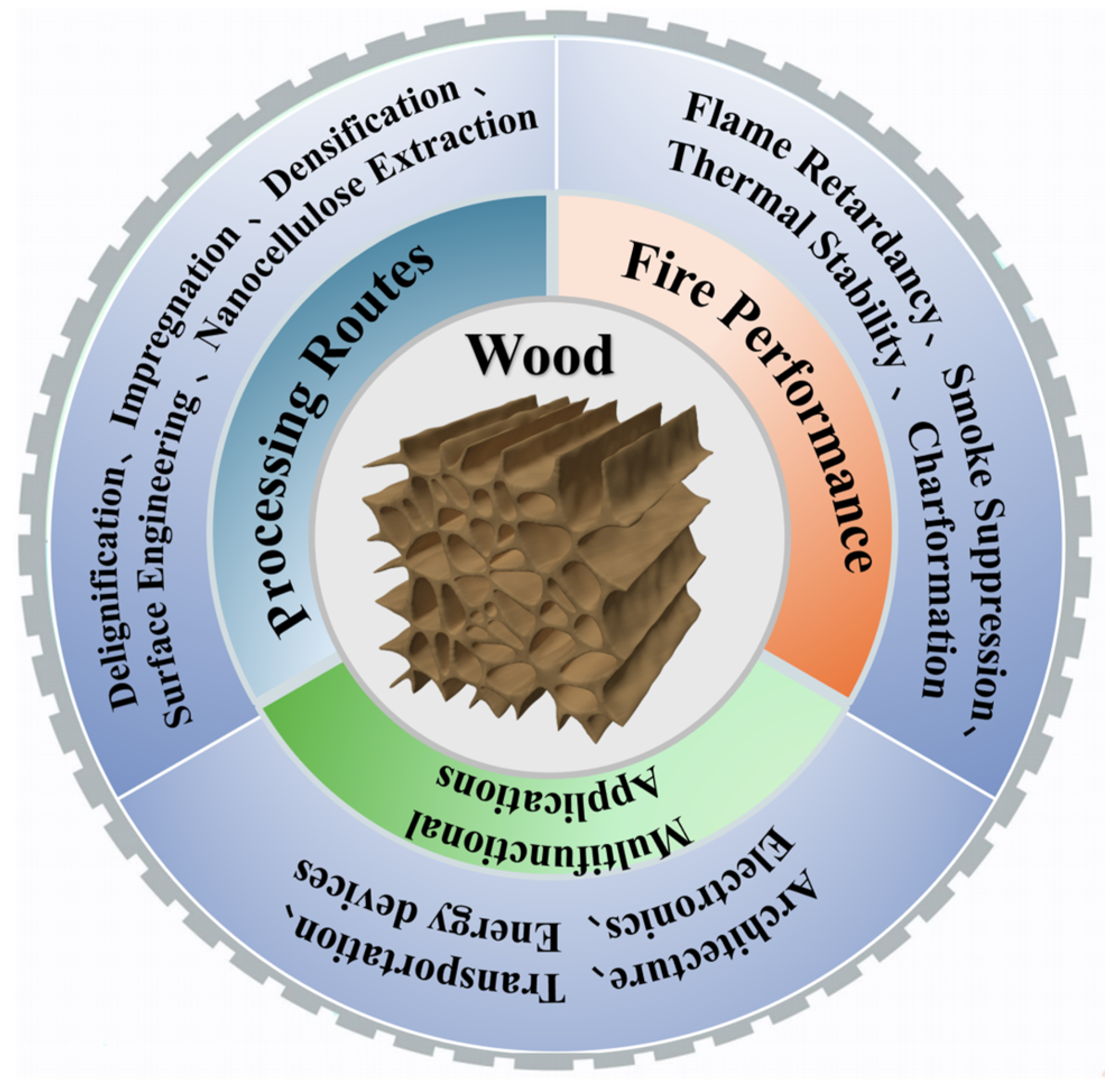

Advances in Wood Processing, Flame-Retardant Functionalization, and Multifunctional Applications

