In-Process Recycling of 35% Glass Fiber-Reinforced Polyamide 6,6 Runners: Effects on Thermomechanical Properties and Viability for Diesel Injector Socket Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Recycling and Specimen Preparation

- Effect of Recycled Content: Ground recycled polymer (RP) was dry-blended with virgin %35GF-PA66 pellets at different weight percentages: 0% (virgin), 2.5%, 5%, 10%, and 15% RP.

- Effect of Multiple Recycling Cycles: Based on initial performance, a fixed blend of 15% RP was chosen. Test specimens were molded, and the runners from this process were ground and re-blended with 85% virgin material to maintain 15% RP content for the next cycle. This process was repeated for up to 10 cycles.

2.3. Characterization

- At least five specimens were tested for each condition for mechanical tests.

- Tensile tests were performed in accordance with ISO 527-2 [25] using a Shimadzu AGS-X universal testing machine (Shimadzu Corporation, Kyoto, Japan) at a crosshead speed of 5 mm/min. Type 1A multipurpose test specimens (170 mm × 10 mm × 4 mm) were used. Tensile strength, elongation at break, and Young’s modulus were determined.

- Three-point bending tests were conducted in accordance with ISO 14125 [26] on the same machine at 5 mm/min. Rectangular specimens with dimensions of 80 mm × 10 mm × 4 mm were tested. Flexural strength, flexural strain, and flexural modulus were recorded.

- Charpy impact tests were performed on unnotched specimens in accordance with ISO 179-1 [27] using an Instron CEAST 9050 impact tester (Instron, Norwood, MA, USA).

- Heat deflection temperature (HDT) was measured in accordance with ISO 75-2 (method A, 1.80 MPa load) [28] using an Instron/Ceast HV3 apparatus (Instron, Norwood, MA, USA).

- Differential scanning calorimetry (DSC) was performed using a TA Instruments DSC250 (TA Instruments, New Castle, DE, USA) in accordance with ISO 11357-1 [29]. Samples (5–10 mg) were heated from 20 °C to 320 °C at 20 °C/min, held for 5 min, cooled to 0 °C at 20 °C/min, and then reheated to 320 °C at 20 °C/min under a nitrogen atmosphere. Melting (Tm) and crystallization (Tc) temperatures and enthalpies were determined.

