Effect of Warm-Mix Additive USP on the Performance of Rubberized Asphalt and Fiber-Reinforced Rubberized Asphalt RAP Interlayer

Abstract

1. Introduction

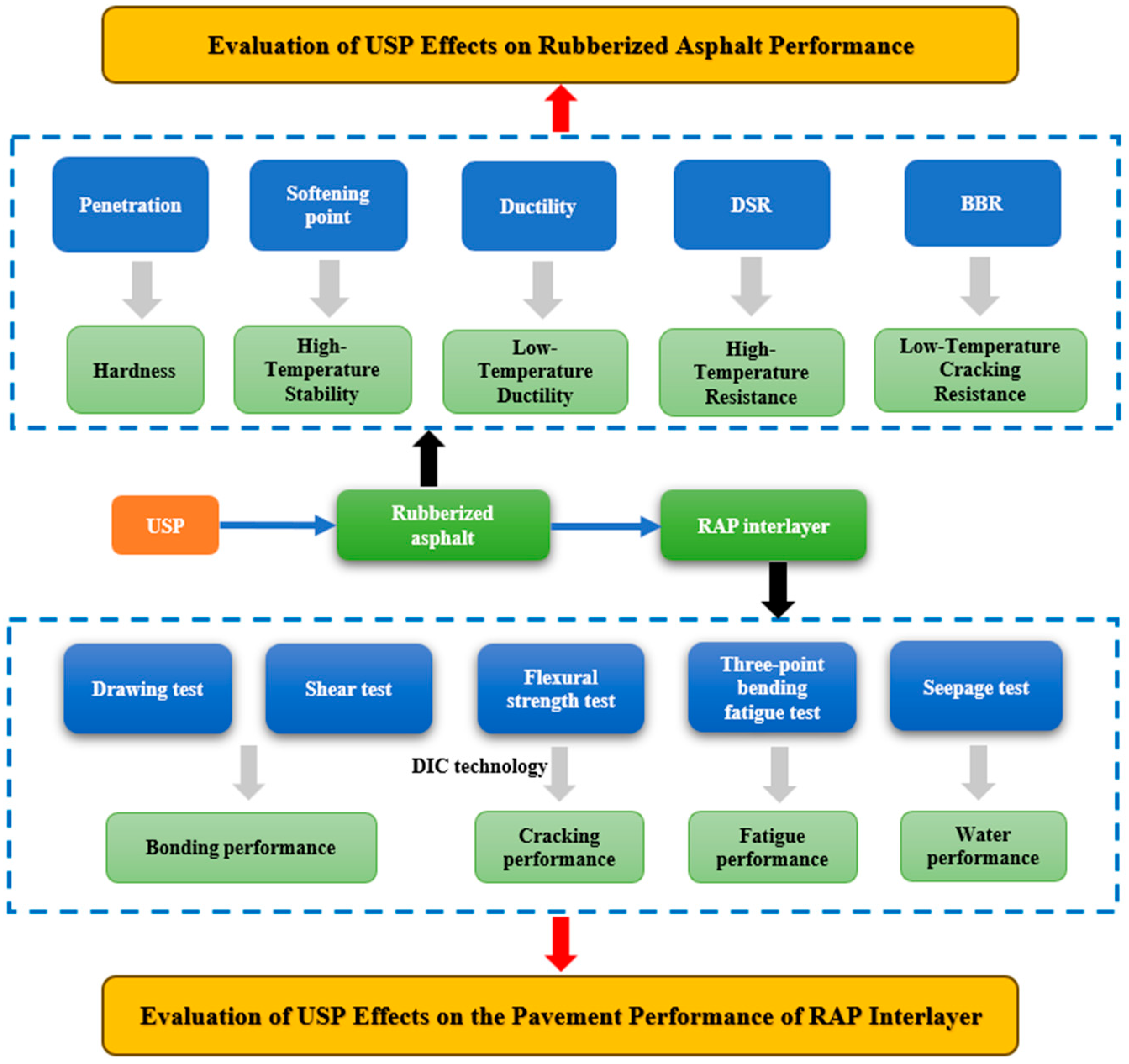

2. Materials and Experimental Methods

2.1. Materials

2.1.1. Binder

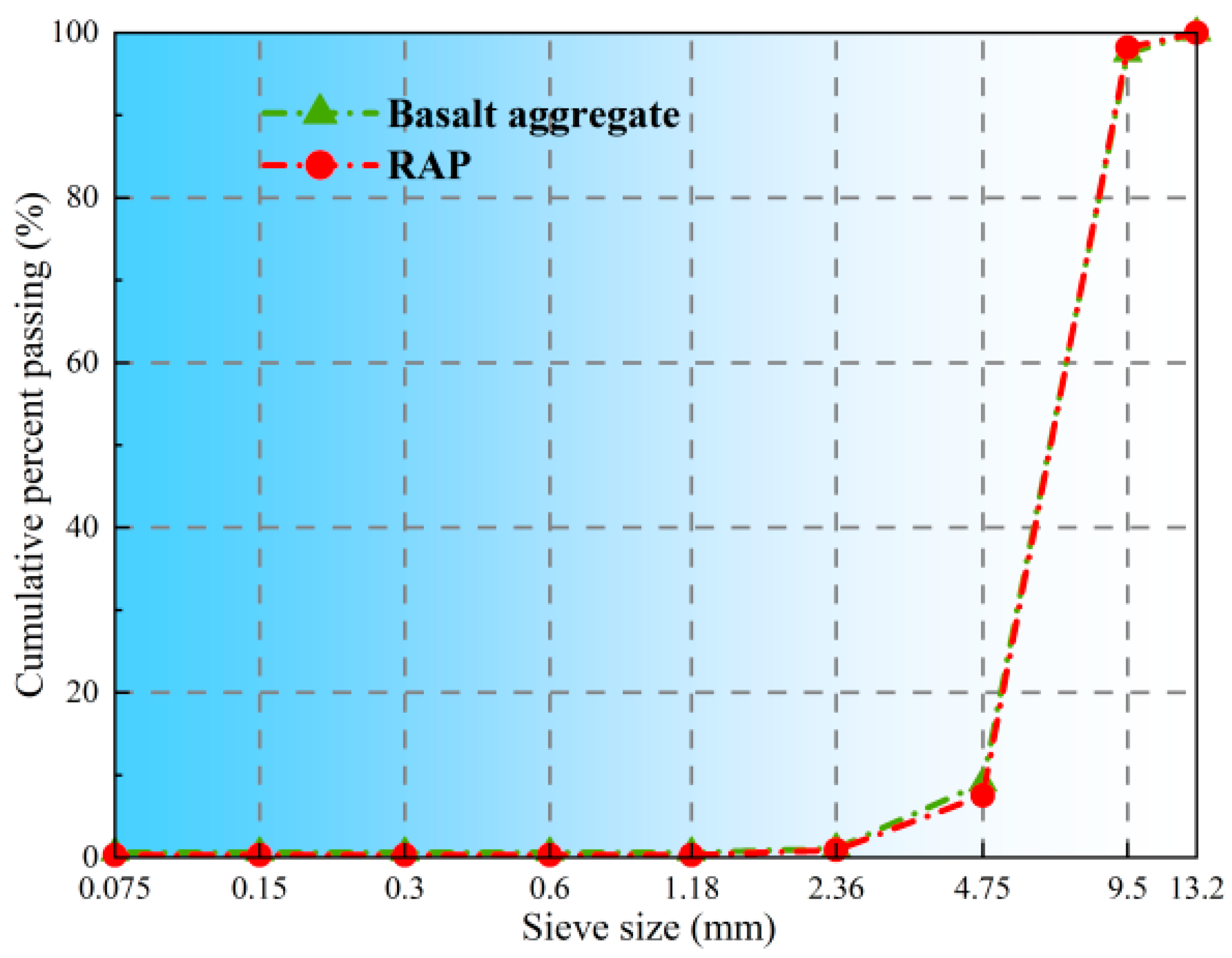

2.1.2. Aggregate

2.1.3. RAP

2.1.4. Basalt Fiber

2.1.5. USP Warm-Mix Modifier

2.2. Material Preparation

2.2.1. Laboratory Preparation of USP Warm-Mix Modified Rubberized Asphalt

2.2.2. Fabrication of USP-Modified RAP Interlayer Specimens

2.3. Experimental Methods

2.3.1. Three Fundamental Binder Tests

2.3.2. Bending Beam Rheometer (BBR) Test

2.3.3. Dynamic Shear Rheometer (DSR) Test

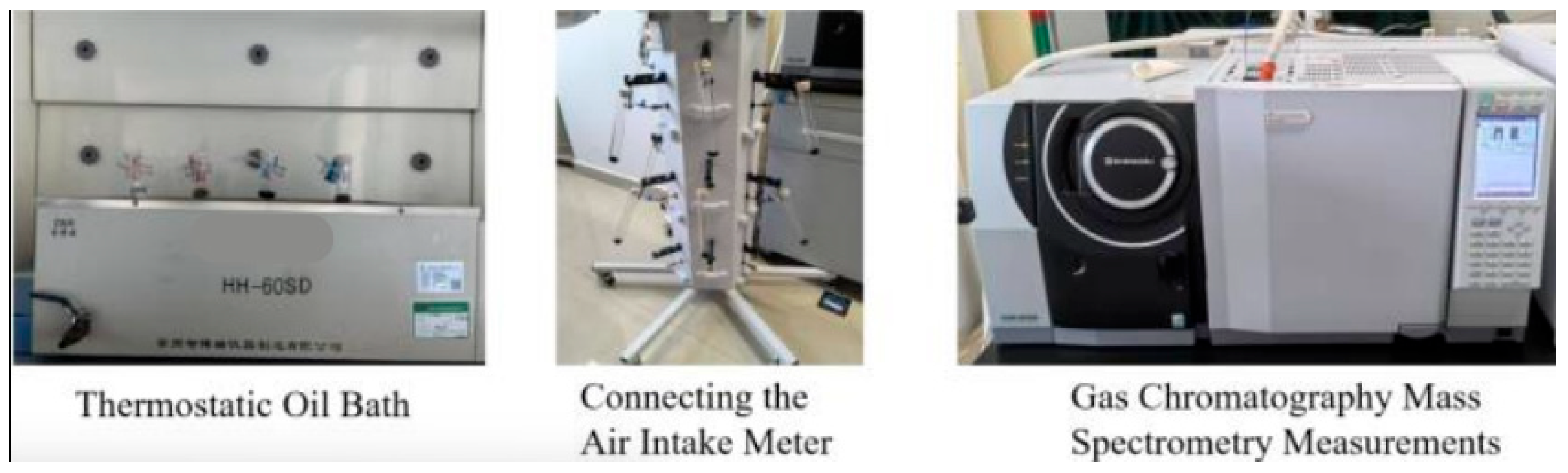

2.3.4. VOCs Emission Test

2.3.5. Pull-Out Test

2.3.6. Shear Strength Test

2.3.7. Permeability Test

2.3.8. Three-Point Bending Fatigue Test

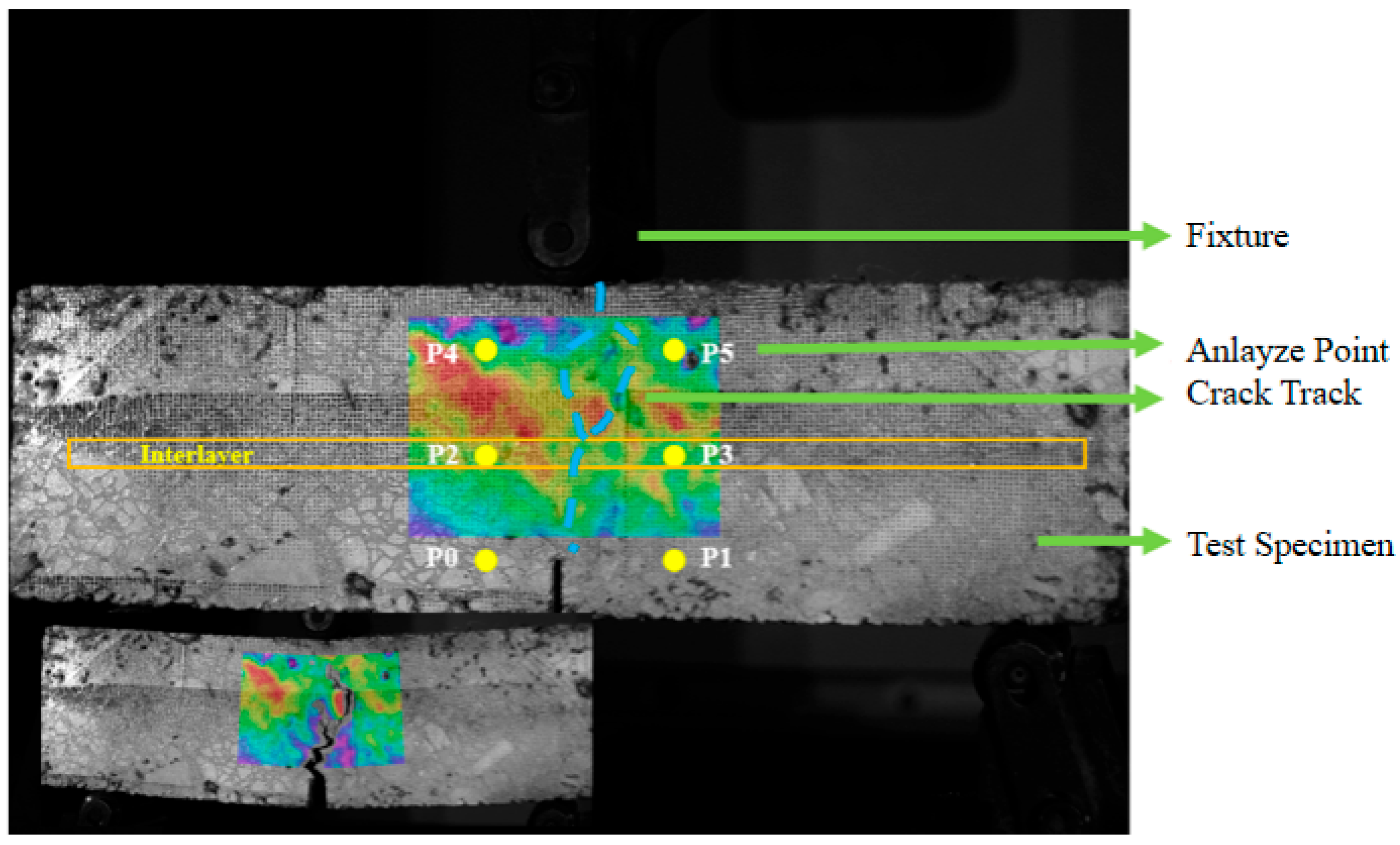