Abstract

1. Introduction

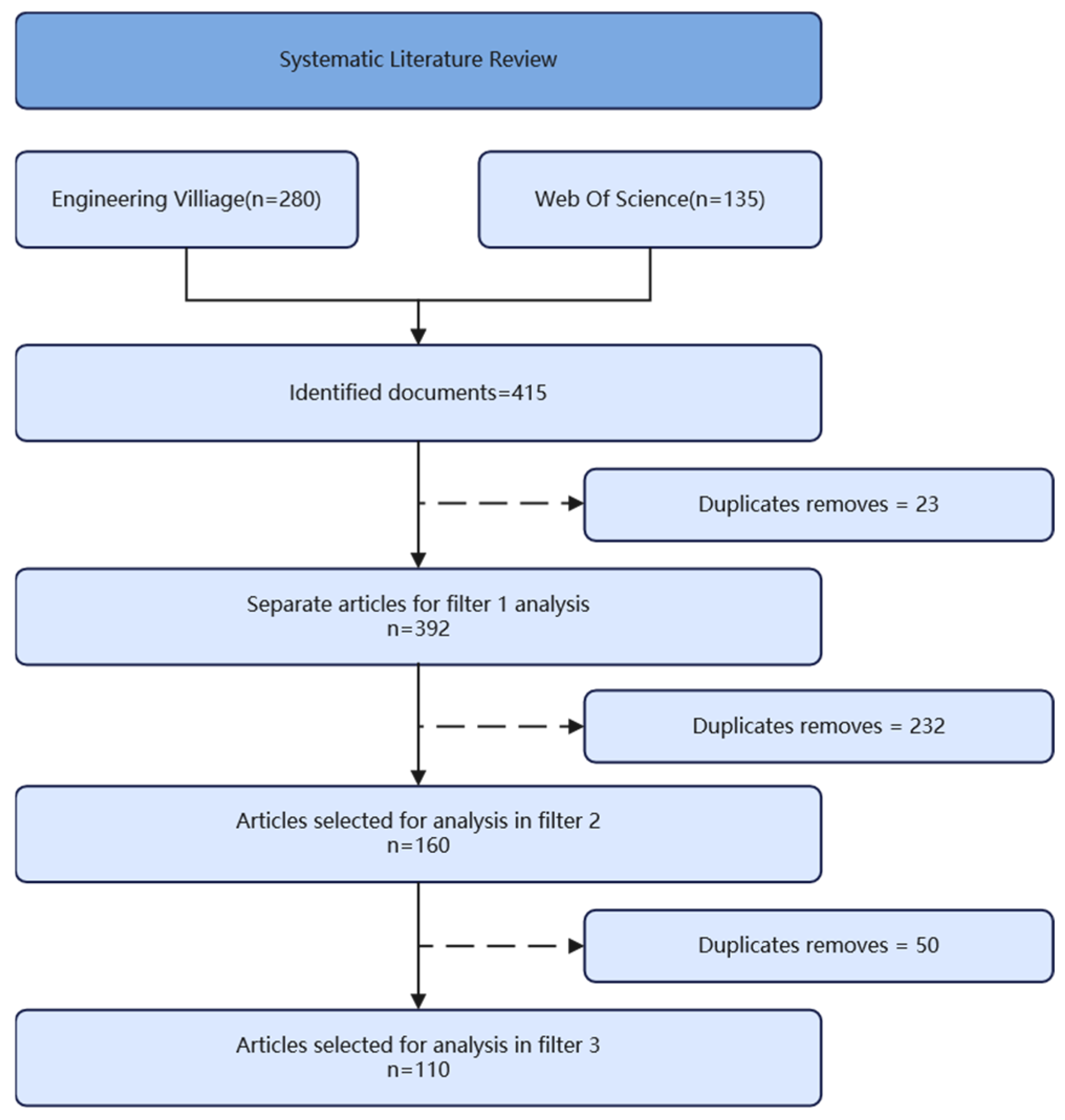

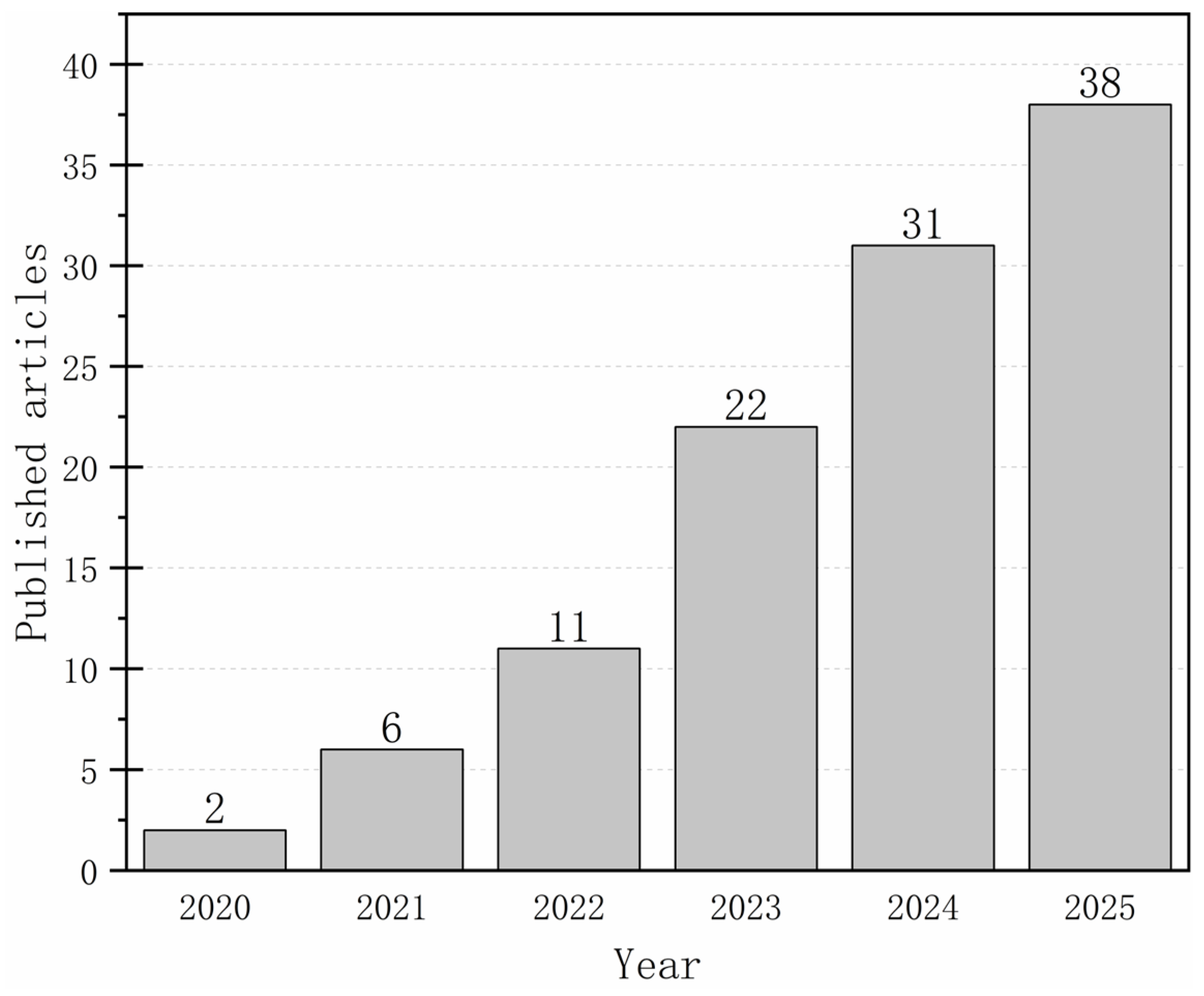

2. Review Methodology

3. The Hierarchical Structure and Composition of Natural Wood

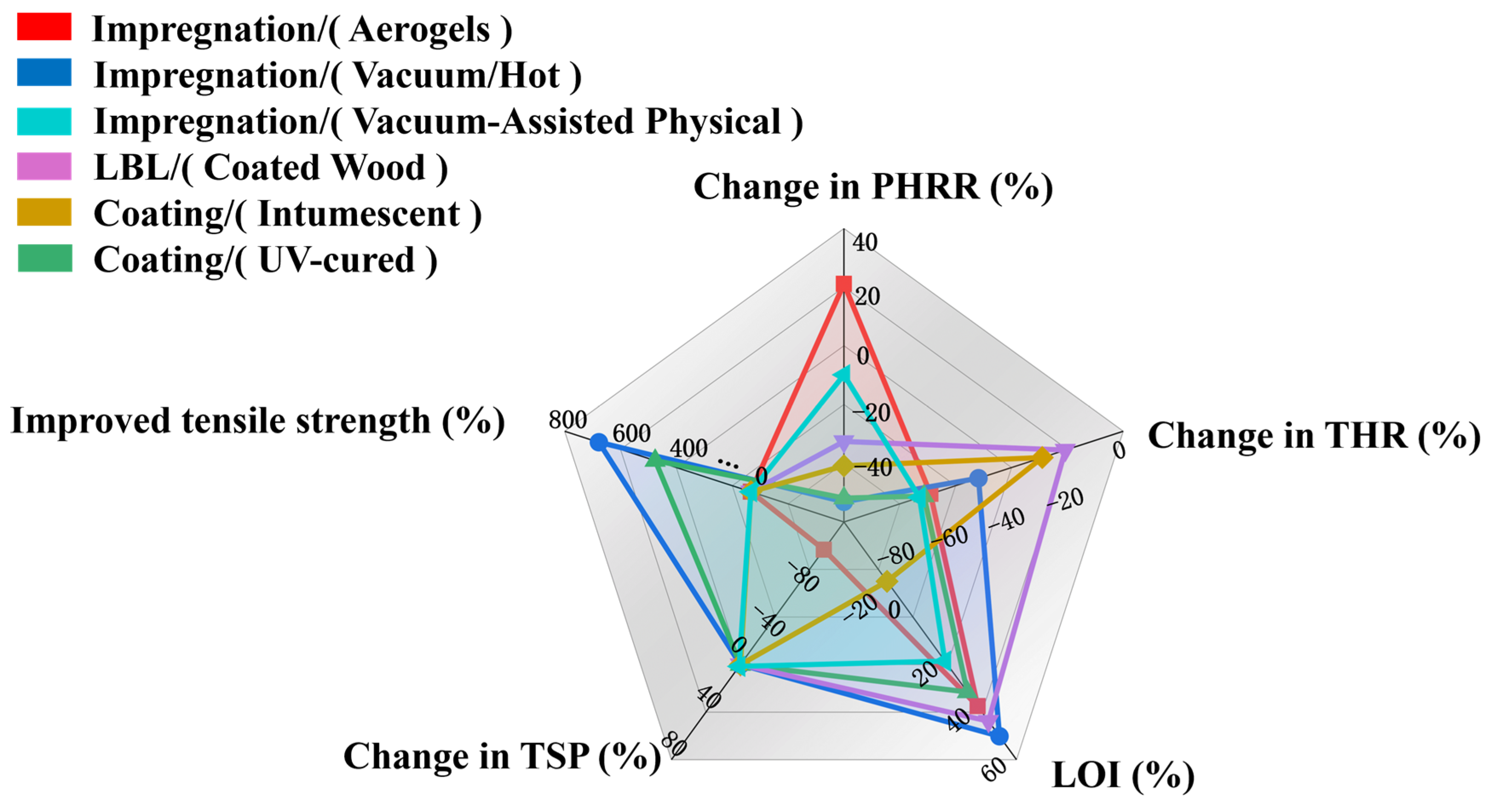

4. Foundational Processing for Functionalization

4.1. Delignification and Densification

4.2. Wood-Derived Nanocellulose

4.3. Implications for Functionalization

5. Flame-Retardant Functionalization of Wood: Mechanisms, Applicability, and Performance Optimization

5.1. Mechanisms of Flame Retardancy in Wood

5.2. Bulk Modification Strategies: Penetrating the Hierarchical Structure

5.2.1. Impregnation with Inorganic Additives

5.2.2. In Situ Mineralization

5.2.3. Reactive Grafting and Covalent Bonding

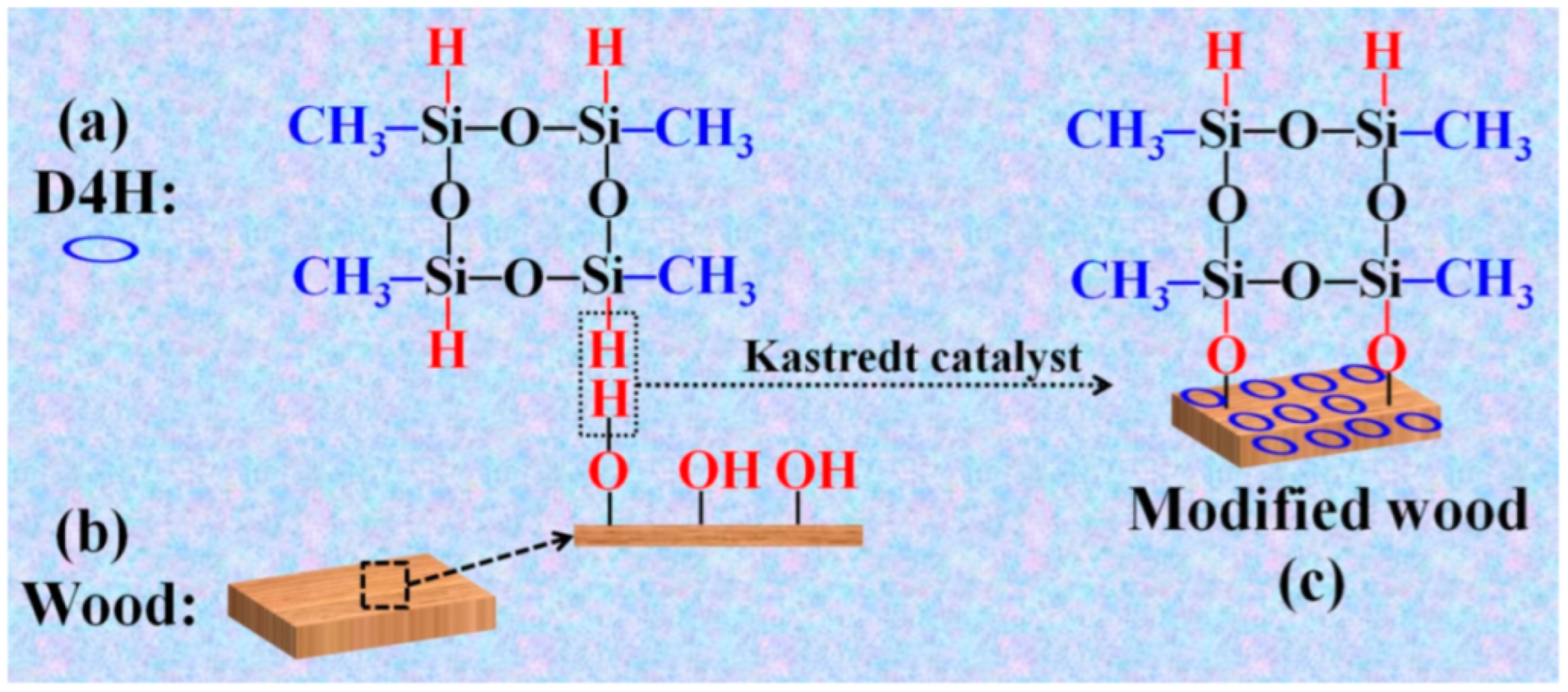

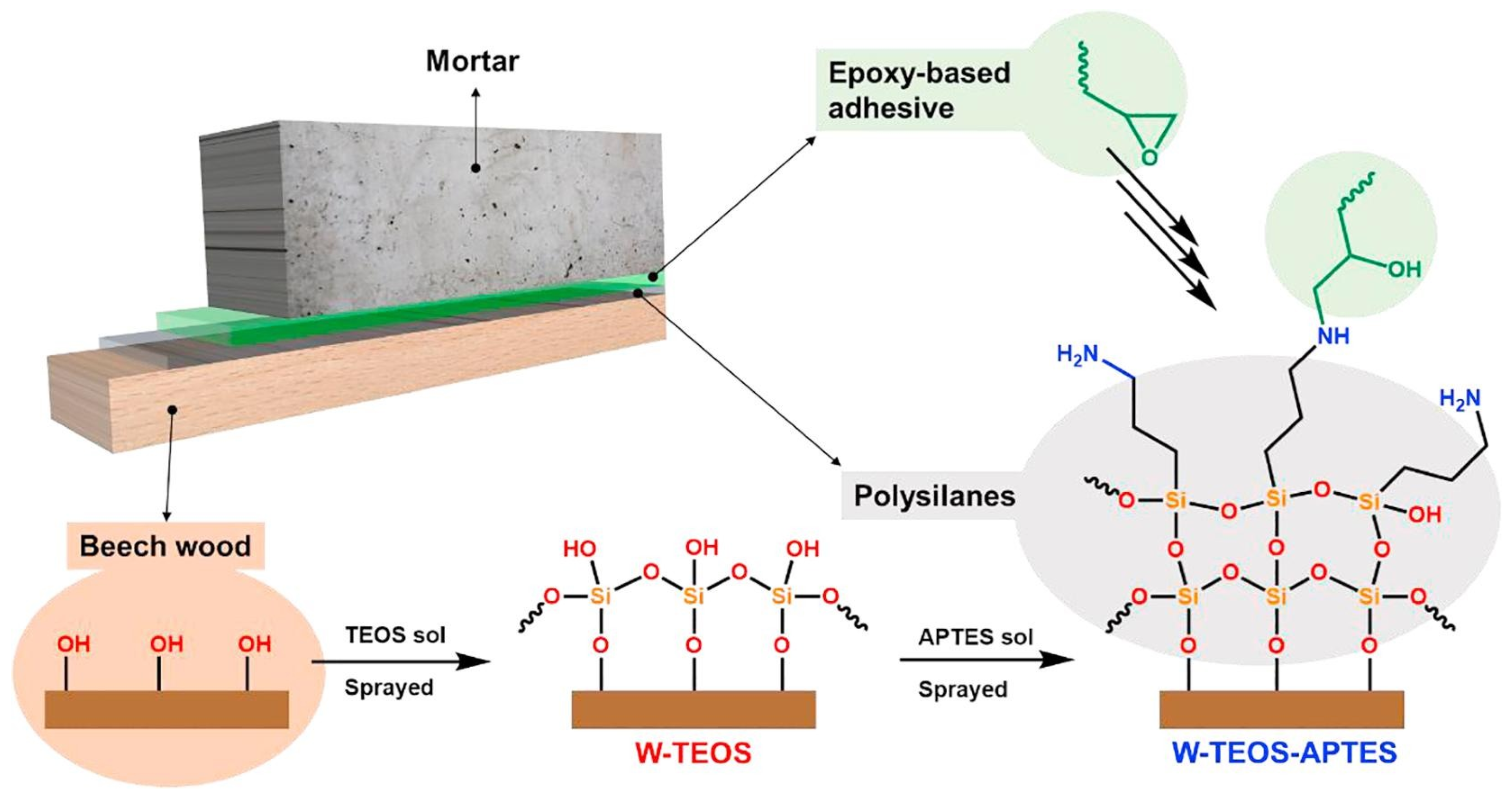

5.3. Surface Engineering Strategies

5.3.1. Dip Coating Techniques

5.3.2. Spray Coating Methods

5.3.3. Layer-by-Layer (LbL) Assembly

5.3.4. Sol–Gel Coating Approaches

5.4. Applicability of Flame-Retardant Strategies

5.5. Performance Trade-Offs of Wood Modification Strategies

| Wood | Flame Retardant Methods | Fillers Content (wt%) | PHRR (KW/m2) | THR (MJ/m2) | LOI (%) | TSP (m2) | Tensile Strength (MPa) | Building-Code Taxonomy | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| LDH-PANI-wood (PANI-LDH/MgAl) | Impregnation of nanofibrous flame-retardant aerogels | 16 wt% LDH + 11 wt% PANI | 272 (+21.1%) | 0.54 (−69%) | 42 | 0.14 (−96.69%) | N/A | N/A | [95] |

| ADP-DW1 (ADP) | Hot-pressing Assisted Chemical Impregnation | 2.0 mol/L ADP | 92.9 (−53.1%) | 29.2 (−51.8%) | 52.1 | N/A | 325.4 (+653%) | Cone calorimeter: ASTM (2017); LOI: GB/T 2406.2-2009 | [96] |

| DW2/PA4 (PA) | Ambient Pressure Impregnation | 4 wt% PA | 96.4 (−51.89%) | 14.2 (−71.37%) | 37.2 | N/A | 138 (+411%) | N/A | [99] |

| FRTW-wood (PAA) | Vacuum-Assisted Polymer Precursor Impregnation | 15 wt% PAA | 53.9 (−56.59%) | 8.6 (−27.37%) | N/A | N/A | 169 (+4125%) | N/A | [100] |

