Design and Characterization of Durable Glass Fibre (GF)-Reinforced PLA and PEEK Biomaterials

Abstract

1. Introduction

2. Materials and Methods

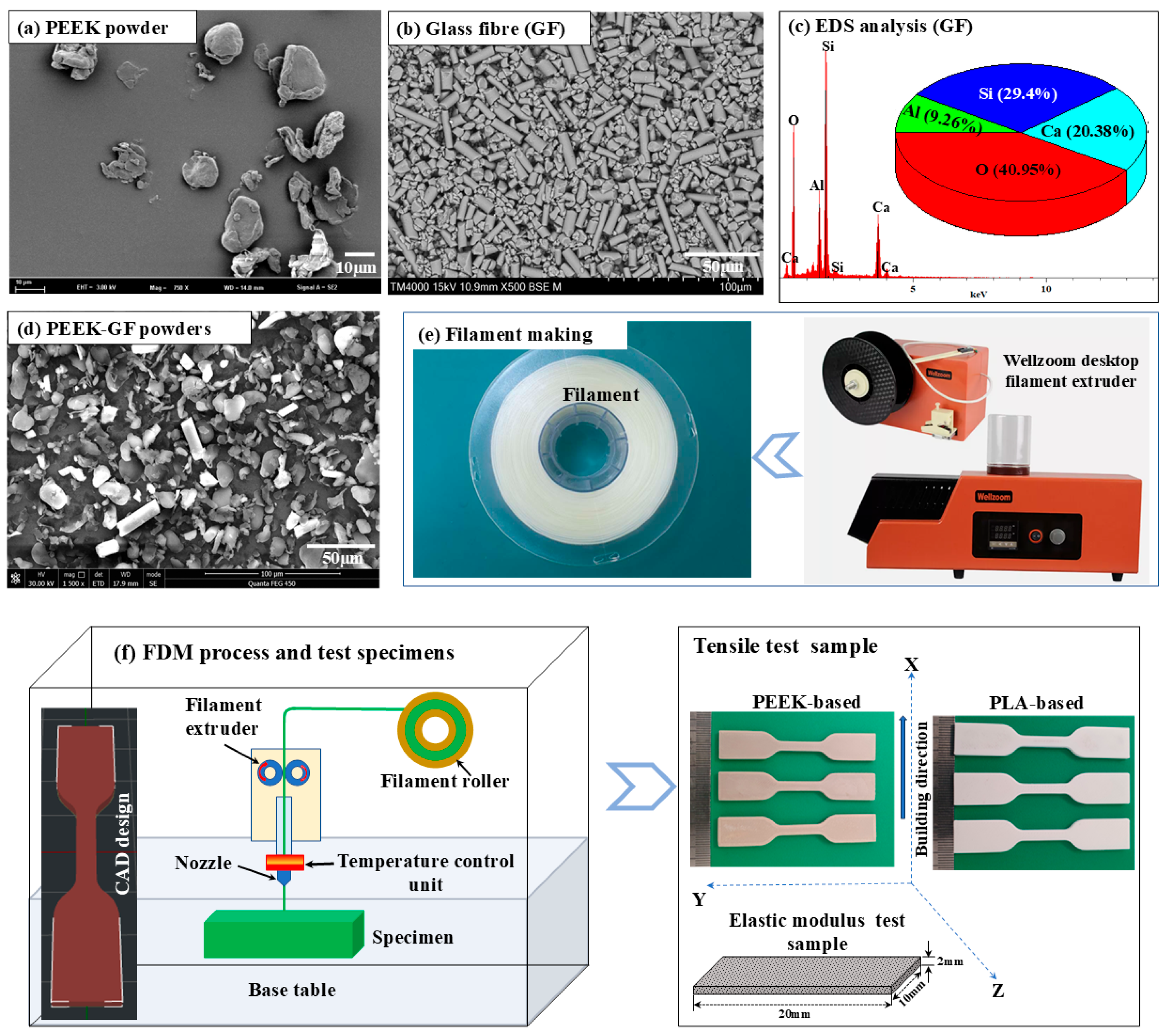