2.3.9. DIC-Based Flexural Strength Test

3. Effect of USP on the Properties of Rubberized Asphalt

3.1. Three Major Indicators

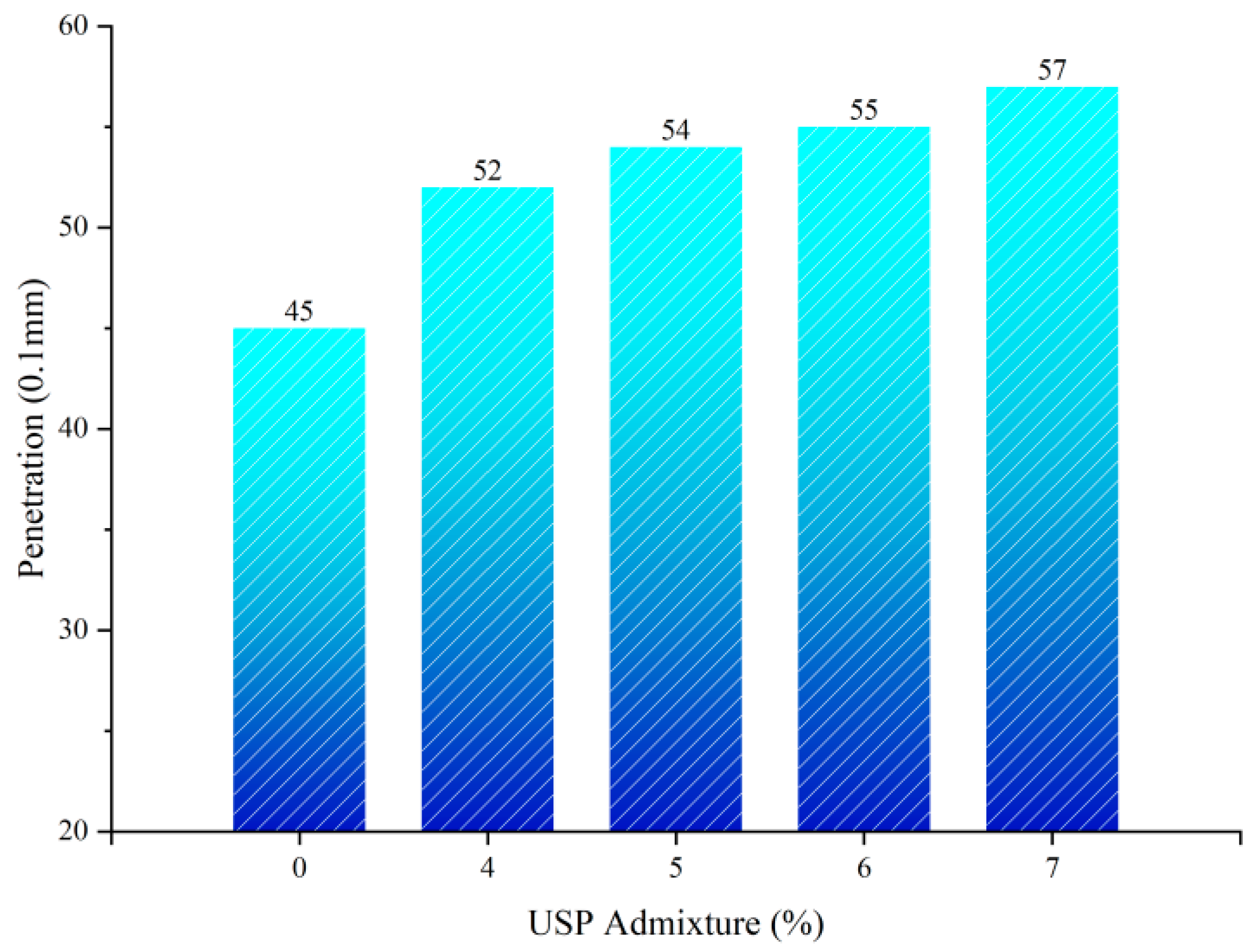

3.1.1. Influence of USP Warm-Mix Modifier on Penetration of Rubberized Asphalt

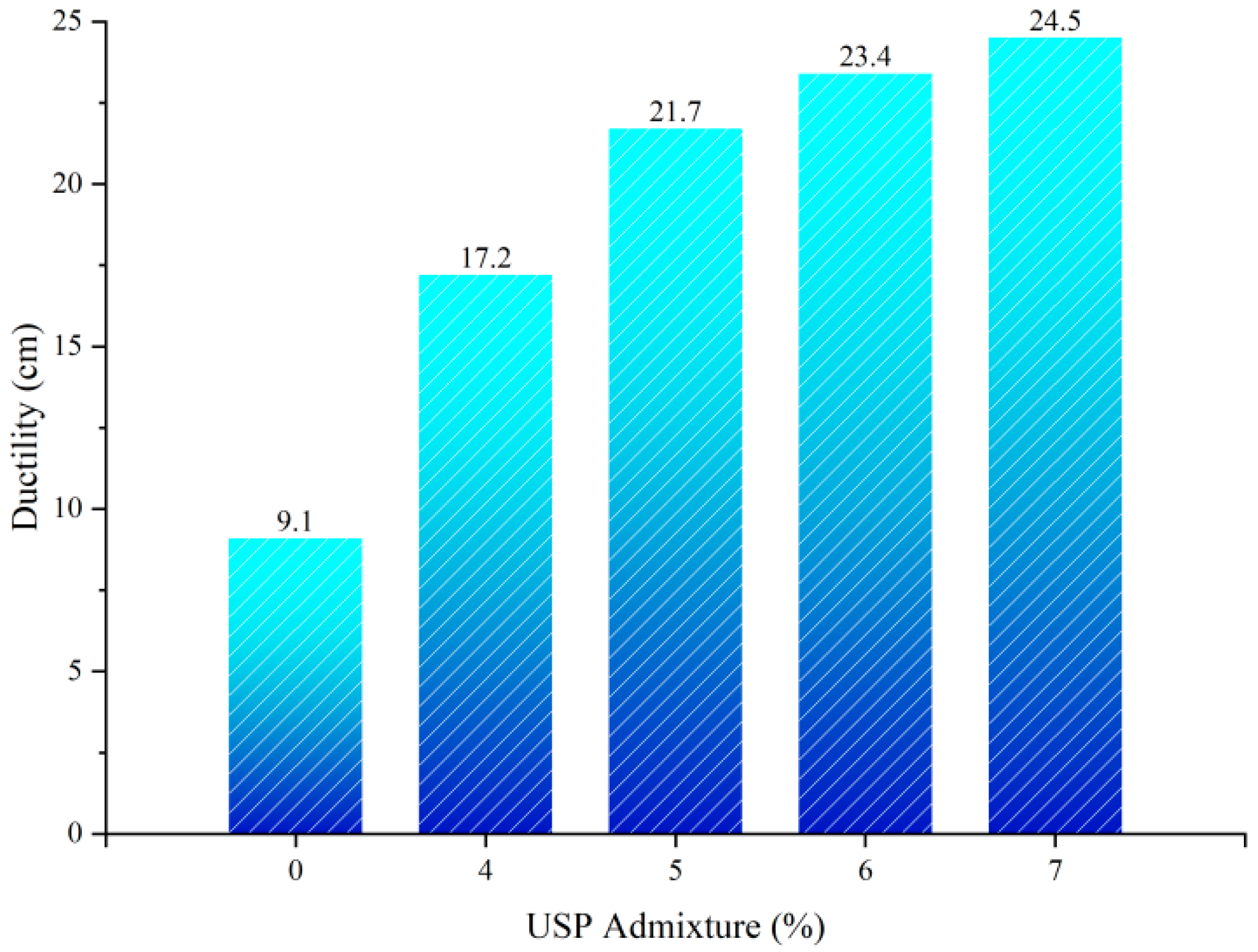

3.1.2. Influence of USP Warm-Mix Modifier on Ductility of Rubberized Asphalt

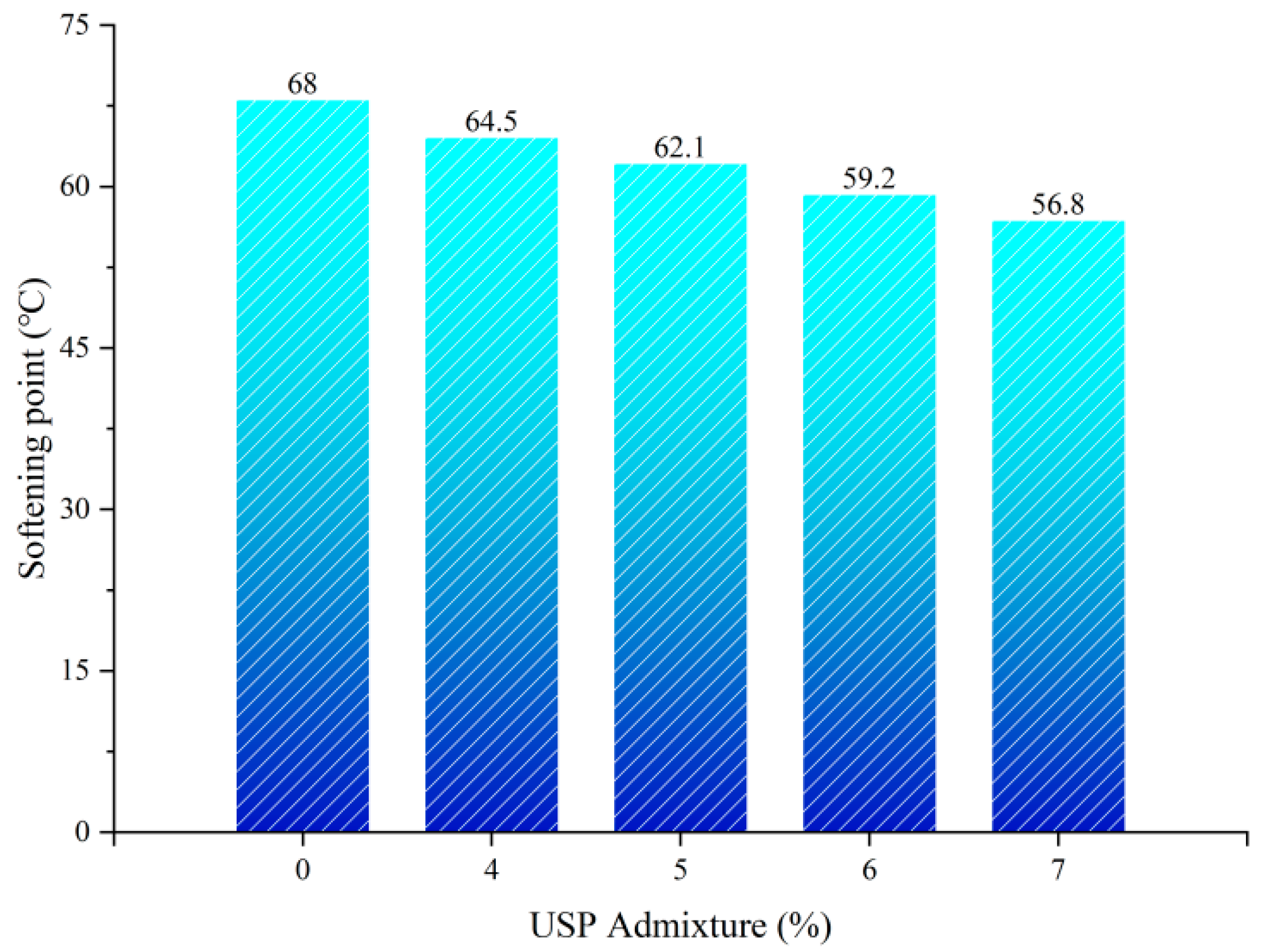

3.1.3. Influence of USP Warm-Mix Modifier on Softening Point of Rubberized Asphalt

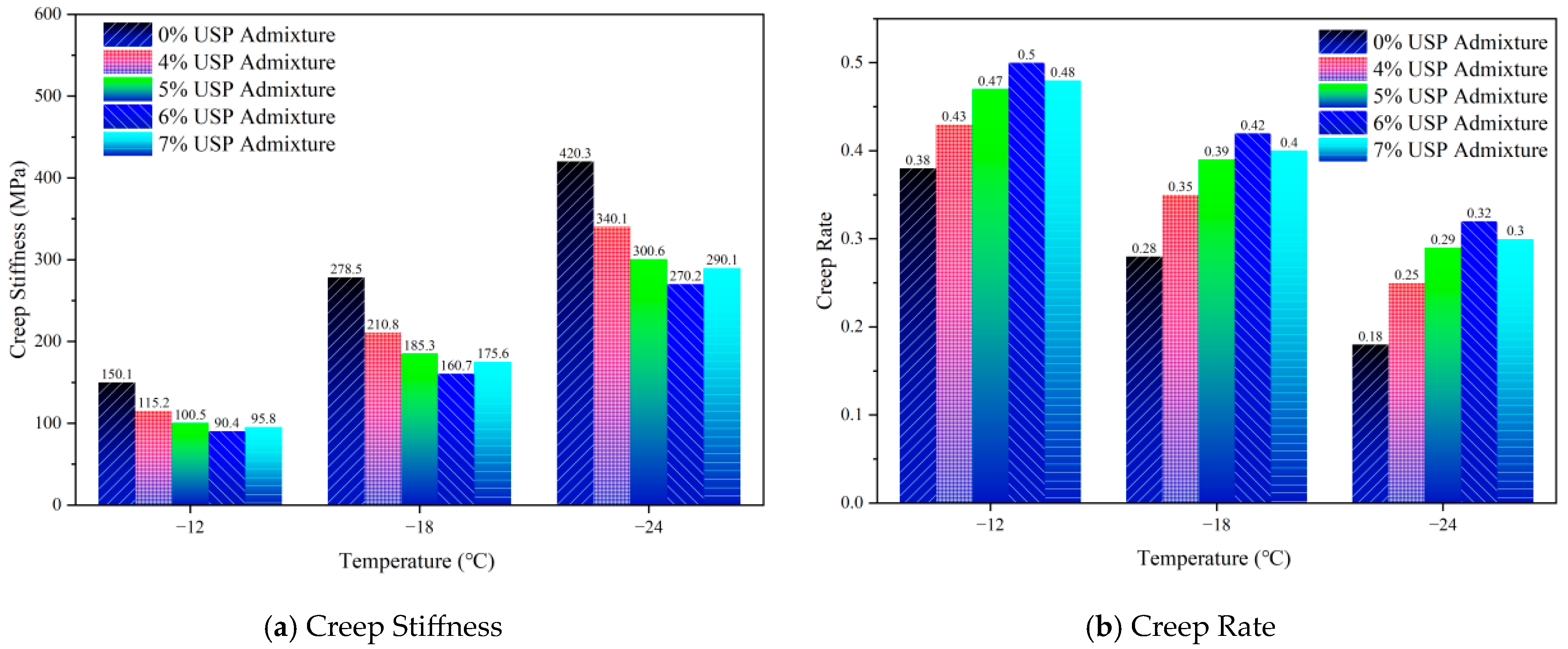

3.2. Low Temperature Rheological Properties

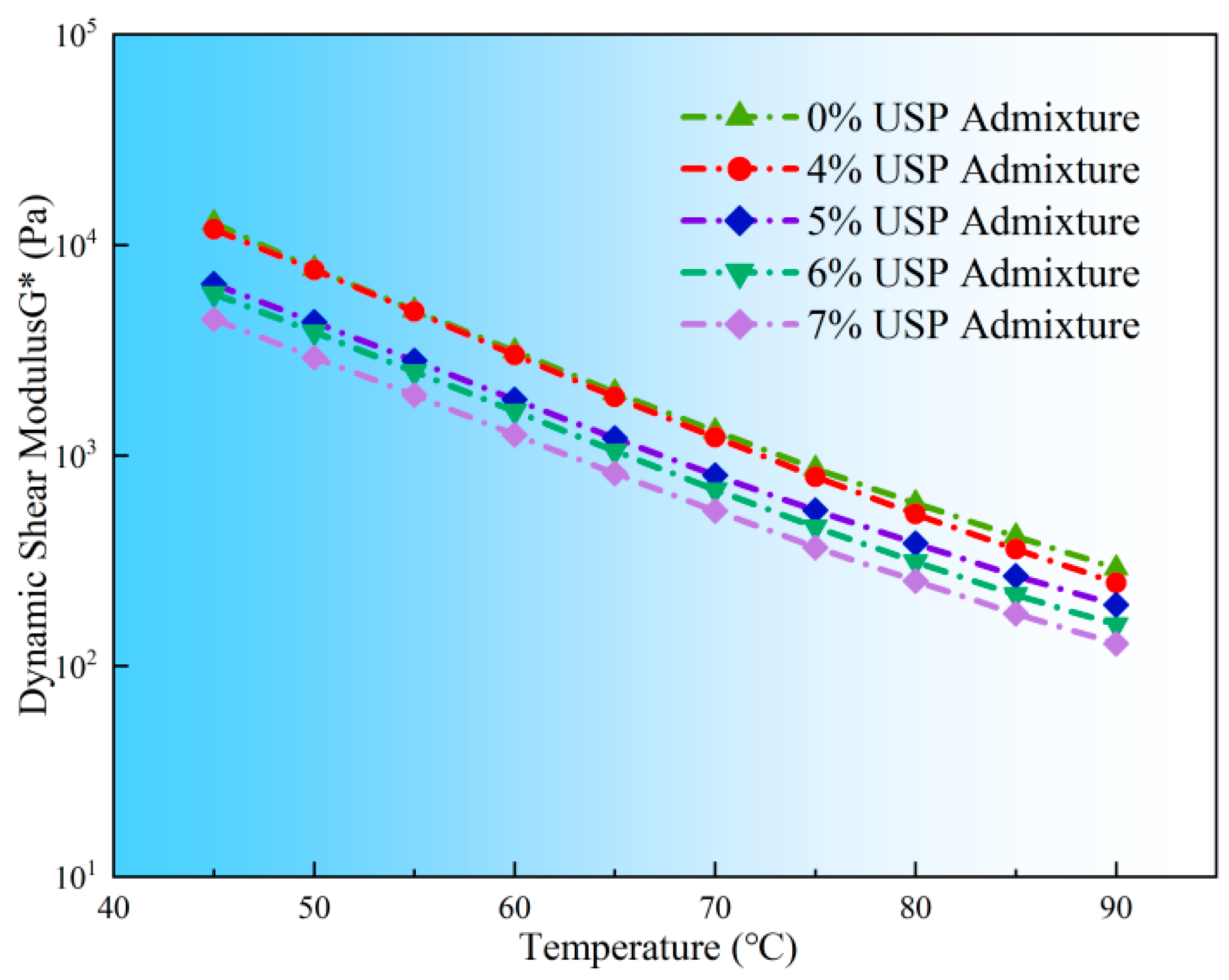

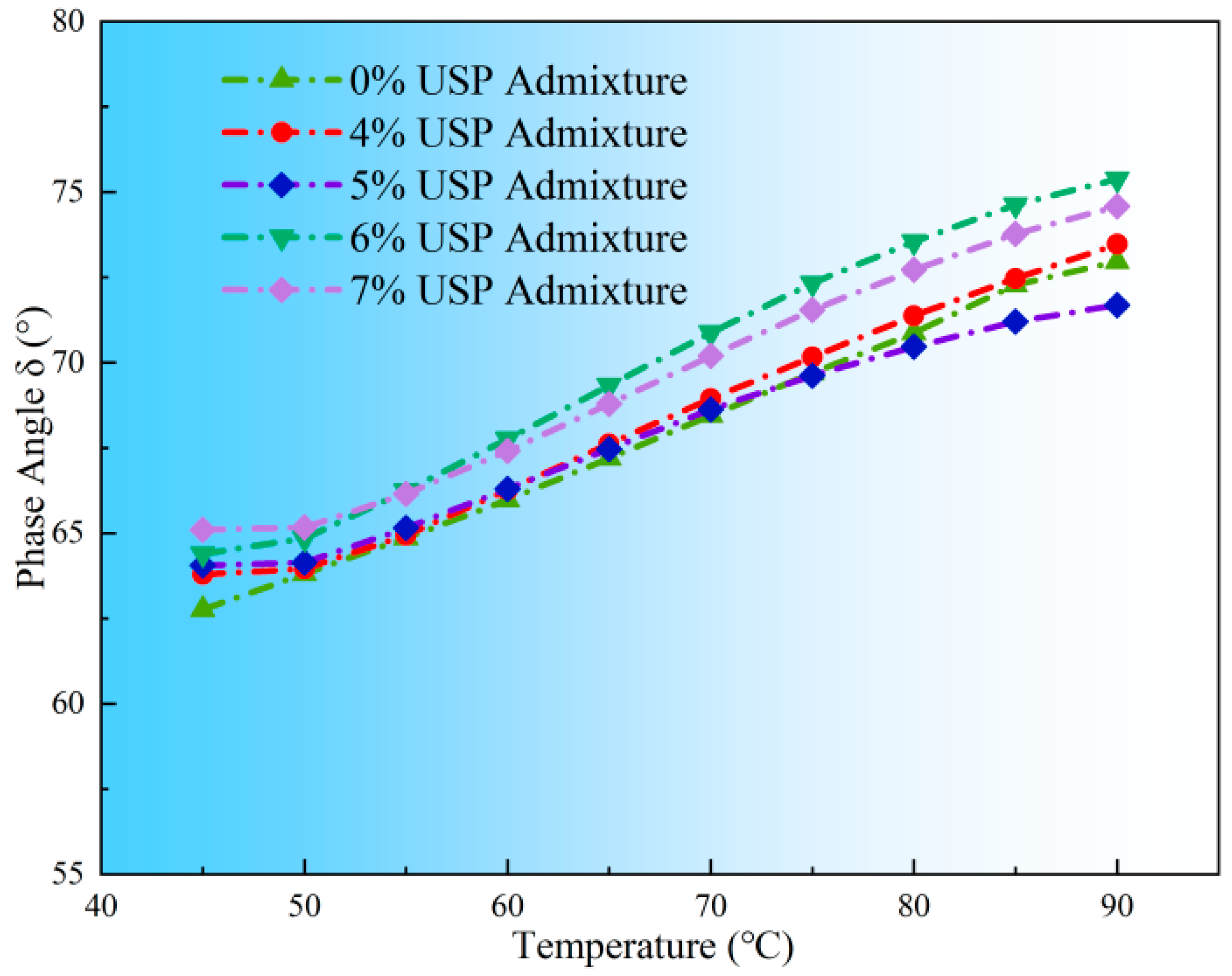

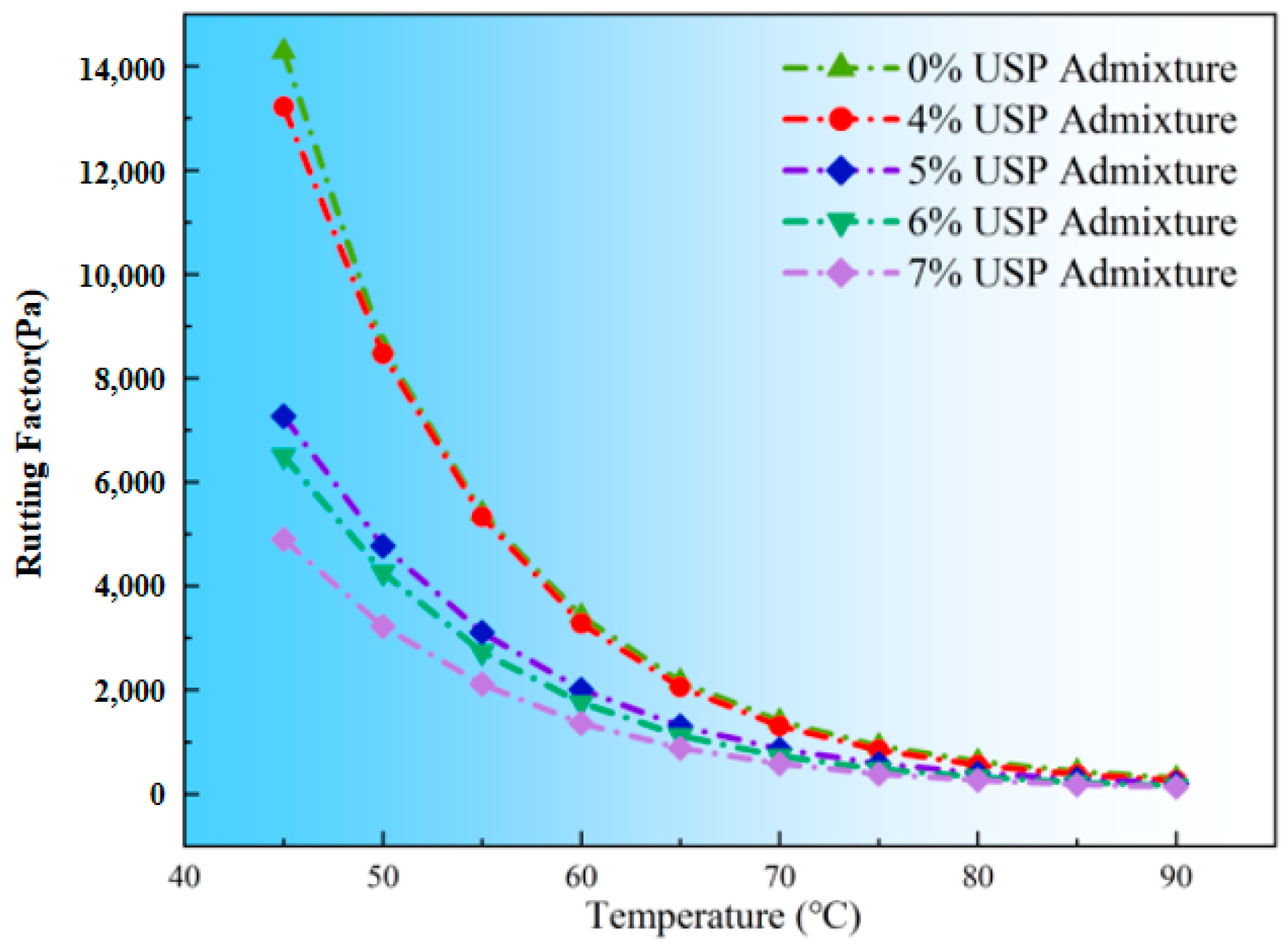

3.3. High Temperature Rheological Properties

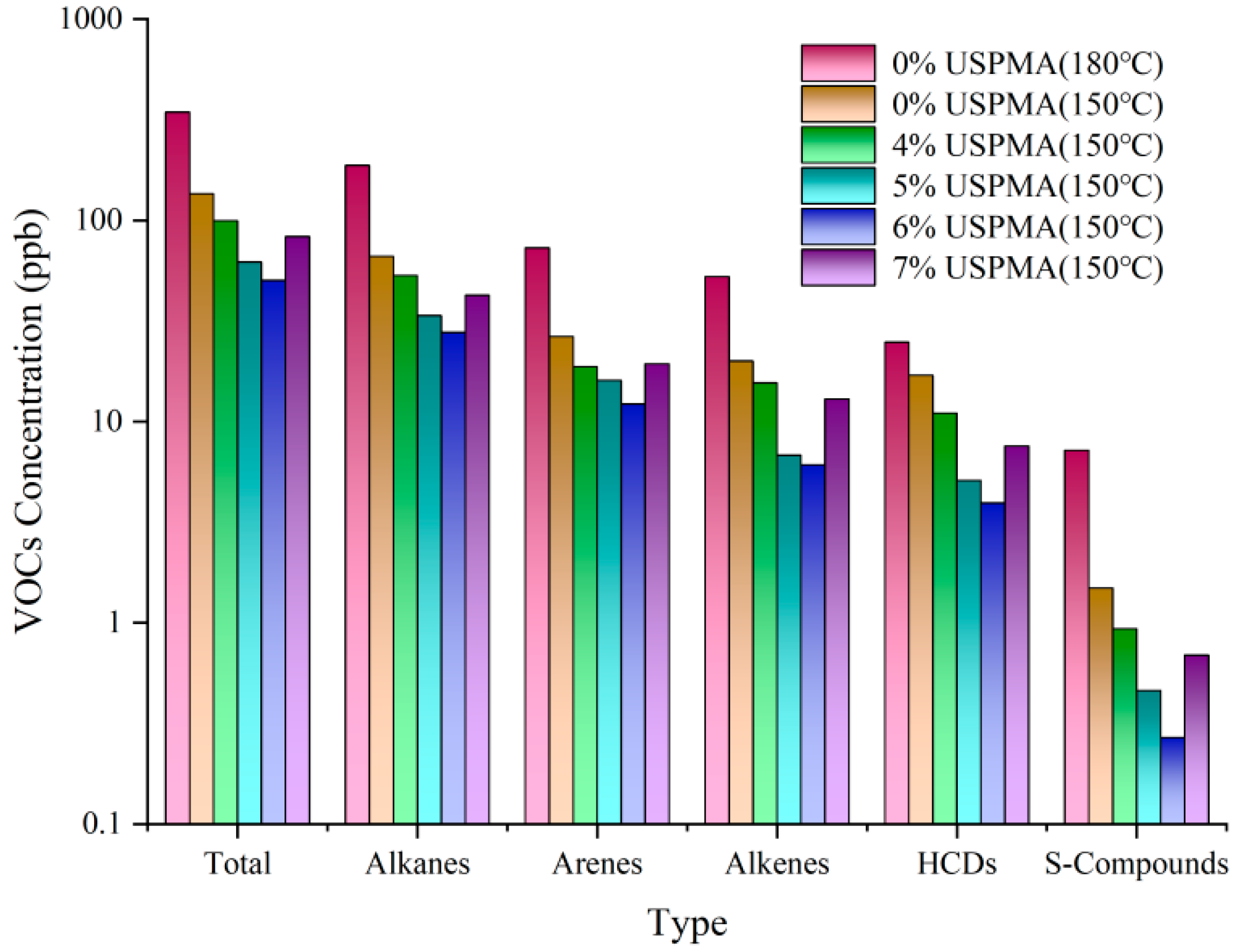

4. Effect of USP on the VOCs Emission of Rubberized Asphalt

5. Effects of USP on the Performance of Fiber-Reinforced Rubberized Asphalt RAP Interlayer

