Characterization and Comparison of Polymer Melt Fluidity Across Three Ultrasonic Plasticization Molding Technologies

Abstract

1. Introduction

2. Experimentation

2.1. Materials

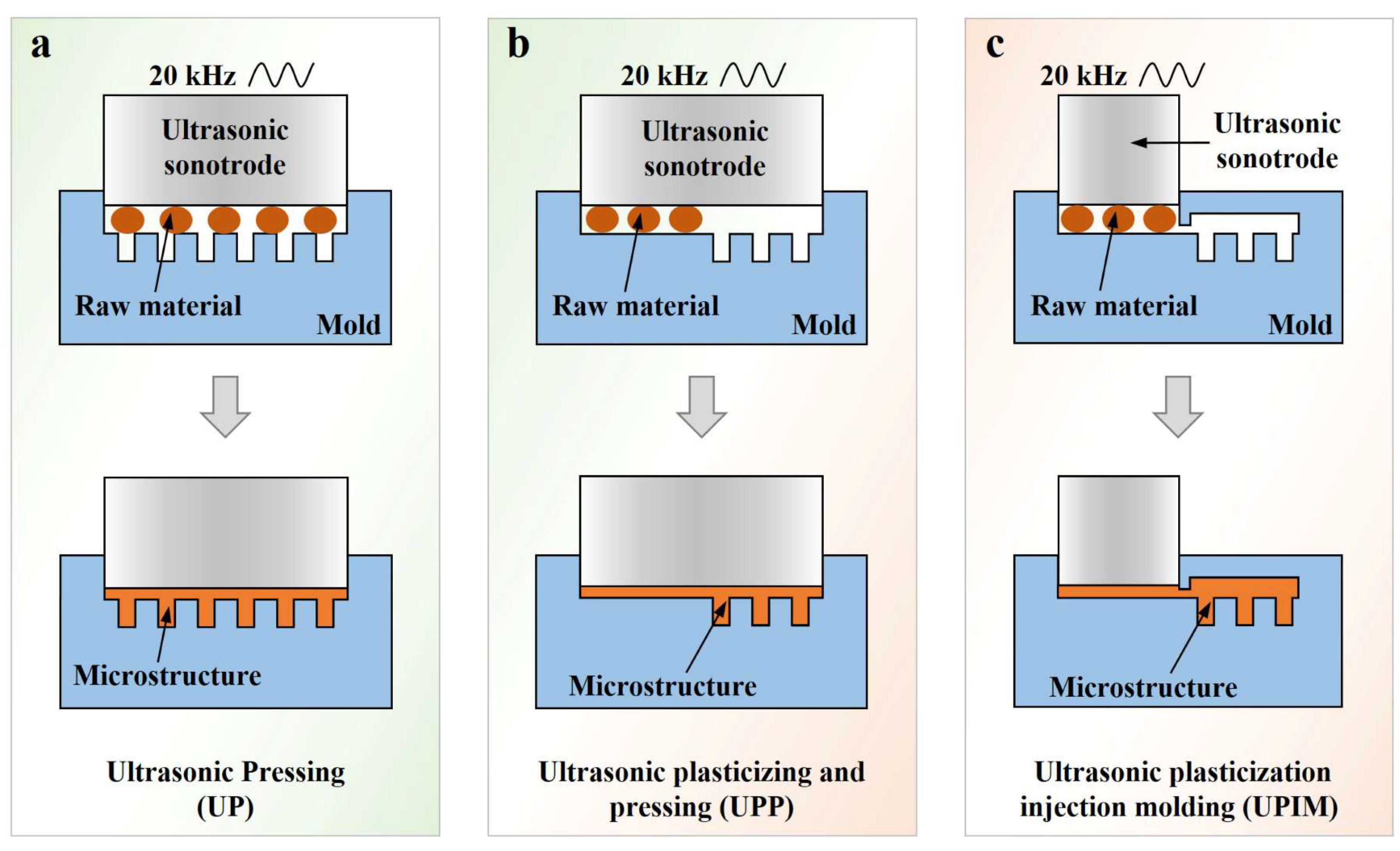

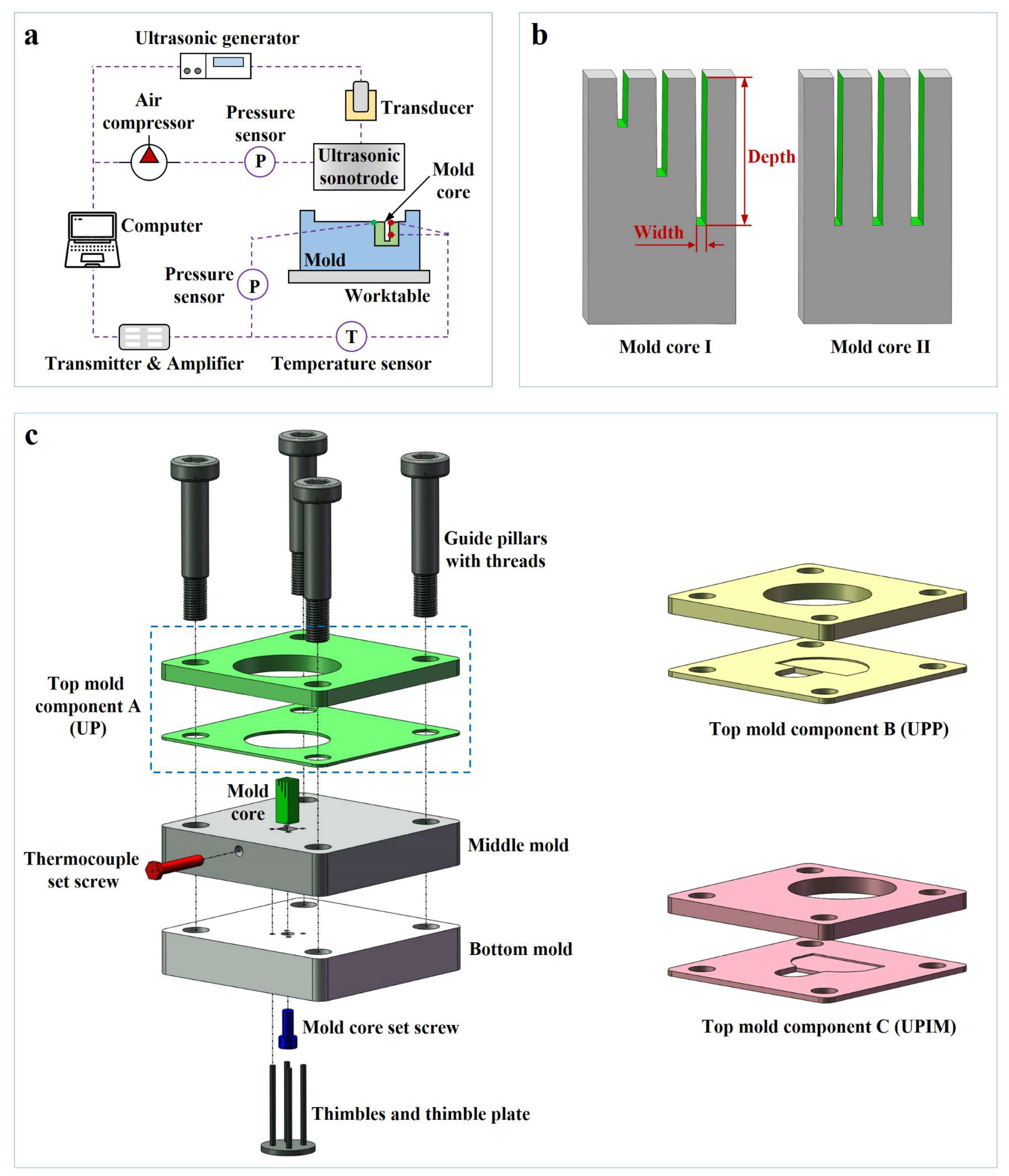

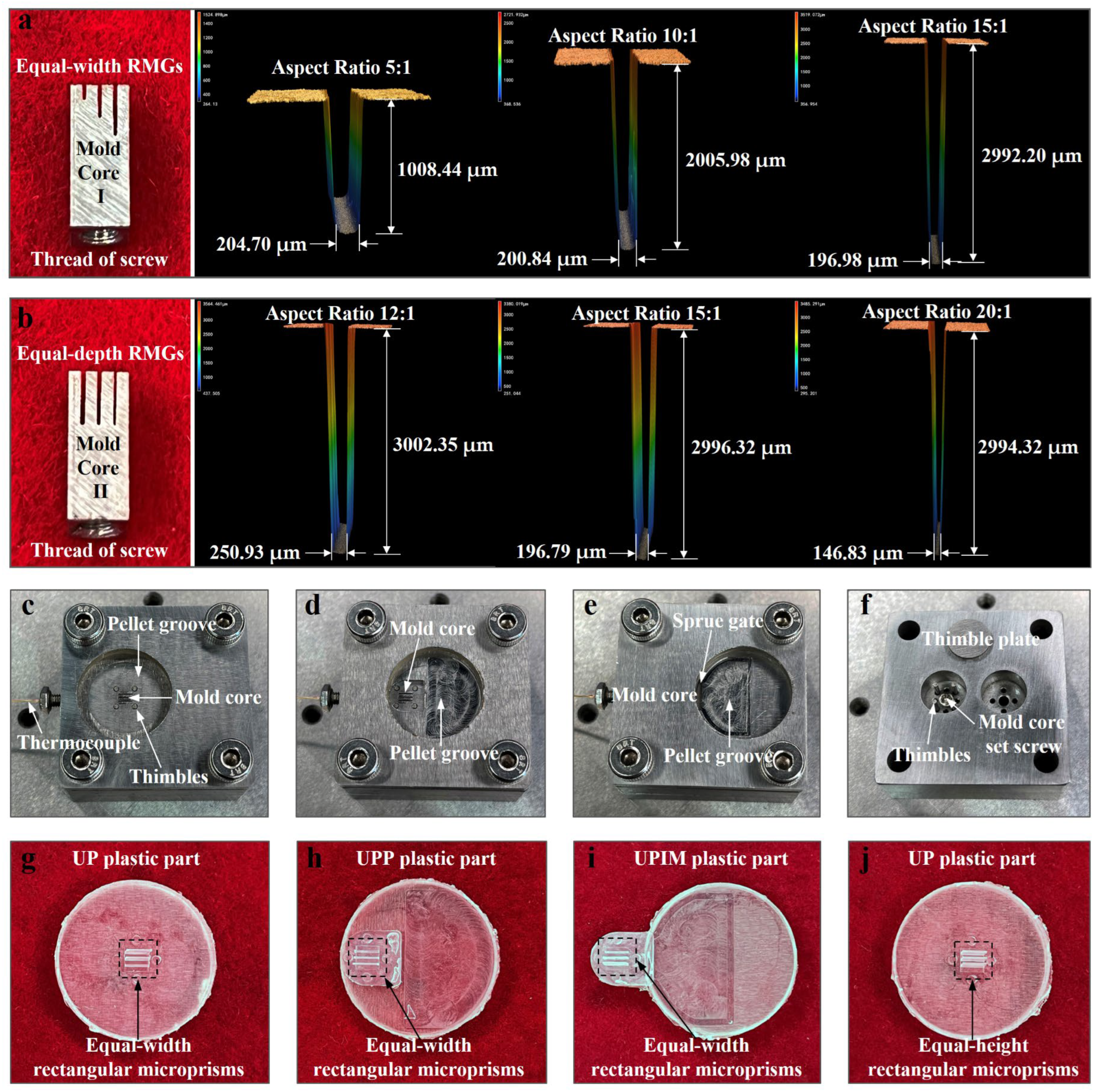

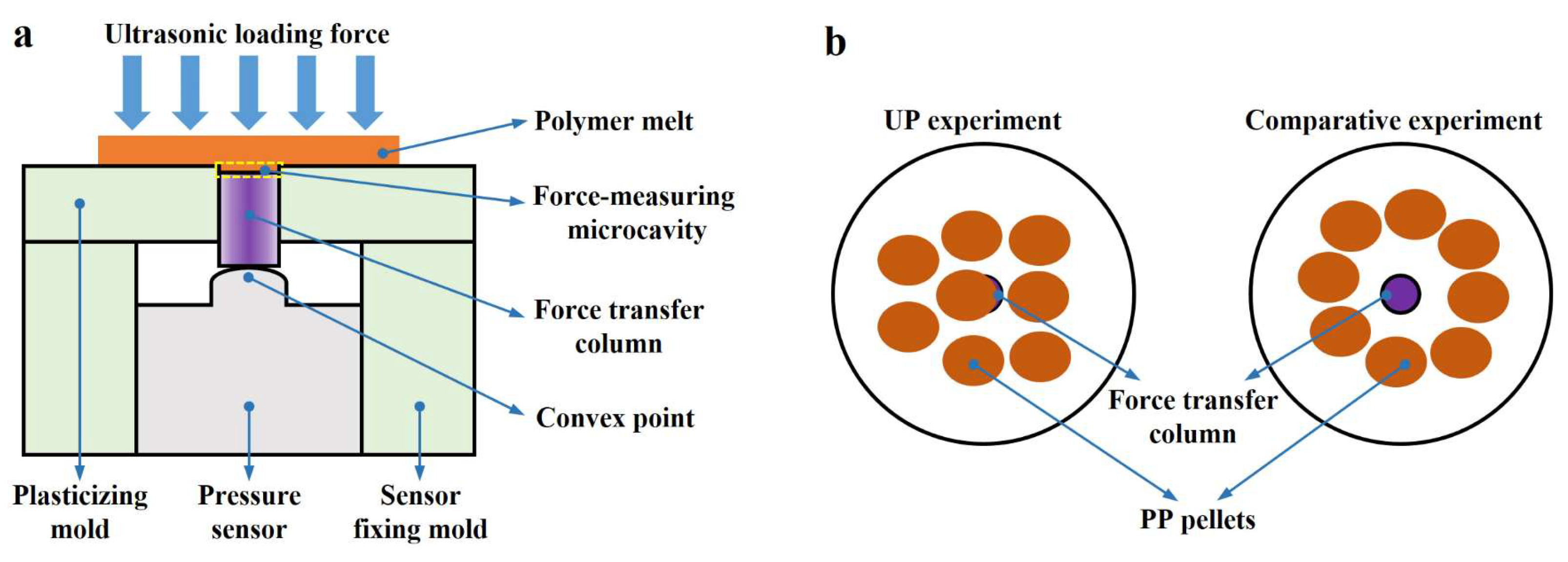

2.2. Equipment and Mold