2.1. Manufacturing PLA- and PEEK-Based Composition

2.2. Characterization of Microstructure and Mechanical Property

2.3. Evaluation of Tribological Performance

3. Results and Discussion

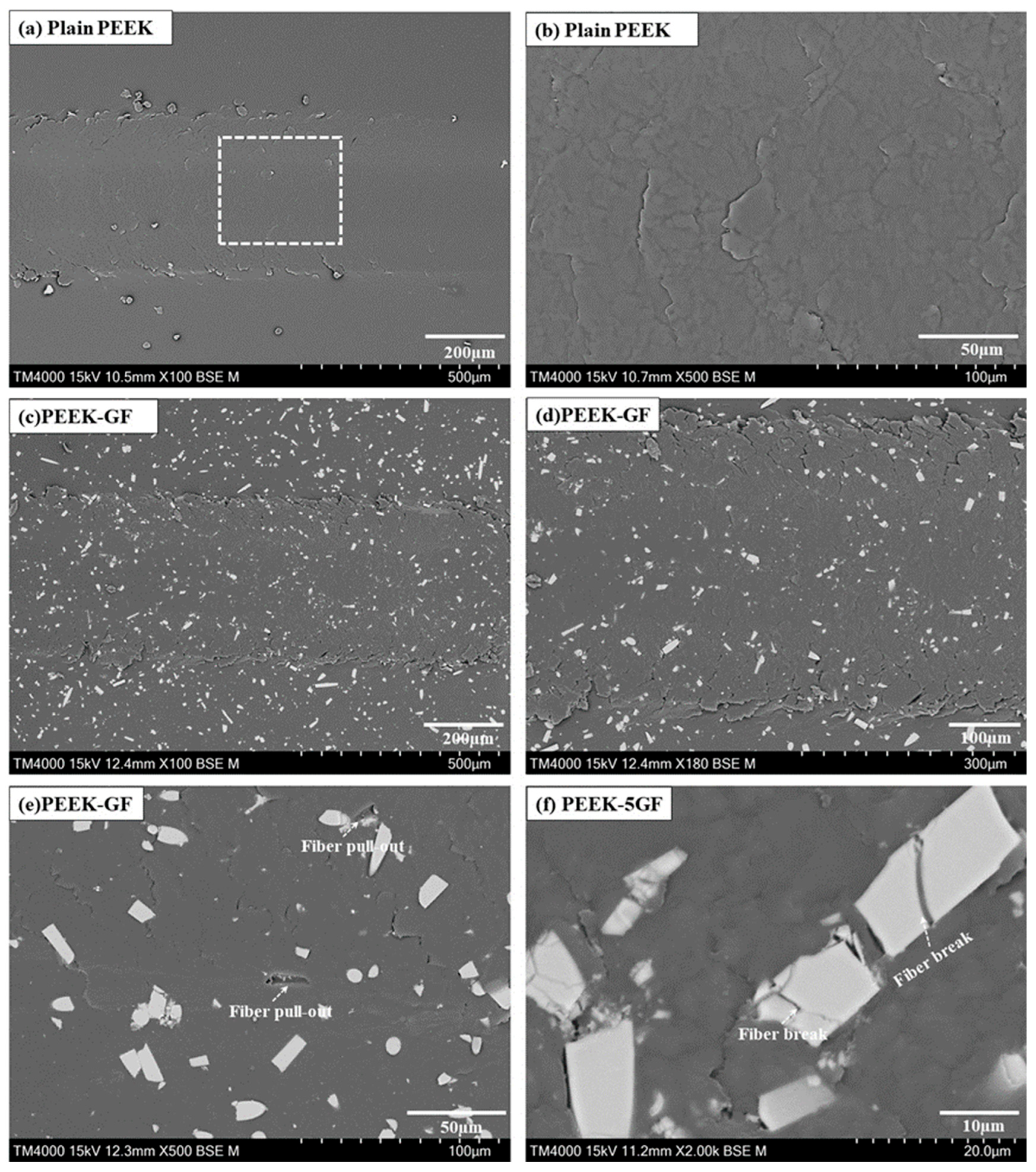

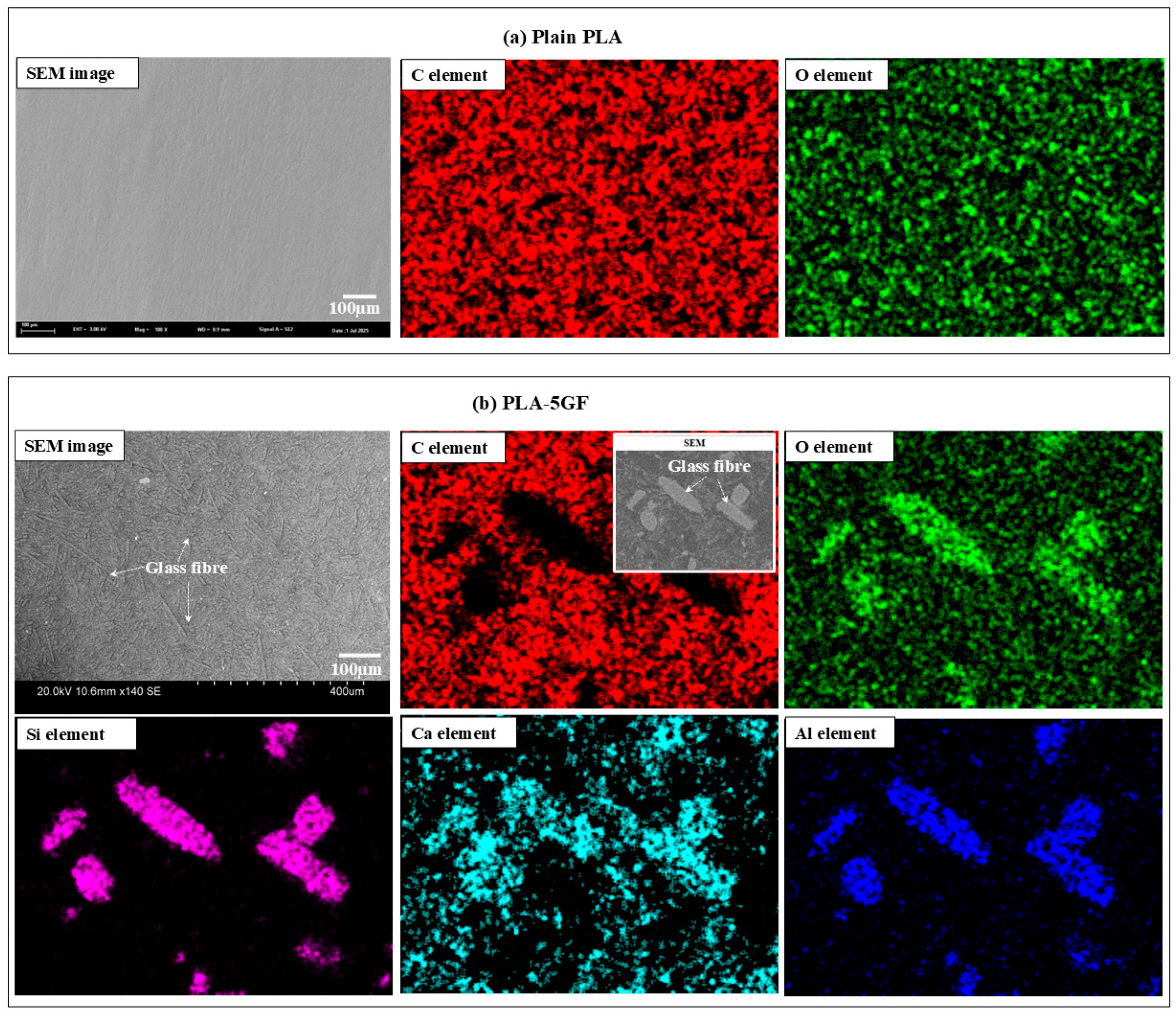

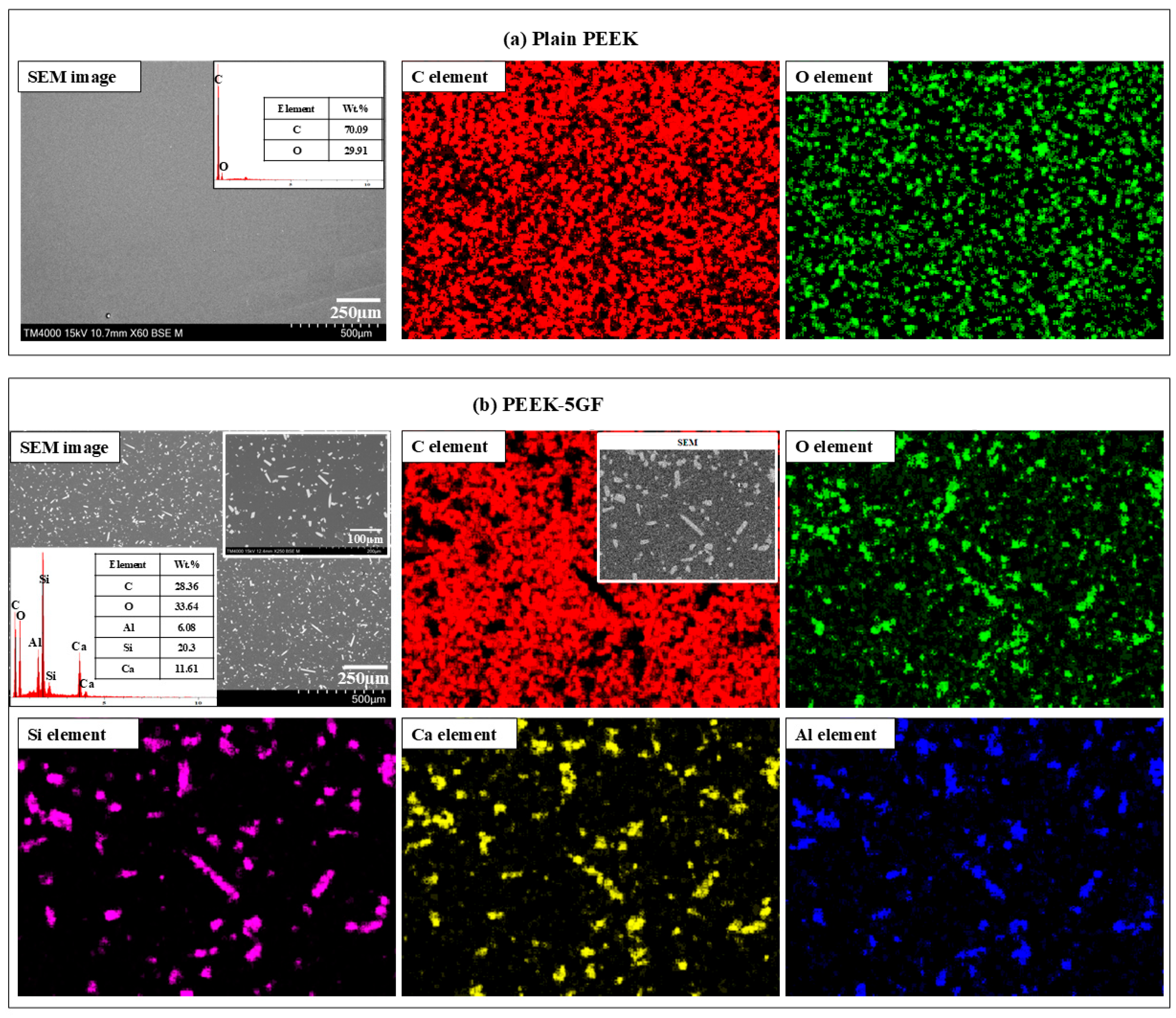