| WL-wood (BN) | Hot-pressing Assisted Chemical Impregnation | 6 wt% BN | 175.2 (−50.1%) | 9.8 (−43.68%) | N/A | N/A | 330 (+864%) | N/A | [101] |

| MW(ZnB) | Vacuum-Assisted Impregnation | 22.1%ZnB | 58 (−46.9%) | 36.5 (−47.9%) | 41.2 | 0.13 (−81.3%) | N/A | LOI: ASTM D2863-2017; Cone calorimeter: ISO 5660-1(2002) | [80] |

| (PEI-APP)15 -CW (PEI/APP/Cu2+/Co2+) | layer-by-layer (LBL) | 1 wt% PEI + 1 wt% + 1 mol/L (Cu2+/Co2+) | 128.87 (−32.6%) | 61.4 (−20.7%) | 47 | N/A | N/A | LOI: GB/T 2406.2-2009 | [91] |

| TW/PEAG-wood (PA/PER/PEG/MF) | Vacuum-Assisted Impregnation | PEAG:MF = 60:120 g | 178.3 (−82.4%) | 9.8 (−84.3%) | 37 | N/A | 153.6 (+500%) | Cone Calorimeter: ASTME1354 | [102] |

| CW(CO-SH/DA/TTC) | UV-cured coating | CO-SH:DA:TTC = 1:0.6:0.6 | 147.63 (−9.9%) | 16.99 (−72.95%) | 26.83 | 2.01 (+1.5%) | N/A | LOI: ASTM D2863; UL-94: ASTM D3801 | [98] |

| MPEA-wood (PEA/MPEAs/MF) | Intumescent fire-retardant coating | PEA:MH = 95:5 | 95.9 (−40.9%) | 2.2 (−29%) | N/A | N/A | N/A | N/A | [97] |

| Steel-EP/9P -MT-HOF -wood (MA/TPA/PA) | Intumescent fire-retardant coating | 9 wt% P-MT-HOF | 380 (−61.6%) | 50 (−32.9%) | 30.3 | 17 (−32.1%) | 79.2 (+39.3%) | N/A | [103] |

6. Various Applications of Wood

6.1. Structural Applications

| Key Raw Materials | Fabrication | Application | Advantage | Predominant Properties | Ref |

|---|---|---|---|---|---|

| APP/TA/Silica sol | Vacuum Pressure Impregnation | Traditional wooden architecture | Excellent collaborative flame retardancy | Mechanical properties | [113] |

| GO/BA | Graded-Penetration Impregnation, Hot-Pressing | Fire alarm | Integrated flame-retardant, fire-warning | Anti-microbial, mechanical enhancement | [114] |

| C-MOFs@ACW | Carbonization of wood | Energy storage | Superior energy density | Enhanced supercapacitor performance and long-term cycle life | [115] |

