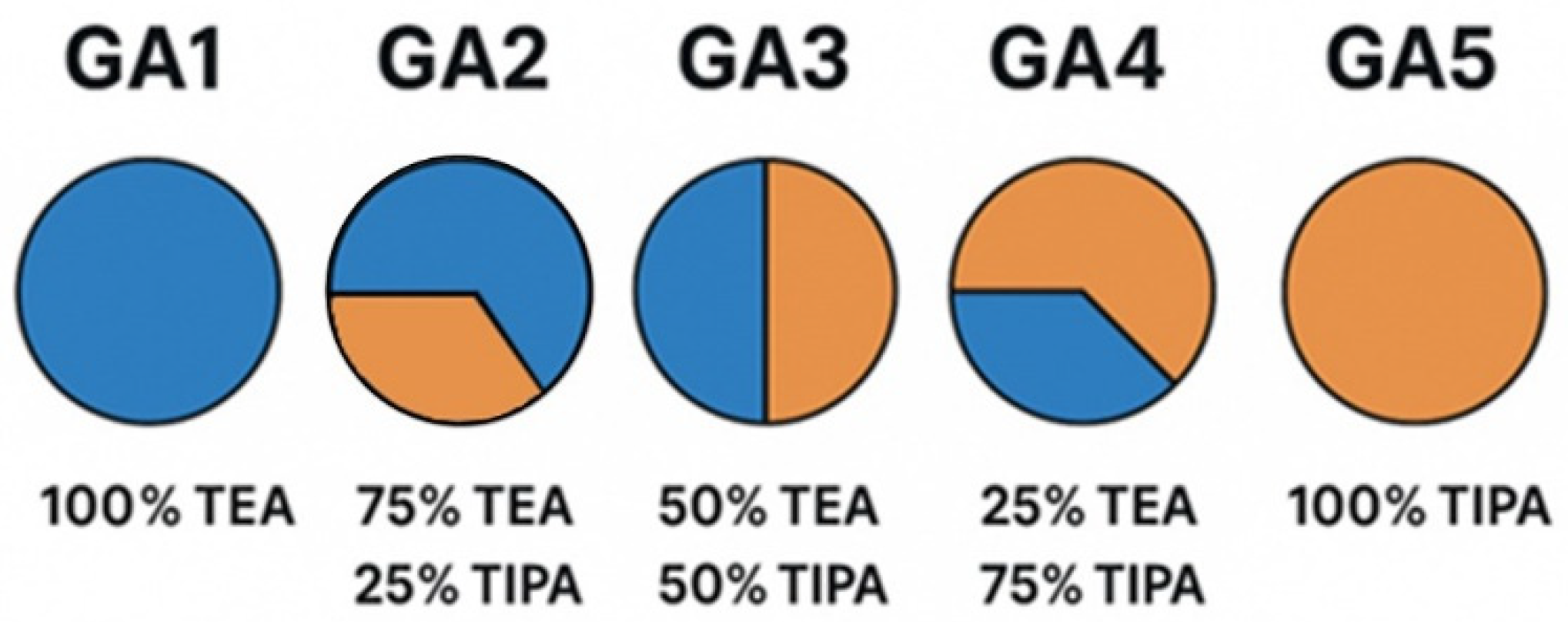

Under this heading, the grinding efficiencies achieved using different proportions of TEA and TIPA as grinding aids (GAs) are discussed, along with the resulting benefits regarding grinding performance and the corresponding particle size distribution of the cement.