3.1. Microstructural Characterization

3.2. Mechanical Property Evaluation

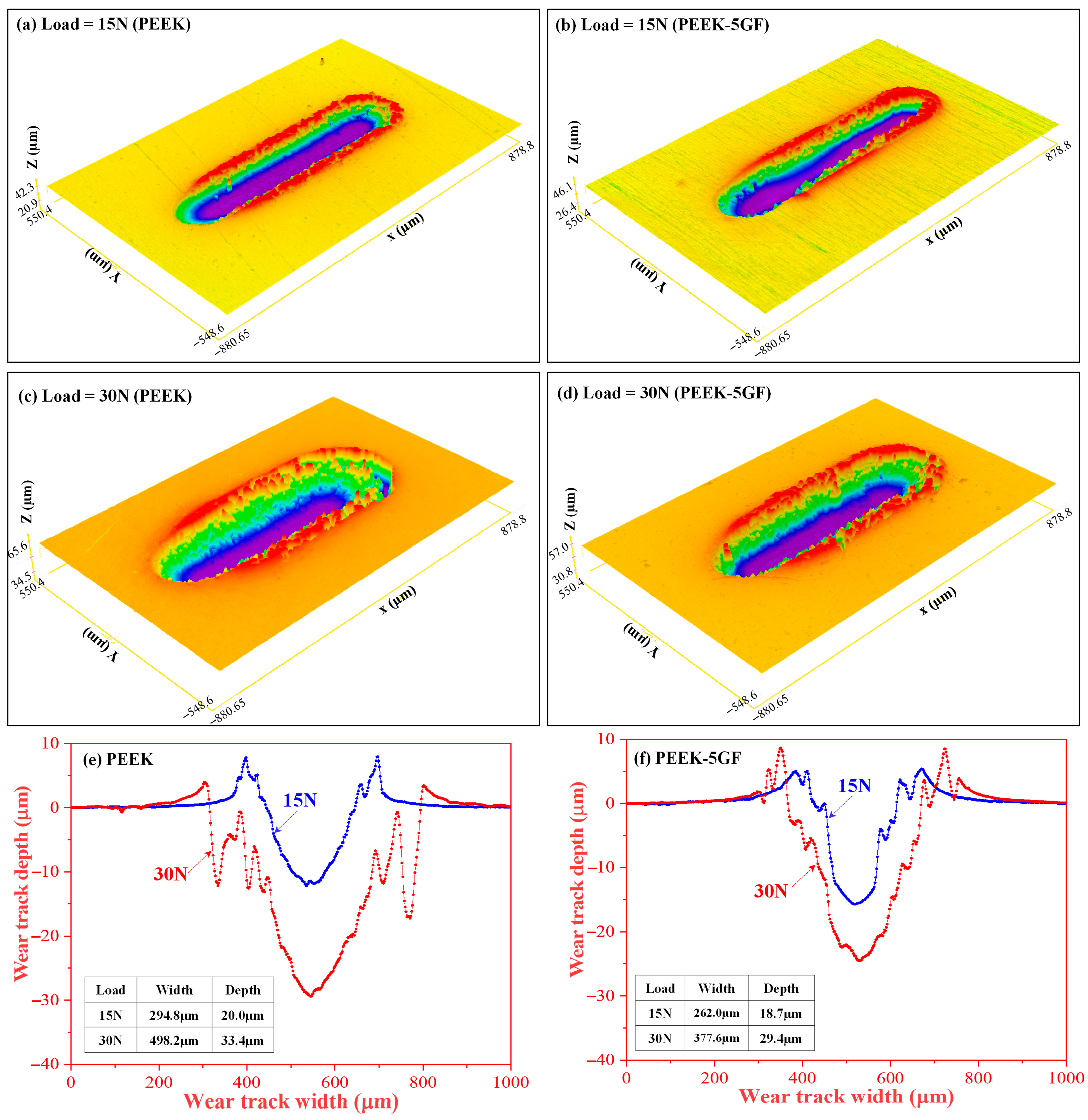

3.3. Assessment of Tribological Performance

4. Conclusions

- (i)