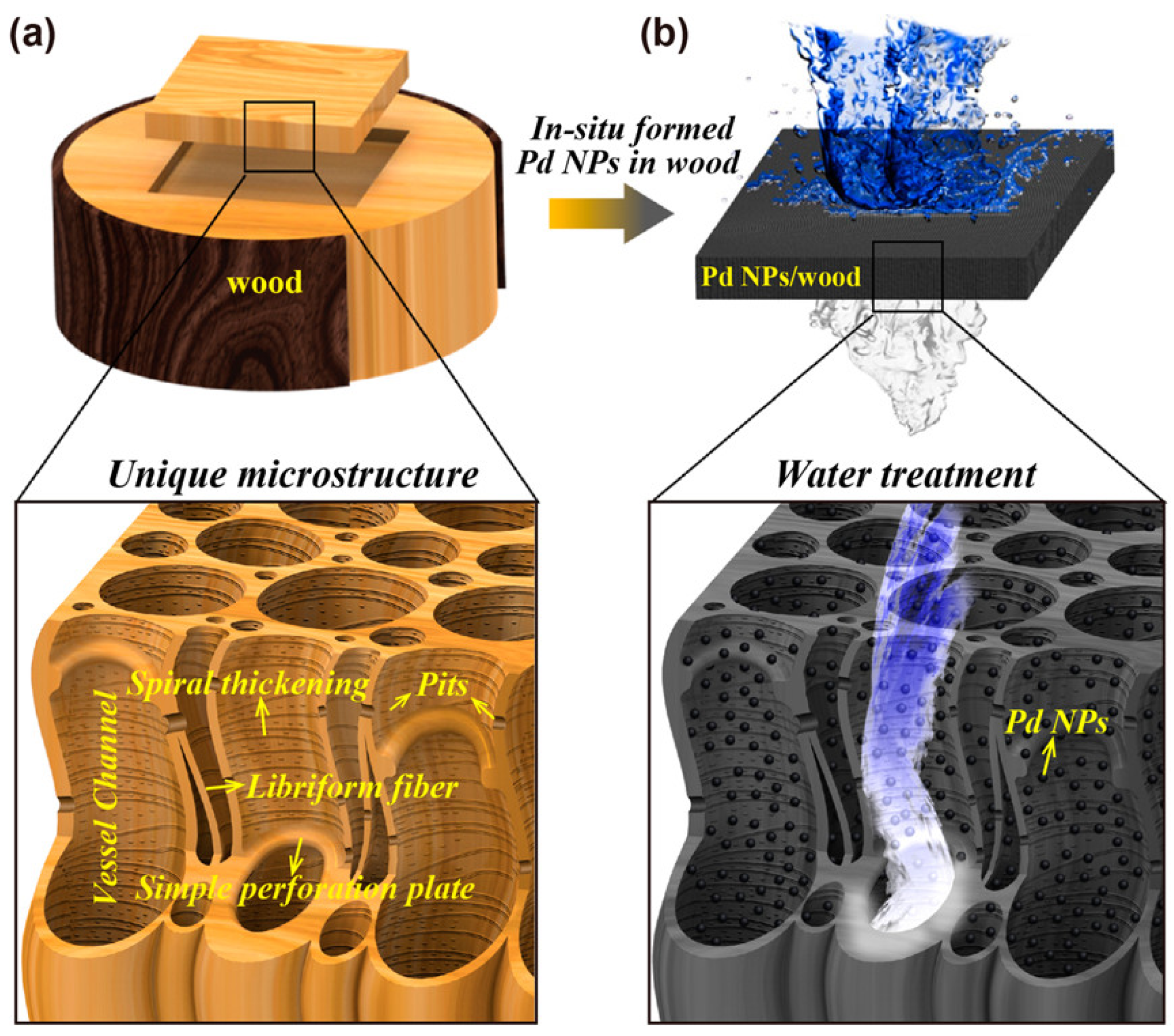

| PdCl2/NaBH4/MB/MO/4-NP | Immersion | Water treatment | Selective high-efficiency degradation | Sustainability | [116] |

| PDMS/SiO2/ETA-APP/PER | Distribution coating | Environmental protections | Self-cleaning, weather-resistant | Durability and environmental adaptability | [29] |

| Carbon Nanoparticles | Flame Treatment | Solar Steam Generation | Low cost, high light absorption rate, hydrophilic, Environmental sustainability | Thermal insulation property and carbon layer has strong adhesion | [117] |

6.2. Environmental Remediation and Water Treatment

6.3. Energy Storage and Conversion Devices

7. Concluding Remarks and Future Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Zhang, D.; Chu, F. Wood-derived functional polymeric materials. Adv. Mater. 2021, 33, 2001135. [Google Scholar] [CrossRef]

- Fang, Z.; Zhang, H.; Qiu, S.; Kuang, Y.; Zhou, J.; Lan, Y.; Sun, C.; Li, G.; Gong, S.; Ma, Z. Versatile wood cellulose for biodegradable electronics. Adv. Mater. Technol. 2021, 6, 2000928. [Google Scholar] [CrossRef]

- Liao, J.; Wang, Y.; Shi, S.; Liu, C.; Sun, Q.; Shen, X. Flexible wood-based triboelectric nanogenerator for versatile self-powered sensing. Sustain. Mater. Technol. 2023, 38, e00771. [Google Scholar] [CrossRef]

- Ge, S.; Ouyang, H.; Ye, H.; Shi, Y.; Sheng, Y.; Peng, W. High-performance and environmentally friendly acrylonitrile butadiene styrene/wood composite for versatile applications in furniture and construction. Adv. Compos. Hybrid Mater. 2023, 6, 44. [Google Scholar] [CrossRef]

- Xiao, S.; Chen, C.; Xia, Q.; Liu, Y.; Yao, Y.; Chen, Q.; Hartsfield, M.; Brozena, A.; Tu, K.; Eichhorn, S.J. Lightweight, strong, moldable wood via cell wall engineering as a sustainable structural material. Science 2021, 374, 465–471. [Google Scholar] [CrossRef] [PubMed]

- Schubert, M.; Panzarasa, G.; Burgert, I. Sustainability in wood products: A new perspective for handling natural diversity. Chem. Rev. 2022, 123, 1889–1924. [Google Scholar] [CrossRef]

- Akpan, E.I.; Wetzel, B.; Friedrich, K. Eco-friendly and sustainable processing of wood-based materials. Green Chem. 2021, 23, 2198–2232. [Google Scholar] [CrossRef]

- Simonsen, M.; Kjønaas, O.J.; Aall, C. Substitution of fossil-energy intensive building materials by wood products–Does it matter? A case study from Western Norway. J. Clean. Prod. 2023, 383, 134941. [Google Scholar] [CrossRef]

- Švajlenka, J.; Pošiváková, T. Innovation potential of wood constructions in the context of sustainability and efficiency of the construction industry. J. Clean. Prod. 2023, 411, 137209. [Google Scholar] [CrossRef]

- Chen, B.; Leiste, U.H.; Fourney, W.L.; Liu, Y.; Chen, Q.; Li, T. Hardened wood as a renewable alternative to steel and plastic. Matter 2021, 4, 3941–3952. [Google Scholar] [CrossRef]

- Sirico, A.; Bernardi, P.; Sciancalepore, C.; Vecchi, F.; Malcevschi, A.; Belletti, B.; Milanese, D. Biochar from wood waste as additive for structural concrete. Constr. Build. Mater. 2021, 303, 124500. [Google Scholar] [CrossRef]

- Pan, Y.; Tannert, T.; Kaushik, K.; Xiong, H.; Ventura, C.E. Seismic performance of a proposed wood-concrete hybrid system for high-rise buildings. Eng. Struct. 2021, 238, 112194. [Google Scholar] [CrossRef]

- Mizera, K.; Borucka, M.; Przybysz, J.; Gajek, A. Identification of Substances Emitted During Combustion and Thermal Decomposition of Wood-Based Materials. Chem. Eng. Trans. 2024, 111, 283–288. [Google Scholar] [CrossRef]

- Trojanová, K.; Veľková, V.; Kačík, F. Volatile Organic Compounds Arising from Wood Polymers on Thermal Loading of Spruce Wood. Polymers 2025, 17, 875. [Google Scholar] [CrossRef] [PubMed]

- Przybysz, J.; Celiński, M.; Mizera, K.; Gloc, M.; Borucka, M.; Gajek, A. Flammability and explosion characteristics of softwood dust. J. Therm. Anal. Calorim. 2023, 148, 10727–10733. [Google Scholar] [CrossRef]

- Dan, S.; Kumar, R. Development of nitrogen-phosphorous and nano-SiO2-based fire retardant system for improved thermal, mechanical, and flame retardant properties in wood. Constr. Build. Mater. 2025, 485, 141786. [Google Scholar] [CrossRef]

- Huang, Y.; Zhou, Q.; Li, L.; Wang, Q.; Guo, C. Construction of waterborne flame-retardant itaconate-based unsaturated polyesters and application for UV-curable hybrid coatings on wood. Prog. Org. Coat. 2023, 183, 107826. [Google Scholar] [CrossRef]

- Wang, X.; Tian, W.; Ye, Y.; Chen, Y.; Wu, W.; Jiang, S.; Wang, Y.; Han, X. Surface modifications towards superhydrophobic wood-based composites: Construction strategies, functionalization, and perspectives. Adv. Colloid Interface Sci. 2024, 326, 103142. [Google Scholar] [CrossRef]