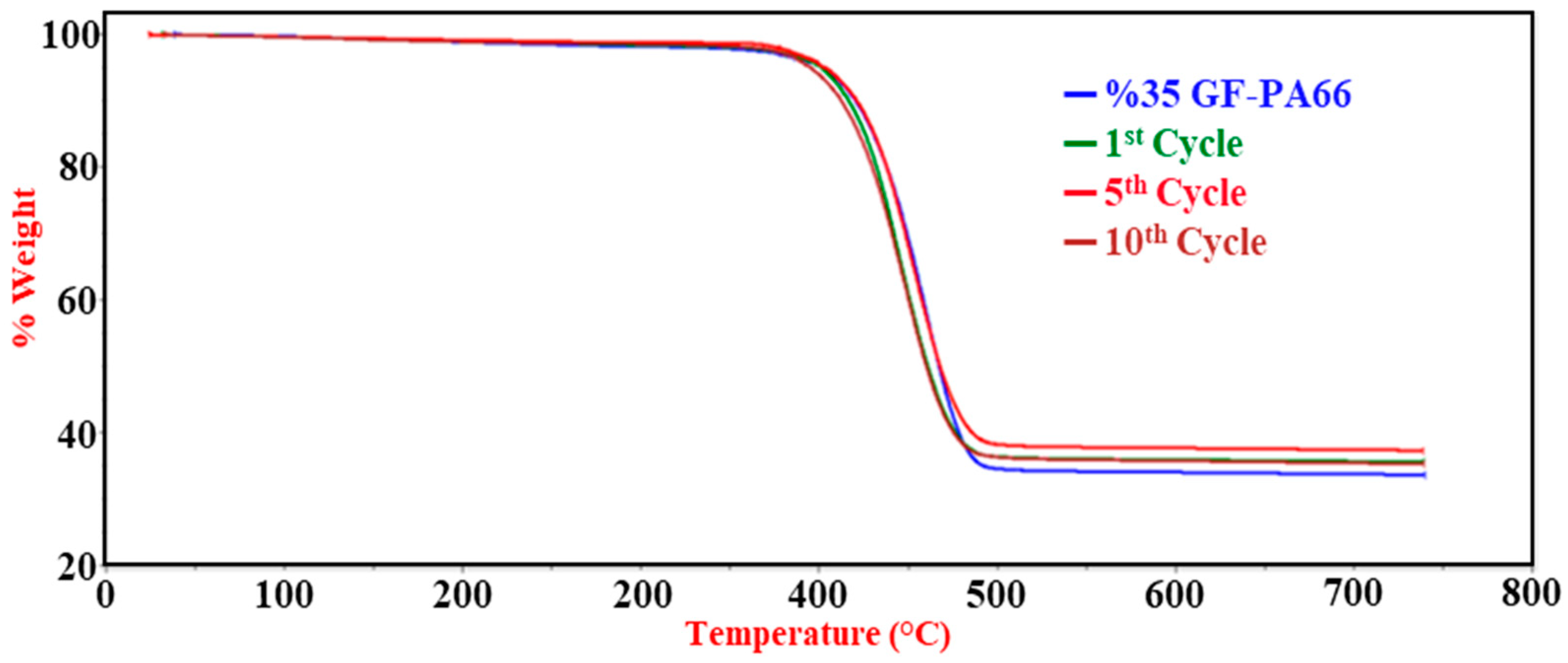

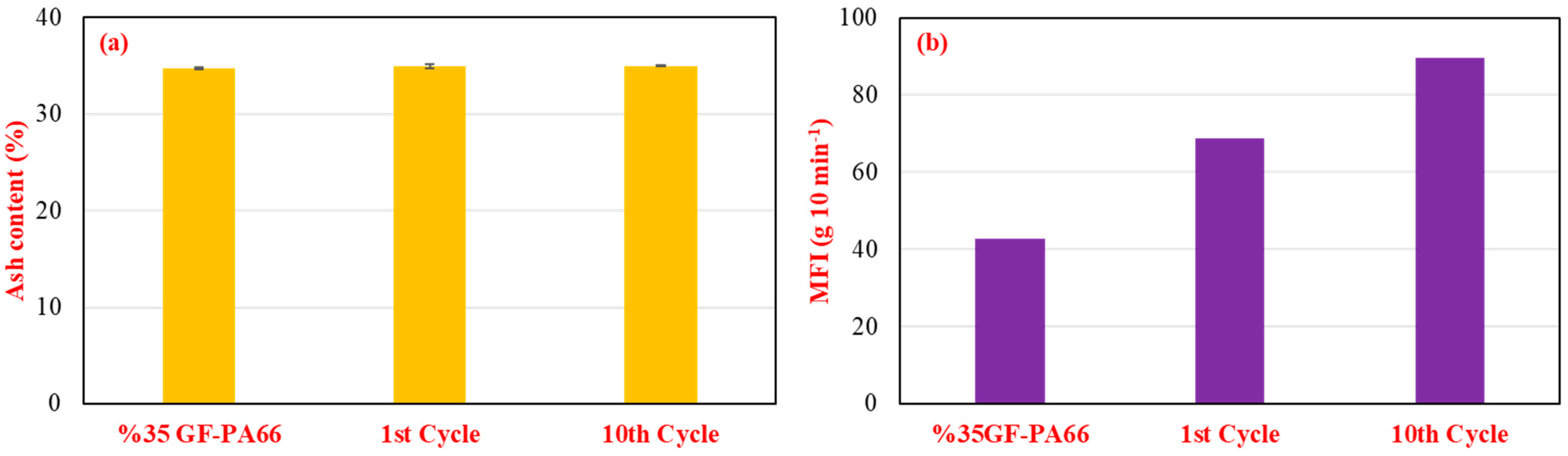

- Thermogravimetric analysis (TGA) was carried out using a TA Instruments Discovery SDT 650 (TA Instruments, New Castle, DE, USA) in accordance with ISO 11358-1 [30]. Samples were heated from room temperature to 600 °C at 20 °C/min under nitrogen, then to 900 °C under oxygen atmosphere to determine degradation temperatures and residual ash content.

- Ash content was also determined separately in accordance with ISO 3451:2019 (method A) [31] by heating samples at 950 °C for 3 h.