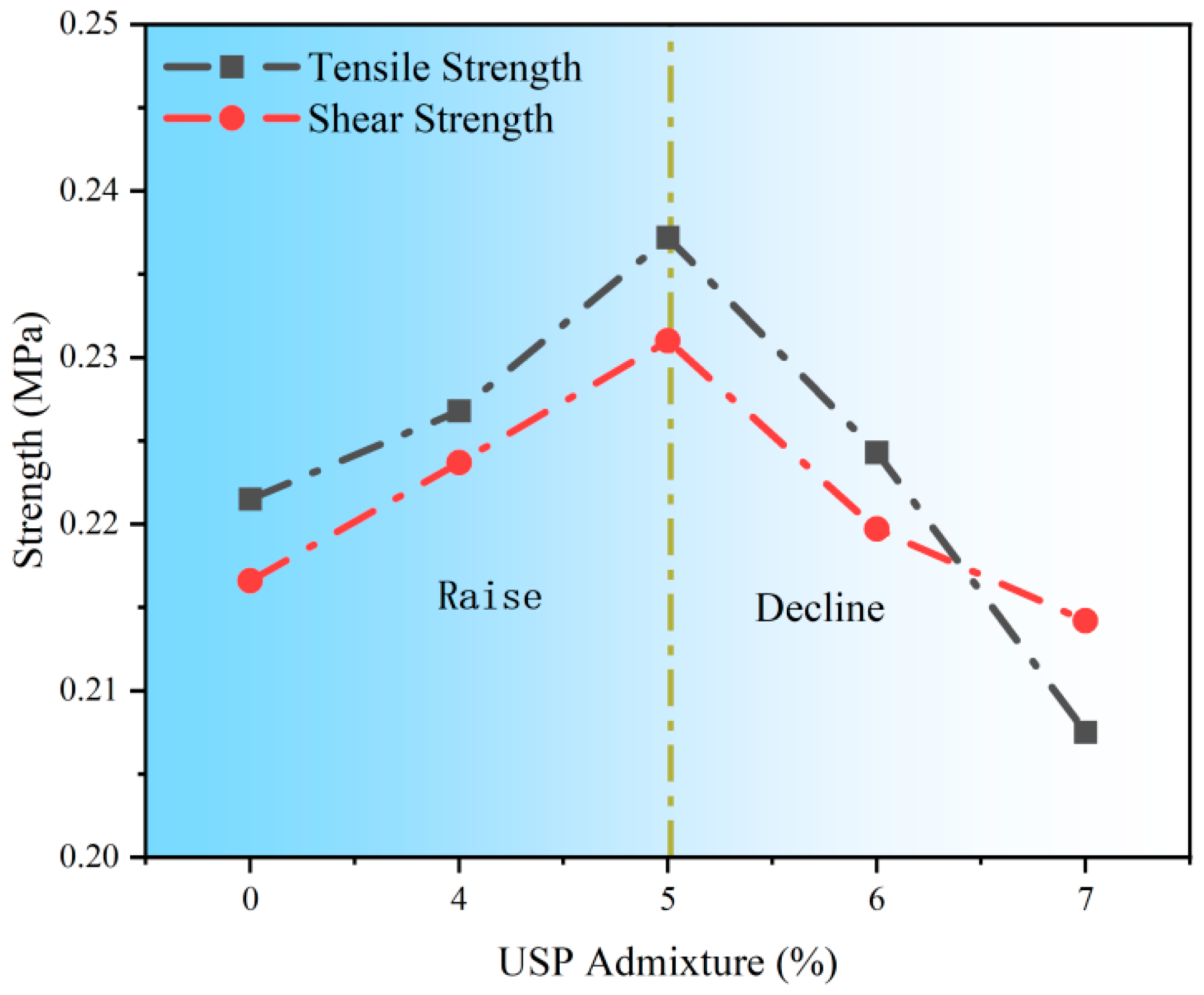

5.1. Bonding Strength

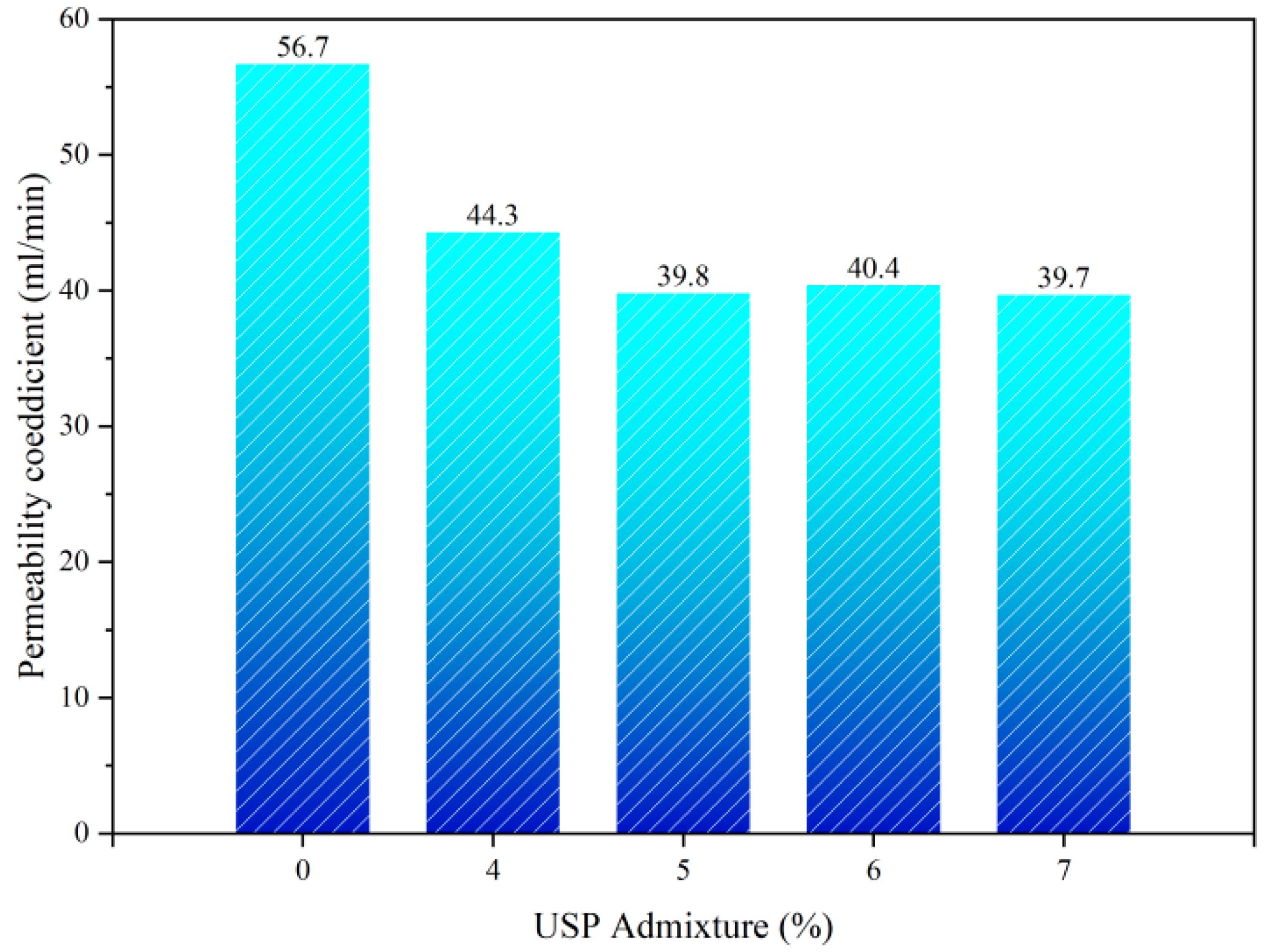

5.2. Water Permeability

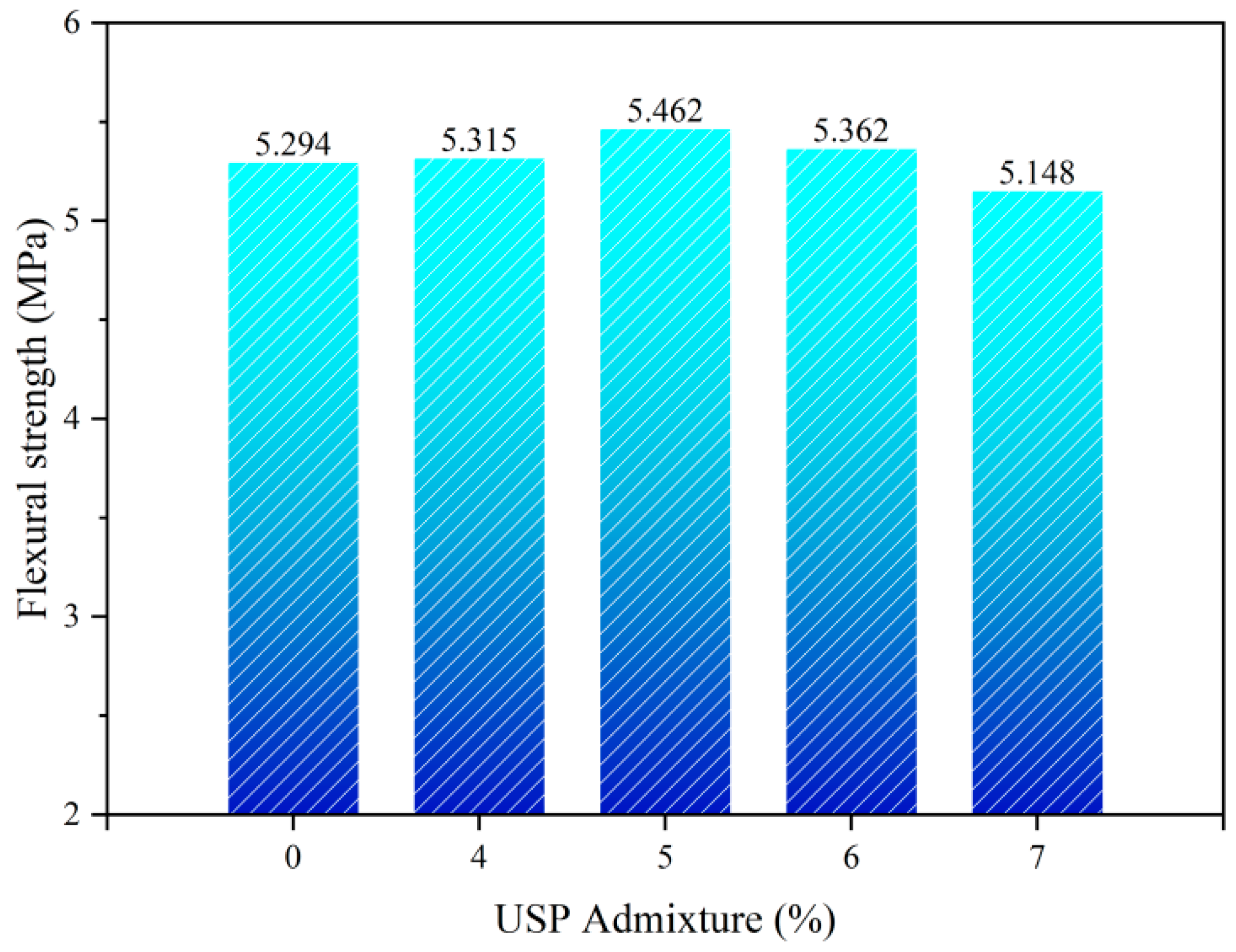

5.3. Flexural Strength

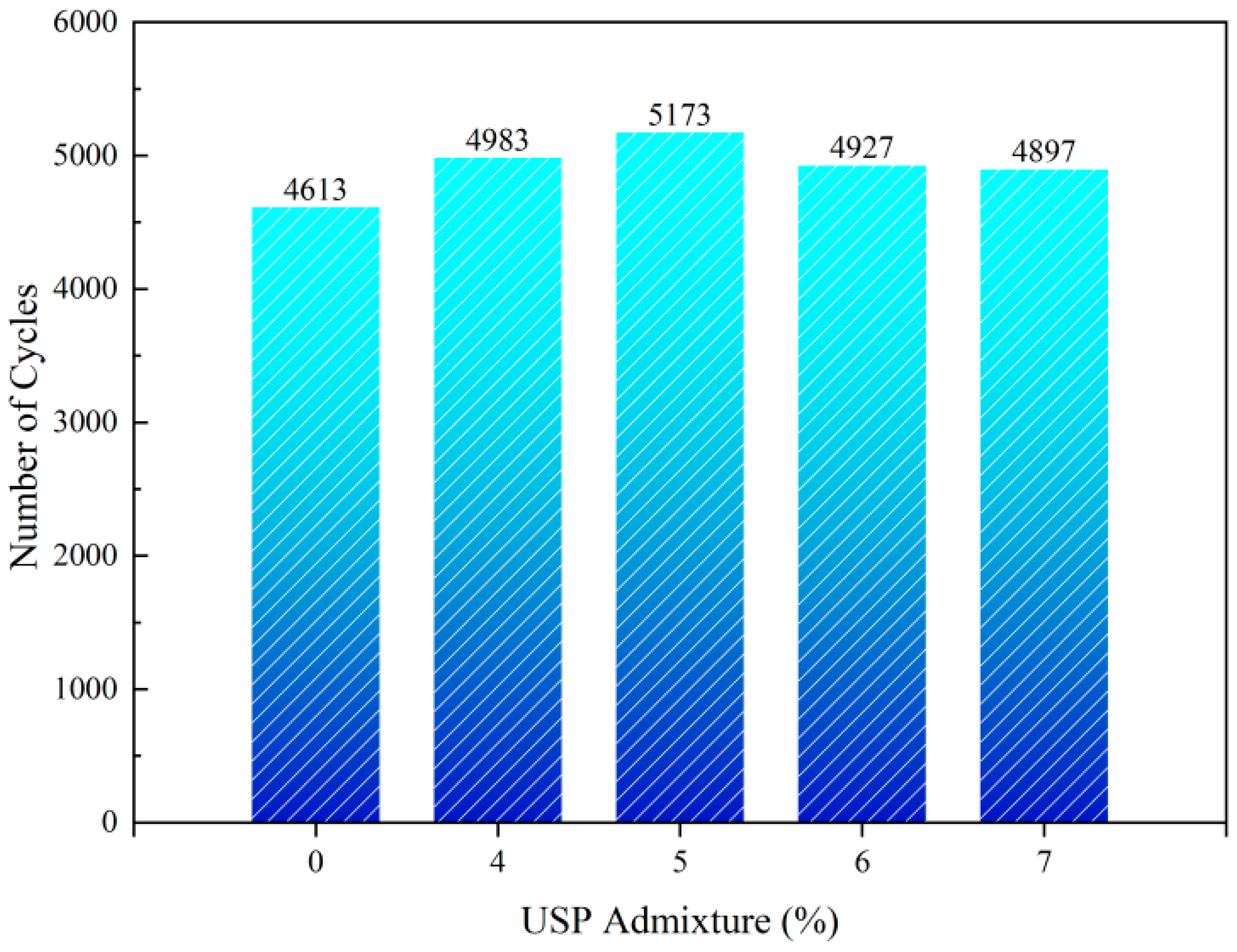

5.4. Fatigue Performance

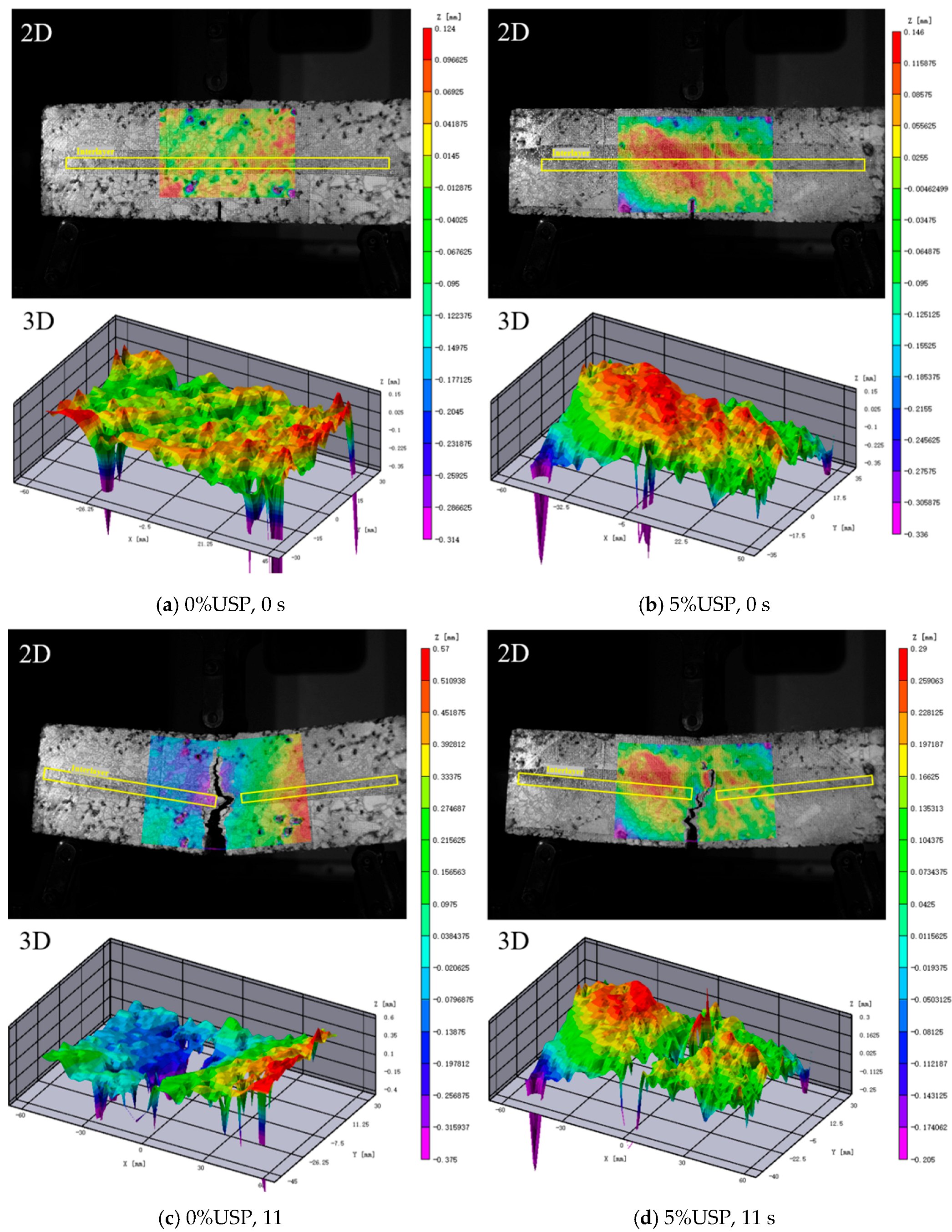

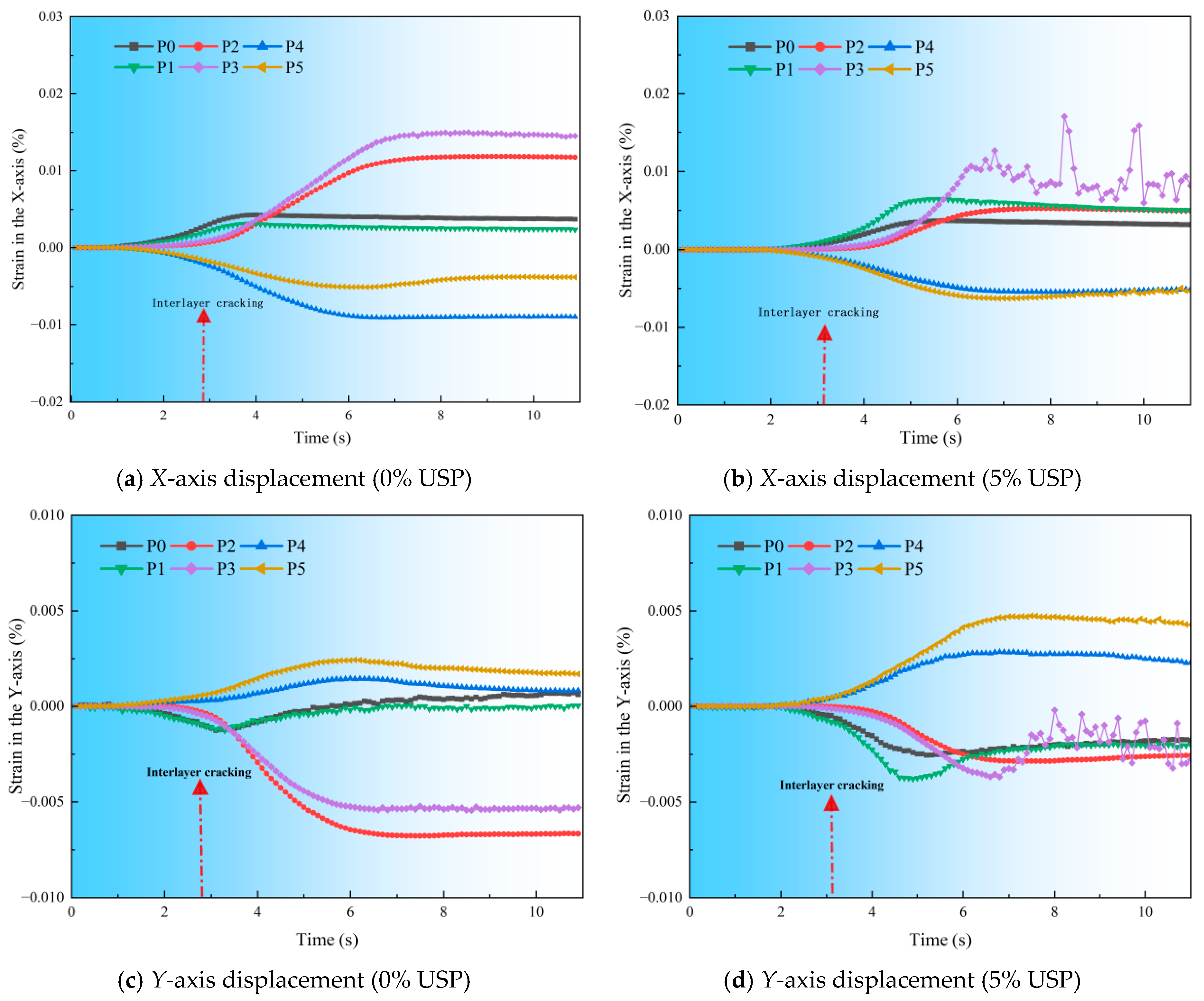

5.5. Fracture Mechanism Analysis Based on DIC Technology

6. Conclusions

- USP significantly improves the low-temperature flexibility and workability of rubberized asphalt by reducing viscosity and enhancing flow, with an optimal dosage of 5% balancing low-temperature performance and high-temperature stability.

- USP effectively suppresses VOC emissions during high-temperature construction. At 150 °C, a 6% dosage reduced total VOC emissions by 62.9% compared to unmodified asphalt at the same temperature and by 85.4% relative to 180 °C unmodified asphalt, attributed to its surface-active properties and superior dispersion at lower temperatures.