- Liu, T.; Du, G.; Wu, Y.; Liu, C.; Yang, H.; Ni, K.; Yin, C.; Ran, X.; Gao, W.; Yang, L. Activated wood surface and functionalized cellulose co-building strong chemical wood bonding performance. Carbohydr. Polym. 2023, 305, 120573. [Google Scholar] [CrossRef]

- Xiong, C.; Wang, T.; Zhang, Y.; Zhu, M.; Ni, Y. Recent progress on green electromagnetic shielding materials based on macro wood and micro cellulose components from natural agricultural and forestry resources. Nano Res. 2022, 15, 7506–7532. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, X.; Li, L.; Lu, R.; Zhang, X. Transparent wood electrode for electrocatalysis: Preparation, micro/nano structures fabrication, functionalization and applications. Chem. Eng. J. 2025, 519, 164935. [Google Scholar] [CrossRef]

- Lu, D.; Ran, Y.; Wang, W.; Huang, Y. Developing adjustable micro-and mesopore structured carbon materials from wood via biotechnology for enhanced capacitive deionization. Chem. Eng. J. 2024, 500, 157043. [Google Scholar] [CrossRef]

- Zhang, Y.; Guan, P.; Zuo, Y.; Li, P.; Bi, X.; Li, X. Preparation of highly-densified modified poplar wood by evacuating the micro-pores of wood through a gas expansion method. Ind. Crops Prod. 2023, 194, 116374. [Google Scholar] [CrossRef]

- Meng, H.; Wen, M.; Shi, J.; Liang, Y.; Jian, H. Biomass flame retardants with application of cellulose, lignin, and hemicellulose from wood resources and their flame retardant technologies in related materials: A review. Sustain. Chem. Pharm. 2024, 42, 101816. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, Y.; Li, P.; Qiao, J.; Wu, Y.; Li, X.; Zuo, Y. Water-resistant, transparent, and highly efficient flame-retardant wood coating. Ind. Crops Prod. 2025, 223, 120061. [Google Scholar] [CrossRef]

- Yu, F.; Ba, Z.; Gao, Z.; Wang, Y.; Xie, Y.; Wang, H.; Qiu, Z.; Xiao, Z. Modification with lignin-based NP flame retardant to improve the flame retardancy and smoke suppression of wood. Chem. Eng. J. 2024, 493, 152827. [Google Scholar] [CrossRef]

- Deng, X.; Li, C.; Sun, X.; Wang, C.; Liu, B.; Li, Y.; Yang, H. Flame-retardant wood-based composite phase change materials based on PDMS/expanded graphite coating for efficient solar-to-thermal energy storage. Appl. Energy 2024, 368, 123454. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, D.; Li, T.; Jiang, J.; Bai, H.; Wang, S.; Wang, Y.; Dong, W. Multifunctional flame-retardant, thermal insulation, and antimicrobial wood-based composites. Biomacromolecules 2023, 24, 957–966. [Google Scholar] [CrossRef]

- Sun, R.-Y.; Wang, F.; Li, C.-B.; Deng, Z.-P.; Song, F.; Wang, Y.-Z. Formulation of environmentally robust flame-retardant and superhydrophobic coatings for wood materials. Constr. Build. Mater. 2023, 392, 131873. [Google Scholar] [CrossRef]

- Yan, D.; Chen, D.; Tan, J.; Yuan, L.; Huang, Z.; Zou, D.; Sun, P.; Tao, Q.; Deng, J.; Hu, Y. Synergistic flame retardant effect of a new NP flame retardant on poplar wood density board. Polym. Degrad. Stab. 2023, 211, 110331. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, X.; Ding, M.; Huang, Y.; Li, L.; Wang, M. In-situ incorporation of metal phytates for green and highly efficient flame-retardant wood with excellent smoke-suppression property. Ind. Crops Prod. 2022, 187, 115287. [Google Scholar] [CrossRef]

- Li, G.; Huang, J.; Zhou, J.; Zhang, Y.; Zhang, C.; Rao, Z.; Fei, L. A flame-retardant wood-based composite with magnesium–aluminium layered double hydroxides for efficient daytime radiative cooling. J. Mater. Chem. A 2024, 12, 1609–1616. [Google Scholar] [CrossRef]

- Alqrinawi, H.; Ahmed, B.; Wu, Q.; Lin, H.; Kameshwar, S.; Shayan, M. Effect of partial delignification and densification on chemical, morphological, and mechanical properties of wood: Structural property evolution. Ind. Crops Prod. 2024, 213, 118430. [Google Scholar] [CrossRef]

- Liang, Y.; Zheng, G.; Xia, C.; Zuo, S.; Ge, S.; Yang, R.; Ma, X.; Fei, B.; Li, J.; Cheng, C.K. Synthesis of ultra-high strength structured material from steam-modified delignification of wood. J. Clean. Prod. 2022, 351, 131531. [Google Scholar] [CrossRef]

- Huang, Y.; Qing, Y.; Chen, Y.; Liao, Y.; Jiang, A.; Li, Y.; Wu, Y.; Tian, C.; Yan, N. NiFe nanoparticle encapsulated into wood carbon for efficient oxygen evolution: Effect of wood delignification. ACS Sustain. Chem. Eng. 2022, 10, 15233–15242. [Google Scholar] [CrossRef]

- Ran, Y.; Lu, D.; Jiang, J.; Huang, Y.; Wang, W.; Cao, J. Deep eutectic solvents-assisted wood densification: A promising strategy for shape-fixation. Chem. Eng. J. 2023, 471, 144476. [Google Scholar] [CrossRef]

- Luan, Y.; Fang, C.-H.; Ma, Y.-F.; Fei, B.-H. Wood mechanical densification: A review on processing. Mater. Manuf. Process. 2022, 37, 359–371. [Google Scholar] [CrossRef]

- Chen, F.; Ritter, M.; Xu, Y.; Tu, K.; Koch, S.M.; Yan, W.; Bian, H.; Ding, Y.; Sun, J.; Burgert, I. Lightweight, Strong, and Transparent Wood Films Produced by Capillary Driven Self-Densification. Small 2024, 20, 2311966. [Google Scholar] [CrossRef]

- Bi, W.; Li, H.; Hui, D.; Gaff, M.; Lorenzo, R.; Corbi, I.; Corbi, O.; Ashraf, M. Effects of chemical modification and nanotechnology on wood properties. Nanotechnol. Rev. 2021, 10, 978–1008. [Google Scholar] [CrossRef]

- Mei, B.; Jiao, P.; Xie, Y.; Zhao, Y.; Li, Y.; Liu, H. Wood derived conductive aerogel with ultrahigh specific surface area and exceptional mechanical flexibility for pressure sensing. Chem. Eng. J. 2024, 500, 157020. [Google Scholar] [CrossRef]

- Liu, R.; Sun, Y.; Sun, Y.; Li, H.; Chen, M.; Long, L.; Gong, J.; Lv, B.; Ni, Y. Biomimetic design of micro-and nano-wrinkle wood surface via coating reinforced with hyperbranched polymer grafted cellulose nanofibers for skin-tactile performance. Carbohydr. Polym. 2024, 334, 122035. [Google Scholar] [CrossRef] [PubMed]

- Mensah, R.A.; Jiang, L.; Renner, J.S.; Xu, Q. Characterisation of the fire behaviour of wood: From pyrolysis to fire retardant mechanisms. J. Therm. Anal. Calorim. 2023, 148, 1407–1422. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Li, Y.; He, J.; Song, B.; Chang, M.; Fang, X.; Yu, L.; Yang, G.; Guo, H.; Liu, Y. Bio-based intelligent multifunctional coating for wood: Flame retardancy, fire warning, smoke suppression, thermal insulation and antibacterial activity. Constr. Build. Mater. 2025, 465, 140244. [Google Scholar] [CrossRef]

- Calovi, M.; Zanardi, A.; Rossi, S. Recent advances in bio-based wood protective systems: A comprehensive review. Appl. Sci. 2024, 14, 736. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, B.; Jiang, H.; Lu, Q.; Wang, L.; Yang, Y.; Cheng, R.; Gao, Q.; Yang, L.; Du, G. Optimization of durable superhydrophobic wood with superstrong ultraviolet resistance and chemical stability. Chem. Eng. J. 2024, 480, 148164. [Google Scholar] [CrossRef]

- Li, Y.; Xiong, Z.; Zhang, M.; He, Y.; Yang, Y.; Liao, Y.; Hu, J.; Wang, M.; Wu, G. Development of highly durable superhydrophobic and UV-resistant wood by E-beam radiation curing. Cellulose 2021, 28, 11579–11593. [Google Scholar] [CrossRef]

- Elina, K.; Mika, K.; Veikko, M.; Anni, H.; Anna-Kaisa, T.; Anna-Maria, V.; Katsushi, K.; Yuko, T.; Jenni, T.; Riina, M.-M. Touch the wood: Antimicrobial properties of wooden and other solid material surfaces differ between dry and moist contamination in public and laboratory exposure. Environ. Adv. 2023, 13, 100416. [Google Scholar] [CrossRef]

- Priadi, T.; Lestari, M.D.; Cahyono, T.D. Posttreatment effects of castor bean oil and heating in treated jabon wood on boron leaching, dimensional stability, and decay fungi inhibition. J. Korean Wood Sci. Technol. 2021, 49, 602–615. [Google Scholar] [CrossRef]

- Wang, T.; Liu, S.; Hu, Y.; Xu, Z.; Hu, S.; Li, G.; Xu, J.; Wang, M.; Zhang, J.; Yu, W. Liquid metal/wood anisotropic conductors for flexible and recyclable electronics. Adv. Mater. Interfaces 2022, 9, 2200172. [Google Scholar] [CrossRef]