3.2.1. Grinding Efficiency

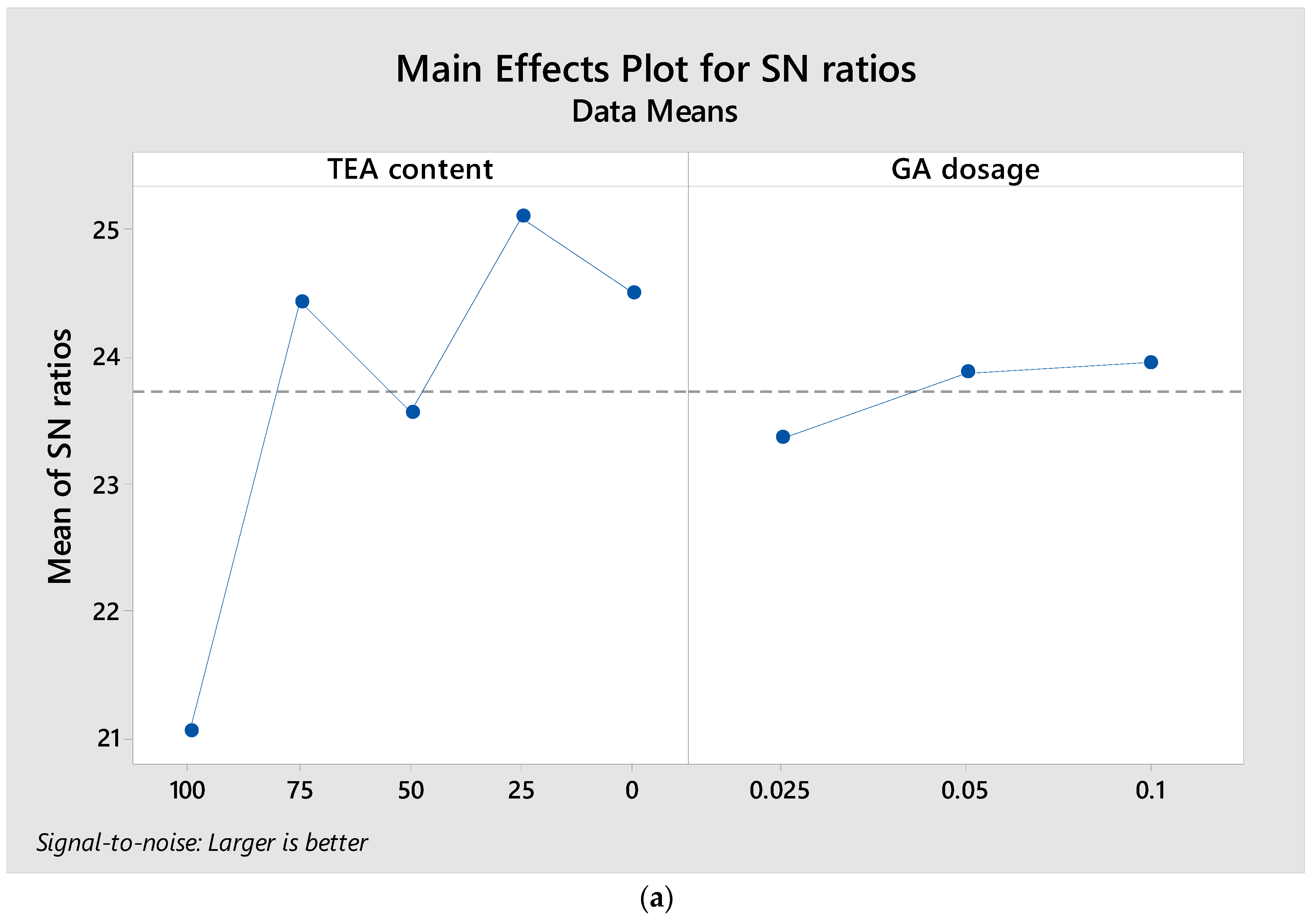

The grinding efficiencies of the GAs used in the study at different dosages are given in

Table 4, and the average energy efficiencies are given in

Figure 4.

Table 4 demonstrates that the type and dosage of grinding aids (GAs) significantly influence the grinding time, energy consumption required to achieve the target Blaine fineness, and the resulting relative energy efficiency. As illustrated in

Figure 4, GAs markedly enhance energy efficiency across all additive types and dosages. Among them, the TEA-only formulation (GA1) yielded the lowest relative energy efficiency at 11.36%, whereas efficiency progressively increased with higher TIPA content. This improvement is attributed to TIPA’s more effective dispersion capability, which reduces interparticle cohesion and lowers the energy demand during grinding [

6].