- For the RAP fiber-reinforced interlayer, a 5% USP dosage maximized key performance metrics: pull-out strength (+7.09%), shear strength (+6.65%), moisture damage resistance (+29.81%), flexural strength (+3.17%), and fatigue life (+12.14%), reflecting USP’s enhancement of asphalt-aggregate adhesion and interfacial cohesion.

- DIC-based analysis demonstrated that USP mitigates crack initiation and propagation by optimizing asphalt rheology and interfacial bonding, improving stress distribution at crack tips, and significantly enhancing crack resistance, thereby extending pavement service life through structural reinforcement.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Pyshyev, S.; Gunka, V.; Grytsenko, Y.; Bratychak, M. Polymer Modified Bitumen: Review. Chem. Chem. Technol. 2025, 19, 631–636. [Google Scholar] [CrossRef]

- Jin, D.; Yin, L.; Xin, K.; You, Z. Comparison of asphalt emulsion-based chip seal and hot rubber asphalt-based chip seal. Case Stud. Constr. Mater. 2023, 18, e02175. [Google Scholar] [CrossRef]

- Nagurskyy, A.; Grynyshyn, O.; Khlibyshyn, Y.; Korchak, B. Use of Rubber Crumb Obtained from Waste Car Tires for the Production of Road Bitumen and Roofing Materials from Residues of Ukrainian Oil Processing. Chem. Chem. Technol. 2023, 17, 674–680. [Google Scholar] [CrossRef]

- Xu, J.; Zheng, M.; Ding, X.; Qiao, R.; Zhang, W. Laboratory proportion design and performance evaluation of Fiber-Reinforced rubber asphalt chip seal based on multiple properties enhancement. Constr. Build. Mater. 2023, 403, 133204. [Google Scholar] [CrossRef]

- Sarkar, T.A.; Elseifi, M.A.; Hossain, Z. Effects of warm-mix additives, anti stripping agent, and graphene nanoplatelet on the cracking resistance, moisture susceptibility, and cost effectiveness of stone mastic asphalt. Constr. Build. Mater. 2024, 438, 137250. [Google Scholar] [CrossRef]