- Liu, B.; Tang, L.; Chen, Q.; Zhu, L.; Zou, X.; Li, B.; Zhou, Q.; Fu, Y.; Lu, Y. Lignin distribution on cell wall micro-morphological regions of fibre in developmental Phyllostachys pubescens culms. Polymers 2022, 14, 312. [Google Scholar] [CrossRef]

- Qiu, L.; Li, C.; Zhang, S.; Wang, S.; Li, B.; Cui, Z.; Tang, Y.; Hu, X. Distinct property of biochar from pyrolysis of poplar wood, bark, and leaves of the same origin. Ind. Crops Prod. 2023, 202, 117001. [Google Scholar] [CrossRef]

- Winandy, J.E.; Wiesner, F.; Hassan, B.; Morrell, J.J. Fire performance of timber: Review for use in wildland-urban interfaces. Holzforschung 2022, 76, 679–698. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Dubois, P. Bio-based flame retardants: When nature meets fire protection. Mater. Sci. Eng. R 2017, 117, 1–25. [Google Scholar] [CrossRef]

- Chen, C.; Hu, L. Nanoscale ion regulation in wood-based structures and their device applications. Adv. Mater. 2021, 33, 2002890. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Wu, Y.; Wu, X.; Hao, J.; Li, X.; Hao, X. Lightweight reinforced wood beams through compression of its surface layers combined with the removal of lignin and hemicellulose. Int. J. Biol. Macromol. 2024, 259, 129306. [Google Scholar] [CrossRef]

- Zhu, M.; Song, J.; Li, T.; Gong, A.; Wang, Y.; Dai, J.; Yao, Y.; Luo, W.; Henderson, D.; Hu, L. Highly Anisotropic, Highly Transparent Wood Composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef]

- Huang, L.; Yang, Y.; Ti, P.; Su, G.; Yuan, Q. Graphene oxide quantum dots attached on wood-derived nanocellulose to fabricate a highly sensitive humidity sensor. Carbohydr. Polym. 2022, 288, 119312. [Google Scholar] [CrossRef]

- Chen, S.; Chen, Y.; Li, D.; Xu, Y.; Xu, F. Flexible and sensitivity-adjustable pressure sensors based on carbonized bacterial nanocellulose/wood-derived cellulose nanofibril composite aerogels. ACS Appl. Mater. Interfaces 2021, 13, 8754–8763. [Google Scholar] [CrossRef]

- Li, H.; Zong, Y.; He, J.; Ding, Q.; Jiang, Y.; Li, X.; Han, W. Wood-inspired high strength and lightweight aerogel based on carbon nanotube and nanocellulose fiber for heat collection. Carbohydr. Polym. 2022, 280, 119036. [Google Scholar] [CrossRef]

- Kotov, N.; Larsson, P.A.; Jain, K.; Abitbol, T.; Cernescu, A.; Wågberg, L.; Johnson, C.M. Elucidating the fine-scale structural morphology of nanocellulose by nano infrared spectroscopy. Carbohydr. Polym. 2023, 302, 120320. [Google Scholar] [CrossRef]

- Luo, Q.; Huang, Y.; Lei, Z.; Peng, J.; Xu, D.; Guo, X.; Wu, Y. Wood-derived nanocellulose hydrogel incorporating gold nanoclusters using in situ multistep reactions for efficient sorption and sensitive detection of mercury ion. Ind. Crops Prod. 2021, 173, 114142. [Google Scholar] [CrossRef]

- Patel, D.K.; Meenatchi, V.; Won, S.-Y.; Han, S.S. Carboxylate functionalized waste wood-derived nanocellulose as carbon dot precursor for ferric ion sensing and multicolored bioimaging. Cellulose 2025, 32, 6477–6493. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, Z.; Zhang, H.; Tian, S.; Fu, S. Wood-derived nanostructured hybrid for efficient flame retarding and electromagnetic shielding. Mater. Des. 2021, 204, 109695. [Google Scholar] [CrossRef]

- Ran, Y.; Ding, J.; Yang, F.; Bao, Q.; Zhu, J.; Du, C.; Tao, P.; Wang, X.; Zhang, S.; Yin, W. A novel organic-inorganic composite flame-retardant coating with excellent compatibility provides superior flame retardancy and smoke suppression for wood. Ind. Crops Prod. 2025, 224, 120286. [Google Scholar] [CrossRef]

- Guo, M.; Pan, Y.; Xu, S.; Wang, W.; Zhang, Y.; Xu, S.; Wu, D.; Zhang, D.; Zhang, S.; Lü, T. Phosphorylated sodium alginate-filled delignified wood-reinforced transparent wood: Crafting flame-retardant composites. Carbohydr. Polym. 2025, 366, 124021. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Huang, Y.; Yang, X.; Liu, L.; Wang, P.; Kan, Z.; Bi, W.; Xu, K.; Du, G.; Zhang, L. Preparation of multifunctional flame-retardant wood composites by crosslinking chitosan-based polymers with phytic acid functionalized UiO-66-NH2. Ind. Crops Prod. 2024, 218, 118938. [Google Scholar] [CrossRef]

- Yan, C.; Fang, Y.; Yan, M.; Yang, R.; Wang, W.; Song, Y.; Wang, Q. Imparting hydrophobicity and flame retardancy to wood using functionalized carbon nanotubes compounded with ammonium polyphosphate. Constr. Build. Mater. 2025, 472, 140886. [Google Scholar] [CrossRef]

- Fan, Z.; He, J.; Fang, X.; Yang, G.; Guo, H.; Liu, Y. Biomimetic mineralization self-assembled biobased functional wood: Improving the flame retardant, hydrophobic, and catalytic detoxification properties of sustainable green building materials. Chem. Eng. J. 2025, 509, 161431. [Google Scholar] [CrossRef]

- Yuan, Y.; Xu, L.; Wang, W. Tri-phase flame retardant system towards advanced energy-saving building materials with highly efficient fire and smoke toxicity reductions. Constr. Build. Mater. 2024, 433, 136719. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, W.; Shi, Y.; Song, L.; Ma, C.; Hu, Y. The influence of highly dispersed Cu2O-anchored MoS2 hybrids on reducing smoke toxicity and fire hazards for rigid polyurethane foam. J. Hazard. Mater. 2020, 382, 121028. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, H.; Yu, B.; Shi, Y.; Wang, W.; Song, L.; Hu, Y.; Zhang, Y. Phosphorus and nitrogen-containing polyols: Synergistic effect on the thermal property and flame retardancy of rigid polyurethane foam composites. Ind. Eng. Chem. Res. 2016, 55, 10813–10822. [Google Scholar] [CrossRef]

- Said, M.S.M.; Tohir, M.Z.M. The effect of ultraviolet coating on containment and fire hazards of phase change materials impregnated wood structure. J. Energy Storage 2020, 32, 101727. [Google Scholar] [CrossRef]

- Song, K.; Ganguly, I.; Eastin, I.; Dichiara, A. High temperature and fire behavior of hydrothermally modified wood impregnated with carbon nanomaterials. J. Hazard. Mater. 2020, 384, 121283. [Google Scholar] [CrossRef]

- Jiang, D.; Huan, Y.; Sun, C.; Hu, C.; Guo, J.; Long, J.; Khan, M.A.; Young, D.P.; Guo, Z. Thermal, mechanical and magnetic properties of functionalized magnetite/vinyl ester nanocomposites. RSC Adv. 2016, 6, 91584–91593. [Google Scholar] [CrossRef]

- Yuan, Y.; Yu, B.; Wang, W. The influence of poorly-/well-dispersed organo-montmorillonite on interfacial compatibility, fire retardancy and smoke suppression of polypropylene/intumescent flame retardant composite system. J. Colloid Interface Sci. 2022, 622, 367–377. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhang, S.; Ding, M.; Wang, M.; Xu, X. Construction of a phytic acid–silica system in wood for highly efficient flame retardancy and smoke suppression. Materials 2021, 14, 4164. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhang, W.; Peng, Y.; Wang, W.; Cao, J. Thermal behavior and flame retardancy of poplar wood impregnated with furfuryl alcohol catalyzed by boron/phosphorus compound system. Ind. Crops Prod. 2022, 176, 114361. [Google Scholar] [CrossRef]

- Song, F.; Xu, X.; Jiang, P.; Chen, Z.; Jia, H.; Yu, W.; Wang, L. Preparation of wood scrimber with low hygroscopicity and high flame retardancy through impregnation of silicon-boron inorganic salt. Constr. Build. Mater. 2025, 467, 140384. [Google Scholar] [CrossRef]

- Xiao, F.; Peng, W.; Li, K.; Yuan, B.; Fontaine, G.; Bourbigot, S. A highly fire-safe wood hybrid based on delignification and multi-component co-impregnation strategies. Constr. Build. Mater. 2025, 489, 142360. [Google Scholar] [CrossRef]

- Zhou, H.; Wen, D.; Hao, X.; Chen, C.; Zhao, N.; Ou, R.; Wang, Q. Nanostructured multifunctional wood hybrids fabricated via in situ mineralization of zinc borate in hierarchical wood structures. Chem. Eng. J. 2023, 451, 138308. [Google Scholar] [CrossRef]

