Low Threshold Voltage and Programmable Patterned Polymer-Dispersed Liquid Crystal Smart Windows

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Methods

- (1)

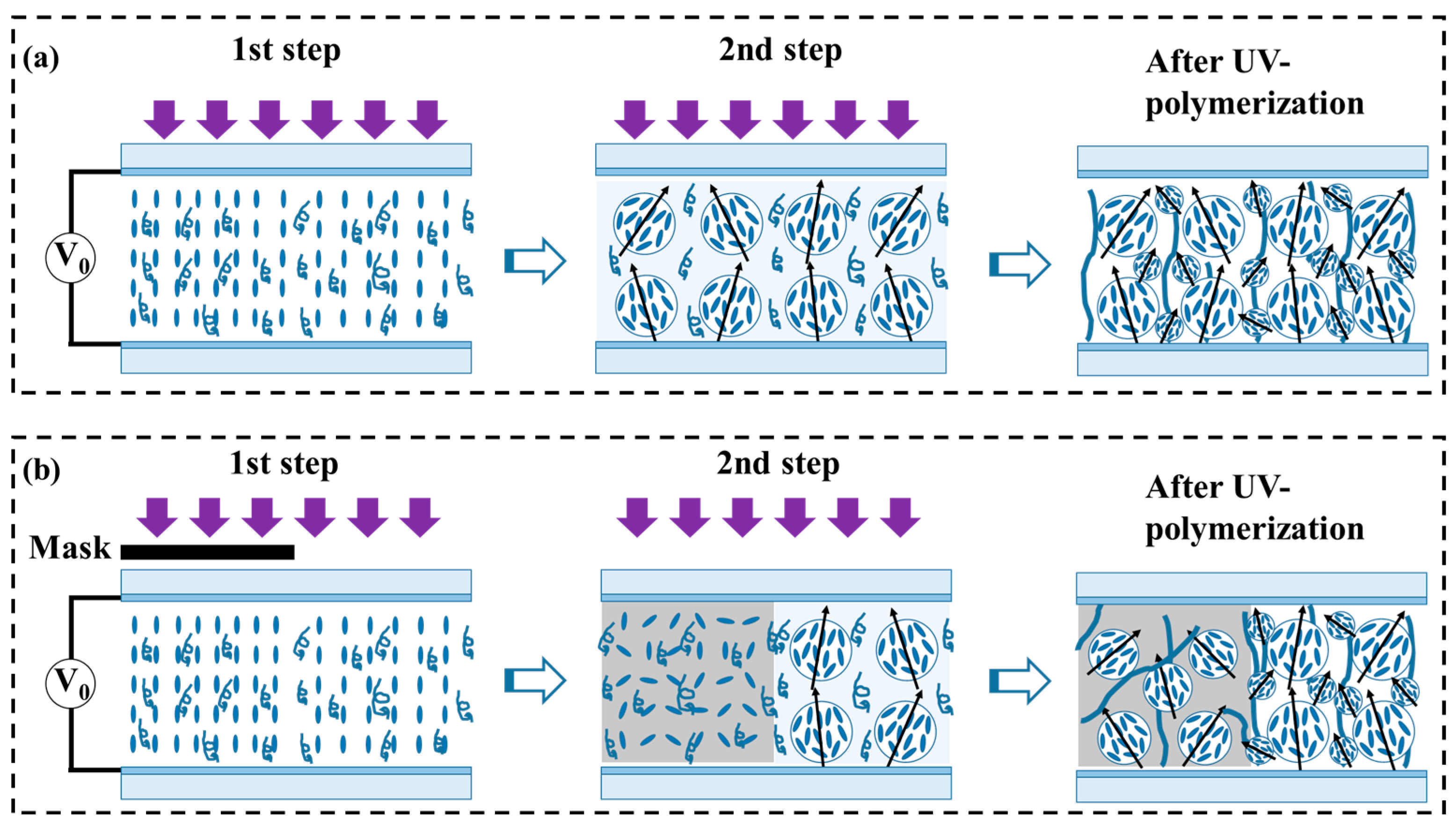

- Uniform PDLC films fabricated by two-step curing with/without electric field

- (2)

- Programmable patterned PDLC film fabricated with a photomask and with/without electric field