2.3. Methodology

2.4. Characterization

3. Results and Discussion

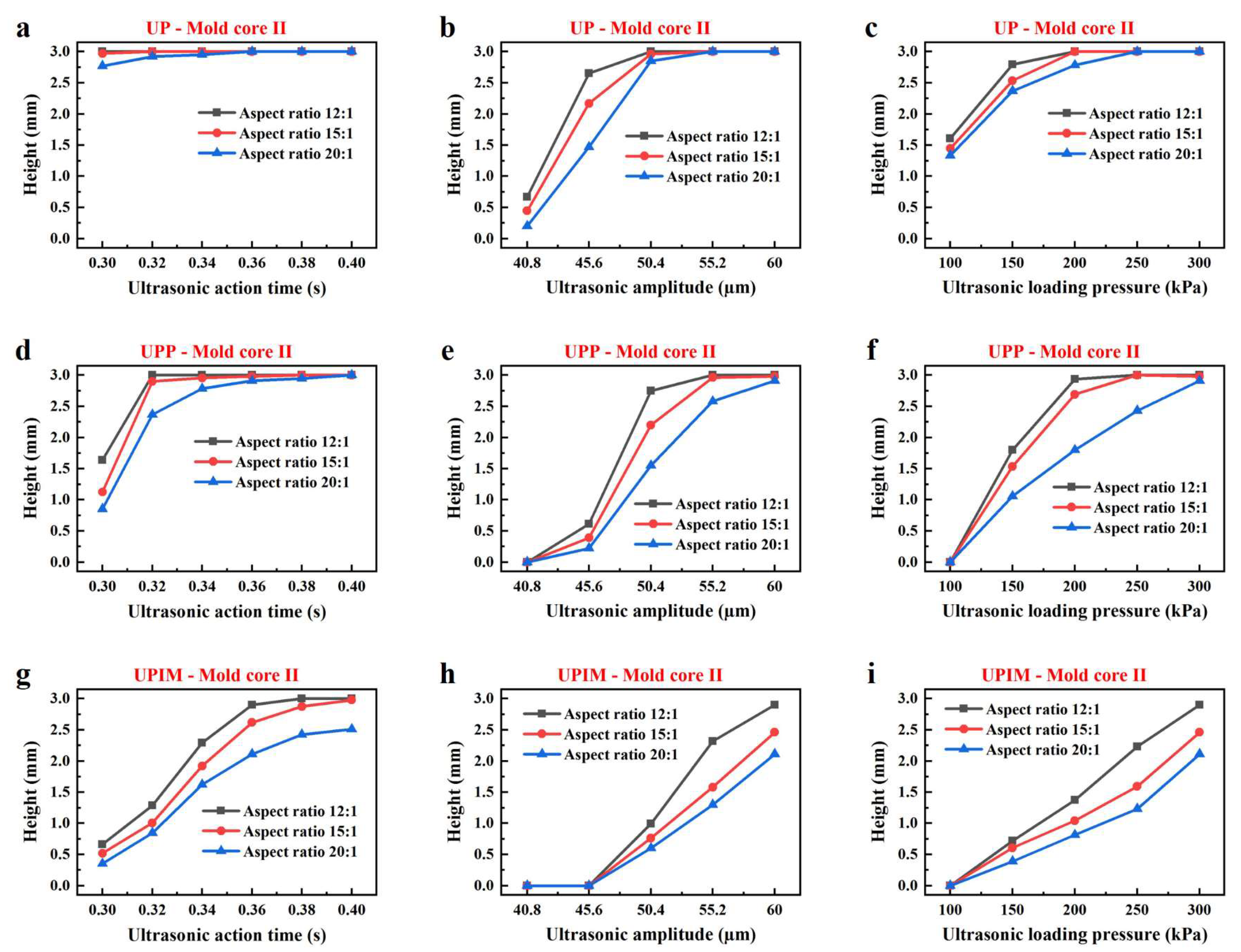

3.1. Characterization and Comparison of the Fluidity

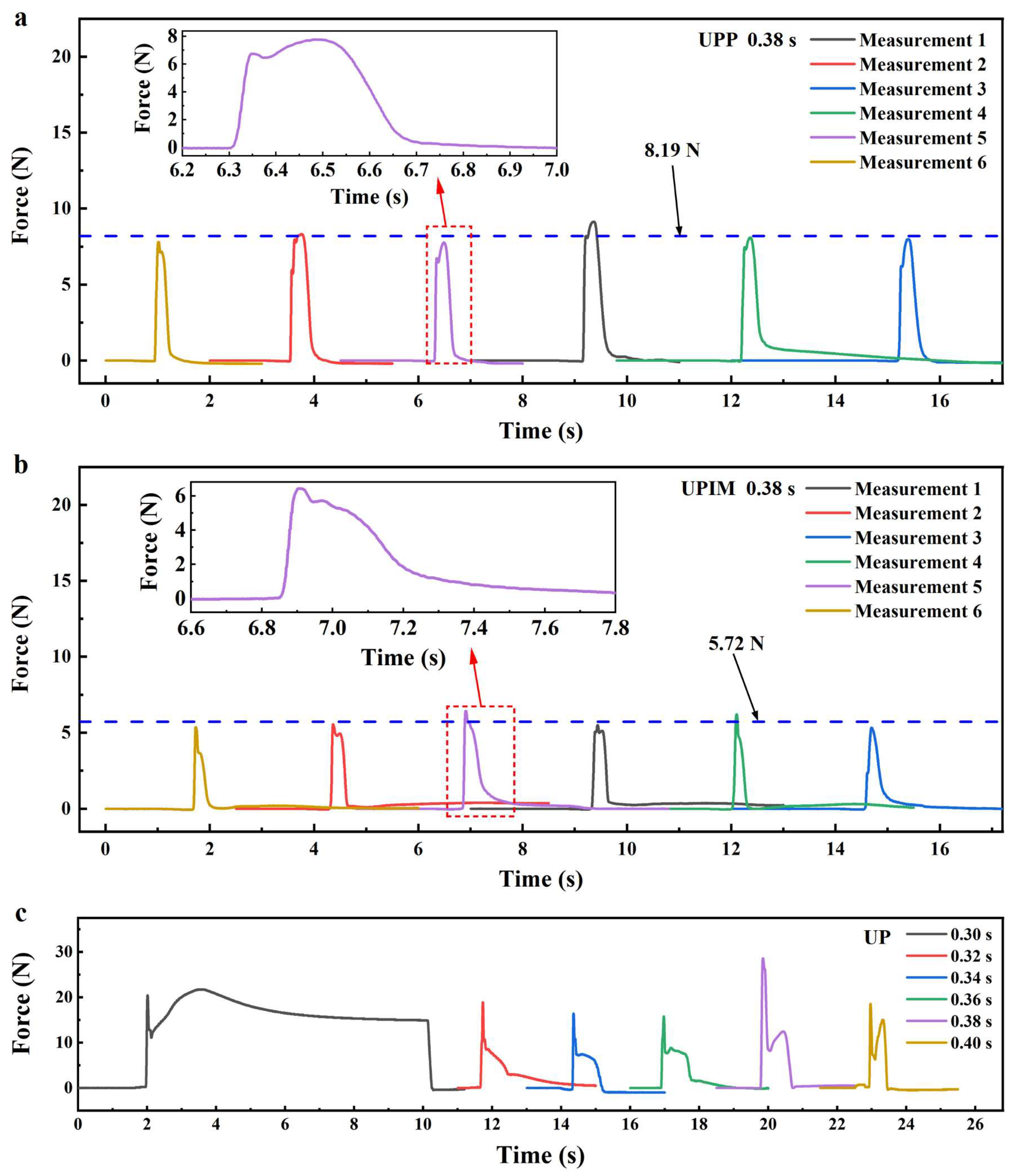

3.2. Melt Temperature and Pressure

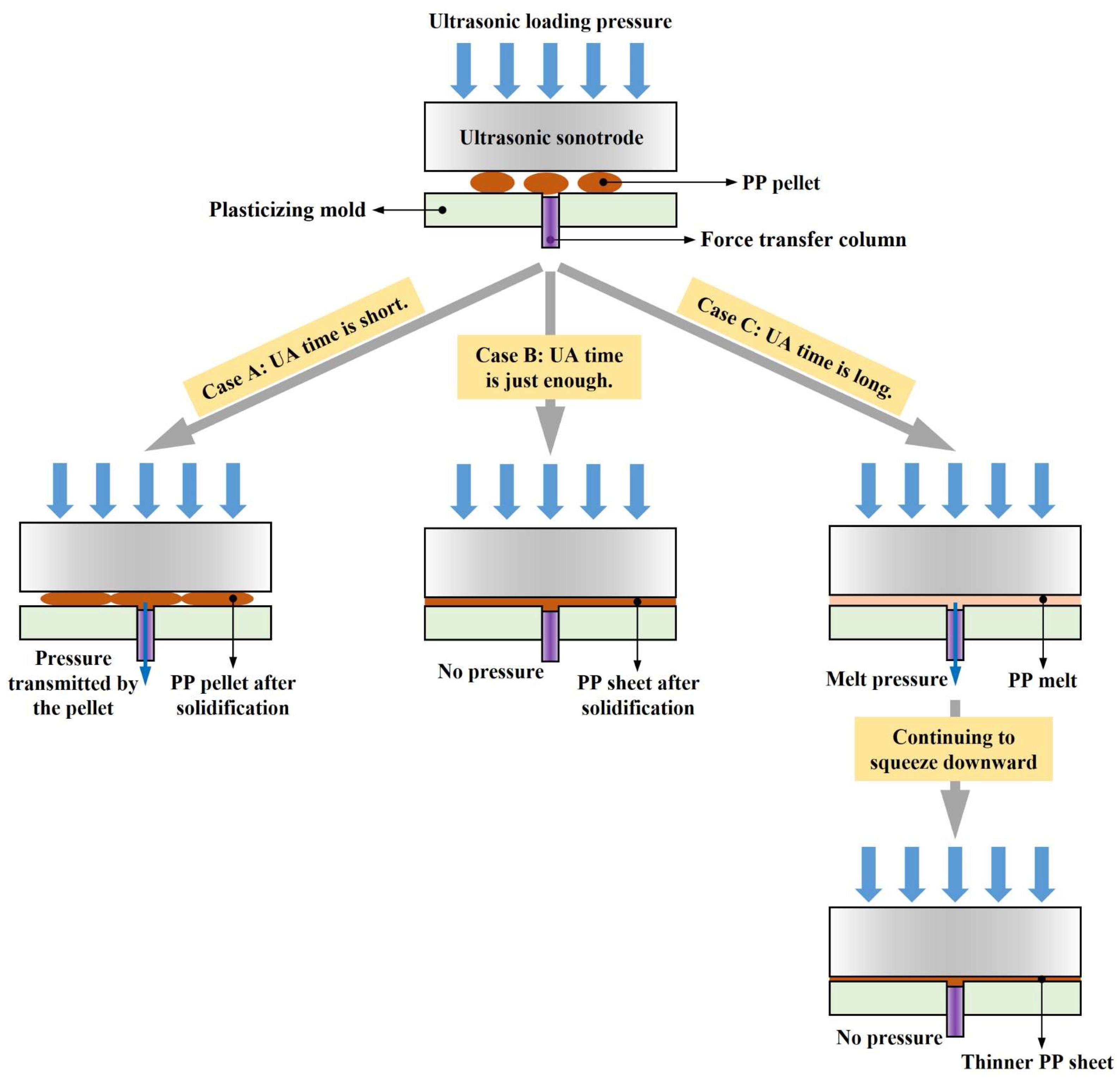

3.3. Ultrasonic Plasticization and Melt Flow Behavior in up