- Wang, D.; Miao, C.; Song, Y.; Yi, Y.; Long, J.; Zhang, Z.; Lei, T. Optimizing aged asphalt performance: Innovative warm mix agent blends and rheological insights. Constr. Build. Mater. 2024, 416, 135107. [Google Scholar] [CrossRef]

- Abdulwahed, H.S.; Aljanabi, K.R.; Abdulkareem, A.H. Optimization of equivalent modulus of RAP-geopolymer-soil mixtures using response surface methodology. J. King Saud Univ. Eng. Sci. 2024, 36, 375–384. [Google Scholar] [CrossRef]

- Meghasri, K.; Mamatha, K.; Dinesh, S. Performance evaluation of WMA mixtures with RAP. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Alizadeh, M.; Hajikarimi, P.; Nejad, F.M. Advancing asphalt mixture sustainability: A review of WMA-RAP integration. Results Eng. 2025, 25, 103678. [Google Scholar] [CrossRef]

- Cai, F.; Xiao, T.; She, H.; Zhao, Y.; Feng, Z.-G.; Zhang, J.; Li, Y. Performance optimization of asphalt blending behavior considering the effect of RAP agglomerates in hot in-place recycled asphalt mixture. Constr. Build. Mater. 2025, 470, 140633. [Google Scholar] [CrossRef]

- Guan, B.; Zhu, T.; Liu, S.; Luo, Z.; Yang, T. Development and evaluation of fiber-enhanced RAP interlayer for HMA overlay treatment. Constr. Build. Mater. 2024, 434, 136731. [Google Scholar] [CrossRef]

- Nouali, M.; Dony, A.; Vignaud, S.; Carter, A. Effect of aging kinetics on the fatigue behavior of asphalt mixtures incorporating various RAP contents. Transp. Eng. 2025, 19, 100312. [Google Scholar] [CrossRef]

- Karimi, F.; Mousavi, S.R.; Miri, M. On the effect of nano calcium carbonate on the flexibility and tensile-shear cracking resistance of greener WMA asphalt concretes containing RAP contents. Case Stud. Constr. Mater. 2024, 20, e03159. [Google Scholar] [CrossRef]