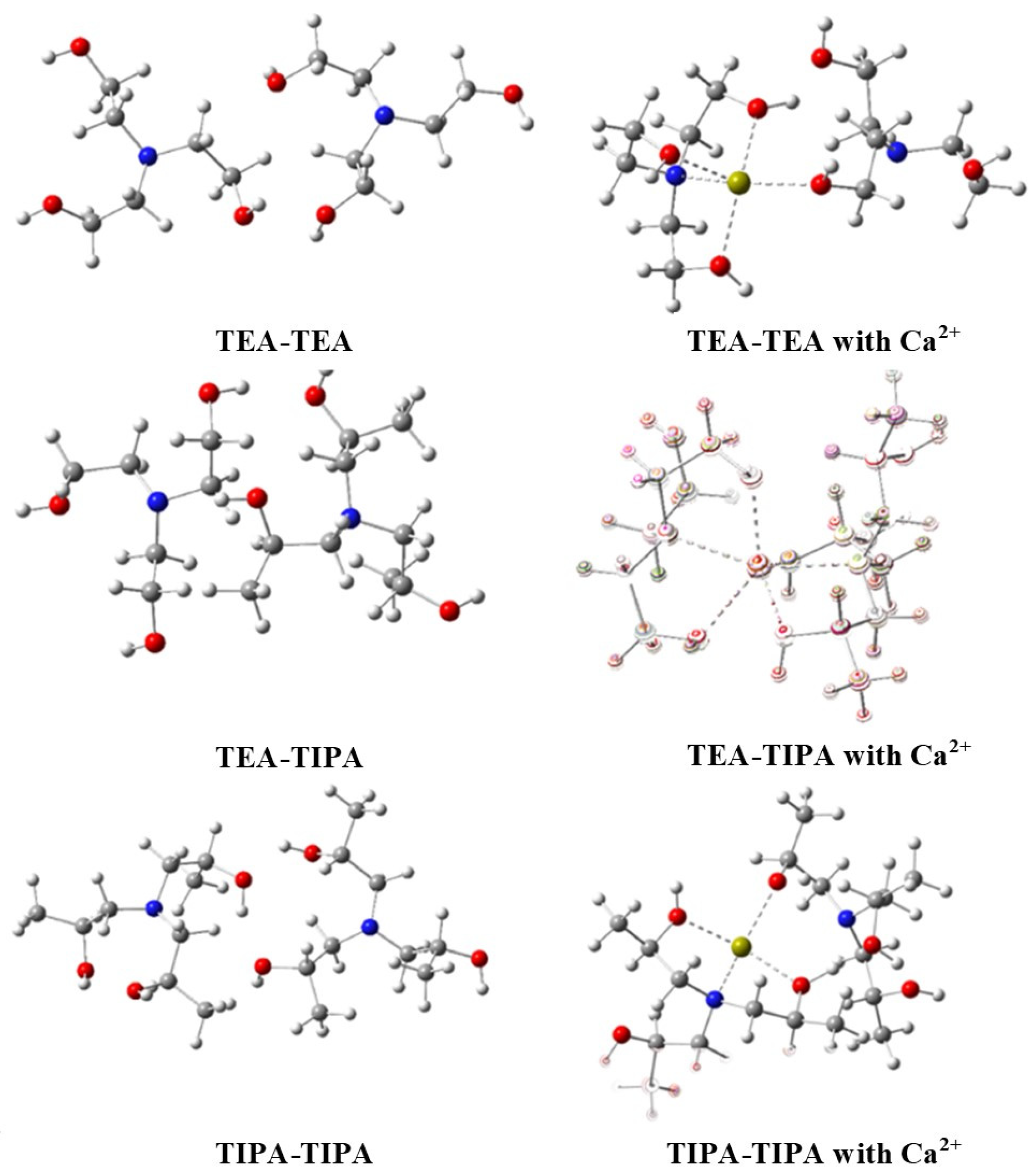

The highest relative energy efficiency, 18%, was obtained using GA4, a blend comprising 25% TEA and 75% TIPA. This outcome suggests that TEA and TIPA operate via distinct mechanisms within the cement matrix and exhibit a synergistic effect when combined in optimal ratios. TEA is known to mitigate particle agglomeration by decreasing electrostatic interactions, facilitating more effective particle breakage [

5,

19,

21]. However, this effect tends to plateau with increasing dosage and becomes limited when TEA is used in isolation. Previous studies indicate that TEA’s action is primarily based on its interaction with Ca

2+ ions at the particle surface, thus restricting its effect to surface modification [

22].

On the other hand, TIPA enhances specific surface area not only through surface interactions but also by promoting a more stable dispersion of fine particles. This is attributed to its strong complexing ability, which prevents the re-agglomeration of particles formed during grinding [

22,

23]. Consequently, TIPA appears more effective than TEA at higher dosages. As illustrated in

Figure 5, TEA–TIPA combinations demonstrated superior grinding performance by synergistically integrating the individual benefits of both additives. Specifically, GA4 delivered the most effective performance by reducing interparticle cohesion through the action of TEA and suppressing the re-agglomeration of fine particles through the effect of TIPA (

Table 4,

Figure 5). Consequently, GA4 enhanced grinding efficiency for the target Blaine fineness by 16.6–18.3% compared to the control (

Table 4). This improvement is attributed to the combined mechanisms: the electrostatic interactions of TEA and the steric hindrance imparted by the methyl groups of TIPA.