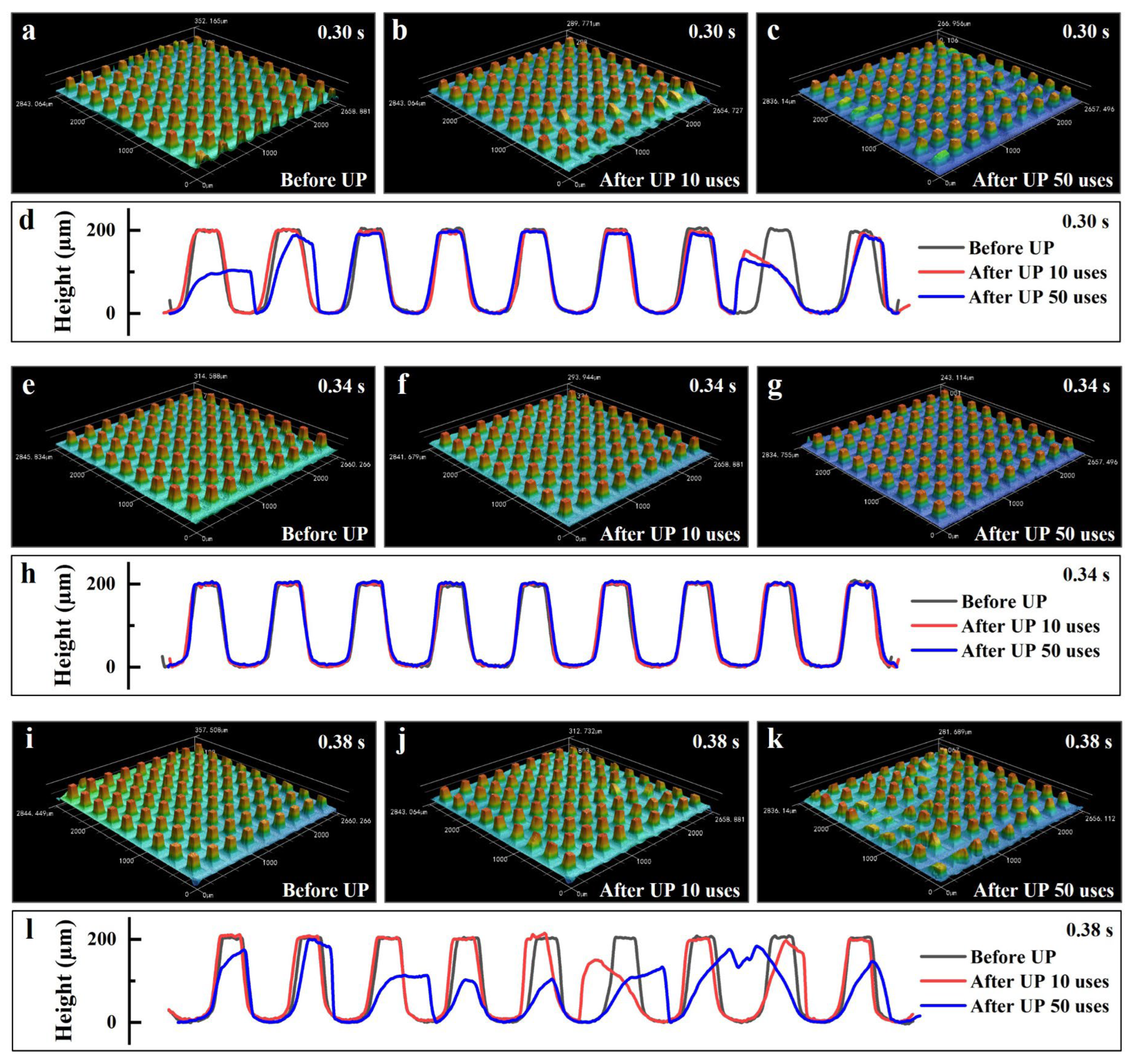

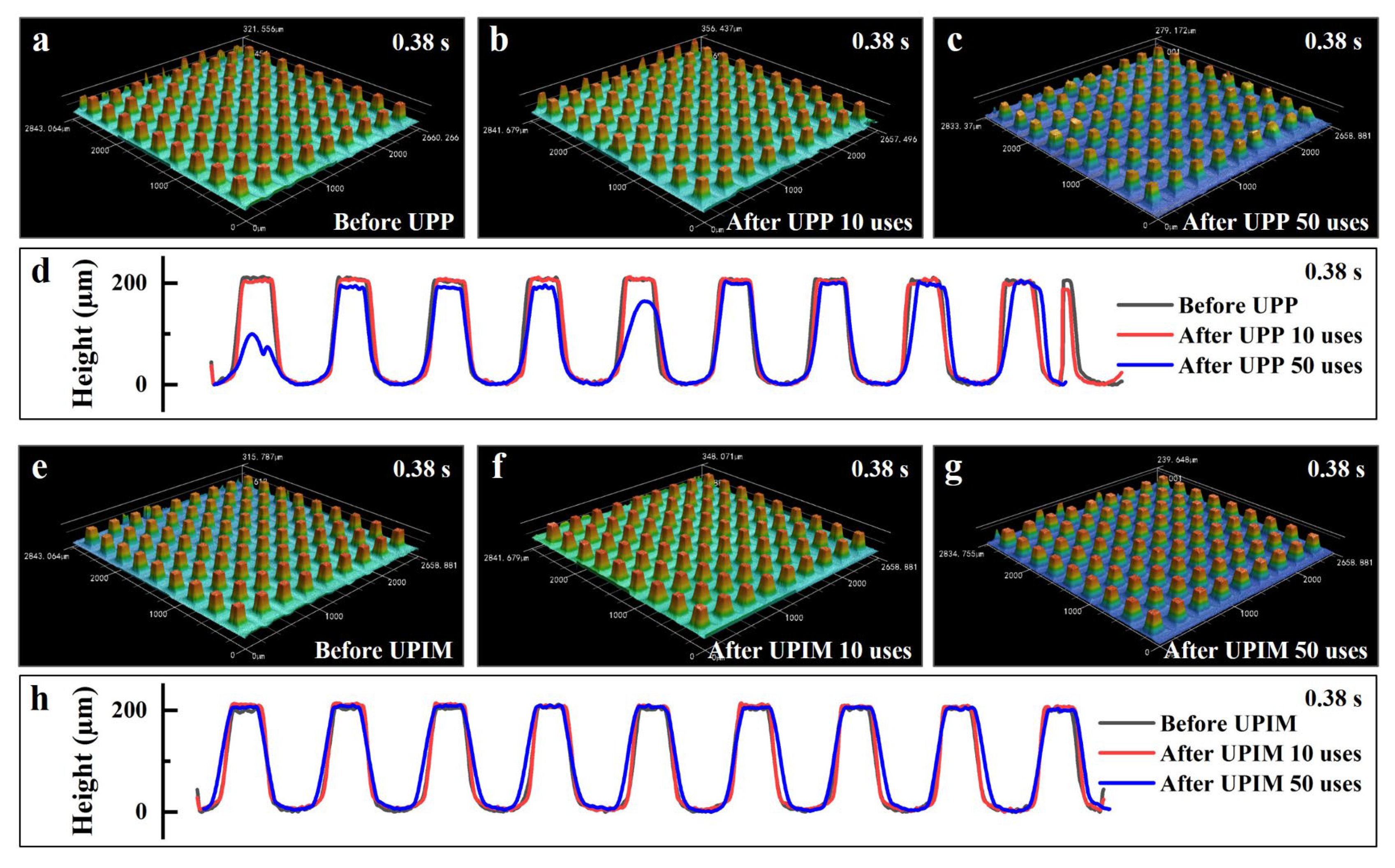

3.4. Template Microstructure Damage Analysis and Comparison

3.5. Interaction Mechanism of the Melt with the Template

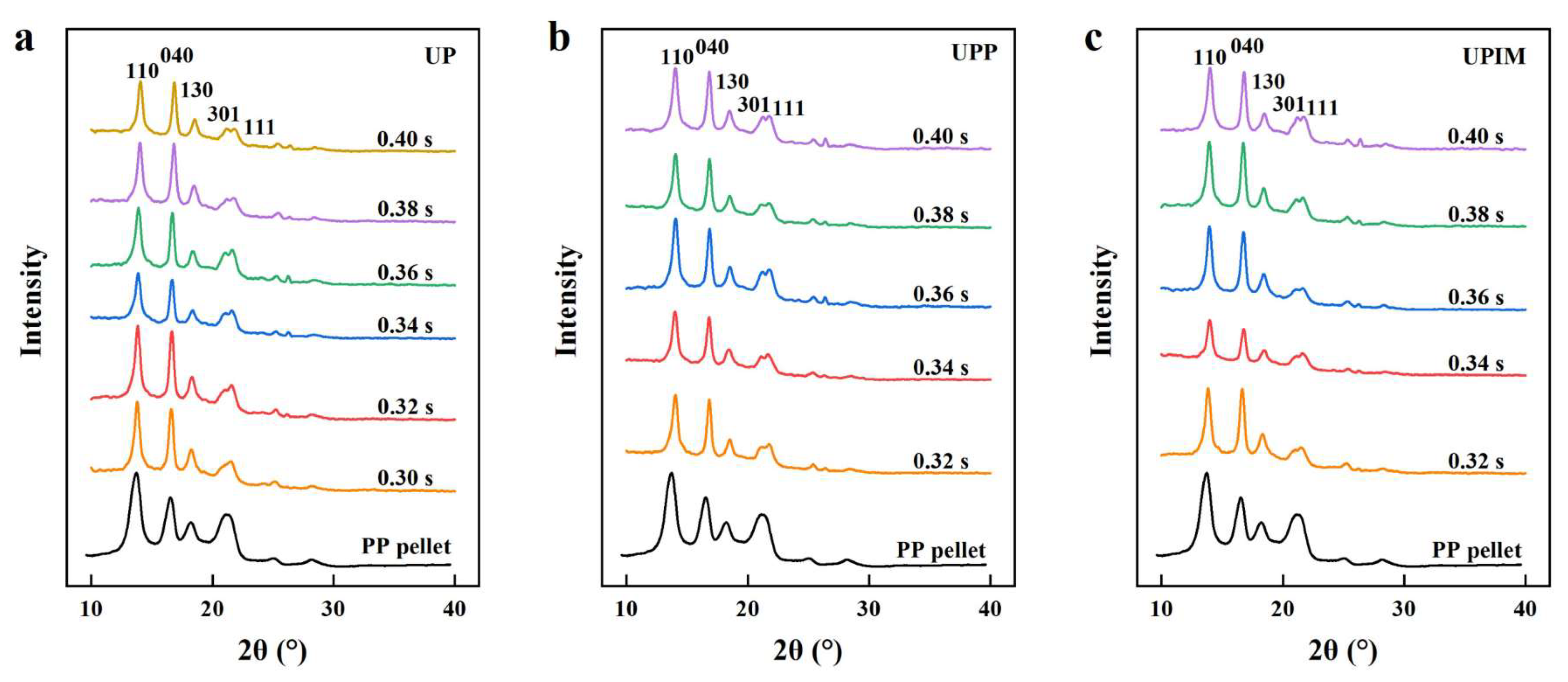

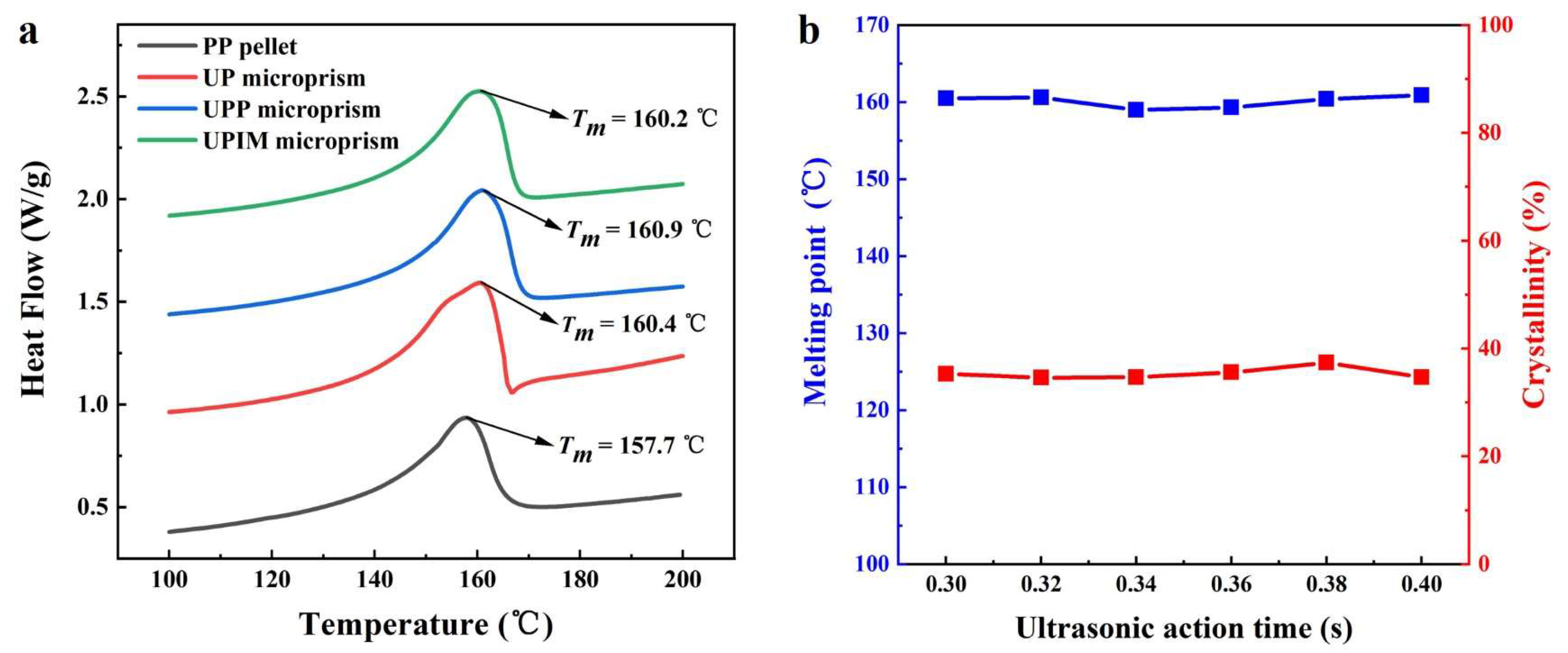

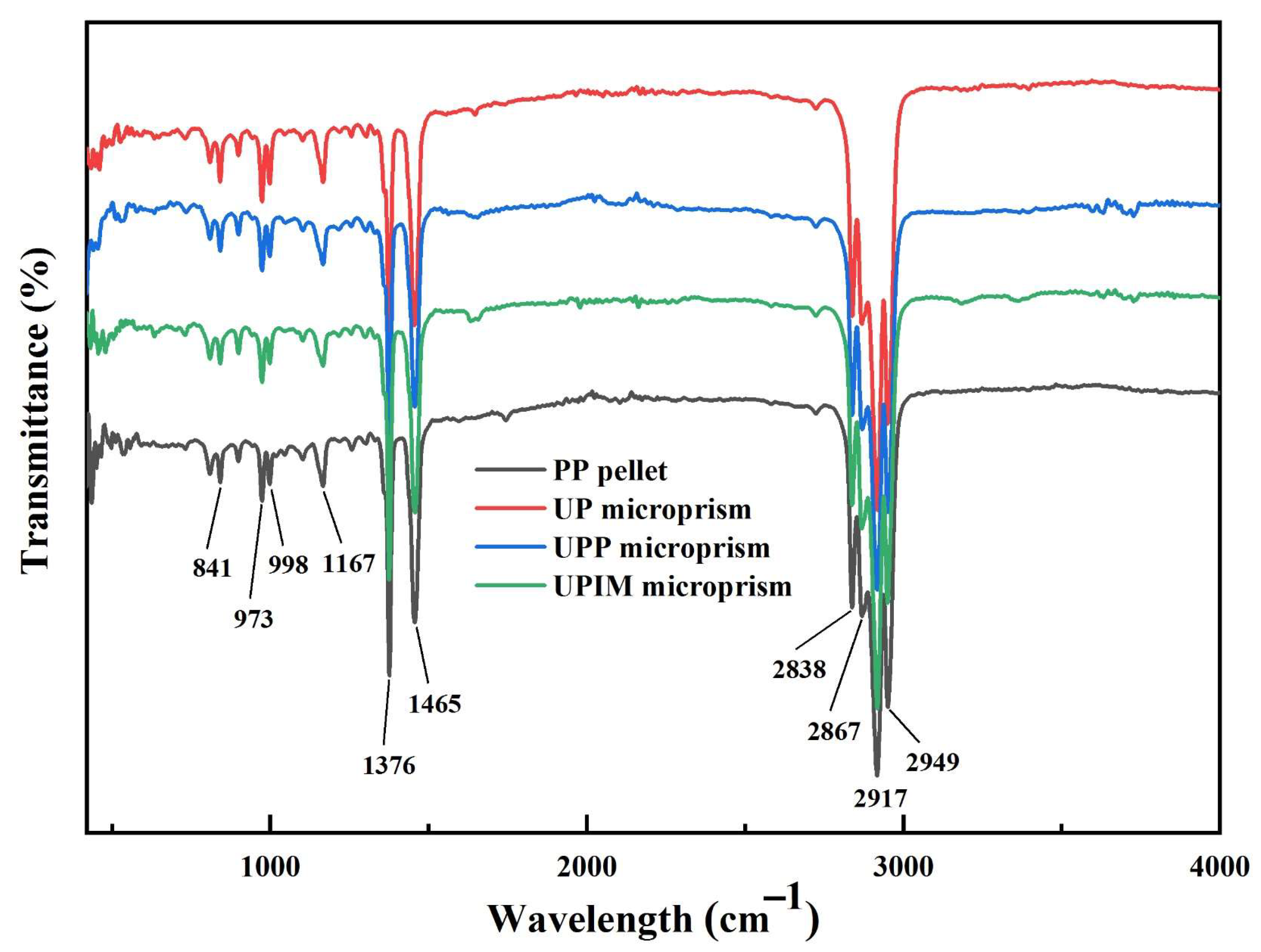

3.6. Microstructure Performance Analysis and Comparison

4. Conclusions

- (1)

- Increasing UA time, ultrasonic amplitude, and loading pressure improved microstructure formation and enhanced melt fluidity in all three processes. Melt fluidity was affected by micropore width rather than depth.

- (2)

- Under identical conditions, UP yielded the best microstructure formation and melt fluidity, followed by UPP and UPIM.

- (3)

- Melt flow behavior improved when the microcavity was located within the action area of the ultrasonic sonotrode and directly subjected to axial vibration.

- (4)

- In UP, continuous ultrasonic vibration maintained melt temperature and pressure during micropore filling, thereby sustaining fluidity.

- (5)

- Among the three processes, UPIM caused the least damage to the template microstructures, followed by UPP, while UP resulted in the most severe damage. The template in UP was subjected to most complex and intense forces.

- (6)

- The effect of UA time on template damage in UP depended on template strength; structurally robust templates could be reused by optimizing processing time.