2.3. Characterization

3. Results and Discussion

3.1. Effect of the Electric Field During the Phase Separation

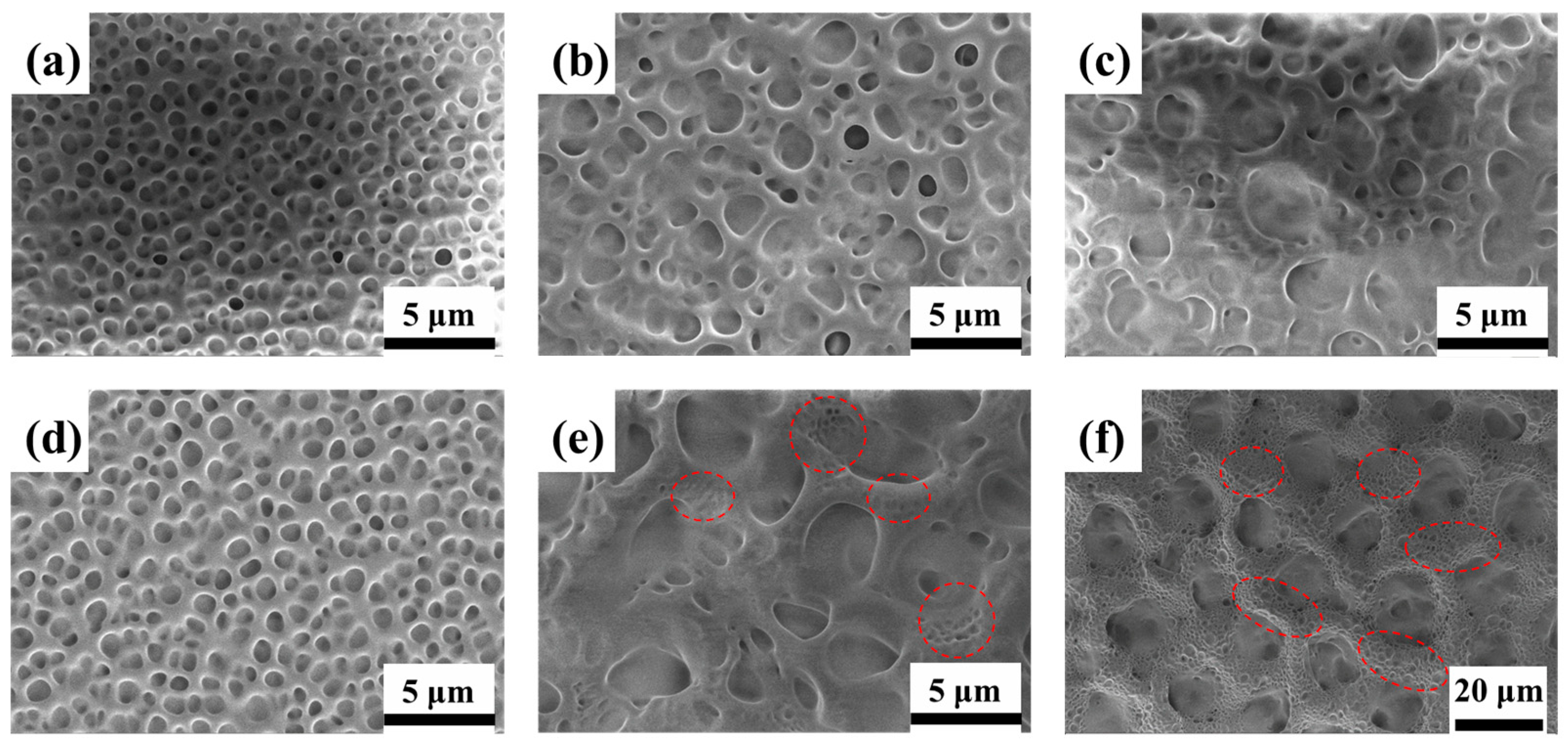

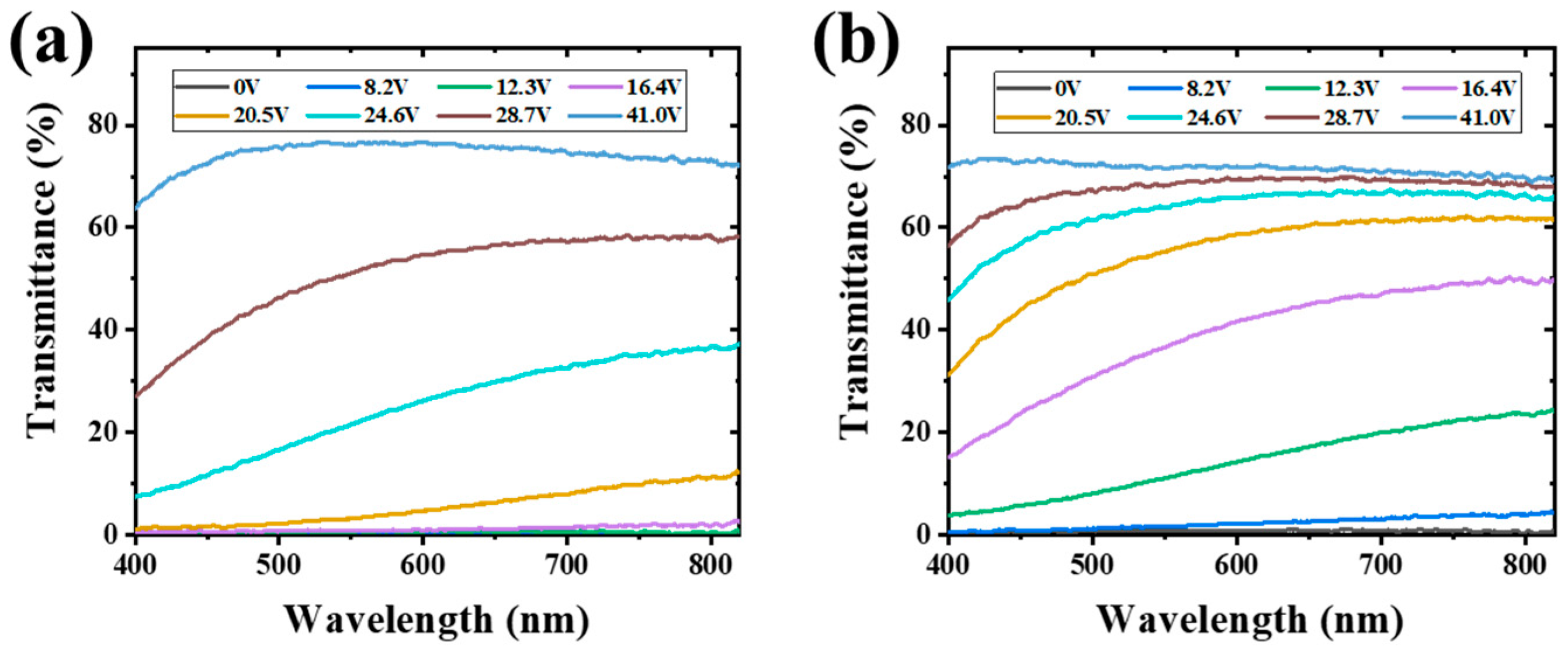

3.1.1. Influence of Composite Ratio

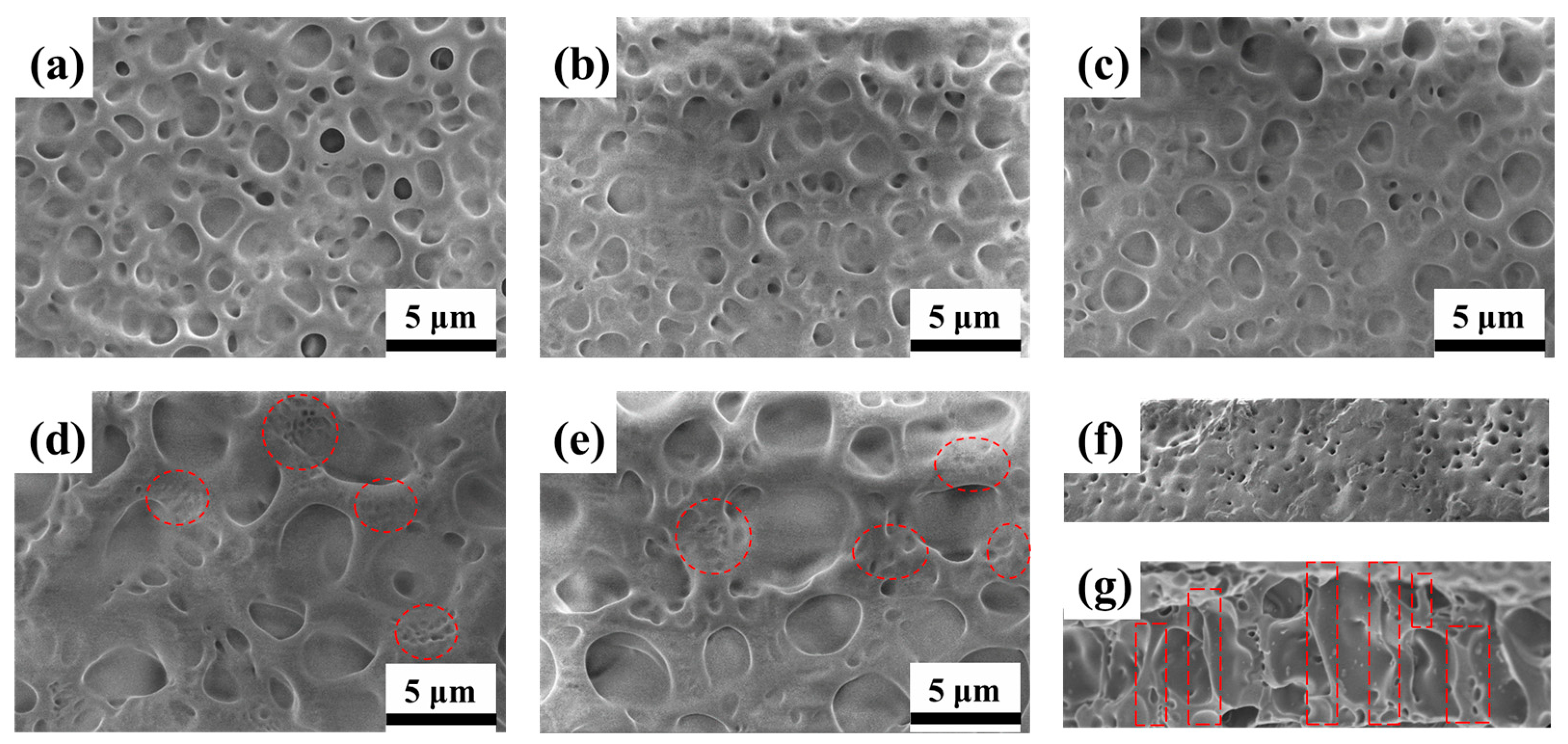

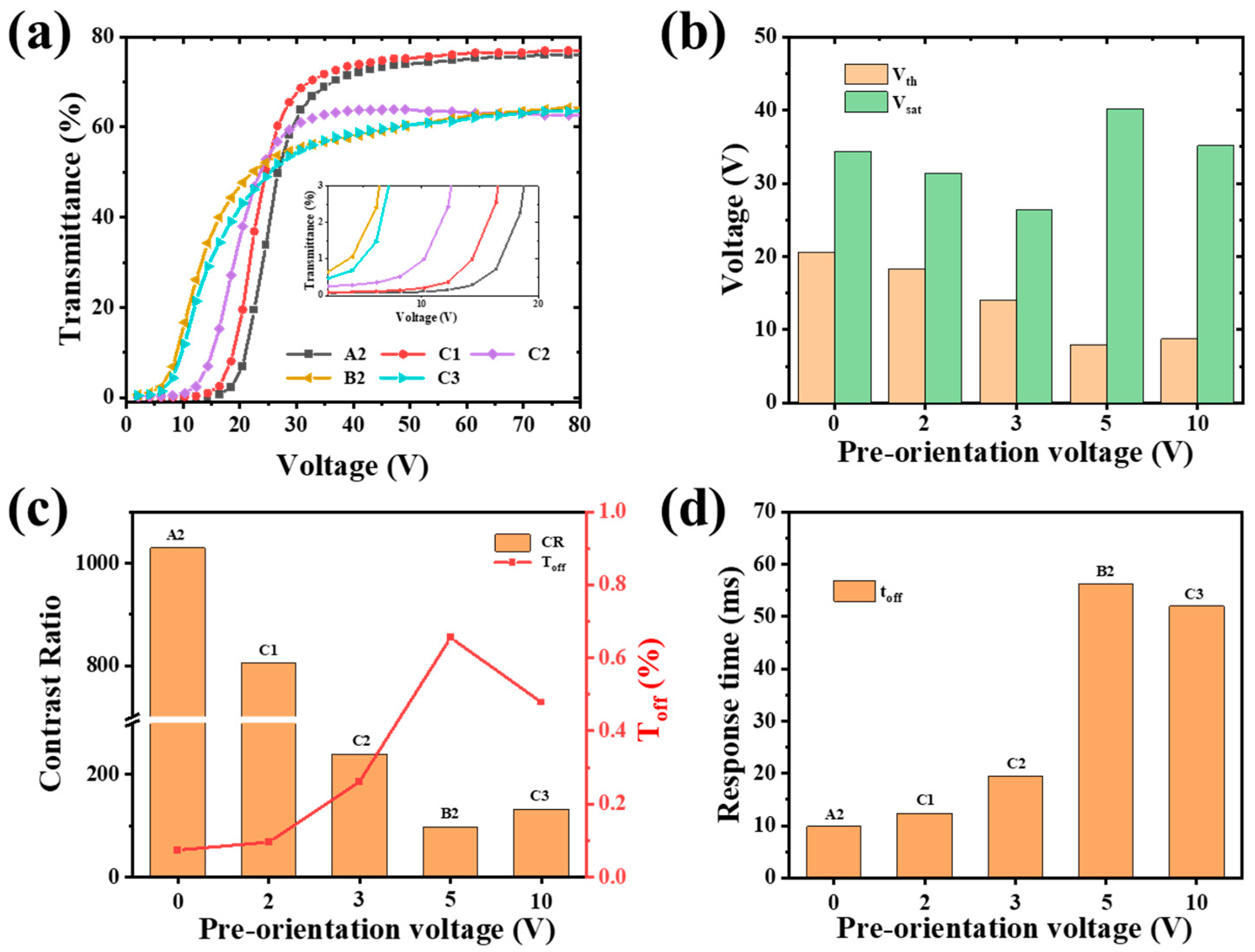

3.1.2. Influence of Different Pre-Orientation Electric Fields with the Same Composite Ratio

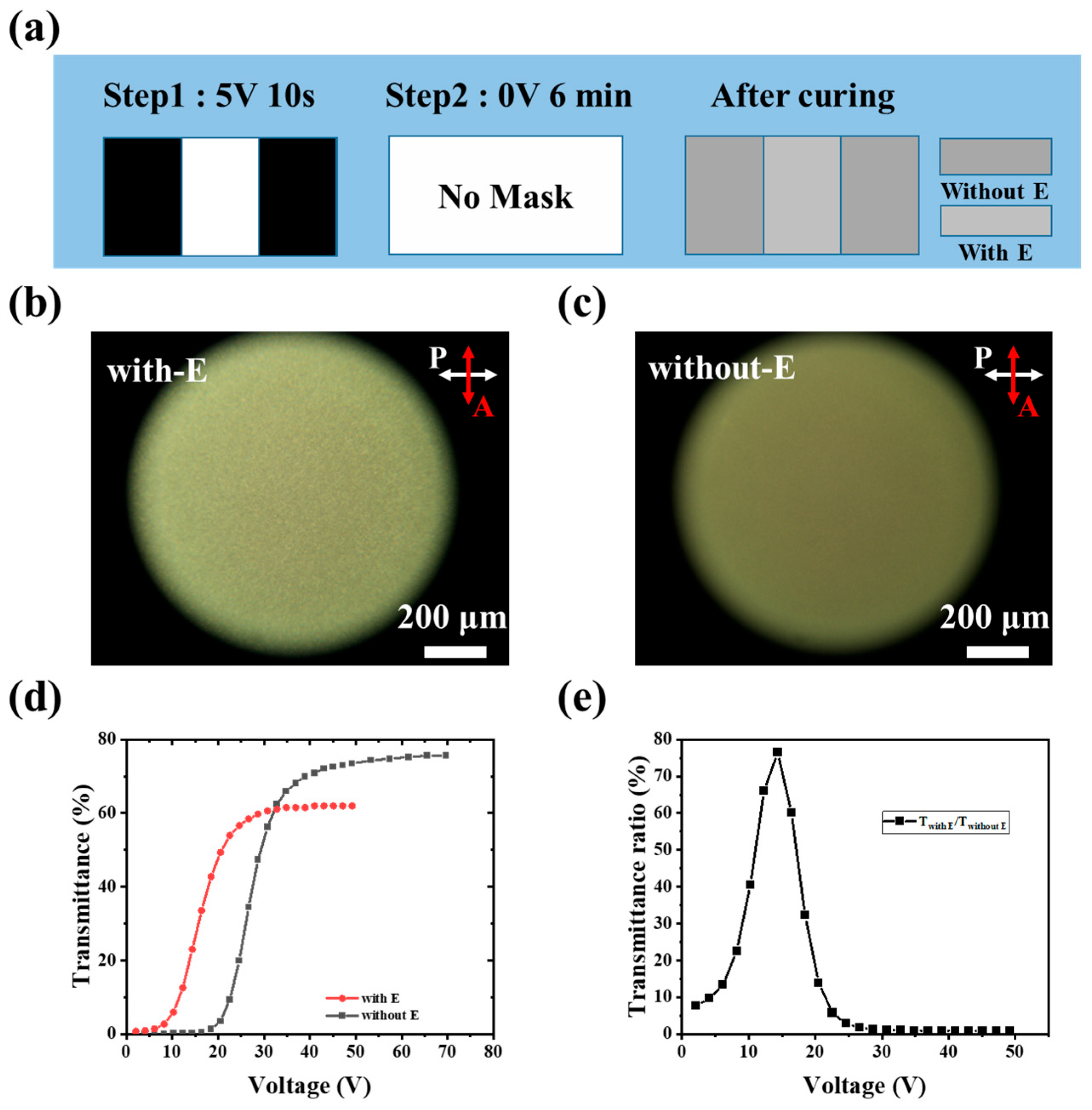

3.1.3. Uniform PDLC Films Cured With/Without Electric Field

3.2. The Patterned PDLC Windows

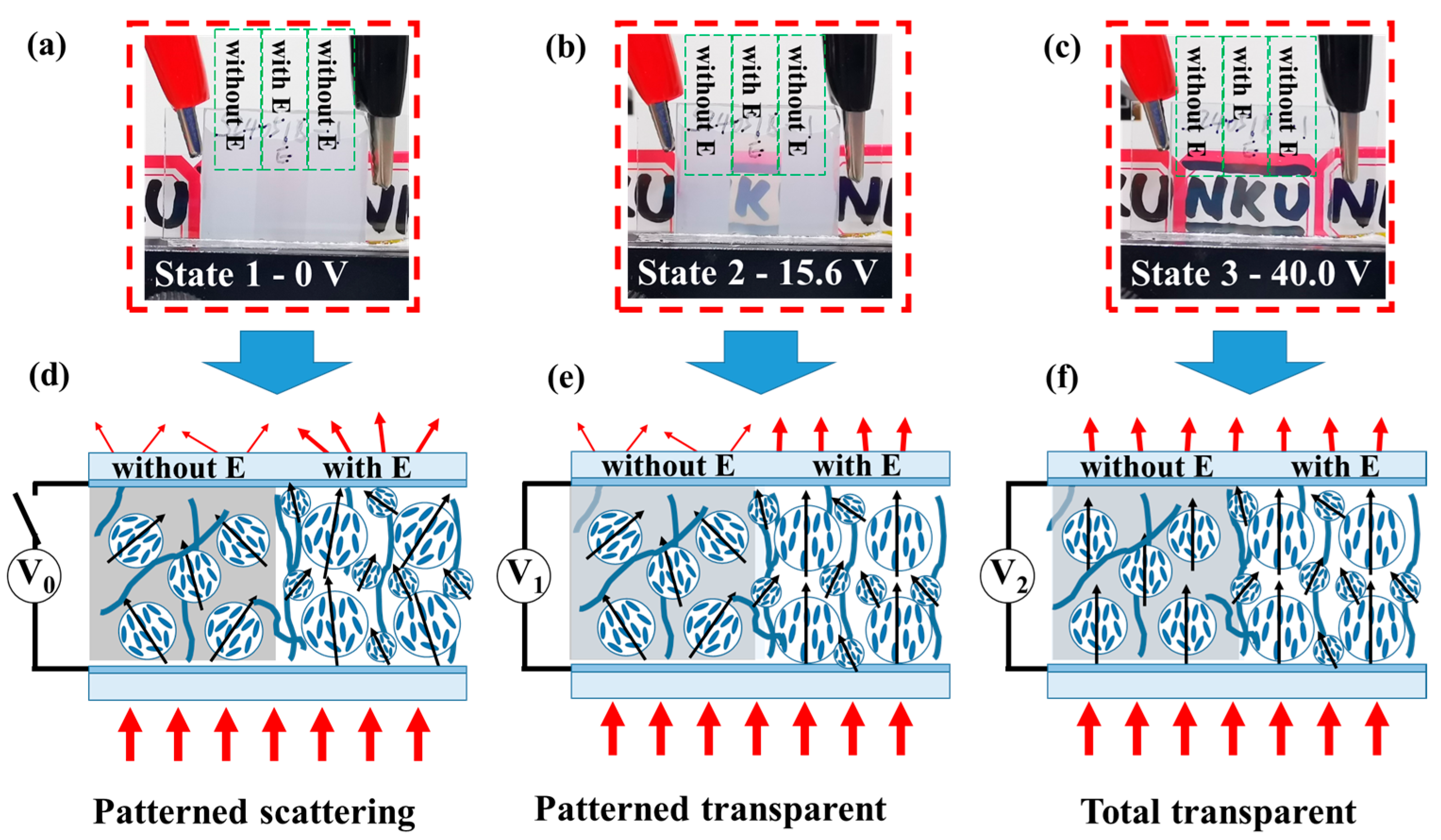

3.2.1. Patterned PDLC Windows Through Two-Step Polymerization with a Photomask