Similar observations were reported by Mao et al. [

22], who found that TEA–TIPA mixtures, when used at specific ratios, improved grinding energy efficiency by 10–20% compared to single-component systems. In the present study, the maximum observed improvement of 18% aligns well with these findings and highlights the importance of admixture optimization.

Although GA5 (100% TIPA) exhibited high grinding efficiency, its performance (16.8%) was slightly lower than that of GA4. This difference may be attributed to TIPA saturation at elevated dosages and an additive–matrix interaction limitation. These results suggest that the effectiveness of grinding aids depends not only on their chemical structure but also on the balance of their physicochemical interactions with cement particles [

24].

Kobya et al. [

21] evaluated the grinding efficiencies of TIPA, DEIPA, DEG, and EG-type GAs at comparable dosages, targeting a Blaine fineness of 4100 ± 100 cm

2/g under similar conditions. Reported average efficiencies relative to the control were 18.6%, 9.7%, 12.6%, and 8.3% for TIPA, DEIPA, DEG, and EG, respectively. In the present study, GA4 (75% TIPA + 25% TEA) exhibited higher performance (

Figure 4) than all GAs reported by Kobya et al. [

21], except for TIPA alone. This finding supports the previously discussed synergistic advantages of combining TEA and TIPA.

In conclusion, the optimized use of TEA and TIPA combinations significantly improves grinding efficiency, offering potential reductions in energy consumption and CO2 emissions within cement production.

3.2.2. Environmental Impact

Based on the collected data, the impact of grinding aid application on annual electrical energy consumption and related CO

2 emissions in the cement grinding process in Türkiye was evaluated. A summary of the estimated results is presented in

Table 5.

As shown in

Table 5, approximately 84 kilotons of cement were produced in Türkiye in 2024 [

25]. Using GAs during this production could result in energy savings of approximately 306 to 598 GWh. Based on national emission factors, where 0.478 kg of CO

2 is emitted per kWh of electricity consumed, applying GAs could prevent an estimated 146 to 286 kilotons of CO

2 emissions [

26].

Considering that a single tree can absorb about 12 kg (0.012 tons) of CO

2 annually through photosynthesis [

27], this reduction corresponds to the annual sequestration capacity of approximately 12 to 23 million trees. For comparison, clinker grinding without using GAs emits around 1500 kilotons of CO

2 per year, equating to the CO

2 absorption capacity of roughly 125 million trees.

Moreover, based on data from the literature [

28], the average annual electricity consumption of a four-person household in Türkiye is approximately 5000 kWh. Thus, the energy savings achieved through GA usage could meet the yearly electricity needs of 61,000 to 120,000 households.

Lower-carbon production can be achieved by partially replacing Portland cement with alternative binders and/or recycled constituents [

1,

2,

3,

8]. The CO

2 benefit from clinker reduction typically exceeds the savings attainable from finish-grinding alone because it directly avoids process (calcination) emissions. Complementary to this, our results indicate that grinding in the presence of GA not only lowers specific energy demand but also refines the particle size distribution and improves powder flow. These effects can enable higher levels of pozzolanic/SCM substitution at equivalent performance, thereby amplifying the environmental gains of clinker reduction. In this sense, GA-processed cements provide an enabling platform for more aggressive pozzolanic substitution regimes and, by extension, more sustainable concrete production.