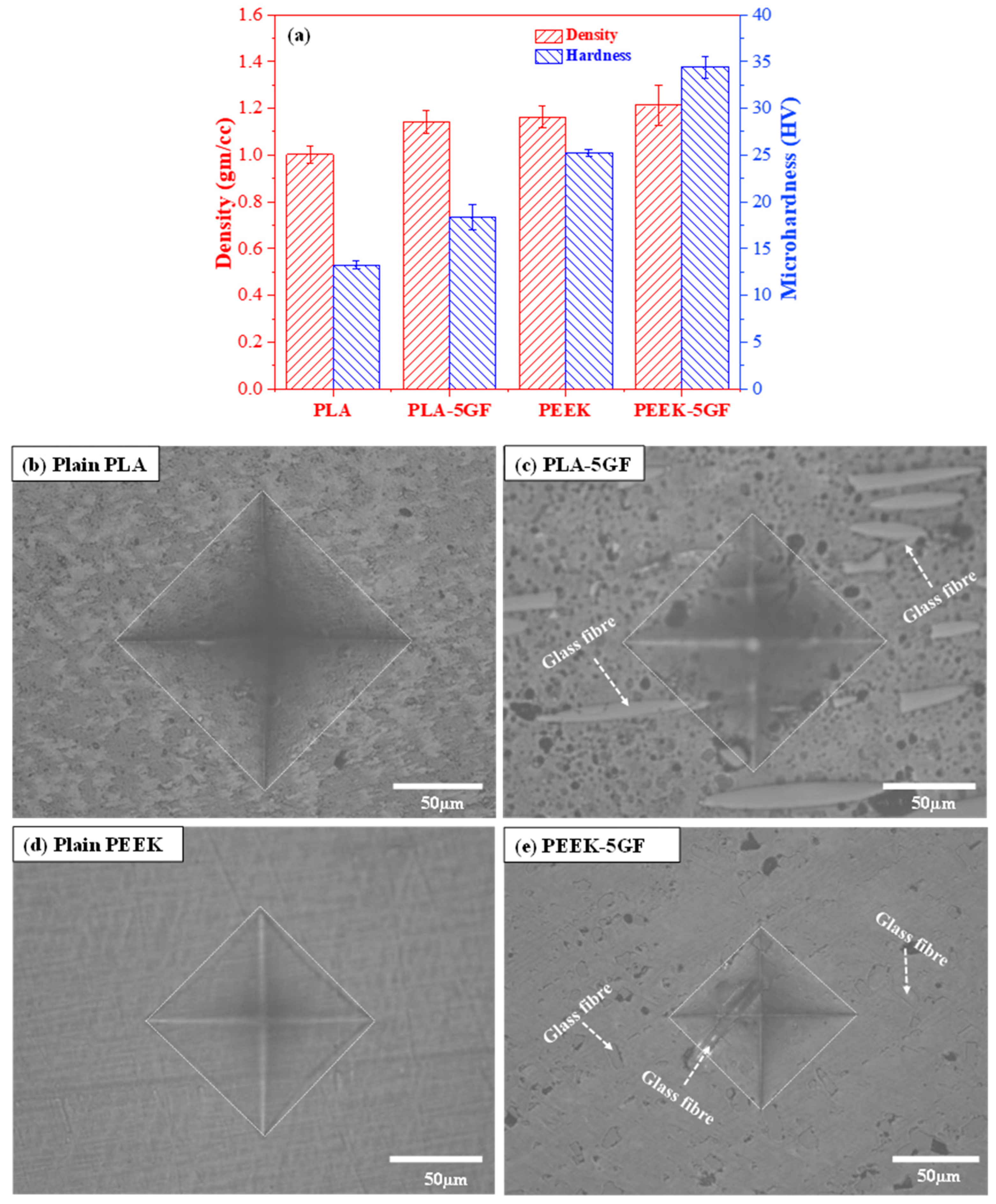

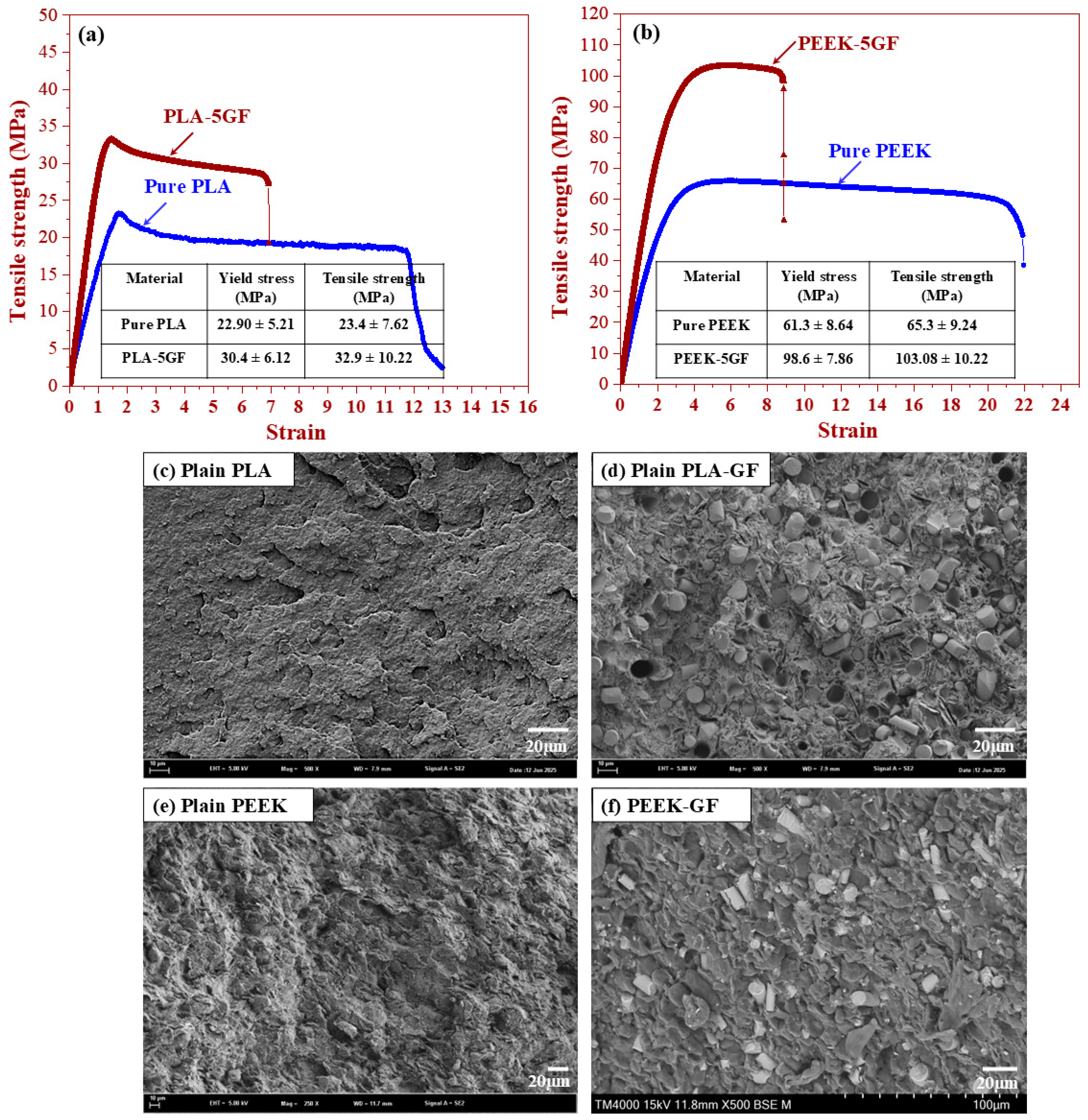

- Microstructural characterization revealed that the incorporated GF uniformly dispersed throughout both the PLA and PEEK matrices. No significant agglomeration, fibre pull-out, or interfacial debonding was observed, indicating strong interfacial adhesion between the GF and polymer phases. Such homogeneous dispersion is fundamental for enhancing the overall structural integrity and mechanical performance of the composites by facilitating efficient load transfer and minimizing stress concentrations within the polymeric network.