3.2.2. Experimental Mechanism Diagram

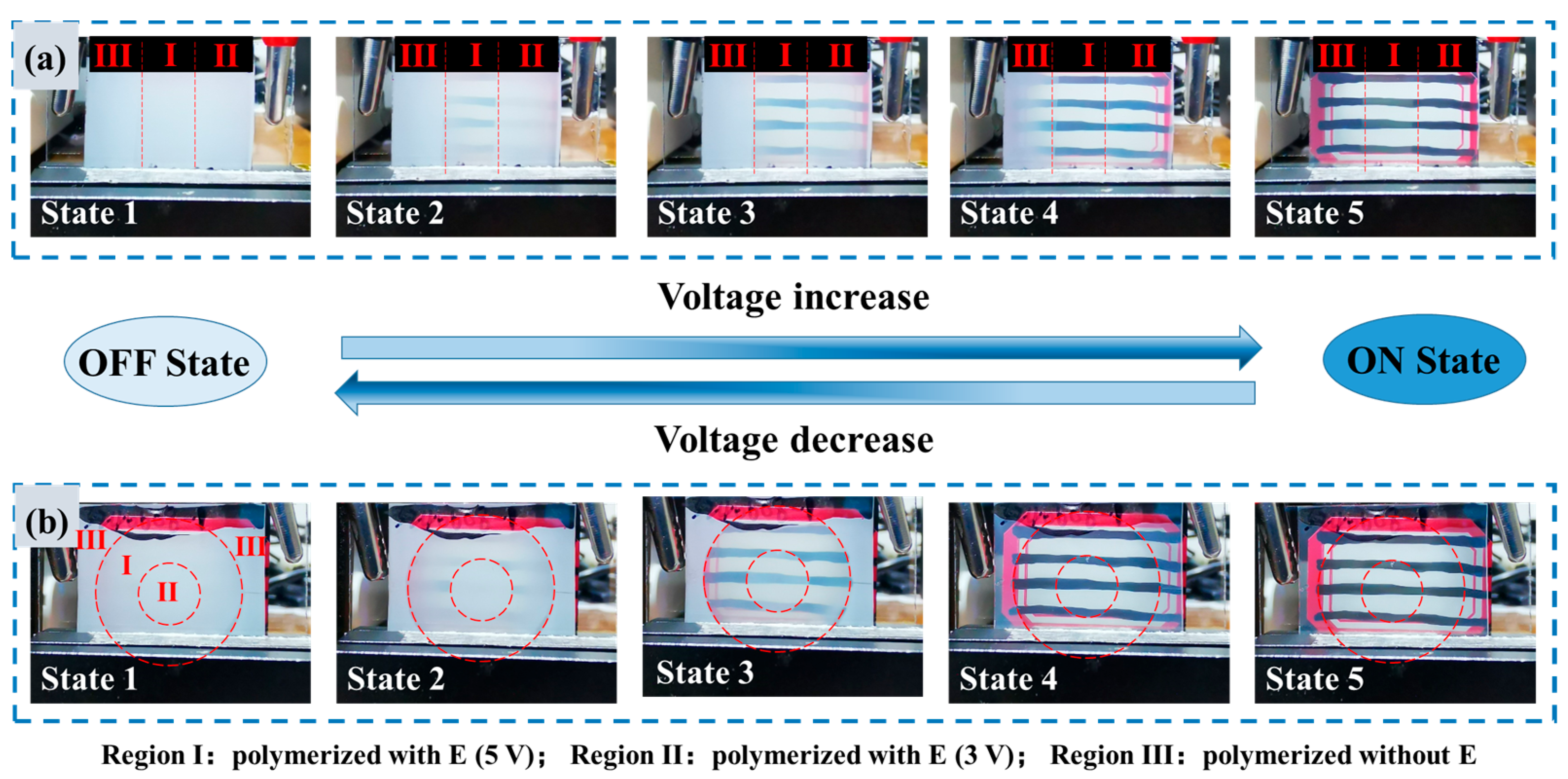

3.3. Programmable and Multilevel Patterned PDLC Films

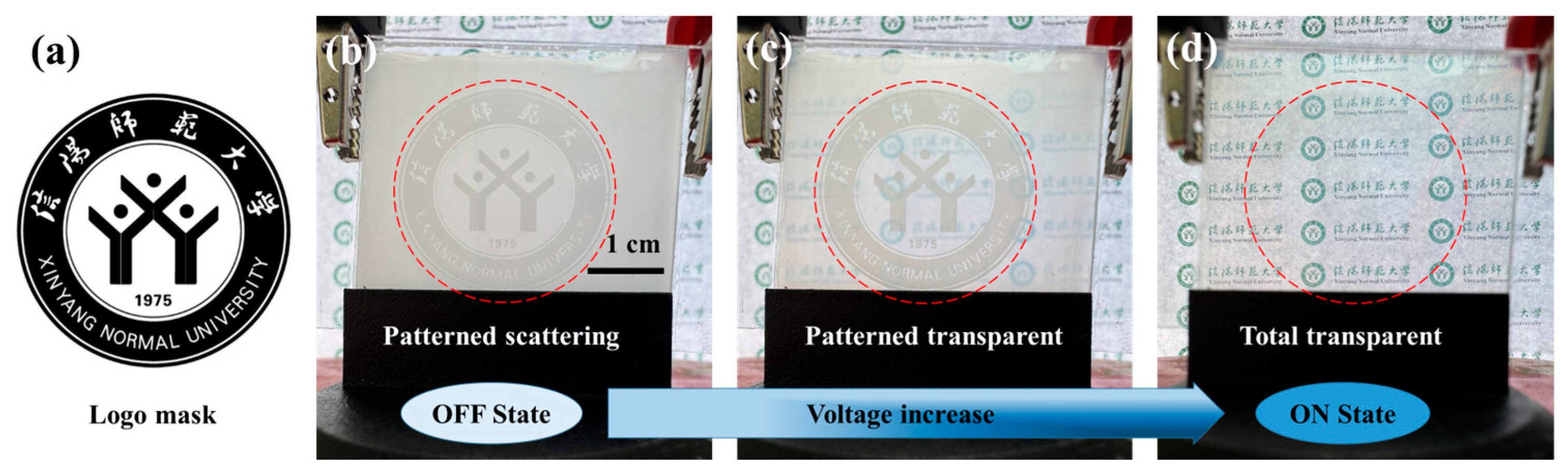

3.3.1. Programmable Logo

3.3.2. Multilevel Pattern

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deng, Y.; Yang, Y.; Xiao, Y.; Zeng, X.; Xie, H.L.; Lan, R.; Zhang, L.; Yang, H. Annual Energy-Saving Smart Windows with Actively Controllable Passive Radiative Cooling and Multimode Heating Regulation. Adv. Mater. 2024, 36, 2401869. [Google Scholar] [CrossRef]

- Ghosh, A. Diffuse transmission dominant smart and advanced windows for less energy-hungry building: A review. J. Build. Eng. 2023, 64, 105604. [Google Scholar] [CrossRef]