- Zhang, M.; Li, H.; Wang, C.; Wang, Z.; Liu, D.; Yang, T.; Deng, Z.; Yuan, G. Performance enhancement of the poplar wood composites biomimetic mineralized by CaCO3. ACS Omega 2022, 7, 29465–29474. [Google Scholar] [CrossRef]

- Xie, S.; Liu, Z.; Feng, A.; Hao, X.; Ou, R.; Sun, L.; Liu, T.; Wang, Q. Flame retardant modification of poplar wood based on sustainable impregnation solution with high biomass content. Ind. Crops Prod. 2024, 215, 118616. [Google Scholar] [CrossRef]

- Shao, C.; Jiang, M.; Zhang, J.; Zhang, Q.; Han, L.; Wu, Y. Construction of a superhydrophobic wood surface coating by layer-by-layer assembly: Self-adhesive properties of polydopamine. Appl. Surf. Sci. 2023, 609, 155259. [Google Scholar] [CrossRef]

- Žigon, J.; Kovač, J.; Petrič, M. The influence of mechanical, physical and chemical pre-treatment processes of wood surface on the relationships of wood with a waterborne opaque coating. Prog. Org. Coat. 2022, 162, 106574. [Google Scholar] [CrossRef]

- Kassaun, B.B.; Fatehi, P. Solvent-Free Lignin-Silsesquioxane wood coating formulation with superhydrophobic and Flame-Retardant functionalities. Chem. Eng. J. 2024, 493, 152582. [Google Scholar] [CrossRef]

- Tang, M.; Fang, X.; Li, B.; Xu, M.; Wang, H.; Cai, S. Hydrophobic modification of wood using tetramethylcyclotetrasiloxane. Polymers 2022, 14, 2077. [Google Scholar] [CrossRef]

- Li, X.; Gao, L.; Wang, M.; Lv, D.; He, P.; Xie, Y.; Zhan, X.; Li, J.; Lin, Z. Recent development and emerging applications of robust biomimetic superhydrophobic wood. J. Mater. Chem. A 2023, 11, 6772–6795. [Google Scholar] [CrossRef]

- Huang, Y.; Ma, T.; Wang, Q.; Guo, C. Synthesis of biobased flame-retardant carboxylic acid curing agent and application in wood surface coating. ACS Sustain. Chem. Eng. 2019, 7, 14727–14738. [Google Scholar] [CrossRef]

- Farid, T.; Wang, Y.; Razaq, A.; Hussain, S.; Tang, W. Layer-by-layer assembling redox wood electrodes for efficient energy storage. Energy Mater. 2024, 4, 400041. [Google Scholar] [CrossRef]

- Zhou, X.; Fu, Q.; Zhang, Z.; Fang, Y.; Wang, Y.; Wang, F.; Song, Y.; Pittman, C.U., Jr.; Wang, Q. Efficient flame-retardant hybrid coatings on wood plastic composites by layer-by-layer assembly. J. Clean. Prod. 2021, 321, 128949. [Google Scholar] [CrossRef]

- Dong, S.; Jiang, H.; Hou, B.; Du, Y.; Jin, C.; Yan, Y. High efficient fire-retardant coatings on wood fabricated by divalent metal ion cross-linked multilayer polyethyleneimine and ammonium polyphosphate polyelectrolytes. Polym. Degrad. Stab. 2022, 204, 110112. [Google Scholar] [CrossRef]

- Kostic, S.; Merk, V.; Berg, J.K.; Hass, P.; Burgert, I.; Cabane, E. Timber-mortar composites: The effect of sol-gel surface modification on the wood-adhesive interface. Compos. Struct. 2018, 201, 828–833. [Google Scholar] [CrossRef]

- Tsvetkova, I.; Krasil’Nikova, L.; Khoroshavina, Y.; Galushko, A.; Frantsuzova Yu, V.; Kychkin, A.; Shilova, O. Sol-gel preparation of protective and decorative coatings on wood. J. Sol-Gel Sci. Technol. 2019, 92, 474–483. [Google Scholar] [CrossRef]

- Gu, F.; He, X.; Wei, Y.; Niu, X.; Cai, Z.; Jiang, B.; Zhu, J.; Wang, W. Exceptional flame-retardant, super strong/tough, and superhydrophobic/self-cleaning wood. Mater. Today 2025, in press. [Google Scholar] [CrossRef]

- Huang, H.; Song, S.S.; Shuai, C.-X.; Xu, Q.-C.; Jiang, Y. Layered double hydroxide-polyaniline nanofibers in lightweight aerogels for bioinspired flame-retardant wood. ACS Appl. Nano Mater. 2023, 6, 4105–4111. [Google Scholar] [CrossRef]

- Fan, C.; Gao, Y.; Li, Y.; Yan, L.; Zhu, D.; Guo, S.; Ou, C.; Wang, Z. A flame-retardant densified wood as robust and fire-safe structural material. Wood Sci. Technol. 2023, 57, 111–134. [Google Scholar] [CrossRef]

- Yan, L.; Xu, Z.; Liu, D. Synthesis and application of novel magnesium phosphate ester flame retardants for transparent intumescent fire-retardant coatings applied on wood substrates. Prog. Org. Coat. 2019, 129, 327–337. [Google Scholar] [CrossRef]

- Wang, T.; Li, L.; Cao, Y.; Wang, Q.; Guo, C. Preparation and flame retardancy of castor oil based UV-cured flame retardant coating containing P/Si/S on wood surface. Ind. Crops Prod. 2019, 130, 562–570. [Google Scholar] [CrossRef]

- Wang, K.; Meng, D.; Wang, S.; Sun, J.; Li, H.; Gu, X.; Zhang, S. Impregnation of phytic acid into the delignified wood to realize excellent flame retardant. Ind. Crops Prod. 2022, 176, 114364. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Z.; Wang, F.; Duan, G.; Xu, W.; Zhang, G.; Yang, H.; Liu, J.; Jiang, S. A flame-retardant and transparent wood/polyimide composite with excellent mechanical strength. Compos. Commun. 2020, 20, 100355. [Google Scholar] [CrossRef]

- Chen, G.; Chen, C.; Pei, Y.; He, S.; Liu, Y.; Jiang, B.; Jiao, M.; Gan, W.; Liu, D.; Yang, B. A strong, flame-retardant, and thermally insulating wood laminate. Chem. Eng. J. 2020, 383, 123109. [Google Scholar] [CrossRef]

- Chu, T.; Gao, Y.; Yi, L.; Fan, C.; Yan, L.; Ding, C.; Liu, C.; Huang, Q.; Wang, Z. Highly fire-retardant optical wood enabled by transparent fireproof coatings. Adv. Compos. Hybrid Mater. 2022, 5, 1821–1829. [Google Scholar] [CrossRef]

- Zou, Y.; Shi, Z.; Li, Y.; Luo, F.; Li, H. Epoxy resins with enhanced mechanical and flame-retardant properties through P/N hydrogen-bonded organic frameworks for wood and steel coatings. Constr. Build. Mater. 2025, 463, 140061. [Google Scholar] [CrossRef]

- Dong, X.; Gan, W.; Shang, Y.; Tang, J.; Wang, Y.; Cao, Z.; Xie, Y.; Liu, J.; Bai, L.; Li, J. Low-value wood for sustainable high-performance structural materials. Nat. Sustain. 2022, 5, 628–635. [Google Scholar] [CrossRef]

- Kumar, A.; Jyske, T.; Petrič, M. Delignified wood from understanding the hierarchically aligned cellulosic structures to creating novel functional materials: A review. Adv. Sustain. Syst. 2021, 5, 2000251. [Google Scholar] [CrossRef]

- Li, W.; Chen, Z.; Yu, H.; Li, J.; Liu, S. Wood-derived carbon materials and light-emitting materials. Adv. Mater. 2021, 33, 2000596. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Liu, Y.; Zhao, L.; Yazdkhasti, A.; Mao, Y.; Siciliano, A.P.; Dai, J.; Jing, S.; Xie, H.; Li, Z. A scalable high-porosity wood for sound absorption and thermal insulation. Nat. Sustain. 2023, 6, 306–315. [Google Scholar] [CrossRef]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef]

- Diddens, I.; Murphy, B.; Krisch, M.; Müller, M. Anisotropic elastic properties of cellulose measured using inelastic X-ray scattering. Macromolecules 2008, 41, 9755–9759. [Google Scholar] [CrossRef]

- Šturcová, A.; Davies, G.R.; Eichhorn, S.J. Elastic modulus and stress-transfer properties of tunicate cellulose whiskers. Biomacromolecules 2005, 6, 1055–1061. [Google Scholar] [CrossRef]

- Lahiji, R.R.; Xu, X.; Reifenberger, R.; Raman, A.; Rudie, A.; Moon, R.J. Atomic force microscopy characterization of cellulose nanocrystals. Langmuir 2010, 26, 4480–4488. [Google Scholar] [CrossRef]

- Li, J.; Han, X.; Yao, S.; Guo, D.; Chu, F. Reinforcing flame retardancy, dimensional stability, and high strength of woods for structural applications through surface densification and chemical modification. Ind. Crops Prod. 2025, 223, 120175. [Google Scholar] [CrossRef]

- Zhao, S.; Wei, S.; Zhao, X.; Yang, H. Effectiveness of APP-TA-silica sol composite flame retardant in enhancing fire resistance of wooden buildings. J. Build. Eng. 2025, 103, 112142. [Google Scholar] [CrossRef]