- (ii)

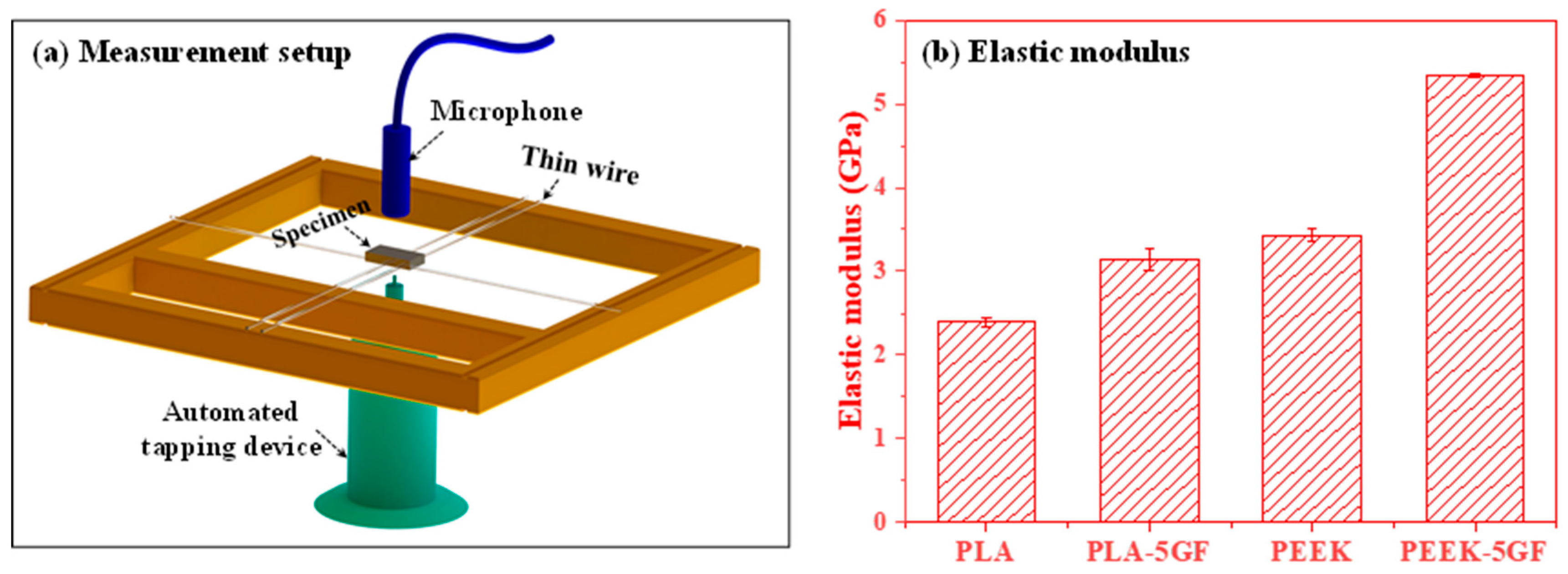

- The mechanical performance evaluation demonstrated that the incorporation of GF reinforcement substantially enhanced the properties of both PLA- and PEEK-based composites compared to their plain matrices. Microhardness measurements revealed increases of 38.3% in the PLA composite and 36.3% in the PEEK composite. Similarly, the ultimate tensile strength of the PLA-based composite increased by 25.1%, while the PEEK-based composite exhibited a 13.4% improvement relative to their plain counterparts. These enhancements are primarily attributed to the effective stress transfer enabled by the strong interfacial adhesion between the GF and polymer phases, coupled with uniform fibre dispersion.

- (iii)