3. Results and Discussion

3.1. Effect of Recycled Content (%RP) on Material Properties

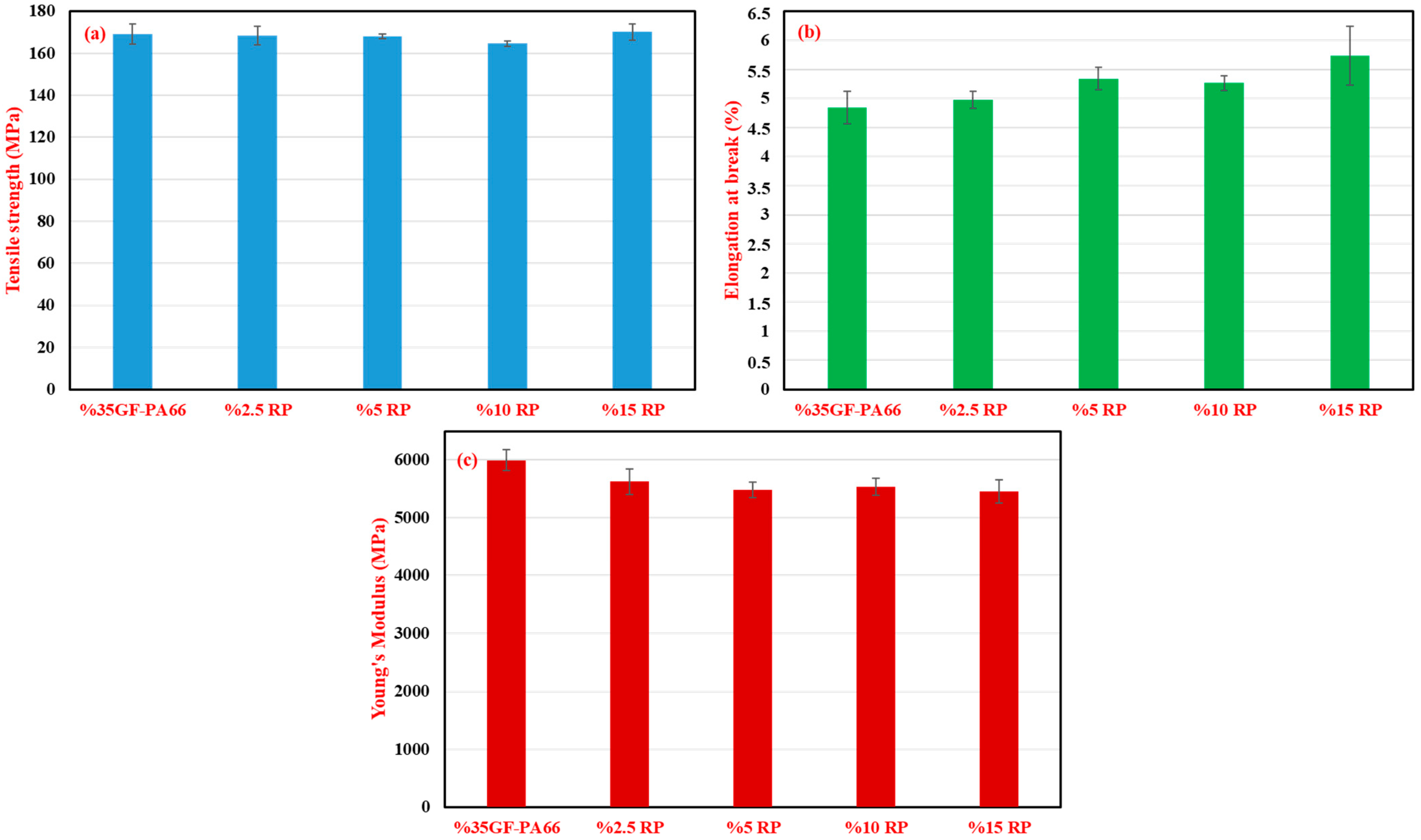

3.1.1. Tensile Properties

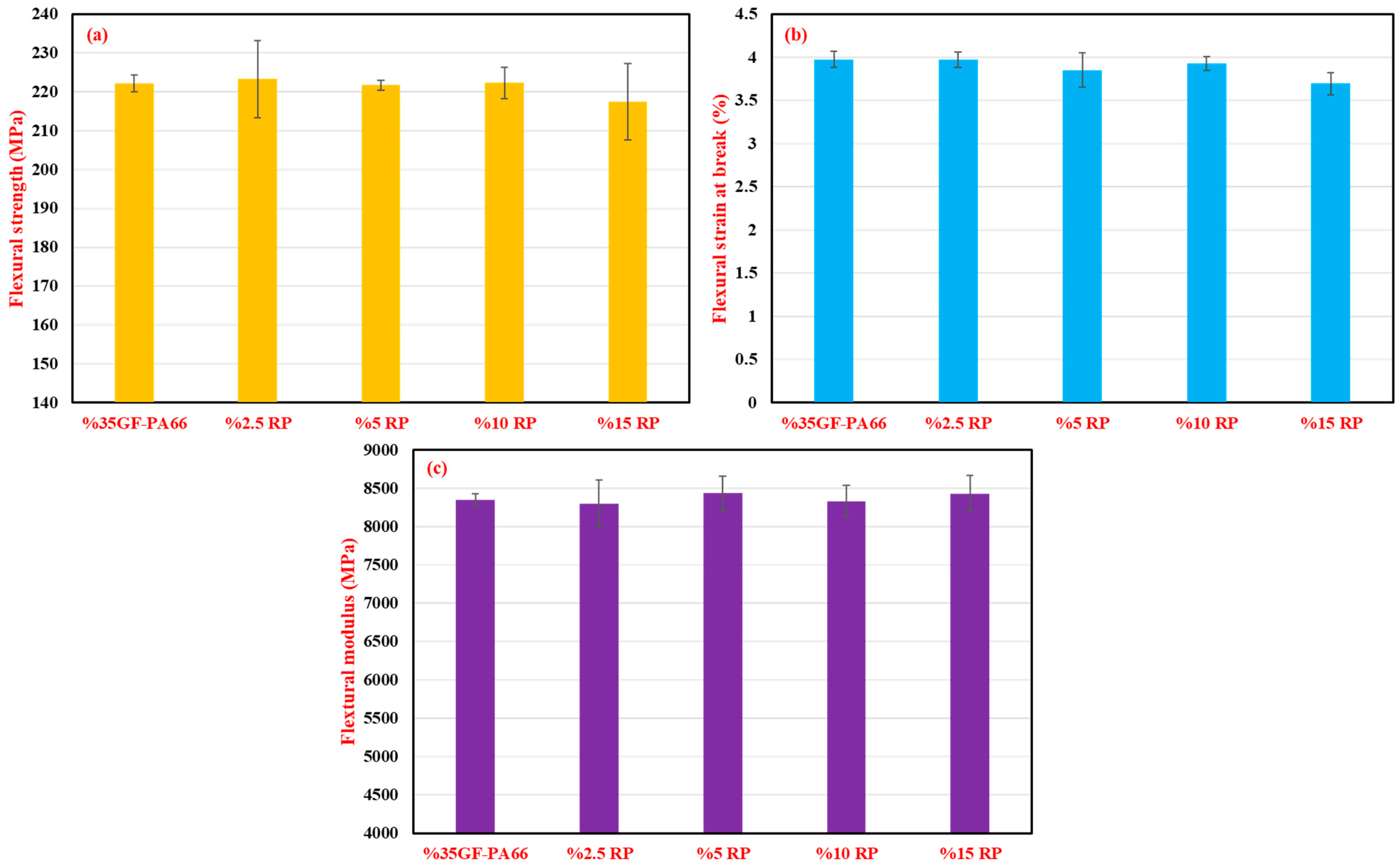

3.1.2. Flexural Properties

3.2. Effect of Multiple Recycling Cycles (15% RP Blend)

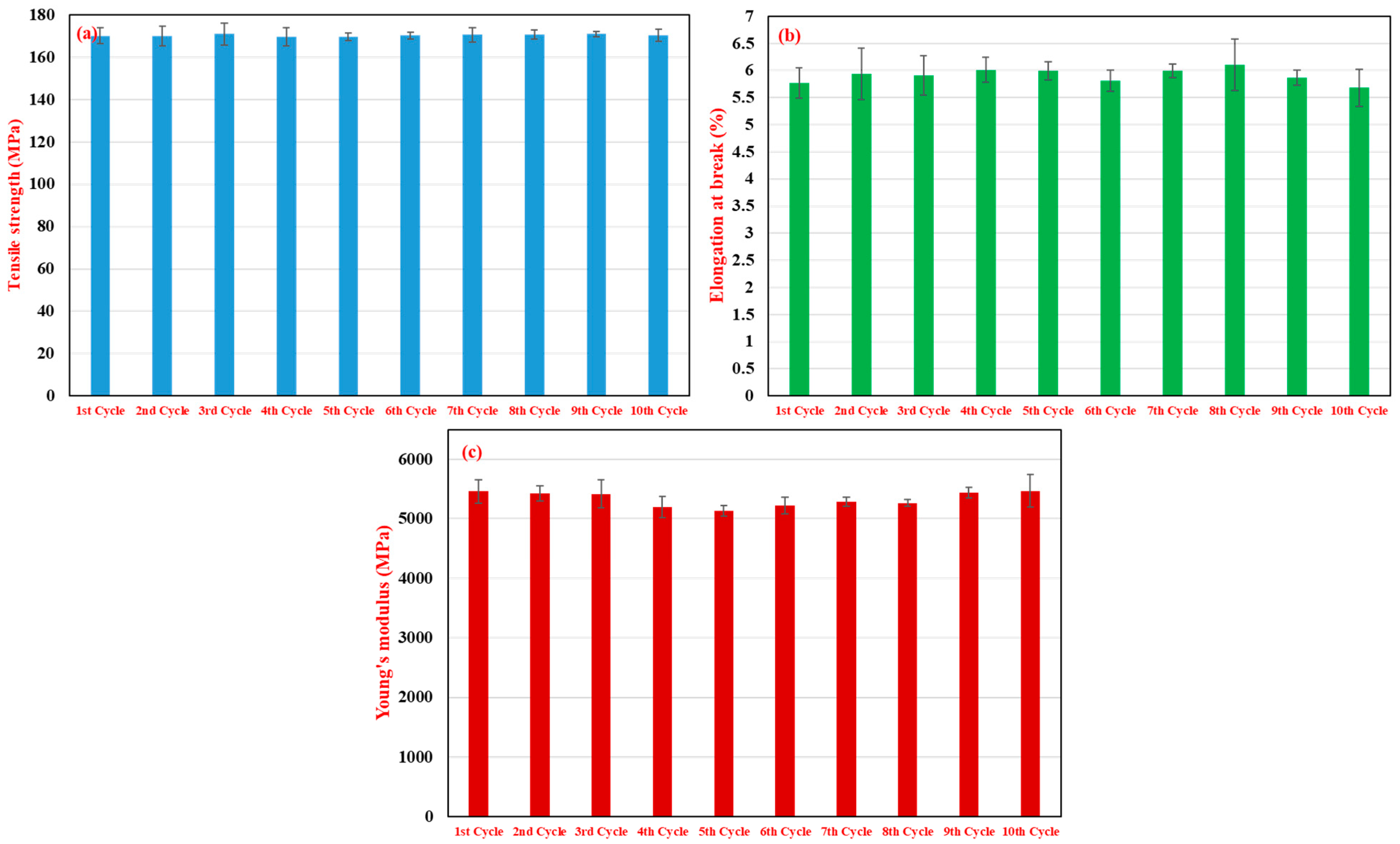

3.2.1. Mechanical Properties

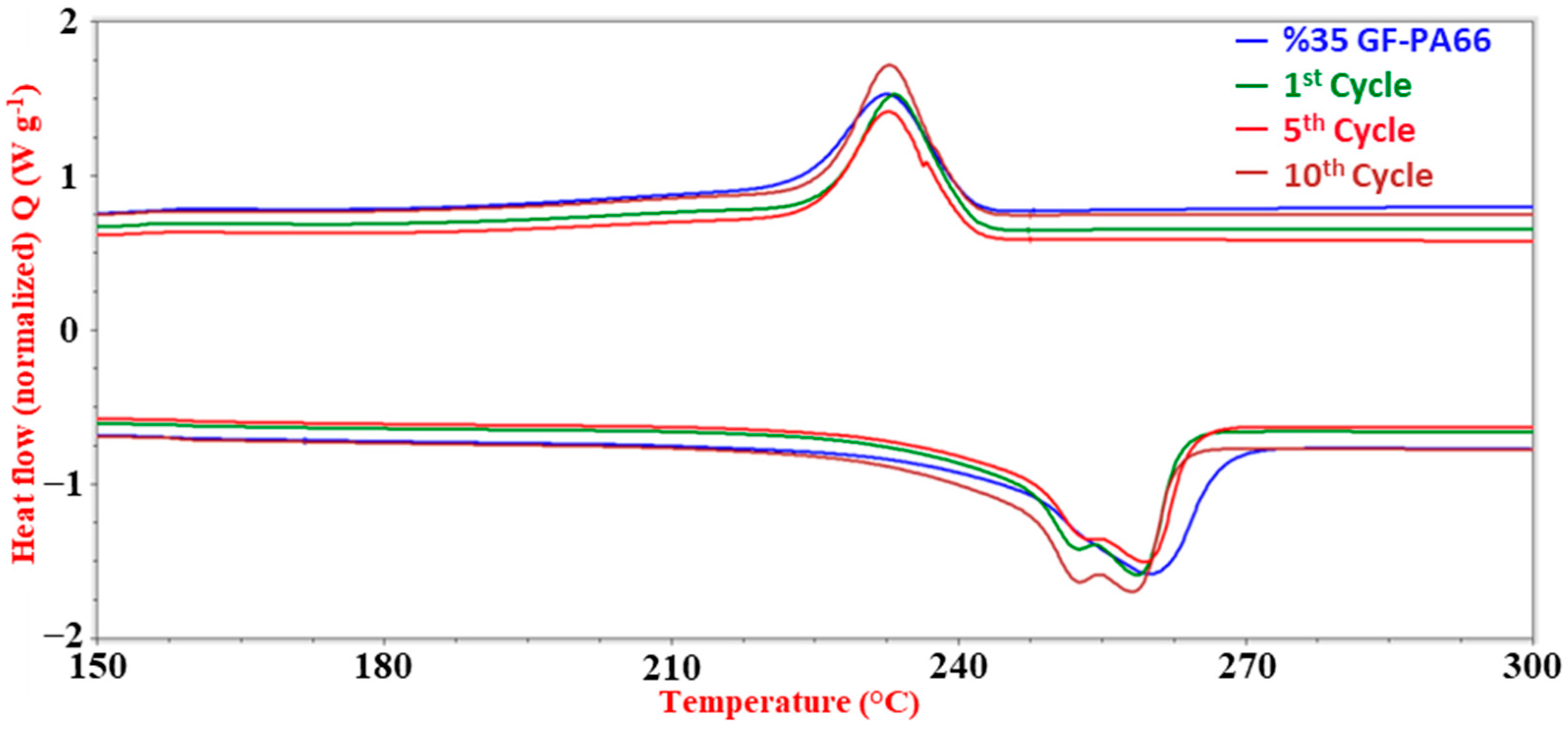

3.2.2. Thermal Properties and MFI

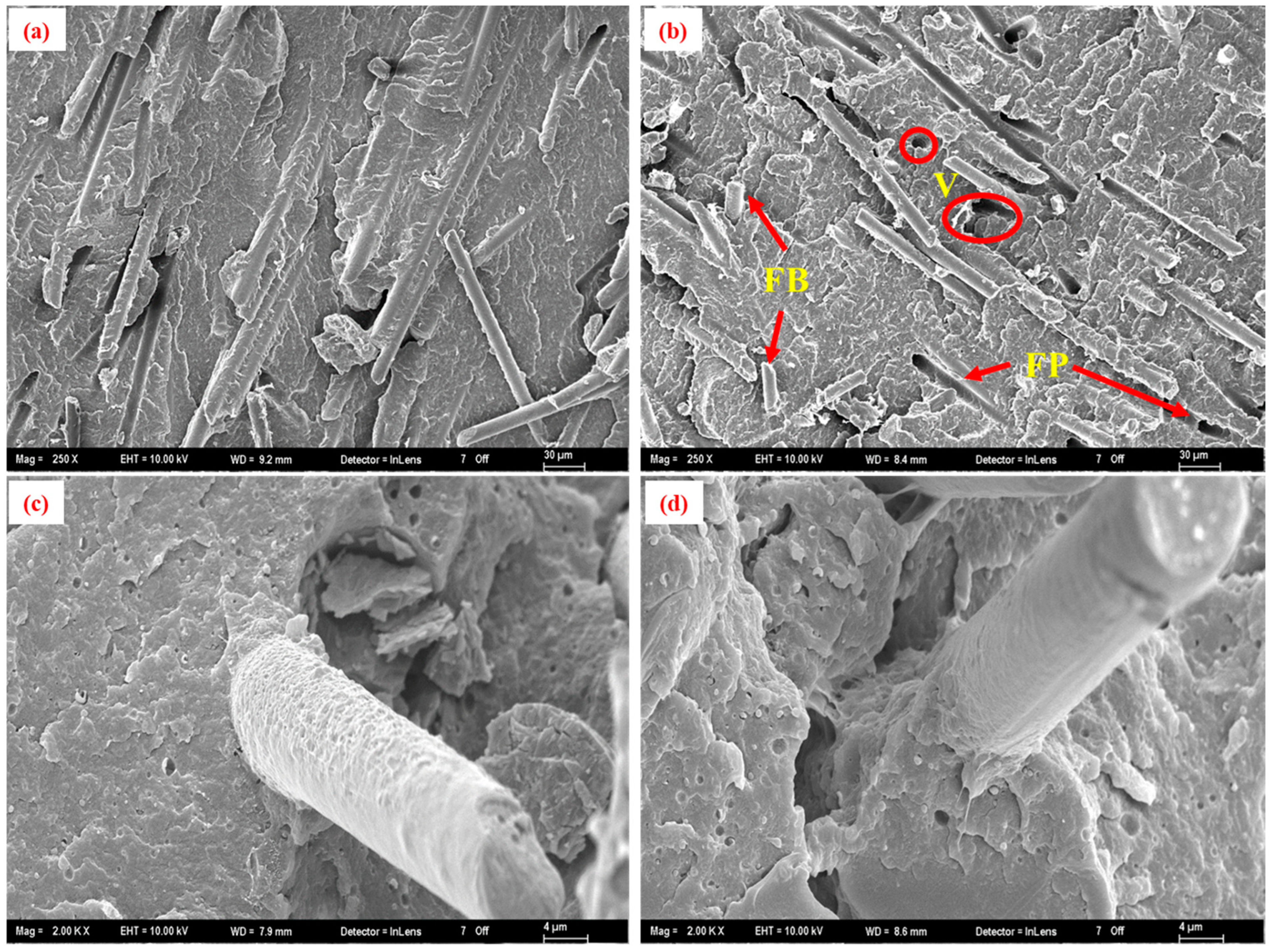

3.3. Morphological Analysis (SEM)

3.4. Overall Discussion

4. Conclusions

- The incorporation of up to 15% recycled %35GF-PA66 runner waste into virgin material resulted in only minor reductions in tensile and flexural strength, while elongation at break tended to increase slightly.

- Multiple reprocessing cycles (up to 10 cycles with a 15% RP blend) demonstrated good retention of tensile strength and Charpy impact energy. HDT remained remarkably stable (variation of ~0.7 °C after 10 cycles), while flexural properties exhibited a more noticeable gradual decline.

