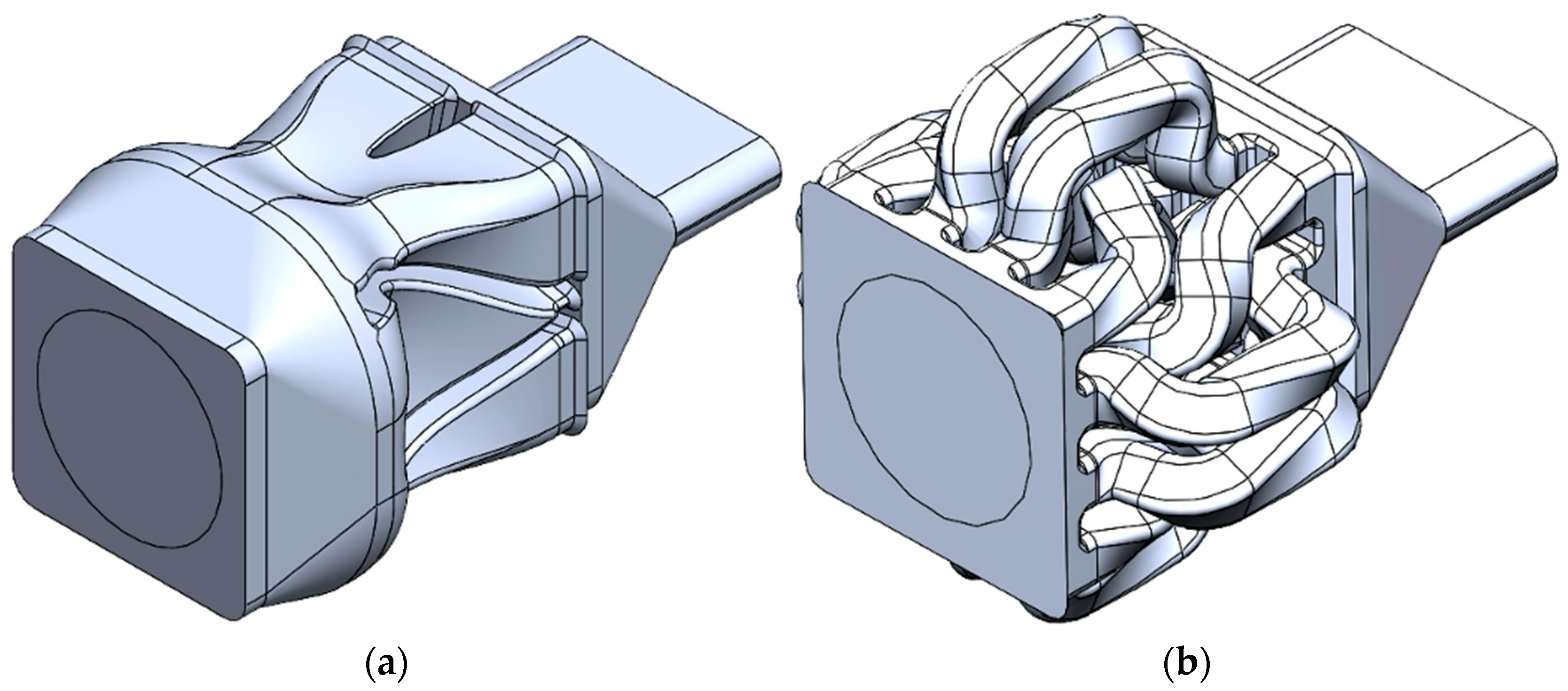

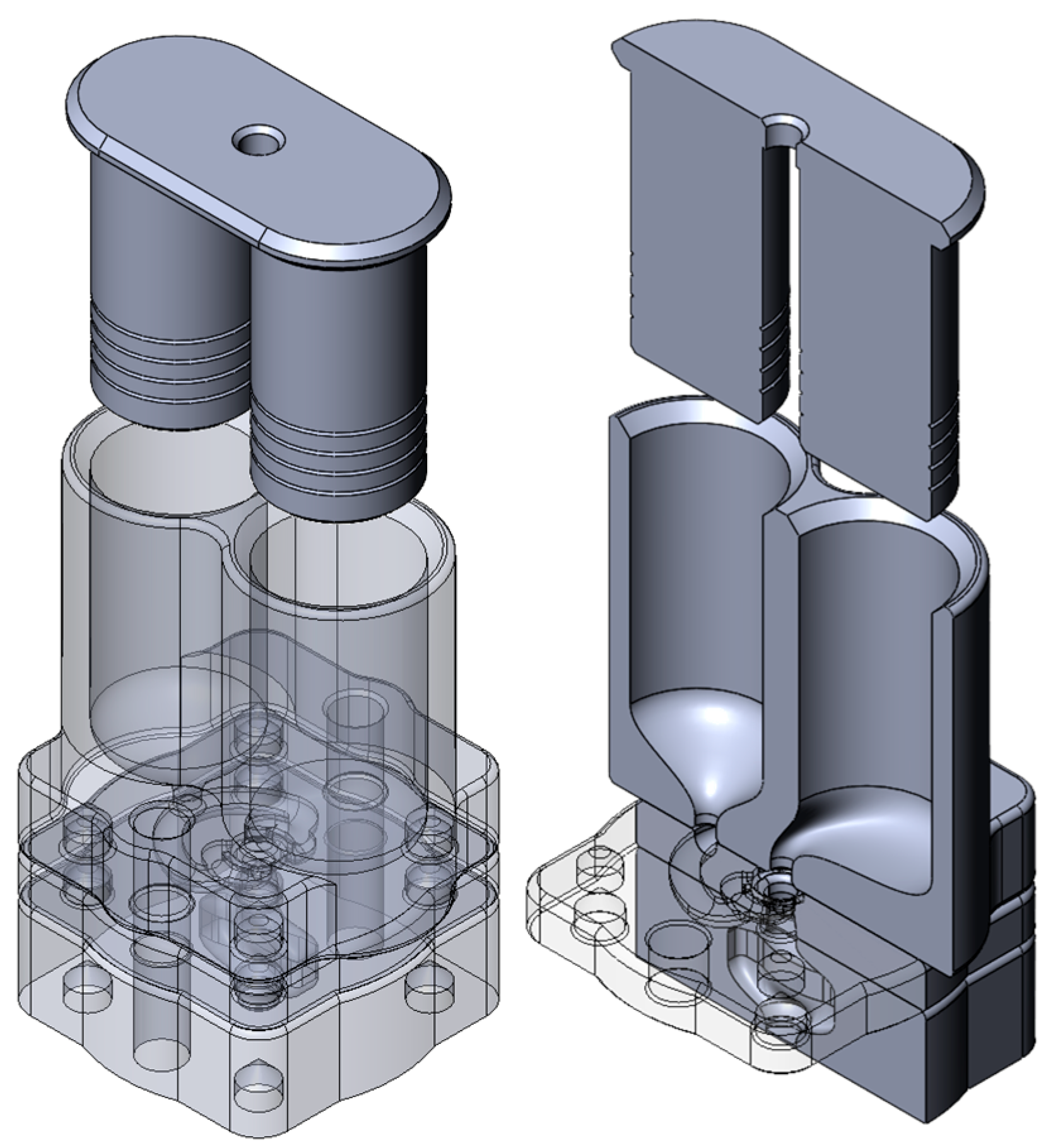

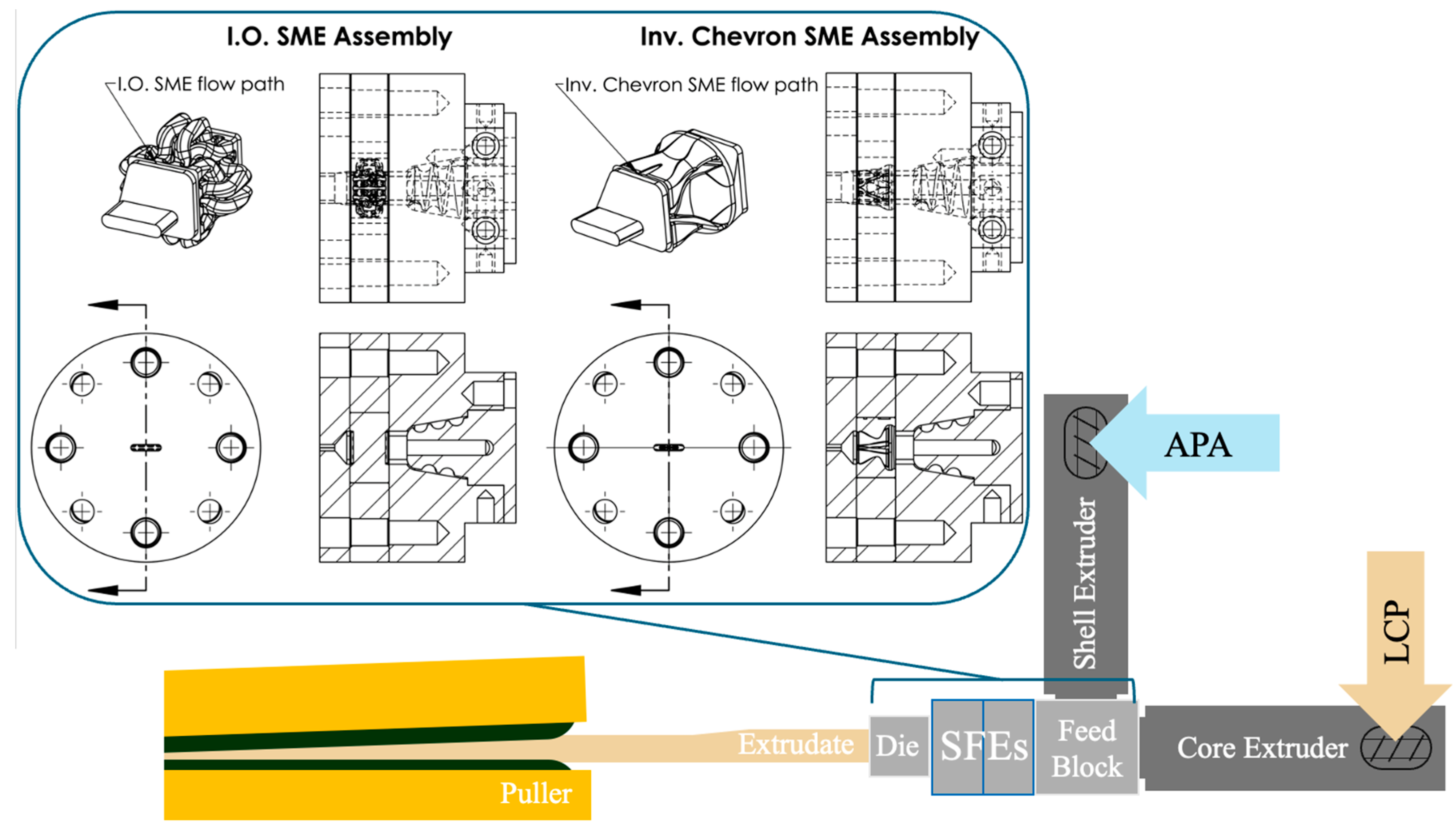

14]. Building on computational modeling of shape-forming elements, this research investigates a new approach for tailoring polymer composite architectures: the usage of shape-forming elements (SFEs) during coextrusion. Unlike layer-multiplying elements (LMEs), SFEs are intended to enable precise control across the composite’s 2D cross-section [

15]. This potential capability opens up new possibilities for manipulating molecular alignment and anisotropy, particularly in blends containing LCPs, which are known for their fibrillar anisotropy, to further enhance mechanical properties [

16,

17]. LCPs are a class of polymers that exhibit a unique combination of high strength, stiffness, and thermal stability due to their ordered molecular structures. When incorporated into polymer blends, LCPs can form fibrillar structures that reinforce the matrix, leading to composites with superior mechanical properties. The alignment of LCP domains during processing is important, as it influences the degree of reinforcement and anisotropy in the final material [

18,

19,

20,

21].