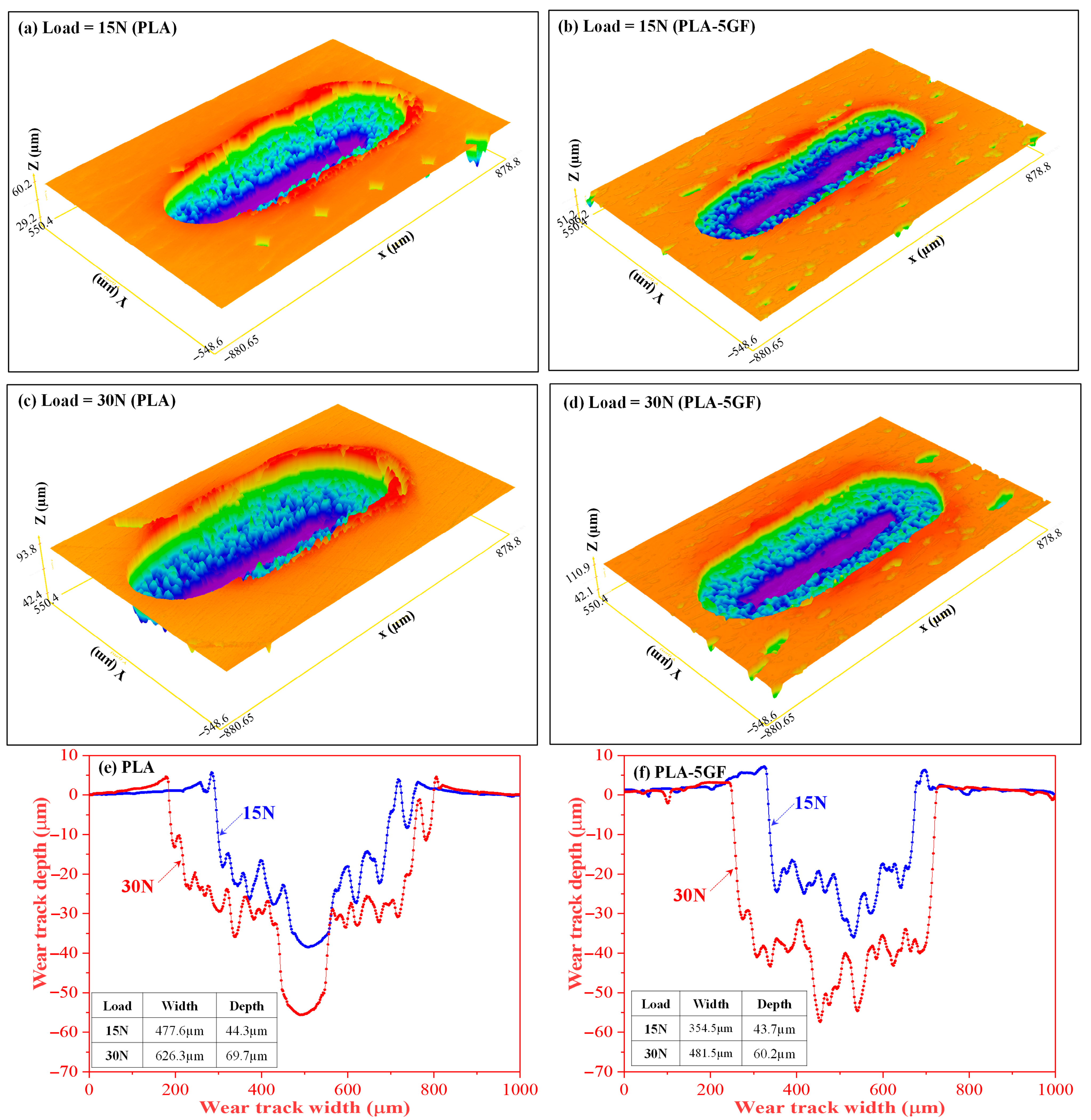

- Tribological assessments revealed a significant enhancement in the wear resistance of the GF-reinforced polymer composites relative to the plain PLA and PEEK matrices. This improvement is attributed to the reinforcing effect of the GF, which bears a greater proportion of the applied load during micro-scratching and hinders the propagation of wear-induced damage. Furthermore, the strong interfacial bonding between the GF and polymer phases contributes to maintaining the composite’s structural integrity under tribological stress, thereby mitigating surface degradation and prolonging service life. These findings underscore the critical role of GF reinforcement in improving the durability and functional performance of additively manufactured polymer composites under frictional conditions.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2008, 1, 30–42. [Google Scholar] [CrossRef]

- Long, M.; Rack, H.J. Titanium alloys in total joint replacement—A materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone tissue engineering using 3D printing. Mater. Today 2013, 16, 496–504. [Google Scholar] [CrossRef]

- Hanawa, T. Metal ion release from metal implants. Mater. Sci. Eng. C 2004, 24, 745–752. [Google Scholar] [CrossRef]

- Wu, G.H.; Hsu, S.H. Review: Polymeric-Based 3D Printing for Tissue Engineering. J. Med. Biol. Eng. 2015, 35, 285–292. [Google Scholar] [CrossRef] [PubMed]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Joshi, M.G.; Advani, S.G.; Miller, F.; Santare, M.H. Analysis of a femoral hip prosthesis designed to reduce stress shielding. J. Biomech. 2000, 33, 1655–1662. [Google Scholar] [CrossRef]

- Middleton, J.C.; Tipton, A.J. Synthetic biodegradable polymers as orthopedic devices. Biomaterials 2000, 21, 2335–2346. [Google Scholar] [CrossRef] [PubMed]

- Memarzadeh, A.; Safaei, B.; Tabak, A.; Sahmani, S.; Kizilors, C. Advancements in additive manufacturing of polymer matrix composites: A systematic review of techniques and properties. Mater. Today Commun. 2023, 36, 106449. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, S.M.; Shafiq, M.; Abbas, N. A review on PLA-based biodegradable materials for biomedical applications. Giant 2024, 18, 100261. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Devine, J.N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials 2007, 28, 4845–4869. [Google Scholar] [CrossRef]

- Ma, R.; Tang, T. Current strategies to improve the bioactivity of PEEK. Int. J. Mol. Sci. 2014, 15, 5426–5445. [Google Scholar] [CrossRef]

- Hallmann, L.; Mehl, A.; Sereno, N.; Hammerle, C.H.F. The improvement of adhesive properties of PEEK through different pre-treatments. Appl. Surf. Sci. 2012, 258, 7213–7218. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Bernard, M.; Jubeli, E.; Pungente, M.D.; Yagoubia, N. Biocompatibility of polymer-based biomaterials and medical devices—Regulations, in vitro screening and risk-management. Biomater. Sci. 2018, 6, 2025–2053. [Google Scholar] [CrossRef]

- Berretta, S.; Evans, K.; Ghita, O. Additive manufacture of PEEK cranial implants: Manufacturing considerations versus accuracy and mechanical performance. Mater. Des. 2018, 139, 141–152. [Google Scholar] [CrossRef]

- Deng, Y.; Zhou, P.; Liu, X.; Wang, L.; Xiong, X.; Tang, Z.; Wei, J.; Wei, S. Preparation, characterization, cellular response and in vivo osseointegration of polyetheretherketone/nano-hydroxyapatite/carbon fiber ternary biocomposite. Colloids Surf. B Biointerfaces 2015, 136, 64–73. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Cao, G.; Li, Y.; Li, N.; Du, Z.; Li, X. Fabrication and biological evaluation of polyether ether ketone (PEEK)/bioceramic composites. Prog. Nat. Sci. Mater. Int. 2022, 32, 334–339. [Google Scholar] [CrossRef]