- Shen, W.; Li, G. Recent Progress in Liquid Crystal-Based Smart Windows: Materials, Structures, and Design. Laser Photonics Rev. 2023, 17, 2200207. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; Xu, J.; He, X.; Yuan, B.; Chen, C.; Zou, C.; Wang, Q.; Gao, Y.; Yu, M.; et al. A novel dual-functional flexible dimming film for smart window applications: Energy saving and self-cleaning performance. Chem. Eng. J. 2024, 488, 150601. [Google Scholar] [CrossRef]

- Gridyakina, A.; Kasian, N.; Chychłowski, M.S.; Kajkowska, M.; Lesiak, P. Advances in multicomponent systems: Liquid crystal/nanoparticles/polymer. Mat. Today Phys. 2023, 38, 101258. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Z.; He, L.; Shi, Y.; Gao, Y.; Yu, M.; Yang, H. Liquid crystal/polymer composites for energy-efficient smart windows with a wide working temperature range and low off-axis haze. Compos. Part A-Appl. S. 2024, 178, 107976. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, S.; Miao, X.; Xie, P.; Sun, N.; Xu, Z.; Zhong, T.; Zhang, L.; Shen, Y. Advancements and Applications of Liquid Crystal/Polymer Composite Films. ACS Mater. Lett. 2023, 5, 2760–2775. [Google Scholar] [CrossRef]

- Boussoualem, M.; Ismaili, M.; Roussel, F. Influence of surface anchoring conditions on the dielectric and electro-optical properties of nematic droplets dispersed in a polymer network. Soft Matter 2014, 10, 367–373. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Wang, T.; Xu, J.; Hu, W.; Gao, Y.; Zou, C.; Yang, H. Steric group-based polymer dispersed liquid crystal composite films with high contrast ratio, low driving voltage and small hysteresis. J. Mol. Liq. 2022, 365, 120152. [Google Scholar] [CrossRef]

- Katariya-Jain, A.; Deshmukh, R.R. Effects of dye doping on electro-optical, thermo-electro-optical and dielectric properties of polymer dispersed liquid crystal films. J. Phys. Chem. Solids 2022, 160, 110363. [Google Scholar] [CrossRef]