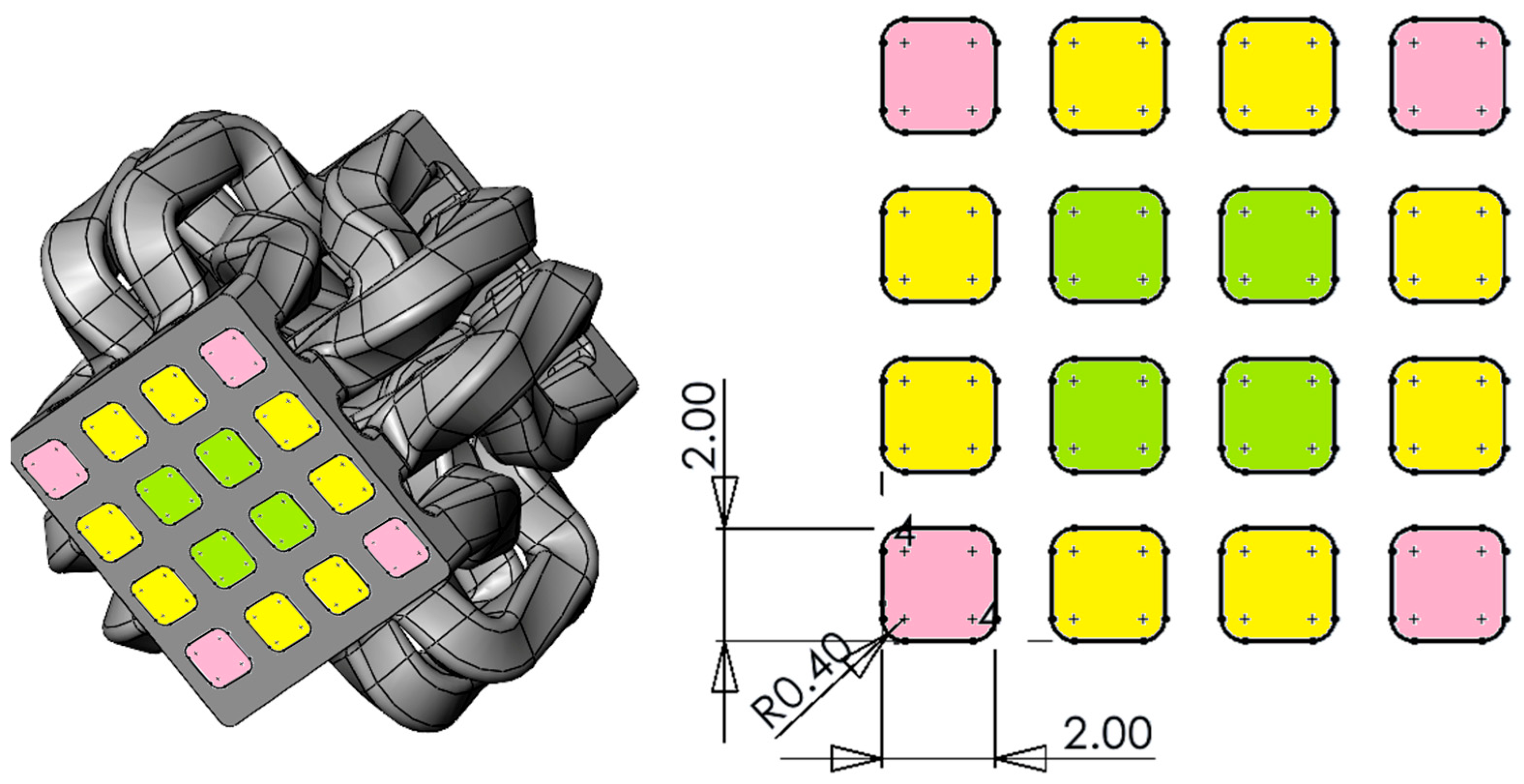

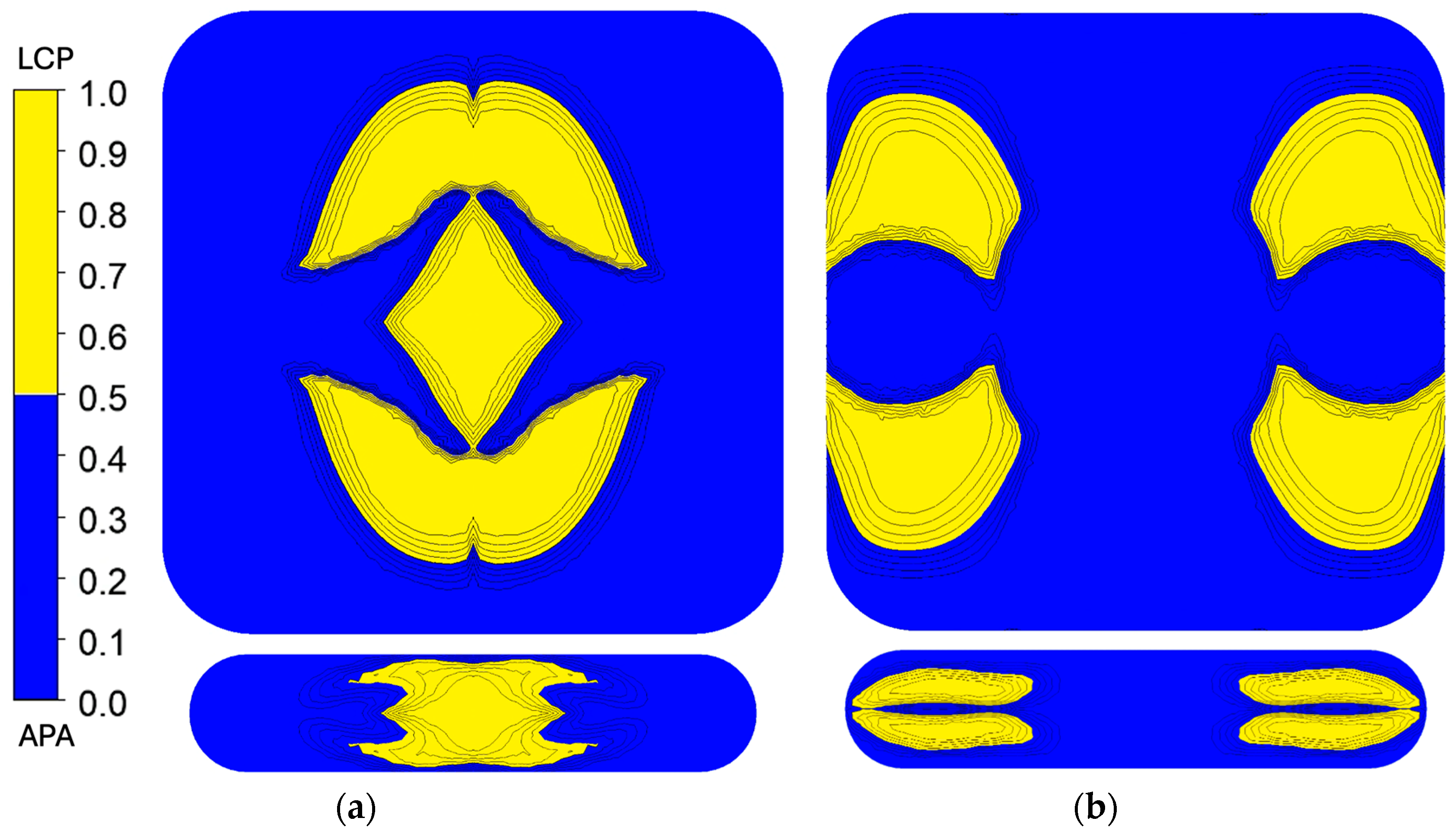

This study aims to design and fabricate coextruded architected composites using an amorphous polyamide (APA) as the matrix and LCP as the reinforcement. The specific objectives of this research are as follows: to evaluate the impact of shape-forming elements and the polymers used on the resulting cross-sectional architecture, to assess the mechanical properties of the composites as a function of SFE-induced architecture, and to investigate the influence of the draw ratio on molecular alignment and anisotropy. By transitioning from the one-dimensional control of LMEs to the two-dimensional control offered by SFEs, this study explores a more versatile method for optimizing structure–property relationships in LCP-based polymer composites.

4. Conclusions

This study demonstrates the potential of coextruded architected polymer composites to achieve tailored mechanical properties by integrating the selected material system of coextruded LCP and APA, SFE designs, and processing conditions. A combination of simulations, polymer clay modeling, and mechanical testing was used to understand the interactions between flow behavior of different materials and the geometry of the SFEs.