3.2.3. Particle Size Distribution

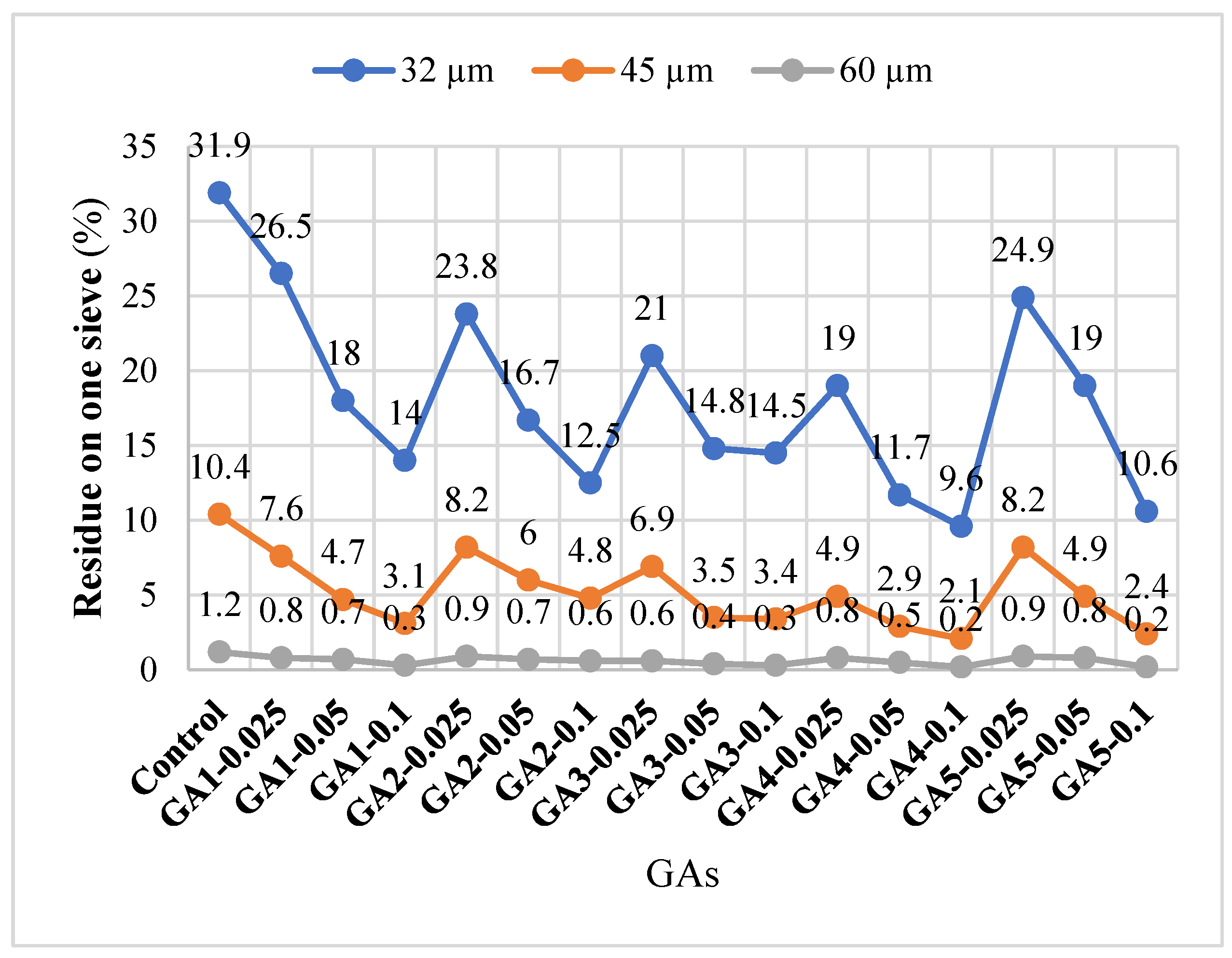

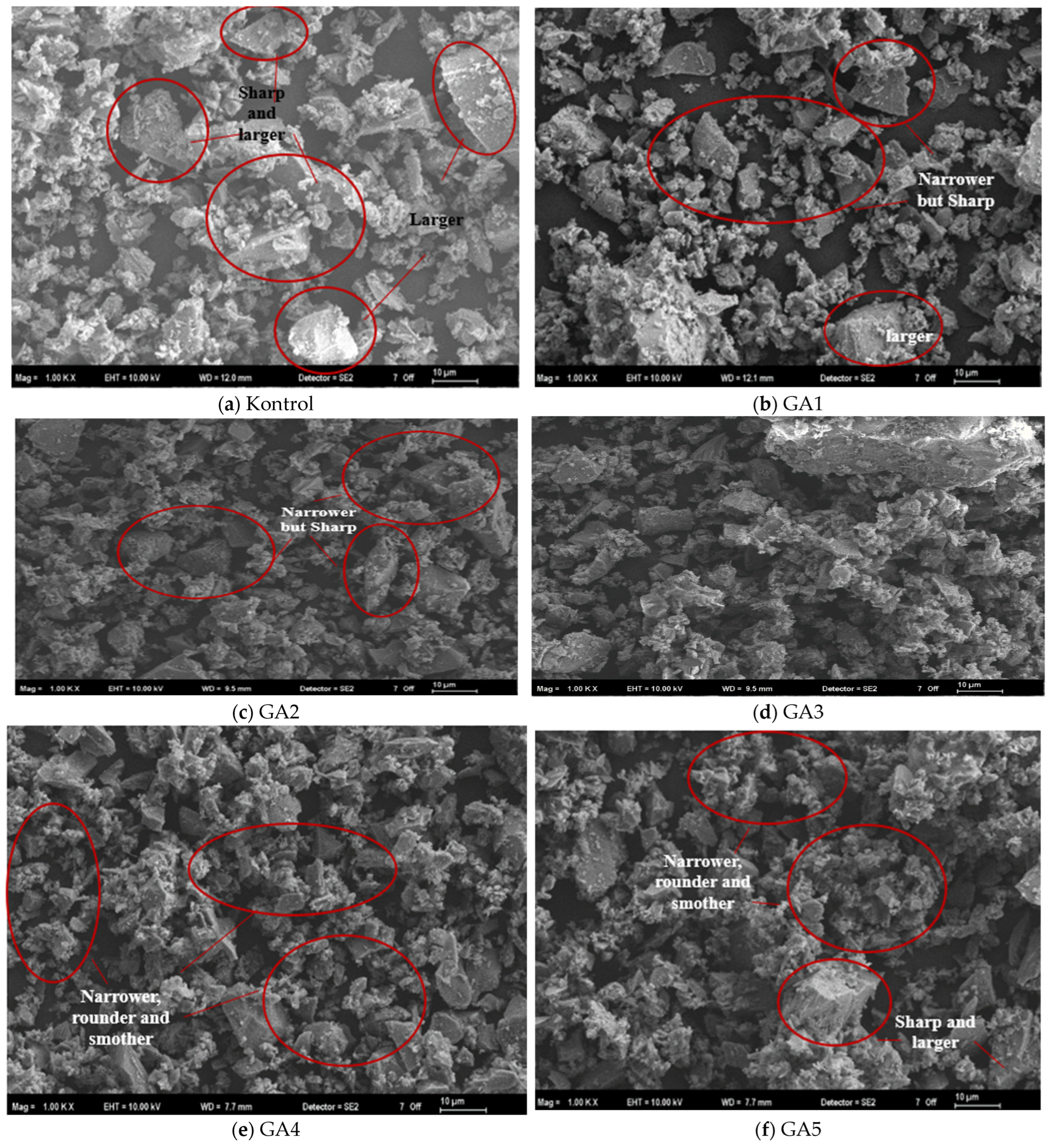

Particle size distribution during cement grinding is a crucial factor that directly influences both cement hydration kinetics and the performance of GAs. This study examined the impact of TEA and TIPA, used in various ratios as GAs, on particle size distribution. Particular attention was given to the percentages of particles retained on 32 µm, 45 µm, and 60 µm sieves, as illustrated in

Figure 5.

GAs significantly increased the fraction of particles below 32 µm, enhancing grinding efficiency compared to the control sample without additives.

Moreover, analysis of the particle fractions passing below 45 µm and 60 µm reveals that GAs effectively reduce coarse particles. The pass rate below 45 µm, which was 31.9% in the control sample, decreased markedly in all GA-containing mixtures. The lowest value, 2.1%, was observed in the GA4-0.1 sample (

Figure 5). This behavior observed in GA4, which consists of 75% TIPA and 25% TEA, aligns with the findings of Mao et al. [

22]. They reported that TIPA effectively dissolves agglomerates and minimizes the film-forming effect on cement surfaces. Additionally, Altun et al. [

29] demonstrated that TEA reduces the likelihood of agglomeration by enhancing electrostatic repulsion between particles, thereby improving grinding efficiency.

A notable observation is that increasing the GA dosage consistently results in finer particle distributions. This suggests that higher dosages enhance the impact-grinding mechanism, where the lubricant effect of the additive dominates, thereby improving grinding medium efficiency [

30].

Additionally, sub-60 µm pass values remaining below 1% in nearly all GA systems indicate effective suppression of coarse fractions. This demonstrates that the additives contribute to a more homogeneous particle size distribution, which increases fineness and potentially boosts cement reactivity by narrowing the particle size distribution curve [

31].

Consequently, TEA and TIPA additives, individually and in combination, positively influence particle size distribution. However, determining the optimum additive ratio and dosage is crucial. The appropriate balance enhances energy efficiency during grinding, producing a more stable and reactive binder with improved performance.