- Khane, Y.; Albukhaty, S.; Sulaiman, G.M.; Fennich, F.; Bensalah, B.; Hafsi, Z.; Aouf, M.; Amar, Z.H.; Aouf, D.; Al-kuraishy, H.M.; et al. Fabrication, characterization and application of biocompatible nanocomposites: A review. Eur. Polym. J. 2024, 214, 113187. [Google Scholar] [CrossRef]

- Kuoa, M.C.; Tsaia, C.M.; Huang, J.C.; Chen, M. PEEK composites reinforced by nano-sized SiO2 and Al2O3 particulates. Mater. Chem. Phys. 2005, 90, 185–195. [Google Scholar] [CrossRef]

- Li, E.Z.; Guo, W.L.; Wang, H.D.; Xu, B.S.; Liu, X.T. Research on tribological behavior of PEEK and glass fiber reinforced PEEK composite. Phys. Procedia 2013, 50, 453–460. [Google Scholar] [CrossRef]

- Arevalo, S.; Arthurs, C.; Molina, M.I.E.; Pruitt, L.; Roy, A. An overview of the tribological and mechanical properties of PEEK and CFR-PEEK for use in total joint replacements. J. Mech. Behav. Biomed. Mater. 2023, 145, 105974. [Google Scholar] [CrossRef]

- Zhao, T.; Jiang, Z.; Ge, Y.; Yin, H.; Yang, Q.; Li, R.; Chen, Z.; Zhang, H.; Liu, X. Mechanical properties, biosafety, and shearing bonding strength of glass fiber–reinforced PEEK composites used as post-core materials. J. Mech. Behav. Biomed. Mater. 2023, 145, 106047. [Google Scholar] [CrossRef]

- Carvalho, W.S.D.; Marzemin, F.; Belei, C.; Petersmann, S.; Arbeiter, F.; Amancio-Filh, S.T. Statistical-based optimization of fused filament fabrication parameters for short-carbon-fiber-reinforced poly-ether-ether-ketone considering multiple loading conditions. Polym. Test. 2023, 128, 108207. [Google Scholar] [CrossRef]

- Vaezi, M.; Chianrabutra, S.; Mellor, B.; Yang, S. Multiple material additive manufacturing—Part 1: A review. Virtual Phys. Prototyp. 2013, 8, 19–50. [Google Scholar] [CrossRef]

- Bose, S.; Roy, M.; Bandyopadhyay, A. Recent advances in bone tissue engineering scaffolds. Trends Biotechnol. 2012, 30, 546–554. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Ma, L.; Liang, H.; Liu, X.; Lei, J.; Li, W.; Wang, K.; Song, Y.; Wang, B.; Li, G.; et al. Osteointegration of 3D-printed fully porous polyetheretherketone scaffolds with different pore sizes. ACS Omega 2020, 5, 26655–26666. [Google Scholar] [CrossRef]

- Huang, D.; Li, Z.; Li, G.; Zhou, F.; Wang, G.; Ren, X.; Su, J. Biomimetic structural design in 3D-printed scaffolds for bone tissue engineering. Mater. Today Biol. 2025, 32, 101664. [Google Scholar] [CrossRef]

- Saini, A.; Elhattab, K.; Gummadi, S.K.; Nadkarni, G.R.; Sikder, P. Fused filament fabrication-3D printing of poly-ether-ether-ketone (PEEK) spinal fusion cages. Mater. Lett. 2022, 328, 133206. [Google Scholar] [CrossRef]

- Deshwal, D.; Belgamwar, S.U.; Bekinal, S.I.; Doddamani, M. Critical review of reinforcement effect in PEEK tribology and its usage in biomedical, coating and bearing applications. Polym. Plast. Technol. Mater. 2025, 64, 1071–1100. [Google Scholar] [CrossRef]

- ASTM E1876-09; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration. ASTM International: West Conshohocken, PA, USA, 2009.

- Currey, J. Cortical bone. In Handbook of Biomaterial Properties; Springer: Berlin/Heidelberg, Germany, 1998; pp. 3–14. [Google Scholar]

- Mozafari, M.; Rabiee, M.; Azami, M.; Maleknia, S. Biomimetic formation of apatite on the surface of porous gelatin/bioactive glass nanocomposite scaffolds. Appl. Surf. Sci. 2010, 257, 1740–1749. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gain, A.K.; Zhang, L. Design and Characterization of Durable Glass Fibre (GF)-Reinforced PLA and PEEK Biomaterials. Polymers 2025, 17, 2536. https://doi.org/10.3390/polym17182536

Gain AK, Zhang L. Design and Characterization of Durable Glass Fibre (GF)-Reinforced PLA and PEEK Biomaterials. Polymers. 2025; 17(18):2536. https://doi.org/10.3390/polym17182536

Chicago/Turabian StyleGain, Asit Kumar, and Liangchi Zhang. 2025. "Design and Characterization of Durable Glass Fibre (GF)-Reinforced PLA and PEEK Biomaterials" Polymers 17, no. 18: 2536. https://doi.org/10.3390/polym17182536

APA StyleGain, A. K., & Zhang, L. (2025). Design and Characterization of Durable Glass Fibre (GF)-Reinforced PLA and PEEK Biomaterials. Polymers, 17(18), 2536. https://doi.org/10.3390/polym17182536