- The melt flow index (MFI) increased significantly with successive recycling cycles, confirming thermomechanical degradation and a reduction in the average molecular weight of the PA66 matrix.

- DSC analysis indicated that the primary melting and crystallization temperatures were largely unaffected by the recycling processes, suggesting the bulk crystalline structure remained stable.

- SEM analysis provided qualitative evidence of fiber attrition and increased void formation at the fiber–matrix interface with more extensive recycling.

- Overall, the in-process mechanical recycling of %35GF-PA66 runners is a technically viable option for applications such as diesel injector sockets, particularly when recycled content is managed (e.g., up to 15%) and the number of reprocessing generations is considered. The observed property changes are generally modest and offer a pathway to significant cost savings and improved manufacturing sustainability.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| %35GF-PA66 | 35% glass fiber-reinforced Polyamide 6,6 |

| PA66-GF | Polyamide 6,6 reinforced with short glass fibers |

| RP | recycled polymer |

| HDT | heat deflection temperature |

| MFI | melt flow index |

| DSC | differential scanning calorimetry |

| TGA | thermogravimetric analysis |

| SEM | scanning electron microscope |

| FRPs | fiber-reinforced polymers |

References

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Güler, T.; Demirci, E.; Yildiz, A.R.; Yavuz, U. Lightweight design of an automobile hinge component using glass fiber polyamide composites. Mater. Test. 2018, 60, 306–310. [Google Scholar] [CrossRef]

- Volpe, V.; Lanzillo, S.; Affinita, G.; Villacci, B.; Macchiarolo, I.; Pantani, R. Lightweight high-performance polymer composite for automotive applications. Polymers 2019, 11, 326. [Google Scholar] [CrossRef]

- Le Gac, P.Y.; Fayolle, B. Impact of fillers (short glass fibers and rubber) on the hydrolysis-induced embrittlement of polyamide 6.6. Compos. Part B Eng. 2018, 153, 256–263. [Google Scholar] [CrossRef]

- Chen, Q.; Chatzigeorgiou, G.; Robert, G.; Meraghni, F. Combination of mean-field micromechanics and cycle jump technique for cyclic response of PA66/GF composites with viscoelastic–viscoplastic and damage mechanisms. Acta Mech. 2023, 234, 1533–1552. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Sayer, S. Mechanical performance of polyamid 66 and influence of glass fiber content on moisture absorption. Mater. Test. 2014, 56, 325–330. [Google Scholar] [CrossRef]

- Jenarthanan, M.; Raja, P.; Sakthivel, M. Mechanical properties, degradation and flue gas analysis of basalt and glass fiber reinforced recycled polypropylene. Mater. Test. 2019, 61, 579–583. [Google Scholar] [CrossRef]