- (7)

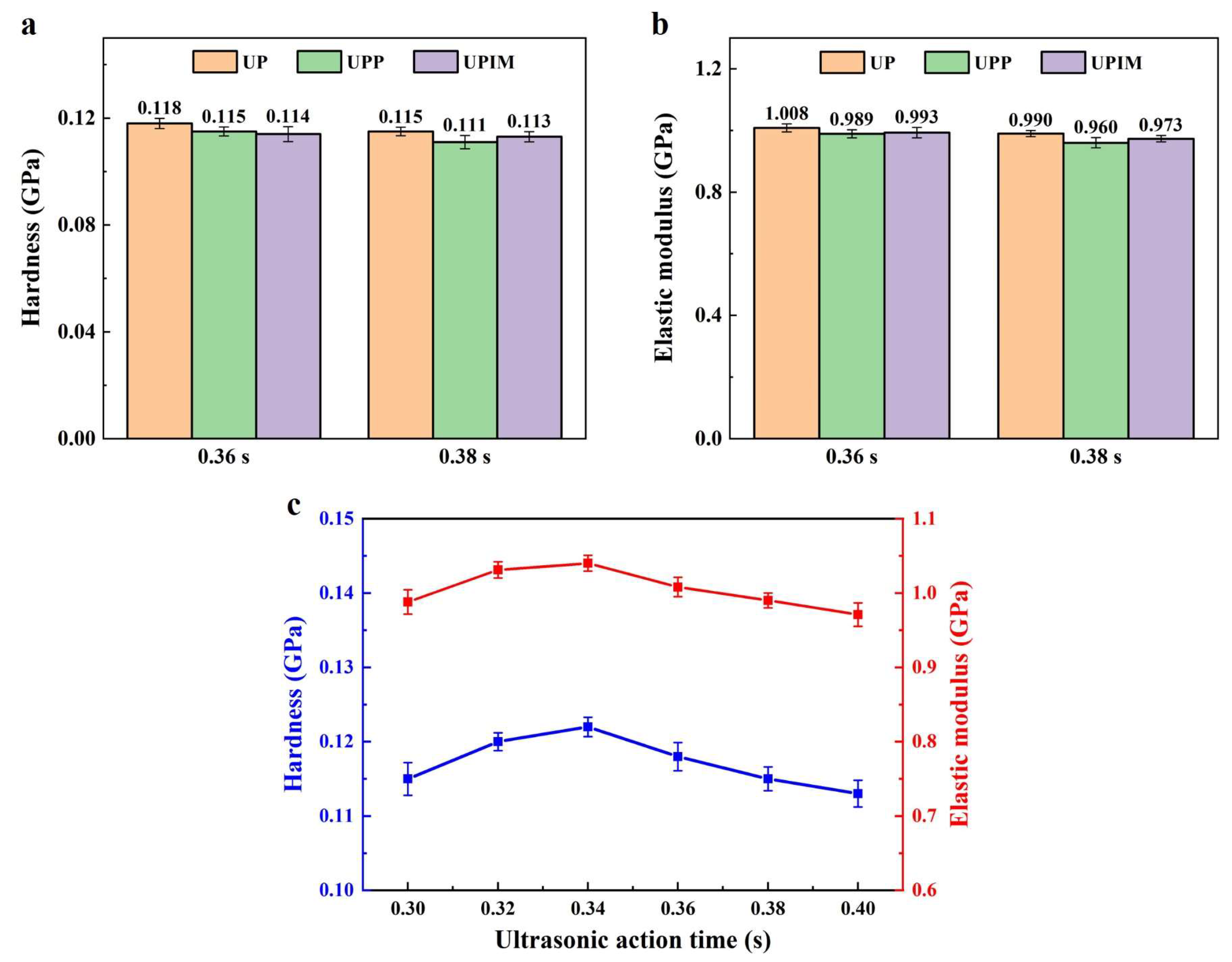

- PP microstructures fabricated through UP, UPP, and UPIM exhibited no significant differences in thermal stability or mechanical properties.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, L.; Yu, Z.D.; Wang, X.Y.; Yao, Z.F.; Lu, Y.; Yang, C.Y.; Wang, J.Y.; Pei, J. Polymer semiconductors: Synthesis, processing, and applications. Chem. Rev. 2023, 123, 7421–7497. [Google Scholar] [CrossRef] [PubMed]

- Rytka, C.; Kristiansen, P.M.; Neyer, A. Iso- and variothermal injection compression moulding of polymer micro- and nanostructures for optical and medical applications. J. Micromech. Microeng. 2015, 25, 065008. [Google Scholar] [CrossRef]

- Sha, B.; Dimov, S.; Griffiths, C.; Packianather, M.S. Investigation of micro-injection moulding: Factors affecting the replication quality. J. Mater. Process. Technol. 2007, 183, 284–296. [Google Scholar] [CrossRef]

- Li, J.M.; Liu, C.; Peng, J. Effect of hot embossing process parameters on polymer flow and microchannel accuracy produced without vacuum. J. Mater. Process. Technol. 2008, 207, 163–171. [Google Scholar] [CrossRef]

- Michaeli, W.; Spennemann, A.; Gärtner, R. New plastification concepts for micro injection molding. Microsyst. Technol. 2002, 8, 55–57. [Google Scholar] [CrossRef]

- Janer, M.; Planta, X.; Riera, D. Ultrasonic moulding: Current state of the technology. Ultrasonics 2020, 102, 106038. [Google Scholar] [CrossRef]

- Iturbe-Ek, J.; Sustaita, A.O.; Aguilar-Viches, D.; Mata-Padilla, J.M.; Ávila-Orta, C.A.; Elizalde, L.E.; Elías-Zúñiga, A.; Lozano, L.M. Insights on the Molecular Behavior of Polypropylene in the Process of Ultrasonic Injection Molding. Polymers 2021, 13, 4010. [Google Scholar] [CrossRef]

- Wu, W.; Peng, H.; Jia, Y.; Jiang, B. Characteristics and mechanisms of polymer interfacial friction heating in ultrasonic plasticization for micro injection molding. Microsyst. Technol. 2017, 23, 1385–1392. [Google Scholar] [CrossRef]

- Jiang, B.; Peng, H.; Wu, W.; Jia, Y.; Zhang, Y. Numerical Simulation and Experimental Investigation of the Viscoelastic Heating Mechanism in Ultrasonic Plasticizing of Amorphous Polymers for Micro Injection Molding. Polymers 2016, 8, 199. [Google Scholar] [CrossRef]

- Peng, T.; Jiang, B.; Zou, Y. Study on the mechanism of interfacial friction heating in polymer ultrasonic plasticization injection molding process. Polymers 2019, 11, 1407. [Google Scholar] [CrossRef] [PubMed]

- Suslick, K.S. Sonochemistry. Science 1990, 247, 1439–1445. [Google Scholar] [CrossRef]

- Chen, G.; Guo, S.; Li, H. Ultrasonic improvement of rheological behavior of polystyrene. J. Appl. Polym. Sci. 2002, 84, 2451–2460. [Google Scholar] [CrossRef]

- Chen, Y.; Li, H. Effect of ultrasound on the viscoelasticity and rheology of polystyrene extruded through a slit die. J. Appl. Polym. Sci. 2006, 100, 2907–2911. [Google Scholar] [CrossRef]

- Janer, M.; Riera, M.D.; Plantà, X. Ultrasonic Molding. In Innovative Development in Micromanufacturing Processes, 1st ed.; Rakesh, P.K., Davim, J.P., Eds.; CRC Press: Boca Raton, FL, USA, 2023; pp. 210–235. [Google Scholar]

- Ferrer, I.; Vives-Mestres, M.; Manresa, A.; Garcia-Romeu, M.L. Replicability of Ultrasonic Molding for Processing Thin-Wall Polystyrene Plates with a Microchannel. Materials 2018, 11, 1320. [Google Scholar] [CrossRef]

- Heredia-Rivera, U.; Ferrer, I.; Vázquez, E. Ultrasonic Molding Technology: Recent Advances and Potential Applications in the Medical Industry. Polymers 2019, 11, 667. [Google Scholar] [CrossRef]

- Liu, S.J.; Dung, Y.T. Ultrasonic vibration hot embossing: A novel technique for molding plastic microstructure. Int. Polym. Proc. 2022, 20, 449–452. [Google Scholar] [CrossRef]

- Yıldırım, E.; Ulku, M.K.; Arıkan, M.A.S. Utilization of cross-correlation function for assessment of replication quality in ultrasonic embossing of microchannels on polymethyl methacrylate. Polym. Eng. Sci. 2024, 64, 3227–3242. [Google Scholar] [CrossRef]