- Che, W.; Li, Z.; Huo, S.; Dinh, T.; Hong, M.; Maluk, C.; Yu, Y.; Xie, Y. Fire-retardant anti-microbial robust wood nanocomposite capable of fire-warning by graded-penetration impregnation. Compos. Part B-Eng. 2024, 280, 111482. [Google Scholar] [CrossRef]

- Zhang, W.; Li, M.; Zhong, L.; Huang, J.; Liu, M. A family of MOFs@Wood-Derived hierarchical porous composites as freestanding thick electrodes of solid supercapacitors with enhanced areal capacitances and energy densities. Mater. Today Energy 2022, 24, 100951. [Google Scholar] [CrossRef]

- Wang, Z.; Jia, C.; Xiang, H.; Zhu, M. Palladium Nanoparticle-Loaded Mesostructural Natural Woods for Efficient Water Treatment. Polymers 2023, 15, 658. [Google Scholar] [CrossRef]

- Xue, G.; Liu, K.; Chen, Q.; Yang, P.; Li, J.; Ding, T.; Duan, J.; Qi, B.; Zhou, J. Robust and low-cost flame-treated wood for high-performance solar steam generation. ACS Appl. Mater. Interfaces 2017, 9, 15052–15057. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, S.; Tian, Z.; Duan, G.; Pan, H.; Yue, Y.; Li, S.; Jian, S.; Yang, W.; Liu, K. MOFs meet wood: Reusable magnetic hydrophilic composites toward efficient water treatment with super-high dye adsorption capacity at high dye concentration. Chem. Eng. J. 2022, 446, 136851. [Google Scholar] [CrossRef]

- Etale, A.; Onyianta, A.J.; Turner, S.R.; Eichhorn, S.J. Cellulose: A review of water interactions, applications in composites, and water treatment. Chem. Rev. 2023, 123, 2016–2048. [Google Scholar] [CrossRef]

- Fang, H.; Yu, Q.; Xie, D.; Cai, Y.; Sun, J.; Chen, B.; Huang, H.; Li, X.; Dai, S.; Shi, S. Flexible bifunctional wood-derived water filtration/photo-Fenton membrane for efficient purification of mixed organic wastewater. Colloids Surf. A Physicochem. Eng. Asp. 2024, 697, 134498. [Google Scholar] [CrossRef]

- Ingida, M.; Bedane, G.; Adugna, F.; Nigusu, D.; Hussen, M.; Sime, C.H. Wastewater treatment using wood Ash and cement as chemical coagulant. Int. J. Anal. Chem. 2023, 2023, 8274687. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Gong, A.S.; Zhu, M.; Chen, G.; Lacey, S.D.; Jiang, F.; Li, Y.; Wang, Y.; Dai, J.; Yao, Y. Mesoporous, three-dimensional wood membrane decorated with nanoparticles for highly efficient water treatment. ACS Nano 2017, 11, 4275–4282. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.-B.; Huang, S.; Liu, C.; Wu, J.; Agarwal, S.; Greiner, A.; Xu, Z.-K. Carboxylated wood-based sponges with underoil superhydrophilicity for deep dehydration of crude oil. J. Mater. Chem. A 2020, 8, 11354–11361. [Google Scholar] [CrossRef]

- Jiang, F.; Hsieh, Y.-L. Amphiphilic superabsorbent cellulose nanofibril aerogels. J. Mater. Chem. A 2014, 2, 6337–6342. [Google Scholar] [CrossRef]

- Shan, X.; Wu, J.; Zhang, X.; Wang, L.; Yang, J.; Chen, Z.; Yu, J.; Wang, X. Wood for application in electrochemical energy storage devices. Cell Rep. Phys. Sci. 2021, 2, 100654. [Google Scholar] [CrossRef]

- Xu, J.; Lei, J.; Ming, N.; Zhang, C.; Huo, K. Rational design of wood-structured thick electrode for electrochemical energy storage. Adv. Funct. Mater. 2022, 32, 2204426. [Google Scholar] [CrossRef]

- Li, Y.; Lu, Q.; Yang, J.; He, W. Delignified wood for thermal energy storage with high efficient photo-thermal conversion efficiency. J. Energy Storage 2024, 80, 110235. [Google Scholar] [CrossRef]

- Xia, R.; Zhang, W.; Yang, Y.; Zhao, J.; Liu, Y.; Guo, H. Transparent wood with phase change heat storage as novel green energy storage composites for building energy conservation. J. Clean. Prod. 2021, 296, 126598. [Google Scholar] [CrossRef]

- Wang, X.; Xu, X.; Fan, D.; Zhang, G.; Lu, Y. wood composites as sustainable energy conversion materials for efficient solar energy harvesting and light management. J. Mater. Sci. 2024, 59, 4383–4403. [Google Scholar] [CrossRef]

- Wang, F.; Cheong, J.Y.; Lee, J.; Ahn, J.; Duan, G.; Chen, H.; Zhang, Q.; Kim, I.D.; Jiang, S. Pyrolysis of enzymolysis-treated wood: Hierarchically assembled porous carbon electrode for advanced energy storage devices. Adv. Funct. Mater. 2021, 31, 2101077. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Y.; Li, J.; Wang, C.; Li, Y. Full-wood photoluminescent and photothermic materials for thermal energy storage. Chem. Eng. J. 2021, 403, 126406. [Google Scholar] [CrossRef]

- Lyu, S.; Chen, Y.; Han, S.; Guo, L.; Yang, N.; Wang, S. Natural sliced wood veneer as a universal porous lightweight substrate for supercapacitor electrode materials. RSC Adv. 2017, 7, 54806–54812. [Google Scholar] [CrossRef]

- Li, Y.; Fu, K.K.; Chen, C.; Luo, W.; Gao, T.; Xu, S.; Dai, J.; Pastel, G.; Wang, Y.; Liu, B. Enabling high-areal-capacity lithium–sulfur batteries: Designing anisotropic and low-tortuosity porous architectures. ACS nano 2017, 11, 4801–4807. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, Y.; Li, Y.; Dai, J.; Song, J.; Yao, Y.; Gong, Y.; Kierzewski, I.; Xie, J.; Hu, L. All-wood, low tortuosity, aqueous, biodegradable supercapacitors with ultra-high capacitance. Energy Environ. Sci. 2017, 10, 538–545. [Google Scholar] [CrossRef]

| Composition of Materials | Preparation Method | Fillers Content | LOI (%) | PHRR (KW/m2) | THR (MJ/m2) | UL-94 Rating | Building-Code Taxonomy | Ref. |

|---|---|---|---|---|---|---|---|---|

| BA/ADP-FA-wood(FA/BA/ADP) | Impregnation | 15 wt% FA + 3.2 wt% BA + 0.8 wt% ADP | 34.4 | 156.57 (−35.8%) | 54.7 (−37.4%) | N/A | LOI: GB/T 2406.2-2009 | [77] |

| WS-SsSt11(Ss/St) | Impregnation | 5%Ss + 5%St | N/A | 190.1 (−31.0%) | 57.2 (−14.9%) | N/A | Cone calorimeter: ISO 5660:2015 | [78] |

| DW-GP/BA(GP/BA) | Impregnation | GP:BA = 10:1 | N/A | 9.2 (−89.5%) | 1.4 (−78.46%) | N/A | Cone calorimeter: ISO 5660-1:2016 | [79] |

| MW22(ZnB) | In situ mineralization | 22.1 wt% ZnB | 41.2 | 58 (−46.9%) | 36.5 (−47.9%) | N/A | LOI: ASTM D2863-2017; Cone calorimeter: ISO 5660-1(2002) | [80] |

| S/C-wood(SA/CaCO3) | In situ mineralization | 29 wt% CaCO3 + 1 wt% SA | N/A | 173.42 (−59.51%) | 24.39 (−48.52%) | N/A | N/A | [81] |

| AMP/FA-wood(FA/AMP) | Reactive grafting and covalent bonding | 20 wt% FA + 8 wt% AMP | 36.3 | 96 (−72.2%) | 36.3 (−48.9%) | V-0 | LOI: ASTM D2863-97; Cone calorimeter: ASTM E1354-2017; UL94: ATSM D3801-10 | [82] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, Y.; Chen, K.; Xu, L.; Zhang, Y.; Xiao, Y.; Yuan, Y.; Wang, W. Advances in Wood Processing, Flame-Retardant Functionalization, and Multifunctional Applications. Polymers 2025, 17, 2677. https://doi.org/10.3390/polym17192677

Fang Y, Chen K, Xu L, Zhang Y, Xiao Y, Yuan Y, Wang W. Advances in Wood Processing, Flame-Retardant Functionalization, and Multifunctional Applications. Polymers. 2025; 17(19):2677. https://doi.org/10.3390/polym17192677

Chicago/Turabian StyleFang, Yatong, Kexuan Chen, Lulu Xu, Yan Zhang, Yi Xiao, Yao Yuan, and Wei Wang. 2025. "Advances in Wood Processing, Flame-Retardant Functionalization, and Multifunctional Applications" Polymers 17, no. 19: 2677. https://doi.org/10.3390/polym17192677

APA StyleFang, Y., Chen, K., Xu, L., Zhang, Y., Xiao, Y., Yuan, Y., & Wang, W. (2025). Advances in Wood Processing, Flame-Retardant Functionalization, and Multifunctional Applications. Polymers, 17(19), 2677. https://doi.org/10.3390/polym17192677