- Kulkarni, S. Robust Process Development and Scientific Molding: Theory and Practice; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2010. [Google Scholar]

- Şahiner, E. Dizel Enjektör Soketi Üretiminde Çıkan Cam Lifi Katkılı Poliamid 6,6 Plastik Enjeksiyon Atıklarının Geri Dönüştürülerek Proseste Kullanılmasının Araştırılması. Master’s Thesis, Bursa Technical University, Bursa, Turkey, 2024. [Google Scholar]

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; COM(2020) 98 final; European Environment Agency: Brussels, Belgium, 2020. [Google Scholar]

- Geueke, B.; Groh, K.; Muncke, J. Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Liu, B.; Zhu, P.; Xu, A.; Bao, L. Investigation of the recycling of continuous fiber-reinforced thermoplastics. J. Thermoplast. Compos. Mater. 2019, 32, 342–356. [Google Scholar] [CrossRef]

- Oladele, I.O.; Omotosho, T.F.; Adediran, A.A. Polymer-Based Composites: An Indispensable Material for Present and Future Applications. Int. J. Polym. Sci. 2020, 2020, 8834518. [Google Scholar] [CrossRef]

- Pietroluongo, M.; Padovano, E.; Frache, A.; Badini, C. Mechanical recycling of an end-of-life automotive composite component. Sustain. Mater. Technol. 2020, 23, e00143. [Google Scholar] [CrossRef]

- Eriksson, P.A.; Albertsson, A.C.; Boydell, P.; Eriksson, K.; Manson, J.A.E. Reprocessing of fiberglass reinforced polyamide 66: Influence on short term properties. Polym. Compos. 1996, 17, 823–829. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 1. Tensile and flexural modulus. Compos. Part A Appl. Sci. Manuf. 1996, 27, 477–484. [Google Scholar] [CrossRef]

- Gültürk, C.; Berber, H. Effects of mechanical recycling on the properties of glass fiber-reinforced polyamide 66 composites in automotive components. E-Polymers 2023, 23, 20230129. [Google Scholar] [CrossRef]

- Bernasconi, A.; Davoli, P.; Rossin, D.; Armanni, C. Effect of reprocessing on the fatigue strength of a fibreglass reinforced polyamide. Compos. Part A Appl. Sci. Manuf. 2007, 38, 710–718. [Google Scholar] [CrossRef]

- Ghabezi, P.; Sam-Daliri, O.; Flanagan, T.; Walls, M.; Harrison, N.M. Mechanical and microstructural analysis of glass Fibre-Reinforced high density polyethylene thermoplastic waste composites manufactured by material extrusion 3D printing technology. Compos. Part A Appl. Sci. Manuf. 2025, 194, 108930. [Google Scholar] [CrossRef]

- Akonda, M.H.; Lawrence, C.A.; Weager, B.M. Recycled carbon fibre-reinforced polypropylene thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 79–86. [Google Scholar] [CrossRef]

- Pegoretti, A.; Kolarik, J.; Slouf, M. Phase structure and tensile creep of recycled poly(ethylene terephthalate)/short glass fibers/impact modifier ternary composites. Express Polym. Lett. 2009, 3, 235–244. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Flanagan, T.; Modi, V.; Finnegan, W.; Harrison, N.; Ghabezi, P. Composite upcycling: An experimental study on mechanical behaviour of injection moulded parts prepared from recycled material extrusion printed parts, previously prepared using glass fibre polypropylene composite industry waste. J. Clean. Prod. 2025, 499, 145280. [Google Scholar] [CrossRef]

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 14125:1998; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 1998.

- ISO 179-1:2023; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 75-2:2013; Plastics—Determination of Temperature of Deflection Under Load—Part 2: Plastics and Ebonite. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 11357-1:2023; Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 11358-1:2022; Plastics—Thermogravimetry (TG) of Polymers—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 3451-1:2019; Plastics—Determination of Ash—Part 1: General Methods. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 1133-1:2011; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. International Organization for Standardization: Geneva, Switzerland, 2011.

- Eriksson, P.A.; Boydell, P.; Månson, J.A.E.; Albertsson, A.C. Durability study of recycled glass-fiber-reinforced polyamide 66 in a service-related environment. J. Appl. Polym. Sci. 1997, 65, 1631–1641. [Google Scholar] [CrossRef]

- Hassan, A.; Yahya, R.; Rafiq, M.I.M.; Hussin, A.; Sheikh, M.R.K.; Hornsby, P.R. Interfacial shear strength and tensile properties of injection-molded, short- and long-glass fiber-reinforced Polyamide 6,6 composites. J. Reinf. Plast. Compos. 2011, 30, 1233–1242. [Google Scholar] [CrossRef]

- Autay, R.; Njeh, A.; Dammak, F. Effect of thermal aging on mechanical and tribological behaviors of short glass fiber–reinforced PA66. J. Thermoplast. Compos. Mater. 2020, 33, 501–515. [Google Scholar]

- Kuram, E.; Ozcelik, B.; Yilmaz, F. The effects of recycling process on thermal, chemical, rheological, and mechanical properties of PC/ABS binary and PA6/PC/ABS ternary blends. J. Elastomers Plast. 2016, 48, 164–181. [Google Scholar] [CrossRef]