- Fei, M.; Cai, Q.; Wu, W.; Yan, X.; Zhao, H.; Yu, K.; Yu, H.; Wu, S.; Zheng, X.; Liu, W.; et al. Surface modified slag fiber reinforced asphalt mixture: Enhancement of pavement performance and field validation. Case Stud. Constr. Mater. 2025, 22, e04505. [Google Scholar] [CrossRef]

- Li, H.; Chu, R.; Cao, J.; Zhou, F.; Guo, K.; Zhang, Q.; Wang, H.; Liu, Y. Sensitive and reproducible on-chip SERS detection by side-polished fiber probes integrated with microfluidic chips. Measurement 2023, 218, 113203. [Google Scholar] [CrossRef]

- Del-Valle-Corte, J.; Orosa, P.; Pasandin, A.R.; Perez, I. Assessing the impact of various industrial wastes on the volumetric and mechanical properties of warm mix asphalt (WMA). Case Stud. Constr. Mater. 2024, 21, e04073. [Google Scholar] [CrossRef]

- Sha, F.; Yang, N.; Duan, X.; Qiao, A.; Chen, H.; Ding, Y. Effects of different warm mixing agents on properties of asphalt and warm mixing asphalt mixture. Case Stud. Constr. Mater. 2025, 22, e04445. [Google Scholar] [CrossRef]

- Sun, M.; He, Z.; Wu, Y.; Sun, D.; Fang, K. Inhibitory effects of surface modified solid acid synergistic warm-mixed flame retardant on asphalt combustion behavior. Constr. Build. Mater. 2025, 465, 140266. [Google Scholar] [CrossRef]

- Keymanesh, M.R.; Amani, S.; Omran, A.T.; Karimi, M.M. Evaluation of the impact of long-term aging on fracture properties of warm mix asphalt (WMA) with high RAP contents. Constr. Build. Mater. 2023, 400, 132671. [Google Scholar] [CrossRef]

- Zhang, H.; Liang, Y.; Liang, B.; Shi, K.; Liu, Z.; Zhang, D.; Zheng, J. Evaluation of aging indicators for warm mix styrene-butadiene-styrene-modified asphalt: Molecular structure and rheological properties. Constr. Build. Mater. 2025, 465, 140264. [Google Scholar] [CrossRef]

- Nithinchary, J.; Dhandapani, B.P.; Mullapudi, R.S. Application of warm mix technology-design and performance characteristics: Review and way forward. Constr. Build. Mater. 2024, 414, 134915. [Google Scholar] [CrossRef]

- JTG E20; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- JTG 3432; Test Methods of Aggregates for Highway Engineering. China Communications Press: Beijing, China, 2024.

- GB/T 260; Test Sieves. Standards Press of China: Beijing, China, 2016.

- CJJ/T 273; Specifications for Design of Asphalt Pavements for Highway Engineering. China Communications Press: Beijing, China, 2019.

- Wang, W.; Cheng, H.; Sun, L.; Sun, Y.; Liu, N. Multi-performance evaluation of recycled warm-mix asphalt mixtures with high reclaimed asphalt pavement contents. J. Clean. Prod. 2022, 377, 134209. [Google Scholar] [CrossRef]

- Zhu, J.; Li, L.; Yin, C.; Zhang, X.; Zhou, X.; Wang, H. Study on viscosity reduction mechanism of warm-mixed rubber modified asphalt: A green sustainable perspective. Case Stud. Constr. Mater. 2024, 21, e03494. [Google Scholar] [CrossRef]

- Li, Y.; Si, Y.; Zhang, K.; Zhu, Y. Investigation of interface mechanics and crack propagation in warm-mixed rubber asphalt mixture under salt-freeze-thaw conditions. Constr. Build. Mater. 2025, 458, 139750. [Google Scholar] [CrossRef]

- Chen, Y.; Naseri, A.; Attari, A.; Zarei, M.; Khordehbinan, M.W.; Pouri, M.A. Evaluation of fracture indices of warm mix asphalt (WMA) modified with nano-additive under pure shear and pure tear deformations. Theor. Appl. Fract. Mech. 2024, 132, 104471. [Google Scholar] [CrossRef]

- Jiang, D.; Cao, Z.; Zhou, B.; Gong, G.; Huang, Z.; Wang, C. Environmental Impact Assessment of Waste Plastic Modified Asphalt Mixtures: VOCs Emission Characteristics, Environmental-health Risks, and Underlying Mechanism. Environ. Res. 2025, 279, 121642. [Google Scholar] [CrossRef] [PubMed]

- Sagar, K.A.; Venudharan, V.; Saha, G. Prospects of warm mix asphalt in maximizing reclaimed asphalt pavement utilization: Review on mix design and performance. Clean. Waste Syst. 2025, 10, 100229. [Google Scholar] [CrossRef]

- Dong, W.; Ma, F.; Fu, Z.; Hou, Y.; Dai, J.; Zhao, Z.; Fang, R. Investigating the properties of a novel organic composite warm mix additive on SBS modified asphalt binder. Constr. Build. Mater. 2024, 444, 137885. [Google Scholar] [CrossRef]

- Diao, H.; Gao, Y.; Luo, K.; Ling, T.; Peng, B.; Shi, W.; Ding, C.; Kuang, W. Evaluation of anti-aging properties for g-C3N4 warm-mix modified asphalt extremely mechanism action. Constr. Build. Mater. 2025, 472, 140907. [Google Scholar] [CrossRef]

| Type | Detection Items | Test Results | Methods (JTG E20-2011 [22]) | |

|---|---|---|---|---|

| Rubber asphalt | Penetration 25 °C, 100 g, 5 s (0.1 mm) | 45 | T 0604 | |

| Penetration index PI | 0.8 | - | ||

| Ductility 5 cm/min, 5 °C (cm) | 90 | T 0605 | ||

| Softening point (°C) | 68 | T 0606 | ||

| Elastic recovery 25 °C (%) | 86 | T 0662 | ||

| Storage stability segregation (°C) | 1.8 | T 0655 | ||

| Residue after RTFOT (163 °C, 85 min) | Mass loss (%) | −0.06 | T 0610 | |

| Penetration ration 25 °C (%) | 76 | |||

| Residual ductility 15 °C (cm) | 28 | |||

| Asphalt in RAP | Penetration at 25 °C (100 g, 5 s, 0.1 mm) | 17 | T 0604 | |

| Ductility at 5 °C (cm) | Brittle | T 0605 | ||

| Ductility at 15 °C (cm) | 11 | T 0605 | ||

| Softening Point (°C) | 71 | T 0606 | ||

| Detection Items | Results | Standard | Methods (JTG 3432-2024 [23]) |

|---|---|---|---|

| Los Angeles abrasion loss (%) | 26 | ≤35 | T 0317 |

| Crushing value (%) | 16 | ≤30 | T 0316 |

| Needle-like content (%) | 11 | ≤20 | T 0312 |

| Asphalt Adhesion (grade) | 6 | >4 | T 0323 |

| Moisture content (%) | 1.4 | ≤2 | T 0304 |

| PSV | 18 | ≤38 | T 0321 |

| Durability (%) | 8 | ≤12 | T 0314 |

| Length (mm) | Single Fiber Diameter (μm) | Density (kg/m3) | Fracture Elongation Rate (%) | Elastic Modulus (GPa) | Pull-Out Strength (MPa) | Moisture Content (%) |

|---|---|---|---|---|---|---|

| 20 | 15 | 2645 | 2.4–3.2 | 90–110 | 3200–4600 | 0.06 |

| Item | Unit | Specification | Methods |

|---|---|---|---|

| Appearance | / | Black or purple-black paste | Visual inspection |

| Odor | / | Odorless | Olfactory test |

| Flash point (open cup) | °C | >120 | JTG E20 T0611 |

| Density | g/cm3 | 0.94–0.99 | JTG E20 T0603 |

| Moisture content | % | <0.2 | GB/T 260-2016 [24] |

| Ash content | % | <0.8 | JTG E20 T0614 |

| Sample ID | Base Asphalt (%) | Crumb Rubber (%) | USP Warm-Mix Additive (%) |

|---|---|---|---|

| RAU-0 | 90 | 10 | 0 |

| RAU-4 | 90 | 10 | 4 |

| RAU-5 | 90 | 10 | 5 |

| RAU-6 | 90 | 10 | 6 |

| RAU-7 | 90 | 10 | 7 |

| USP Admixture | 0% | 0% | 4% | 5% | 6% | 7% |

|---|---|---|---|---|---|---|

| Temperature | 180 °C | 150 °C | 150 °C | 150 °C | 150 °C | 150 °C |

| Alkanes | 187.42 | 66.23 | 53.21 | 33.63 | 27.71 | 42.40 |

| Arenes | 72.84 | 26.45 | 18.73 | 16.00 | 12.24 | 19.34 |

| Alkenes | 52.47 | 19.98 | 15.55 | 6.82 | 6.10 | 12.94 |

| HCD * | 24.79 | 16.99 | 11.01 | 5.11 | 3.94 | 7.57 |

| S-Compounds * | 7.20 | 1.49 | 0.94 | 0.46 | 0.27 | 0.69 |

| Total | 344.72 | 135.60 | 99.44 | 62.02 | 50.27 | 82.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.; Ding, B.; Hua, Y.; Liu, W.; Li, J. Effect of Warm-Mix Additive USP on the Performance of Rubberized Asphalt and Fiber-Reinforced Rubberized Asphalt RAP Interlayer. Polymers 2025, 17, 2616. https://doi.org/10.3390/polym17192616

Han J, Ding B, Hua Y, Liu W, Li J. Effect of Warm-Mix Additive USP on the Performance of Rubberized Asphalt and Fiber-Reinforced Rubberized Asphalt RAP Interlayer. Polymers. 2025; 17(19):2616. https://doi.org/10.3390/polym17192616

Chicago/Turabian StyleHan, Jianhang, Bin Ding, Yong Hua, Wenbo Liu, and Jun Li. 2025. "Effect of Warm-Mix Additive USP on the Performance of Rubberized Asphalt and Fiber-Reinforced Rubberized Asphalt RAP Interlayer" Polymers 17, no. 19: 2616. https://doi.org/10.3390/polym17192616

APA StyleHan, J., Ding, B., Hua, Y., Liu, W., & Li, J. (2025). Effect of Warm-Mix Additive USP on the Performance of Rubberized Asphalt and Fiber-Reinforced Rubberized Asphalt RAP Interlayer. Polymers, 17(19), 2616. https://doi.org/10.3390/polym17192616