- Yang, K.J.; Yoon, D.Y. Electro-optical characteristics of dye-doped polymer dispersed liquid crystals. J. Ind. Eng. Chem. 2011, 17, 543–548. [Google Scholar] [CrossRef]

- Kim, E.; Liu, Y.; Hong, S.J.; Han, J.I. Effect of SiO2 nanoparticle doping on electro-optical properties of polymer dispersed liquid crystal lens for smart electronic glasses. Nano Converg. 2015, 2, 1–4. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, Y.; Li, X.; Gao, H.; Guo, Z.; Wang, D.; Luan, Y.; Wang, L. Preparation and Characterization of Bilayer Polymer-Dispersed Liquid Crystals Doped with Gd2O3 Nanoparticles and Rhodamine B Base Fluorescent Dye. Molecules 2024, 29, 1126. [Google Scholar] [CrossRef]

- Zhang, Z.; He, X.; Zhang, L.; Xu, J.; Yuan, B.; Chen, C.; Zou, C.; Wang, Q.; Gao, Y.; Yu, M.; et al. A novel low-voltage fast-response electrically controlled dimming film based on fluorinated PDLC for smart window applications. Chem. Eng. J. 2024, 479, 147668. [Google Scholar] [CrossRef]

- Liu, F.; Cao, H.; Mao, Q.; Song, P.; Yang, H. Effects of monomer structure on the morphology of polymer networks and the electro-optical properties of polymer-dispersed liquid crystal films. Liq. Cryst. 2012, 39, 419–424. [Google Scholar] [CrossRef]

- Ye, L.; Lv, C.; Li, F.; Wang, Y.; Liu, B.; Cui, Y. Effect of alignment layer on polymer-dispersed liquid crystal random laser. J. Mod. Opt. 2017, 64, 1429–1434. [Google Scholar] [CrossRef]

- Lin, Y.H.; Ren, H.; Wu, S.T. High contrast polymer-dispersed liquid crystal in a 90° twisted cell. Appl. Phys. Lett. 2004, 84, 4083–4085. [Google Scholar] [CrossRef]

- Liu, G.Z.; Xia, D.L.; Yang, W.J.; Huang, Z.Q. The surface rubbing effect on morphologies of LC droplets and electro-optic properties of flexible PDLC films. Sci. China Ser. B 2009, 52, 2329–2335. [Google Scholar] [CrossRef]

- Wu, J.J.; Wang, C.M. Electro-optical properties of aligned polymer dispersed liquid crystal films. Phys. Lett. A 1997, 232, 149–154. [Google Scholar] [CrossRef]

- Sandford O’Neill, J.J.; Salter, P.S.; Zhao, Z.; Chen, B.; Daginawalla, H.; Booth, M.J.; Elston, S.J.; Morris, S.M. 3D Switchable Diffractive Optical Elements Fabricated with Two-Photon Polymerization. Adv. Opt. Mater. 2022, 10, 2102446. [Google Scholar] [CrossRef]

- Sandford O’Neill, J.J.; Salter, P.S.; Booth, M.J.; Elston, S.J.; Morris, S.M. Electrically-tunable positioning of topological defects in liquid crystals. Nat. Commun. 2020, 11, 2203. [Google Scholar] [CrossRef]

- Guo, S.M.; Liang, X.; Zhang, C.H.; Chen, M.; Shen, C.; Zhang, L.Y.; Yuan, X.; He, B.F.; Yang, H. Preparation of a Thermally Light-Transmittance-Controllable Film from a Coexistent System of Polymer-Dispersed and Polymer-Stabilized Liquid Crystals. ACS Appl. Mater. Interfaces 2017, 9, 2942–2947. [Google Scholar] [CrossRef]

- Liang, X.; Chen, M.; Chen, G.; Li, C.; Han, C.; Zhang, J.; Zhang, J.; Zhang, L.; Yang, H. Effects of polymer micro-structures on the thermo-optical properties of a flexible soft-mater film based on liquid crystals/polymer composite. Polymer 2018, 146, 161–168. [Google Scholar] [CrossRef]

- Li, W.S.; Ma, L.L.; Gong, L.L.; Li, S.S.; Yang, C.; Luo, B.; Hu, W.; Chen, L.J. Interlaced cholesteric liquid crystal fingerprint textures via sequential UV-induced polymer-stabilization. Opt. Mater. Express 2015, 6, 19–28. [Google Scholar] [CrossRef]

- Li, W.S.; Shen, Y.; Chen, Z.J.; Cui, Q.; Li, S.S.; Chen, L.J. Demonstration of patterned polymer-stabilized cholesteric liquid crystal textures for anti-counterfeiting two-dimensional barcodes. Appl. Opt. 2017, 56, 601–606. [Google Scholar] [CrossRef]

- He, Z.; Li, J.; Zhang, W.; Gao, J.; Ma, C.; Yao, R.; Yao, X.; Miao, Z.; Wang, D. The regulation of electro-optical properties of the polymer dispersed liquid crystal films doped ZnO whiskers under applied pre-orientation voltage. Liq. Cryst. 2022, 49, 1964–1973. [Google Scholar] [CrossRef]

- Lu, H.; Wang, H.; Bai, H.; Wang, Y.; Qiu, L.; Zhu, J.; Xu, M. Polymer-dispersed liquid crystal with low driving voltage utilising reaction selectivity of two-stage polymerisation. Liq. Cryst. 2024, 51, 761–772. [Google Scholar] [CrossRef]

- Lin, H.; Zhao, Y.; Jiao, X.; Gao, H.; Guo, Z.; Wang, D.; Luan, Y.; Wang, L. Preparation and Application of Polymer-Dispersed Liquid Crystal Film with Step-Driven Display Capability. Molecules 2024, 29, 1109. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Zhao, Y.; He, Z.; Gao, H.; Du, Z.; Zhang, H.; Li, C.; Wang, D.; Luan, Y. Dye-assisted bicomponent spun nanofibers toward PDLC electro-optical properties modulation and controlled patterning display. Appl. Mater. Today 2024, 38, 102260. [Google Scholar] [CrossRef]