- Maspoch, M.L.; Ferrando, H.E.; Velasco, J.I. Characterisation of filled and recycled PA6. Macromol. Symp. 2003, 194, 295–304. [Google Scholar] [CrossRef]

- La Mantia, F. Handbook of Plastics Recycling; Rapra Technology Ltd.: Shawbury, UK, 2004. [Google Scholar]

- Incarnato, L.; Scarfato, P.; Di Maio, L.; Acierno, D. Structure and rheology recycled PET modified by reactive extrusion. Polymer 2000, 41, 6825–6831. [Google Scholar] [CrossRef]

- Licea-Claveríe, A.; Valdez, J.O.; García-Hernández, E.; Zizumbo, A.; Álvarez-Castillo, A.; Castaño, V.M. Reprocessing effects on the properties of a hybrid nylon 6,6-composite reinforced with short glass and carbon fibers. J. Reinf. Plast. Compos. 2002, 21, 847–856. [Google Scholar] [CrossRef]

- Shi, J.; Bao, L.; Kobayashi, R.; Kato, J.; Kemmochi, K. Reusing recycled fibers in high-value fiber-reinforced polymer composites: Improving bending strength by surface cleaning. Compos. Sci. Technol. 2012, 72, 1298–1303. [Google Scholar] [CrossRef]

- Felfel, R.M.; Ahmed, I.; Parsons, A.J.; Haque, P.; Walker, G.S.; Rudd, C.D. Investigation of crystallinity, molecular weight change, and mechanical properties of PLA/PBG bioresorbable composites as bone fracture fixation plates. J. Biomater. Appl. 2012, 26, 765–789. [Google Scholar] [CrossRef]

- Dericiler, K.; Zafar, S.; Sas, H.S.; Saner Okan, B. The effect of reinforcement aspect ratio on the performance of PA66 composites with recycled carbon fiber and upcycled graphene nanoplatelets: An interface characterization from process to modeling. J. Appl. Polym. Sci. 2023, 140, e54352. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Şahiner, E.; Altın, Y. Investigation of the Recycling of Glass Fiber Reinforced Polyamide 6.6 Plastic Injection Wastes from the Production of Diesel Injector Sockets and Their Reuse in the Process. In Proceedings of the 13th International Fiber and Polymer Research Symposium, Bolu, Turkey, 3–4 November 2023. [Google Scholar]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Injection Speed | 70 mm/s | Nozzle Temperature | 260 °C |

| Screw Speed | 40% | Zone 1 Temperature | 275 °C |

| Shot Size | 75 mm | Zone 2 Temperature | 270 °C |

| Holding Pressure Time | 10 s | Zone 3 Temperature | 265 °C |

| Cooling Time | 15 s | Feed Zone Temperature | 30 °C |

| Mold Temperature | 80 °C | Back Pressure | 5 bar |

| Parameter | Tc (°C) | ΔHc (J/g) | Tm (°C) | ΔHm (J/g) |

|---|---|---|---|---|

| Virgin (%35GF-PA66) | 232.57 | 33.83 | 259.89 | 43.15 |

| 1st Cycle | 233.19 | 35.07 | 252.58 | 45.05 |

| 258.71 | ||||

| 5th Cycle | 232.68 | 33.62 | 253.78 | 44.08 |

| 259.41 | ||||

| 10th Cycle | 232.76 | 36.3 | 252.71 | 47.92 |

| 258.19 |

| Recycling Cycle | Tmax-degrad (°C) (N2) | Weight Loss (%) (N2, ~350–500 °C) | Residual Ash (%) (at 900 °C, O2) |

|---|---|---|---|

| Virgin (%35GF-PA66) | 459.88 | 66.34 | 33.67 |

| 1st Cycle | 444.56 | 64.42 | 35.82 |

| 5th Cycle | 452.89 | 62.69 | 37.31 |

| 10th Cycle | 447.57 | 64.72 | 35.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sahiner, E.; Altin, Y. In-Process Recycling of 35% Glass Fiber-Reinforced Polyamide 6,6 Runners: Effects on Thermomechanical Properties and Viability for Diesel Injector Socket Production. Polymers 2025, 17, 2569. https://doi.org/10.3390/polym17192569

Sahiner E, Altin Y. In-Process Recycling of 35% Glass Fiber-Reinforced Polyamide 6,6 Runners: Effects on Thermomechanical Properties and Viability for Diesel Injector Socket Production. Polymers. 2025; 17(19):2569. https://doi.org/10.3390/polym17192569

Chicago/Turabian StyleSahiner, Elif, and Yasin Altin. 2025. "In-Process Recycling of 35% Glass Fiber-Reinforced Polyamide 6,6 Runners: Effects on Thermomechanical Properties and Viability for Diesel Injector Socket Production" Polymers 17, no. 19: 2569. https://doi.org/10.3390/polym17192569

APA StyleSahiner, E., & Altin, Y. (2025). In-Process Recycling of 35% Glass Fiber-Reinforced Polyamide 6,6 Runners: Effects on Thermomechanical Properties and Viability for Diesel Injector Socket Production. Polymers, 17(19), 2569. https://doi.org/10.3390/polym17192569