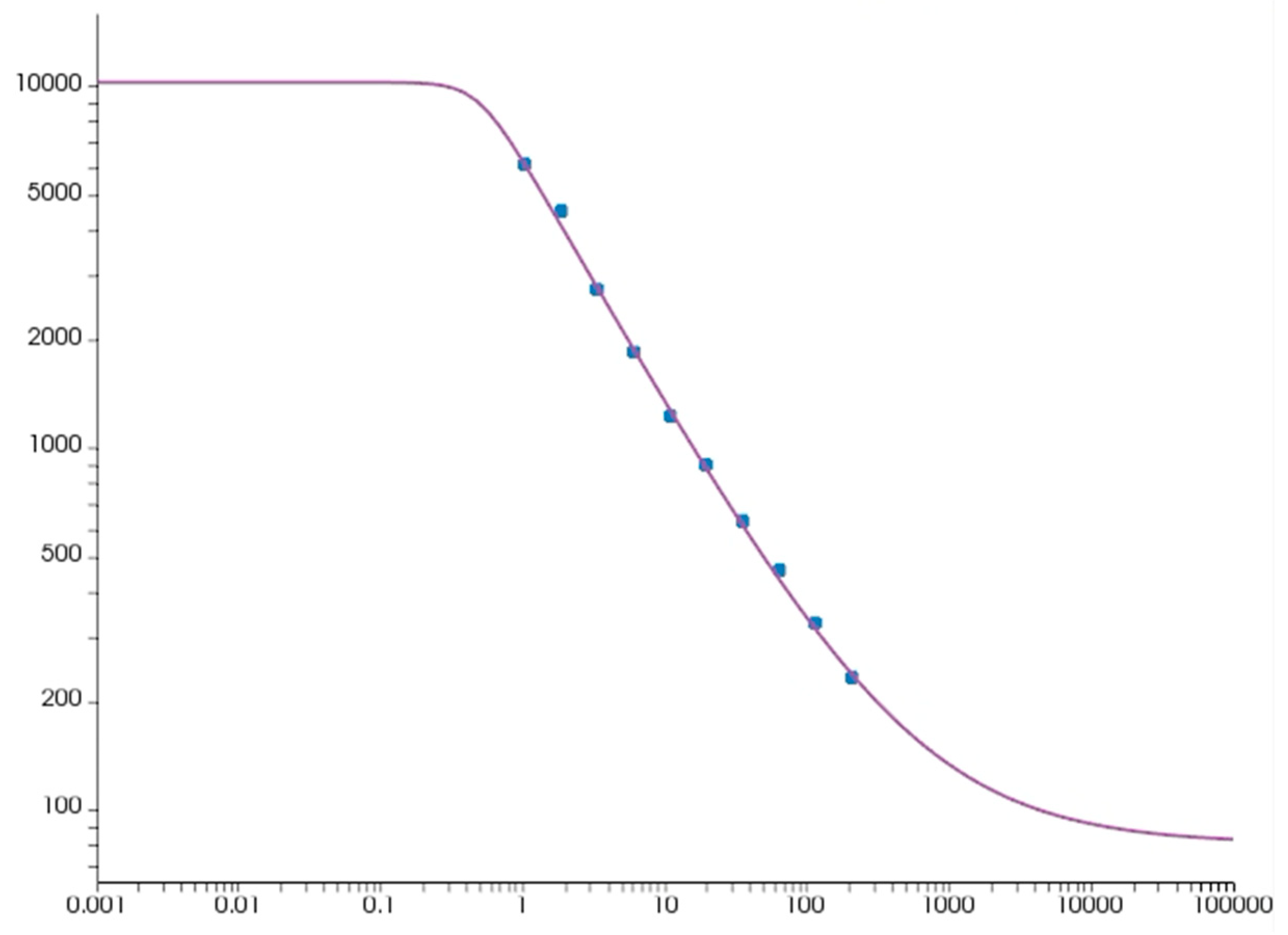

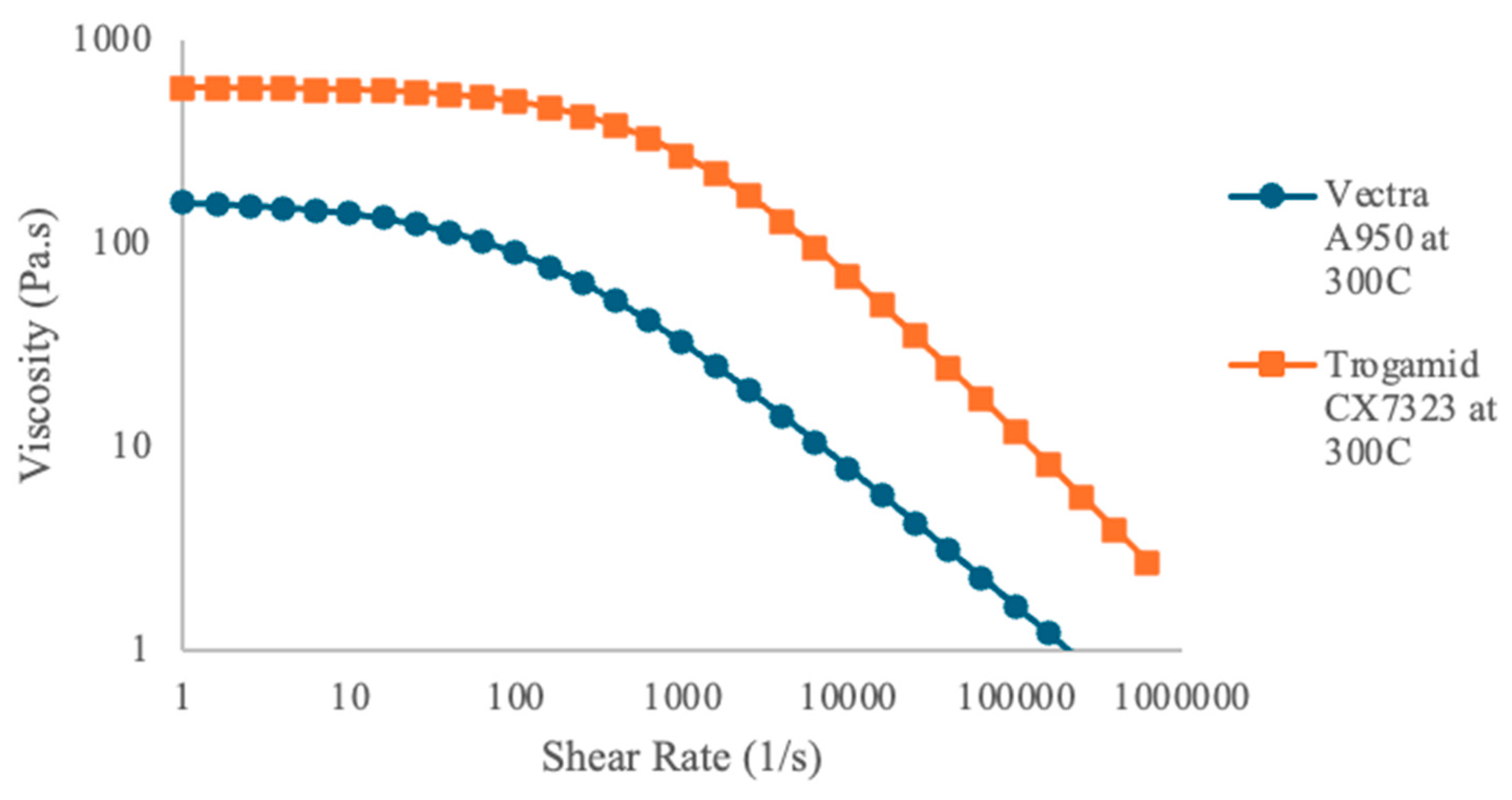

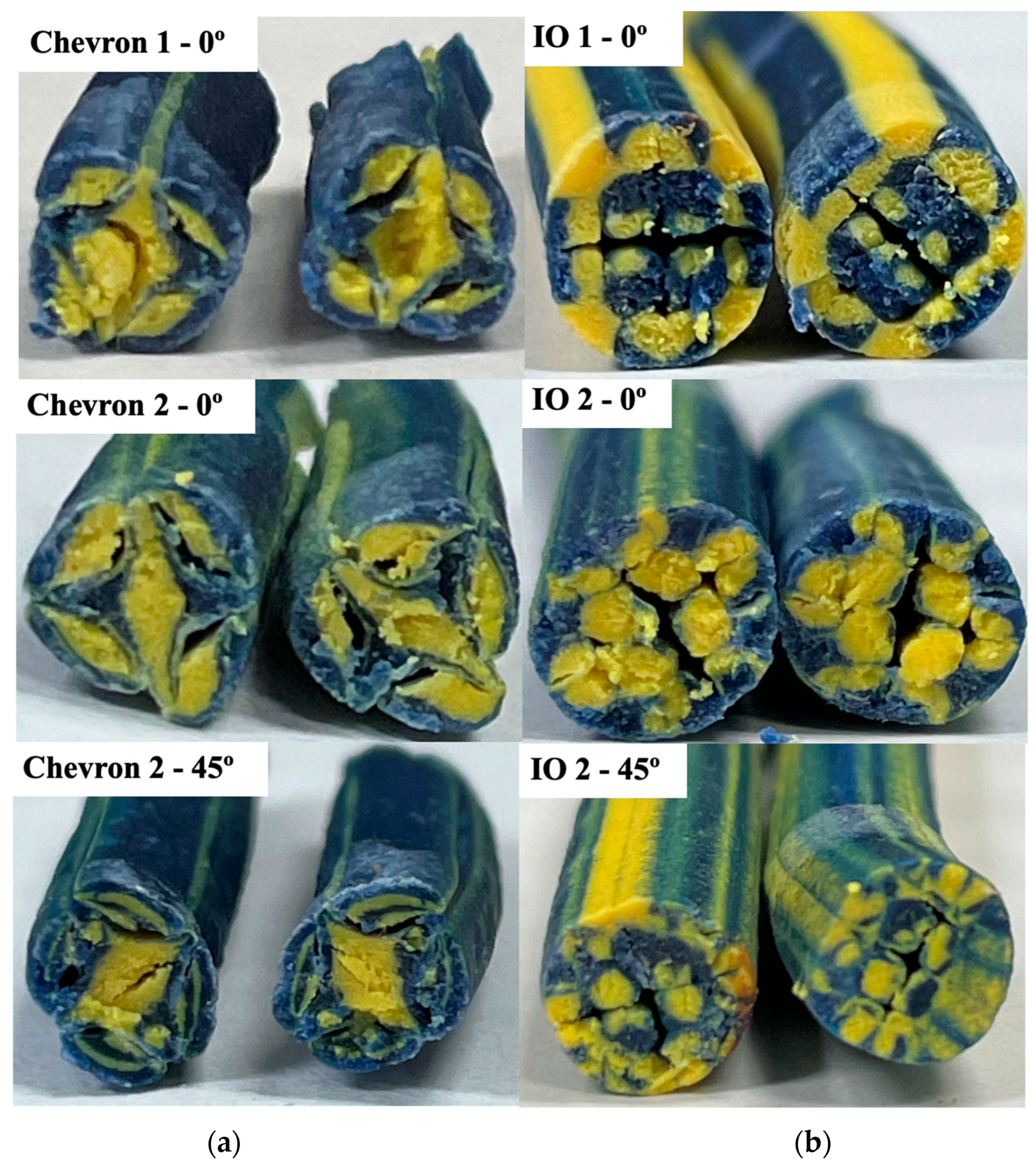

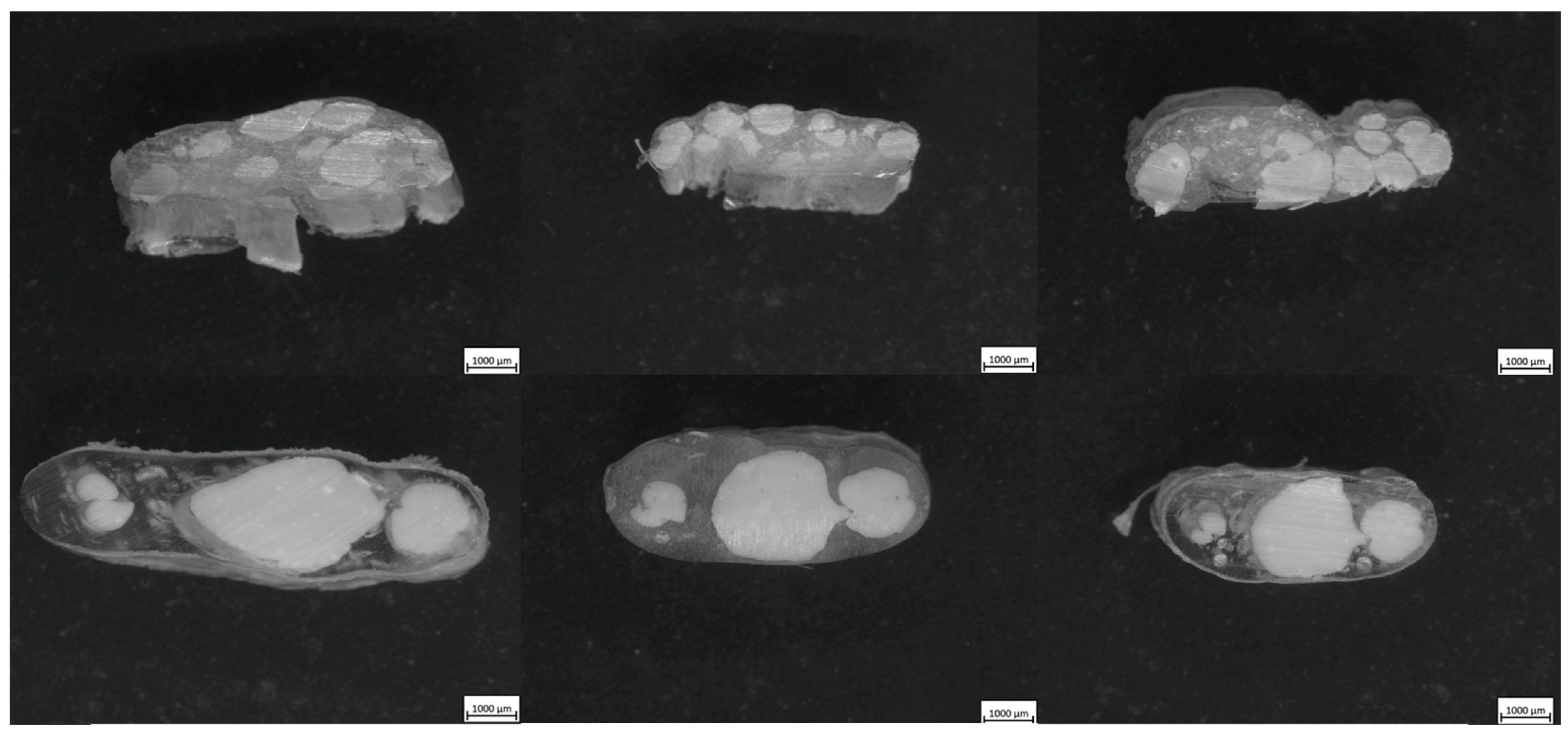

The rheological behavior of APA, LCP, and the polymer clay was essential for interpreting flow behavior and validating simulations with experimental results. The Cross–WLF model described the shear- and temperature-dependent viscosity of the APA/LCP system, while the BCY model captured the pseudoplastic behavior of the polymer clay. Simulations of polymer clay allowed the effect of geometry to be isolated from rheological contrast, providing a useful baseline for evaluating SFE performance. In particular, the Chevron configuration produced interface evolution that closely matched the polymer prototypes, while the I.O. configuration showed slightly more deviation, especially in the polymer system. These discrepancies were attributed to factors not captured by the idealized simulation, including die surface texture, wall slip, and the large viscosity mismatches between the LCP and APA phases.