- Wang, X.; Lin, H.; Zhao, Y.; He, Z.; Gao, H.; Gao, J.; Wang, D.; Luan, Y. The role of sub-regional electrostatic spinning nanofiber loaded with WO3 nanoparticle in modulating electro-optic performance and stepwise display of polymer dispersed liquid crystal. Liq. Cryst. 2024, 51, 2435–2451. [Google Scholar] [CrossRef]

- Kamal, W.; Li, M.M.; Lin, J.D.; Parry, E.; Jin, Y.H.; Elston, S.J.A.A. Castrejón-Pita, S.M. Morris, Spatially Patterned Polymer Dispersed Liquid Crystals for Image-Integrated Smart Windows. Adv. Opt. Mater. 2022, 10, 2101748. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, J.; Ren, Y.; Sun, C.; Hu, W.; Yang, H.; Yang, D.K. Programmable Patterned Dynamic Scattering of Liquid Crystals/Epoxy-based Polymer Composite Film Sandwiched between Two Fully Covered Electrodes. Adv. Opt. Mater. 2023, 11, 2300537. [Google Scholar] [CrossRef]

- Yan, J.; Fan, X.; Liu, Y.; Qu, K.; Yu, Y.; Li, R.Z. UV-patterned polymer dispersed liquid crystals: Impact of UV curing on electro-optical properties of image-embedded smart windows. Appl. Mater. Today 2023, 32, 101840. [Google Scholar] [CrossRef]

- Yan, J.; Fan, X.W.; Liu, Y.F.; Yu, Y.; Fang, Y.M.; Li, R.Z. Passive patterned polymer dispersed liquid crystal transparent display. Chin. Opt. Lett. 2022, 20, 013301. [Google Scholar] [CrossRef]

- Lu, Y.F.; Yang, D.L.; Gao, H.; Du, X.; Zhao, Y.Z.; Wang, D.; He, Z.M.; Miao, Z.C.; Cao, H.; Yang, Z.; et al. Enhanced electro-optical properties of polymer-dispersed liquid crystals co-doped with fluorescent molecules and nanoparticles for multifunctional applications. Chem. Eng. J. 2024, 485, 149654. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, X.; Yang, D.; Zhong, Z.; Gao, H.; Du, X.; Zhao, Y.; He, Z.; Cao, H.; Yang, Z.; et al. PDLC flexible films with multiple fluorescence and voltage modulated modes and intelligent coding for applications in anti-counterfeiting and transparent displays. Chem. Eng. J. 2024, 496, 153742. [Google Scholar] [CrossRef]

- Zhang, Q.; He, X. Complex Effects of the External Electric Fields on the Phase Separation of Polymer Blends. Macromolecules 2024, 57, 597–605. [Google Scholar] [CrossRef]

- Li, C.; Chen, M.; Shen, W.; Chen, G.; Zhang, L.; Yang, H. A study on the polymer structures and electro-optical properties of epoxy-mercaptan-based polymer dispersed liquid crystal films. Liq. Cryst. 2019, 46, 1718–1726. [Google Scholar] [CrossRef]

- Zhang, W.; Lin, J.; Yu, T.; Lin, S.; Yang, D. Effect of electric field on phase separation of polymer dispersed liquid crystal. Eur. Polym. J. 2003, 39, 1635–1640. [Google Scholar] [CrossRef]

- Jia, M.; Zhao, Y.; Gao, H.; Wang, D.; Miao, Z.; Cao, H.; Yang, Z.; He, W. The Electro-optical study of Al2O3 nanoparticles doped polymer dispersed liquid crystal films. Liq. Cryst. 2021, 49, 39–49. [Google Scholar] [CrossRef]

| Sample | E7 (wt. %) | NOA65 (wt. %) | 1st Step | 2nd Step |

|---|---|---|---|---|

| A1 | 50 | 50 | 0 V, 10 s | 0 V, 6 min |

| A2 | 60 | 40 | 0 V, 10 s | 0 V, 6 min |

| A3 | 70 | 30 | 0 V, 10 s | 0 V, 6 min |

| B1 | 50 | 50 | 5 V, 10 s | 0 V, 6 min |

| B2 | 60 | 40 | 5 V, 10 s | 0 V, 6 min |

| B3 | 70 | 30 | 5 V, 10 s | 0 V, 6 min |

| C1 | 60 | 40 | 2 V, 10 s | 0 V, 6 min |

| C2 | 60 | 40 | 3 V, 10 s | 0 V, 6 min |

| C3 | 60 | 40 | 10 V, 10 s | 0 V, 6 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, Z.; Wang, Z.; Jin, H.; Cui, X.; Liu, M.; Chen, T.; Wang, L.; Sun, H.; Soltani, T.; Zhang, X. Low Threshold Voltage and Programmable Patterned Polymer-Dispersed Liquid Crystal Smart Windows. Polymers 2025, 17, 2531. https://doi.org/10.3390/polym17182531

Ji Z, Wang Z, Jin H, Cui X, Liu M, Chen T, Wang L, Sun H, Soltani T, Zhang X. Low Threshold Voltage and Programmable Patterned Polymer-Dispersed Liquid Crystal Smart Windows. Polymers. 2025; 17(18):2531. https://doi.org/10.3390/polym17182531

Chicago/Turabian StyleJi, Zhichao, Zhenyuan Wang, Hongxu Jin, Xinying Cui, Meijun Liu, Tianzhen Chen, Lei Wang, Haibin Sun, Taoufik Soltani, and Xinzheng Zhang. 2025. "Low Threshold Voltage and Programmable Patterned Polymer-Dispersed Liquid Crystal Smart Windows" Polymers 17, no. 18: 2531. https://doi.org/10.3390/polym17182531

APA StyleJi, Z., Wang, Z., Jin, H., Cui, X., Liu, M., Chen, T., Wang, L., Sun, H., Soltani, T., & Zhang, X. (2025). Low Threshold Voltage and Programmable Patterned Polymer-Dispersed Liquid Crystal Smart Windows. Polymers, 17(18), 2531. https://doi.org/10.3390/polym17182531