- Zhu, Y.; Bengsch, S.; Zheng, L.; Long, Y.; Roth, B.W.; Wurz, M.C.; Twiefel, J.; Wallaschek, J. Experimental Investigation of the Rapid Fabrication of Micron and Submicron Structures on Polymers Utilizing Ultrasonic Assisted Embossing. Polymers 2021, 13, 2417. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Wu, S.; Xu, B.; Ma, J.; Du, J.; Lei, J. Fabrication of Low-Cost Porous Carbon Polypropylene Composite Sheets with High Photothermal Conversion Performance for Solar Steam Generation. Polymers 2024, 16, 2813. [Google Scholar] [CrossRef] [PubMed]

- Zeng, K.; Wu, X.; Liang, X.; Xu, B.; Wang, Y.; Chen, X.; Cheng, R.; Luo, F. Process and properties of micro-ultrasonic powder molding with polypropylene. Int. J. Adv. Manuf. Technol. 2014, 70, 515–522. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Y.; Chen, S.; Ma, J.; Wu, X.; Shi, H.; Fu, L.; Xu, B. Fabrication of microplastic parts with a hydrophobic surface by micro ultrasonic powder moulding. J. Manuf. Process. 2020, 56, 180–188. [Google Scholar] [CrossRef]

- Pan, L.; Wu, W.; Liu, J.; Li, X. Ultrasonic plasticization microinjection precision molding of polypropylene microneedle arrays. ACS Appl. Polym. Mater. 2023, 5, 9354–9363. [Google Scholar] [CrossRef]

- Olmo, C.; Franco, L.; del Valle, L.J.; Puiggalí, J. Biodegradable Polylactide Scaffolds with Pharmacological Activity by Means of Ultrasound Micromolding Technology. Appl. Sci. 2020, 10, 3106. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Y.; Liu, Z.; Ma, J.; Zhang, Z.; Ruan, W.; Ren, S.; Peng, T.; Wu, X.; Shi, H. Ultrasonic injection molding of glass fiber reinforced polypropylene parts using tungsten carbide-cobalt mold core. Mater. Des. 2021, 205, 109771. [Google Scholar] [CrossRef]

- Lee, C.H.; Jung, P.G.; Lee, S.M.; Park, S.H.; Shin, B.S.; Kim, J.H.; Hwang, K.Y.; Kim, K.M.; Ko, J.S. Replication of polyethylene nano-micro hierarchical structures using ultrasonic forming. J. Micromech. Microeng. 2010, 20, 035018. [Google Scholar] [CrossRef]

- Li, Z.; Fu, J.; Zhang, L.; Ma, J.; Shen, J. Rapid forming of nanowire array on polyvinylidene fluoride polymer surfaces at room temperature by ultrasonic loading. Adv. Eng. Mater. 2023, 25, 2200700. [Google Scholar] [CrossRef]

- Wu, S.; Du, J.; Xu, S.; Lei, J.; Ma, J.; Zhu, L. Ultrasonic Plasticizing and Pressing of High-Aspect Ratio Micropillar Arrays with Superhydrophobic and Superoleophilic Properties. Processes 2024, 12, 856. [Google Scholar] [CrossRef]

- Yan, C.Z. Polymer Materials for 3D Printing; Chemical Industry Press: Beijing, China, 2020. [Google Scholar]

- Jiang, B.; Zou, Y.; Liu, T.; Wu, W. Characterization of the Fluidity of the Ultrasonic Plasticized Polymer Melt by Spiral Flow Testing under Micro-Scale. Polymers 2019, 11, 357. [Google Scholar] [CrossRef]

- Dealy, J.M.; Larson, R.G. Structure and Rheology of Molten Polymers; Hanser Publishers: Cincinnati, OH, USA, 2006. [Google Scholar]

- Baird, D.G.; Collias, D.I. Polymer Processing: Principles and Design, 2nd ed.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Cao, Y.; Li, H. Influence of ultrasound on the processing and structure of polypropylene during extrusion. Polym. Eng. Sci. 2002, 42, 1534–1540. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, K. Morphology and mechanical properties of polypropylene micro-arrays by micro-injection molding. Int. J. Adv. Manuf. Technol. 2009, 40, 490–496. [Google Scholar] [CrossRef]

- Wu, R. Modern Analysis Technology-Application in Polymer; Shanghai Science and Technology Press: Shanghai, China, 1987. [Google Scholar]

- Dimassi, S.N.; Hahladakis, J.N.; Daly Yahia, M.N.; Ahmad, M.I.; Sayadi, S.; Al-Ghouti, M.A. Insights into the Degradation Mechanism of PET and PP under Marine Conditions Using FTIR. J. Hazard Mater. 2023, 447, 130796. [Google Scholar] [CrossRef] [PubMed]

| Group | Raw Material | Ultrasonic Action Time (s) | Ultrasonic Amplitude (μm) | Ultrasonic Loading Pressure (kPa) |

|---|---|---|---|---|

| Group A | PP | 0.30, 0.32, 0.34, 0.36, 0.38, 0.40 | 60 | 300 |

| Group B | PP | 0.36 | 40.8, 45.6, 50.4, 55.2, 60 | 300 |

| Group C | PP | 0.36 | 60 | 100, 150, 200, 250, 300 |

| Group D | PS | 0.28, 0.30, 0.32, 0.34, 0.36, 0.38, 0.40 | 60 | 300 |

| Group E | PC | 0.42, 0.44, 0.46, 0.48, 0.50, 0.52, 0.54 | 60 | 300 |

| Type | Aspect Ratio | Design Dimension | Actual Dimension | ||

|---|---|---|---|---|---|

| Width (µm) | Depth (µm) | Width (µm) | Depth (µm) | ||

| Equal-width RMGs (Mold core I) | 5:1 | 200 | 1000 | 204.70 | 1008.44 |

| 10:1 | 200 | 2000 | 200.84 | 2005.98 | |

| 15:1 | 200 | 3000 | 196.98 | 2992.20 | |

| Equal-depth RMGs (Mold core II) | 12:1 | 250 | 3000 | 250.93 | 3002.35 |

| 15:1 | 200 | 3000 | 196.79 | 2996.32 | |

| 20:1 | 150 | 3000 | 146.83 | 2994.32 | |

| Process | Maximum Melt Temperature at Microgroove Inlet, Tmax-inlet (°C) | Maximum Melt Temperature Inside Microgroove, Tmax-inside (°C) | Difference Between Tmax-inlet and Tmax-inside (°C) |

|---|---|---|---|

| UP | 478.8 | 438.3 | 40.5 |

| UPP | 278.4 | 254.4 | 24.0 |

| UPIM | 236.9 | 139.0 | 97.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Du, J.; Liang, J.; Zhu, L.; Lei, J. Characterization and Comparison of Polymer Melt Fluidity Across Three Ultrasonic Plasticization Molding Technologies. Polymers 2025, 17, 2576. https://doi.org/10.3390/polym17192576

Wu S, Du J, Liang J, Zhu L, Lei J. Characterization and Comparison of Polymer Melt Fluidity Across Three Ultrasonic Plasticization Molding Technologies. Polymers. 2025; 17(19):2576. https://doi.org/10.3390/polym17192576

Chicago/Turabian StyleWu, Shiyun, Jianjun Du, Junfeng Liang, Likuan Zhu, and Jianguo Lei. 2025. "Characterization and Comparison of Polymer Melt Fluidity Across Three Ultrasonic Plasticization Molding Technologies" Polymers 17, no. 19: 2576. https://doi.org/10.3390/polym17192576

APA StyleWu, S., Du, J., Liang, J., Zhu, L., & Lei, J. (2025). Characterization and Comparison of Polymer Melt Fluidity Across Three Ultrasonic Plasticization Molding Technologies. Polymers, 17(19), 2576. https://doi.org/10.3390/polym17192576