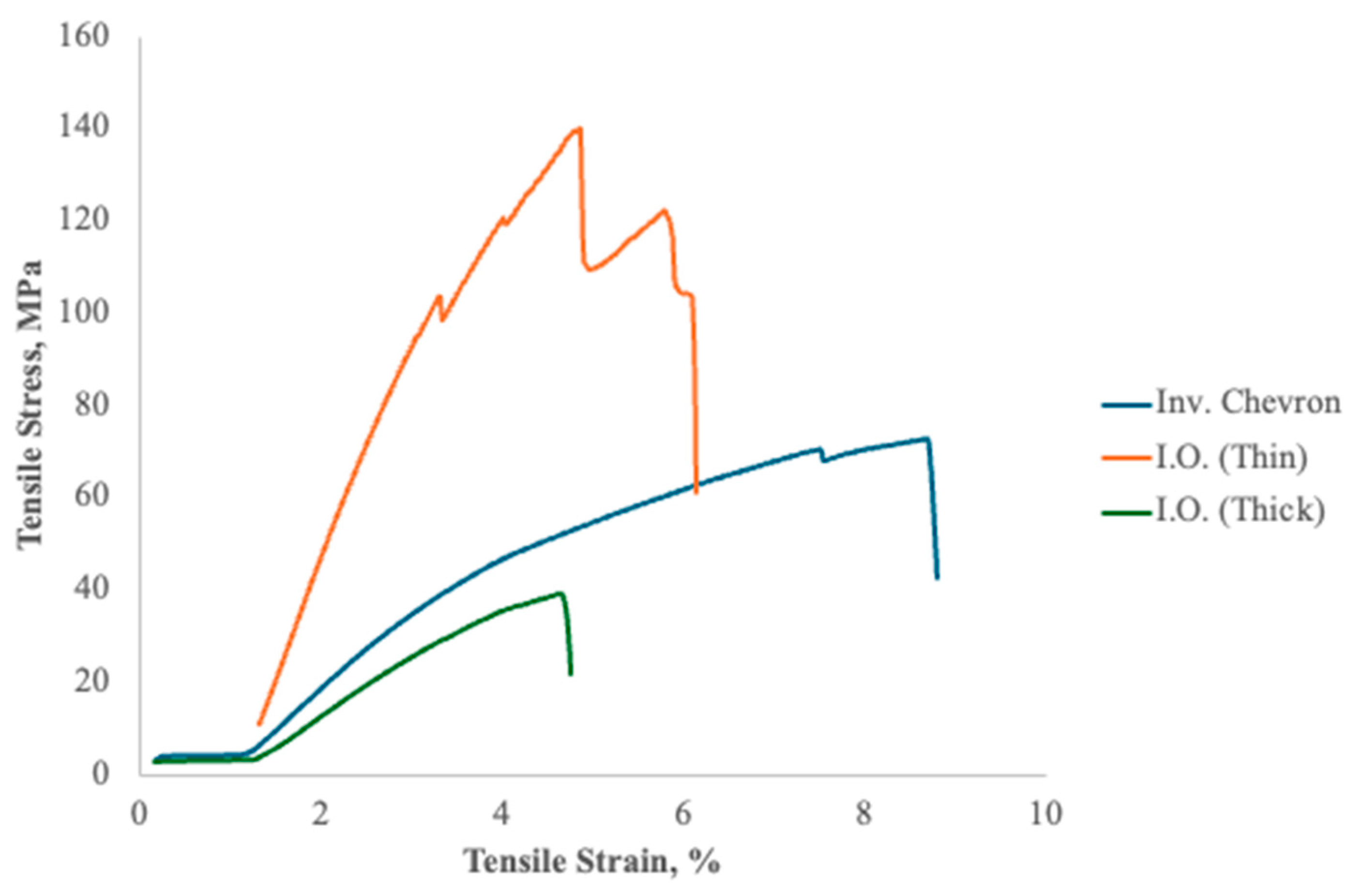

The significant differences in cross-sections in the polymer coextrusion from the simulation predictions were consistent with interfacial flow instabilities commonly reported in systems with strong rheological differences. These results reinforce the importance of combining physical prototyping with simulation to assess geometric effects independently of material complexities. The polymer clay model, in particular, served as a control that helped distinguish between geometry-driven and material-driven discrepancies in flow behavior. Simulations also revealed the importance of matching the rheological properties of core and shell materials for effective shaping. The low-viscosity, shear-thinning behavior of LCP enabled molecular alignment under extensional flow, which contributed to enhanced stiffness and strength along the extrusion direction.

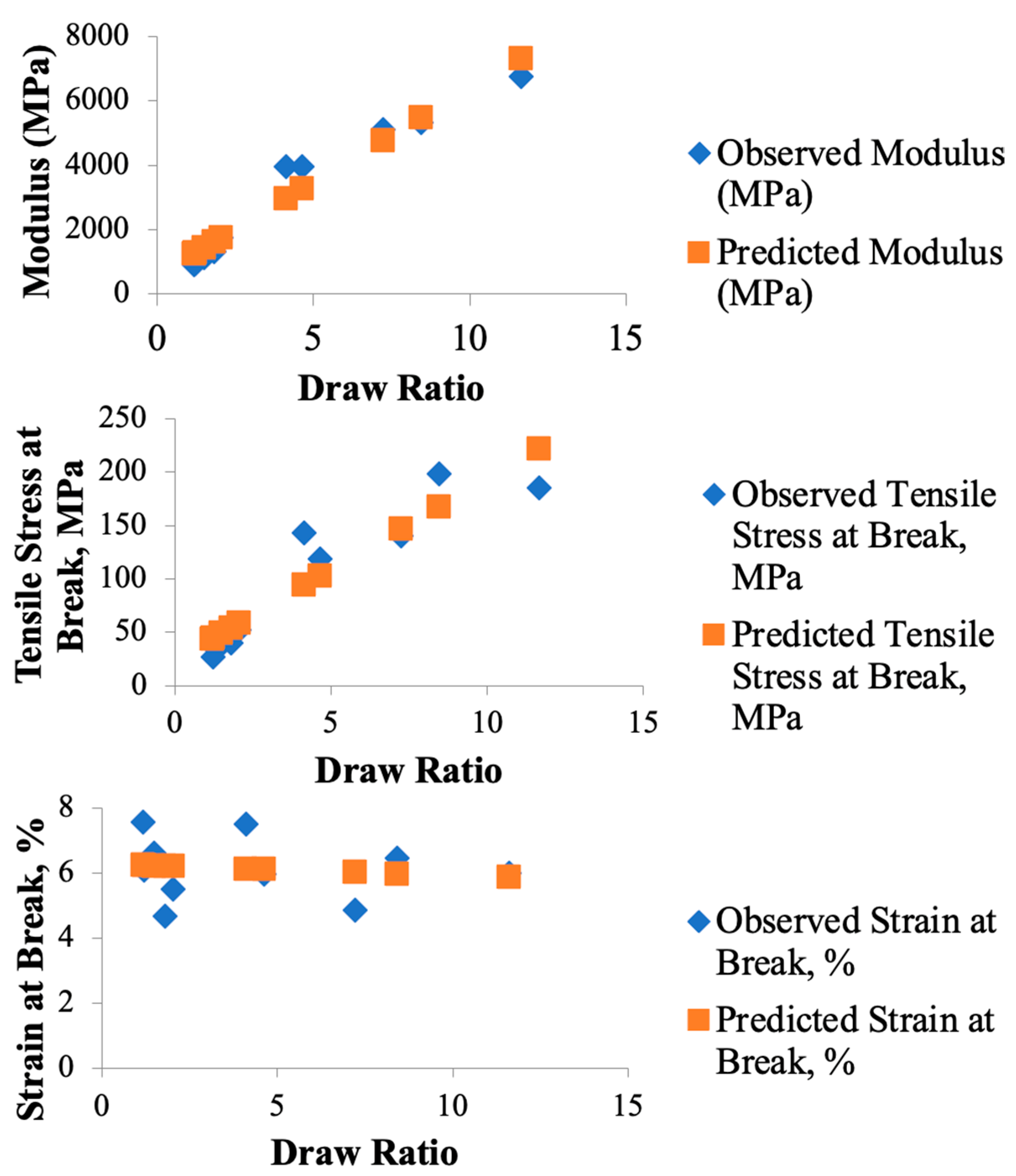

Experimental characterization also confirmed that the draw ratio was a key parameter influencing composite mechanical performance. Regression analysis showed that the modulus had the strongest correlation with the draw ratio, followed by stress at break, while strain at break remained largely unaffected, highlighting a tradeoff between reinforcement and ductility.

Despite the advances achieved with the I.O. configuration and optimized draw ratios, this study also identified challenges associated with anisotropy and brittleness. While alignment improves stiffness and strength along the flow direction, the transverse properties remain limited, increasing susceptibility to transverse fractures. Future work should explore a different design approach to ensure a more accurate result between the predicted SFE cross-section during the validation process and also during coextrusion with polymeric materials.